EP0340554A2 - Container with a cover inserted in its upper side, and protected by a seal - Google Patents

Container with a cover inserted in its upper side, and protected by a seal Download PDFInfo

- Publication number

- EP0340554A2 EP0340554A2 EP89107178A EP89107178A EP0340554A2 EP 0340554 A2 EP0340554 A2 EP 0340554A2 EP 89107178 A EP89107178 A EP 89107178A EP 89107178 A EP89107178 A EP 89107178A EP 0340554 A2 EP0340554 A2 EP 0340554A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- sealing cap

- closure

- closure according

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/18—Arrangements of closures with protective outer cap-like covers or of two or more co-operating closures

- B65D51/20—Caps, lids, or covers co-operating with an inner closure arranged to be opened by piercing, cutting, or tearing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/06—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages

- B65D47/061—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages with telescopic, retractable or reversible spouts, tubes or nozzles

- B65D47/063—Closures with discharging devices other than pumps with pouring spouts or tubes; with discharge nozzles or passages with telescopic, retractable or reversible spouts, tubes or nozzles with flexible parts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/18—Arrangements of closures with protective outer cap-like covers or of two or more co-operating closures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D55/00—Accessories for container closures not otherwise provided for

- B65D55/02—Locking devices; Means for discouraging or indicating unauthorised opening or removal of closure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0006—Upper closure

- B65D2251/0031—Membrane

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0037—Intermediate closure(s)

- B65D2251/0046—Intermediate closure(s) of the 41-type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2251/00—Details relating to container closures

- B65D2251/0003—Two or more closures

- B65D2251/0068—Lower closure

- B65D2251/0087—Lower closure of the 47-type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2401/00—Tamper-indicating means

Definitions

- the innovation relates to a container with a top opening having a profiled edge area and an upper bottom which is made of plastic and is closed by a screw cap and which is overlaid by a sealing device and is introduced into the removal opening.

- sealing devices are in use in a number of different versions.

- external sealing devices are also known in which sealing disks that can be torn open or torn off are injection-molded together with parts of the closure or are applied to the closure and are kept above it.

- Sealing devices applied subsequently to the closure can be designed as foils glued to the closure, for example plastic-clad metal foils, but thicker sheet metal plates can also be provided, which are either inserted into plastic parts of the closure or held by a ring that fixes the closure, for example, clinched it are.

- the innovation is therefore based on the task of creating a container with a closure overlaid with a clearly visible sealing device, which results in safe, easily inspectable protection against unauthorized opening of the container while being easy to manufacture and requiring little effort.

- a sealing cap made of thin sheet metal the circular base of which is enclosed by a circumferential jacket, at the lower end of which is connected an inwardly directed collar which engages behind a profiled ring molded onto a flange which adjoins the base of the closure upwards.

- the pressing can be done easily and practically in the same operation with the introduction of the closure itself if the profile ring is sawtooth-shaped such that the collar of the Sealing cap can be guided over a flat flank of the profile ring and is held by a steep flank after it has passed.

- the removal of the top surface of the sealing cap for opening the container can be facilitated if the base surface is equipped with a pre-punched tear line which expediently has a circular shape and whose diameter is selected such that the parts of the closure to be pulled out pass through the opening delimited by the tear line capital.

- a sheet metal top shelf 1 of a container is shown broken off, which turns in the form of a jacket 2 downwards or inwards to form a removal opening.

- the lower region of the jacket turns to an annular surface 3, the outer end of which is bent downwards and inwards again.

- the flange 4 of the base 5 is supported on the annular surface 3 of a pressed-in closure consisting of plastic.

- a reinforcement of the base 5 of the closure designed as a bulge 6 has passed the annular surface 3 and its inwardly bent end region in such a way that the end face of the tubular free end is supported against the bulge 6 and the base 5 of the closure is mechanically and reliably sealed holds.

- an extendable bellows 7 adjoins the base 5, which merges into a pouring spout 8 provided with an external thread, within which a sealing disk 9 is provided, which extends along grooves provided as predetermined breaking points by pulling on a handle 10 the pouring spout is removable.

- a screw cap 11 is firmly screwed onto the external thread of the pouring spout 8, the top plate 12 of which is equipped with a sealing cone which engages in the mouth of the pouring spout 8.

- the Head disc 12 has, opposite one another, two webs 13, to which approximately semi-circular handle brackets 14 adjoin which can be pivoted up about film hinges.

- the closure including the screw cap, is overlaid by a sealing cap 15 made of relatively thin sheet metal, which consists of a circular base area to which a downwardly extending jacket 16 connects, the lower end of which has an inwardly directed collar 17 which connects one to the flange 4 molded profile ring 18 engages behind.

- a sealing cap 15 made of relatively thin sheet metal, which consists of a circular base area to which a downwardly extending jacket 16 connects, the lower end of which has an inwardly directed collar 17 which connects one to the flange 4 molded profile ring 18 engages behind.

- the height of the jacket 2 of the top floor 1, taking into account the thickness of the flange 5, the height of the profile ring 18 and that of the jacket 16, is dimensioned such that the upper cover surfaces of the top floor 1 and the sealing cap 15 are at the same height after the closure has been inserted , and the inside width of the jacket 2 and the outer diameter of the jacket 16 are chosen so that the mutually facing surfaces of the jacket enclose such a small space that although the application of the sealing cap 15 is not hindered, an introduction of tools in the by However, the gap formed between them becomes impossible at least without clearly visible damage.

- the sealing cap 15 is first inserted into the pressing tool and the assembled closure is applied, so that when the base 5 is pressed into the removal opening of the top panel 1, the sealing cap is also at the same time Profile ring 18 is pressed.

- the profile ring 18 has an approximately sawtooth-shaped profile, the flat flank of which is directed upwards and facilitates the sliding over of the collar 17, while the steep flank upwards push the sealing cap whose collar holds in place.

- the steep flank of the profile ring 18 can also be designed to be slightly inclined in order to facilitate the removal of the shape from the closure, it can be oriented normal to the axis or it can also be undercut.

- the collar 17 can be rolled onto the sealing cap 15, for example to form an approximately semicircular profile; but it has also proven useful to shape the collar only substantially approximately semicircular and to keep it stretched over a short length in the region of the free end of the profile, this stretched region of the profile being able to extend relatively steeply inwards to vertically.

- FIG. 2 shows, with an opening 19, into which a tool, for example a screwdriver, can be used.

- a tool for example a screwdriver

- the opening of the sealing device can be facilitated if, according to FIG. 4, the top surface of the sealing cap is provided with a pre-punched tear line 20, which expediently runs circularly with a diameter which allows the parts of the closure to be pulled through.

- the opening 21 which facilitates opening is expediently designed such that one of its sides runs along the tear line or the tear line 20 forms one of its sides. Otherwise, such an opening can be shaped in the form of a segment or else in the shape of a crescent moon, the second of the curved lines being curved in the same direction as the tear line or in the opposite direction. It is also not necessary for this second curved side that the curvature along the side is constant; In particular, it may be advisable to increase the curvature from the center to the ends and to end it at right angles or even at an acute angle on the tear line.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Closing Of Containers (AREA)

Abstract

Description

Die Neuerung betrifft einen Behälter mit einem eine einen profilierten Randbereich aufweisende Entnahmeöffnung enthaltenden Oberboden und einem in die Entnahmeöffnung eingebrachten, aus Kunststoff bestehenden und durch eine Schraubkappe abgeschlossenen Verschluß, der von einer Siegelvorrichtung überfangen ist.The innovation relates to a container with a top opening having a profiled edge area and an upper bottom which is made of plastic and is closed by a screw cap and which is overlaid by a sealing device and is introduced into the removal opening.

Derartige, Behälter abschließende, aus Kunststoff bestehende Verschlüsse sind in einer Anzahl variierter Ausführungen in Gebrauch. Außer und gegebenenfalls neben im Verschluß selbst angeordneten und von dessen Schraubkappe überfangenene Siegelvorrichtungen, deren Zustand nicht ohne weiteres erkennbar ist, sind auch äußere Siegelvorrichtungen bekannt, bei denen auf- bzw. abreißbare Siegelscheiben mit Teilen des Verschlusses gemeinsam gespritzt sind oder auf den Verschluß aufgebracht sind und über diesem gehalten sind. Nachträglich auf den Verschluß aufgebrachte Siegelvorrichtungen können als mit dem Verschluß verklebte Folien ausgebildet sein, bspw. kunststoffkaschierte Metallfolien, es können aber auch stärkere Blechscheiben vorgesehen sein, die entweder in Kunststoffteile des Verschlusses eingesetzt sind oder von einem den Verschluß fixierenden, bspw. geclinchten Ring gehalten sind. Es hat sich jedoch gezeigt, daß ein vollkommener Schutz gegen unberechtigten Anbruch nicht gegeben ist. Blechplatten, aber auch Folien, können nach vorsichtigem Entfernen bzw. nach vorsichtigem Aufschneiden bspw. auf unter ihnen liegende Teile des Verschlusses derart aufgeklebt werden, daß zumindest auch bei mäßig sorgfältigem Betrachten die Manipulation nicht ohne weiteres zu entdecken ist. In einer Anzahl von Fällen besteht darüber hinaus die Möglichkeit, den an sich elastischen Kunststoffverschluß vermittels von Werkzeugen aus dem Oberboden des Behälters herauszudrücken oder herauszuziehen, ohne daß ein derartiges unberechtigtes Öffnen sinnfällig angezeigt wird.Such, container-closing, plastic closures are in use in a number of different versions. In addition to and, if necessary, in addition to sealing devices arranged in the closure itself and overlaid by its screw cap, the condition of which is not readily recognizable, external sealing devices are also known in which sealing disks that can be torn open or torn off are injection-molded together with parts of the closure or are applied to the closure and are kept above it. Sealing devices applied subsequently to the closure can be designed as foils glued to the closure, for example plastic-clad metal foils, but thicker sheet metal plates can also be provided, which are either inserted into plastic parts of the closure or held by a ring that fixes the closure, for example, clinched it are. However, it has been shown that there is no complete protection against unauthorized opening. Sheet metal plates, but also foils, can be carefully Removing or, after careful cutting, for example, glued to parts of the closure underneath them in such a way that the manipulation cannot be easily discovered, at least even when viewed with moderate care. In a number of cases, there is also the possibility of pushing or pulling out the elastic plastic closure by means of tools from the top of the container without such an unauthorized opening being indicated.

Die Neuerung geht daher von der Aufgabe aus, einen Behälter mit einem von einer gut sichtbaren Siegelvorrichtung überfangenen Verschluß zu schaffen, der bei leichter Herstellbarkeit und geringem Aufwande einen sicheren, leicht inspizierbaren Schutz gegen unberechtigen Anbruch des Gebindes ergibt.The innovation is therefore based on the task of creating a container with a closure overlaid with a clearly visible sealing device, which results in safe, easily inspectable protection against unauthorized opening of the container while being easy to manufacture and requiring little effort.

Gelöst wird diese Aufgabe durch eine aus dünnem Metallblech bestehende Siegelkappe, deren kreisförmige Grundfläche von einem umlaufenden Mantel umschlossen ist, an dessen unteres Ende sich ein einwärts gerichteter Bund anschließt, der einen an einen an die Basis des Verschlusses nach oben anschließenden Flansch angeformten Profilring hintergreift. Hiermit wird erreicht, daß die sich mit ihrem hintergreifenden Bund relativ fest haltende Siegelkappe zwar noch verhältnismäßig leicht vom Verschluß abheben läßt, die hierbei aufzuwendenden Kräfte jedoch die aus dünnem Metallblech bestehende Siegelkappe derart bleibend verformen, daß ein Wiederausrichten der Grundfläche in eine Ebene und ein nochmaliges Aufdrücken zumindest durch die gestörte Ebene der Grundfläche sofort erkennbar sind. Das Aufdrücken läßt sich leicht und praktisch im gleichen Arbeitsgang mit dem Einbringen des Verschlusses selbst bewirken, wenn der Profilring sägezahnartig derart aufgebaut ist, daß der Bund der Siegelkappe über eine flache Flanke des Profilringes führbar ist und nach deren Passieren durch eine steile Flanke gehalten wird. Als wesentlich hat sich noch gezeigt, den die Entnahmeöffnung des Oberbodens umgrenzenden Randbereich derart zu profilieren, daß ein nach unten gerichteter Mantel entsteht, an den die den Verschluß aufnehmende Ringfläche anschließt, und der die Siegelkappe derart umschließt, daß einerseits die oberen Deckflächen des Oberbodens und der Siegelkappe praktisch in einer Ebene stehen und andererseits der Mantel des Oberbodens den der Siegelkappe mit einer so geringen Distanz umschließt, daß zwar das Einbringen der Siegelkappe nicht gehemmt wird, das Ansetzen von Werkzeugen jedoch praktisch unmöglich oder zumindest leicht erkenntlich gemacht wird. Das Entfernen der Deckfläche der Siegelkappe zum Anbruch des Gebindes läßt sich erleichtern, wenn die Grundfläche mit einer vorgestanzten Reißlinie ausgestattet wird, die zweckmäßig kreisförmig verläuft, und deren Durchmesser so gewählt ist, daß die auszuziehenden Teile des Verschlusses die durch die Reißlinie begrenzte Öffnung zu passieren vermögen.This problem is solved by a sealing cap made of thin sheet metal, the circular base of which is enclosed by a circumferential jacket, at the lower end of which is connected an inwardly directed collar which engages behind a profiled ring molded onto a flange which adjoins the base of the closure upwards. This ensures that the sealing cap with its engaging collar can still be lifted off the closure relatively easily, but the forces to be used here permanently deform the sealing cap, which is made of thin sheet metal, in such a way that realignment of the base area into one plane and one more time Press on at least through the disturbed level of the base area are immediately recognizable. The pressing can be done easily and practically in the same operation with the introduction of the closure itself if the profile ring is sawtooth-shaped such that the collar of the Sealing cap can be guided over a flat flank of the profile ring and is held by a steep flank after it has passed. It has also been shown to be essential to profile the edge region delimiting the removal opening of the top floor in such a way that a downward-facing jacket is formed, to which the ring surface receiving the closure is connected, and which surrounds the sealing cap in such a way that on the one hand the upper cover surfaces of the top floor and the sealing cap are practically in one plane and on the other hand the jacket of the top cover encloses the sealing cap with such a small distance that although the introduction of the sealing cap is not inhibited, the attachment of tools is practically impossible or at least made easily recognizable. The removal of the top surface of the sealing cap for opening the container can be facilitated if the base surface is equipped with a pre-punched tear line which expediently has a circular shape and whose diameter is selected such that the parts of the closure to be pulled out pass through the opening delimited by the tear line capital.

Zweckmäßige und vorteilhafte Weiterbildungen sind den weiteren Unteransprüchen zu entnehmen.Appropriate and advantageous developments can be found in the further subclaims.

Im einzelnen sind die Merkmale der Erfindung anhand der folgenden Beschreibung eines Ausführungsbeispieles in Verbindung mit dieses darstellenden Zeichnungen erläutert. Es zeigen hierbei

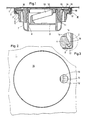

Figur 1 einen Schnitt durch einen abgebrochen dargestellten Oberboden eines Behälters mit einem in dessen Entnahmeöffnung eingesetzten, von einer Siegelkappe überfangenen Verschluß,Figur 2 eine Aufsicht auf die Anordnung nach Fig. 1,Figur 3 vergrößert einen den Bund der Siegelkappe aufweisenden Ausschnitt der Fig. 1, undFigur 4 eine der Fig. 2 entsprechende Aufsicht mit einer eine Reißlinie aufweisenden Siegelkappe.

- 1 shows a section through an upper floor of a container, shown broken off, with a closure inserted into its removal opening and overlaid by a sealing cap,

- FIG. 2 shows a top view of the arrangement according to FIG. 1,

- FIG. 3 enlarges a section of FIG. 1 and the collar of the sealing cap

- 4 shows a top view corresponding to FIG. 2 with a sealing cap having a tear line.

In den Figuren ist abgebrochen ein aus Blech bestehender Oberboden 1 eines Behälters dargestellt, der zur Bildung einer Entnahmeöffnung sich in Form eines Mantels 2 nach unten bzw. nach innen wendet. Der untere Bereich des Mantels wendet sich zu einer Ringfläche 3, deren äußeres Ende wieder nach unten-einwärts gebogen ist. Auf die Ringfläche 3 stützt sich der Flansch 4 der Basis 5 eines eingepreßten, aus Kunststoff bestehenden Verschlusses ab. Beim Einpressen hat eine als Wulst 6 ausgebildete Verstärkung der Basis 5 des Verschlusses die Ringfläche 3 und deren nach innen gebogenen Endbereich derart passiert, daß die Stirnfläche des rohrartigen freien Endes sich gegen den Wulst 6 stützt und die Basis 5 des Verschlusses mechanisch sicher und verläßlich abgedichtet hält.In the figures, a sheet metal

In an sich bekannter Art schließt sich an die Basis 5 ein ausziehbarer Balgen 7 an, der in eine mit einem Außengewinde versehene Gießtülle 8 übergeht, innerhalb deren eine Siegelscheibe 9 vorgesehen ist, die entlang von als Sollbruchstellen vorgesehenen Nuten durch Ziehen an einer Handhabe 10 aus der Gießtülle herauslösbar ist. Auf das Außengewinde der Gießtülle 8 ist eine Schraubkappe 11 fest aufgeschraubt, deren Kopfscheibe 12 mit einem in die Mündung der Gießtülle 8 dichtend eingreifenden Dichtkonus ausgestattet ist. Die Kopfscheibe 12 weist, einander gegenüberliegend, zwei Stege 13 auf, an die sich um Filmscharniere hochschwenkbare, etwa halbkreisförmige Griffbügel 14 anschließen.In a manner known per se, an

Überfangen ist der Verschluß samt Schraubkappe durch eine aus relativ dünnem Blech erstellte Siegelkappe 15, die aus einer kreisförmigen Grundfläche besteht, an die sich ein nach unten erstreckender Mantel 16 anschließt, dessen unteres Ende einen einwärts gerichteten Bund 17 aufweist, der einen an den Flansch 4 angeformten Profilring 18 hintergreift. Hierbei ist die Höhe des Mantels 2 des Oberbodens 1 unter Berücksichtigung der Stärke des Flansches 5, der Höhe des Profilringes 18 sowie der des Mantels 16 so bemessen, daß die oberen Deckflächen des Oberbodens 1 sowie der Siegelkappe 15 nach Einsetzen des Verschlusses auf gleicher Höhe stehen, und die lichte Weite des Mantels 2 sowie der Außendurchmesser des Mantels 16 sind so gewählt, daß die einander zugekehrten Flächen der Mäntel einen so geringen Zwischenraum einschließen, daß zwar das Aufbringen der Siegelkappe 15 nicht behindert wird, ein Einführen von Werkzeugen in den durch den Zwischenraum gebildeten Spalt jedoch zumindest ohne gut sichtbare Beschädigungen unmöglich wird.The closure, including the screw cap, is overlaid by a sealing

Die Montage des Verschlusses wird durch die Einführung der Siegelkappe 15 praktisch nicht erschwert: In das pressende Werkzeug werden zunächst die Siegelkappe 15 eingelegt und der montierte Verschluß aufgebracht, so daß beim Einpressen der Basis 5 in die Entnahmeöffnung des Oberbodens 1 gleichzeitig auch die Siegelkappe über den Profilring 18 gedrückt wird. Erleichtert wird dieses, wie der vergrößerte Ausschnitt der Fig. 3 zeigt, noch dadurch, daß der Profilring 18 ein etwa sägezahnförmiges Profil aufweist, dessen flache Flanke nach oben gerichtet ist und das Darübergleiten des Bundes 17 erleichtert, während die steile Flanke nach Auf schieben der Siegelkappe deren Bund rastend hält. Die steile Flanke des Profilringes 18 kann noch geringfügig geneigt ausgeführt sein, um das Entformen des Verschlusses zu erleichtern, sie kann achsnormal gerichtet oder aber auch hinterschnitten sein. Der Bund 17 kann, bspw. unter Bildung eines etwa halbkreisförmigen Profiles, an die Siegelkappe 15 angerollt sein; es hat sich aber auch bewährt, den Bund nur im wesentlichen etwa halbkreisförmig zu formen und im Bereiche des freien Endes des Profiles dieses über eine geringe Länge gestreckt zu halten, wobei dieser gestreckte Bereich des Profiles relativ steil nach innen geneigt bis vertikal verlaufen kann.The installation of the closure is practically not made difficult by the introduction of the sealing cap 15: the sealing

Zur Erleichterung des Entfernens der Siegelkappe 15 ist diese, wie die Aufsicht der Fig. 2 zeigt, mit einer Durchbrechung 19 versehen, in die mittels eines Werkzeuges, bspw. eines Schraubenziehers, eingegriffen werden kann. Zum Abheben der Siegelkappe sind zwar nur unerhebliche Kräfte erforderlich; da die Siegelkappe aber aus recht dünnem Blech, bspw. Weißblech, hergestellt ist, ergeben sich hierbei Verformungen nicht nur im direkten Umgebungsbereich der Durchbrechung 19; durch das Ausheben bereits an einem Umfangsbereich des Profilringes 18 und Festhalten an weiteren Bereichen wird praktisch in jedem Falle der Entnahme der Siegelkappe diese geknickt und so stark deformiert, daß auch nach Richtversuchen stets auf den ersten Blick erkennbar sein wird, daß diese Siegelkappe bereits entnommen und hierbei verformt wurde.In order to facilitate the removal of the

Erleichtern läßt sich das Öffnen der Siegelvorrichtung, wenn gemäß Fig. 4 die Deckfläche der Siegelkappe mit einer vorgestanzten Reißlinie 20 versehen ist, die zweckmäßig kreisförmig mit einem Durchmesser verläuft, der das Hindurchziehen der Teile des Verschlusses gestattet. In einem solchen Fall wird zweckmäßig die das Anbrechen erleichternde Durchbrechung 21 so ausgeführt, daß eine ihrer Seiten entlang der Reißlinie verläuft bzw. die Reißlinie 20 eine ihrer Seiten bildet. Im übrigen kann eine solche Durchbrechung in Form eines Segmentes oder aber auch halbmondförmig geformt sein, wobei die zweite der gekrümmten Linien nach der gleichen Richtung durchgekrümmt sein kann wie die Reißlinie oder nach der entgegengesetzten Richtung. Es ist auch nicht erforderlich, daß bei dieser zweiten gekrümmten Seite die Krümmung entlang der Seite konstant ist; insbesondere kann es sich empfehlen, die Krümmung von der Mitte zu den Enden hin zunehmen zu lassen und rechtwinklig oder gar im spitzen Winkel auf der Reißlinie enden zu lassen.The opening of the sealing device can be facilitated if, according to FIG. 4, the top surface of the sealing cap is provided with a

Damit wird eine leicht inspizierbare Siegelvorrichtung geschaffen, die bereits jeden Versuch eines Anbruches deutlich sichtbar macht. Durch die geringe Distanz zwischen den Mänteln 2 des Oberbodens 1 und 16 der Siegelkappe 15 wird gleichzeitig auch bereits jeder Versuch eines Anbruches deutlich angezeigt, bspw. ein Versuch, den aus Kunststoff bestehenden Verschluß insgesamt aus der Entnahmeöffnung des Behälters herauszuheben. Die Distanz zwischen dem Mantel der Entnahmeöffnung und dem der Siegelöffnung ist hierbei so gering gewählt, daß schon der Versuch des Einführens eines Werkzeuges nur unter Verletzung und Verformung der Siegelkappe möglich ist und damit deutlich erkennbar wird.This creates an easily inspectable sealing device that makes every attempt at opening clearly visible. Due to the small distance between the

Claims (9)

gekennzeichnet durch

eine aus dünnem Metallblech bestehende Siegelkappe (15), deren kreisförmige Grundfläche von einem umlaufenden Mantel (16) umschlossen ist, an dessen unteres Ende sich ein einwärts gerichteter Bund (17) anschließt, der einen an einen an die Basis des Verschlusses nach oben anschließenden Flansch (4) angeformten Profilring (18) hintergreift.1. Container with an upper opening containing a profiled edge area and a top made of plastic and closed by a screw cap, which is overlaid by a sealing device, which is introduced into the removal opening,

marked by

a sealing cap (15) made of thin sheet metal, the circular base of which is enclosed by a circumferential jacket (16), at the lower end of which an inwardly directed collar (17) connects, which connects to a flange which adjoins the base of the closure upwards (4) molded profile ring (18) engages behind.

dadurch gekennzeichnet,

daß der Profilring (18) ein sägezahnartiges Profil aufweist, dessen flache Flanke nach oben und dessen steile, achsnormale oder hinterschnittene Flanke nach unten gerichtet sind, und daß die steile Flanke vom Bund (17) der Siegelkappe (15) hintergriffen ist.2. container with a closure according to claim 1,

characterized,

that the profile ring (18) has a sawtooth-like profile, the flat flank of which is directed upwards and whose steep, axially normal or undercut flank is directed downward, and that the steep flank of the collar (17) of the sealing cap (15) is engaged.

daß der die Entnahmeöffnung umschließende profilierte Randbereich des Oberbodens (1) einen nach innen eingezogenen Mantel (2) aufweist, dessen lichte Weite den Außendurchmesser der Siegelkappe (15) nur geringfügig überschreitet,

daß sich an den Mantel (2) eine Ringfläche (3) zur Auflage des Flansches (4) der Basis (5) des Verschlusses anschließt, deren inneren Bereich zur Stützung eines Wulstes (6) der Basis (5) sich nach unten wendet,

und daß die Höhe des Mantels (2) so bemessen ist, daß die Deckfläche der Siegelkappe (15) im wesentlichen auf gleicher Höhe steht wie die des Oberbodens (1).3. Container with a closure according to claim 1 or 2, characterized in

that the profiled edge area of the top panel (1) surrounding the removal opening has an inwardly drawn-in jacket (2), the clear width of which only slightly exceeds the outside diameter of the sealing cap (15),

that an annular surface (3) adjoins the jacket (2) for supporting the flange (4) of the base (5) of the closure, the inner area of which for supporting a bead (6) of the base (5) turns downward,

and that the height of the jacket (2) is dimensioned so that the top surface of the sealing cap (15) is substantially at the same height as that of the top floor (1).

dadurch gekennzeichnet,

daß der Bund (17) an den Mantel (16) der Siegelkappe (15) angerollt und/oder kreisbogenförmig ausgebildet ist.4. Container with a closure according to one of claims 1 to 3,

characterized,

that the collar (17) is rolled onto the jacket (16) of the sealing cap (15) and / or is designed in the form of a circular arc.

dadurch gekennzeichnet,

daß ein freies Ende des Bundes (17) ein gestrecktes, vertikales oder nach innen geneigtes Profil aufweist.5. container with a closure according to claim 4,

characterized,

that a free end of the collar (17) has an elongated, vertical or inwardly inclined profile.

dadurch gekennzeichnet,

daß die Grundfläche der Siegelkappe (15) eine Durchbrechung (19, 21) aufweist.6. Container with a closure according to one of claims 1 to 5,

characterized,

that the base of the sealing cap (15) has an opening (19, 21).

dadurch gekennzeichnet,

daß die Grundfläche der Siegelkappe (15) eine vorgestanzte, vorzugsweise kreisförmige Reißlinie (20) aufweist.7. container with a closure according to one of claims 1 to 6,

characterized,

that the base of the sealing cap (15) has a pre-punched, preferably circular tear line (20).

dadurch gekennzeichnet,

daß eine Seite der Durchbrechung (21) entlang der Reißlinie (20) verläuft.8. container with a closure according to claim 7,

characterized,

that one side of the opening (21) runs along the tear line (20).

gekennzeichnet durch

eine segment- oder halbmondförmige Durchbrechung (21).9. container with a closure according to one of claims 6 to 8,

marked by

a segment or crescent-shaped opening (21).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8805761U | 1988-04-30 | ||

| DE8805761 | 1988-04-30 | ||

| DE8900736U DE8900736U1 (en) | 1988-04-30 | 1989-01-24 | Container with a closure incorporated into its top and covered by a sealing device |

| DE8900736U | 1989-01-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0340554A2 true EP0340554A2 (en) | 1989-11-08 |

| EP0340554A3 EP0340554A3 (en) | 1990-01-31 |

Family

ID=25952984

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89107178A Withdrawn EP0340554A3 (en) | 1988-04-30 | 1989-04-21 | Container with a cover inserted in its upper side, and protected by a seal |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0340554A3 (en) |

| DE (1) | DE8900736U1 (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5111970A (en) * | 1991-03-12 | 1992-05-12 | Rapak, Inc. | Fluid dispenser having a removable sealing diaphragm |

| US5133486A (en) * | 1991-01-18 | 1992-07-28 | Phoenix Closures, Inc. | Tamper evident pull ring pour spout |

| FR2679205A1 (en) * | 1991-07-17 | 1993-01-22 | Bohor Jean Claude | Package allowing the retrieval of liquids or products (used or new) inside this package, which can also be used as a package for new liquids or products |

| DE4130950A1 (en) * | 1991-09-18 | 1993-04-01 | Stolz Heinrich Gmbh | Closure with screw cap, to lock on container socket - has cap lid with fold-up brackets, covered by coated sealing cap of aluminium which is in connection with container support |

| EP0569897A1 (en) * | 1992-05-11 | 1993-11-18 | Herberts Gesellschaft mit beschränkter Haftung | Child resistant device for closing containers |

| FR2711359A1 (en) * | 1993-10-20 | 1995-04-28 | Novembal Sa | Closure stopper, stopping device comprising such a stopper and package comprising such a stopper or such a stopping device |

| WO1999006297A1 (en) * | 1997-07-28 | 1999-02-11 | INNOCOS INNOVATIVE VERPACKUNGEN FüR DIE KOSMETISCHE INDUSTRIE GMBH | Cap with decorative snap-on ring |

| DE19901713A1 (en) * | 1999-01-18 | 2000-07-27 | Stolz Heinrich | Container neck with inner plastics-coated aluminum barrier tamper-evident seal has plastics screw-top outer neck and second inner neck with weak point link to inner face of outer neck |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2715915B1 (en) * | 1994-02-10 | 1996-04-19 | Eric Guarnieri | Hermetic container with retractable neck. |

| DE29515681U1 (en) * | 1995-10-02 | 1995-12-07 | B. Braun Melsungen Ag, 34212 Melsungen | Safety cap for containers |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1859008A (en) * | 1930-09-05 | 1932-05-17 | Mundo Products Inc | Detachable spout for containers |

| DE633751C (en) * | 1933-10-20 | 1936-08-05 | Franz Haggenmiller | Closure for vessels, especially bottles |

| US2306973A (en) * | 1940-04-18 | 1942-12-29 | Mysels George | Container closure |

| GB688534A (en) * | 1949-03-08 | 1953-03-11 | Irvin Henry Rieke | Improvements in pouring spouts for liquid containers |

| FR1533032A (en) * | 1966-08-04 | 1968-07-12 | Sealing cap for the container sampling opening | |

| US3604740A (en) * | 1969-02-04 | 1971-09-14 | Rieke Corp | Container closure combination |

| FR2152429A1 (en) * | 1971-09-14 | 1973-04-27 | Remy | |

| EP0161746A2 (en) * | 1984-05-16 | 1985-11-21 | Rieke Corporation | Vented nestable pouring spout |

| DE3524742A1 (en) * | 1984-07-14 | 1986-01-16 | Schiwa GmbH, 4519 Glandorf | Stopper for infusion container |

| US4568006A (en) * | 1982-06-03 | 1986-02-04 | American Flange & Manufacturing Co. Inc. | Nestable self-venting spout |

| EP0221419A2 (en) * | 1985-11-07 | 1987-05-13 | Jacob Berg GmbH & Co. KG | Tamper-proof closure for containers |

-

1989

- 1989-01-24 DE DE8900736U patent/DE8900736U1/en not_active Expired

- 1989-04-21 EP EP89107178A patent/EP0340554A3/en not_active Withdrawn

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1859008A (en) * | 1930-09-05 | 1932-05-17 | Mundo Products Inc | Detachable spout for containers |

| DE633751C (en) * | 1933-10-20 | 1936-08-05 | Franz Haggenmiller | Closure for vessels, especially bottles |

| US2306973A (en) * | 1940-04-18 | 1942-12-29 | Mysels George | Container closure |

| GB688534A (en) * | 1949-03-08 | 1953-03-11 | Irvin Henry Rieke | Improvements in pouring spouts for liquid containers |

| FR1533032A (en) * | 1966-08-04 | 1968-07-12 | Sealing cap for the container sampling opening | |

| US3604740A (en) * | 1969-02-04 | 1971-09-14 | Rieke Corp | Container closure combination |

| FR2152429A1 (en) * | 1971-09-14 | 1973-04-27 | Remy | |

| US4568006A (en) * | 1982-06-03 | 1986-02-04 | American Flange & Manufacturing Co. Inc. | Nestable self-venting spout |

| EP0161746A2 (en) * | 1984-05-16 | 1985-11-21 | Rieke Corporation | Vented nestable pouring spout |

| DE3524742A1 (en) * | 1984-07-14 | 1986-01-16 | Schiwa GmbH, 4519 Glandorf | Stopper for infusion container |

| EP0221419A2 (en) * | 1985-11-07 | 1987-05-13 | Jacob Berg GmbH & Co. KG | Tamper-proof closure for containers |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5133486A (en) * | 1991-01-18 | 1992-07-28 | Phoenix Closures, Inc. | Tamper evident pull ring pour spout |

| US5111970A (en) * | 1991-03-12 | 1992-05-12 | Rapak, Inc. | Fluid dispenser having a removable sealing diaphragm |

| FR2679205A1 (en) * | 1991-07-17 | 1993-01-22 | Bohor Jean Claude | Package allowing the retrieval of liquids or products (used or new) inside this package, which can also be used as a package for new liquids or products |

| DE4130950A1 (en) * | 1991-09-18 | 1993-04-01 | Stolz Heinrich Gmbh | Closure with screw cap, to lock on container socket - has cap lid with fold-up brackets, covered by coated sealing cap of aluminium which is in connection with container support |

| EP0569897A1 (en) * | 1992-05-11 | 1993-11-18 | Herberts Gesellschaft mit beschränkter Haftung | Child resistant device for closing containers |

| FR2711359A1 (en) * | 1993-10-20 | 1995-04-28 | Novembal Sa | Closure stopper, stopping device comprising such a stopper and package comprising such a stopper or such a stopping device |

| WO1999006297A1 (en) * | 1997-07-28 | 1999-02-11 | INNOCOS INNOVATIVE VERPACKUNGEN FüR DIE KOSMETISCHE INDUSTRIE GMBH | Cap with decorative snap-on ring |

| DE19901713A1 (en) * | 1999-01-18 | 2000-07-27 | Stolz Heinrich | Container neck with inner plastics-coated aluminum barrier tamper-evident seal has plastics screw-top outer neck and second inner neck with weak point link to inner face of outer neck |

| DE19901713C2 (en) * | 1999-01-18 | 2002-01-31 | Stolz Heinrich | Closure for a container |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0340554A3 (en) | 1990-01-31 |

| DE8900736U1 (en) | 1989-03-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69311372T2 (en) | ADDITIONAL DEVICE FOR SEALING CAN FOR DRINKS OR THE LIKE. | |

| DE2461119C2 (en) | Sealing cap | |

| DE69508462T2 (en) | Tamper-evident closure | |

| DE69207543T2 (en) | Metal container that can be partially opened along a line of weakness | |

| EP0086970B1 (en) | Construction and mounting process for a cap and cap for a container neck provided with a screw-thread or a bead | |

| EP0161565B1 (en) | Closure cap | |

| DE3422546C2 (en) | Container cap | |

| DE60105809T2 (en) | CAN COVER | |

| DE2341077C3 (en) | Sheet metal container lid with at least one rigid closure part that can be moved into the container | |

| EP0340554A2 (en) | Container with a cover inserted in its upper side, and protected by a seal | |

| DE2507823B2 (en) | PACKAGING UNIT MADE OF A HANDLE AND BOTTLE-LIKE CONTAINERS | |

| DE2007930A1 (en) | Removable tank cover plate | |

| EP0697345A2 (en) | Sealing disc with griptab | |

| EP0085355A1 (en) | Device for the connection of air-channel elements provided with flange sections at their edges which form openings for corner angles | |

| DE4106110C2 (en) | ||

| DE19712364A1 (en) | Bottle snap closure cap | |

| EP0216268A2 (en) | Plastic container with closure | |

| DE3811362A1 (en) | Container fitted with a closure | |

| DE1984477U (en) | CLOSING CAP. | |

| EP0319005A2 (en) | Container provided with a closure | |

| DE69500480T2 (en) | Closure device for bottles | |

| DE1303572B (en) | ||

| DE4041831C2 (en) | Closure for a filling opening of a container | |

| DE9203852U1 (en) | Liquid container | |

| DE9213716U1 (en) | Device for manually closing bottle caps |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19890516 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| DIN1 | Information on inventor provided before grant (deleted) | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HEINRICH STOLZ GMBH & CO. KG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 17Q | First examination report despatched |

Effective date: 19920611 |

|

| 18W | Application withdrawn |

Withdrawal date: 19920713 |