EP0406684A1 - Diesel fuel additive - Google Patents

Diesel fuel additive Download PDFInfo

- Publication number

- EP0406684A1 EP0406684A1 EP90112229A EP90112229A EP0406684A1 EP 0406684 A1 EP0406684 A1 EP 0406684A1 EP 90112229 A EP90112229 A EP 90112229A EP 90112229 A EP90112229 A EP 90112229A EP 0406684 A1 EP0406684 A1 EP 0406684A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- vinyl acetate

- ethylene

- eva

- weight

- additives

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/146—Macromolecular compounds according to different macromolecular groups, mixtures thereof

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/192—Macromolecular compounds

- C10L1/195—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/192—Macromolecular compounds

- C10L1/195—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- C10L1/197—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and an acyloxy group of a saturated carboxylic or carbonic acid

- C10L1/1973—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and an acyloxy group of a saturated carboxylic or carbonic acid mono-carboxylic

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L10/00—Use of additives to fuels or fires for particular purposes

- C10L10/14—Use of additives to fuels or fires for particular purposes for improving low temperature properties

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/16—Hydrocarbons

- C10L1/1616—Hydrocarbons fractions, e.g. lubricants, solvents, naphta, bitumen, tars, terpentine

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10L—FUELS NOT OTHERWISE PROVIDED FOR; NATURAL GAS; SYNTHETIC NATURAL GAS OBTAINED BY PROCESSES NOT COVERED BY SUBCLASSES C10G, C10K; LIQUEFIED PETROLEUM GAS; ADDING MATERIALS TO FUELS OR FIRES TO REDUCE SMOKE OR UNDESIRABLE DEPOSITS OR TO FACILITATE SOOT REMOVAL; FIRELIGHTERS

- C10L1/00—Liquid carbonaceous fuels

- C10L1/10—Liquid carbonaceous fuels containing additives

- C10L1/14—Organic compounds

- C10L1/18—Organic compounds containing oxygen

- C10L1/192—Macromolecular compounds

- C10L1/195—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds

- C10L1/196—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and a carboxyl group or salts, anhydrides or esters thereof homo- or copolymers of compounds having one or more unsaturated aliphatic radicals each having one carbon bond to carbon double bond, and at least one being terminated by a carboxyl radical or of salts, anhydrides or esters thereof

- C10L1/1963—Macromolecular compounds obtained by reactions involving only carbon-to-carbon unsaturated bonds derived from monomers containing a carbon-to-carbon unsaturated bond and a carboxyl group or salts, anhydrides or esters thereof homo- or copolymers of compounds having one or more unsaturated aliphatic radicals each having one carbon bond to carbon double bond, and at least one being terminated by a carboxyl radical or of salts, anhydrides or esters thereof mono-carboxylic

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B3/00—Engines characterised by air compression and subsequent fuel addition

- F02B3/06—Engines characterised by air compression and subsequent fuel addition with compression ignition

Definitions

- the invention relates to additives for diesel fuels with a deposit-preventing effect on paraffin crystals and with improved filterability, in particular for middle distillates.

- ethylene-vinyl acetate copolymers have been used as flow improvers for middle distillates.

- EVA copolymers ethylene-vinyl acetate copolymers

- the 20% and 90% distillation points differ within a temperature range of 65-100 degrees C and / or as a flow improver for a distillate fuel whose 90% distillation point and boiling point differ 10-20 degrees C, ie for so-called "narrow boiling distillates”.

- the additive can also be a mixture of two copolymers.

- EP-A 254 284 relates to a process for improving the flowability of mineral oils and mineral oil distillates by adding mixtures of an ethylene-vinyl acetate-diisobutylene terpolymer and an ethylene-vinyl acetate copolymer.

- the terpolymer preferably has a molecular weight Mn of 500- 10,000 and preferably contains 6 to 20 CH3 groups per 100 CH2 groups in the side chains, which do not originate from the acetate residue

- the EVA copolymer preferably has a molecular weight Mn of 500 to 10,000 and contains 2 to 10 CH3 groups 100 CH2 groups.

- Flow improvers for mineral oils and distillates are also known from DE-A 35 01 384, which contain two copolymers, namely an ethylene-vinyl acetate copolymer with 25-35% by weight vinyl acetate content and a viscosity of 200-1,500 mPa ⁇ s (at 140 degrees C) and an ethylene-propene-vinyl acetate copolymer with 25 - 35 wt .-% vinyl acetate and a viscosity of 200 - 1 500 mPa s.

- JP-B 62 119 296 (Chem. Abstr. 107, 80 830 m) describes a flow improver for fuel oils which consists, on the one hand, of a copolymer of ethylene with at least one carboxylic acid vinyl ester with a molecular weight ⁇ 1 100 and, on the other hand, of a copolymer Ethylene with a vinyl carboxylate with a molecular weight in the range 500-10,000.

- Additives with a pour-point improving effect for gasoline, kerosene and EVA-based fuel oils are also proposed in JP-B 58 194 988 (cf. Chem. Abstr. 100, 177 634u). These are additives consisting of 2 - 98% ethylene-vinyl ester copolymers and the remaining parts of ethylene-vinyl acetate copolymer, acrylic acid ester-ethylene copolymer and the like.

- Middle distillates - as is customary in the petroleum industry - are understood to mean fractions which usually include gas oils (boiling point 170-350 degrees C, in particular 225-350 degrees C TBP according to ASTM 2892), diesel fuels, aviation turbine fuels and heating oils.

- gas oils boiling point 170-350 degrees C, in particular 225-350 degrees C TBP according to ASTM 2892

- diesel fuels diesel fuels

- aviation turbine fuels heating oils.

- fractions with a boiling range above 170 degrees C, preferably above 225 degrees C cf. Winnacker-Küchler, 4th edition, vol. 6, Carl Hanser Verlag, Kunststoff 1982

- the additives according to the invention are used for "high final boiling” diesel fuels.

- the person skilled in the art generally understands this to mean diesel fuels with a boiling point> 380 degrees C, a difference between the boiling point and 90% - distillation point> 30 degrees C.

- component A) is in the form of a terpolymer, it is a copolymer of 20-35% by weight of vinyl acetate, 50 to 70% by weight of ethylene and 5 to 15% by weight of a third monomer, selected from the group of Olefins, especially the alkyl dienes (used per se as comonomer) represented by, for example, diisobutylene, isobutylene, or the alkenes with more than 2 carbon atoms, represented, for example, by propene.

- a third monomer selected from the group of Olefins, especially the alkyl dienes (used per se as comonomer) represented by, for example, diisobutylene, isobutylene, or the alkenes with more than 2 carbon atoms, represented, for example, by propene.

- a measured viscosity of ⁇ spec / c of 6 - 50 ml / g corresponds approximately to a molecular weight Mw of approximately 1,000-10,000.

- a melt viscosity index (MFI) of 20-1,000 corresponds approximately to a molecular weight Mw of 20,000-10 The latter, higher molecular weight ethylene-vinyl acetate copolymers correspond to the type of hot melt adhesive available on the market.

- the analytical determinations (molecular weight, etc.) for ethylene-vinyl acetate copolymers can be carried out according to Brauer et al. Chem. Techn. 24, 630-635 (1977).

- the viscosity ⁇ spec / c is determined in accordance with DIN 1342, DIN 51 562 and DIN 7745.

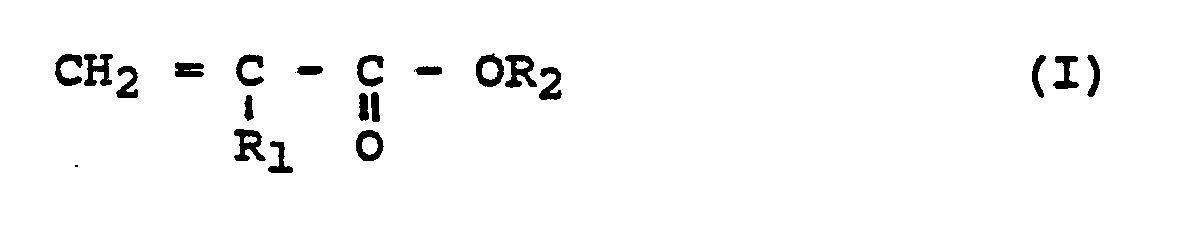

- the polyalkyl (meth) acrylates C) can be prepared in a manner known per se by (radical) polymerization from the known monomers of the formula I. wherein R1 is hydrogen or methyl and R2 is an optionally branched alkyl radical having 6-26, preferably 8-24, in particular 12-20, carbon atoms.

- the polyalkyl (meth) acrylates are preferably prepared by means of solution polymerization and in a special embodiment in the presence of components A) or / and B).

- Suitable solvents LM are, for example, those described above in which the monomers dissolve and which permit polymerization at elevated temperature. A boiling point of at least 50 degrees C at 760 mm should be mentioned as a guideline.

- the solvents LM therefore fall, for example, in the group of hydrocarbons such as kerosene (boiling range 180-210 degrees C), the naphthenic oils, the paraffin-based oils or the gas oils.

- the ratios are chosen so that the polymer formed to the solvent LM is in a weight ratio of 80:20 to 20:80, preferably 60:40 to 25:75.

- a weight ratio of solvent LM to polymer of 1: 1 can be given.

- the polymerization of the monomers of the formula I can be carried out as follows: In a suitable polymerization vessel equipped with a stirrer, reflux condenser and thermometer, the monomers of the formula I are heated to a temperature above 50 ° C. in the solvent. A protective gas such as nitrogen or an inert gas such as argon or helium is expediently introduced over a certain period of time, for example for one hour, and the process is continued under protective gas.

- the polymerization is initiated by free-radical initiators known per se, preferably of the lipophilic type, in particular per compounds such as butyl perpivalate, tert-butyl peroctoate.

- the initiator additive is usually in the range 0.1 to 2% by weight, based on the monomers (cf. H. Rauch-Puntigam, Th. Völker, Acryl- und Methacrylitatien, Springer Verlag 1967).

- the additives according to the invention are generally available as relatively concentrated polymer solutions in the solvents LM.

- the polymer content in the concentrates is 20-80% by weight. They are advantageously added to the oils or fractions, the flowability or filterability of which is to be improved, in such amounts that they contain 10-1000 ppm, preferably 50 to 500 ppm, of the polymeric additions according to the present invention.

- the positive effect of the additives according to the invention is particularly pronounced when applied to middle distillates, especially middle distillates which contain more than 0.5% by weight of n-alkanes with chain lengths ⁇ 25 carbon atoms and especially those middle distillates whose boiling point is above 230 degrees at 760 mm pressure.

- CFPP stands for "Cold Filter Plugging Point”.

- the viscosity ⁇ spec / c is determined in accordance with DIN 1342, DlN 51 562 and DlN 7745.

- the melt viscosity [MFI] is determined in accordance with DIN 53 735 or ASTM 1268-62T.

- the ethylene-vinyl acetate copolymers and terpolymers which are used in the examples below have a degree of branching between 3 and 15 CH3 groups per 100 CH2 groups.

- ethylene-vinyl acetate copolymers and optionally polyalkyl (meth) acrylates are dissolved in kerosene (boiling point 180-220 degrees C) in the mixing ratio given in the respective examples by stirring at 80 degrees C within 2 hours.

- the amount of kerosene is chosen so that 50% solutions result in all cases.

- EVA-A1 and 37.5 G EVA-B6 are dissolved in 750 g kerosene (180 - 210 ° C) by stirring at a temperature of 90 ° C.

- a mixture of 1,500 g of iso-C10 methacrylate and 22.5 g of tert-butyl peroctoate is then added to the solution presented under a nitrogen atmosphere within 2 hours by means of a metering pump at 90 ° C. After the feed has ended, a further 1.5 g of tert-butyl peroctoate are added.

- the total polymerization time is 16 hours.

- the polymer is composed of 47.5 parts EVA-A1, 2.5 parts EVA-B6 and 50 parts polyisodecyl methacrylate.

- the additional amounts of the additives each relate to the 50% solutions of Examples 1-8 or the 75% solutions of Example 10, which were heated before the addition.

- DK 2 example Amount added (ppm) 150 250 500 1 -4 -10 -11 2nd -9 -10 3rd -11 See EVA-A1 -1 -7 -9

Abstract

Description

Die Erfindung betrifft Additive für Dieselkraftstoffe mit ablagerungsverhindernder Wirkung auf Paraffinkristalle und mit verbesserter Filtrierbarkeit, insbesondere für Mitteldestillate.The invention relates to additives for diesel fuels with a deposit-preventing effect on paraffin crystals and with improved filterability, in particular for middle distillates.

Der Rückgriff der erdölfördernden Industrie auf Vorkommen von zum Teil minderer Qualität hat bestehende Probleme bei der Erdölproduktion verstärkt bzw. hat diese Probleme erst richtig ins Bewußtsein gerückt.

In diesem Zusammenhang ist auch der Paraffingehalt von Erdölen und Erdölprodukten zu sehen. Die Paraffine kristallisieren beim Abkühlen aus, wodurch die Fließfähigkeit der Öle bzw. Ölprodukte bei tieferen Temperaturen herabgesetzt wird und bei genügend tiefer Temperatur ganz zum Erliegen kommen kann. Beim Erwärmen gehen die auskristallisierten Paraffine im allgemeinen wieder in der Ölmatrix in Losung.

Die Technik hat Additive, sogenannte "Pour-Point"-Erniedriger (Pour Point Temperatur, bei der das Öl gerade noch fließt, vgl. DIN 51 597) entwickelt, die den "Pour Point" bereits in Konzentration zwischen 0,05 und 1 Gew.-% wirksam herabsetzen (vgl. Ullmanns Encyclopädie der technischen Chemie, 4. Auflage, Band 20, Verlag Chemie 1981).The oil industry 's recourse to deposits of inferior quality has exacerbated existing problems in oil production or has only brought these problems to the fore.

The paraffin content of petroleum and petroleum products should also be seen in this context. The paraffins crystallize on cooling, as a result of which the fluidity of the oils or oil products is reduced at lower temperatures and can come to a complete standstill at a sufficiently low temperature. When heated, the crystallized paraffins generally go back into solution in the oil matrix.

The technology has developed additives, so-called "pour point" lowers (pour point temperature at which the oil is still flowing, cf. DIN 51 597), which already have the "pour point" in a concentration between 0.05 and 1 wt .-% effectively reduce (see. Ullmanns Encyclopedia of technical chemistry, 4th edition, volume 20, Verlag Chemie 1981).

In der Praxis haben hauptsächlich Ethylen-Vinylacetat-Copolymeren (EVA-Copolymeren) als Fließverbesserer für Mitteldestillate Anwendung gefunden. In der EP-A 113 581 wird der Zusatz von Additiven auf der Basis von Copolymeren aus Ethylen und dem Vinylester einer Carbonsäure mit 1 - 4 Kohlenstoffatomen und einem Molgewicht (Zahlenmittel) von 1 000 bis 6 000 als Fließverbesserer für ein Petroleum-Kraftstoff, dessen 20 % und 90 % Destillationspunkte innerhalb eines Temperaturbereichs von 65 - 100 Grad C differieren und/oder als Fließverbesserer für einen Destillat-Brennstoff, dessen 90 % Destillationspunkt und Siedepunkt 10 - 20 Grad C differieren, also für sogenannte "Narrow Boiling Destillate." Das Additive kann hierbei auch eine Mischung zweier Copolymerer sein.In practice, mainly ethylene-vinyl acetate copolymers (EVA copolymers) have been used as flow improvers for middle distillates. In EP-A 113 581 the addition of additives based on copolymers of ethylene and the vinyl ester of a carboxylic acid with 1-4 carbon atoms and a molecular weight (number average) of 1,000 to 6,000 as a flow improver for a petroleum fuel, the 20% and 90% distillation points differ within a temperature range of 65-100 degrees C and / or as a flow improver for a distillate fuel whose 90% distillation point and boiling point differ 10-20 degrees C, ie for so-called "narrow boiling distillates". The additive can also be a mixture of two copolymers.

Diese Patentanmeldung wählt nach dem Vorbild der US-A 3 048 479 nach dem Prinzip aus, daß mittels des einen Copolymeren die Nucleation des Paraffinwachses ("Nucleator") gefördert und mittels des anderen Copolymerisats das Kristallwachstum der Paraffine verhindert werden soll ("growth arrestor"). Konkret handelt es sich nach der EP-A in beiden Fällen um Ethylen-Vinylacetat-Copolymere.This patent application, based on the model of US Pat. No. 3,048,479, selects on the principle that the nucleation of the paraffin wax ("nucleator") is promoted by means of one copolymer and the crystal growth of the paraffins is to be prevented by the other copolymer ("growth arrestor" ). Specifically, according to EP-A, both cases are ethylene-vinyl acetate copolymers.

Die EP-A 254 284 betrifft ein Verfahren zur Verbesserung der Fließfähigkeit von Mineralölen und Mineralöldestillaten, durch Zusatz von Mischungen aus einem Ethylen-Vinylacetat-Diisobutylen-Terpolymerisat und einem Ethylen-Vinylacetat-Copolymerisat. Das Terpolymerisat hat bevorzugt ein Molgewicht Mn von 500 - 10 000 und enthält bevorzugt pro 100 CH₂-Gruppen 6 bis 20 CH₃-Gruppen in den Seitenketten, die nicht aus dem Acetatrest stammen, das EVA-Copolymere besitzt vorzugsweise ein Molgewicht Mn von 500 bis 10 000 und enthält 2 bis 10 CH₃-Gruppen auf 100 CH₂-Gruppen.EP-A 254 284 relates to a process for improving the flowability of mineral oils and mineral oil distillates by adding mixtures of an ethylene-vinyl acetate-diisobutylene terpolymer and an ethylene-vinyl acetate copolymer. The terpolymer preferably has a molecular weight Mn of 500- 10,000 and preferably contains 6 to 20 CH₃ groups per 100 CH₂ groups in the side chains, which do not originate from the acetate residue, the EVA copolymer preferably has a molecular weight Mn of 500 to 10,000 and contains 2 to 10 CH₃ groups 100 CH₂ groups.

Auch aus der DE-A 35 01 384 sind Fließverbesserer für Mineralöle bzw. -Destillate bekannt, die zwei Copolymere enthalten, nämlich ein Ethylen-Vinylacetat-Copolymeres mit 25 - 35 Gew.-% Vinylacetat-Gehalt und einer Viskosität von 200 - 1 500 mPa·s (bei 140 Grad C) und ein Ethylen-Propen-Vinylacetat-Copolymeres mit ebenfalls 25 - 35 Gew.-% Vinylacetat und einer Viskosität von 200 - 1 500 mPa s.Flow improvers for mineral oils and distillates are also known from DE-A 35 01 384, which contain two copolymers, namely an ethylene-vinyl acetate copolymer with 25-35% by weight vinyl acetate content and a viscosity of 200-1,500 mPa · s (at 140 degrees C) and an ethylene-propene-vinyl acetate copolymer with 25 - 35 wt .-% vinyl acetate and a viscosity of 200 - 1 500 mPa s.

In der JP-B 62 119 296 (Chem. Abstr. 107, 80 830 m) wird ein Fließverbesserer für Brennstoff-Öle beschrieben, der aus einerseits einem Copolymeren aus Ethylen mit mindestens einem Carbonsäurevinylester mit einem Molgewicht < 1 100 und andererseits einem Copolymeren aus Ethylen mit einem Carbonsäurevinylester mit einem Molgewicht im Bereich 500 - 10 000.JP-B 62 119 296 (Chem. Abstr. 107, 80 830 m) describes a flow improver for fuel oils which consists, on the one hand, of a copolymer of ethylene with at least one carboxylic acid vinyl ester with a molecular weight <1 100 and, on the other hand, of a copolymer Ethylene with a vinyl carboxylate with a molecular weight in the range 500-10,000.

Additive mit pour-point verbessernder Wirkung für Gasolin, Kerosin und Kraftstoff-öle auf EVA-Basis werden auch in der JP-B 58 194 988 (vgl. Chem. Abstr. 100, 177 634u) vorgeschlagen. Es handelt sich dabei um Additive, bestehend zu 2 - 98 % Ethylen-Vinylester-Copolymeren und zu den restlichen Anteilen aus Ethylen-Vinylacetat-Copolymer, Acrylsäureester-Ethylen-Copolymer u.ä. In einer weiter zurückliegenden Druckschrift (DE-A 20 48 308) war der Zusatz eines Ethylen-Vinylacetat-Copolymeren in Form eines Gemisches, beispielsweise aus Teilen eines Copolymeren mit dem Molgewicht 3 000 und 3 000 Teilen eines Copolymeren mit dem Molgewicht 9 000 empfohlen worden. Pfropfpolymere von langkettigen Estern der (Meth)acrylsäure auf Ethylen-Vinylacetat-Copolymere werden in der DE-A 37 25 059 als Fließverbesserer für Mitteldestillate empfohlen.Additives with a pour-point improving effect for gasoline, kerosene and EVA-based fuel oils are also proposed in JP-B 58 194 988 (cf. Chem. Abstr. 100, 177 634u). These are additives consisting of 2 - 98% ethylene-vinyl ester copolymers and the remaining parts of ethylene-vinyl acetate copolymer, acrylic acid ester-ethylene copolymer and the like. In a previous publication (DE-A 20 48 308) the addition of an ethylene-vinyl acetate copolymer in the form of a mixture was, for example, from Parts of a copolymer with a molecular weight of 3,000 and 3,000 parts of a copolymer with a molecular weight of 9,000 have been recommended. DE-A 37 25 059 recommends graft polymers of long-chain esters of (meth) acrylic acid on ethylene-vinyl acetate copolymers as flow improvers for middle distillates.

Wie aus den Druckschriften des Standes der Technik hervorgeht, werden Mischungen von Ethylen-Vinylester-Copolymerisaten verschiedener Typen als Öladditive empfohlen, wobei speziell deren fließverbessernde Wirkung hervorgehoben wird. Das Konzept, Mischungen zu verwenden, genügt allerdings nicht, um daraus bereits konkrete Regeln zum technischen Handeln ableiten zu können. Verständlicherweise spielen Typ und Art bzw. Provenienz der Öle bzw. Ölprodukte eine entscheidende Rolle. Andererseits ist nicht nur die Zusammensetzung sondern auch das Molekulargewicht eines polymeren Additivs von bestimmendem Einfluß auf dessen spezifische Wirksamkeit. Die der vorliegenden Erfindung zugrundeliegende Aufgabe liegt darin, Additive für Mitteldestillate der Erdölindustrie zur Verfügung zu stellen. Speziell bezieht sich die Aufgabe auf Dieselkraftstoffe, besonders mit Schwerpunkt "High Final Boiling"-Dieselkraftstoffe. Die vorliegende Aufgabe bestand speziell darin, Additive zur Verfügung zu stellen, welche die Ablagerung von Paraffinkristallen bei tiefen Temperaturen verhindern und die Filtrierbarkeit der Erdölprodukte verbessern.As is apparent from the prior art documents, mixtures of ethylene-vinyl ester copolymers of various types are recommended as oil additives, the flow-improving effect of which is particularly emphasized. However, the concept of using mixtures is not enough to derive concrete rules for technical action. Understandably, the type and type or provenance of the oils or oil products play a decisive role. On the other hand, not only the composition but also the molecular weight of a polymeric additive has a determining influence on its specific effectiveness. The object on which the present invention is based is to provide additives for middle distillates in the petroleum industry. The task specifically relates to diesel fuels, especially with a focus on "high final boiling" diesel fuels. The present task was specifically additives to provide, which prevent the deposition of wax crystals at low temperatures and improve the filterability of petroleum products.

Unter Mitteldestillaten werden - wie in der Erdölindustrie üblich - Fraktionen verstanden, die üblicherweise Gasöle (Siedelage 170 - 350 Grad C, insbesondere 225 - 350 Grad C TBP nach ASTM 2892) Dieselkraftstoffe, Flugturbinenkraftstoffe und Heizöle einschließen. Im allgemeinen werden darunter gerechnet Fraktionen mit einem Siedebereich oberhalb 170 Grad C, vorzugsweise oberhalb 225 Grad C (vgl. Winnacker-Küchler, 4. Auflage, Bd. 6, Carl Hanser Verlag, München 1982). Insbesondere richtet sich der Einsatz der erfindungsgemäßen Additive auf "High Final Boiling"-Dieselkraftstoffe. Darunter versteht der Fachmann im allgemeinen Dieselkraftstoffe mit Siedeendpunkten > 380 Grad C, eine Differenz zwischen Siedeendpunkt und 90 %- Destillationspunkt > 30 Grad C.Middle distillates - as is customary in the petroleum industry - are understood to mean fractions which usually include gas oils (boiling point 170-350 degrees C, in particular 225-350 degrees C TBP according to ASTM 2892), diesel fuels, aviation turbine fuels and heating oils. In general, fractions with a boiling range above 170 degrees C, preferably above 225 degrees C (cf. Winnacker-Küchler, 4th edition, vol. 6, Carl Hanser Verlag, Munich 1982) are included. In particular, the additives according to the invention are used for "high final boiling" diesel fuels. The person skilled in the art generally understands this to mean diesel fuels with a boiling point> 380 degrees C, a difference between the boiling point and 90% - distillation point> 30 degrees C.

Insbesondere dienen die erfindungsgemäßen Additive als Fließverbesserer für Mitteldestillate, die mehr als 0,5 Gew.-% n-Alkane mit Kettenlänge ≧ C25 enthalten, speziell solcher Mitteldestillate, deren Siedepunkt (bei 760 mm Druck) über 360 Grad C liegt.In particular, the additives according to the invention serve as flow improvers for middle distillates which contain more than 0.5% by weight n-alkanes with chain length ≧ C25, especially those middle distillates whose boiling point (at 760 mm pressure) is above 360 degrees C.

Die Additive gemäß der vorliegenden Erfindung bestehen aus:

- A) 20 - 95 Gew.-Teilen eines Ethylen-Vinylacetat-Copolymeren oder eines Ethylen-Vinylacetat-Terpolymeren mit einer spezifischen Viskosität von η sp/c = 6 - 50 ml/g (gemessen bei 25 Grad C in Xylol) einem Vinylacetatgehalt von 25 - 35 Gew.-% und einem Verzweigungsgrad von 3 bis 15 CH₃-Gruppen pro 100 CH₂-Gruppen.

und - B) 1 - 80 Gew.-Teilen eines Ethylen-Vinylacetat-Copolymeren mit einem Schmelzviskositätsindex von 20 bis 1 000 g/10 mm und einem Vinylacetatgehalt von 15 - 35 Gew.-%. und

- C) 0 - 75 Gew.-Teilen, vorzugsweise 1 - 70, insbesondere 5 bis 66 Gew.-Teile eines Polyalkyl(meth)acrylats mit 6 - 26, vorzugsweise 8 - 24 Kohlenstoffatomen im Alkylrest.

- A) 20-95 parts by weight of an ethylene-vinyl acetate copolymer or an ethylene-vinyl acetate terpolymer with a specific viscosity of η sp / c = 6 - 50 ml / g (measured at 25 degrees C in xylene) a vinyl acetate content of 25 - 35 wt .-% and a degree of branching of 3 to 15 CH₃ groups per 100 CH₂ groups.

and - B) 1-80 parts by weight of an ethylene-vinyl acetate copolymer with a melt viscosity index of 20 to 1000 g / 10 mm and a vinyl acetate content of 15-35% by weight. and

- C) 0-75 parts by weight, preferably 1-70, in particular 5 to 66 parts by weight of a polyalkyl (meth) acrylate with 6-26, preferably 8-24, carbon atoms in the alkyl radical.

Falls die Komponente A) als Terpolymeres vorliegt, handelt es sich um ein Copolymerisat aus 20 - 35 Gew.-% Vinylacetat, 50 bis 70 Gew.-% Ethylen und 5 bis 15 Gew.-% eines dritten Monomeren, ausgewählt aus der Gruppe der Olefine, speziell der (an sich als Comonomer einschlägig verwendeten) Alkyl-Diene, vertreten durch beispielsweise Diisobutylen, Isobutylen oder der Alkene mit mehr als 2 Kohlenstoffatomen vertreten beispielsweise durch Propen.If component A) is in the form of a terpolymer, it is a copolymer of 20-35% by weight of vinyl acetate, 50 to 70% by weight of ethylene and 5 to 15% by weight of a third monomer, selected from the group of Olefins, especially the alkyl dienes (used per se as comonomer) represented by, for example, diisobutylene, isobutylene, or the alkenes with more than 2 carbon atoms, represented, for example, by propene.

Die Herstellung der einzelnen Komponenten aus Ethylen-Vinylacetat-Copolymeren und -Terpolymeren gemäß A) und B) ist - wie bereits ausgeführt - Stand der Technik. (Vgl. DE-A 36 16 056; EP-A 99 646 oder DE-A 19 14 756). Vorteilhaft erfolgt die Herstellung durch Copolymerisation der Monomeren im Autoklaven bei Temperaturen von 80 - 150 Grad C und Drücken von 5 - 16 mPa s in Gegenwart von Radikalinitiatoren, wie z.B. Peroxiden und in geeigneten, inerten organischen Lösungsmitteln, (Vgl. Winnacker-Küchler, 4. Auflage, Bd. 6, 570, Carl Hanser Verlag, München 1982). Erfindungsgemäß brauchbare Vertreter der Typen sind z.B. im Handel erhältlich. Eine gemessene Viskosität von η spec/c von 6 - 50 ml/g entspricht in etwa einem Molgewicht Mw von ca. 1 000 - 10 000. Ein Schmelzviskositätsindex (MFI) von 20 - 1 000 entspricht etwa einem Molgewicht Mw von 20 000 - 10 000. Die letztgenannten, höhermolekularen Ethylen-Vinylacetat-Copolymeren entsprechen dabei dem Typ der marktgängigen Schmelzkleber.The production of the individual components from ethylene-vinyl acetate copolymers and terpolymers according to A) and B) is - as already stated - state of the art. (See DE-A 36 16 056; EP-A 99 646 or DE-A 19 14 756). The preparation is advantageously carried out by copolymerization of the monomers in an autoclave at temperatures of 80- 150 degrees C and pressures of 5 - 16 mPa s in the presence of radical initiators, such as peroxides and in suitable, inert organic solvents, (see Winnacker-Küchler, 4th edition, Vol. 6, 570, Carl Hanser Verlag, Munich 1982 ). Representatives of the types which can be used according to the invention are commercially available, for example. A measured viscosity of η spec / c of 6 - 50 ml / g corresponds approximately to a molecular weight Mw of approximately 1,000-10,000. A melt viscosity index (MFI) of 20-1,000 corresponds approximately to a molecular weight Mw of 20,000-10 The latter, higher molecular weight ethylene-vinyl acetate copolymers correspond to the type of hot melt adhesive available on the market.

Die analytischen Bestimmungen (Molgewicht etc.) bei Ethylen-Vinylacetat-Copolymeren können nach Brauer et al. Chem. Techn. 24, 630 - 635 (1977) vorgenommen werden. Die Bestimmung der Viskosität η spec/c wird im Anschluß an DIN 1342, DIN 51 562 und DIN 7745 vorgenommen.

Die Herstellung der Polyalkyl(meth)acrylate C) kann in an sich bekannter Weise durch (radikalische) Polymerisation aus den bekannten Monomeren der Formel I erfolgen

The polyalkyl (meth) acrylates C) can be prepared in a manner known per se by (radical) polymerization from the known monomers of the formula I.

Vorzugsweise wird die Herstellung der Polyalkyl(meth)acrylate mittels Lösungspolymerisation und bei einer besonderen Ausführungsart in Anwesenheit der Komponenten A) oder/und B) vorgenommen.

Als Lösemittel LM kommen beispielsweise einschlägig vorbeschriebene, in welchen sich die Monomeren lösen, und die eine Polymerisation bei erhöhter Temperatur erlauben, infrage. Als Richtwert sei ein Siedepunkt von mindestens 50 Grad C bei 760 mm genannt.

Die Lösungsmittel LM fallen demnach z.B. in die Gruppe der Kohlenwasserstoffe wie Kerosin (Siedebereich 180 - 210 Grad C), der naphthenbasischen Öle, der paraffinbasischen Öle oder der Gasöle.The polyalkyl (meth) acrylates are preferably prepared by means of solution polymerization and in a special embodiment in the presence of components A) or / and B).

Suitable solvents LM are, for example, those described above in which the monomers dissolve and which permit polymerization at elevated temperature. A boiling point of at least 50 degrees C at 760 mm should be mentioned as a guideline.

The solvents LM therefore fall, for example, in the group of hydrocarbons such as kerosene (boiling range 180-210 degrees C), the naphthenic oils, the paraffin-based oils or the gas oils.

Im allgemeinen werden die Verhältnisse so gewählt, daß das gebildete Polymerisat zum Lösemittel LM im Gewichtsverhältnis 80 : 20 bis 20 : 80, vorzugsweise 60 : 40 bis 25 : 75 steht.

Als Faustregel kann ein Gewichtsverhältnis Lösungsmittel LM zu Polymerisat von 1 : 1 angegeben werden.In general, the ratios are chosen so that the polymer formed to the solvent LM is in a weight ratio of 80:20 to 20:80, preferably 60:40 to 25:75.

As a rule of thumb, a weight ratio of solvent LM to polymer of 1: 1 can be given.

Bei der Durchführung der Polymerisation der Monomeren der Formel I kann wie folgt verfahren werden:

In einem geeigneten Polymerisationsgefäß, ausgestattet mit Rührer, Rückflußkühler und Thermometer werden die Monomeren der Formel I in dem Lösungsmittel auf eine Temperatur oberhalb 50 Grad C erwärmt. Zweckmäßig wird zunächst über einen gewissen Zeitraum, z.B. eine Stunde lang ein Schutzgas wie z.B. Stickstoff oder ein Edelgas wie Argon oder Helium eingeleitet und weiter unter Schutzgas gearbeitet. Die Polymerisation wird durch an sich bekannte radikalische Initiatoren, vorzugsweise des lipophilen Typs, insbesondere Perverbindungen wie Butylperpivalat, tert.Butylperoctoat in Gang gebracht. Der Initiatorzusatz liegt gewöhnlich im Bereich 0,1 bis 2 Gew.-% bezogen auf die Monomeren (vgl. H. Rauch-Puntigam, Th. Völker, Acryl- und Methacrylverbindungen, Springer Verlag 1967).The polymerization of the monomers of the formula I can be carried out as follows:

In a suitable polymerization vessel equipped with a stirrer, reflux condenser and thermometer, the monomers of the formula I are heated to a temperature above 50 ° C. in the solvent. A protective gas such as nitrogen or an inert gas such as argon or helium is expediently introduced over a certain period of time, for example for one hour, and the process is continued under protective gas. The polymerization is initiated by free-radical initiators known per se, preferably of the lipophilic type, in particular per compounds such as butyl perpivalate, tert-butyl peroctoate. The initiator additive is usually in the range 0.1 to 2% by weight, based on the monomers (cf. H. Rauch-Puntigam, Th. Völker, Acryl- und Methacrylverbindungen, Springer Verlag 1967).

Zur Regelung des Molekulargewichts können auch Regler z.B. die bekannten Schwefelregler, insbesondere Mercaptane wie Dodecylmercaptan in den üblichen Mengen von 0,5 - 5 Gew.-% bezogen auf die Monomeren zugesetzt werden.

Als Gesamtpolymerisationsdauer kann üblicherweise ein Zeitraum von etwa 4 - 16 Stunden angenommen werden. Das Polymerisat kann in an sich bekannter Weise, beispielsweise durch Ausfällung, isoliert werden, zweckmäßig richtet man es jedoch so ein, daß es in Lösung weiterverarbeitet werden kann.To regulate the molecular weight, it is also possible to add regulators, for example the known sulfur regulators, in particular mercaptans such as dodecyl mercaptan, in the customary amounts of 0.5-5% by weight, based on the monomers.

A period of about 4 to 16 hours can usually be assumed as the total polymerization time. The polymer can be isolated in a manner known per se, for example by precipitation, but it is expedient to set it up in such a way that it can be processed further in solution.

Die Polymerisation der Monomeren der Formel I in Anwesenheit der Ethylen-Vinylacetat-Copolymeren bzw. -Terpolymeren kann in prinzipiell gleicher Weise vorgenommen werden:

Das Lösen der Polymeren A) und B) in Lösungsmitteln LM wird vorteilhaft durch Erwärmen beispielsweise auf Temperaturen im Bereich 90 ± 10 Grad C unter Rühren unterstützt. Im weiteren werden vorteilhaft bei erhöhter Temperatur unter Berücksichtigung der Zerfallstemperaturen der verwendeten Initiatoren etwa bis 90 Grad C und unter einem Schutzgas die Monomeren der Formel I plus Initiator zudosiert, vorteilhaft mittels Dosierungspumpe und innerhalb eines gewissen Zeitraums, beispielsweise 2 ± 1/2 Stunden. Vorteilhafterweise gibt man nach Ende des Monomerzulaufs noch einmal Initiator zu, als Anhalt etwa 5 - 15 % der bereits zugesetzten Menge. Als Gesamtpolymerisationsdauer kann in der Regel etwa 4 - 16 Stunden angesetzt werden.The polymerization of the monomers of the formula I in the presence of the ethylene-vinyl acetate copolymers or terpolymers can in principle be carried out in the same way:

The dissolution of the polymers A) and B) in solvents LM is advantageously supported by heating, for example, to temperatures in the range 90 ± 10 degrees C. with stirring. Furthermore, the monomers of the formula I plus initiator are advantageously metered in at elevated temperature, taking into account the decomposition temperatures of the initiators used, and under a protective gas, advantageously by means of a metering pump and within a certain period of time, for example 2 ± 1/2 hours. Advantageously, once the monomer feed has ended, initiator is added again, as a reference about 5-15% of the amount already added. The total polymerization time can generally be set at about 4 to 16 hours.

Die erfindungsgemäßen Additive stehen in der Regel als relativ konzentrierte Polymerlösungen in den Lösungsmitteln LM zur Verfügung. Im allgemeinen beträgt der Gehalt an Polymerisat in den Konzentraten 20 - 80 Gew.-%.

Man setzt sie vorteilhaft den Ölen bzw. Fraktionen, deren Fließfähigkeit bzw. Filtrierbarkeit zu verbessern ist, in solchen Mengen zu, daß diese 10 - 1 000 ppm vorzugsweise 50 bis 500 ppm an den polymeren Additionen gemäß der vorliegenden Erfindung enthalten.

Die positive Wirkung der erfindungsgemäßen Additive zeigt sich besonders ausgeprägt in der Anwendung auf Mitteldestillate, vor allem bei Mitteldestillaten, die mehr als 0,5 Gew.-% n-Alkane mit Kettenlängen ≧ 25 C-Atome enthalten und speziell solchen Mitteldestillaten, deren Siedepunkt über 230 Grad bei 760 mm Druck liegt.

Vor allem zeigen sich die überragenden wachsablagerungsverhindernden Eigenschaften der erfindungsgemäßen Polymermischungen in vollem Umfang nur bei Dieselkraftstoffen mit hohen Anteilen an langkettigen n-Alkanen, wie oben beschrieben. Meist handelt es sich dabei um "High Final Boiling"-Dieselkraftstoffe, teilweise aber auch um Dieselkraftstoffe mit normalem Siedeverlauf. In vielen Dieselkraftstoffen mit geringen Anteilen an langkettigen Alkanen treten dagegen die fließverbessernden Eigenschaften gegenüber den wachsablagerungsverhindernden in den Vordergrund.The additives according to the invention are generally available as relatively concentrated polymer solutions in the solvents LM. In general, the polymer content in the concentrates is 20-80% by weight.

They are advantageously added to the oils or fractions, the flowability or filterability of which is to be improved, in such amounts that they contain 10-1000 ppm, preferably 50 to 500 ppm, of the polymeric additions according to the present invention.

The positive effect of the additives according to the invention is particularly pronounced when applied to middle distillates, especially middle distillates which contain more than 0.5% by weight of n-alkanes with chain lengths ≧ 25 carbon atoms and especially those middle distillates whose boiling point is above 230 degrees at 760 mm pressure.

Above all, the outstanding wax-deposit-preventing properties of the polymer mixtures according to the invention are only fully evident in diesel fuels with high proportions of long-chain n-alkanes, as described above. Most of these are "high final boiling" diesel fuels, but some are also diesel fuels with a normal boiling point. In contrast, in many diesel fuels with low proportions of long-chain alkanes, the flow-improving properties compared to the wax deposition-preventing agents come to the fore.

Eines der Ziele, die sich die vorliegende Erfindung gesteckt hatte, bestand darin, Additive vor Verfügung zu stellen, die sowohl wachsablagerungsverhindernde als auch fließverbessernde Wirkung, wenn nicht über den ganzen Bereich der Mitteldestillate so doch für wichtige Segmente derselben, aufweisen. Dieses Ziel konnte überraschenderweise durch die erfindungsgemäße Polymer-Kombination aus den Komponenten A), B) und gegebenenfalls C) erreicht werden.

Besonders hervorzuheben ist auch die vorzügliche Lagerstabilität von Konzentratformen der erfindungsgemäßen Additive, speziell bei Anwesenheit der Komponente C). Bemerkenswert ist in diesem Zusammenhang, daß der Vorteil einer verbesserten Lagerstabilität nicht durch generelle Abstriche bei der Wirksamkeit erkauft wird.One of the objectives of the present invention was to provide additives which have both wax-preventing and flow-enhancing effects, if not over the entire range of middle distillates, but for important segments thereof. This goal was surprisingly achieved by the polymer combination of components A), B) and optionally C) according to the invention.

Of particular note is the excellent storage stability of concentrate forms of the additives according to the invention, especially in the presence of component C). It is noteworthy in this context that the advantage of improved storage stability is not bought through general cuts in effectiveness.

Die folgenden Beispiele dienen zur Erläuterung der Erfindung.The following examples serve to illustrate the invention.

CFPP steht für "Cold Filter Plugging Point". Die Bestimmung der Viskosität ηspec/c wird im Anschluß an DIN 1342, DlN 51 562 und DlN 7745 vorgenommen. Die Bestimmung der Schmelzviskosität [MFI] erfolgt nach DIN 53 735 bzw. ASTM 1268-62T.CFPP stands for "Cold Filter Plugging Point". The viscosity η spec / c is determined in accordance with DIN 1342, DlN 51 562 and DlN 7745. The melt viscosity [MFI] is determined in accordance with DIN 53 735 or ASTM 1268-62T.

Die vorstehend genannten Lösungsmittel LM sind wie folgt charakterisiert:

- Kerosin (Siedebereich 180 - 210°C

- Gasöle (Siedebereich 225 - 350°C; vgl. DIN 51 567)

- Paraffinbasische Lösungsmittel, bestehend aus

- Fraktion 1 (Siedebereich 250 - 275°C / Normaldruck Dichte d₁₅ < 0,825)

- Fraktion 2 (Siedebereich 275 - 300°C / 53 mbar bei Dichte d₁₅ < 0,876)

- Fraktion 1 (Siedebereich 250 - 275°C / Normaldruck bei Dichte d₁₅ > 0,860)

- Fraktion 2 (Siedebereich 275 - 300°C / 53 mbar bei Dichte d₁₅ > 0,934)

- Kerosene (boiling range 180 - 210 ° C

- Gas oils (boiling range 225 - 350 ° C; see DIN 51 567)

- Paraffin-based solvents consisting of

- Fraction 1 (boiling range 250 - 275 ° C / normal pressure density d₁₅ <0.825)

- Fraction 2 (boiling range 275 - 300 ° C / 53 mbar at density d₁₅ <0.876)

- Fraction 1 (boiling range 250 - 275 ° C / normal pressure at density d₁₅> 0.860)

- Fraction 2 (boiling range 275 - 300 ° C / 53 mbar at density d₁₅> 0.934)

Die Ethylen-Vinylacetat-Copolymere und -terpolymere, die in den folgenden Beispielen zur Anwendung kommen, besitzen einen Verzweigungsgrad zwischen 3 und 15 CH₃-Gruppen pro 100 CH₂-Gruppen.The ethylene-vinyl acetate copolymers and terpolymers which are used in the examples below have a degree of branching between 3 and 15 CH₃ groups per 100 CH₂ groups.

Die Ethylen-Vinylacetat-Copolymeren und gegebenenfalls Polyalkyl(meth)acrylate werden in dem in den jeweiligen Beispielen angegebenen Mischungsverhältnis in Kerosin (Siedepunkt 180 - 220 Grad C) durch Rühren bei 80 Grad C innerhalb 2 Stunden gelöst. Die Kerosinmenge wird so gewählt, daß in allen Fällen 50 %ige Lösungen resultieren.The ethylene-vinyl acetate copolymers and optionally polyalkyl (meth) acrylates are dissolved in kerosene (boiling point 180-220 degrees C) in the mixing ratio given in the respective examples by stirring at 80 degrees C within 2 hours. The amount of kerosene is chosen so that 50% solutions result in all cases.

Die nachfolgenden Beispiele 1 - 8 werden unter Verwendung der folgenden Ethylen-Vinylacetat-Copolymeren bzw. -Terpolymeren hergestellt:

- EVA-A1 = Ethylen-Vinylacetat-Diisobutylen-Terpolymer (61 : 28 : 11, ηsp/c (Xylol, 25 Grad C) = 16 ml/g)

- EVA-A2 = Ethylen-Vinylacetat-Copolymer, VA-Gehalt = 32 Gew.-% ηsp/c (Xylol, 25 Grad C) = 19 ml/g

- EVA-B3 = Ethylenvinylacetat Copolymer, 28 Gew.-% VA, Melt Flow Index MFI 150 [g/10 min]

- EVA-B4 = Ethylenvinylacetat Copolymer, 28 Gew.-% VA, MFI 400 [g/10 min]

- EVA-B5 = Ethylenvinylacetat Copolymer, 28 Gew.-% VA, MFI 800 [g/10 min]

- EVA-B6 = Ethylenvinylacetat Copolymer, 19 Gew.-% VA, MFI 12 [g/10 min]

- EVA-B7 = Ethylenvinylacetat Copolymer, 18 Gew.-% VA, MFI 150 [g/10 min]

- EVA-A1 = ethylene-vinyl acetate-diisobutylene terpolymer (61: 28: 11, η sp / c (xylene, 25 degrees C) = 16 ml / g)

- EVA-A2 = ethylene-vinyl acetate copolymer, VA content = 32% by weight η sp / c (xylene, 25 degrees C) = 19 ml / g

- EVA-B3 = ethylene vinyl acetate copolymer, 28% by weight VA, melt flow index MFI 150 [g / 10 min]

- EVA-B4 = ethylene vinyl acetate copolymer, 28% by weight VA, MFI 400 [g / 10 min]

- EVA-B5 = ethylene vinyl acetate copolymer, 28% by weight VA, MFI 800 [g / 10 min]

- EVA-B6 = ethylene vinyl acetate copolymer, 19% by weight VA, MFI 12 [g / 10 min]

- EVA-B7 = ethylene vinyl acetate copolymer, 18% by weight VA, MFI 150 [g / 10 min]

In einem Rundkolben mit Säbelrührer und Rückflußkühler werden 712,5 EVA-A1 und 37,5 G EVA-B6 durch Rühren bei einer Temperatur von 90 Grad C in 750 g Kerosin (180 - 210 Grad C) gelöst. Anschließend wird der vorgelegten Lösung unter Stickstoff-Atmosphäre ein Gemisch aus 1 500 g Iso-C₁₀-methacrylat und 22,5 g tert.-Butylperoctoat innerhalb von 2 Stunden mittels einer Dosierpumpe bei 90 Grad C zugesetzt. Nach Ende des Zulaufs werden weitere 1,5 g tert.-Butylperoctoat zugegeben. Die Gesamtpolymerisationsdauer beträgt 16 Stunden. Das Produkt enthält insgesamt 75 % Polymerisat, ist bei Raumtemperatur fließfähig ηakt. (40 Grad C) = 4 500 mPa·s) und weißlichtrübe. Der Festpunkt liegt bei +5 Grad C. Das Polymerisat setzt sich zusammen aus 47,5 Teilen EVA-A1, 2,5 Teilen EVA-B6 und 50 Teilen Polyisodecylmethacrylat.In a round bottom flask with saber stirrer and reflux condenser, 712.5 EVA-A1 and 37.5 G EVA-B6 are dissolved in 750 g kerosene (180 - 210 ° C) by stirring at a temperature of 90 ° C. A mixture of 1,500 g of iso-C₁₀ methacrylate and 22.5 g of tert-butyl peroctoate is then added to the solution presented under a nitrogen atmosphere within 2 hours by means of a metering pump at 90 ° C. After the feed has ended, a further 1.5 g of tert-butyl peroctoate are added. The total polymerization time is 16 hours. The product contains a total of 75% polymer, is at room temperature flowable η act . (40 degrees C) = 4 500 mPa · s) and off-white. The fixed point is +5 degrees C. The polymer is composed of 47.5 parts EVA-A1, 2.5 parts EVA-B6 and 50 parts polyisodecyl methacrylate.

Das nachfolgende Beispiel 10 beschreibt die Herstellung der Komponente C).Example 10 below describes the preparation of component C).

In einem 2 l-Vierhalskolben wurden 600 g Talgfettmethacrylat, 600 g eines naphthenbasischen Öles mit einer Viskosität von 1,2 mm²/s bei 100 Grad C auf 75 Grad C erwärmt. 1 Stunde lang wurde N₂ eingeleitet, dann wurden 15 g Dodecylmercaptan und 4,8 g t-Butylperpivalat zugegeben. Nach 4 Stunden wurden erneut 1,2 g t-Butylperpivalat zugegeben. Nach 12 Stunden war die Polymerisation beendet.

ηsp/c (20 Grad C, CHCl₃) = 10 ml/g

Umsatz: 98,7 %.In a 2 l four-necked flask, 600 g of tallow fat methacrylate, 600 g of a naphthenic oil with a viscosity of 1.2 mm² / s were heated to 75 ° C at 100 ° C. N₂ was introduced for 1 hour, then 15 g of dodecyl mercaptan and 4.8 g of t-butyl perpivalate were added. After 4 hours, 1.2 g of t-butyl perpivalate were added again. The polymerization was complete after 12 hours.

η sp / c (20 degrees C, CHCl₃) = 10 ml / g

Sales: 98.7%.

Die Fließverbesserer gemäß den Beispielen 1 - 8 werden einer Reihe von Produkten aus dem Bereich der Mitteldestillate zugesetzt. Die mit DK1 bis DK7 bezeichneten Produkte werden im folgenden angegeben:

- DK 1 bezeichnet Dieselkraftstoff aus einer englischen Raffinierie

- DK 2 bezeichnet Dieselkraftstoff aus einer deutschen Rafinerie

- DK 3 bezeichnet Dieselkraftstoff aus einer deutschen Raffinerie

- DK 4 bezeichnet Dieselkraftstoff aus einer französischen Raffinerie

- DK 5 bezeichnet Dieselkraftstoff aus einer griechichen Raffinerie

- DK 6 bezeichnet Dieselkraftstoff aus einer deutschen Raffinerie

- DK 7 bezeichnet Dieselkraftstoff aus einer deutschen Raffinerie.

- DK 1 denotes diesel fuel from an English refinery

- DK 2 denotes diesel fuel from a German refinery

- DK 3 denotes diesel fuel from a German refinery

- DK 4 denotes diesel fuel from a French refinery

- DK 5 refers to diesel fuel from a Greek refinery

- DK 6 denotes diesel fuel from a German refinery

- DK 7 refers to diesel fuel from a German refinery.

In der folgenden Tabelle wird der CFPP (nach DIN 51 428 bzw. J. of the Institute of Petroleum Vol., 52, (510)) angegeben.

Die Zusatzmengen der Additive beziehen sich jeweils auf die 50 %igen Lösungen der Beispiele 1 - 8 bzw. die 75 %ige des Beispiels 10, die vor der Zugabe erwärmt wurden.

Proben des additivierten DK werden in graduierte 20 ml Meßzylinder gefüllt und auf eine Temperatur 5 Grad C unterhalb des Cloud Point (CP) abgekühlt. Anschließend wird zeitabhängig die Sedimentation der Paraffinkristalle beobachtet und in % Sedimentation angegeben. Die Bestimmung des Cloud Point (CP) erfolgt nach DIN 51 597.

Claims (3)

dadurch gekennzeichnet,

daß die Additive aus den Komponenten

A) 20 - 95 Gew.-Teilen eines Ethylen-Vinylacetat-Copolymeren oder eines Ethylen-Vinylacetat-Terpolymeren mit einer spezifischen Viskosität von ηsp/c = 5 - 50 ml/g (gemessen bei 25 Grad C in Xylol) einem Vinylacetatgehalt von 25 - 35 Gew.-% und einem Verzweigungsgrad von 3 bis 15 CH₃-Gruppen pro 100 CH₂-Gruppen

und

B) 1 - 80 Gew.-Teilen eines Ethylen-Vinylacetat-Copolymeren mit einem Schmelzviskositatsindex von 20 bis 1 000 g/10 mm und einem Vinylacetatgehalt von 15 - 35 Gew.-%

und

C) 0 - 75 Gew.-Teilen eines Polyalkyl(meth)acrylats mit 6 bis 26 Kohlenstoffatomen im Alkylrest,

aufgebaut sind.1 additives with a deposit-preventing effect on paraffin crystals and a flow-improving effect in middle distillates based on ethylene-vinyl acetate copolymers,

characterized,

that the additives from the components

A) 20-95 parts by weight of an ethylene-vinyl acetate copolymer or an ethylene-vinyl acetate terpolymer with a specific viscosity of η sp / c = 5-50 ml / g (measured at 25 degrees C in xylene) and a vinyl acetate content of 25 - 35 wt .-% and a degree of branching of 3 to 15 CH₃ groups per 100 CH₂ groups

and

B) 1-80 parts by weight of an ethylene-vinyl acetate copolymer with a melt viscosity index of 20 to 1000 g / 10 mm and a vinyl acetate content of 15-35% by weight.

and

C) 0-75 parts by weight of a polyalkyl (meth) acrylate having 6 to 26 carbon atoms in the alkyl radical,

are set up.

in Gegenwart der Komponenten A) und B) gewonnen wurde.3. Additives according to claims 1 and 2, characterized in that component C) by polymerization of monomers of the formula I.

was obtained in the presence of components A) and B).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT90112229T ATE76093T1 (en) | 1989-07-06 | 1990-06-27 | ADDITIVES FOR DIESEL FUEL. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3922146 | 1989-07-06 | ||

| DE3922146A DE3922146A1 (en) | 1989-07-06 | 1989-07-06 | ADDITIVES FOR DIESEL FUEL |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0406684A1 true EP0406684A1 (en) | 1991-01-09 |

| EP0406684B1 EP0406684B1 (en) | 1992-05-13 |

Family

ID=6384368

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90112229A Expired - Lifetime EP0406684B1 (en) | 1989-07-06 | 1990-06-27 | Diesel fuel additive |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0406684B1 (en) |

| JP (1) | JPH0345693A (en) |

| AT (1) | ATE76093T1 (en) |

| CA (1) | CA2020571A1 (en) |

| DE (2) | DE3922146A1 (en) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0620265A1 (en) * | 1993-04-08 | 1994-10-19 | Leuna-Werke Gmbh | Fuel composition with improved low temperature flow behaviour |

| EP1731589A2 (en) * | 2005-06-10 | 2006-12-13 | Malaysian Palm Oil Board | Palm-based biodiesel formulation |

| FR2903418A1 (en) * | 2006-07-10 | 2008-01-11 | Total France Sa | USE OF COMPOUNDS REVELATING THE EFFICACY OF FILTRABILITY ADDITIVES IN HYDROCARBON DISTILLATES, AND SYNERGIC COMPOSITION CONTAINING THEM. |

| DE102006033150B4 (en) * | 2006-07-18 | 2008-10-16 | Clariant International Limited | Additives for improving the cold properties of fuel oils |

| WO2011035947A1 (en) | 2009-09-25 | 2011-03-31 | Evonik Rohmax Additives Gmbh | A composition to improve cold flow properties of fuel oils |

| WO2012130535A1 (en) | 2011-03-25 | 2012-10-04 | Evonik Rohmax Additives Gmbh | A composition to improve oxidation stability of fuel oils |

| EP2514803A1 (en) * | 2011-04-21 | 2012-10-24 | Infineum International Limited | Improvements in fuel oils |

| WO2014040919A1 (en) | 2012-09-13 | 2014-03-20 | Evonik Oil Additives Gmbh | A composition to improve low temperature properties and oxidation stability of vegetable oils and animal fats |

| WO2014118370A1 (en) | 2013-02-04 | 2014-08-07 | Evonik Industries Ag | Cold flow improver with broad applicability in mineral diesel, biodiesel and blends thereof |

| US8961622B2 (en) | 2006-07-18 | 2015-02-24 | Clariant Finance (Bvi) Limited | Additives for improving the cold properties of fuel oils |

| US8979951B2 (en) | 2006-07-18 | 2015-03-17 | Clariant Finance (Bvi) Limited | Additives for improving the cold properties of fuel oils |

| ITMI20132043A1 (en) * | 2013-12-06 | 2015-06-07 | Eni Spa | COMPOSITIONS BASED ON ETHYLENE-VINYLACETATE COPOLYMERS AND THEIR USE AS ANTI-GELIFICATION ADDITIVES OF PARAFFIN-GRADE OIL WHEELS |

| DE102015226635A1 (en) | 2015-12-23 | 2017-06-29 | Clariant International Ltd | Polymer compositions with improved handleability |

| WO2023083941A1 (en) | 2021-11-15 | 2023-05-19 | Evonik Operations Gmbh | Ethylene vinyl acetate-based dispersions suitable as pour point depressants with improved performance and stability |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006022698B4 (en) * | 2006-05-16 | 2008-10-02 | Clariant International Limited | Composition of fuel oils |

| DE102006022720B4 (en) * | 2006-05-16 | 2008-10-02 | Clariant International Limited | Cold flow improver for vegetable or animal fuel oils |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1112808A (en) * | 1966-06-20 | 1968-05-08 | Exxon Research Engineering Co | Improved middle distillate fuel composition |

| FR2073842A5 (en) * | 1969-12-18 | 1971-10-01 | Shell Int Research | |

| DE2048308A1 (en) * | 1970-10-01 | 1972-04-06 | Badische Anilin & Soda Fabrik AG, 6700 Ludwigshafen | Pour point depressants - for paraffinic crude oils consisting of mixed ethylene-vinyl acetate copolymers |

| US3862825A (en) * | 1969-12-02 | 1975-01-28 | William M Sweeney | Low pour point gas fuel from waxy crudes |

| EP0003489A1 (en) * | 1977-12-20 | 1979-08-22 | Imperial Chemical Industries Plc | Crude oil having improved cold flow properties |

| GB2189251A (en) * | 1986-04-19 | 1987-10-21 | Roehm Gmbh | Oil flow-improving additives |

| EP0254284A1 (en) * | 1986-07-25 | 1988-01-27 | Hoechst Aktiengesellschaft | Process to improve the flowability of mineral oils and mineral oil distillates |

| GB2207924A (en) * | 1987-07-29 | 1989-02-15 | Roehm Gmbh | Polymeric flow improvers |

-

1989

- 1989-07-06 DE DE3922146A patent/DE3922146A1/en not_active Withdrawn

-

1990

- 1990-06-27 DE DE9090112229T patent/DE59000124D1/en not_active Expired - Lifetime

- 1990-06-27 EP EP90112229A patent/EP0406684B1/en not_active Expired - Lifetime

- 1990-06-27 AT AT90112229T patent/ATE76093T1/en active

- 1990-07-06 JP JP2177630A patent/JPH0345693A/en active Pending

- 1990-07-06 CA CA002020571A patent/CA2020571A1/en not_active Abandoned

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1112808A (en) * | 1966-06-20 | 1968-05-08 | Exxon Research Engineering Co | Improved middle distillate fuel composition |

| US3862825A (en) * | 1969-12-02 | 1975-01-28 | William M Sweeney | Low pour point gas fuel from waxy crudes |

| FR2073842A5 (en) * | 1969-12-18 | 1971-10-01 | Shell Int Research | |

| DE2048308A1 (en) * | 1970-10-01 | 1972-04-06 | Badische Anilin & Soda Fabrik AG, 6700 Ludwigshafen | Pour point depressants - for paraffinic crude oils consisting of mixed ethylene-vinyl acetate copolymers |

| EP0003489A1 (en) * | 1977-12-20 | 1979-08-22 | Imperial Chemical Industries Plc | Crude oil having improved cold flow properties |

| GB2189251A (en) * | 1986-04-19 | 1987-10-21 | Roehm Gmbh | Oil flow-improving additives |

| EP0254284A1 (en) * | 1986-07-25 | 1988-01-27 | Hoechst Aktiengesellschaft | Process to improve the flowability of mineral oils and mineral oil distillates |

| GB2207924A (en) * | 1987-07-29 | 1989-02-15 | Roehm Gmbh | Polymeric flow improvers |

Cited By (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0620265A1 (en) * | 1993-04-08 | 1994-10-19 | Leuna-Werke Gmbh | Fuel composition with improved low temperature flow behaviour |

| EP1731589A2 (en) * | 2005-06-10 | 2006-12-13 | Malaysian Palm Oil Board | Palm-based biodiesel formulation |

| EP1731589A3 (en) * | 2005-06-10 | 2009-09-09 | Malaysian Palm Oil Board | Palm-based biodiesel formulation |

| EA019894B1 (en) * | 2006-07-10 | 2014-07-30 | Тоталь Раффинаж Маркетинг | Use of compounds for reducing filterability temperature of hydrocarbon distillates |

| FR2903418A1 (en) * | 2006-07-10 | 2008-01-11 | Total France Sa | USE OF COMPOUNDS REVELATING THE EFFICACY OF FILTRABILITY ADDITIVES IN HYDROCARBON DISTILLATES, AND SYNERGIC COMPOSITION CONTAINING THEM. |

| WO2008006965A3 (en) * | 2006-07-10 | 2008-02-28 | Total France | Use of efficiency reveal compounds of filterability additives in hydrocarbon distillates, and synergic composition comprising them |

| KR101535507B1 (en) * | 2006-07-10 | 2015-07-09 | 토탈 마케팅 서비스 | Use of compounds revealing the efficiency of filterability additives in hydrocarbon distillates, and synergic composition containing same |

| US20100058653A1 (en) * | 2006-07-10 | 2010-03-11 | Total Raffinage Marketing | Use of compounds revealing the efficiency of filterability additives in hydrocarbon distillates, and synergic composition containing same |

| US9481845B2 (en) | 2006-07-10 | 2016-11-01 | Total Raffinage Marketing | Use of compounds revealing the efficiency of filterability additives in hydrocarbon distillates, and synergic composition containing same |

| US20170037332A1 (en) * | 2006-07-10 | 2017-02-09 | Total Raffinage Marketing | Use Of Compounds Revealing The Efficiency Of Filterability Additives In Hydrocarbon Distillates, And Synergic Composition Containing Same |

| EP3399009A1 (en) * | 2006-07-10 | 2018-11-07 | Total Marketing Services | Use of compounds showing the efficiency of filterability additives in hydrocarbon distillates, and fuel composition containing same |

| CN101511974B (en) * | 2006-07-10 | 2013-10-09 | 道达尔炼油与销售部 | Use of compounds revealing the efficiency of filterability additives in hydrocarbon distillates, and synergic composition containing same |

| US8961622B2 (en) | 2006-07-18 | 2015-02-24 | Clariant Finance (Bvi) Limited | Additives for improving the cold properties of fuel oils |

| US8968428B2 (en) | 2006-07-18 | 2015-03-03 | Clariant Produkte (Deutschland) Gmbh | Additives for improving the cold properties of fuel oils |

| US8979951B2 (en) | 2006-07-18 | 2015-03-17 | Clariant Finance (Bvi) Limited | Additives for improving the cold properties of fuel oils |

| DE102006033150B4 (en) * | 2006-07-18 | 2008-10-16 | Clariant International Limited | Additives for improving the cold properties of fuel oils |

| US10131776B2 (en) | 2009-09-25 | 2018-11-20 | Evonik Oil Additives Gmbh | Composition to improve cold flow properties of fuel oils |

| EP2305753A1 (en) | 2009-09-25 | 2011-04-06 | Evonik RohMax Additives GmbH | A composition to improve cold flow properties of fuel oils |

| WO2011035947A1 (en) | 2009-09-25 | 2011-03-31 | Evonik Rohmax Additives Gmbh | A composition to improve cold flow properties of fuel oils |

| WO2012130535A1 (en) | 2011-03-25 | 2012-10-04 | Evonik Rohmax Additives Gmbh | A composition to improve oxidation stability of fuel oils |

| EP2514803A1 (en) * | 2011-04-21 | 2012-10-24 | Infineum International Limited | Improvements in fuel oils |

| AU2013314451B2 (en) * | 2012-09-13 | 2016-10-13 | Evonik Oil Additives Gmbh | A composition to improve low temperature properties and oxidation stability of vegetable oils and animal fats |

| WO2014040919A1 (en) | 2012-09-13 | 2014-03-20 | Evonik Oil Additives Gmbh | A composition to improve low temperature properties and oxidation stability of vegetable oils and animal fats |

| WO2014118370A1 (en) | 2013-02-04 | 2014-08-07 | Evonik Industries Ag | Cold flow improver with broad applicability in mineral diesel, biodiesel and blends thereof |

| WO2015083131A1 (en) * | 2013-12-06 | 2015-06-11 | Versalis S.P.A. | Compositions based on ethylene-vinyl acetate copolymers and their use as anti-gelling additives of paraffinic crude oils |

| ITMI20132043A1 (en) * | 2013-12-06 | 2015-06-07 | Eni Spa | COMPOSITIONS BASED ON ETHYLENE-VINYLACETATE COPOLYMERS AND THEIR USE AS ANTI-GELIFICATION ADDITIVES OF PARAFFIN-GRADE OIL WHEELS |

| RU2675529C1 (en) * | 2013-12-06 | 2018-12-19 | ВЕРСАЛИС С.п.А. | Compositions based on ethylene-vinyl acetate copolymers and their use as anti-gelling additives of paraffinic crude oils |

| US10370607B2 (en) | 2013-12-06 | 2019-08-06 | Versalis S.P.A. | Compositions based on ethylene-vinyl acetate copolymers and their use as anti-gelling additives of paraffinic crude oils |

| DE102015226635A1 (en) | 2015-12-23 | 2017-06-29 | Clariant International Ltd | Polymer compositions with improved handleability |

| US10889773B2 (en) | 2015-12-23 | 2021-01-12 | Clariant International Ltd. | Polymer compositions allowing easier handling |

| WO2023083941A1 (en) | 2021-11-15 | 2023-05-19 | Evonik Operations Gmbh | Ethylene vinyl acetate-based dispersions suitable as pour point depressants with improved performance and stability |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0345693A (en) | 1991-02-27 |

| CA2020571A1 (en) | 1991-01-07 |

| DE3922146A1 (en) | 1991-01-17 |

| ATE76093T1 (en) | 1992-05-15 |

| DE59000124D1 (en) | 1992-06-17 |

| EP0406684B1 (en) | 1992-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0236844B1 (en) | Use of additives for mineral oils with modified pour- point characteristics | |

| EP0406684B1 (en) | Diesel fuel additive | |

| EP0271738B1 (en) | Process for the manufacture of copolymers of ethylene and their use as additives to mineral oil and mineral oil fractions | |

| EP0126363B1 (en) | Use of copolymer from esters and amides of acrylic and/or methacrylic acids as pour point depressants in paraffin solutions | |

| EP0398101B1 (en) | Reaction products of aminoalkylene-polycarboxylic acids with secondary amines and crude oil middle distillates containing them | |

| EP0922716B1 (en) | Process for the manufacture of terpolymers of ethylene and their use as additives to mineral oil and mineral oil distillates | |

| EP0463518B1 (en) | Terpolymers of ethylene, their preparation and their use for mineral oil distillates | |

| EP0254284B1 (en) | Process to improve the flowability of mineral oils and mineral oil distillates | |

| EP0140274A2 (en) | Lubricating oil additives | |

| DE3725059A1 (en) | POLYMER FLOW IMPROVERS FOR MEDIUM DISTILLATES | |

| EP0258572B1 (en) | Process to improve the flowability of mineral oils and mineral oil distillates | |

| EP0405270B1 (en) | Process to improve mineral oil and mineral oil distillate flowability | |

| EP0931825B1 (en) | Process and product to improve cold flow properties of fuel oils | |

| DE19802690C2 (en) | Additive for improving the cold flow properties of fuel oils | |

| EP0892012B1 (en) | Flow improvers for mineral oils | |

| EP0890633B1 (en) | Use of copolymers of ethylene and unsaturated carboxylic esters in middle distillates to improve cold flow properties | |

| EP0407906B1 (en) | Mineral oils with improved flow behaviour | |

| DE4333680A1 (en) | Copolymers based on ethylene, and the use thereof as flow improvers in petroleum middle distillates | |

| DE19816797C2 (en) | Use of nitrogen-containing ethylene copolymers for the production of fuel oils with improved lubrication | |

| EP0925274B1 (en) | Flow improver for crude-oil middle distillates | |

| EP0251002B1 (en) | Process to improve the flowability of mineral oils and mineral oil distillates | |

| DE10254640A1 (en) | Use of homopolymers of ethylenically unsaturated esters to improve the effect of cold flow improvers | |

| DE4341765A1 (en) | Ethylene copolymers for reducing flow temp. of petroleum middle distillate | |

| DD154869A3 (en) | FUEL COMPOSITION WITH IMPROVED FLOW ASSETS AT DEEP TEMPERATURES |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19910125 |

|

| 17Q | First examination report despatched |

Effective date: 19911017 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19920513 Ref country code: DK Effective date: 19920513 Ref country code: NL Effective date: 19920513 Ref country code: SE Effective date: 19920513 Ref country code: BE Effective date: 19920513 |

|

| REF | Corresponds to: |

Ref document number: 76093 Country of ref document: AT Date of ref document: 19920515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59000124 Country of ref document: DE Date of ref document: 19920617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19920627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19920630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19920630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19920814 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19921002 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26 | Opposition filed |

Opponent name: HOECHST AKTIENGESELLSCHAFT,FRANKFURT(MAIN) Effective date: 19930203 |

|

| 26 | Opposition filed |

Opponent name: HOECHST AKTIENGESELLSCHAFT,FRANKFURT(MAIN) Effective date: 19930203 Opponent name: EXXON CHEMICAL PATENTS INC. Effective date: 19930211 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940528 Year of fee payment: 5 |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950615 Year of fee payment: 6 |

|

| 27W | Patent revoked |

Effective date: 19950312 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state |

Free format text: 950312 |

|

| ITF | It: translation for a ep patent filed |

Owner name: DE DOMINICIS & MAYER S.R.L. |