EP0484656A2 - Device for metering exhaust gases into the combustion chamber of an internal combustion engine - Google Patents

Device for metering exhaust gases into the combustion chamber of an internal combustion engine Download PDFInfo

- Publication number

- EP0484656A2 EP0484656A2 EP91115249A EP91115249A EP0484656A2 EP 0484656 A2 EP0484656 A2 EP 0484656A2 EP 91115249 A EP91115249 A EP 91115249A EP 91115249 A EP91115249 A EP 91115249A EP 0484656 A2 EP0484656 A2 EP 0484656A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- drive

- valve

- actuating device

- check valve

- internal combustion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000002485 combustion reaction Methods 0.000 title claims abstract description 16

- 239000007789 gas Substances 0.000 title claims abstract description 8

- 239000012530 fluid Substances 0.000 claims description 3

- 230000003111 delayed effect Effects 0.000 claims description 2

- 238000001514 detection method Methods 0.000 claims 1

- 230000003213 activating effect Effects 0.000 abstract 1

- 238000004064 recycling Methods 0.000 abstract 1

- 230000000875 corresponding effect Effects 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 238000007789 sealing Methods 0.000 description 3

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 239000000567 combustion gas Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D21/00—Controlling engines characterised by their being supplied with non-airborne oxygen or other non-fuel gas

- F02D21/06—Controlling engines characterised by their being supplied with non-airborne oxygen or other non-fuel gas peculiar to engines having other non-fuel gas added to combustion air

- F02D21/08—Controlling engines characterised by their being supplied with non-airborne oxygen or other non-fuel gas peculiar to engines having other non-fuel gas added to combustion air the other gas being the exhaust gas of engine

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/52—Systems for actuating EGR valves

- F02M26/64—Systems for actuating EGR valves the EGR valve being operated together with an intake air throttle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/65—Constructional details of EGR valves

- F02M26/66—Lift valves, e.g. poppet valves

- F02M26/67—Pintles; Spindles; Springs; Bearings; Sealings; Connections to actuators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D9/00—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits

- F02D9/02—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits concerning induction conduits

- F02D2009/0201—Arrangements; Control features; Details thereof

- F02D2009/0276—Throttle and EGR-valve operated together

Definitions

- the invention relates to a device according to the preamble of claim 1.

- Such a device is known from the manual "Autoelektrik, Autoelektronik am Otto engine” from Bosch.

- the throttle valve and the check valve are provided with drive means which can be actuated independently of one another.

- the known device is extremely expensive to manufacture. It is also characterized by an unsatisfactory operational reliability.

- the invention has for its object to develop a device of the type mentioned in such a way that there is a significantly improved operational reliability with less cost to manufacture.

- the drive means of the check valve and the throttle valve can only be actuated together by a common actuating device.

- the device can be manufactured and assembled inexpensively. It is also characterized by excellent operational reliability, which surprisingly already then there is a significant reduction in polluting exhaust gas emissions if an additional use of electronic control devices is dispensed with. Use of the device according to the invention is therefore particularly recommended when equipping internal combustion engines in which greater attention is paid to the cost-effective availability of the required parts.

- the design of the device depends largely on the design of the drive means of the shut-off valve and throttle valve.

- the throttle valve is fixed non-rotatably on an actuating shaft and can be adjusted to the desired extent by a relative rotation of the actuating shaft.

- check valves it is more common to achieve a change in the flow cross-section by a linear reciprocating movement of an actuator.

- the joint operation of such a check valve and such a throttle valve therefore requires the use of actuating means which are suitable for converting a reciprocating movement into a rotary movement.

- a large number of mechanical aids are known in this regard.

- the actuator of the valve By using a spindle drive, it is possible to arrange the actuator of the valve on an axis of movement which forms an extension of the axis of rotation of the throttle valve shaft.

- the production is particularly simple and there is the further advantage that the housing of the valve can be attached in the immediate vicinity of the intake pipe and, if necessary, as an integral part of the same.

- the actuating device is designed as a cam drive

- a cam plate is expediently fastened interchangeably, which makes it possible to make an otherwise identically designed device usable for internal combustion engines of different sizes by simply exchanging the cam plate.

- the actuating device can comprise a rack and pinion drive, which makes it possible to bridge large spatial distances between the throttle valve shaft and the actuator of the valve.

- a similar advantage results in an embodiment in which the actuating device is formed by a connecting rod drive. In the latter case, the manufacturing costs are comparatively lower, but it is necessary to generate a static preload, for example by means of a compression spring, in order to suppress unwanted play.

- Bowden cables enable the valve to be decoupled from the throttle valve shaft in terms of vibration. This improves durability.

- cam drives is also possible.

- the actuating device of the valve can comprise a servo drive, which is controlled on the basis of an electrical, hydraulic or pneumatic coupling by the throttle valve or its drive means.

- the control characteristic of the valve can be particularly easily adapted to special requirements of the application in such designs.

- the shut-off valve has a closing element which can be brought into engagement with a valve seat, the closing element and / or the valve seat being self-locking on the respective assigned drive or holding means are arranged in the direction of movement of the closing member, so that in the open position of the check valve there is always a cross-section of a matching size.

- the valve seat can be formed, for example, by the end face of a tube which extends axially parallel to the direction of movement of the closing member and which is received in a self-locking manner in an enclosing bore by means of an elastic sealing element.

- the auxiliary drive of the valve can comprise a spring element in order to compensate for play of the actuating means used.

- the spring is expediently designed as a compression spring and arranged in such a way that, when the load is released, it causes the actuator of the valve to be brought into a closed position.

- auxiliary drive used in this case can comprise at least one servo motor which can be actuated by a signal, the servo motor being connected in a signal-conducting manner to a control unit determining the operating characteristics of the internal combustion engine. In this way, it can be achieved that optimum control of the shut-off valve also results if the actual operating data of the internal combustion engine deviate considerably from the normal circumstances, which can be the case, for example, in the event of a malfunction.

- the auxiliary drive can comprise an electromagnet. In such a case, it can be obtained inexpensively and can be controlled particularly easily.

- the drive device of the check valve can be provided with a device for relatively delayed opening and for throttle valve-synchronous closing.

- the device can be formed, for example, by an asymmetrical fluid damper.

- Corresponding fluid dampers are known per se. They are used, for example, in the area of wheel suspension in motor vehicles.

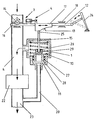

- the sketch shows a schematic representation of a device for the metered introduction of combustion gases into the combustion chamber of an internal combustion engine 22 with an intake pipe 6, in which a throttle valve 3 is arranged and an exhaust pipe 23, the intake pipe 6 and the exhaust pipe 23 through a line 20 with a check valve 1 contained therein are connected and wherein the check valve 1 and the throttle valve 3 drive means are assigned to transfer to an open position.

- a throttle valve 3 is arranged in the intake pipe 6 and is fixed non-rotatably on the outer circumference of a throttle valve shaft 14.

- the throttle valve shaft 14 is provided outside the intake pipe 6 with a ring gear which is in engagement with a rack 16.

- This is connected by a linkage 12 to the accelerator pedal 24 and can be set in a reciprocating relative movement, resulting in a relative rotation of the throttle valve shaft 14 and at the same time a change in the assignment of the throttle valve to the wall of the intake pipe 6 surrounding it. That per unit of time through the intake pipe 6 enforceable gas volume can be changed as needed.

- a cam 17 is attached on the rack 16, a cam 17 is attached. This is provided with a cam track 13 which is in engagement with a roller 25 of the actuator 15 of the check valve 1.

- the pressure of the roller 25 against the cam track 13 causes a pressure spring 10, which is supported on the one hand on a projection of the actuator 15 projecting outward in the radial direction and on the other hand on a component of the housing 11 of the check valve 1.

- the closing member 29 of the check valve 1 is thereby automatically transferred to an open position when the actuating linkage 12 is displaced relative to the left.

- it reaches an open position in a defined manner, as a result of which a quantity of exhaust gas of a defined size is transferred from the exhaust pipe 23 into the intake pipe 6 per unit time.

- the relevant circumstances can be adapted to the requirements of the specific application.

- the ratio of the mixture of fresh and exhaust gases supplied to the internal combustion engine 22 per unit of time through the intake pipe 6 can thereby be changed to the required extent.

- the associated closing member 29 and the associated valve seat 28 are self-locking in the opening direction, but are displaceably supported on the associated supporting parts.

- the closing member 29 is supported by means of elastically deformed sealing rings 26 made of heat-resistant material on a column-shaped section of the actuator 15 which extends parallel to the opening direction and the valve seat 28 formed by the end face of a tube in the same way by means of two elastic sealing rings 27 in a bore of the housing 11 which extends parallel to the opening direction.

- an auxiliary drive 4 is provided for the check valve 1.

- This consists of an electromagnet supported on the toothed rack 16, which is connected to the cam disk 17 and makes it possible, depending on special circumstances, to shift it parallel to the longitudinal direction of the toothed rack 16 and in this way the opening characteristic of the check valve 1 with respect to the throttle valve 3 to change and adapt to special circumstances.

- This possibility is of great advantage in order to achieve optimal operating behavior. It may be dispensed with and the cam plate is rigidly attached to the rack 16 in this case.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Control Of Throttle Valves Provided In The Intake System Or In The Exhaust System (AREA)

- Valve Device For Special Equipments (AREA)

- Output Control And Ontrol Of Special Type Engine (AREA)

- Combustion Methods Of Internal-Combustion Engines (AREA)

- Exhaust-Gas Circulating Devices (AREA)

- Other Investigation Or Analysis Of Materials By Electrical Means (AREA)

- Investigating Or Analysing Materials By Optical Means (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung nach dem Oberbegriff von Anspruch 1.The invention relates to a device according to the preamble of

Eine solche Vorrichtung ist aus dem Handbuch "Autoelektrik, Autoelektronik am Ottomotor" der Firma Bosch bekannt. Die Drosselklappe und das Sperrventil sind dabei mit voneinander unabhängig betätigbaren Antriebsmitteln versehen. Die bekannte Vorrichtung ist hierdurch äußerst teuer herzustellen. Sie zeichnet sich außerdem durch eine nur wenig befriedigende Betriebssicherheit aus.Such a device is known from the manual "Autoelektrik, Autoelektronik am Otto engine" from Bosch. The throttle valve and the check valve are provided with drive means which can be actuated independently of one another. The known device is extremely expensive to manufacture. It is also characterized by an unsatisfactory operational reliability.

Der Erfindung liegt die Aufgabe zugrunde, eine Vorrichtung der eingangs genannten Art derart weiterzuentwickeln, daß sich bei kostengünstigerer Herstellbarkeit eine wesentlich verbesserte Betriebssicherheit ergibt.The invention has for its object to develop a device of the type mentioned in such a way that there is a significantly improved operational reliability with less cost to manufacture.

Diese Aufgabe wird erfindungsgemäß bei einer Vorrichtung der eingangs genannten Art mit den kennzeichnenden Merkmalen von Anspruch 1 gelöst. Auf vorteilhafte Ausgestaltungen nehmen die Ansprüche 2 bis 16 Bezug.This object is achieved according to the invention in a device of the type mentioned at the outset with the characterizing features of

Bei der erfindungsgemäßen Vorrichtung ist es vorgesehen, daß die Antriebsmittel des Sperrventils und der Drosselklappe durch eine gemeinsame Betätigungseinrichtung nur gemeinsam betätigbar sind. Die Vorrichtung läßt sich hierdurch kostengünstig herstellen und montieren. Sie zeichnet sich außerdem durch eine ausgezeichnete Betriebssicherheit aus, wobei sich überraschenderweise bereits dann eine deutliche Verminderung von umweltbelastenden Abgasemissionen ergibt, wenn auf eine ergänzende Verwendung von elektronischen Steuereinrichtungen verzichtet wird. Eine Verwendung der erfindungsgemäßen Vorrichtung empfiehlt sich dadurch insbesondere bei der Ausstattung von solchen Verbrennungskraftmaschinen, bei denen einer kostengünstigen Verfügbarkeit der benötigten Teile größere Aufmerksamkeit gewidmet wird.In the device according to the invention it is provided that the drive means of the check valve and the throttle valve can only be actuated together by a common actuating device. As a result, the device can be manufactured and assembled inexpensively. It is also characterized by excellent operational reliability, which surprisingly already then there is a significant reduction in polluting exhaust gas emissions if an additional use of electronic control devices is dispensed with. Use of the device according to the invention is therefore particularly recommended when equipping internal combustion engines in which greater attention is paid to the cost-effective availability of the required parts.

Die Ausbildung der Vorrichtung hängt maßgeblich von der Gestaltung des Antriebsmittels von Sperrventil und Drosselklappe ab. Im Normalfall ist davon auszugehen, daß die Drosselklappe unverdrehbar auf einer Betätigungswelle festgelegt und durch eine Relativverdrehung der Betätigungswelle im gewünschten Maße verstellbar ist. Bei Sperrventilen ist es demgegenüber eher gebräuchlich, durch eine geradlinige Hin- und Herbewegung eines Stellgliedes eine Veränderung des Durchflußquerschnittes zu erzielen. Das gemeinsame Betätigen eines solchen Sperrventils und einer solchen Drosselklappe erfordert daher die Verwendung von Betätigungsmitteln, die geeignet sind, eine hin- und hergehende Bewegung in eine Drehbewegung umzuwandeln. Diesbezüglich ist eine Vielzahl mechanischer Hilfsmittel bekannt.The design of the device depends largely on the design of the drive means of the shut-off valve and throttle valve. In the normal case it can be assumed that the throttle valve is fixed non-rotatably on an actuating shaft and can be adjusted to the desired extent by a relative rotation of the actuating shaft. In the case of check valves, on the other hand, it is more common to achieve a change in the flow cross-section by a linear reciprocating movement of an actuator. The joint operation of such a check valve and such a throttle valve therefore requires the use of actuating means which are suitable for converting a reciprocating movement into a rotary movement. A large number of mechanical aids are known in this regard.

Durch die Verwendung eines Spindeltriebs besteht die Möglichkeit, das Stellglied des Ventils auf einer Bewegungsachse anzuordnen, die eine Verlängerung der Rotationsachse der Drosselklappenwelle bildet. Die Herstellung ist besonders einfach und es ergibt sich der weitere Vorteil, daß das Gehäuse des Ventils in unmittelbarer Nähe des Ansaugrohres angebracht werden kann und gegebenenfalls als integrierter Bestandteil desselben.By using a spindle drive, it is possible to arrange the actuator of the valve on an axis of movement which forms an extension of the axis of rotation of the throttle valve shaft. The production is particularly simple and there is the further advantage that the housing of the valve can be attached in the immediate vicinity of the intake pipe and, if necessary, as an integral part of the same.

Bei einer Ausführung, bei der die Betätigungseinrichtung als Kurventrieb gestaltet ist, resultiert eine vereinfachte Möglichkeit, die Öffnungscharakteristika der Drosselklappe einerseits und des Ventils andererseits in der Weise aneinander anzupassen, daß sich ein optimiertes Betriebsverhalten der jeweiligen Verbrennungskraftmaschine ergibt. Zweckmäßigerweise wird eine solche Kurvenscheibe austauschbar befestigt, was es ermöglicht, eine ansonsten identisch gestaltete Vorrichtung durch einfachen Austausch der Kurvenscheibe für Verbrennungskraftmaschinen unterschiedlicher Größe brauchbar zu machen.In an embodiment in which the actuating device is designed as a cam drive, there is a simplified possibility of adapting the opening characteristics of the throttle valve on the one hand and the valve on the other to one another in such a way that an optimized operating behavior of the respective internal combustion engine results. Such a cam plate is expediently fastened interchangeably, which makes it possible to make an otherwise identically designed device usable for internal combustion engines of different sizes by simply exchanging the cam plate.

Die Betätigungseinrichtung kann einen Zahnstangentrieb umfassen, was es gestattet, große räumliche Entfernungen zwischen der Drosselklappenwelle und dem Stellglied des Ventils zu überbrücken. Ein ähnlicher Vorteil resultiert bei einer Ausführung, bei der die Betätigungseinrichtung durch einen Pleueltrieb gebildet ist. Im letztgenannten Falle sind die Herstellkosten vergleichsweise geringer, es ist jedoch erforderlich, eine statische Vorlast, beispielsweise durch eine Druckfeder, zu erzeugen, um unerwünschtes Spiel zu unterdrücken.The actuating device can comprise a rack and pinion drive, which makes it possible to bridge large spatial distances between the throttle valve shaft and the actuator of the valve. A similar advantage results in an embodiment in which the actuating device is formed by a connecting rod drive. In the latter case, the manufacturing costs are comparatively lower, but it is necessary to generate a static preload, for example by means of a compression spring, in order to suppress unwanted play.

Bei Verwendung von Ventilen, bei denen das Stellglied durch eine Relativverdrehung betätigbar ist, besteht demgegenüber die Möglichkeit, eine Schubstangenverbindung zwischen der Drosselklappenwelle und der Welle des entsprechenden Stellgliedes des Ventiles vorzusehen. Dabei besteht zugleich die Möglichkeit, in Abhängigkeit von den radialen Abständen zwischen der jeweiligen Anlenkstelle der Schubstange und der Drehachse des Stellgliedes die Öffnungscharakteristika in gezielter Weise aneinander anzupassen.In contrast, when using valves in which the actuator can be actuated by a relative rotation, there is the possibility of providing a connecting rod connection between the throttle valve shaft and the shaft of the corresponding actuator of the valve. At the same time, there is the possibility, depending on the radial distances between the respective articulation point of the push rod and the axis of rotation of the actuator, of adapting the opening characteristics to one another in a targeted manner.

Bowdenzüge ermöglichen die Realisierung einer schwingungstechnischen Abkopplung des Ventils von der Drosselklappenwelle. Die Dauerhaltbarkeit wird hierdurch verbessert. Eine Verwendung von Nockentrieben ist ebenfalls möglich.Bowden cables enable the valve to be decoupled from the throttle valve shaft in terms of vibration. This improves durability. The use of cam drives is also possible.

Die Betätigungseinrichtung des Ventils kann einen Servoantrieb umfassen, der auf der Grundlage einer elektrischen, hydraulischen oder pneumatischen Kopplung durch die Drosselklappe oder deren Antriebsmittel gesteuert ist. Die Ansteuerungscharakteristik des Ventils läßt sich bei solchen Ausführungen besonders einfach speziellen Erfordernissen des Anwendungsfalles anpassen.The actuating device of the valve can comprise a servo drive, which is controlled on the basis of an electrical, hydraulic or pneumatic coupling by the throttle valve or its drive means. The control characteristic of the valve can be particularly easily adapted to special requirements of the application in such designs.

Um während einer sehr langen Gebrauchsdauer der erfindungsgemäßen Vorrichtung eine gleichbleibende Ansteuerungscharakteristik zu erhalten, hat es sich als vorteilhaft bewährt, wenn das Sperrventil ein Schließglied aufweist, das mit einem Ventilsitz in Eingriff bringbar ist, wobei das Schließglied und/oder der Ventilsitz selbsthemmend auf dem jeweils zugeordneten Antriebs- bzw. Haltemittel in Bewegungsrichtung des Schließgliedes angeordnet sind, so daß sich in der Offenstellung des Sperrventils stets ein Übertrittsquerschnitt von übereinstimmender Größe ergibt. Der Ventilsitz kann beispielsweise durch die Stirnseite eines Rohres gebildet sein, welches sich achsparallel zur Bewegungsrichtung des Schließgliedes erstreckt und das mittels eines elastischen Dichtungselementes selbsthemmend in einer umschließenden Bohrung aufgenommen ist. Auch beim Auftreten von Anbackungserscheinungen im Bereich der Stirnseite ergibt sich in diesem Falle unabhängig von der Gebrauchsdauer stets ein übereinstimmender Öffnungsquerschnitt. Eine entsprechende Befestigung ist selbstverständlich auch auf Seiten des Schließgliedes möglich. In diesem Falle ist es lediglich erforderlich, das Schließglied als solches unabhängig von seinem eigentlichen Antriebsmittel auszubilden und an diesem entsprechend den vorstehenden Darlegungen verschiebbar festzulegen.In order to maintain a constant control characteristic over a very long period of use of the device according to the invention, it has proven to be advantageous if the shut-off valve has a closing element which can be brought into engagement with a valve seat, the closing element and / or the valve seat being self-locking on the respective assigned drive or holding means are arranged in the direction of movement of the closing member, so that in the open position of the check valve there is always a cross-section of a matching size. The valve seat can be formed, for example, by the end face of a tube which extends axially parallel to the direction of movement of the closing member and which is received in a self-locking manner in an enclosing bore by means of an elastic sealing element. Even if caking phenomena occur in the area of the end face, this always results in a matching opening cross-section, regardless of the period of use. A corresponding attachment is of course also possible on the part of the closing member. In this In this case, it is only necessary to design the closing element as such independently of its actual drive means and to fix it displaceably in accordance with the above statements.

Der Hilfsantrieb des Ventils kann ein Federelement umfassen, um einen Spielausgleich der zur Anwendung gelangenden Betätigungsmittel zu bewirken. Zweckmäßigerweise ist die Feder dabei als Druckfeder gestaltet und so angeordnet, daß sie bei einer Entlastung eine Überführung des Stellgliedes des Ventils in eine Geschlossenstellung bewirkt.The auxiliary drive of the valve can comprise a spring element in order to compensate for play of the actuating means used. The spring is expediently designed as a compression spring and arranged in such a way that, when the load is released, it causes the actuator of the valve to be brought into a closed position.

Es besteht auch die Möglichkeit, die Drosselklappe und das Sperrventil durch eine elektrische Welle zu verbinden und auf diese Weise gemeinsam betätigbar zu machen. Der in diesem Falle zur Anwendung gelangende Hilfsantrieb kann mindestens einen signalbetätigbaren Servo-Motor umfassen, wobei der Servo-Motor signalleitend mit einem Betriebskenndaten der Verbrennungskraftmaschine bestimmenden Steuergerät verbunden ist. Hierdurch läßt sich erreichen, daß sich eine optimale Ansteuerung des Sperrventils auch dann ergibt, wenn die tatsächlichen Betriebsdaten der Verbrennungskraftmaschine in erheblichem Maße von den normalen Gegebenheiten abweichen, was beispielsweise bei einer Betriebsstörung der Fall sein kann.There is also the possibility of connecting the throttle valve and the check valve by means of an electrical shaft and in this way making it operable together. The auxiliary drive used in this case can comprise at least one servo motor which can be actuated by a signal, the servo motor being connected in a signal-conducting manner to a control unit determining the operating characteristics of the internal combustion engine. In this way, it can be achieved that optimum control of the shut-off valve also results if the actual operating data of the internal combustion engine deviate considerably from the normal circumstances, which can be the case, for example, in the event of a malfunction.

Der Hilfsantrieb kann einen Elektromagneten umfassen. Er läßt sich in einem solchen Falle kostengünstig erhalten und besonders einfach ansteuern.The auxiliary drive can comprise an electromagnet. In such a case, it can be obtained inexpensively and can be controlled particularly easily.

Die Antriebseinrichtung des Sperrventils kann mit einer Einrichtung zum relativ verzögerten Öffnen und zum drosselklappensynchronen Schließen versehen sein. Eine solche Einrichtung kann beispielsweise durch einen unsymmetrischen Strömungsmitteldämpfer gebildet sein. Entsprechende Strömungsmitteldämpfer sind an sich bekannt. Sie gelangen beispielsweise im Bereich der Radfederung von Kraftfahrzeugen zur Anwendung.The drive device of the check valve can be provided with a device for relatively delayed opening and for throttle valve-synchronous closing. Such The device can be formed, for example, by an asymmetrical fluid damper. Corresponding fluid dampers are known per se. They are used, for example, in the area of wheel suspension in motor vehicles.

Der Gegenstand der Erfindung wird nachfolgend anhand der als Anlage beigefügten Skizze weiter verdeutlicht:The subject matter of the invention is further illustrated below with the aid of the sketch attached as an attachment:

Die Skizze zeigt in schematischer Darstellung eine Vorrichtung zum dosierten Einleiten von Verbrennungsgasen in den Brennraum einer Verbrennungskraftmaschine 22 mit einem Ansaugrohr 6, in dem eine Drosselklappe 3 angeordnet ist und einem Abgasrohr 23, wobei das Ansaugrohr 6 und das Abgasrohr 23 durch eine Leitung 20 mit einem darin enthaltenen Sperrventil 1 verbunden sind und wobei dem Sperrventil 1 und der Drosselklappe 3 Antriebsmittel zur Überführung in eine Offenstellung zugeordnet sind. In dem Ansaugrohr 6 ist eine Drosselklappe 3 angeordnet, welche unverdrehbar an dem Außenumfang einer Drosselklappenwelle 14 festgelegt ist. Die Drosselklappenwelle 14 ist außerhalb des Ansaugrohres 6 mit einem Zahnkranz versehen, der mit einer Zahnstange 16 in Eingriff steht. Diese ist durch ein Gestänge 12 mit dem Fahrpedal 24 verbunden und in eine hin- und hergehende Relativbewegung versetzbar, wobei sich eine Relativverdrehung der Drosselklappenwelle 14 ergibt und damit zugleich eine Veränderung der Zuordnung der Drosselklappe zu der sie umschließenden Wandung des Ansaugrohres 6. Das je Zeiteinheit durch das Ansaugrohr 6 durchsetzbare Gasvolumen läßt sich hierdurch nach Bedarf verändern.The sketch shows a schematic representation of a device for the metered introduction of combustion gases into the combustion chamber of an

An der Zahnstange 16 ist eine Kurvenscheibe 17 befestigt. Diese ist mit einer Kurvenbahn 13 versehen, welche mit einer Rolle 25 des Stellgliedes 15 des Sperrventiles 1 im Eingriff steht. Die Andrückung der Rolle 25 an die Kurvenbahn 13 bewirkt eine Andrückfeder 10, welche einerseits auf einem in radialer Richtung nach außen vorspringenden Ansatz des Stellgliedes 15 abgestützt ist und andererseits auf einem Bestandteil des Gehäuses 11 des Sperrventils 1. Das Schließglied 29 des Sperrventils 1 wird hierdurch bei einer Relativverschiebung des Stellgestänges 12 nach links selbsttätig in eine Offenstellung überführt. In Abhängigkeit von der Gestalt der Kurvenbahn 13 gelangt es hierbei definiert in eine Offenstellung, wodurch je Zeiteinheit eine Abgasmenge definierter Größe aus dem Abgasrohr 23 in das Ansaugrohr 6 überführt wird. In Abhängigkeit von der Ausbildung der Kurvenbahn 13 lassen sich die diesbezüglichen Gegebenheiten den Erfordernissen des speziellen Anwendungsfalles angleichen. Das Verhältnis des der Verbrennungskraftmaschine 22 je Zeiteinheit durch das Ansaugrohr 6 zugeführten Gemisches aus Frisch- und Abgasen läßt sich hierdurch im erforderlichen Maße verändern.On the

Um im langfristigen Gebrauch eine unveränderliche Öffnungscharakteristik des Sperrventils 1 zu erreichen ist es bei dem gezeigten Ausführungsbeispiel vorgesehen, das zugehörige Schließglied 29 und den zugehörigen Ventilsitz 28 in Öffnungsrichtung selbsthemmend, jedoch verschiebbar auf den zugehörigen Tragteilen abzustützen. Hierzu ist das Schließglied 29 mittels elastisch verformter Dichtringe 26 aus wärmebeständigem Werkstoff auf einem sich parallel zur Öffnungsrichtung erstreckenden, säulenförmigen Abschnitt des Stellgliedes 15 abgestützt und der durch die Stirnseite eines Rohres gebildete Ventilsitz 28 in gleicher Weise mittels zweier elastischer Dichtringe 27 in einer sich parallel zur Öffnungsrichtung erstreckenden Bohrung des Gehäuses 11. In Abhängkeit vom Umfang der sich bei längerer Dauer der Benutzung ergebenden Anbackungen im Bereich der miteinander in Eingriff bringbaren Flächen des Schließgliedes 29 und des Ventilsitzes 28 resultiert ein entsprechend große Relativverschiebung beider Teile in der Schließstellung, wodurch sich bei der anschließenden Betätigung eine völlig unveränderte Öffnungscharakteristik ergibt. Ein entsprechender Effekt läßt sich ebenfalls erreichen, wenn nur eines der beiden Teile relativ verschiebbar abgestützt ist.In order to achieve an unchangeable opening characteristic of the

Bei dem gezeigten Ausführungsbeispiel ist ein Hilfsantrieb 4 für das Sperrventil 1 vorgesehen. Dieser besteht aus einem auf der Zahnstange 16 abgestützten Elektromagneten, der mit der Kurvenscheibe 17 verbunden ist und es ermöglicht, diese in Abhängigkeit von besonderen Gegebenheiten parallel zur Längsrichtung der Zahnstange 16 zu verschieben und auf diese Weise die Öffnungcharakteristik des Sperrventils 1 in bezug auf die Drosselklappe 3 zu verändern und besonderen Gegebenheiten anzupassen. Für die Erzielung eines optimalen Betriebsverhaltens ist diese Möglichkeit von großem Vorteil. Sie ist gegebenenfalls verzichtbar und die Kurvenscheibe in diesem Falle in starrer Weise an der Zahnstange 16 befestigt.In the embodiment shown, an auxiliary drive 4 is provided for the

Claims (16)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4035176A DE4035176C3 (en) | 1990-11-06 | 1990-11-06 | Device for the metered feeding of burned gases into the combustion chamber of an internal combustion engine |

| DE4035176 | 1990-11-06 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0484656A2 true EP0484656A2 (en) | 1992-05-13 |

| EP0484656A3 EP0484656A3 (en) | 1992-07-29 |

| EP0484656B1 EP0484656B1 (en) | 1994-11-30 |

Family

ID=6417694

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91115249A Expired - Lifetime EP0484656B1 (en) | 1990-11-06 | 1991-09-10 | Device for metering exhaust gases into the combustion chamber of an internal combustion engine |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5213087A (en) |

| EP (1) | EP0484656B1 (en) |

| JP (1) | JP2566080B2 (en) |

| AT (1) | ATE114783T1 (en) |

| DE (2) | DE4035176C3 (en) |

| ES (1) | ES2064844T3 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1686256A1 (en) * | 2005-01-31 | 2006-08-02 | Kwang Yang Motor Co., Ltd. | Exhaust gas recycling valve for a vehicle |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4229110C1 (en) * | 1992-09-01 | 1993-10-07 | Freudenberg Carl Fa | Device for the temporary storage and metered feeding of volatile fuel components located in the free space of a tank system into the intake pipe of an internal combustion engine |

| DE4333295A1 (en) * | 1993-09-30 | 1995-06-14 | Bosch Gmbh Robert | Device for controlling exhaust gas recirculation quantities |

| US6095123A (en) * | 1999-01-11 | 2000-08-01 | Ford Global Technologies, Inc. | Valve and valve control method |

| US6390079B1 (en) * | 2000-08-21 | 2002-05-21 | Siemens Canada Limited | Exhaust gas recirculation valve including cam linkage for converting constant angular motion to non-linear motion |

| EP1270924A3 (en) * | 2001-06-28 | 2004-01-07 | Delphi Technologies, Inc. | Integrated intake manifold assembly for an internal combustion engine |

| JP4015889B2 (en) * | 2002-06-28 | 2007-11-28 | 株式会社豊田自動織機 | EGR control device for internal combustion engine |

| JP4196837B2 (en) * | 2004-01-15 | 2008-12-17 | トヨタ自動車株式会社 | Control device for internal combustion engine |

| DE102004060842A1 (en) * | 2004-12-17 | 2006-06-29 | Deutz Ag | Diesel engine has suction line with exhaust gas return flap arranged in it which is mechanically coupled with accelerator pedal such that it is not actuated with partial load and exhaust gas is conveyed |

| US7069919B1 (en) * | 2005-01-06 | 2006-07-04 | Caterpillar Inc | Method and apparatus for controlling the ratio of ambient air to recirculated gases in an internal combustion engine |

| US7237531B2 (en) * | 2005-06-17 | 2007-07-03 | Caterpillar Inc. | Throttle and recirculation valves having a common planetary drive |

| JP5287953B2 (en) * | 2011-04-27 | 2013-09-11 | 株式会社デンソー | Low pressure EGR device |

| FR3044360B1 (en) * | 2015-11-30 | 2019-08-23 | Valeo Systemes Thermiques | SYSTEM AND METHOD FOR DEACTIVATING AT LEAST ONE CYLINDER OF AN ENGINE, INTAKE COLLECTOR AND HEAT EXCHANGER COMPRISING SAID SYSTEM |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2128646A1 (en) * | 1970-06-04 | 1971-12-09 | General Motors Corp., Detroit, Mich. (V.StA.) | Internal combustion engine with exhaust gas recirculation to the intake duct |

| GB1299310A (en) * | 1970-07-27 | 1972-12-13 | Ford Motor Co | Internal combustion engine having an exhaust gas recirculation system |

| FR2219304A1 (en) * | 1973-02-23 | 1974-09-20 | Honda Motor Co Ltd | |

| DE2315432A1 (en) * | 1973-03-28 | 1974-10-10 | Volkswagenwerk Ag | DEVICE FOR REDUCING POLLUTANT EMISSIONS FROM COMBUSTION ENGINE |

| US3916857A (en) * | 1972-08-31 | 1975-11-04 | Nippon Denso Co | Means for controlling the exhaust recirculation |

| US4005692A (en) * | 1973-07-05 | 1977-02-01 | Toyota Jidosha Kogyo Kabushiki Kaisha | Carburetor arranged for recirculating exhaust gases |

| DE2529208A1 (en) * | 1975-07-01 | 1977-02-03 | Bosch Gmbh Robert | Engine mixture control system - has regulator multiplying relationship between engine parameter and exhaust gas quantity returned |

| FR2372319A1 (en) * | 1976-11-25 | 1978-06-23 | Mitsubishi Motors Corp | EXHAUST GAS RECYCLING DEVICE |

| FR2506389A1 (en) * | 1981-05-25 | 1982-11-26 | Mikuni Kogyo Kk | EXHAUST GAS RECIRCULATION VALVE AND VALVE CONTROL METHOD |

| EP0363021A1 (en) * | 1988-10-05 | 1990-04-11 | Ford Motor Company Limited | Fast response exhaust gas recirculation (EGR) system |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1262252A (en) * | 1969-01-20 | 1972-02-02 | Nissan Motor | Exhaust recirculation system for motor vehicles |

| JPS5122563B2 (en) * | 1972-03-02 | 1976-07-10 | ||

| JPS5256808Y2 (en) * | 1973-06-20 | 1977-12-22 | ||

| JPS50102725A (en) * | 1974-01-23 | 1975-08-14 | ||

| US3989018A (en) * | 1974-02-15 | 1976-11-02 | Volkswagenwerk Aktiengesellschaft | Exhaust gas recycling apparatus |

| US4149503A (en) * | 1976-10-01 | 1979-04-17 | Nippon Soken, Inc. | Exhaust gas recirculation system for an internal combustion engine |

| JPS53109018A (en) * | 1977-03-04 | 1978-09-22 | Mitsubishi Motors Corp | Suction control device |

| JPS54141924A (en) * | 1978-04-25 | 1979-11-05 | Aisan Ind Co Ltd | Exhaust gas recycling device |

| DE2823671A1 (en) * | 1978-05-31 | 1979-12-06 | Bosch Gmbh Robert | DEVICE FOR EXHAUST GAS RECIRCULATION |

| JPS5510013A (en) * | 1978-07-06 | 1980-01-24 | Toyota Motor Corp | Division-operation controlled multi-cylinder internal combustion engine |

| JPS5523314A (en) * | 1978-08-02 | 1980-02-19 | Toyota Motor Corp | Apparatus for controlling re-circulation of exhaust gas discharged from engine |

| JPS5542260A (en) * | 1978-09-19 | 1980-03-25 | Fuji Titan Kogyo Kk | Production of alpha-type hemihydrate gypsum from gypsum |

| US4479473A (en) * | 1983-01-10 | 1984-10-30 | Ford Motor Company | Diesel engine emission control system |

| SE450147B (en) * | 1985-10-31 | 1987-06-09 | Electrolux Ab | GASREGLERINGSANORDNING |

| DE3722048A1 (en) * | 1987-07-03 | 1989-01-12 | Bosch Gmbh Robert | INTERNAL COMBUSTION ENGINE, ESPECIALLY OTTO ENGINE |

-

1990

- 1990-11-06 DE DE4035176A patent/DE4035176C3/en not_active Expired - Lifetime

-

1991

- 1991-09-10 AT AT91115249T patent/ATE114783T1/en active

- 1991-09-10 DE DE59103681T patent/DE59103681D1/en not_active Expired - Lifetime

- 1991-09-10 ES ES91115249T patent/ES2064844T3/en not_active Expired - Lifetime

- 1991-09-10 EP EP91115249A patent/EP0484656B1/en not_active Expired - Lifetime

- 1991-10-08 US US07/772,802 patent/US5213087A/en not_active Expired - Fee Related

- 1991-11-05 JP JP3288381A patent/JP2566080B2/en not_active Expired - Lifetime

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2128646A1 (en) * | 1970-06-04 | 1971-12-09 | General Motors Corp., Detroit, Mich. (V.StA.) | Internal combustion engine with exhaust gas recirculation to the intake duct |

| GB1299310A (en) * | 1970-07-27 | 1972-12-13 | Ford Motor Co | Internal combustion engine having an exhaust gas recirculation system |

| US3916857A (en) * | 1972-08-31 | 1975-11-04 | Nippon Denso Co | Means for controlling the exhaust recirculation |

| FR2219304A1 (en) * | 1973-02-23 | 1974-09-20 | Honda Motor Co Ltd | |

| DE2315432A1 (en) * | 1973-03-28 | 1974-10-10 | Volkswagenwerk Ag | DEVICE FOR REDUCING POLLUTANT EMISSIONS FROM COMBUSTION ENGINE |

| US4005692A (en) * | 1973-07-05 | 1977-02-01 | Toyota Jidosha Kogyo Kabushiki Kaisha | Carburetor arranged for recirculating exhaust gases |

| DE2529208A1 (en) * | 1975-07-01 | 1977-02-03 | Bosch Gmbh Robert | Engine mixture control system - has regulator multiplying relationship between engine parameter and exhaust gas quantity returned |

| FR2372319A1 (en) * | 1976-11-25 | 1978-06-23 | Mitsubishi Motors Corp | EXHAUST GAS RECYCLING DEVICE |

| FR2506389A1 (en) * | 1981-05-25 | 1982-11-26 | Mikuni Kogyo Kk | EXHAUST GAS RECIRCULATION VALVE AND VALVE CONTROL METHOD |

| EP0363021A1 (en) * | 1988-10-05 | 1990-04-11 | Ford Motor Company Limited | Fast response exhaust gas recirculation (EGR) system |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1686256A1 (en) * | 2005-01-31 | 2006-08-02 | Kwang Yang Motor Co., Ltd. | Exhaust gas recycling valve for a vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| DE4035176A1 (en) | 1992-05-07 |

| EP0484656A3 (en) | 1992-07-29 |

| DE4035176C3 (en) | 1997-11-13 |

| JP2566080B2 (en) | 1996-12-25 |

| DE59103681D1 (en) | 1995-01-12 |

| EP0484656B1 (en) | 1994-11-30 |

| ES2064844T3 (en) | 1995-02-01 |

| DE4035176C2 (en) | 1992-08-27 |

| US5213087A (en) | 1993-05-25 |

| JPH04265454A (en) | 1992-09-21 |

| ATE114783T1 (en) | 1994-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69014645T2 (en) | GAS PEDAL FOR AN ELECTRONIC THROTTLE ACTUATION SYSTEM. | |

| DE69810850T2 (en) | Exhaust gas recirculation valve | |

| EP0245614B1 (en) | Poppet valve control device for a reciprocating piston internal-combustion engine | |

| DE3446133C2 (en) | ||

| EP0484656B1 (en) | Device for metering exhaust gases into the combustion chamber of an internal combustion engine | |

| DE19524941B4 (en) | load adjusting | |

| DE3040144A1 (en) | DEVICE FOR CONTROLLING THE DRIVING SPEED AND CONTROLLING THE IDLE SPEED IN MOTOR VEHICLES WITH OTTO ENGINE | |

| DE102004014700A1 (en) | Throttle device for internal combustion engine, has integral plug-type slide bearing with a closed-bottom tube to support the sliding part of the throttle shaft and has its outer circumference fitted into the insertion hole | |

| DE4111259C1 (en) | ||

| DE2924391A1 (en) | DEVICE FOR LIMITING THE SPEED OF A MOTOR VEHICLE | |

| DE4111240C1 (en) | ||

| WO2009053217A1 (en) | Internal combustion engine | |

| EP0500622A1 (en) | Drive arrangement for a camshaft fitted in the cylinder head of an internal combustion engine. | |

| EP1063403B1 (en) | Load control device | |

| DE2336927A1 (en) | ELECTROMAGNETIC PRESSURE CONTROL VALVE FOR INCOMPRESSIBLE MEDIA | |

| DE4027397C1 (en) | ||

| DE102009053428A1 (en) | Actuator for converting a rotary motion into a linear motion | |

| DE3327977C1 (en) | Device for releasing a clutch | |

| DE3918361A1 (en) | Drive arrangement for a camshaft of an internal combustion engine | |

| EP1649200B1 (en) | Subunit for an additional control valve device used for an intake pipe of a reciprocating internal combustion engine | |

| WO1998042953A1 (en) | Valve for an internal combustion engine | |

| EP0752528B1 (en) | Exhaust gas recirculation valve | |

| DE19747031A1 (en) | Variable valve control for internal combustion engines | |

| WO2003018966A1 (en) | Valve mechanism with a variable valve opening cross-section | |

| WO2021219193A1 (en) | Adjustment device for an internal combustion engine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19920316 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19921008 |

|

| ITF | It: translation for a ep patent filed | ||

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FIRMA CARL FREUDENBERG |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 114783 Country of ref document: AT Date of ref document: 19941215 Kind code of ref document: T |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE ES FR GB |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19941212 |

|

| REF | Corresponds to: |

Ref document number: 59103681 Country of ref document: DE Date of ref document: 19950112 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 91115249.4 |

|

| NLXE | Nl: other communications concerning ep-patents (part 3 heading xe) |

Free format text: PAT.BUL.01/95 PATENTNUMBER 0484656 SHOULD BE DELETED |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2064844 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EUG | Se: european patent has lapsed |

Ref document number: 91115249.4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960905 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19970828 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970917 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19970924 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19971211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980910 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF THE APPLICANT RENOUNCES Effective date: 19980911 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19980910 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20001102 |