EP0504445B1 - Apparatus and method for commingling continuous multifilament yarns - Google Patents

Apparatus and method for commingling continuous multifilament yarns Download PDFInfo

- Publication number

- EP0504445B1 EP0504445B1 EP91104188A EP91104188A EP0504445B1 EP 0504445 B1 EP0504445 B1 EP 0504445B1 EP 91104188 A EP91104188 A EP 91104188A EP 91104188 A EP91104188 A EP 91104188A EP 0504445 B1 EP0504445 B1 EP 0504445B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- yarn

- commingling

- yarns

- bar

- filaments

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H51/00—Forwarding filamentary material

- B65H51/005—Separating a bundle of forwarding filamentary materials into a plurality of groups

- B65H51/01—Separating a bundle of forwarding filamentary materials into a plurality of groups by means of static electricity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H51/00—Forwarding filamentary material

- B65H51/015—Gathering a plurality of forwarding filamentary materials into a bundle

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02G—CRIMPING OR CURLING FIBRES, FILAMENTS, THREADS, OR YARNS; YARNS OR THREADS

- D02G3/00—Yarns or threads, e.g. fancy yarns; Processes or apparatus for the production thereof, not otherwise provided for

- D02G3/02—Yarns or threads characterised by the material or by the materials from which they are made

- D02G3/04—Blended or other yarns or threads containing components made from different materials

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02J—FINISHING OR DRESSING OF FILAMENTS, YARNS, THREADS, CORDS, ROPES OR THE LIKE

- D02J1/00—Modifying the structure or properties resulting from a particular structure; Modifying, retaining, or restoring the physical form or cross-sectional shape, e.g. by use of dies or squeeze rollers

- D02J1/18—Separating or spreading

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a method and an apparatus for commingling two or more continuous multiple filament yarns into a single yarn according to the preamble of claim 1 and to the preamble of claim 16 and known, for instance, from document JP-B-47 003 861.

- commingled yarns make possible the manufacture of advanced thermoplastic composite parts in very complex shapes.

- commingled carbon and polyether ether ketone (PEEK) yarns are desirable, because, in a mold under heat and pressure, the PEEK melts and flows around the carbon fibers, forming a lightweight, reinforced plastic without the complications of the more traditional wet epoxy and polyester resin systems.

- Curzio U.S. Patent No. 4,539,249 discloses combining graphite fibers from one spool with thermoplastic resin fibers from other spools by passing thermoplastic and graphite fibers through a guide plate, twisting these fibers and overwrapping these fibers with additional resin fibers from additional spools to provide a blended yarn.

- JP-B-47 003 861 discloses a method for doubling two or more non-twisted multifilament yarns having different properties wherein the yarns are charged with static electricity and simultaneously relaxed between two sets of rollers, wherein the fibers of the yarns are simultaneously opened and mixed.

- the document DE-A-3 730 207 discloses an apparatus for combining and twisting two multifilament yarns, wherein the two yarns are electrostatically charged at different polarities so that they adhere to one another.

- the charged yarn is guided over a friction surface wherein between the yarn and the friction surface a rotating relative movement is carried out, of which the axis is essentially in the direction of motion of the multifilament yarn. This is to the end that the filaments which are separated by the electrostatic charge are wound around the multifilament yarn mechanically.

- Fig. 1 is a schematic representation of commingling apparatus according to the invention.

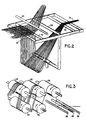

- Fig. 2 is a perspective diagrammatic view showing air ribboning and commingling components of the Fig. 1 apparatus.

- Fig. 3 is a perspective diagrammatic view of rollers of the Fig. 1 apparatus that are used for generating static electricity in a yarn to provide a flat opened ribbon according to the invention.

- commingling apparatus 10 in use commingling polyether ether ketone (PEEK) continuous multiple filament yarns 12 from freely rotatable supply rolls 14 and continuous multiple filament graphite yarn 16 from freely rotatable supply roll 18.

- PEEK polyether ether ketone

- apparatus 10 includes gathering guide 20, motor-driven pinch rollers 22, 24, three pretensioning bars 26, five motor-driven charge-inducing rollers 28 (1/32" thick virgin PTFE Teflon surface layers, available from DuPont, mounted on 4" steel support rollers), and ribboning bar 30.

- apparatus 10 On the path of travel for graphite yarn 16, apparatus 10 includes driven shaft 32, idler shaft 34, support rod 36, air curtain element 38 (a tube connected to a source of pressurized air and having a single row of downwardly directed holes along its length), and support rod 40. Downstream of support rod 40 and ribboning bar 30 are commingling bar 42, two free-wheeling rollers 43, atomizer 44 (for spraying sizing onto the filaments), and take-up unit 48 (including a traversing mechanism not shown) for wrapping the commingled yarn on take-up roll 49. Rollers 28 are electrically isolated, to permit the static charges to build up on the yarn. Downstream of rollers 28, ribboning bar 30, commingling bar 42, and rollers 43 are grounded, permitting bleeding of the charges.

- Pinch rolls 22, 24, driven shaft 32, and take-up unit 48 are driven by a common first drive system (not shown) to achieve the desired velocity of yarn through the apparatus.

- Rollers 28 are driven by a common second drive system (not shown) that provides variable speed from 0 to 200 feet per minute surface velocity, twice as fast as the typical yarn velocity of 33 meters (100 feet) per minute.

- the continuous multiple filament PEEK yarns 12 and graphite yarn 16 are separately opened up into flat opened ribbons, the flat opened ribbons are combined so as to have interleaving of different filaments, and the resulting combined flat ribbon is narrowed and wound up on the takeup roll.

- the graphite and PEEK yarns travel at approximately 100 feet per minute through apparatus 10.

- the three yarns pass through and are combined at guide 20. From there they are driven between pinch rollers 22, 24 and through pretensioning bars 26 to rollers 28. Pretensioning bars 26 assist providing desired tension in the PEEK yarns as they travel past and around rollers 28.

- the PEEK yarn cannot be opened up by application of an air curtain and, therefore, is opened up by generating a static charge on it through the use of rollers 28.

- Rollers 28 are driven at speeds to cause relative travel between the PEEK filaments and the Teflon surface. Rolls 28 develop a charge that is opposite that developed in the PEEK fibers, causing the fibers to be attracted to the rollers, and increasing the tension in fibers 12 as they pass through the five rollers 28.

- the charge applied to the PEEK filaments can be adjusted as necessary to provide the desired opening of the individual filaments, and the desired width of the flat ribbon that matches that of the flat ribbon of graphite yarns. From ribboning bar 30, the flat opened ribbon of PEEK yarns passes over commingling bar 42.

- Graphite yarn 16 travels from supply roll 18 between driven shaft 32 and idler shaft 34. Driven shaft 32 is driven at a speed equal to that of take-up roll 49 and pinch rolls 22, 24. The speed of driven shaft 32 can be adjusted if necessary to provide the loop between support rod 36 and support rod 40.

- the graphite yarn can be opened up into an open ribbon by the application of an air curtain, because the graphite fibers are not greatly attracted to each other.

- the pressurized curtain causes the loop to extend in the direction of air flow and the individual graphite filaments to separate so that the graphite yarn is in a flat opened ribbon state when it joins with the PEEK ribbon at the commingling bar 42.

- the opened ribbons of PEEK and graphite are joined together, and the different filaments are interleaved.

- the combined flat opened ribbon passes under and over free-wheeling rollers 43 and past atomizer 44, at which sizing is sprayed to cause the individual filaments to tend to adhere to each other.

- the charges have been bled sufficiently to permit the fibers to be in close proximity to each other.

- the commingled yarn has about a 3,8 cm (1 1/2") width, which is reduced to about 0,3 to 0,6 cm (1/8" to 1/4") by the guide of take-up unit 48, which wraps the commingled yarn on take-up roll 49.

- the commingled yarn can be stored indefinitely and used to produce woven, drapable, reinforced thermoplastic fabric on conventional equipment.

- heat and pressure is applied, and the PEEK flows around the reinforcing graphite fibers and bonds the graphite fibers together.

- the homogeneous nature of the commingled yarn provides intimate contact between the individual filaments of the component PEEK and graphite, thereby, providing improved wet out and bonding.

- the process is superior to other methods of assembling such yarns, for example, twisting and/or parallel winding, because the individual filaments of the component yarns are more homogeneously distributed throughout the resulting yarn. Because the yarn is commingled rather than layered, the component materials are more evenly distributed in the final product, resulting in better blending of reinforcing graphite fibers and resin matrix fibers, thereby producing superior products.

- the speed of travel through apparatus 10 has an effect on the quality of the product, in particular its homogeneity. It was found that as the speed was increased from 6,6 meters per sec (20 fpm) to around 23 meters per sec (70 fpm) there was not much noticeable effect on homogeneity; at around 23 meters per sec (70 fpm), improvements in quality were first noted, and increasing speed from 23 meters per sec (70 fpm) to over 33 meters per sec (100 fpm) resulted in further improvements in homogeneity. Continuing to increase speed above 33 meters per sec (100 fpm) should improve homogeneity even further. It is believed that the increased speed promotes parallel PEEK filaments during travel to the commingling bar. One factor permitting the high speeds is that there are no mechanical separating elements, e.g., comb teeth, which would limit speed and potentially damage filaments.

- sizing roll 45 (a roller partially located in a trough containing a sizing liquid) could be used to apply sizing to the yarns, and materials other than Teflon can be used in the static charge-inducing body.

Description

- The invention relates to a method and an apparatus for commingling two or more continuous multiple filament yarns into a single yarn according to the preamble of claim 1 and to the preamble of

claim 16 and known, for instance, from document JP-B-47 003 861. - It is sometimes desirable to commingle or hybridize two or more continuous multiple filament yarns into a single yarn to provide the combined beneficial characteristics of the two different materials in a single yarn. Such commingled yarns make possible the manufacture of advanced thermoplastic composite parts in very complex shapes. For example, commingled carbon and polyether ether ketone (PEEK) yarns are desirable, because, in a mold under heat and pressure, the PEEK melts and flows around the carbon fibers, forming a lightweight, reinforced plastic without the complications of the more traditional wet epoxy and polyester resin systems.

- Curzio U.S. Patent No. 4,539,249 discloses combining graphite fibers from one spool with thermoplastic resin fibers from other spools by passing thermoplastic and graphite fibers through a guide plate, twisting these fibers and overwrapping these fibers with additional resin fibers from additional spools to provide a blended yarn.

- The patent document JP-B-47 003 861 (Abstract) discloses a method for doubling two or more non-twisted multifilament yarns having different properties wherein the yarns are charged with static electricity and simultaneously relaxed between two sets of rollers, wherein the fibers of the yarns are simultaneously opened and mixed.

- The document DE-A-3 730 207 discloses an apparatus for combining and twisting two multifilament yarns, wherein the two yarns are electrostatically charged at different polarities so that they adhere to one another. In accordance with one embodiment disclosed in this document the charged yarn is guided over a friction surface wherein between the yarn and the friction surface a rotating relative movement is carried out, of which the axis is essentially in the direction of motion of the multifilament yarn. This is to the end that the filaments which are separated by the electrostatic charge are wound around the multifilament yarn mechanically.

- It has been dicovered that commingling of two or more different continuous multifilament yarns can be improved by the method as claimed in claim 1 and by the apparatus as claimed in

claim 16. One essential advantage of the invention is that a very homogeneous mixing of different yarns is permitted. Further advantages are that the individual filaments in the commingled yarn remain parallel. The feed yarns are blended with a high degree of homogeneity, and the process is very economical. - Other advantages and features of the invention will be apparent from the following description of a preferred embodiment thereof and from the claims.

- The preferred embodiment will now be described.

- Fig. 1 is a schematic representation of commingling apparatus according to the invention.

- Fig. 2 is a perspective diagrammatic view showing air ribboning and commingling components of the Fig. 1 apparatus.

- Fig. 3 is a perspective diagrammatic view of rollers of the Fig. 1 apparatus that are used for generating static electricity in a yarn to provide a flat opened ribbon according to the invention.

- Referring to Figs. 1-3, there is shown commingling

apparatus 10 in use commingling polyether ether ketone (PEEK) continuousmultiple filament yarns 12 from freely rotatable supply rolls 14 and continuous multiplefilament graphite yarn 16 from freelyrotatable supply roll 18. On the path of travel of PEEKyarn 12,apparatus 10 includes gatheringguide 20, motor-drivenpinch rollers pretensioning bars 26, five motor-driven charge-inducing rollers 28 (1/32" thick virgin PTFE Teflon surface layers, available from DuPont, mounted on 4" steel support rollers), and ribboningbar 30. On the path of travel forgraphite yarn 16,apparatus 10 includes drivenshaft 32,idler shaft 34,support rod 36, air curtain element 38 (a tube connected to a source of pressurized air and having a single row of downwardly directed holes along its length), andsupport rod 40. Downstream ofsupport rod 40 andribboning bar 30 are comminglingbar 42, two free-wheeling rollers 43, atomizer 44 (for spraying sizing onto the filaments), and take-up unit 48 (including a traversing mechanism not shown) for wrapping the commingled yarn on take-up roll 49.Rollers 28 are electrically isolated, to permit the static charges to build up on the yarn. Downstream ofrollers 28, ribboningbar 30,commingling bar 42, androllers 43 are grounded, permitting bleeding of the charges. -

Pinch rolls shaft 32, and take-up unit 48 are driven by a common first drive system (not shown) to achieve the desired velocity of yarn through the apparatus.Rollers 28 are driven by a common second drive system (not shown) that provides variable speed from 0 to 200 feet per minute surface velocity, twice as fast as the typical yarn velocity of 33 meters (100 feet) per minute. - In the example shown in Fig. 1, three

multiple filament yarns 12 from three rolls of PEEK (available from Celanese under the trade designation 300/100 SP-301A PEEK) were blended with one continuous filament graphite yarn 16 (3K unsized carbon tow available from BASF under the trade designation Celion) to provide the desired proportion of the two. - In operation, in general, the continuous multiple

filament PEEK yarns 12 andgraphite yarn 16 are separately opened up into flat opened ribbons, the flat opened ribbons are combined so as to have interleaving of different filaments, and the resulting combined flat ribbon is narrowed and wound up on the takeup roll. The graphite and PEEK yarns travel at approximately 100 feet per minute throughapparatus 10. - Discussing the processing of

PEEK yarns 12 first, the three yarns pass through and are combined atguide 20. From there they are driven betweenpinch rollers pretensioning bars 26 torollers 28.Pretensioning bars 26 assist providing desired tension in the PEEK yarns as they travel past and aroundrollers 28. The PEEK yarn cannot be opened up by application of an air curtain and, therefore, is opened up by generating a static charge on it through the use ofrollers 28.Rollers 28 are driven at speeds to cause relative travel between the PEEK filaments and the Teflon surface. Rolls 28 develop a charge that is opposite that developed in the PEEK fibers, causing the fibers to be attracted to the rollers, and increasing the tension infibers 12 as they pass through the fiverollers 28. (I.e., the attraction must be overcome in pulling the yarns off of the surfaces of the rollers.) Around 6000 volts is generated in passing throughrollers 28, and the electrical charge applied to the yarn filaments causes them to repel each other. Because the cross-sectional configuration of the chargedyarn leaving rolls 28 thus tends to be circular, the open filament bundle is drawn under ribboningbar 30 under tension to force the bundle into the shape of a flat opened ribbon. As is seen in Fig. 3, by the time the filaments leave ribboningbar 30, they are in parallel configuration, and the ribbon is approximately two to four inches wide. By varying the tension in the PEEK yarns and the speeds ofrollers 28, the charge applied to the PEEK filaments can be adjusted as necessary to provide the desired opening of the individual filaments, and the desired width of the flat ribbon that matches that of the flat ribbon of graphite yarns. Fromribboning bar 30, the flat opened ribbon of PEEK yarns passes over comminglingbar 42. - By using static-inducing rolls with controllable speed, one can control both the charge on the yarn and the tension, thereby controlling the separation and the width of the flat opened ribbon of PEEK to provide better control of the commingling with the opened ribbon of graphite.

-

Graphite yarn 16 travels fromsupply roll 18 between drivenshaft 32 andidler shaft 34.Driven shaft 32 is driven at a speed equal to that of take-up roll 49 andpinch rolls shaft 32 can be adjusted if necessary to provide the loop betweensupport rod 36 andsupport rod 40. The graphite yarn can be opened up into an open ribbon by the application of an air curtain, because the graphite fibers are not greatly attracted to each other. The pressurized curtain causes the loop to extend in the direction of air flow and the individual graphite filaments to separate so that the graphite yarn is in a flat opened ribbon state when it joins with the PEEK ribbon at thecommingling bar 42. - At commingling

bar 42, the opened ribbons of PEEK and graphite are joined together, and the different filaments are interleaved. From comminglingbar 42, the combined flat opened ribbon passes under and over free-wheeling rollers 43 andpast atomizer 44, at which sizing is sprayed to cause the individual filaments to tend to adhere to each other. By the time the PEEK filaments reachatomizer 44, the charges have been bled sufficiently to permit the fibers to be in close proximity to each other. Atatomizer 44, the commingled yarn has about a 3,8 cm (1 1/2") width, which is reduced to about 0,3 to 0,6 cm (1/8" to 1/4") by the guide of take-up unit 48, which wraps the commingled yarn on take-uproll 49. - The commingled yarn can be stored indefinitely and used to produce woven, drapable, reinforced thermoplastic fabric on conventional equipment. In use in fabricating lightweight, reinforced thermoplastic products, heat and pressure is applied, and the PEEK flows around the reinforcing graphite fibers and bonds the graphite fibers together. The homogeneous nature of the commingled yarn provides intimate contact between the individual filaments of the component PEEK and graphite, thereby, providing improved wet out and bonding. The process is superior to other methods of assembling such yarns, for example, twisting and/or parallel winding, because the individual filaments of the component yarns are more homogeneously distributed throughout the resulting yarn. Because the yarn is commingled rather than layered, the component materials are more evenly distributed in the final product, resulting in better blending of reinforcing graphite fibers and resin matrix fibers, thereby producing superior products.

- The speed of travel through

apparatus 10 has an effect on the quality of the product, in particular its homogeneity. It was found that as the speed was increased from 6,6 meters per sec (20 fpm) to around 23 meters per sec (70 fpm) there was not much noticeable effect on homogeneity; at around 23 meters per sec (70 fpm), improvements in quality were first noted, and increasing speed from 23 meters per sec (70 fpm) to over 33 meters per sec (100 fpm) resulted in further improvements in homogeneity. Continuing to increase speed above 33 meters per sec (100 fpm) should improve homogeneity even further. It is believed that the increased speed promotes parallel PEEK filaments during travel to the commingling bar. One factor permitting the high speeds is that there are no mechanical separating elements, e.g., comb teeth, which would limit speed and potentially damage filaments. - Other embodiments of the invention are within the scope of the following claims. For example other yarns besides the PEEK and graphite, e.g., polyphenylene sulfide (PPS), can be used and commingled using

apparatus 10. Also more orfewer rolls 28 can be used to provide the charge depending on the material, and a plurality of different yarns can be provided at supply rolls 14. Also each of the yarns being commingled could be rubbed against a static charge-inducing body prior to combining them. Also, instead ofatomizer 44, sizing roll 45 (a roller partially located in a trough containing a sizing liquid) could be used to apply sizing to the yarns, and materials other than Teflon can be used in the static charge-inducing body.

Claims (29)

- A method of commingling two or more different continuous multiple filament yarns (12, 16) into a single yarn comprising

continuously supplying separate first and second different continuous multiple filament yarns (12, 16),

rubbing said first yarn (12) against a static charge-inducing body that is supported in an electrically isolated manner to apply static charge to said first yarn (12) to tend to cause separation of individual multiple filaments of said first yarn (12)

characterized in that

said body is a variable-speed rotatably-driven roll (28) having a tangential speed that is in the same direction as and is faster than that of said filaments of said first yarn (12),

all multiple filament strands of said first yarn (12) proceeding in the same direction with respect to the direction of rotation of said roll (28),

and said method further comprising

causing said first yarn (12) to form a first opened ribbon,

separately opening up said second multiple filament yarn (16) to form a second opened ribbon, and

combining said first and second ribbons so as to cause mixing of different individual filaments,

said first yarn (12) not being driven by any drive means after said rubbing against said static charge inducing body (28) and prior to said combining said first and second yarns (12, 16). - The method of claim 1 wherein said first yarn is made of nonconductive material, and said second yarn is made of conductive material.

- The method of claim 2 wherein said first fibers are thermoplastic, and said second fibers are carbon fibers.

- The method of claim 3 wherein said thermoplastic fibers are polyether ether ketone.

- The method of claim 3 wherein said thermoplastic fibers are polyphenylene sulfide.

- The method of claim 1 wherein said second yarn is opened into said opened ribbon using an air curtain directed to a loop of said filaments hanging between two support rods.

- The method of claim 1 wherein said combining of opened ribbons includes bringing them together over a commingling bar.

- The method of claim 7 wherein said opening of said first yarn includes traveling under tension around a ribboning bar to spread out filaments that have said static charge on them.

- The method of claim 1 further comprising applying sizing to said combined opened ribbon after said combining.

- The method of claim 9 further comprising reducing the width of said combined opened ribbon after applying said sizing.

- The method of claim 8 in which said yarns travel at greater than approximately 23 meters (70 feet) per minute.

- The method of claim 11 in which said yarns travel at greater than approximately 23 meters (100 feet) per minute.

- The method of claim 1 wherein said tangential speed is adjusted so as to control tension.

- The method of claim 1 wherein said tangential speed is adjusted so as to control the amount of static charge.

- The method of claim 1 wherein said rubbing includes rubbing against a plurality of variable-speed rotatably-driven rolls (26), said first yarn (12) alternately contacting different sides of said rolls.

- Apparatus for commingling two or more different continuous multiple filament yarns (12, 16) into a single yarn comprising

supply means (14, 18) for continuously supplying separate first and second different continuous multiple filament yarns (12, 16),

a static charge-inducing body that is supported in an electrically isolated manner to apply static charge to said first yarn (12) supplied from said supply means (14) as said yarn travels past and rubs against said body to tend to cause separation of individual multiple filaments of said first yarn (12),

characterized in that

said body is a variable-speed rotatably-driven roll (28) capable of having a tangential speed that is in the same direction as and is faster than that of said filaments of said first yarn (12),

all multiple filament strands of said first yarn proceed in the same direction with respect to the direction of rotation of said roll (28),

means (30) for causing said first yarn (12) to form a first opened ribbon,

and said apparatus further comprises

means (38) for separately opening said second multiple filament yarn (16) to provide a second opened ribbon, and

means (42) for combining said first and second ribbons so as to cause mixing of different individual filaments,

said apparatus not having any drive means present along the path of said first yarn (12) from said static charge inducing body (28) to said means for combining (42). - The apparatus of claim 16 wherein said means (38) separately opening comprises means for providing an air curtain to open said second yarn.

- The apparatus of claim 16 wherein said means for combining (42) includes a commingling bar over which said first and second opened ribbons travel.

- The apparatus of claim 18 further comprising a ribboning bar (30) between said body (28) between said body (28) and said commingling bar (42) to spread out filaments of said first yarn (12) that have said charge applied to them.

- The apparatus of claim 19 further comprising an atomizer (44) for applying sizing to said combined opened ribbon after leaving said commingling bar (42).

- The apparatus of claim 19 further comprising a sizing roll for applying sizing to said combined opened ribbon after leaving said commingling bar.

- The apparatus of claim 18 wherein said commingling bar (42) is grounded.

- The apparatus of claim 19 wherein said commingling bar (42) and said ribboning bar (30) are grounded.

- The apparatus of claim 19 in which said apparatus is capable of causing said yarns (12, 16) to travel through said apparatus at greater than approximately 23 meters (70 feet) per minute.

- The apparatus of claim 24 in which said apparatus is capable of causing said yarns (12, 16) to travel through said apparatus at greater than approximately 33 meters (100 feet) per minute.

- The apparatus of claim 16 where said first yarn is made of nonconductive material, and said second yarn is made of conductive material.

- The apparatus of claim 16 wherein said tangential speed is adjustable so as to control tension.

- The apparatus of claim 16 wherein said tangential speed is adjustable so as to control the amount of static charge.

- The apparatus of claim 16 further comprising additional variable-speed rotatably-driven rolls (26), said first (12) yarn alternately contacting different sides of said rolls (26).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US2124887A | 1987-03-03 | 1987-03-03 | |

| US07/377,175 US5000807A (en) | 1987-03-03 | 1989-07-10 | Apparatus and method for commingling continuous multifilament yarns |

| CA002038542A CA2038542C (en) | 1989-07-10 | 1991-03-18 | Apparatus and method for commingling continuous multifilament yarns |

| JP3216726A JP2708978B2 (en) | 1989-07-10 | 1991-03-19 | Apparatus and method for mixing continuous multifilament yarn |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0504445A1 EP0504445A1 (en) | 1992-09-23 |

| EP0504445B1 true EP0504445B1 (en) | 1995-12-27 |

Family

ID=27426843

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91104188A Expired - Lifetime EP0504445B1 (en) | 1987-03-03 | 1991-03-18 | Apparatus and method for commingling continuous multifilament yarns |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0504445B1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201604047D0 (en) | 2016-03-09 | 2016-04-20 | Coats Ltd J & P | Thread |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0156599B1 (en) * | 1984-03-15 | 1988-11-09 | BASF Aktiengesellschaft | Composite carbon fibre and thermoplastic fiber blends |

| DE3730207A1 (en) * | 1987-09-09 | 1989-03-30 | Fritz Stahlecker | Method for the consolidation of drafted fibre slithers |

-

1991

- 1991-03-18 EP EP91104188A patent/EP0504445B1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0504445A1 (en) | 1992-09-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5000807A (en) | Apparatus and method for commingling continuous multifilament yarns | |

| US5241731A (en) | Apparatus for commingling continuous multifilament yarns | |

| RU2126367C1 (en) | Method of spinning composite thread and device for its embodiment | |

| US5355567A (en) | Process for preparing engineered fiber blend | |

| US4159619A (en) | Method for producing novelty yarns | |

| EP0057583B1 (en) | Synthetic yarn and yarn-like structures and a method for their production | |

| KR100601346B1 (en) | Method and apparatus for spinning, drawing, and winding a yarn | |

| TWI427201B (en) | Process and device for manufacturing a composite strand | |

| EP0465917B1 (en) | Method and apparatus for manufacturing continuous fiber glass strand reinforcing mat | |

| US4997503A (en) | Filament winding apparatus and method | |

| US5182839A (en) | Apparatus and method for commingling continuous multifilament yarns | |

| US3664115A (en) | Method of making a semi-continuous filament combination yarn | |

| EP0431439B1 (en) | Method of and apparatus for manufacturing glass fiber mat | |

| EP0504445B1 (en) | Apparatus and method for commingling continuous multifilament yarns | |

| JPS61229535A (en) | Method and device for manufacturing fiber reinforced resin sheet | |

| US3444683A (en) | Manufacture of endless threadlike products of thermoplastic materials | |

| US3889034A (en) | Chenille yarn and method of making same | |

| GB2115446A (en) | Yarn manufacturing method and apparatus | |

| US5639307A (en) | Fiber bundle coating apparatus | |

| US3175348A (en) | Process and apparatus for making bulked filament yarns | |

| US3197351A (en) | Preparation of thin, highly directionalized filament structures | |

| CN109208140B (en) | Device and method for splitting a fiber bundle | |

| US3771306A (en) | Fibrillation process | |

| US11846044B2 (en) | Device and method for producing fancy yarns | |

| US4403744A (en) | Method and apparatus for controlling strand tension during winding |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19930303 |

|

| 17Q | First examination report despatched |

Effective date: 19940510 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19951227 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19951227 Ref country code: CH Effective date: 19951227 Ref country code: AT Effective date: 19951227 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19951227 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19951227 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19951227 Ref country code: LI Effective date: 19951227 Ref country code: DK Effective date: 19951227 |

|

| REF | Corresponds to: |

Ref document number: 132210 Country of ref document: AT Date of ref document: 19960115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 69115882 Country of ref document: DE Date of ref document: 19960208 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960327 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19960331 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030319 Year of fee payment: 13 Ref country code: FR Payment date: 20030319 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20030331 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040318 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040318 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |