EP0441102A1 - Punched cardboard element for keeping and showing sweets and the like - Google Patents

Punched cardboard element for keeping and showing sweets and the like Download PDFInfo

- Publication number

- EP0441102A1 EP0441102A1 EP90830092A EP90830092A EP0441102A1 EP 0441102 A1 EP0441102 A1 EP 0441102A1 EP 90830092 A EP90830092 A EP 90830092A EP 90830092 A EP90830092 A EP 90830092A EP 0441102 A1 EP0441102 A1 EP 0441102A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sheet

- punched

- flaps

- element according

- holes

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000009508 confectionery Nutrition 0.000 title claims abstract description 6

- 239000011111 cardboard Substances 0.000 title description 2

- 239000000463 material Substances 0.000 claims description 3

- 244000299461 Theobroma cacao Species 0.000 claims description 2

- 235000019219 chocolate Nutrition 0.000 claims description 2

- 239000011359 shock absorbing material Substances 0.000 claims 1

- 230000037431 insertion Effects 0.000 abstract description 3

- 238000003780 insertion Methods 0.000 abstract description 3

- 238000005452 bending Methods 0.000 description 3

- 241001660693 Trapezia Species 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 230000001413 cellular effect Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000001473 noxious effect Effects 0.000 description 1

- 239000011087 paperboard Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000002910 solid waste Substances 0.000 description 1

- 238000003856 thermoforming Methods 0.000 description 1

- 210000002105 tongue Anatomy 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/44—Integral, inserted or attached portions forming internal or external fittings

- B65D5/50—Internal supporting or protecting elements for contents

- B65D5/5028—Elements formed separately from the container body

- B65D5/5035—Paper elements

- B65D5/5038—Tray-like elements formed by folding a blank and presenting openings or recesses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/60—Containers, packaging elements or packages, specially adapted for particular articles or materials for sweets or like confectionery products

Definitions

- the present invention relates to an element for holding and presenting confectionery products, particularly chocolates and the like, which is adapted to define a plurality of seats for the products.

- thermoforming elements are made by the thermoforming of sheets of plastics material for insertion in boxes of punched card.

- a plurality of cells arranged in an ordered array are therefore thermoformed in the sheets, and serve both to keep the products in position and to prevent direct contact between the products and the bottom of the box which, as a result of any pressures or knocks, could damage the products contained.

- thermoformed plastics elements As well as requiring special equipment which is somewhat different from that normally used in the paper and cardboard sector, the production of these thermoformed plastics elements considerably increases the environmental impact of the box as regards solid waste. In fact, the thermoformed sheet is not biodegradable and may produce noxious gases if it is burnt.

- the object of the present invention is to provide an element of the type specified at the beginning of the description which does not have the aforesaid disadvantages and which is also completely biodegradable.

- the element comprises a flat sheet of card or similar material having a plurality of annular punched lines and, within the punched lines, slits which define a plurality of holes in the sheet when the flaps defined between the slits and the punched lines are bent, the holes having at least two opposite side walls for retaining the products.

- the card element can fulfil the same function as a thermoformed cellular element of known type, providing considerable advantages in terms of cost and environmental impact.

- an element for holding and presenting confectionery products is generally indicated 10 and comprises a flat punched sheet of card 12 with straight punched lines 12a and a plurality of annular punched lines 12b.

- These punched lines which define lines of bending, are of the so-called half-cut type, that is, they are formed by cutting through half the thickness of the sheet 12.

- the punched sheet 12 has a first rectangular portion A bounded by the straight punched lines 12a which are adapted to define lateral gluing flaps 14, and a second portion B which is joined to the first in correspondence with a straight punched line 15 broken by substantially U-shaped slits 16.

- the second portion B of the punched sheet 12 also has straight punched lines 12a adapted to define lateral gluing flaps 17 for cooperating with the lateral flaps 14 in known manner.

- the annular punched lines 12b are substantially rectangular with rounded corners and are arranged in an ordered array in the first portion A of the punched sheet 12.

- Slits 18 are provided within each annular punched line 12b and comprise I-shaped central portions 18a whose stems are parallel to and equidistant from the longer sides of the respective rectangular punched lines 12b, and four connecting portions 18b between the tips of the ends of the I-shaped central portions 18a and the rounded corners V of the punched lines 12b.

- the slits 18 and the annular punched line 12b thus define two resilient flaps 20 of card in the form of isosceles trapezia and two support flaps 22 having portions which are also in the form of isosceles trapezia and the shorter bases of which extend to form rectangular portions, indicated 22a in the drawings.

- the second portion B of the punched card sheet 12 has a plurality of rectangular holes 24 arranged in positions such that, when the element 10 is assembled, they correspond to the longer sides of the rectangular punched lines 12b to which the support flaps 22 are articulated. Adjacent rectangular holes 24 are joined by shorter central portions so are generally to define substantially double-T-shaped holes 25.

- the second portion B of the punched sheet 12 is bent underneath the first portion A along the straight punched line 12a joining the first and second portions and along the punched line 15.

- the slits 16 define support portions 27 which project downwardly so as to keep the first portion A of the sheet 12 at a constant distance from a support plane, for example, the bottom of a box.

- the support flaps 22 and the resilient flaps 20 are bent so as to form a plurality of holes 28 in the first portion A of the punched sheet 12 defining, with the bent flaps 20 and 22, a plurality of seats S for substantially parallelepipedal products.

- the support flaps 22 When the support flaps 22 are bent, their rectangular ends 22a are fitted into respective retangular holes 24 so as to project below the plane of the second portion B of the punched sheet 12 ( Figures 2 and 3) and have the function of forming a support on the bottom of the box.

- the rectangular end portions 22a of the support flaps 22 are therefore situated in the plane defined by the bent and glued flaps 14 and the support portions 27 so as to keep the frames C defined by the holes 28 in the punched sheet 12 at a predetermined distance from the lower support plane constituted, for example, by the bottom of a box.

- the resilient flaps 20 "float” and, by virtue of the resilient force biassing them towards a configuration in which they are coplanar with the frames C, help to keep the products in position by eliminating the clearance between the products and the seats S.

- the support flaps 22, on the other hand, are kept apart by virtue of their engagement in the holes 24 in the punched sheet 12.

- the embodiment shown in Figures 5-7 in which the same reference numerals are retained for similar elements, includes a third portion D of the punched sheet 12 which, in the assembled configuration, is adapted to constitute the bottom of the box.

- the element 10 for holding and presenting the products can be used as the base of a box which can be completed by a suitable lid E, shown in broken outline in Figure 6.

- a finished box can be produced by the superposition of two elements 10, in which one glued lateral flap 21 can be used as a hinge.

- both the base and the lid of the box have cells for the improved restraint and protection of the products.

- the variant shown in Figures 10-13 may be used to advantage.

- the first portion A of the punched sheet 12 has annular punched lines 30 which are substantially square with curved sides 30a connected by rounded corners 30b.

- annular punched lines 30 which are substantially square with curved sides 30a connected by rounded corners 30b.

- two slits 32 arranged along the diagonals of the punched outline and a central square hole 33 define four, substantially-triangular support flaps 34 which, when the element 10 is assembled, are adapted to be inserted in corresponding holes 35 provided in the second portion B below the first portion A of the punched element 12 and arranged in correspondence with the curved sides 30a of the punched line 30.

- the flaps 34 form curved vertical walls which are adapted to fit the rounded products perfectly.

- the free appendages of the flaps 34 below the portion B of the punched sheet 12 act as feet and as supports for the upper frame wall C.

- the element 10 of the variant of Figures 10-13 can be inserted in the bottom of a box or can be used as the base of a box if a third portion of the punched sheet is included, as described in connection with the variants shown in Figures 5-7 or 8-9.

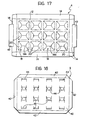

- the variant shown in Figures 14-18 although substantially similar to the solution shown in Figures 1-3, differs therefrom in that the punched element 12 does not have a second portion which can be bent but is assembled with an auxiliary sheet 40 which is glued or heat-sealed in correspondence with bent edges 42 and in correspondence with bent lateral flaps 43 of the punched sheet 12.

- the auxiliary sheet 40 also has a plurality of rectangular holes 44 for cooperating with support flaps 22 defined by the annular punched lines 12b and by the shaped slits 18.

- FIG. 19 and 20 has a punched sheet 12 substantially corresponding to that shown in Figure 17.

- a flat corrugated pad M of the type used, for example, as a resilient element between the products and the lid of a box is interposed between the sheet and the bottom of the box F, shown in broken outline in Figure 16.

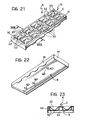

- the holding and presentation element shown in Figures 21-23 is substantially similar to that shown in Figures 1-4 but differs therefrom in the different shapes of the slits 18 which define tongues 50 bent relative to the flaps 20 and 22 and heat-sealed to the lower portion B of the punched element 12.

- the holes in the flat portion, in to which the support flaps fit, are therefore no longer necessary and only aligned central holes 53 are provided for enabling the insertion of suitable locating devices for keeping the upper frame wall C of the punched sheet 12 in position during the heat-sealing.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

- Packages (AREA)

- Food-Manufacturing Devices (AREA)

- Punching Or Piercing (AREA)

- Packaging Frangible Articles (AREA)

Abstract

Description

- The present invention relates to an element for holding and presenting confectionery products, particularly chocolates and the like, which is adapted to define a plurality of seats for the products.

- Currently, such elements are made by the thermoforming of sheets of plastics material for insertion in boxes of punched card. A plurality of cells arranged in an ordered array are therefore thermoformed in the sheets, and serve both to keep the products in position and to prevent direct contact between the products and the bottom of the box which, as a result of any pressures or knocks, could damage the products contained.

- As well as requiring special equipment which is somewhat different from that normally used in the paper and cardboard sector, the production of these thermoformed plastics elements considerably increases the environmental impact of the box as regards solid waste. In fact, the thermoformed sheet is not biodegradable and may produce noxious gases if it is burnt.

- The object of the present invention is to provide an element of the type specified at the beginning of the description which does not have the aforesaid disadvantages and which is also completely biodegradable.

- According to the invention, this object is achieved by virtue of the fact that the element comprises a flat sheet of card or similar material having a plurality of annular punched lines and, within the punched lines, slits which define a plurality of holes in the sheet when the flaps defined between the slits and the punched lines are bent, the holes having at least two opposite side walls for retaining the products.

- By virtue of these characteristics, the card element can fulfil the same function as a thermoformed cellular element of known type, providing considerable advantages in terms of cost and environmental impact.

- Further advantages and characteristics of the holding and presentation element according to the invention will become clear from the detailed description which follows, given purely by way of non-limiting example, with reference to the appended drawings, in which:

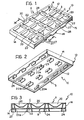

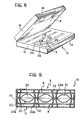

- Figure 1 is a perspective view of a holding and presentation element according to the invention,

- Figure 2 is a perspective view of the element of Figure 1 from below,

- Figure 3 is a section taken on the line III-III of Figure 1,

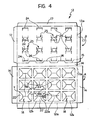

- Figure 4 is a view of a flat punched element from which the element of Figure 1 is made,

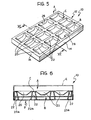

- Figure 5 is a perspective view of a first embodiment of the element of Figure 1,

- Figure 6 is a section taken on the line VI-VI of Figure 5,

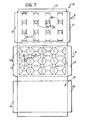

- Figure 7 is a plan view of the punched sheet from which the element of Figure 5 is made,

- Figure 8 is a perspective view of a variant of the embodiment of Figure 5,

- Figure 9 is a cross-section of the element of Figure 8 in a closed configuration,

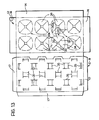

- Figure 10 is a perspective view of a third embodiment of the element according to the invention,

- Figure 11 is a perspective view of an element of Figure 8 from below,

- Figure 12 is a section taken on the line XII-XII of Figure 10,

- Figure 13 is a plan view of the punched sheet from which the element of Figure 10 is made,

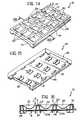

- Figure 14 is a perspective view of a fourth embodiment of the element according to the invention,

- Figure 15 is a perspective view of the element of Figure 14 from below,

- Figure 16 is a section taken on the line XVI-XVI of Figure 14,

- Figure 17 is a view of an upper, flat punched element from which the element of Figure 14 is made,

- Figure 18 is a view of a lower, flat punched element from which the element of Figure 14 is made,

- Figure 19 is an exploded perspective view of a fifth embodiment of the element according to the invention,

- Figure 20 is a section taken on the line XX-XX of Figure 19,

- Figure 21 is a perspective view of a sixth embodiment of an element according to the invention,

- Figure 22 is a perspective view of the element of Figure 21 from below, and

- Figure 23 is a section taken on the line XXIII-XXIII of Figure 17.

- With reference to the drawings, an element for holding and presenting confectionery products is generally indicated 10 and comprises a flat punched sheet of

card 12 with straight punchedlines 12a and a plurality of annularpunched lines 12b. These punched lines, which define lines of bending, are of the so-called half-cut type, that is, they are formed by cutting through half the thickness of thesheet 12. - With particular reference to the embodiment shown in Figures 1-4, the punched

sheet 12 has a first rectangular portion A bounded by the straight punchedlines 12a which are adapted to definelateral gluing flaps 14, and a second portion B which is joined to the first in correspondence with a straight punchedline 15 broken by substantially U-shapedslits 16. The second portion B of the punchedsheet 12 also has straight punchedlines 12a adapted to definelateral gluing flaps 17 for cooperating with thelateral flaps 14 in known manner. - The annular punched

lines 12b are substantially rectangular with rounded corners and are arranged in an ordered array in the first portion A of the punchedsheet 12.Slits 18 are provided within each annularpunched line 12b and comprise I-shapedcentral portions 18a whose stems are parallel to and equidistant from the longer sides of the respective rectangular punchedlines 12b, and four connecting portions 18b between the tips of the ends of the I-shapedcentral portions 18a and the rounded corners V of thepunched lines 12b. Theslits 18 and the annular punchedline 12b thus define tworesilient flaps 20 of card in the form of isosceles trapezia and twosupport flaps 22 having portions which are also in the form of isosceles trapezia and the shorter bases of which extend to form rectangular portions, indicated 22a in the drawings. - The second portion B of the

punched card sheet 12 has a plurality ofrectangular holes 24 arranged in positions such that, when theelement 10 is assembled, they correspond to the longer sides of the rectangular punchedlines 12b to which thesupport flaps 22 are articulated. Adjacentrectangular holes 24 are joined by shorter central portions so are generally to define substantially double-T-shaped holes 25. - When the

element 10 is assembled, the second portion B of the punchedsheet 12 is bent underneath the first portion A along the straight punchedline 12a joining the first and second portions and along thepunched line 15. During this bending, theslits 16 definesupport portions 27 which project downwardly so as to keep the first portion A of thesheet 12 at a constant distance from a support plane, for example, the bottom of a box. After the second portion B has been bent relative to the first portion A and thelateral flaps support flaps 22 and theresilient flaps 20 are bent so as to form a plurality ofholes 28 in the first portion A of the punchedsheet 12 defining, with thebent flaps support flaps 22 are bent, theirrectangular ends 22a are fitted into respectiveretangular holes 24 so as to project below the plane of the second portion B of the punched sheet 12 (Figures 2 and 3) and have the function of forming a support on the bottom of the box. Therectangular end portions 22a of thesupport flaps 22 are therefore situated in the plane defined by the bent and gluedflaps 14 and thesupport portions 27 so as to keep the frames C defined by theholes 28 in thepunched sheet 12 at a predetermined distance from the lower support plane constituted, for example, by the bottom of a box. - The

resilient flaps 20 "float" and, by virtue of the resilient force biassing them towards a configuration in which they are coplanar with the frames C, help to keep the products in position by eliminating the clearance between the products and the seats S. The support flaps 22, on the other hand, are kept apart by virtue of their engagement in theholes 24 in the punchedsheet 12. - The embodiment shown in Figures 5-7, in which the same reference numerals are retained for similar elements, includes a third portion D of the punched

sheet 12 which, in the assembled configuration, is adapted to constitute the bottom of the box. In this embodiment, therefore, theelement 10 for holding and presenting the products can be used as the base of a box which can be completed by a suitable lid E, shown in broken outline in Figure 6. - Alternatively, a finished box can be produced by the superposition of two

elements 10, in which one gluedlateral flap 21 can be used as a hinge. In this variant, shown in Figures 8 and 9, both the base and the lid of the box have cells for the improved restraint and protection of the products. - For confectionery products of rounded shape, the variant shown in Figures 10-13 may be used to advantage. In this variant, the first portion A of the punched

sheet 12 has annular punched lines 30 which are substantially square withcurved sides 30a connected byrounded corners 30b. Within each punched line 30, twoslits 32 arranged along the diagonals of the punched outline and acentral square hole 33 define four, substantially-triangular support flaps 34 which, when theelement 10 is assembled, are adapted to be inserted incorresponding holes 35 provided in the second portion B below the first portion A of the punchedelement 12 and arranged in correspondence with thecurved sides 30a of the punched line 30. The curved lines of bending in correspondence with the punchedsides 30a give the upper frame wall C of the element 10 a wavy appearance, as shown in Figure 10. Moreover, in their opened-out configuration, theflaps 34 form curved vertical walls which are adapted to fit the rounded products perfectly. The free appendages of theflaps 34 below the portion B of the punchedsheet 12 act as feet and as supports for the upper frame wall C. To advantage, theelement 10 of the variant of Figures 10-13 can be inserted in the bottom of a box or can be used as the base of a box if a third portion of the punched sheet is included, as described in connection with the variants shown in Figures 5-7 or 8-9. - The variant shown in Figures 14-18, although substantially similar to the solution shown in Figures 1-3, differs therefrom in that the punched

element 12 does not have a second portion which can be bent but is assembled with anauxiliary sheet 40 which is glued or heat-sealed in correspondence withbent edges 42 and in correspondence with bentlateral flaps 43 of the punchedsheet 12. Theauxiliary sheet 40 also has a plurality ofrectangular holes 44 for cooperating withsupport flaps 22 defined by the annular punchedlines 12b and by theshaped slits 18. - The variant shown in Figures 19 and 20 has a punched

sheet 12 substantially corresponding to that shown in Figure 17. A flat corrugated pad M of the type used, for example, as a resilient element between the products and the lid of a box is interposed between the sheet and the bottom of the box F, shown in broken outline in Figure 16. - The holding and presentation element shown in Figures 21-23 is substantially similar to that shown in Figures 1-4 but differs therefrom in the different shapes of the

slits 18 which definetongues 50 bent relative to theflaps element 12. The holes in the flat portion, in to which the support flaps fit, are therefore no longer necessary and only alignedcentral holes 53 are provided for enabling the insertion of suitable locating devices for keeping the upper frame wall C of the punchedsheet 12 in position during the heat-sealing. - Naturally, it is possible to heat-seal only two opposite flaps to the portion B whilst the other two flaps can be left free or, according to a further variant, can be fitted into holes in the portion B in exactly the same way as that shown in Figures 2 and 3. A firmer element is thus produced since the heat-sealed flaps keep the upper frame wall C of the

element 10 joined to the lower base wall B for the products whilst the flaps fitted into the corresponding holes act as lower supports on the bottom of the box. - The above description shows clearly the advantages of the holding and presentation element according to the invention which, by virtue of its particular characteristics, can be used not only as an accessory for a box but as an integral and structural part of the box itself.

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT90830092T ATE97088T1 (en) | 1990-01-10 | 1990-03-13 | CUT-OUT CARDBOARD PLATE FOR HOLDING AND DISPLAYING CANDY AND SIMILAR PRODUCTS. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT6701290 | 1990-01-10 | ||

| IT67012A IT1239850B (en) | 1990-01-10 | 1990-01-10 | DIE CARDBOARD ELEMENT FOR HOLDING AND PRESENTING DESSERIES AND SIMILAR PRODUCTS |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0441102A1 true EP0441102A1 (en) | 1991-08-14 |

| EP0441102B1 EP0441102B1 (en) | 1993-11-10 |

Family

ID=11298882

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90830092A Expired - Lifetime EP0441102B1 (en) | 1990-01-10 | 1990-03-13 | Punched cardboard element for keeping and showing sweets and the like |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0441102B1 (en) |

| AT (1) | ATE97088T1 (en) |

| DE (1) | DE69004564T2 (en) |

| ES (1) | ES2046767T3 (en) |

| IT (1) | IT1239850B (en) |

Cited By (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0472998A1 (en) * | 1990-08-16 | 1992-03-04 | Jacobs Suchard AG | Packing for confectionary |

| FR2687648A1 (en) * | 1992-02-21 | 1993-08-27 | Legrand Sa | Packaging grid for engaging devices |

| EP0558461A1 (en) * | 1992-02-25 | 1993-09-01 | SAFFAPACK S.r.l. | Cellular container |

| EP0564414A1 (en) * | 1992-03-16 | 1993-10-06 | SAFFAPACK S.r.l. | Box, in particular for sweets such as chocolates |

| EP0633203A1 (en) * | 1993-07-06 | 1995-01-11 | Manfred Scholz | Packaging insert for packaging chocolates or the like |

| EP0937657A1 (en) * | 1998-02-24 | 1999-08-25 | BARTOLINI SAS di Bartolini Adriano & C. | Product combining a sweet speciality and a disposable game involving questions on works of art |

| WO2001038198A1 (en) | 1999-11-19 | 2001-05-31 | Susanne Pfaffenbichler | Packaging for fragile or crushable goods |

| EP1136370A1 (en) | 2000-03-21 | 2001-09-26 | Societe Des Produits Nestle S.A. | Display package for food items |

| RU2225820C1 (en) * | 2002-07-12 | 2004-03-20 | Общество с ограниченной ответственностью "Основание-2" | Correxy |

| RU2236369C2 (en) * | 2002-10-02 | 2004-09-20 | Общество с ограниченной ответственностью "Основание-2" | Correxy |

| FR2860505A1 (en) * | 2003-10-03 | 2005-04-08 | Knauf Snc | Packaging for fresh food product, has case and covering whose dimensions are chosen for providing free height between lower surface of cavity of base of case and top surface of cell of covering |

| RU2255885C1 (en) * | 2003-12-30 | 2005-07-10 | Общество с ограниченной ответственностью "Основание-2" | Apron |

| RU2256592C2 (en) * | 2003-07-07 | 2005-07-20 | Общество с ограниченной ответственностью "Основание-2" | Correx |

| EP1602280A1 (en) * | 2004-08-10 | 2005-12-07 | CARTOTECNICA ESSE-BI S.r.l. | Baking tin and manufacturing method thereof |

| FR2902410A1 (en) * | 2006-06-16 | 2007-12-21 | Smurfit Kappa France Sas Soc P | Plate/boat type packaging for e.g. fresh dairy product, has bottom with slots that are positioned on another bottom to receive object when packaging is formatted, where each opening of latter bottom receives projection from spaces |

| WO2011035923A1 (en) * | 2009-09-24 | 2011-03-31 | Seda S.P.A. | Blank and packaging produced therefrom |

| RU2495808C1 (en) * | 2012-08-07 | 2013-10-20 | Виктор Михайлович Коршунов | Box for confectionary items and method of its packaging |

| EP2746186A1 (en) * | 2012-12-24 | 2014-06-25 | Soremartec S.A. | Wrapped confectionery products positioning and retaining device and flat blanks assembly for formimg said device |

| GB2520989A (en) * | 2013-12-06 | 2015-06-10 | Mondelez Uk R & D Ltd | Packaging |

| JP2016043974A (en) * | 2014-08-25 | 2016-04-04 | 王子ホールディングス株式会社 | Paper holder |

| US20180178950A1 (en) * | 2016-12-27 | 2018-06-28 | Steve Kohn | Device for moving and storing potted plants and other objects having a base |

| CN108455079A (en) * | 2018-03-21 | 2018-08-28 | 郑州甲乙贝包装设计有限公司 | A kind of fruit packaging cushion pad |

| CN109051169A (en) * | 2018-08-08 | 2018-12-21 | 珠海格力电器股份有限公司 | packaging structure and packaging assembly |

| EP3683158A1 (en) * | 2019-01-15 | 2020-07-22 | Multi Packaging Solutions UK Limited | Carrier |

| EP3699110A1 (en) * | 2019-02-21 | 2020-08-26 | A & R Carton GmbH | Carrier made of foldable flat material for preferably small-size products |

| GB2589053A (en) * | 2019-07-24 | 2021-05-26 | Concept Packaging Services Ltd | Improvements in and relating to fitments |

| WO2023010611A1 (en) * | 2021-07-31 | 2023-02-09 | 深圳市裕同包装科技股份有限公司 | Packaging box and paperboard structure |

| US11884462B2 (en) | 2019-11-25 | 2024-01-30 | Multi Packaging Solutions Uk Limited | Tray |

| EP4321448A1 (en) * | 2022-08-08 | 2024-02-14 | Van Genechten Packaging N.V. | Packaging with carton inlays |

| US12116182B2 (en) | 2021-07-31 | 2024-10-15 | ShenZhen YUTO Packaging Technology Co., Ltd | Packaging box and paperboard structure |

| WO2025021479A3 (en) * | 2023-07-26 | 2025-05-01 | Mayr-Melnhof Karton Ag | Packaging insert, packaging, set for producing a packaging insert, and method and device for producing a packaging insert |

| DE202024104761U1 (en) * | 2024-08-22 | 2025-08-25 | Mayr-Melnhof Karton Ag | Packaging insert, packaging and cutting for the production of a packaging insert |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE738917C (en) * | 1938-12-14 | 1943-09-04 | Lothar Alexander Fritz Hilbric | Box for ampoules and like |

| FR1016194A (en) * | 1950-04-12 | 1952-11-04 | Packaging | |

| GB1264412A (en) * | 1969-06-04 | 1972-02-23 | ||

| DE8907594U1 (en) * | 1989-06-21 | 1989-11-02 | Hermann Schött GmbH Offsetdruckerei, 4050 Mönchengladbach | Packaging insert |

| DE8907593U1 (en) * | 1989-06-21 | 1989-11-02 | Hermann Schött GmbH Offsetdruckerei, 4050 Mönchengladbach | Packaging insert |

-

1990

- 1990-01-10 IT IT67012A patent/IT1239850B/en active IP Right Grant

- 1990-03-13 ES ES199090830092T patent/ES2046767T3/en not_active Expired - Lifetime

- 1990-03-13 DE DE69004564T patent/DE69004564T2/en not_active Expired - Fee Related

- 1990-03-13 AT AT90830092T patent/ATE97088T1/en not_active IP Right Cessation

- 1990-03-13 EP EP90830092A patent/EP0441102B1/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE738917C (en) * | 1938-12-14 | 1943-09-04 | Lothar Alexander Fritz Hilbric | Box for ampoules and like |

| FR1016194A (en) * | 1950-04-12 | 1952-11-04 | Packaging | |

| GB1264412A (en) * | 1969-06-04 | 1972-02-23 | ||

| DE8907594U1 (en) * | 1989-06-21 | 1989-11-02 | Hermann Schött GmbH Offsetdruckerei, 4050 Mönchengladbach | Packaging insert |

| DE8907593U1 (en) * | 1989-06-21 | 1989-11-02 | Hermann Schött GmbH Offsetdruckerei, 4050 Mönchengladbach | Packaging insert |

Cited By (37)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0472998A1 (en) * | 1990-08-16 | 1992-03-04 | Jacobs Suchard AG | Packing for confectionary |

| FR2687648A1 (en) * | 1992-02-21 | 1993-08-27 | Legrand Sa | Packaging grid for engaging devices |

| EP0558461A1 (en) * | 1992-02-25 | 1993-09-01 | SAFFAPACK S.r.l. | Cellular container |

| EP0564414A1 (en) * | 1992-03-16 | 1993-10-06 | SAFFAPACK S.r.l. | Box, in particular for sweets such as chocolates |

| EP0633203A1 (en) * | 1993-07-06 | 1995-01-11 | Manfred Scholz | Packaging insert for packaging chocolates or the like |

| EP0937657A1 (en) * | 1998-02-24 | 1999-08-25 | BARTOLINI SAS di Bartolini Adriano & C. | Product combining a sweet speciality and a disposable game involving questions on works of art |

| WO2001038198A1 (en) | 1999-11-19 | 2001-05-31 | Susanne Pfaffenbichler | Packaging for fragile or crushable goods |

| EP1136370A1 (en) | 2000-03-21 | 2001-09-26 | Societe Des Produits Nestle S.A. | Display package for food items |

| RU2225820C1 (en) * | 2002-07-12 | 2004-03-20 | Общество с ограниченной ответственностью "Основание-2" | Correxy |

| RU2236369C2 (en) * | 2002-10-02 | 2004-09-20 | Общество с ограниченной ответственностью "Основание-2" | Correxy |

| RU2256592C2 (en) * | 2003-07-07 | 2005-07-20 | Общество с ограниченной ответственностью "Основание-2" | Correx |

| FR2860505A1 (en) * | 2003-10-03 | 2005-04-08 | Knauf Snc | Packaging for fresh food product, has case and covering whose dimensions are chosen for providing free height between lower surface of cavity of base of case and top surface of cell of covering |

| RU2255885C1 (en) * | 2003-12-30 | 2005-07-10 | Общество с ограниченной ответственностью "Основание-2" | Apron |

| EP1602280A1 (en) * | 2004-08-10 | 2005-12-07 | CARTOTECNICA ESSE-BI S.r.l. | Baking tin and manufacturing method thereof |

| FR2902410A1 (en) * | 2006-06-16 | 2007-12-21 | Smurfit Kappa France Sas Soc P | Plate/boat type packaging for e.g. fresh dairy product, has bottom with slots that are positioned on another bottom to receive object when packaging is formatted, where each opening of latter bottom receives projection from spaces |

| WO2011035923A1 (en) * | 2009-09-24 | 2011-03-31 | Seda S.P.A. | Blank and packaging produced therefrom |

| RU2495808C1 (en) * | 2012-08-07 | 2013-10-20 | Виктор Михайлович Коршунов | Box for confectionary items and method of its packaging |

| ITTO20121146A1 (en) * | 2012-12-24 | 2014-06-25 | Soremartec Sa | POSITIONING AND RETENTION DEVICE FOR SWEETENED PRODUCTS AND TOGETHER WITH LOCKED PLANS FOR THE REALIZATION OF SUCH A DEVICE |

| EP2746186A1 (en) * | 2012-12-24 | 2014-06-25 | Soremartec S.A. | Wrapped confectionery products positioning and retaining device and flat blanks assembly for formimg said device |

| GB2520989A (en) * | 2013-12-06 | 2015-06-10 | Mondelez Uk R & D Ltd | Packaging |

| JP2016043974A (en) * | 2014-08-25 | 2016-04-04 | 王子ホールディングス株式会社 | Paper holder |

| US20180178950A1 (en) * | 2016-12-27 | 2018-06-28 | Steve Kohn | Device for moving and storing potted plants and other objects having a base |

| US10934052B2 (en) * | 2016-12-27 | 2021-03-02 | Steve Kohn | Device for moving and storing potted plants and other objects having a base |

| CN108455079A (en) * | 2018-03-21 | 2018-08-28 | 郑州甲乙贝包装设计有限公司 | A kind of fruit packaging cushion pad |

| CN109051169A (en) * | 2018-08-08 | 2018-12-21 | 珠海格力电器股份有限公司 | packaging structure and packaging assembly |

| US11542081B2 (en) | 2019-01-15 | 2023-01-03 | Multi Packaging Solutions Uk Limited | Carrier |

| EP3683158A1 (en) * | 2019-01-15 | 2020-07-22 | Multi Packaging Solutions UK Limited | Carrier |

| GB2580609A (en) * | 2019-01-15 | 2020-07-29 | Multi Packaging Solutions Uk Ltd | Carrier |

| EP3699110A1 (en) * | 2019-02-21 | 2020-08-26 | A & R Carton GmbH | Carrier made of foldable flat material for preferably small-size products |

| GB2589053A (en) * | 2019-07-24 | 2021-05-26 | Concept Packaging Services Ltd | Improvements in and relating to fitments |

| GB2589053B (en) * | 2019-07-24 | 2023-08-30 | Concept Packaging Services Ltd | Improvements in and relating to fitments |

| US11884462B2 (en) | 2019-11-25 | 2024-01-30 | Multi Packaging Solutions Uk Limited | Tray |

| WO2023010611A1 (en) * | 2021-07-31 | 2023-02-09 | 深圳市裕同包装科技股份有限公司 | Packaging box and paperboard structure |

| US12116182B2 (en) | 2021-07-31 | 2024-10-15 | ShenZhen YUTO Packaging Technology Co., Ltd | Packaging box and paperboard structure |

| EP4321448A1 (en) * | 2022-08-08 | 2024-02-14 | Van Genechten Packaging N.V. | Packaging with carton inlays |

| WO2025021479A3 (en) * | 2023-07-26 | 2025-05-01 | Mayr-Melnhof Karton Ag | Packaging insert, packaging, set for producing a packaging insert, and method and device for producing a packaging insert |

| DE202024104761U1 (en) * | 2024-08-22 | 2025-08-25 | Mayr-Melnhof Karton Ag | Packaging insert, packaging and cutting for the production of a packaging insert |

Also Published As

| Publication number | Publication date |

|---|---|

| DE69004564D1 (en) | 1993-12-16 |

| IT9067012A1 (en) | 1991-07-11 |

| IT9067012A0 (en) | 1990-01-10 |

| EP0441102B1 (en) | 1993-11-10 |

| ES2046767T3 (en) | 1994-02-01 |

| IT1239850B (en) | 1993-11-15 |

| DE69004564T2 (en) | 1994-06-01 |

| ATE97088T1 (en) | 1993-11-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0441102A1 (en) | Punched cardboard element for keeping and showing sweets and the like | |

| US4953705A (en) | Package having detent-engaged cushioning lining | |

| US4113096A (en) | Packing box for china | |

| US5669493A (en) | Carton for cigarette packs | |

| WO1995003223A1 (en) | Packaging container blank | |

| EP0119043A2 (en) | Packaging boxes or cartons | |

| JPH0350061Y2 (en) | ||

| EP0087306A2 (en) | Packaging boxes or cartons | |

| JPH061335A (en) | Packing holding panel and packing device | |

| EP0036785A1 (en) | Packaging containers | |

| JP3881728B2 (en) | Partition packaging box | |

| JP3083439U (en) | Packaging box | |

| JP2001031175A (en) | Packaging structure | |

| US5076435A (en) | Packaging for food | |

| JPH08104317A (en) | Packaging box being equipped with double structure | |

| JP3008254U (en) | Packaging container | |

| JPS6219580Y2 (en) | ||

| JP3037809U (en) | Product protection buffer box | |

| JPH0423830Y2 (en) | ||

| JPH0669119U (en) | Wrapping paper box with divider | |

| JPS5937461Y2 (en) | Connection box for disconnection | |

| JPH066265U (en) | Cushioning material for packing | |

| JP3164316U (en) | Cushioning material, package and package | |

| JPH0639723U (en) | Assembled interior fittings for bottle storage boxes | |

| JP2002037343A (en) | Cushion material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19911011 |

|

| 17Q | First examination report despatched |

Effective date: 19930205 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19931110 Ref country code: AT Effective date: 19931110 |

|

| REF | Corresponds to: |

Ref document number: 97088 Country of ref document: AT Date of ref document: 19931115 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 69004564 Country of ref document: DE Date of ref document: 19931216 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2046767 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Effective date: 19940313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940314 Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 19940314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940331 Ref country code: BE Effective date: 19940331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| BERE | Be: lapsed |

Owner name: CARTOTECNICA CHIERESE S.P.A. Effective date: 19940331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19941001 |

|

| 26N | No opposition filed | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| EUG | Se: european patent has lapsed |

Ref document number: 90830092.4 Effective date: 19941010 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990216 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19990224 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19990226 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19990330 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000313 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000313 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050313 |