EP0319087A2 - Profil für Kühlschränke und dergleichen, hergestellt aus einem im wesentlichen harten Werkstoff, versehen mit einer hermetischen Abdichtung aus einem im wesentlichen weichen Werkstoff - Google Patents

Profil für Kühlschränke und dergleichen, hergestellt aus einem im wesentlichen harten Werkstoff, versehen mit einer hermetischen Abdichtung aus einem im wesentlichen weichen Werkstoff Download PDFInfo

- Publication number

- EP0319087A2 EP0319087A2 EP88202688A EP88202688A EP0319087A2 EP 0319087 A2 EP0319087 A2 EP 0319087A2 EP 88202688 A EP88202688 A EP 88202688A EP 88202688 A EP88202688 A EP 88202688A EP 0319087 A2 EP0319087 A2 EP 0319087A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- structural shape

- door

- counter

- gasket

- shape according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/08—Parts formed wholly or mainly of plastics materials

- F25D23/082—Strips

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B7/00—Special arrangements or measures in connection with doors or windows

- E06B7/16—Sealing arrangements on wings or parts co-operating with the wings

- E06B7/22—Sealing arrangements on wings or parts co-operating with the wings by means of elastic edgings, e.g. elastic rubber tubes; by means of resilient edgings, e.g. felt or plush strips, resilient metal strips

- E06B7/23—Plastic, sponge rubber, or like strips or tubes

- E06B7/2314—Plastic, sponge rubber, or like strips or tubes characterised by the material

Definitions

- European patent application Nr. 84201887 to the same owner discloses a structural shape made from a substantially rigid plastic material for refrigertaor cabinets, or the like, wherein the door of the cabinet comprises a counter-door, with said structural shape bearing a bellows-like acting gasket made from a substantially less rigid material, which accomplishes a tight sealing between the door and the cabinet, with the structural shape and the gasket being suitably coupled with each other, or manufactured as one single piece by means of the co-extrusion of said materials of different stiffness, so as to make it possible the gasket, which is less rigid, to be quickly detached from the structural shape, whichs is more rigid, along the region of their mutual connection.

- the structural shape is provided, on its side destined to be placed in a position opposite to the cabinet when in use, with two flat faces between which a groove is defined, which is suitable for receiving a spare gasket

- the structural shape is provided, along at least one of its sides, with an elastically yielding side flange, which acts as a spring in order to provide a snap-coupling with the counter-door, during the step of components assemblage.

- the object of the present invention is substantially an improvement of the structural shape as disclosed in said European patent application.

- a first purpose of the present invention is to improve in a decidedly advantageous way the structure of the spring which is used in order to fasten the structural shape to the counter-door.

- structural shapes known from the prior art totally made from a rigid material, it is of basic importance to obtain a very good elasticity of the spring, which must yield under the pressure applied by the counter-door during the assemblage step, and then elastically return - once that said pressure is relieved - to spring-like lock the edge of said counter-door.

- the present invention proposes a structural shape made from a substantially rigid material for refrigerator cabinets and the like, in which the door of the cabinet comprises a counter-door, with said structural shape bearing a tubular bellows-like gasket made from a substantially soft material, which accomplished a tight sealing between the door and the case of said cabinet, with the structural shape and the gasket being suitably coupled with each other, or manufactured as one single piece by means of the co-extrusion of said substantially rigid and said substantially soft materials, with said structural shape being provided with at least one side, elastically yielding flange which acts as a spring in order to accomplish a snap-coupling with the counter-door during the step of components assemblage, characterized in that in said side flange the fulcrum of the spring is constituted by an elbow-shaped insert of said substantially soft material fabricated inside the substantially rigid material the structural shape is made from.

- the structural shape is made, e.g., from rigid PVC; the gasket, the insert of the structural shape which acts as the fulcrum of the spring, and the other soft parts are made from soft, plasticized PVC.

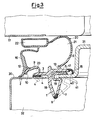

- a structural shape 1 has a complex cross-section, which on its side which, in its operating position ( Figure 3), is opposite to the case 17 of a refrigerator cabinet, has two faces 3 and 5 substantially planar an extending on mutually staggered planes.

- the face 5 and with a side tight-sealing stripe 15, and the face 3 is provided with a tight-sealing stripe 4, with both of said stripes being made from a soft material, co-extruded with the rigid material of the structural shape.

- the cross-section of the structural shape 1 takes an irregular-"T" shape due to the effect of a rib 18 which extends verifically in the direction opposite to the direction towards the cabinet 17, assuming a configuration slightly bent outwards.

- a side flange 7 extends in the direction of the face 5, with said side flange 7 being elastically yielding as a spring around a fulcrum 8, which is constituted by an elbow-shaped insert made from a soft material co-extruded with the rigid material which constitutes the structural shape.

- the side flange 7 ends with a groove-shaped configuration 19, having a "C"-shaped cross-section ending with a tooth 41 suitable for getting engaged with the counter-door.

- a flange 9 extends laterally, with said flange 9 being directed otwards and inclined towards the door of the cabinet.

- a flange 9 ends with a tooth 10.

- a groove 23 is thus defined.

- the structural shape 1 is made from a rigid plastic material, e.g., PVC, fabricated by extrusion, cut and welded in correspondence of the corners, so to form a frame which reproduces the perimetrical outline of the door of the refrigerator cabinet onto which it has to be applied.

- PVC polyvinyl styrene

- the gasket 20 has a tubular cross-section which defines a chamber 21 acting as a bellows, and a seat 22 suitable for receiving a bar of a magnetic material.

- the inner side wall, indicated by the reference numeral 6, of the gasket 20, is bonded to the face 5 of the structural shape in correspondence of the co-extrusion region 13, and the external side wall, indicated by the reference numeral 16, is bonded to the side flange 9 of the structural shape along a junction region 12.

- the configuration of the lower portion of the external side wall 16 of the gasket (a wall which can be suitably differentiated into two regions of different thickness, or of different stiffness, in order to give lateral stability to the same wall), is characteristic according to the herein exemplified form of practical embodiment of the present invention: in fact, the wall 16 extends downwards beyond the region 12 of junction with the structural shape, ending with a foot 2 which comes to rest against the counter-door when the parts are assembled in their operating position, so as render the structural shape 1 not any longer visible in such a position.

- the tight-sealing stripes 4 and 15 represent gaskets for containing the material foamed during the foaming operation which is carried out at the end of the assemblage step, in order to endow the door with heat-insulating characteristics.

- the stripe 15 is so made, as to provide a tight sealing, compensating for the distance between the face 5 of the structural shape and the counter-door 31, between which an air gap 40 is defined, in order to leave a free room for the elastic return of the tooth 41 of the side flange 7, and make easier the movement of engagement of said tooth on the counter-door.

- the tight-sealing stripe 15 serves to facilitate such a movement of the side flange 7, because it preserves the distance between the face 5 of the structural shape and the counter-door 31, leaving a free clearance for the tooth 41 to move inside the air gap 40.

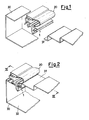

- the structural shape 1 bearing the gasket 18 is suitably prearranged in a frame shape, and in this form is it supplied to the manufacturer of the refrigerator cabinet; as Figures 1 and 2 schematically show, said manufacturer can assemble, in one operation only, the door 30 of steel sheet with the counter-door 31 of plastic material, by snapwise (spring-like) inserting the structural shape 1, which gets interlocked with the counter-door thanks to the action of the side flange 7, which behaves as a spring.

- the structural shape 1 is made move downwards, e.g , by means of a suitable mechanical arm, towards the counter-door 31, e.g , suitably positioned on a support which keeps it blocked.

- the arm of the side flange 7, in the initial position shown in Figure 1, and shown in chain in Figure 3 comes into contact with the edge of the counter-door 31, by being urged by the thrust applied by this latter yields and starts elastically bending inwards, as a spring, around he fulcrum 8, which is considerably flexible.

- the so-assembled structural shape 1 and the counter-door 31 are then leant on the door 30, and the whole is blocked by carrying out the foaming inside the air gap 32.

- FIG. 4 shows, when the soft co-extruded gasket 20 deteriorates due to wear, a rapid replacement can be carried out by tearing it off along the regions 12 and 13 of junction with the structural shape, and inserting a new gasket 33 inside the groove 23.

- a spare gasket of soft PVC is characterzied by a base 34 from whose external side end a vertical foot 35 extends. From the end of this latter foot, a wedge-shaped foot 11 of co-extruded rigid PVC, ending with a tooth 14, extends in the direction of the groove 23 of the structural shape.

- the gasket 33 is inserted laterally by causing the rigid wedge 11 to slide along the door 30, and pushing. In this way, under the thrust applied by the wedge, the flange 9 elastically opens wide by a short distance receiving the tooth 14, which, by stopping against the tooth 10 of the structural shape, fastens the spare gasket in its position.

- the advantages and the improvements which can be obtained with the structural shape according to the instant invention are many: first of all, the accomplishment of the spring which snapwise engages the counter-door - with the fulcrum being constituted by a co-extruded insert made from a soft material - makes it possible a high flexibility of said spring to be attained, with no need for its thickness to be reduced and measured with precision.

- the elbow-shaped insert makes it possible approximately the same flexibility of the spring to be obtained, which one would have in a structural shape entirely consisting of a rigid material in case the fulcrum thickness of this latter was approximately equal to half of the thickness of the insert according to the present invention.

- a further advantage of the present invention is accomplished, according to a form of practical embodiment thereof, thanks to the extended structure of the external side wall of the bellows of the gasket which - as seen - comes to rest against the counter-door, so as to render not any longer visible the flat face of the rigid structural shape.

- the rigid structural shape (see Figures 3 and 4) remains completely hidden when is assembled on the refrigerator, it can be suitably manufactured from a non-coloured material, with a strong reduction in the added costs, and in production scraps

- a further advantage derives from the operation of replacement of the original gasket with the spare gasket, which can be obtained thanks to the herein exemplified form of practical embodiment of the sructural shape.

- the insertion of the spare gasket takes place laterally in the purposely provided external groove with which the structural shape is provided.

- a groove remains hence in a free and accessible position, ideal for being able to receive, during the manufacturing step, a male element acting as a gauge for maintaining constant its shape, as well as its distance from the door plane.

- Such a feature is very useful in order to make it possible said groove - which must receive the rigid interlocking wedge the spare gasket is provided with - to be correctly and constantly dimensioned, preventing any risks that difficulties may be met when this latter is inserted, in case the groove is too narrow, or an excessive backlash exists, in case the groove is too wide.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Refrigerator Housings (AREA)

- Gasket Seals (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT2289587 | 1987-12-04 | ||

| IT22895/87A IT1223221B (it) | 1987-12-04 | 1987-12-04 | Profilo perfezionato in materiale sostanzialmente rigido, per mobili frigoriferi e simili, dotato di una guarnizione di tenuta in materiale sostanzialmente morbido |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0319087A2 true EP0319087A2 (de) | 1989-06-07 |

| EP0319087A3 EP0319087A3 (de) | 1990-04-25 |

Family

ID=11201641

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88202688A Withdrawn EP0319087A3 (de) | 1987-12-04 | 1988-11-25 | Profil für Kühlschränke und dergleichen, hergestellt aus einem im wesentlichen harten Werkstoff, versehen mit einer hermetischen Abdichtung aus einem im wesentlichen weichen Werkstoff |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0319087A3 (de) |

| JP (1) | JPH0528460Y2 (de) |

| DE (1) | DE319087T1 (de) |

| DK (1) | DK672888A (de) |

| IT (1) | IT1223221B (de) |

| YU (1) | YU47296B (de) |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0559267A3 (en) * | 1992-03-05 | 1993-12-08 | Ilpea Ind Spa | Gasket in particular for internal doors |

| WO1994006993A1 (en) * | 1992-09-22 | 1994-03-31 | Universal Technologies Pty., Ltd. | Panel with compressible edge member |

| DE29511425U1 (de) * | 1995-07-14 | 1995-11-09 | Liebherr-Hausgeräte GmbH, 88416 Ochsenhausen | Profil zur Dichtung einer Tür oder Klappe gegenüber einem Korpusteil |

| DE29619300U1 (de) * | 1996-11-07 | 1996-12-19 | REHAU AG + Co., 95111 Rehau | Profil zur Dichtung einer Tür |

| EP0713067A3 (de) * | 1994-11-18 | 1997-07-09 | Bs Electrodomesticos Sa | Dichtung für Kühlschrank |

| EP0905464A1 (de) * | 1997-09-30 | 1999-03-31 | Industrie Ilpea S.P.A. | Plastikprofil mit einem steifen verformbaren Unterteil für Kühlschränke |

| US5916076A (en) * | 1996-01-15 | 1999-06-29 | Industrie Ilpea S.P.A. | Plastics structural shape for refrigerator cabinets |

| EP0959312A3 (de) * | 1998-05-18 | 2000-02-02 | Liebherr-Hausgeräte Gmbh | Profil zur Dichtung einer Tür oder Klappe gegenüber einem Korpusteil |

| WO2000028267A1 (en) | 1998-11-05 | 2000-05-18 | Industrie Ilpea S.P.A. | Gasket for refrigerators with a profiled outer door |

| DE19907147A1 (de) * | 1999-02-19 | 2000-08-24 | Bsh Bosch Siemens Hausgeraete | Kältegerätetür |

| WO2002063227A1 (en) | 2001-02-02 | 2002-08-15 | Industrie Ilpea S.P.A. | Profile in particular for refrigerator furniture units |

| WO2002066912A1 (en) | 2001-02-02 | 2002-08-29 | Industrie Ilpea S.P.A. | Method and apparatus for assembling in an automated manner a sealing profile on an inner door for refrigerators |

| WO2002070971A1 (en) | 2001-03-07 | 2002-09-12 | Industrie Ilpea S.P.A. | Improved sealing assembly for refrigerator cabinets and the like with a profile made of plastic material |

| WO2003048662A1 (en) | 2001-12-04 | 2003-06-12 | Industrie Ilpea S.P.A. | Seal for refrigerator furniture units and the like, able in particular to compensate for manufacturing tolerances |

| WO2003052334A1 (en) | 2001-12-18 | 2003-06-26 | Rehau Ltd | An improved gasket |

| WO2006079650A1 (en) | 2005-01-28 | 2006-08-03 | Industrie Ilpea S.P.A. | Gasket for refrigerator cabinets with high heat insulation properties |

| WO2012076509A1 (en) | 2010-12-10 | 2012-06-14 | Industrie Ilpea S.P.A. | Magnetic gasket for refrigerator cabinets |

| US8240091B2 (en) | 2005-03-21 | 2012-08-14 | Industrie Ilpea S.P.A. | Double-seal gasket for refrigerator cabinets with high heat insulation properties |

| EP2843334A1 (de) | 2013-08-28 | 2015-03-04 | Electrolux Appliances Aktiebolag | Dichtung für wärmeisolierte Schränke |

| WO2017108189A1 (de) * | 2015-12-23 | 2017-06-29 | Rehau Ag + Co | Kühl- und/oder gefriergerät |

| WO2017108190A1 (de) * | 2015-12-23 | 2017-06-29 | Rehau Ag + Co | Profilanordnung, insbesondere für ein kühl- und/oder gefriergerät |

| US9841223B2 (en) | 2014-12-01 | 2017-12-12 | Samsung Electronics Co., Ltd. | Refrigerator |

| CN111713795A (zh) * | 2020-07-21 | 2020-09-29 | 北京英华高科技环保有限公司 | 一种新型防病毒智能头盔 |

| EP3569757B1 (de) | 2018-05-16 | 2022-08-03 | BSH Hausgeräte GmbH | Tür eines haushaltsgeräts mit einem dichtelement, das ein abschlussteil in der form eines ringabschnitts aufweist |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3378956A (en) * | 1965-02-23 | 1968-04-23 | Goodrich Co B F | Extruded sealing member |

| GB1240441A (en) * | 1970-01-02 | 1971-07-21 | Ford Motor Co | Weatherstrip |

| US4305230A (en) * | 1979-12-19 | 1981-12-15 | Jarrow Products, Inc. | Sealing retainer |

| DE3022381A1 (de) * | 1980-06-14 | 1981-12-24 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | Profildichtung |

| EP0146994B1 (de) * | 1983-12-23 | 1989-01-25 | ILPEA S.p.A. | Kunststoffprofil für Kühlschränke |

| FR2566723A1 (fr) * | 1984-06-27 | 1986-01-03 | Mesnel Sa Ets | Joint de carrosserie d'automobiles, originalement basculant et ainsi a double fonction |

| IT8522093V0 (it) * | 1985-06-05 | 1985-06-05 | Ilpea Spa | Profilo composto in materia plastica per mobili, specie frigoriferi, con porta e controporta fissata mediante viti e con guarnizione fissata al profilo. |

-

1987

- 1987-12-04 IT IT22895/87A patent/IT1223221B/it active

-

1988

- 1988-11-25 EP EP88202688A patent/EP0319087A3/de not_active Withdrawn

- 1988-11-25 DE DE198888202688T patent/DE319087T1/de active Pending

- 1988-12-02 DK DK672888A patent/DK672888A/da not_active Application Discontinuation

- 1988-12-02 YU YU219988A patent/YU47296B/sh unknown

- 1988-12-05 JP JP1988158453U patent/JPH0528460Y2/ja not_active Expired - Lifetime

Cited By (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0559267A3 (en) * | 1992-03-05 | 1993-12-08 | Ilpea Ind Spa | Gasket in particular for internal doors |

| WO1994006993A1 (en) * | 1992-09-22 | 1994-03-31 | Universal Technologies Pty., Ltd. | Panel with compressible edge member |

| EP0713067A3 (de) * | 1994-11-18 | 1997-07-09 | Bs Electrodomesticos Sa | Dichtung für Kühlschrank |

| DE29511425U1 (de) * | 1995-07-14 | 1995-11-09 | Liebherr-Hausgeräte GmbH, 88416 Ochsenhausen | Profil zur Dichtung einer Tür oder Klappe gegenüber einem Korpusteil |

| US5916076A (en) * | 1996-01-15 | 1999-06-29 | Industrie Ilpea S.P.A. | Plastics structural shape for refrigerator cabinets |

| DE29619300U1 (de) * | 1996-11-07 | 1996-12-19 | REHAU AG + Co., 95111 Rehau | Profil zur Dichtung einer Tür |

| RU2210704C2 (ru) * | 1997-09-30 | 2003-08-20 | Индустрие Ильпеа С.п.А. | Пластмассовый профиль с гофрированной прокладкой |

| EP0905464A1 (de) * | 1997-09-30 | 1999-03-31 | Industrie Ilpea S.P.A. | Plastikprofil mit einem steifen verformbaren Unterteil für Kühlschränke |

| US6058657A (en) * | 1997-09-30 | 2000-05-09 | Industrie Ilpea S.P.A. | Plastic material profile for refrigerators having a rigid deformable base |

| EP0959312A3 (de) * | 1998-05-18 | 2000-02-02 | Liebherr-Hausgeräte Gmbh | Profil zur Dichtung einer Tür oder Klappe gegenüber einem Korpusteil |

| WO2000028267A1 (en) | 1998-11-05 | 2000-05-18 | Industrie Ilpea S.P.A. | Gasket for refrigerators with a profiled outer door |

| DE19907147A1 (de) * | 1999-02-19 | 2000-08-24 | Bsh Bosch Siemens Hausgeraete | Kältegerätetür |

| WO2002066912A1 (en) | 2001-02-02 | 2002-08-29 | Industrie Ilpea S.P.A. | Method and apparatus for assembling in an automated manner a sealing profile on an inner door for refrigerators |

| WO2002063227A1 (en) | 2001-02-02 | 2002-08-15 | Industrie Ilpea S.P.A. | Profile in particular for refrigerator furniture units |

| US6785948B2 (en) | 2001-02-02 | 2004-09-07 | Industrie Ilpea S.P.A. | Method and apparatus for assembling in an automated manner a sealing profile on an inner door for refrigerators |

| US7080485B2 (en) | 2001-02-02 | 2006-07-25 | Industrie Ilpea S.P.A. | Gasket for refrigerator furniture units |

| WO2002070971A1 (en) | 2001-03-07 | 2002-09-12 | Industrie Ilpea S.P.A. | Improved sealing assembly for refrigerator cabinets and the like with a profile made of plastic material |

| US7219471B2 (en) * | 2001-03-07 | 2007-05-22 | Industrie Ilpea S.P.A. | Refrigerator cabinet sealing assembly having a bellows-seal gasket |

| WO2003048662A1 (en) | 2001-12-04 | 2003-06-12 | Industrie Ilpea S.P.A. | Seal for refrigerator furniture units and the like, able in particular to compensate for manufacturing tolerances |

| WO2003052334A1 (en) | 2001-12-18 | 2003-06-26 | Rehau Ltd | An improved gasket |

| WO2006079650A1 (en) | 2005-01-28 | 2006-08-03 | Industrie Ilpea S.P.A. | Gasket for refrigerator cabinets with high heat insulation properties |

| US8104228B2 (en) | 2005-01-28 | 2012-01-31 | Industrie Ilpea S.P.A. | Gasket for refrigerator cabinets with high heat insulation properties |

| US8240091B2 (en) | 2005-03-21 | 2012-08-14 | Industrie Ilpea S.P.A. | Double-seal gasket for refrigerator cabinets with high heat insulation properties |

| WO2012076509A1 (en) | 2010-12-10 | 2012-06-14 | Industrie Ilpea S.P.A. | Magnetic gasket for refrigerator cabinets |

| US9121635B2 (en) | 2010-12-10 | 2015-09-01 | Industrie Ilpea S.P.A. | Magnetic gasket for refrigerator cabinets |

| EP2843334A1 (de) | 2013-08-28 | 2015-03-04 | Electrolux Appliances Aktiebolag | Dichtung für wärmeisolierte Schränke |

| US9841223B2 (en) | 2014-12-01 | 2017-12-12 | Samsung Electronics Co., Ltd. | Refrigerator |

| WO2017108189A1 (de) * | 2015-12-23 | 2017-06-29 | Rehau Ag + Co | Kühl- und/oder gefriergerät |

| WO2017108190A1 (de) * | 2015-12-23 | 2017-06-29 | Rehau Ag + Co | Profilanordnung, insbesondere für ein kühl- und/oder gefriergerät |

| US11098525B2 (en) | 2015-12-23 | 2021-08-24 | Rehau Ag + Co. | Profiled arrangement, particularly for a refrigerator and/or freezer device |

| EP3569757B1 (de) | 2018-05-16 | 2022-08-03 | BSH Hausgeräte GmbH | Tür eines haushaltsgeräts mit einem dichtelement, das ein abschlussteil in der form eines ringabschnitts aufweist |

| CN111713795A (zh) * | 2020-07-21 | 2020-09-29 | 北京英华高科技环保有限公司 | 一种新型防病毒智能头盔 |

Also Published As

| Publication number | Publication date |

|---|---|

| YU47296B (sh) | 1995-01-31 |

| IT1223221B (it) | 1990-09-19 |

| IT8722895A0 (it) | 1987-12-04 |

| DE319087T1 (de) | 1989-12-07 |

| JPH0528460Y2 (de) | 1993-07-21 |

| YU219988A (sh) | 1992-07-20 |

| EP0319087A3 (de) | 1990-04-25 |

| JPH0191881U (de) | 1989-06-16 |

| DK672888D0 (da) | 1988-12-02 |

| DK672888A (da) | 1989-06-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0319087A2 (de) | Profil für Kühlschränke und dergleichen, hergestellt aus einem im wesentlichen harten Werkstoff, versehen mit einer hermetischen Abdichtung aus einem im wesentlichen weichen Werkstoff | |

| US4411401A (en) | Headrail mounting bracket | |

| US3411247A (en) | Refrigerator door frame | |

| US5584526A (en) | Fixedly installable window pane for motor vehicles | |

| US7219471B2 (en) | Refrigerator cabinet sealing assembly having a bellows-seal gasket | |

| US5743047A (en) | Seal for simultaneously sealing a door window pane and a door opening on a motor vehicle | |

| CA1051485A (en) | Trim molding assembly | |

| US4700509A (en) | Sealing gasket between a door and its related shoulder on a cabinet, in particular of a refrigerator | |

| US5916076A (en) | Plastics structural shape for refrigerator cabinets | |

| ITMI982406A1 (it) | Guarnizione per frogoriferi con controporta sagomata. | |

| US3323256A (en) | Sealing gasket of combined rigid and flexible extrusions | |

| US3333364A (en) | Lined window guide channel | |

| US5761860A (en) | Panel mounting structure | |

| PL187051B1 (pl) | Uszczelka mająca postać kształtownika, zwłaszcza z tworzywa sztucznego | |

| EP0416899A1 (de) | Streifenanordnung für Kraftfahrzeuge | |

| US5890784A (en) | Drawer slide | |

| UA78200C2 (en) | Improved profile, in particular for refrigerator furniture units | |

| US4512045A (en) | Structural assembly, for shower partition or the like | |

| KR0167594B1 (ko) | 창 또는 문의 프레임에 유리판 또는 충전 플레이트용 지지스트립을 고정시키기 위한 플라스틱 홀더 | |

| US2549315A (en) | Windshield mounting | |

| US2500297A (en) | Weather strip for bus or car window construction | |

| US2983969A (en) | Building construction | |

| US3359686A (en) | Window glass channel | |

| US2757422A (en) | Door jamb sealing strip | |

| JPH0733950B2 (ja) | 冷蔵庫の扉 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| DET | De: translation of patent claims | ||

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900917 |

|

| 17Q | First examination report despatched |

Effective date: 19910425 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19920505 |