EP0535262B1 - Adjustable chair which is adaptable to a person's stature, particularly rotatable chair - Google Patents

Adjustable chair which is adaptable to a person's stature, particularly rotatable chair Download PDFInfo

- Publication number

- EP0535262B1 EP0535262B1 EP91116685A EP91116685A EP0535262B1 EP 0535262 B1 EP0535262 B1 EP 0535262B1 EP 91116685 A EP91116685 A EP 91116685A EP 91116685 A EP91116685 A EP 91116685A EP 0535262 B1 EP0535262 B1 EP 0535262B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- seat

- backrest

- chair

- transverse axis

- support arms

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C1/00—Chairs adapted for special purposes

- A47C1/02—Reclining or easy chairs

- A47C1/022—Reclining or easy chairs having independently-adjustable supporting parts

- A47C1/023—Reclining or easy chairs having independently-adjustable supporting parts the parts being horizontally-adjustable seats ; Expandable seats or the like, e.g. seats with horizontally adjustable parts

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C1/00—Chairs adapted for special purposes

- A47C1/02—Reclining or easy chairs

- A47C1/031—Reclining or easy chairs having coupled concurrently adjustable supporting parts

- A47C1/032—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest

- A47C1/03261—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest characterised by elastic means

- A47C1/03272—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest characterised by elastic means with coil springs

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C1/00—Chairs adapted for special purposes

- A47C1/02—Reclining or easy chairs

- A47C1/031—Reclining or easy chairs having coupled concurrently adjustable supporting parts

- A47C1/032—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest

- A47C1/03255—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest with a central column, e.g. rocking office chairs

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C1/00—Chairs adapted for special purposes

- A47C1/02—Reclining or easy chairs

- A47C1/031—Reclining or easy chairs having coupled concurrently adjustable supporting parts

- A47C1/032—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest

- A47C1/03261—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest characterised by elastic means

- A47C1/03266—Reclining or easy chairs having coupled concurrently adjustable supporting parts the parts being movably-coupled seat and back-rest characterised by elastic means with adjustable elasticity

Definitions

- the invention relates to a multi-adjustable, adaptable to the size of the chair, in particular swivel chair, in which the seat back independent of the seat is held by two support arms that extend from a first transverse axis under the seat laterally from this to the rear and variable in length as in different lengths can be determined by a locking device.

- a chair of this type is known from DE 33 23 171 A1.

- the well-known chair already has an adjustable seat height.

- the support arms designed as a hollow tube, which form an angle of 30 ° with the horizontal here, mean that when the height of the backrest is raised above the seat, the seat depth increases at the same time.

- neither the backrest nor the seat can be tilted.

- Permanent mechanics and synchronous mechanisms are also known.

- the seat is rigidly connected to the chair base, i.e. cannot be tilted, while the backrest is attached to the chair base so that it can be tilted against the action of a spring.

- the backrest can thus be optimally matched to the back regardless of the seat. Since the rigid seat does not follow the movements of the backrest, there are also considerable disadvantages.

- the seat and backrest are coupled in such a way that when the backrest is returned, the seat is also tilted backwards.

- the seat weight portion already causes the backrest to tip backwards even in the front sitting position, so that it loses its supporting effect.

- a chair with synchronous mechanism (DE 38 17 761 C2) is also known, in which the backrest is held by two support arms running on both sides of the seat at approximately 40 ° to the rear, which are in their foremost region, i.e. under the front edge of the seat rigid seat supports are pivotally mounted. Between this pivot axis and the connection of the support arms to the backrest, a downwardly projecting mounting bracket is provided, on which the seat with its central region is rotatably mounted.

- the object of the invention is therefore to propose a chair with synchronous mechanism in which the seat depth, backrest height and armrest height can be adjusted at the same time and the synchronous mechanism in the front seat posture is automatically locked so that the seat force does not lead to a reduction in the support effect of the backrest on the back.

- the backrest is supported by two support arms which are mounted on the seat and extend laterally from this to the rear and are variable in length and which can be locked in different lengths by a locking device.

- This adjusts the seat depth and backrest height at the same time.

- the upper part of the telescopically subdivided, length-adjustable support arm is also provided with an armrest, then the armrest height is also adjusted at the same time.

- the seat depth, backrest height and armrest height can thus be adjusted synchronously with a single, sensible adjustment.

- a single chair construction can also be made accessible to an extremely wide range of user sizes, since there is a particularly large size change range.

- This size change range is decisively shaped by the fact that the support arms form an angle of at least 45 °, preferably over 50 ° and at least almost 52 ° with the horizontal in the rest position. Because in this way a height adjustment range of the upper support point of the iliac crest of 180 - 230 mm is achieved. At the same time, the armrest has a height adjustment range of 200 to 260 mm above the seating point and the seat depth can also be changed over a wide range. Given the steep position of the support arms, the optimal articulation point for their lower ends is at a distance of one third of the seat depth from the front edge of the seat.

- the seat is first mounted in the mechanical housing in the usual manner at its front end about a horizontal axis.

- the seat is also pushed up by a spring, just as another spring pushes the backrest forward.

- a rigid support is set between the mechanism housing and the seat at a distance from the pivot axis of the seat. This is designed so that it is only released when the backrest is clearly and deliberately deflected by the user to the rear, and then the synchronizing mechanism can take effect.

- the rigid support does not have any effect on the load on the seat by the user on the backrest. This does not swing back when the user sits down, nor is the force of the spring pushing the backrest forward reduced.

- the advantages of permanent mechanics and synchronous mechanics are actually combined in one chair with easy adjustment.

- the support arms are extended beyond their articulation under the seat and each carry a swivel plate, which itself, or preferably via another, on the one hand on the swivel plate and on the other hand on the transverse axis between the two levers the support articulated pull lever is connected to it and thereby dissolves or sets it up.

- this chair is also pushed upwards by a spring and the backrest is pushed forward.

- the spring pushing the seat upwards is inserted between the mechanical housing acting as the support and the seat, the point of application of this spring pushing the seat upwards being in the vicinity of the transverse axis arranged thirdly below the seat from its front edge.

- Mechanical springs are used as springs, which have the advantage of the progressive effect compared to the almost linear identification of a gas spring: with increasing deflection, the restoring force increases. This is particularly important for the restoring force on the backrest for ergonomic reasons.

- the seat is given an inclination of 3 to 4 ° forward in the rest position. This is the starting point for the synchronous kinematics after the support of the seat has been released, so that a pre-rotation of the pelvis is initiated to straighten the spine.

- the specified forward tilt is a compromise between this effect achieved and a limitation of the forward tilt to a value which prevents the user from sliding forward from the seat.

- FIG. 1 shows a chair with a chair base 10, to which a mechanical housing 12 is rigidly connected, which covers or supports all the parts explained below.

- a seat 14 is pivoted in the mechanical housing 12 at its front end about a transverse axis.

- a backrest 16 is not directly connected to the seat, but via telescopic support arms 18 with locking device 20 and armrests 22.

- the lower end of the support arms 18 is in each case on a horizontally and transversely extending first transverse axis 24 pivoted. This applies to the lower or inner part of the telescopic support arm.

- the upper or outer part of the telescopic support arms 18 connected to the backrest has the armrest. The user can release the rigid connection of the two parts of the support arms 18 against each other by actuating the locking device and the upper part of the support arms guided in the manner indicated in the figure on the lower part of the Pull the support arms up and fix them in the desired position.

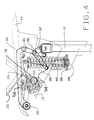

- Fig. 3 shows the corresponding structure in detail.

- the mechanical housing 12 is fastened on the chair base 10 and holds the support arms 18 of the backrest (not shown in the figure) via the first transverse axis 24 and the seat 14 via a second transverse axis 26.

- the first transverse axis 24 is to be arranged at a third of the total seat depth and as high as possible, that is to say close to the seat 14.

- the second transverse axis 26 lies in the foremost region of the seat shell 12, that is to say at the front edge of the seat.

- the seat 14 is slightly inclined forward. For this purpose, it is pressed upwards by a spring, as will be explained in more detail below with reference to FIG. 4.

- the spring pivots the seat 14 about the second transverse axis 26 in the counterclockwise direction. This pivoting is limited by a rigid support from two levers connected in a third transverse axis 28.

- the somewhat longer lever 30 is articulated at its upper end on the underside of the seat 14 and approximately vertically above the axis of the chair base 10, specifically on a dimensionally stable seat support 34 integrated in the seat 14, the front end in the mechanical housing 12 is pivotally mounted on the second transverse axis 26.

- the figure also shows that the lower end of the somewhat shorter lever 32 is articulated somewhat next to and in front of the axis of the chair base 10.

- the lever 32 is also supported with a rear-facing nose on top of the chair foot on a cushion.

- the figure in particular clearly shows that the two levers 30, 32 are approximately aligned with one another, so that they form a rigid support for the seat 14 in the basic position shown in FIG. 3 (backrest in front), which is further supported by the nose of the lever 32 is. In this position, the rear end of the seat 14 cannot therefore descend downward due to the support. Rather, a rigid triangular combination of seat 14, support from levers 30, 32 and mechanical housing 12 is formed. As a result, the synchronous mechanism in the foremost position of the backrest 16 is rendered ineffective.

- Fig. 3 shows an embodiment in which the pivot plate 36 is connected to the pull lever 38 in a link 40 such that the connecting line of link 40 and attachment of the lower ends of the support arms 18 on the pivot plate on the support arms 18 is perpendicular.

- the pivot plate 36 further carries at its rear upper end in recesses 42 a cross bar 50 as the point of engagement of a compression spring 46 (see below) which presses the backrest 16 forward.

- the swivel plate has three transverse holes 44 at the front, with the aid of which, according to the wishes of the user, different backrest positions can be fixed by a pin guided in the mechanical housing.

- the pull lever 38 has the effect that when the user leans against the backrest 16, pushes it backwards and thus pivots the support arms 18 clockwise about the first transverse axis 24, the pivot plate 36 via the pull lever 38 on the third transverse axis 28 pulls, the angle between the levers 30, 32 is increasingly reduced and after the pivoting of the support arms 18 by a few degrees, the rigid support of the seat 14 on the mechanical housing 12 is released.

- the seat 14 is now released and can move through the synchronous mechanism coupled to the backrest with its rear section pivoting downward about the second transverse axis 26 when the backrest 16 is pivoted further backward.

- Fig. 4 now shows, in addition, a compression spring 46 in the form of a mechanical coil spring, which is set axially parallel to the axis of the chair foot 10 in front of this in a corresponding receptacle 48 of the mechanism housing 12 and with its upper end on a cross bar 50 and via this on the swivel plate 36 and thus engages on the backrest 16 via the support arms 18, which is therefore pressed forward by the compression springs 46. If the user of the chair leans against the backrest 16, the compression spring designed as a mechanical coil spring is compressed accordingly between the crossbar 50 and its receptacle 48 and thus progressively increases its restoring force on the backrest in accordance with the spring constant.

- a compression spring 46 in the form of a mechanical coil spring, which is set axially parallel to the axis of the chair foot 10 in front of this in a corresponding receptacle 48 of the mechanism housing 12 and with its upper end on a cross bar 50 and via this on the swivel plate 36 and thus engages on

- a compression spring 52 in the form of a mechanical coil spring can be seen, which is inserted between a first linkage 54 on the mechanical housing 12, and a second linkage 56 on the seat support 34, which is in the region of the first transverse axis 24 on the underside of the Seat 14 is provided.

- the compression spring 52 thus serves to press the seat 14 upward about the second transverse axis 26, that is to say to pivot it counterclockwise in FIG. 4.

- the exemplary embodiments shown in FIG. 4 for the springs 46, 52 are only two examples of numerous possibilities for spring loading of the seat 14 and backrest 16 with which these are held in the basic position. It is also clear that the compression spring 46 not only brings the backrest into the foremost position, but at the same time also ensures that in this position the rigid support from the levers 30 and 32 is again set up when this by pivoting the backrest to the rear once resolved in the manner discussed above.

Landscapes

- Health & Medical Sciences (AREA)

- Dentistry (AREA)

- General Health & Medical Sciences (AREA)

- Chairs Characterized By Structure (AREA)

- Chairs For Special Purposes, Such As Reclining Chairs (AREA)

- Chair Legs, Seat Parts, And Backrests (AREA)

Abstract

Description

Die Erfindung betrifft einen mehrfach verstellbaren, an die Körpergröße anpaßbaren Stuhl, insbesondere Drehstuhl, bei dem die vom Sitz unabhängige Rückenlehne von zwei Tragarmen gehalten ist, die sich ausgehend von einer ersten Querachse unterm Sitz seitlich von diesem nach hinten oben erstrecken und längenveränderlich so wie in unterschiedlichen Längen durch eine Arretiervorrichtung feststellbar sind.The invention relates to a multi-adjustable, adaptable to the size of the chair, in particular swivel chair, in which the seat back independent of the seat is held by two support arms that extend from a first transverse axis under the seat laterally from this to the rear and variable in length as in different lengths can be determined by a locking device.

Ein Stuhl dieser Art ist bekannt aus der DE 33 23 171 A1. Der bekannte Stuhl hat bereits eine verstellbare Sitzhöhe. Überdies wird durch die hier einen Winkel von 30° mit der Horizontalen bildenden, als Hohlrohr ausgeführten Tragarme erreicht, daß bei einer Anhebung der Höhe der Rückenlehne über dem Sitz gleichzeitig die Sitztiefe zunimmt. Im übrigen sind bei diesem vorbekannten Stuhl weder die Rückenlehne noch der Sitz kippbar.A chair of this type is known from DE 33 23 171 A1. The well-known chair already has an adjustable seat height. Moreover, the support arms designed as a hollow tube, which form an angle of 30 ° with the horizontal here, mean that when the height of the backrest is raised above the seat, the seat depth increases at the same time. Moreover, in this previously known chair, neither the backrest nor the seat can be tilted.

Bekannt sind überdies schon Permanentmechaniken und Synchronmechaniken. Bei der Permanentmechanik ist der Sitz starr mit dem Stuhlfuß verbunden, also nicht kippbar, während die Rückenlehne gegen die Wirkung einer Feder kippbar am Stuhlfuß befestigt ist. Es kann somit bei der Permanentmechanik die Rückenlehne unabhängig vom Sitz optimal auf den Rücken abgestimmt werden. Da der starre Sitz aber Bewegungen der Rückenlehne nicht mitmacht, treten auch erhebliche Nachteile auf. Bei der Synchronmechanik sind Sitz und Rückenlehne so gekoppelt, daß beim Zurückführen der Rückenlehne auch der Sitz nach hinten abgekippt wird. Das führt aber dazu, daß bei Synchronmechaniken der Sitzgewichtsanteil auch in vorderer Sitzposition die Rückenlehne bereits nach hinten abkippen läßt, so daß sie ihre stützende Wirkung verliert.Permanent mechanics and synchronous mechanisms are also known. In the case of permanent mechanics, the seat is rigidly connected to the chair base, i.e. cannot be tilted, while the backrest is attached to the chair base so that it can be tilted against the action of a spring. With the permanent mechanism, the backrest can thus be optimally matched to the back regardless of the seat. Since the rigid seat does not follow the movements of the backrest, there are also considerable disadvantages. In the synchronous mechanism, the seat and backrest are coupled in such a way that when the backrest is returned, the seat is also tilted backwards. However, this leads to the fact that with synchronous mechanisms, the seat weight portion already causes the backrest to tip backwards even in the front sitting position, so that it loses its supporting effect.

Um diesen Nachteil zu vermeiden, ist es schon bekannt (DE GM 85 29 663) zwischen den Träger der Rückenlehne und den Träger des Sitzes Hebel und eine zusätzliche Feder anzuordnen, die der Rückenlehne in der Ruhestellung einen vergrößerten Widerstand gegen das Verschwenken verleiht.To avoid this disadvantage, it is already known (DE GM 85 29 663) to arrange levers and an additional spring between the support of the backrest and the support of the seat, which gives the backrest in the rest position an increased resistance to pivoting.

Bekannt ist auch schon ein Stuhl mit Synchronmechanik (DE 38 17 761 C2), bei dem die Rückenlehne von zwei beidseits des Sitzes unter etwa 40° nach hinten oben verlaufenden Tragarmen gehalten ist, die in ihrem vordersten Bereich, also unter der Vorderkante des Sitzes am starren Sitzträger schwenkbar gelagert sind. Dabei ist zwischen dieser Schwenkachse und der Verbindung der Tragarme mit der Rückenlehne eine nach unten ragende Lagerlasche vorgesehen, an der der Sitz mit seinem mittleren Bereich drehbar gelagert ist.A chair with synchronous mechanism (

Schließlich ist es auch bekannt (DE 40 18 436 A1), bei Stühlen, deren Rückenlehne über schräg nach hinten oben verlaufende Tragarme getragen wird, mit diesen Tragarmen auch eine Armlehne des Stuhls zu verbinden.Finally, it is also known (DE 40 18 436 A1) to connect an armrest of the chair to these support arms in chairs whose backrest is supported by support arms which run obliquely backwards.

Die Erfahrung zeigt, daß das Publikum zu zahlreiche Verstellmöglichkeiten an Stühlen nicht auszunützen in der Lage ist. Weiter erscheint es wünschenswert, auch bei einem Stuhl mit Synchronmechanik den Vorteil der Permanentmechanik bezüglich einer vom Gewicht des Sitzenden unbeeinträchtigten aktiven lordosierenden Rückenabstützung aufrecht zu erhalten. Schließlich muß heute dafür gesorgt werden, daß ein und derselbe Stuhl ohne entscheidende Umkonstruktion für Personen ganz unterschiedlicher Größe (vgl. DIN 33402) geeignet ist, wobei die Kompromißwerte (DIN 4551) möglichst zu verbessern sind.Experience shows that the public is unable to take advantage of numerous adjustment options on chairs. Furthermore, it also appears desirable to maintain the advantage of permanent mechanics in the case of a chair with synchronous mechanism in terms of active lordosing back support which is unaffected by the weight of the seated person. Finally, it must be ensured today that one and the same chair is suitable for people of very different sizes (cf. DIN 33402) without any major redesign, whereby the compromise values (DIN 4551) should be improved as far as possible.

Aufgabe der Erfindung ist es deshalb, einen Stuhl mit Synchronmechanik vorzuschlagen, bei dem Sitztiefe, Rückenlehnenhöhe und Armlehnenhöhe gleichzeitig verstellbar und die Synchronmechanik in der vorderen Sitzhaltung selbsttätig gesperrt ist, so daß die Sitzkraft nicht zu einer Verminderung der Stützwirkung der Rückenlehne auf den Rücken führt.The object of the invention is therefore to propose a chair with synchronous mechanism in which the seat depth, backrest height and armrest height can be adjusted at the same time and the synchronous mechanism in the front seat posture is automatically locked so that the seat force does not lead to a reduction in the support effect of the backrest on the back.

Diese Aufgabe wird durch die in den Ansprüchen gekennzeichnete Erfindung gelöst.This object is achieved by the invention characterized in the claims.

Man erkennt zunächst, daß die Rückenlehne von zwei am Sitz gelagerten und seitlich von diesem nach hinten oben erstreckte und längenveränderlichen Tragarmen gehaltert ist, die in unterschiedlichen Längen durch eine Arretiervorrichtung feststellbar sind. Dadurch werden Sitztiefe und Rückenlehnenhöhe gleichzeitig verstellt. Ist gemäß einem besonderen Merkmal der Erfindung der obere Teil des teleskopisch unterteilten längenveränderlichen Tragarms auch noch mit einer Armlehne versehen, dann wird überdies gleichzeitig auch die Armlehnenhöhe verstellt. Mit einer einzigen sinnfälligen Verstellung werden somit synchron die Sitztiefe, die Rückenlehnenhöhe und die Armlehnenhöhe verstellbar gemacht. Dadurch kann überdies auch eine einzige Stuhlkonstruktion einem äußerst weiten Bereich von Benutzergrößen zugänglich gemacht werden, da sich ein besonders großer Größenveränderungsbereich ergibt.It can be seen first of all that the backrest is supported by two support arms which are mounted on the seat and extend laterally from this to the rear and are variable in length and which can be locked in different lengths by a locking device. This adjusts the seat depth and backrest height at the same time. If, according to a special feature of the invention, the upper part of the telescopically subdivided, length-adjustable support arm is also provided with an armrest, then the armrest height is also adjusted at the same time. The seat depth, backrest height and armrest height can thus be adjusted synchronously with a single, sensible adjustment. As a result, a single chair construction can also be made accessible to an extremely wide range of user sizes, since there is a particularly large size change range.

Dieser Größenveränderungsbereich wird entscheidend davon geprägt, daß die Tragarme in der Ruhestellung mit der Horizontalen einen Winkel von mindestens 45°, vorzugsweise über 50° und zumindest nahezu 52° bilden. Denn dadurch wird normgerecht ein Höhenverstellbereich des oberen Abstützpunktes des Beckenkammes von 180 - 230 mm erreicht. Gleichzeitig hat die Armlehne einen Höhenverstellungsbereich von 200 bis 260 mm über dem Einsitzpunkt und läßt sich die Sitztiefe ebenfalls in einem weiten Bereich verändern. Bei der angegebenen steilen Stellung der Tragarme liegt der optimale Anlenkpunkt für deren untere Enden in einem Abstand von einem Drittel der Sitztiefe vom vorderen Sitzrand.This size change range is decisively shaped by the fact that the support arms form an angle of at least 45 °, preferably over 50 ° and at least almost 52 ° with the horizontal in the rest position. Because in this way a height adjustment range of the upper support point of the iliac crest of 180 - 230 mm is achieved. At the same time, the armrest has a height adjustment range of 200 to 260 mm above the seating point and the seat depth can also be changed over a wide range. Given the steep position of the support arms, the optimal articulation point for their lower ends is at a distance of one third of the seat depth from the front edge of the seat.

Zur Erzielung der erwünschten Synchronmechanik ist zunächst einmal der Sitz auf übliche Weise an seinem vorderen Ende um eine horizontale Achse schwenkbar in dem Mechanikgehäuse gelagert. Auch wird der Sitz ebenso durch eine Feder nach oben gedrückt, wie eine weitere Feder die Rückenlehne nach vorne drückt. Entscheidend ist aber nun, daß in der normalen aufrechten Stellung der Rückenlehne die Synchronmechanik dadurch unwirksam gemacht wird, daß zwischen Mechanikgehäuse und Sitz in Abstand von der Schwenkachse des Sitzes eine starre Abstützung eingestellt wird. Diese wird so ausgebildet, daß sie erst bei einer deutlichen und absichtlichen Auslenkung der Rückenlehne durch den Benutzer nach hinten aufgelöst wird und dann die Synchronmechanik wirksam werden läßt. Zunächst ist durch die starre Abstützung aber keine Rückwirkung der Belastung des Sitzes durch den Benutzer auf die Rückenlehne gegeben. Diese schwenkt beim Hinsetzen des Benutzers weder nach hinten weg, noch wird die Kraft der die Rückenlehne nach vorne drückenden Feder vermindert. Somit sind tatsächlich die Vorteile der Permanentmechanik und der Synchronmechanik bei einfacher Verstellmöglichkeit in einem Stuhl kombiniert.In order to achieve the desired synchronous mechanism, the seat is first mounted in the mechanical housing in the usual manner at its front end about a horizontal axis. The seat is also pushed up by a spring, just as another spring pushes the backrest forward. It is crucial, however, that in the normal upright position of the backrest the synchronizing mechanism is rendered ineffective in that a rigid support is set between the mechanism housing and the seat at a distance from the pivot axis of the seat. This is designed so that it is only released when the backrest is clearly and deliberately deflected by the user to the rear, and then the synchronizing mechanism can take effect. First of all, the rigid support does not have any effect on the load on the seat by the user on the backrest. This does not swing back when the user sits down, nor is the force of the spring pushing the backrest forward reduced. Thus, the advantages of permanent mechanics and synchronous mechanics are actually combined in one chair with easy adjustment.

Es ist weiter entscheidend, daß dies mit einer unkomplizierten Mechanik erreicht wird. Dabei kommt es entscheidend auch auf die einfache Konstruktion der starren Abstützung des Sitzes in vorderster Stellung der Rückenlehne an. Diese erfolgt über zwei Hebel, die miteinander in einer Achse gelenkig verbunden und mit ihren jeweils anderen Enden der eine an der Unterseite des Sitzes, der andere an dem Mechanikgehäuse oder am Stuhlfuß angelenkt sind. Die beiden Hebel sollen dabei in der Ruhestellung miteinander fluchten, so daß sie ein starres Abstützglied bilden. In der die beiden Hebel gelenkig verbindenden Querachse greift nun direkt, in der Regel aber indirekt, das untere Ende der Tragarme an, die unterm Sitz gelenkig gelagert sind. Wenn sich nun der Benutzer auf dem zunächst starr abgestützten Sitz nach hinten lehnt und dabei durch den Druck auf die Rückenlehne auch die Tragarme verschwenkt, ziehen diese an der die beiden fluchtenden Hebel verbindenden Querachse, heben so die Abstützung des Sitzes nach einem gewissen Schwenkwinkel und allmählich auf, so daß der Stuhl dann funktioniert, wie ein Stuhl mit üblicher Synchronmechanik.It is also crucial that this is achieved with an uncomplicated mechanism. It is crucial also on the simple construction of the rigid support of the seat in the foremost position of the backrest. This takes place via two levers which are connected to one another in an articulated manner and with their respective other ends, one on the underside of the seat, the other on the mechanism housing or on the chair foot. The two levers should align with each other in the rest position so that they form a rigid support member. In the transverse axis which connects the two levers in an articulated manner, the lower end of the support arms, which are articulated under the seat, now acts directly, but generally indirectly. If the user leans back on the initially rigidly supported seat and swivels the support arms due to the pressure on the backrest, they pull on the transverse axis connecting the two aligned levers, thus lifting the seat support after a certain swivel angle and gradually so that the chair then functions like a chair with the usual synchronous mechanism.

Die Konstruktion wird dann besonders einfach, wenn für diesen Zweck die Tragarme über ihre Anlenkung unter dem Sitz hinaus verlängert werden und je eine Schwenkplatte tragen, die selbst direkt oder vorzugsweise über einen weiteren, einerseits an der Schwenkplatte und andererseits an der Querachse zwischen den beiden Hebeln der Abstützung angelenkten Zughebel mit dieser verbunden ist und sie dadurch auflöst bzw. aufstellt.The construction becomes particularly simple if, for this purpose, the support arms are extended beyond their articulation under the seat and each carry a swivel plate, which itself, or preferably via another, on the one hand on the swivel plate and on the other hand on the transverse axis between the two levers the support articulated pull lever is connected to it and thereby dissolves or sets it up.

Die gesamte erläuterte Kinematik ist dabei frei von Kraftanlenkungen. Selbstverständlich wird aber, wie oben schon angegeben, auch bei diesem Stuhl durch je eine Feder der Sitz nach oben und die Rückenlehne nach vorne gedrückt. Dabei wird die den Sitz nach oben drückende Feder zwischen das als Träger fungierende Mechanikgehäuse und den Sitz eingesetzt, wobei der Angriffspunkt dieser den Sitz nach oben drückenden Feder in der Nachbarschaft der hoch unterm Sitz im Drittelabstand von seinem Vorderrand angeordneten Querachse liegen soll.The entire kinematics explained are free of power linkages. Of course, as already mentioned above, this chair is also pushed upwards by a spring and the backrest is pushed forward. The spring pushing the seat upwards is inserted between the mechanical housing acting as the support and the seat, the point of application of this spring pushing the seat upwards being in the vicinity of the transverse axis arranged thirdly below the seat from its front edge.

Es liegt auf der Hand, daß auch die Feder für das Nachvornedrücken der Rückenlehne zweckmäßig in dem tragenden Mechanikgehäuse unter dem Sitz untergebracht werden muß. Man läßt sie hierzu ebenfalls an den Schwenkplatten der Tragarme angreifen. Durch entsprechende Auslegung der Anlenkung kann dabei erreicht werden, daß die Wirkrichtung der Feder im fraglichen Verstellbereich immer möglichst nahe der optimalen Wirkrichtung der Feder ist.It is obvious that the spring for pushing the backrest forward must also be conveniently accommodated in the supporting mechanical housing under the seat. They are also allowed to attack the swivel plates of the support arms for this purpose. By appropriate design of the articulation it can be achieved that the direction of action of the spring in the adjustment range in question is always as close as possible to the optimal direction of action of the spring.

Als Federn werden mechanische Federn verwendet, die gegenüber der nahezu linearen Kennung einer Gasfeder den Vorteil der progressiven Wirkung haben: mit zunehmender Auslenkung nimmt die Rückstellkraft zu. Das ist insbesondere bei der Rückstellkraft auf die Rückenlehne aus ergonomischen Gründen von Bedeutung.Mechanical springs are used as springs, which have the advantage of the progressive effect compared to the almost linear identification of a gas spring: with increasing deflection, the restoring force increases. This is particularly important for the restoring force on the backrest for ergonomic reasons.

Schließlich wird bei dem Stuhl dem Sitz in Ruhestellung eine Neigung von 3 bis 4° nach vorne gegeben. Dies ist dann der Ausgangspunkt für die Synchronkinematik nach Auflösung der Abstützung des Sitzes, so daß eine Vorrotation des Beckens zur Aufrichtung der Wirbelsäule eingeleitet wird. Die angegebene Vorneigung ist ein Kompromiß zwischen dieser erzielten Wirkung und einer Begrenzung der Vorneigung auf einen Wert, der ein nach vorne Herunterrutschen des Benutzers von der Sitzfläche ausschließt.Finally, the seat is given an inclination of 3 to 4 ° forward in the rest position. This is the starting point for the synchronous kinematics after the support of the seat has been released, so that a pre-rotation of the pelvis is initiated to straighten the spine. The specified forward tilt is a compromise between this effect achieved and a limitation of the forward tilt to a value which prevents the user from sliding forward from the seat.

Schließlich ist noch darauf hinzuweisen, daß die für diesen Stuhl gewählte Konstruktion die Sitztiefenverstellung vom Sitzwinkel völlig unabhängig macht, so daß auch eine von der Sitztiefenverstellung unabhängige Sitzwinkelverstellung erzielt ist.Finally, it should be pointed out that the construction chosen for this chair makes the seat depth adjustment completely independent of the seat angle, so that a seat angle adjustment independent of the seat depth adjustment is also achieved.

Weitere Einzelheiten und Vorteile ergeben sich aus der folgenden Beschreibung der Zeichnung.Further details and advantages result from the following description of the drawing.

Es zeigen

- Fig. 1

- eine Ausführungsform des erfindungsgemäßen Stuhls mit Veranschaulichung verschiedener Verstellmöglichkeiten

- Fig. 2

- eine Veranschaulichung des weiten Anpassungsbereiches des Stuhls an verschiedene Körpergrößen,

- Fig. 3

- eine Ausführungsform der erfindungsgemäßen Sperrung der Synchronmechanik in vorderster Position der Rückenlehne, und

- Fig. 4

- eine um Einzelheiten ergänzte Darstellung.

- Fig. 1

- an embodiment of the chair according to the invention with illustration of various adjustment options

- Fig. 2

- an illustration of the wide range of adaptation of the chair to different body sizes,

- Fig. 3

- an embodiment of the locking of the synchronous mechanism according to the invention in the foremost position of the backrest, and

- Fig. 4

- a representation supplemented with details.

Fig. 1 zeigt einen Stuhl mit einem Stuhlfuß 10, mit der starr ein Mechanikgehäuse 12 verbunden ist, das alle im folgenden erläuterten Teile nach unten abdeckt bzw. abstützt. Ein Sitz 14 ist in dem Mechanikgehäuse 12 an seinem vorderen Ende um eine Querachse schwenkbar angelenkt. Eine Rückenlehne 16 ist, wie in der Figur klar gezeigt ist, mit dem Sitz nicht unmittelbar verbunden, sondern über teleskopische Tragarme 18 mit Arretiervorrichtung 20 und Armlehnen 22. Dabei ist das untere Ende der Tragarme 18 jeweils auf einer horizontal und quer verlaufenden ersten Querachse 24 schwenkbar gelagert. Dies gilt also für den unteren oder inneren Teil des teleskopischen Tragarmes. Hingegen weist der mit der Rückenlehne verbundene obere bzw. äußere Teil der teleskopischen Tragarme 18 die Armlehne auf. Der Benutzer kann durch Betätigen der Arretiervorrichtung die starre Verbindung der beiden Teile der Tragarme 18 gegeneinander lösen und den oberen Teil der Tragarme auf die in der Figur angedeutete Weise geführt auf dem unteren Teil der Tragarme nach oben ziehen und in der gewünschten Stellung wieder festlegen.1 shows a chair with a

Dabei ist in Fig. 1 klar zu erkennen, daß mit dieser einen Betätigung die Rückenlehnenhöhe, die Armlehnenhöhe und die Sitztiefe gleichzeitig verstellt werden.It can be clearly seen in Fig. 1 that with this one actuation the backrest height, the armrest height and the seat depth are adjusted simultaneously.

Fig. 2 dient der Veranschaulichung der Tatsache, daß hiermit auch in einem weiten Bereich ein und dieselbe Konstruktion sehr unterschiedlichen Körpergrößen angepaßt werden kann, wie das von einem Großserienprodukt gefordert werden muß. Die Forderungen der einschlägigen Normen werden dabei bezüglich des Verstellbereiches eingehalten oder sogar erheblich ausgeweitet. Deutlich ist zu erkennen, daß selbst der Stuhl mit Armlehne, wie in Fig. 2 gezeigt, sowohl bei kleinen als auch bei großen Personen und der entsprechenden Einstellung unter die Tischkante ein ebenfalls entsprechendes der Personengröße verstellbaren Tisches paßt. Gut zu erkennen ist auf den Darstellungen von Fig. 2 auch, daß der Rücken durch die Rückenlehne eine gute Lordosenunterstützung erfährt, andererseits aber unter diesem Abstützpunkt auch für Personen unterschiedlicher Größe im Freiraum zwischen Rückenlehne und Sitz genügend Platz für das Gesäß bleibt, wie das die Forderung der Ergonomen ist. Gut erkennbar ist in Fig. 2 aufgrund der Seitenansicht auch, daß die Rückenlehne im Horizontalschnitt deutlich konkav ausgeführt ist, so daß der Körper des Sitzenden gut eingebettet wird.2 serves to illustrate the fact that the same construction can be adapted to very different body sizes in a wide range, as must be required of a large-scale product. The requirements of the relevant standards are complied with or even significantly expanded with regard to the adjustment range. It can be clearly seen that even the chair with armrest, as shown in FIG. 2, fits a table that is also adjustable in size for people, both for small and tall people and the appropriate setting under the edge of the table. It can also be clearly seen on the illustrations in FIG. 2 that the back is given good lumbar support by the backrest, but on the other hand, under this support point, there is also enough space for the buttocks for people of different sizes in the space between the backrest and seat, such as that Ergonomists demand. 2 that the backrest is clearly concave in horizontal section, so that the body of the seated person is well embedded.

Oben wurde schon darauf hingewiesen, daß aus ergonomischen Gründen der gezeigte Stuhl zwar mit einer Synchronmechanik ausgerüstet ist, so daß bei nach hinten Kippen der Rückenlehne 16 auch der hintere Rand des Sitzes 14 gleichzeitig nach unten wegkippt, dabei aber diese übliche Funktion der Synchronmechanik in der vordersten Stellung der Rückenlehne 16 zunächst gesperrt ist.It has already been mentioned above that for ergonomic reasons the chair shown is indeed equipped with a synchronous mechanism, so that when the

Fig. 3 zeigt den entsprechenden Aufbau im einzelnen. Auf dem Stuhlfuß 10 ist das Mechanikgehäuse 12 befestigt, das über die erste Querachse 24 die Tragarme 18 der (in der Figur nicht gezeigten) Rückenlehne und über eine zweite Querachse 26 den Sitz 14 hält. Die erste Querachse 24 ist bei einem Drittel der gesamten Sitztiefe und möglichst hoch, also dicht unter dem Sitz 14 anzuordnen. Die zweite Querachse 26 liegt im vordersten Bereich der Sitzschale 12, also an der Vorderkante des Sitzes.Fig. 3 shows the corresponding structure in detail. The

Der Sitz 14 ist, wie man das in Fig. 3 deutlich erkennen kann, etwas nach vorne geneigt. Hierfür ist er von einer Feder nach oben gedrückt, wie das unten anhand von Fig. 4 noch näher erläutert wird. Die Feder verschwenkt den Sitz 14 um die zweite Querachse 26 im Gegenuhrzeigersinn. Diese Verschwenkung wird aber begrenzt durch eine starre Abstützung aus zwei in einer dritten Querachse 28 verbundenen Hebeln. In der Figur ist klar zu erkennen, daß der etwas längere Hebel 30 an seinem oberen Ende auf der Unterseite des Sitzes 14 und in etwa vertikal über der Achse des Stuhlfußes 10 angelenkt ist und zwar an einem in dem Sitz 14 integrierten formstabilen Sitzträger 34, dessen vorderes Ende im Mechanikgehäuse 12 auf der zweiten Querachse 26 schwenkbar gelagert ist. Ebenso zeigt die Figur, daß das untere Ende des etwas kürzeren Hebels 32 etwas neben der Achse des Stuhlfußes 10 und vor dieser angelenkt ist. Der Hebel 32 stützt sich überdies mit einer nach hinten weisenden Nase oben auf dem Stuhlfuß über ein Dämpfkissen ab. Die Figur läßt insbesondere klar erkennen, daß die beiden Hebel 30, 32 annähernd miteinander fluchten, so daß sie eine starre Abstützung des Sitzes 14 in der in Fig. 3 gezeigten Grundstellung (Rückenlehne vorne) bilden, die durch die Nase des Hebels 32 noch unterstützt ist. In dieser Stellung kann also aufgrund der Abstützung das hintere Ende des Sitzes 14 nicht nach unten abtauchen. Es ist vielmehr ein starrer Dreiecksverbund von Sitz 14, Abstützung aus den Hebeln 30, 32 und Mechanikgehäuse 12 gebildet. Dadurch ist die Synchronmechanik in der vordersten Stellung der Rückenlehne 16 unwirksam gemacht.As can be clearly seen in FIG. 3, the

In Fig. 3 erkennt man nun weiter, daß die Tragarme 18 seitlich des Sitzes 14 nicht etwa in der ersten Querachse 24 enden, sondern über die erste Querachse hinaus verlängert und hier mit einer Schwenkplatte 36 drehschlüssig verbunden sind. Fig. 3 zeigt eine Ausführungsform, bei der die Schwenkplatte 36 mit dem Zughebel 38 in einer Anlenkung 40 derart verbunden ist, daß die Verbindungslinie von Anlenkung 40 und Befestigung der unteren Enden der Tragarme 18 an der Schwenkplatte auf den Tragarmen 18 senkrecht steht. Die Schwenkplatte 36 trägt weiter an ihrem hinteren oberen Ende in Ausnehmungen 42 eine Querstange 50 als Angriffspunkt einer Druckfeder 46 (siehe unten), die die Rückenlehne 16 nach vorne drückt. Schließlich hat die Schwenkplatte vorne drei Querlöcher 44, mit deren Hilfe nach Wunsch des Benutzers verschiedene Lehnenstellungen durch einen im Mechanikgehäuse geführten Stift fixiert werden können.In Fig. 3 it can be seen further that the

Der Zughebel 38 hat die Wirkung, daß dann, wenn sich der Benutzer gegen die Rückenlehne 16 lehnt, diese nach hinten drückt und damit die Tragarme 18 im Uhrzeigersinn um die erste Querachse 24 verschwenkt, die Schwenkplatte 36 über den Zughebel 38 an der dritten Querachse 28 zieht, den Winkel zwischen den Hebeln 30, 32 zunehmend verkleinert und nach der Verschwenkung der Tragarme 18 um einige Grad somit die starre Abstützung des Sitzes 14 an dem Mechanikgehäuse 12 auflöst. Damit ist jetzt der Sitz 14 freigegeben und kann sich durch die Synchronmechanik mit der Rückenlehne gekoppelt mit seinem hinteren Abschnitt um die zweite Querachse 26 schwenkend nach unten bewegen, wenn die Rückenlehne 16 weiter nach hinten verschwenkt wird. Wie erläutert, ist dies aber in der vordersten Stellung der Rückenlehne zunächst nicht der Fall: anders als bei üblichen Synchronmechaniken sonst, wird hier also beim Niedersetzen des Benutzers auf dem Sitz 14 keine Rückwirkung auf die Rückenlehne zugelassen, die deshalb nicht schon beim Niedersetzen entgegen der angestrebten Wirkung nach hinten ausweicht.The

Fig. 4 zeigt aber nun zusätzlich eine Druckfeder 46 in Form einer mechanischen Schraubenfeder, die achsparallel zur Achse des Stuhlfußes 10 vor diesem in eine entsprechende Aufnahme 48 des Mechanikgehäuses 12 eingestellt ist und mit ihrem oberen Ende an einer Querstange 50 und über diese an der Schwenkplatte 36 und damit über die Tragarme 18 an der Rückenlehne 16 angreift, die also durch die Druckfedern 46 nach vorne gedrückt wird. Lehnt sich der Benutzer des Stuhls gegen die Rückenlehne 16, so wird die als mechanische Schraubenfeder ausgeführte Druckfeder entsprechend zwischen der Querstange 50 und ihrer Aufnahme 48 komprimiert und erhöht somit progressiv entsprechend der Federkonstante ihre Rückstellkraft auf die Rückenlehne.Fig. 4 now shows, in addition, a

In Fig. 4 ist weiter eine Druckfeder 52 in Gestalt einer mechanischen Schraubenfeder zu erkennen, die zwischen eine erste Anlenkung 54 an dem Mechanikgehäuse 12, und eine zweite Anlenkung 56 am Sitzträger 34 eingesetzt ist, die im Bereich der ersten Querachse 24 auf der Unterseite des Sitzes 14 vorgesehen ist. Die Druckfeder 52 dient somit dazu, den Sitz 14 um die zweite Querachse 26 jeweils nach oben zu drücken, also in Fig. 4 im Gegenuhrzeigersinn zu verschwenken.In Fig. 4, a

Selbstverständlich sind die in Fig. 4 gezeigten Ausführungsbeispiele für die Federn 46, 52 nur zwei Beispiele für zahlreiche Möglichkeiten der Federbeaufschlagung von Sitz 14 und Rückenlehne 16, mit der diese in Grundstellung gehalten werden. Es ist überdies klar, daß die Druckfeder 46 nicht nur die Rückenlehne in die vorderste Stellung bringt, sondern gleichzeitig auch dafür sorgt, daß in dieser Stellung wiederum die starre Abstützung aus den Hebeln 30 und 32 aufgestellt wird, wenn diese durch Verschwenken der Rückenlehne nach hinten einmal auf die oben erläuterte Weise aufgelöst war.Of course, the exemplary embodiments shown in FIG. 4 for the

Oben wurde schon erläutert, daß die Rückenlehnenhöhe, die Armlehnenhöhe und die Sitztiefe bei dem gezeigten Stuhl synchron, also alle drei gleichzeitig verstellt und mit der Arretiervorrichtung 20 festgelegt werden. Auch die Federkennung der Druckfeder 46 für die Aufstellung der Rückenlehne 16 wird mit Hilfe des üblichen Stellrades 58 verstellt. Die Druckfeder 52 wird passend gewählt.It has already been explained above that the backrest height, the armrest height and the seat depth in the chair shown synchronously, that is, all three are adjusted at the same time and fixed with the locking

Insgesamt ergibt sich bei einfacher Konstruktion ein den Normen und den Bedürfnissen der Ergonomie entsprechender und den Benutzer durch seine Verstellmöglichkeit nicht überfordernder Stuhl, der überdies für sehr unterschiedliche Körpergrößen der Benutzer in seiner Konstruktion unverändert bleiben kann.All in all, with a simple construction, there is a chair which corresponds to the norms and the needs of ergonomics and which does not overwhelm the user due to its adjustment possibility, which chair can also remain unchanged in construction for very different body sizes of the users.

Claims (10)

- A chair, in particular a swivel chair, with multiple adjustment for adapting to different body sizes, in which the backrest (16), which is independent of the seat (14), is held by two support arms (18), which extend either side of the seat backwards and upwards from a first transverse axis (24) beneath the seat, are adjustable in their length and can be locked in different lengths by a locking device (20), characterised in that in the inoperative position the support arms (18) form an angle of at least 45°, preferably exceeding 50° and at least approximately 52° with the horizontal,

the first transverse axis (24) is arranged as a pivot axis for the lower end of the support arms in a height-adjustable mechanics housing (12) in front of the chair leg (10) and at a distance of one third of the seat depth from the front seat edge,

the seat (14) is mounted at its front end in the mechanics housing (12) so as to pivot about a second transverse axis (26) and is pushed upwards by a spring (52),

the backrest (16) is pushed forwards via a spring (46) acting upon the support arms (18), and the synchronisation coupling of the seat (14) and backrest (16) is suspended in the foremost position of the backrest by a rigid support system (30, 32) supporting the seat (14) against the seat shell (12). - A chair according to claim 1, characterised in that the part of the telescopically length-adjustable support arms (18) connected to the backrest (16) also supports an armrest (22).

- A chair according to claim 1, characterised in that the springs acting upon the backrest (16) and seat (14) are mechanical springs.

- A chair according to claim 3, characterised in that the spring (52) pushing the seat (14) upwards acts upon the seat in the vicinity of the first transverse axis (24).

- A chair according to one of claims 1 to 4, characterised in that, in the foremost position of the backrest (16), the rigid support system of the seat (14) is effected against the seat shell (12) via two levers (30, 32), which are connected at a third transverse axis (28), upon which the lower end of the support arm (18) also acts in each case.

- A chair according to claim 5, characterised in that the actuation of the lower end of the support arm (18) upon the third transverse axis is effected via a draw lever (38).

- A chair according to one of claims 1 to 6, characterised in that the lower parts of the support arms (18) each support a pivot plate (36), which is secured to an extension of the support arms beyond the first transverse axis (24).

- A chair according to claim 6 or 7, characterised in that the approximately triangular pivot plate (36) comprises an articulation site (40) at its lower rear end for the draw lever (38) and at its upper rear end comprises a recess (42) for a transverse rod (50), acting upon which is a compression spring (46), which acts upon the backrest and is arranged at least approximately axially parallel to the chair leg (10) in the mechanics housing (12).

- A chair according to one of claims 6 to 8, characterised in that the upper of the two support levers (30) acts upon the seat (14) at least approximately in the extension of the axis of the chair leg (10).

- A chair according to one of claims 1 to 9, characterised in that the seat (14) is inclined forwards by 3 to 4 degrees relative to the horizontal in its rigidly supported position.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP91116685A EP0535262B1 (en) | 1991-09-30 | 1991-09-30 | Adjustable chair which is adaptable to a person's stature, particularly rotatable chair |

| ES91116685T ES2080211T3 (en) | 1991-09-30 | 1991-09-30 | CHAIR ADAPTABLE TO THE HEIGHT, MULTIPLE GRADUATION, ESPECIALLY SWIVEL CHAIR. |

| DE59107042T DE59107042D1 (en) | 1991-09-30 | 1991-09-30 | Multi-adjustable, height-adjustable chair, especially swivel chair. |

| AT91116685T ATE131016T1 (en) | 1991-09-30 | 1991-09-30 | MULTIPLE ADJUSTABLE CHAIR THAT ADJUSTS TO THE BODY SIZE, ESPECIALLY SWIVEL CHAIR. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP91116685A EP0535262B1 (en) | 1991-09-30 | 1991-09-30 | Adjustable chair which is adaptable to a person's stature, particularly rotatable chair |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0535262A1 EP0535262A1 (en) | 1993-04-07 |

| EP0535262B1 true EP0535262B1 (en) | 1995-12-06 |

Family

ID=8207225

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91116685A Expired - Lifetime EP0535262B1 (en) | 1991-09-30 | 1991-09-30 | Adjustable chair which is adaptable to a person's stature, particularly rotatable chair |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0535262B1 (en) |

| AT (1) | ATE131016T1 (en) |

| DE (1) | DE59107042D1 (en) |

| ES (1) | ES2080211T3 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040189073A1 (en) * | 2003-03-28 | 2004-09-30 | Donald Chadwick | Adjustable chair |

| US10485346B2 (en) * | 2018-01-22 | 2019-11-26 | Knoll, Inc. | Chair tilt mechanism |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1239451B (en) * | 1962-05-29 | 1967-04-27 | Dr Dr Hans W Juergens | Chair with height-adjustable seat and adjustable backrest |

| US3215470A (en) * | 1964-05-22 | 1965-11-02 | Milsco Mfg Co | Seat with adjustable elements |

| DE1808395B2 (en) * | 1968-11-12 | 1970-09-03 | ||

| DE3608718A1 (en) * | 1986-03-15 | 1987-09-17 | Drabert Soehne | SEAT FURNITURE |

| DE3838999A1 (en) * | 1988-11-18 | 1990-05-23 | Roeder Gmbh | CHAIR, ESPECIALLY WORK OR OFFICE CHAIR |

-

1991

- 1991-09-30 AT AT91116685T patent/ATE131016T1/en not_active IP Right Cessation

- 1991-09-30 DE DE59107042T patent/DE59107042D1/en not_active Expired - Fee Related

- 1991-09-30 EP EP91116685A patent/EP0535262B1/en not_active Expired - Lifetime

- 1991-09-30 ES ES91116685T patent/ES2080211T3/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| ES2080211T3 (en) | 1996-02-01 |

| DE59107042D1 (en) | 1996-01-18 |

| ATE131016T1 (en) | 1995-12-15 |

| EP0535262A1 (en) | 1993-04-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102012107778B4 (en) | Chair, especially office chair | |

| DE69132601T2 (en) | Device for a reclining chair | |

| EP2374371B1 (en) | Seating furniture with a seat that can be pivoted into a position that assists in standing up | |

| AT402602B (en) | CHAIR CHAIR | |

| EP2051606B1 (en) | Armchair | |

| DE19830418B4 (en) | chair arrangement | |

| EP1358821B1 (en) | Office chair with a user-weight-dependent energy storage device | |

| EP2888975B1 (en) | Work chair with a synchronous mechanism and flexing spring | |

| EP1769704B1 (en) | Seating/lying furniture | |

| WO2007000270A1 (en) | Synchronisation mechanism | |

| EP2070444B1 (en) | Office chair | |

| EP2070446A1 (en) | Office chair with adjustable backrest and means to limit the slope of the backrest | |

| EP0233974B1 (en) | Tilting device for sitting-furniture | |

| EP2670279B1 (en) | Synchron mechanics | |

| DE202014011308U1 (en) | seating | |

| EP0535262B1 (en) | Adjustable chair which is adaptable to a person's stature, particularly rotatable chair | |

| DE102004012850B4 (en) | Backrest for a chair comprises a rigid frame or support element and a flexible or bendable support element for forming a back support | |

| DE202014101592U1 (en) | chair | |

| EP2477523B1 (en) | Tilting mechanism for an office chair | |

| DE19700617C2 (en) | armchair | |

| EP2111138B1 (en) | Seating furniture comprising a pivotable foot part | |

| DE1159147B (en) | Lever control device for the leg rest of an adjustable chair | |

| WO2014183851A1 (en) | Synchronizing mechanism | |

| WO2012041448A1 (en) | Synchronizing mechanism | |

| EP1074202B1 (en) | Seating furniture |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19930811 |

|

| 17Q | First examination report despatched |

Effective date: 19950410 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Effective date: 19951206 |

|

| REF | Corresponds to: |

Ref document number: 131016 Country of ref document: AT Date of ref document: 19951215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59107042 Country of ref document: DE Date of ref document: 19960118 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2080211 Country of ref document: ES Kind code of ref document: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19960116 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWALTSBUERO JEAN HUNZIKER |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960306 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19960930 Ref country code: LI Effective date: 19960930 Ref country code: GB Effective date: 19960930 Ref country code: CH Effective date: 19960930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19961001 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: WIESNER-HAGER MOBEL G.M.B.H. Effective date: 19960930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19970401 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960930 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19970401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19971011 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080903 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080905 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100401 |