EP0428032B1 - Vessel with a pouring spout - Google Patents

Vessel with a pouring spout Download PDFInfo

- Publication number

- EP0428032B1 EP0428032B1 EP90121105A EP90121105A EP0428032B1 EP 0428032 B1 EP0428032 B1 EP 0428032B1 EP 90121105 A EP90121105 A EP 90121105A EP 90121105 A EP90121105 A EP 90121105A EP 0428032 B1 EP0428032 B1 EP 0428032B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- flap

- guide channel

- vessel

- pouring spout

- pivot axis

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005096 rolling process Methods 0.000 claims description 16

- 230000005484 gravity Effects 0.000 claims description 2

- 235000013336 milk Nutrition 0.000 description 4

- 239000008267 milk Substances 0.000 description 4

- 210000004080 milk Anatomy 0.000 description 4

- 239000007788 liquid Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 2

- 235000015203 fruit juice Nutrition 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G19/00—Table service

- A47G19/12—Vessels or pots for table use

Definitions

- the invention relates to a jug with a pouring spout, which in its lid has a flap which can be pivoted away for pouring about a pivot axis and which in the closed state rests on the pouring spout, which on the side of the pivot axis remote from the pouring spout has a lever arm projecting in a guide channel running transversely to the pivot axis has against which a roller body arranged in the guide channel rolls by gravity for automatic opening of the flap when the can is poured into the inclined position required for this purpose.

- a lever arm projecting in a guide channel running transversely to the pivot axis has against which a roller body arranged in the guide channel rolls by gravity for automatic opening of the flap when the can is poured into the inclined position required for this purpose.

- Closing the pouring spout is advantageous in milk churns so that the milk does not dry out and so that no contaminants, for example flies, can get into the milk. Even with cans with fruit juices or the like, closing the pouring spout is particularly useful when the jug is used outdoors. In the case of a coffee pot, closing the pouring spout is particularly useful if it is designed as a thermos flask, so that no undesirable large heat loss occurs via the open pouring spout.

- the guide channel runs horizontally.

- a ball is arranged in it as a rolling body, which, due to a curved course of the lever arm of the flap projecting into the guide channel, runs from the lever arm down to the front of the lever arm when it is parked.

- Flaps for closing the pouring spout can often only be opened with a relatively large amount of force. Basically, the static friction of the flap must first be overcome in the first moment of opening. Often such flaps also tend to stick to the pouring spout because the liquid to be poured out of the jug has an adhesive effect, which is the case, for example, with fruit juices or milk. In order to then be able to exert the force required for opening, the rolling body must be relatively large.

- the invention has for its object to design a jug of the type mentioned so that the flap can be opened reliably with a relatively light rolling body.

- the rolling body when the liquid is poured out, the rolling body first moves in the direction of the pivot axis of the flap and then hits the lever arm of the flap projecting into the guide channel. As a result, the flap is opened jerkily and with a clearly audible clacking sound even if it is relatively stiff due to an adhesive effect of the liquid contained in the jug or greater static friction of its pivot axis.

- the kinetic energy of the rolling element also ensures that a stiff flap can be opened even with a relatively light rolling element. Due to the gradient of the guide channel, the rolling body also hits audibly with momentum against the end of the guide channel facing away from the flap after the can has been switched off, so that the rest position of the Roll body is also acoustically perceptible.

- a steel ball could be provided as a rolling element in a closed guide channel.

- the can is particularly advantageous in appearance if the rolling body is a ring in which a short pin protrudes from one side of the guide channel. The short pin allows the ring to be inserted from above into the guide channel while tilting it, but prevents the ring from falling out of the guide channel by itself during normal use of the can.

- the flap can be stored in a simple manner in the lid of the jug if the pivot axis of the flap is formed by two lateral pins of the flap, each of which engages in a recess in an upwardly facing cheek of the lid of the jug.

- each recess is designed as a groove leading obliquely from above into the side surface of the respective cheek facing the flap. This configuration makes it possible to remove the flap from the lid without tools by pushing it towards the middle of the lid and at the same time allowing movement upward from the lid level. This easy disassembly makes it particularly easy to clean the flap and of course the entire lid.

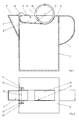

- the jug shown as a whole in FIG. 1 consists of a container 1 which has a pouring spout 2 on its front and a handle 3 on its opposite side. At the top, the container 1 is covered by a lid 4.

- the cover 4 has a guide channel 5 with a bottom surface 6 which extends slightly inclined in the direction of the handle 3.

- the pouring spout 2 is covered at the top by a flap 7 which can be tilted about a pivot axis 8 fastened to the cover 4 and has a lever arm 9 projecting into the guide channel 5.

- a short pin 11 protrudes slightly from the side into the roller body 10, which is designed as a ring, and thereby prevents it from coming up out of the guide channel 5 by itself.

- FIG. 2 shows that the flap 7 has two lateral pins 12, 13, which form its pivot axis 8 and engage in upwardly directed cheeks 14, 15 of the cover 4. Furthermore, the rolling body 10 is shown in the top view according to FIG. Also visible is the pin 11, which is slightly in the rolling body 10 engaging ring engages.

- Figures 4 and 5 show the example of the cheek 14 that a recess 16 is provided in the side surface facing the flap 7. This is designed as a groove which is open towards the flap 7 and extends obliquely from the rear downward to the pivot axis 8. This configuration enables the flap 7 with its pins 12, 13 to be simply inserted into the recesses 16 of the cheeks 14 from behind. 15 to insert.

Landscapes

- Table Devices Or Equipment (AREA)

- Cookers (AREA)

- Lubricants (AREA)

- Motor Or Generator Frames (AREA)

- Closures For Containers (AREA)

Abstract

Description

Die Erfindung betrifft eine Kanne mit einer Ausgußtülle, welche in ihrem Deckel eine zum Ausgießen um eine Schwenkachse wegschwenkbare, im geschlossenen Zustand auf der Ausgußtülle aufliegende Klappe aufweist, welche auf der der Ausgußtülle abgewandten Seite der Schwenkachse einen in einem quer zur Schwenkachse verlaufenden Führungskanal ragenden Hebelarm hat, gegen den zum selbsttätigen Öffnen der Klappe ein in dem Führungskanal angeordneter Rollkörper durch die Schwerkraft rollt, wenn die Kanne zum Ausgießen in die hierzu erforderliche Schräglage gebracht wird. Eine solche Kanne ist Gegenstand der US-A-1 356 754.The invention relates to a jug with a pouring spout, which in its lid has a flap which can be pivoted away for pouring about a pivot axis and which in the closed state rests on the pouring spout, which on the side of the pivot axis remote from the pouring spout has a lever arm projecting in a guide channel running transversely to the pivot axis has against which a roller body arranged in the guide channel rolls by gravity for automatic opening of the flap when the can is poured into the inclined position required for this purpose. Such a can is the subject of US-A-1 356 754.

Das Verschließen der Ausgußtülle ist bei Milchkannen vorteilhaft, damit die Milch nicht eintrocknet und damit keine Verunreinigungen, beispielsweise Fliegen, in die Milch gelangen können. Auch bei Kannen mit Fruchtsäften oder dergleichen ist ein Verschließen der Ausgußtülle insbesondere dann sinnvoll, wenn die Kanne im Freien benutzt wird. Bei einer Kaffekanne ist das Verschließen der Ausgußtülle vor allem dann sinnvoll, wenn sie als Thermoskanne ausgebildet ist, damit über die offene Ausgußtülle kein unerwünscht großer Wärmeverlust eintritt.Closing the pouring spout is advantageous in milk churns so that the milk does not dry out and so that no contaminants, for example flies, can get into the milk. Even with cans with fruit juices or the like, closing the pouring spout is particularly useful when the jug is used outdoors. In the case of a coffee pot, closing the pouring spout is particularly useful if it is designed as a thermos flask, so that no undesirable large heat loss occurs via the open pouring spout.

Bei der bekannten Kanne verläuft der Führungskanal horizontal. Als Rollkörper ist in ihm eine Kugel angeordnet, welche aufgrund eines gekrümmten Verlaufs des in den Führungskanal ragenden Hebelarmes der Klappe beim Abstellen der Kanne von dem Hebelarm herunter bis vor ihn läuft.In the known jug, the guide channel runs horizontally. A ball is arranged in it as a rolling body, which, due to a curved course of the lever arm of the flap projecting into the guide channel, runs from the lever arm down to the front of the lever arm when it is parked.

Klappen zum Verschließen der Ausgußtülle können oftmals nur mit einem relativ großen Kraftaufwand geöffnet werden. Grundsätzlich muß im ersten Moment des Öffnens zunächst die Haftreibung der Klappe überwunden werden. Oftmals neigen solche Klappen auch dazu, auf der Ausgußtülle zu haften, weil die aus der Kanne auszugießende Flüssigkeit klebende Wirkung hat, was beispielsweise bei Fruchtsäften oder Milch der Fall ist. Um dann die zum öffnen erforderliche Kraft ausüben zu können, muß der Rollkörper relativ groß sein.Flaps for closing the pouring spout can often only be opened with a relatively large amount of force. Basically, the static friction of the flap must first be overcome in the first moment of opening. Often such flaps also tend to stick to the pouring spout because the liquid to be poured out of the jug has an adhesive effect, which is the case, for example, with fruit juices or milk. In order to then be able to exert the force required for opening, the rolling body must be relatively large.

Der Erfindung liegt die Aufgabe zugrunde, eine Kanne der eingangs genannten Art so auszubilden, daß mit einem relativ leichten Rollkörper die Klappe zuverlässig geöffnet werden kann.The invention has for its object to design a jug of the type mentioned so that the flap can be opened reliably with a relatively light rolling body.

Diese Aufgabe wird erfindungsgemäß dadurch gelöst, daß der Führungskanal auf seiner ganzen Länge zu der Seite Gefälle hat, die dem in ihn ragenden Hebelarm der Klappe abgewandt ist.This object is achieved in that the guide channel over its entire length to the side that faces away from the lever arm of the flap protruding into it.

Durch diese Gestaltung einer Kanne bewegt sich beim Ausgießen von Flüssigkeit zunächst der Rollkörper in Richtung der Schwenkachse der Klappe und trifft dann mit Schwung gegen den in den Führungskanal ragenden Hebelarm der Klappe. Hierdurch wird die Klappe ruckartig und mit einem gut hörbaren Klack-Geräusch selbst dann zuverlässig geöffnet, wenn sie aufgrund einer Klebewirkung der in der Kanne enthaltenen Flüssigkeit oder größer Haftreibung ihrer Schwenkachse relativ schwergängig ist. Durch die kinetische Energie des Rollkörpers wird zudem erreicht, daß auch mit einem relativ leichten Rollkörper eine schwergängige Klappe geöffnet werden kann. Durch das Gefälle des Führungskanals trifft der Rollkörper nach dem Abstellen der Kanne ebenfalls gut hörbar mit Schwung gegen das der Klappe abgewandte Ende des Führungskanals, so daß das Erreichen der Ruheposition des Rollkörpers ebenfalls akustisch wahrnehmbar ist.With this design of a can, when the liquid is poured out, the rolling body first moves in the direction of the pivot axis of the flap and then hits the lever arm of the flap projecting into the guide channel. As a result, the flap is opened jerkily and with a clearly audible clacking sound even if it is relatively stiff due to an adhesive effect of the liquid contained in the jug or greater static friction of its pivot axis. The kinetic energy of the rolling element also ensures that a stiff flap can be opened even with a relatively light rolling element. Due to the gradient of the guide channel, the rolling body also hits audibly with momentum against the end of the guide channel facing away from the flap after the can has been switched off, so that the rest position of the Roll body is also acoustically perceptible.

Als Rollkörper könnte man wie beim Stand der Technik eine Stahlkugel in einem geschlossenen Führungskanal vorsehen. Vom Aussehen her ist die Kanne besonders vorteilhaft ausgebildet, wenn der Rollkörper ein Ring ist, in welchem von einer Seite des Führungskanals ein kurzer Stift ragt. Der kurze Stift ermöglicht ein Einsetzen des Ringes unter Verkanten desselben von oben her in den Führungskanal, verhindert jedoch, daß bei normalem Gebrauch der Kanne der Ring von selbst aus dem Führungskanal herausfallen kann.As in the prior art, a steel ball could be provided as a rolling element in a closed guide channel. The can is particularly advantageous in appearance if the rolling body is a ring in which a short pin protrudes from one side of the guide channel. The short pin allows the ring to be inserted from above into the guide channel while tilting it, but prevents the ring from falling out of the guide channel by itself during normal use of the can.

Die Klappe kann auf einfache Weise im Deckel der Kanne gelagert werden, wenn die Schwenkachse der Klappe durch zwei seitliche Stifte der Klappe gebildet ist, welche in jeweils eine Ausnehmung einer nach oben weisenden Wange des Deckels der Kanne greift.The flap can be stored in a simple manner in the lid of the jug if the pivot axis of the flap is formed by two lateral pins of the flap, each of which engages in a recess in an upwardly facing cheek of the lid of the jug.

Vorteilhaft ist es auch, wenn jede Ausnehmung als schräg von oben in die der Klappe zugewandte Seitenfläche der jeweiligen Wange hinein führende Nut ausgebildet ist. Diese Ausgestaltung ermöglicht es, die Klappe ohne Werkzeug vom Deckel zu entfernen, indem man sie zur Deckelmitte hin schiebt und dabei gleichzeitig eine Bewegung aus der Deckelebene heraus nach oben zuläßt. Durch diese leichte Demontierbarkeit kann die Klappe und natürlich auch der gesamte Deckel besonders leicht gereinigt werden.It is also advantageous if each recess is designed as a groove leading obliquely from above into the side surface of the respective cheek facing the flap. This configuration makes it possible to remove the flap from the lid without tools by pushing it towards the middle of the lid and at the same time allowing movement upward from the lid level. This easy disassembly makes it particularly easy to clean the flap and of course the entire lid.

Die Erfindung läßt zahlreiche Ausführungsformen zu. Zur weiteren Verdeutlichung ihres Grundprinzips ist eine davon in der Zeichnung dargestellt und wird nachfolgend beschrieben. Diese zeigt in

- Fig. 1 einen senkrechten Schnitt durch eine erfindungsgemäß gestaltete Kanne,

- Fig. 2 eine Draufsicht auf die Kanne,

- Fig. 3 eine Vorderansicht der Kanne,

- Fig. 4 eine Ansicht einer eine Klappe der Kanne lagernden Wange des Deckels der Kanne,

- Fig. 5 eine Ansicht von der Seite auf die Wange.

- 1 is a vertical section through a jug designed according to the invention,

- 2 is a plan view of the jug,

- 3 is a front view of the jug,

- 4 is a view of a flap of the jug supporting cheek of the lid of the jug,

- Fig. 5 is a side view of the cheek.

Die in Figur 1 als Ganzes gezeigte Kanne besteht aus einem Behälter 1, welcher an seiner Vorderseite eine Ausgußtülle 2 und an seiner hierzu gegenüberliegenden Seite einen Griff 3 hat. Nach oben hin ist der Behälter 1 von einem Deckel 4 abgedeckt. Der Deckel 4 hat einen Führungskanal 5 mit einer Bodenfläche 6, die in Richtung des Griffes 3 geringfügig geneigt verläuft.The jug shown as a whole in FIG. 1 consists of a

Die Ausgußtülle 2 ist nach oben hin von einer Klappe 7 abgedeckt, welche um eine am Deckel 4 befestigte Schwenkachse 8 kippbar ist und einen in den Führungskanal 5 ragenden Hebelarm 9 hat. Innerhalb des Führungskanals 5 ist weiterhin ein Rollkörper 10 angeordnet, bei dem es sich um einen auf der Bodenfläche 6 frei abrollbaren Ring handelt. Ein kurzer Stift 11 ragt von der Seite her geringfügig in den als Ring ausgebildeten Rollkörper 10 und verhindert dadurch, daß dieser von selbst nach oben hin aus dem Führungskanal 5 gelangen kann.The

Die Figur 2 zeigt, daß die Klappe 7 zwei seitliche Stifte 12, 13 hat, die ihre Schwenkachse 8 bilden und in nach oben gerichtete Wangen 14, 15 des Deckels 4 eingreifen. Weiterhin ist in der Draufsicht gemäß Figur 2 der Rollkörper 10 dargestellt. Ebenfalls zu sehen ist der Stift 11, welcher geringfügig in den den Rollkörper 10 bildenden Ring eingreift.FIG. 2 shows that the

In Figur 3 sieht man die Ausgußtülle 2 von vorn. Weiterhin sind die in den Wangen 14, 15 gelagerte Klappe 7 und der Rollkörper 10 dargestellt.In Figure 3 you can see the

Die Figuren 4 und 5 zeigen am Beispiel der Wange 14, daß in der der Klappe 7 zugewandten Seitenfläche eine Ausnehmung 16 vorgesehen ist. Diese ist als eine zur Klappe 7 hin offene Nut ausgebildet und verläuft von hinten schräg nach vorn unten bis zur Schwenkachse 8. Diese Ausgestaltung ermöglicht es, die Klappe 7 von hinten her mit ihren Stiften 12, 13 einfach in die Ausnehmungen 16 der Wangen 14, 15 einzuschieben.Figures 4 and 5 show the example of the

- 1 Behälter1 container

- 2 Ausgußtülle2 pouring spout

- 3 Griff3 handle

- 4 Deckel4 lids

- 5 Führungskanal5 guide channel

- 6 Bodenfläche6 floor space

- 7 Klappe7 flap

- 8 Schwenkachse8 swivel axis

- 9 Hebelarm9 lever arm

- 10 Rollkörper10 rolling elements

- 11 Stift11 pin

- 12 Stift12 pin

- 13 Stift13 pin

- 14 Wange14 cheek

- 15 Wange15 cheek

- 16 Ausnehmung16 recess

Claims (4)

- Vessel with a pouring spout which has, in its lid (4), a flap (7) which can be pivoted out round a pivot axis (8) for pouring, rests on the pouring spout (2) in the closed state and, on the side of the pivot axis (8) remote from the pouring spout (2) has a lever arm (9) which projects in a guide channel (5) extending transversely to the pivot axis (8) and against which a rolling body (10) arranged in the guide channel (5) rolls due to gravity for the automatic opening of the flap (7) when the vessel is brought into the oblique position required for pouring, characterised in that the guide channel (5) has a gradient to the side over its entire length, which is turned away from the lever arm (9) of the flap (7) projecting into it.

- Vessel according to claim 1, characterised in that the rolling body (10) is a ring in which a short pin (11) projects from one side of the guide channel (5).

- Vessel according to claims 1 or 2, characterised in that the pivot axis (8) of the flap (7) is formed by two lateral pins (14, 15) of the flap (7) which engages in a respective recess (16) of an upwardly directed cheek (14, 15) of the lid (4) of the vessel.

- Vessel according to claim 3, characterised in that each recess (16) is designed as a groove leading obliquely from the top into the lateral face of the respective cheek (14, 15) facing the flap (7).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3937581 | 1989-11-11 | ||

| DE3937581A DE3937581A1 (en) | 1989-11-11 | 1989-11-11 | CAN WITH A POUR |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0428032A1 EP0428032A1 (en) | 1991-05-22 |

| EP0428032B1 true EP0428032B1 (en) | 1992-12-23 |

Family

ID=6393344

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90121105A Expired - Lifetime EP0428032B1 (en) | 1989-11-11 | 1990-11-03 | Vessel with a pouring spout |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0428032B1 (en) |

| AT (1) | ATE83629T1 (en) |

| DE (3) | DE3937581A1 (en) |

| DK (1) | DK0428032T3 (en) |

| ES (1) | ES2036882T3 (en) |

| GR (1) | GR3007421T3 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4326335A1 (en) * | 1993-08-05 | 1995-02-09 | Juergen Dohle | Container with lid for transporting liquid, in particular liquid hot media |

| DE10256872B4 (en) * | 2002-12-04 | 2005-11-10 | Leifheit Ag | pot |

| DE102004014646B3 (en) | 2004-03-25 | 2005-07-14 | Brita Gmbh | Lid for jug has closing element in form of seesaw turning on axis on lid, having closing plate on one arm and counterweight on other |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE30975C (en) * | M. SACHS in Nürnberg | Automatic lid closure for beer mug | ||

| US1356754A (en) * | 1920-02-07 | 1920-10-26 | Baughman David | Receptacle-closure |

| FR642685A (en) * | 1927-03-22 | 1928-09-01 | Improvements to pots, vases and various utensils such as teapots | |

| GB431247A (en) * | 1934-11-09 | 1935-07-03 | Bulpitt & Sons Ltd | Improvements in vessels for containing liquids |

| DE1077403B (en) * | 1953-06-23 | 1960-03-10 | Walter Conrad Dr | Household water boilers |

| FR1101310A (en) * | 1954-03-20 | 1955-10-05 | Automatic bottle stopper | |

| FR1106951A (en) * | 1954-08-28 | 1955-12-27 | Container and closure device for containers | |

| FR1120605A (en) * | 1955-01-25 | 1956-07-10 | Celluloid | Pouring cap |

| FR1472515A (en) * | 1965-03-23 | 1967-03-10 | Helios Kg Bulle & Co | Automatic closing system for insulating jugs |

| US3650439A (en) * | 1969-11-25 | 1972-03-21 | Mike S Shimooka | Automatic sugar dispenser |

| IT1028371B (en) * | 1974-05-30 | 1979-01-30 | Ferrante Rafael | DOSING CONTAINER FOR POWDERING OR GRANULAR PRODUCTS |

| US4102477A (en) * | 1976-08-30 | 1978-07-25 | Jong Un Yoon | Sugar dispensing apparatus |

| IT1069012B (en) * | 1976-10-22 | 1985-03-21 | Perrella Emilio | DISTRIBUTOR CONTAINER |

| DE8610515U1 (en) * | 1986-04-17 | 1986-06-26 | Rowenta-Werke Gmbh, 6050 Offenbach | Liquid container |

| US4776501A (en) * | 1987-08-31 | 1988-10-11 | Seaquist Closures | Self-closing, press-to-open, dispensing closure |

| EP0332885A1 (en) * | 1988-03-17 | 1989-09-20 | Societe Des Produits Nestle S.A. | Reclosable container made from a synthetic material |

-

1989

- 1989-11-11 DE DE3937581A patent/DE3937581A1/en not_active Withdrawn

- 1989-11-11 DE DE8913659U patent/DE8913659U1/en not_active Expired - Lifetime

-

1990

- 1990-11-03 DK DK90121105.2T patent/DK0428032T3/en active

- 1990-11-03 DE DE9090121105T patent/DE59000659D1/en not_active Expired - Fee Related

- 1990-11-03 AT AT90121105T patent/ATE83629T1/en not_active IP Right Cessation

- 1990-11-03 ES ES199090121105T patent/ES2036882T3/en not_active Expired - Lifetime

- 1990-11-03 EP EP90121105A patent/EP0428032B1/en not_active Expired - Lifetime

-

1993

- 1993-03-22 GR GR930400613T patent/GR3007421T3/el unknown

Also Published As

| Publication number | Publication date |

|---|---|

| GR3007421T3 (en) | 1993-07-30 |

| DE3937581A1 (en) | 1991-05-16 |

| EP0428032A1 (en) | 1991-05-22 |

| DE8913659U1 (en) | 1990-01-18 |

| ES2036882T3 (en) | 1993-06-01 |

| DK0428032T3 (en) | 1993-02-22 |

| ATE83629T1 (en) | 1993-01-15 |

| DE59000659D1 (en) | 1993-02-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69007095T2 (en) | LIQUID CONTAINERS. | |

| DE4024656A1 (en) | GARBAGE CAN | |

| DE4429662B4 (en) | holder | |

| DE69005705T2 (en) | Dishwasher with removable and vertically displaceable basket. | |

| DE69703627T2 (en) | BREW BEVERAGE DEVICE | |

| EP0442076B1 (en) | Vessel for holding hot drinks, in particular coffee or tea | |

| EP2721975B1 (en) | Beverage preparation machine | |

| EP0428032B1 (en) | Vessel with a pouring spout | |

| DE19611301C2 (en) | Cassette for storing elongated objects | |

| DE69316886T2 (en) | Door opening mechanism for ejecting a magnetic tape cassette | |

| DE3827512A1 (en) | Device for storing and serving food | |

| DE20114012U1 (en) | Presentation containers for food | |

| DE4042113C2 (en) | Container device with tiltable receptacle | |

| DE3041105C2 (en) | Dumping device for garbage containers with a device for opening the lid | |

| DE2302560C3 (en) | Box shaped coin holder | |

| DE4123733A1 (en) | Closure for outlet pipe of container - has elastically deformable tongue to bias swivel part | |

| DE10031448B4 (en) | Counter module with hood | |

| CH149657A (en) | Storage device for containers commonly used in the household, such as garbage cans, cleaning buckets, ash kettles and the like. | |

| DE1285131B (en) | A pourer for liquid with a lid that can be opened and closed automatically by means of the pouring handle | |

| DE4022241A1 (en) | POT OR JUG WITH A HANDLE | |

| DE3139112A1 (en) | Swing lid closure for containers | |

| DE2021255A1 (en) | Vacuum jug with hinged lid | |

| DE718768C (en) | Goods shaft for self-sellers | |

| DE2816157C3 (en) | Cabinet-like furniture, especially a refrigerator or the like. | |

| DE29603000U1 (en) | Hood, in particular a fresh-keeping hood |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19910726 |

|

| 17Q | First examination report despatched |

Effective date: 19910904 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 83629 Country of ref document: AT Date of ref document: 19930115 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19921222 |

|

| REF | Corresponds to: |

Ref document number: 59000659 Country of ref document: DE Date of ref document: 19930204 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2036882 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3007421 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 90121105.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19951001 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19951020 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19951023 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19951031 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19951106 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19951110 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19951127 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19951129 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19951130 Year of fee payment: 6 Ref country code: GR Payment date: 19951130 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960110 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960123 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19961103 Ref country code: GB Effective date: 19961103 Ref country code: DK Effective date: 19961103 Ref country code: AT Effective date: 19961103 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19961104 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19961104 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19961130 Ref country code: CH Effective date: 19961130 Ref country code: BE Effective date: 19961130 |

|

| BERE | Be: lapsed |

Owner name: ARNOLD GERHARD Effective date: 19961130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19970531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19970601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19961103 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: MM2A Free format text: 3007421 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970731 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19970601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970801 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 90121105.2 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19971213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051103 |