EP0249908A2 - Fat liquoring agent based on sulphosuccinic-acid monoamide - Google Patents

Fat liquoring agent based on sulphosuccinic-acid monoamide Download PDFInfo

- Publication number

- EP0249908A2 EP0249908A2 EP87108533A EP87108533A EP0249908A2 EP 0249908 A2 EP0249908 A2 EP 0249908A2 EP 87108533 A EP87108533 A EP 87108533A EP 87108533 A EP87108533 A EP 87108533A EP 0249908 A2 EP0249908 A2 EP 0249908A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- sulfosuccinic acid

- fatliquor

- leather

- furs

- acid monoamides

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C14—SKINS; HIDES; PELTS; LEATHER

- C14C—CHEMICAL TREATMENT OF HIDES, SKINS OR LEATHER, e.g. TANNING, IMPREGNATING, FINISHING; APPARATUS THEREFOR; COMPOSITIONS FOR TANNING

- C14C9/00—Impregnating leather for preserving, waterproofing, making resistant to heat or similar purposes

- C14C9/02—Impregnating leather for preserving, waterproofing, making resistant to heat or similar purposes using fatty or oily materials, e.g. fat liquoring

Definitions

- the invention relates to fatliquors based on sulfosuccinic acid monoamides and the use thereof for the hydrophobization of leather and furs and to a process for the hydrophobization of leather and furs.

- DE-OS 16 69 347 describes a process for greasing leather using sulfosuccinic acid esters which are emulsifiable in water, but no leather waterproofing effects are achieved.

- the invention therefore relates to fatliquors based on sulfosuccinic acid monoamides for the hydrophobization of leather and furs.

- Preferred fatliquoring agents contain sulfosuccinic acid monoamides in the form of their alkali and / or ammonium salts.

- Salts of sulfosuccinic acid monoamides with one or two 12-24 C atoms containing, preferably with one or two 14-22 C atoms containing, straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components are particularly preferred.

- the sulfosuccinic acid monoamides are prepared in a manner known per se by reacting equimolar amounts of maleic anhydride and the corresponding primary and / or secondary alkylamines at about 50 to 65 ° C. Following a post-reaction time at about 90 to 100 ° C., which is dependent on the amounts used, the reaction mixture is mixed with a maleic anhydride to an approximately equimolar amount of alkali metal and / or ammonium Hydrogen sulfites or alkali and / or ammonium sulfites reacted at about 80 to 100 ° C (see for example in Lindner: "Surfactants, Textile Aids, Washing Raw Materials", Vol. II, p. 755,ticianl.

- the primary and / or secondary alkylamines used have 12-14 carbon atoms, preferably 14-22 carbon atoms in the straight-chain and / or branched-chain, saturated and / or unsaturated alkyl radicals. Tallow and / or behenylamine, for example, are preferably used.

- the fatliquoring agents according to the invention can contain sulfosuccinic acid monoamides as the only component.

- the fatliquoring agents according to the invention preferably contain, as further components, known hydrophobizing and / or impregnating fatliquoring agents and / or neutral oils.

- Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in straight and / or branched, saturated and / or unsaturated alkyl radical, polycarboxylic acid partial esters, for example citric acid partial alkyl esters with 16-24 C atoms in the straight and / or branched chain, saturated and / or unsaturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 C. -Atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl chains of the fatty acid component.

- Animal oils and / or vegetable fats and oils such as claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters, for example, are particularly suitable as neutral oils which are contained in fatliquoring agents based on sulfosuccinic acid monoamides chlorinated tallow fatty acid methyl ester, long-chain hydrocarbons and / or chlorinated paraffins.

- fatliquors based on sulfosuccinic acid monoamides can also contain fatty substances and mixtures thereof produced by sulfating, sulfonating, sulfitating, sulfochlorinating or phosphatizing fats and / or oils.

- the proportion of these fatty substances in fat-releasing agents containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance.

- the proportion of sulfosuccinic acid monoamides containing one or two 12 to 24 carbon atoms, preferably 14 to 22 carbon atoms containing straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, based in each case on the active substance.

- the fatliquoring agents according to the invention are present, for example, in the form of pastes, aqueous emulsions or microemulsions.

- leather and furs are treated in particular with fatliquoring agents in the form of their alkali and / or ammonium salts.

- salts of the sulfosuccinic acid monoamides which contain one or two 12-24 C atoms, preferably one or two 14-22 C atoms, straight and / or branched chain, saturated and / or unsaturated alkyl chains in the amine components is special prefers.

- leather and furs can be greased with sulfosuccinic acid monoamides alone.

- a preferred embodiment is the treatment of leather and furs with fatliquoring agents which contain the sulfosuccinic acid monoamides according to the invention in combination with hydrophobizing and / or impregnating fatliquoring agents and / or neutral oils.

- Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl radicals, polycarboxylic acid partial esters, for example partial citric acid partial alkyl esters with 12 to 24 carbon atoms in the straight and / or branched, saturated and / or unsaturated saturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 carbon atoms in the straight and / or branched chain, saturated and / or unsaturated fatty acid residues.

- polycarboxylic acid partial esters for example partial citric acid partial alkyl esters with 12 to 24 carbon

- Animal and / or vegetable fats and oils for example claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters, for example chlorinated tallow fatty acid methyl ester, and long-chain hydrocarbons are particularly suitable as neutral oil components in the fatliquoring agents of the process according to the invention and / or chlorinated paraffins.

- the fatliquoring agents of the process according to the invention can contain fat substances and mixtures thereof produced by sulfation, sulfonation, sulfitination, sulfochlorination or phosphatization of fats and / or oils.

- the proportion of these fatty substances in fatty acids containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance.

- the proportion of sulfosuccinic acid monoamides is between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, in each case based on active substance.

- the lubricants suitable for the process according to the invention are present, for example, in the form of pastes, aqueous emulsions or microemulsions.

- colored leather and furs are optionally dipped in an aqueous liquor at about 35 to 70 ° C., preferably at about 40 to 55 ° C., with degreasing agents based on sulfosuccinic acid greased monoamides.

- degreasing agents based on sulfosuccinic acid greased monoamides.

- the pH of the liquor liquor is between about 4 and 8, preferably between about 4 and 6.

- the licker lubrication can be followed by a treatment with a polyacrylate tanning agent known per se, before a pH between about 3.8 and with acid, for example formic acids 4.2 is set. Thereafter, the fatliquoring agents based on sulfosuccinic acid monoamides are fixed in a known manner with polyvalent metal salts, in particular with aluminum, chromium, titanium and / or zirconium salts in aqueous form. The amounts of salts used are between about one and ten percent by weight based on the weight of the fold or skin.

- leather and furs can be treated with fatliquoring agents based on sulfosuccinic acid monoamides by adding all the fatliquoring constituents together to the liquor.

- fatliquoring agents based on sulfosuccinic acid monoamides

- a more or less pronounced water resistance is achieved.

- Fatting agents preferably used contain sulfosuccinic acid monoamides in the form of their alkali and / or ammonium salts.

- Fatting agents which contain salts of sulfosuccinic acid monoamides with one or two 12 to 24 C atoms, preferably with one or two 14 to 22 C atoms containing straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components are particularly preferred used.

- fatliquoring agents which contain sulfosuccinic acid monoamides as the only component can be used.

- fatliquoring agents are preferably used which, in addition to sulfosuccinic acid monoamides, contain hydrophobing and / or impregnating fatliquoring agents and / or neutral oils as further components.

- Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl radicals, polycarboxylic acid partial esters such as partial citric acid partial alkyl esters with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 C. -Atoms in the straight and / or branched chain, saturated and / or unsaturated fatty acid residues.

- Suitable neutral oils are in particular animal and / or vegetable fats and oils, for example claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters such as chlorinated tallow fatty acid methyl ester, long-chain hydrocarbons and / or chlorinated paraffins.

- the fatliquors to be used according to the invention may contain, as further constituents, fat substances and mixtures thereof produced by sulfation, sulfonation, sulfitination, sulfochlorination or phosphatization of fats and / or oils.

- the proportion of these fatty substances in fat-releasing agents containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance.

- the proportion of sulfosuccinic acid monoamides is between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, based in each case on the active substance.

- the fatliquors to be used according to the invention are, for example, in the form of pastes, aqueous emulsions or microemulsions.

- the fatliquoring agents according to the invention are well absorbed by leather and furs and are distributed very evenly over the entire leather cross section. Furthermore, the leather and furs have a pronounced waterproofness. Compared to leather and furs, which are greased with fatty agents containing sulfosuccinic acid esters, leather and furs, which have been treated with the greasing agents according to the invention, have a significantly delayed passage of water and a reduced water absorption. The coloration of the leather and furs treated with the fatliquoring agents according to the invention is more uniform and brilliant than that of leather and fur that has been treated with fatliquoring agents containing sulfosuccinic acid monoesters.

- JZ iodine number

- AZ amine number

- AS active substance

- min. Minutes

- h hours.

- the indication "%" means “percent by weight”.

- C chain of the underlying behenylamine 15% C16, 31% C18, 10% C20, 40% C22.

- the corresponding monoamide was prepared from 98.1 g (1 mol) of maleic anhydride and 270 g (1 mol) of tallow amine. The monoamide was then at 20 to 40 ° C in an aqueous solution containing ammonium bisulfite, prepared by introducing 64 g (1 mol) of sulfur dioxide into a solution of 700 g of water and 200 g of 20% ammonia solution (about 1.1 mol of ammonia) at 20 ° C. After stirring for one hour at 40 ° C. and for two hours at 80 ° C., a well flowing dispersion with about 35% by weight of active substance was obtained.

- Cowhide leather Chrome-tanned cowhide wet blue - pH 3.8, fold thickness 1.8 mm - is processed in the usual way, but without the addition of anionic surfactants, as follows: Then a fatliquoring agent AF is added to the liquor.

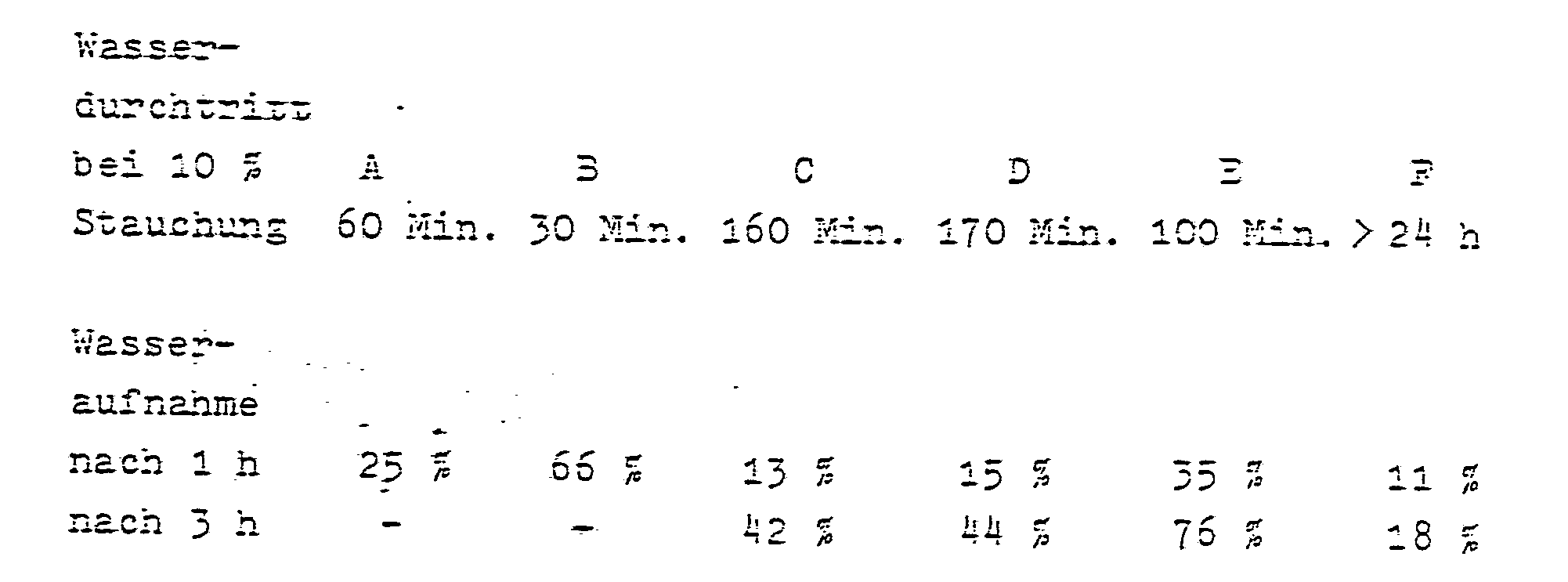

- leathers A and C Compared to leathers B and E, leathers A and C had a significantly delayed water penetration and reduced water absorption.

- the coloring of leather A and C was more uniform and brilliant compared to leather B and E.

- leathers A, C, D and F were rated 5 and leathers B and E were rated 4 on a 6-point rating scale. In this level 1 means bad coloring and level 6 excellent coloring.

Landscapes

- Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Treatment And Processing Of Natural Fur Or Leather (AREA)

- Materials Applied To Surfaces To Minimize Adherence Of Mist Or Water (AREA)

Abstract

Fettungsmittel auf Basis von Sulfobernsteinsäuremonoamiden eignen sich zur Hydrophobierung von Leder und Pelzen. Lubricants based on sulfosuccinic acid monoamides are suitable for waterproofing leather and furs.

Description

Die Erfindung betrifft Fettungsmittel auf Basis von Sulfobernsteinsäuremonoamiden und Verwendung derselben zur Hydrophobierung von Leder und Pelzen sowie ein Verfahren zu Hydrophobierung von Leder und Pelzen.The invention relates to fatliquors based on sulfosuccinic acid monoamides and the use thereof for the hydrophobization of leather and furs and to a process for the hydrophobization of leather and furs.

In der DE-OS 16 69 347 wird ein Verfahren zum Fetten von Leder unter Verwendung von in Wasser emulgierbaren Sulfobernsteinsäureestern beschrieben, wobei jedoch keine Wasserdichteeffekte der Leder erzielt werden.DE-OS 16 69 347 describes a process for greasing leather using sulfosuccinic acid esters which are emulsifiable in water, but no leather waterproofing effects are achieved.

Des weiteren sind aus DE-OS 34 19 405 Fettungsmittel zur Herstellung von Leder und Pelzen bekannt, die Sulfobernsteinsäureester in Kombination mit bestimmten anionischen und/oder nichtionischen Emulgatoren enthalten. Auch mit diesen Fettungsmitteln, die in der Gerbflotte eingesetzt werden, wird eine Hydrophobierung der Leder und Pelze nicht erzielt.Furthermore, from DE-OS 34 19 405 fatliquoring agents for the production of leather and furs are known which contain sulfosuccinic acid esters in combination with certain anionic and / or nonionic emulsifiers. Even with these greasing agents, which are used in the tanning liquor, the leather and furs are not rendered hydrophobic.

In der älteren deutschen Patentanmeldung P 35 07 241.5 wird ein Verfahren zur Herstellung wasserdichter Leder und Pelze unter Verwendung von imprägnierenden und/oder hydrophobierenden Fettungsmitteln mit einem Gehalt an Sulfobernsteinsäuremonoestersalzen mit C12-24-Fettresten beschrieben. Mit diesen Fettungsmitteln werden Leder und Pelze im Anschluß an die Nachgerbung in wäßriger Flotte behandelt und anschließend nach Absäuerung die Fettungs mittel durch Zugabe von Chrom- und/oder Aluminiumsalzen fixiert. Die erhaltenen Leder und Pelze zeichnen sich durch akzeptable Wasserdichte-Effekte aus.In the older German patent application P 35 07 241.5, a process for the production of waterproof leather and furs using impregnating and / or hydrophobic greasing agents containing sulfosuccinic acid monoester salts with C 12-24 fat residues is described. These greasing agents are used to treat leather and furs after retanning in an aqueous liquor and then, after acidification, the greasing medium fixed by adding chrome and / or aluminum salts. The leather and furs obtained are characterized by acceptable waterproof effects.

Es wurde nun die überraschende Feststellung gemacht, daß Leder und Pelze, die mit den erfindungsgemäßen Fettungsmitteln auf Basis von Sulfobernsteinsäuremonoamiden behandelt wurden, gegenüber dem oben genannten Stand der Technik deutlich verbesserte Hydrophierungseigenschaften besitzen.It has now been made the surprising finding that leather and furs which have been treated with the fatliquoring agents according to the invention based on sulfosuccinic acid monoamides have significantly improved hydrophilization properties compared to the prior art mentioned above.

Gegenstand der Erfindung sind daher Fettungsmittel auf Basis von Sulfobernsteinsäuremonoamiden zur Hydrophobierung von Leder und Pelzen.The invention therefore relates to fatliquors based on sulfosuccinic acid monoamides for the hydrophobization of leather and furs.

Bevorzugte Fettungsmittel enthalten Sulfobernsteinsäuremonoamide in Form ihrer Alkali- und/oder Ammoniumsalze.Preferred fatliquoring agents contain sulfosuccinic acid monoamides in the form of their alkali and / or ammonium salts.

Besonders bevorzugt werden Salze der Sulfobernsteinsäuremonoamide mit ein oder zwei 12 - 24 C-Atome enthaltenden, vorzugsweise mit ein oder zwei 14 - 22 C-Atome enthaltenden gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Alkylresten in den Aminkomponenten.Salts of sulfosuccinic acid monoamides with one or two 12-24 C atoms containing, preferably with one or two 14-22 C atoms containing, straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components are particularly preferred.

Die Sulfobernsteinsäuremonoamide werden in an sich bekannter Weise hergestellt, indem äquimolare Mengen an Maleinsäureanhydrid und den entsprechenden primären und/oder sekundären Alkylaminen bei etwa 50 bis 65 °C zur Reaktion gebracht werden. Im Anschluß an eine von den Einsatzmengen abhängige Nachreaktionszeit bei etwa 90 bis 100 °C wird das Reaktionsgemisch mit einer Maleinsäureanhydrid annähernd äquimolaren Menge an Alkali- und/oder Ammonium hydrogensulfiten oder Alkali- und/oder Ammoniumsulfiten bei etwa 80 bis 100 °C umgesetzt (siehe beispielsweise in Lindner: "Tenside, Textilhilfsmittel, Waschrohstoffe", Bd. II, S. 755, Wissenschaftl. Verlagsges. mbH Stuttgart 1964). Die eingesetzten primären und/oder sekundären Alkylamine besitzen 12 - 14 C-Atome, vorzugsweise 14 - 22 C-Atome in den gerad- und/oder verzweigtkettigen, gesättigen und/oder ungesättigten Alkylresten. Bevorzugt kommen beispielsweise Talg- und/oder Behenylamin zum Einsatz.The sulfosuccinic acid monoamides are prepared in a manner known per se by reacting equimolar amounts of maleic anhydride and the corresponding primary and / or secondary alkylamines at about 50 to 65 ° C. Following a post-reaction time at about 90 to 100 ° C., which is dependent on the amounts used, the reaction mixture is mixed with a maleic anhydride to an approximately equimolar amount of alkali metal and / or ammonium Hydrogen sulfites or alkali and / or ammonium sulfites reacted at about 80 to 100 ° C (see for example in Lindner: "Surfactants, Textile Aids, Washing Raw Materials", Vol. II, p. 755, Wissenschaftl. Verlagsges. mbH Stuttgart 1964). The primary and / or secondary alkylamines used have 12-14 carbon atoms, preferably 14-22 carbon atoms in the straight-chain and / or branched-chain, saturated and / or unsaturated alkyl radicals. Tallow and / or behenylamine, for example, are preferably used.

Die erfindungsgemäßen Fettungsmittel können Sulfobernsteinsäuremonoamide als einzige Komponente enthalten.The fatliquoring agents according to the invention can contain sulfosuccinic acid monoamides as the only component.

Vorzugsweise enthalten die erfindungsgemäßen Fettungsmittel jedoch als weitere Komponenten an sich bekannte hydrophobierende und/oder imprägnierende Fettungsmittel und/oder Neutralöle.However, the fatliquoring agents according to the invention preferably contain, as further components, known hydrophobizing and / or impregnating fatliquoring agents and / or neutral oils.

Geeignete hydrophobierende und/oder imprägnierende Fettungsmittel sind beispielsweise oxidierte und/oder sulfoxidierte C16-30-Kohlenwasserstoffe und/oder C32-40-Wachse, Alkylphosphate mit 12 bis 24 C-Atomen im gerad- und/oder verzweigtkettigten, gesättigten und/oder ungesättigten Alkylrest, Polycarbonsäurepartialester, beispielsweise Citronensäurepartialalkylester mit 16 - 24 C-Atomen in den gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Veresterungskomponenten und/oder Partialester von Polyalkoholen beispielsweise Sorbitan-, Glycerin- und/oder Pentaerythritfettsäureester mit 12 bis 24 C-Atomen in den gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Alkylketten der Fettsäurekomponente.Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in straight and / or branched, saturated and / or unsaturated alkyl radical, polycarboxylic acid partial esters, for example citric acid partial alkyl esters with 16-24 C atoms in the straight and / or branched chain, saturated and / or unsaturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 C. -Atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl chains of the fatty acid component.

Als Neutralöle, die in Fettungsmitteln auf Basis von Sulfobernsteinsäuremonoamiden enthalten sind, eignen sich insbesondere tierische und/oder pflanzliche Fette und Öle wie Klauenöl, Fischöl, Talge, Sojaöl, Sonnenblumenöl, Palmöl und/oder Kokosöl, chlorierte und/oder nicht chlorierte Fettsäuremethylester, beispielsweise chlorierter Talgfettsäuremthylester, langkettige Kohlenwasserstoffe und/oder Chlorparaffine.Animal oils and / or vegetable fats and oils such as claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters, for example, are particularly suitable as neutral oils which are contained in fatliquoring agents based on sulfosuccinic acid monoamides chlorinated tallow fatty acid methyl ester, long-chain hydrocarbons and / or chlorinated paraffins.

Im Rahmen der Erfindung können Fettungsmittel auf Basis von Sulfobernsteinsäuremonoamiden auch durch Sulfatierung, Sulfonierung, Sulfitierung, Sulfochlorierung oder Phosphatierung von Fetten und/oder Ölen hergestellte Fettstoffe sowie deren Mischungen enthalten. Der Anteil dieser Fettstoffe in Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln kann bis zu etwa 40 Gew.-% - bezogen auf Aktivsubstanz - betragen. Leder und Pelze, die mit solchen Fettungsmittelgemischen behandelt werden, zeichnen sich im Vergleich zu Leder und Pelzen, die mit Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln ohne sulfatierte, sulfonierte, sulfitierte, sulfochlorierte und/oder phosphatierte Fettstoffe behandelt werden, durch gegebenenfalls weniger gute Hydrophobierungseigenschaften, jedoch durch sehr hohe Weichheit aus.In the context of the invention, fatliquors based on sulfosuccinic acid monoamides can also contain fatty substances and mixtures thereof produced by sulfating, sulfonating, sulfitating, sulfochlorinating or phosphatizing fats and / or oils. The proportion of these fatty substances in fat-releasing agents containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance. Leather and furs, which are treated with such fatliquor mixtures, are distinguished by possibly less good hydrophobing properties in comparison to leather and fur, which are treated with fatliquors containing sulfosuccinic acid monoamide without sulfated, sulfonated, sulfited, sulfochlorinated and / or phosphated fat substances very high softness.

In den erfindungsgemäßen Fettungsmitteln, die neben Sulfobernsteinsäuremonoamiden weitere Komponenten enthalten (Fettungsmittelgemische) liegt der Anteil an Sulfobernsteinsäuremonoamiden mit ein oder zwei 12 bis 24 C-Atomen enthaltenden, vorzugsweise 14 bis 22 C-Atomen enthaltenden gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Alkylresten in den Aminkomponenten zwischen etwa 10 und etwa 60 Gewichtsprozent, vorzugsweise zwischen etwa 20 und etwa 50 Gewichtsprozent, jeweils bezogen auf Aktivsubstanz.In the fatliquoring agents according to the invention, which contain further components in addition to sulfosuccinic acid monoamides (fatliquor mixtures), the proportion of sulfosuccinic acid monoamides containing one or two 12 to 24 carbon atoms, preferably 14 to 22 carbon atoms containing straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, based in each case on the active substance.

Die erfindungsgemäßen Fettungsmittel liegen beispielsweise in Form von Pasten, wäßrigen Emulsionen oder Mikroemulsionen vor.The fatliquoring agents according to the invention are present, for example, in the form of pastes, aqueous emulsions or microemulsions.

Gegenstand der Erfindung ist ferner ein Verfahren zur Hydrophobierung von Leder und Pelzen, das dadurch gekennzeichnet ist, daß gegebenenfalls gefärbte Leder und Pelze

- a) mit Fettungsmitteln auf Basis von Sulfobernsteinsäuremonoamiden behandelt

und anschließend folgende an sich bekannte Maßnahmen durchgeführt werden: - b) gewünschtenfalls Behandlung mit Polyacrylat-Gerbstoffen,

- c) Absäuerung bis zu einem pH-Wert zwischen etwa 3,8 und etwa 4,2 und

- d) Fixierung der Fettungsmittel zu a) durch Zugabe polyvalenter Metallsalze.

- a) treated with fatliquors based on sulfosuccinic acid monoamides

and then the following known measures are carried out: - b) if desired, treatment with polyacrylate tanning agents,

- c) acidification to a pH between about 3.8 and about 4.2 and

- d) fixation of the fatliquoring agent to a) by adding polyvalent metal salts.

Erfindungsgemäß werden Leder und Pelze insbesondere mit Fettungsmitteln in Form ihrer Alkali- und/oder Ammoniumsalze behandelt.According to the invention, leather and furs are treated in particular with fatliquoring agents in the form of their alkali and / or ammonium salts.

Die Behandlung mit Salzen der Sulfobernsteinsäuremonoamide, die ein oder zwei 12 - 24 C-Atome enthaltende, vorzugsweise ein oder zwei 14 - 22 C-Atome enthaltende gerad- und/oder verzweigtkettige, gesättigte und/oder ungesättigte Alkylketten in den Aminkomponenten enthalten, ist besonders bevorzugt.The treatment with salts of the sulfosuccinic acid monoamides which contain one or two 12-24 C atoms, preferably one or two 14-22 C atoms, straight and / or branched chain, saturated and / or unsaturated alkyl chains in the amine components is special prefers.

Nach dem erfindungsgemäßen Verfahren können Leder und Pelze mit Sulfobernsteinsäuremonoamiden alleine gefettet werden.In the process according to the invention, leather and furs can be greased with sulfosuccinic acid monoamides alone.

Eine bevorzugte Ausführungsform stellt jedoch die Behandlung der Leder und Pelze mit Fettungsmitteln dar, die die erfindungsgemäßen Sulfobernsteinsäuremonoamide in Kombination mit hydrophobierenden und/oder imprägnierenden Fettungsmitteln und/oder Neutralölen enthalten.A preferred embodiment, however, is the treatment of leather and furs with fatliquoring agents which contain the sulfosuccinic acid monoamides according to the invention in combination with hydrophobizing and / or impregnating fatliquoring agents and / or neutral oils.

Geeignete hydrophobierende und/oder imprägnierende Fettungsmittel sind beispielsweise oxidierte und/oder sulfoxidierte C16-30-Kohlenwasserstoffe und/oder C32-40-Wachse, Alkylphosphate mit 12 bis 24 C-Atomen in den gerad- und/oder verzweigtkettigen,gesättigten und/oder ungesättigten Alkylresten, Polycarbonsäurepartialester, beispielsweise Citronensäurepartialalkylester mit 12 bis 24 Kohlenstoffatomen in den gerad- und/oder verzweigtkettigten,gesättigten und/oder unge sättigten Veresterungskomponenten und/oder Partialester von Polyalkoholen beispielsweise Sorbitan-, Glycerin- und/oder Pentaerythritfettsäureester mit 12 bis 24 Kohlenstoffatomen in den gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Fettsäureresten.Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl radicals, polycarboxylic acid partial esters, for example partial citric acid partial alkyl esters with 12 to 24 carbon atoms in the straight and / or branched, saturated and / or unsaturated saturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 carbon atoms in the straight and / or branched chain, saturated and / or unsaturated fatty acid residues.

Als Neutralölkomponente in den Fettungsmitteln des erfindungsgemäßen Verfahrens eignen sich insbesondere tierische und/oder pflanzliche Fette und Öle beispielsweise Klauenöl, Fischöl, Talge, Sojaöl, Sonnenblumenöl, Palmöl und/oder Kokosöl, chlorierte und/oder nicht chlorierte Fettsäuremethylester, beispielsweise chlorierter Talgfettsäuremethylester, langkettige Kohlenwasserstoffe und/oder Chlorparaffine.Animal and / or vegetable fats and oils, for example claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters, for example chlorinated tallow fatty acid methyl ester, and long-chain hydrocarbons are particularly suitable as neutral oil components in the fatliquoring agents of the process according to the invention and / or chlorinated paraffins.

Als weitere Bestandteile können die Fettungsmittel des erfindungsgemäßen Verfahrens durch Sulfatierung, Sulfonierung, Sulfitierung, Sulfochlorierung oder Phosphatierung von Fetten und/oder Ölen hergestellte Fettstoffe sowie deren Mischungen enthalten. Der Anteil dieser Fettstoffe kann in Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln bis zu etwa 40 Gew.-% - bezogen auf Aktivsubstanz - betragen. Leder und Pelze, die mit solchen Fettungsmittelgemischen behandelt werden, zeichnen sich im Vergleich zu Leder und Pelzen, die mit Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln ohne sulfatierte, sulfonierte, sulfitierte, sulfochlorierte und/oder phosphatierte Fettstoffe behandelt werden, durch gegebenenfalls weniger gute Hydrophobierungseigenschaften, jedoch durch sehr hohe Weichheit aus.As further constituents, the fatliquoring agents of the process according to the invention can contain fat substances and mixtures thereof produced by sulfation, sulfonation, sulfitination, sulfochlorination or phosphatization of fats and / or oils. The proportion of these fatty substances in fatty acids containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance. Leather and furs, which are treated with such fatliquor mixtures, are distinguished by possibly less good hydrophobing properties in comparison to leather and fur, which are treated with fatliquors containing sulfosuccinic acid monoamide without sulfated, sulfonated, sulfited, sulfochlorinated and / or phosphated fat substances very high softness.

In den für das erfindungsgemäße Verfahren geeigneten Fettungsmitteln, die neben Sulfobernsteinsäuremonoamiden weitere Komponenten enthalten (Fettungsmittelgemische) liegt der Anteil an Sulfobernsteinsäuremonoamiden zwischen etwa 10 und etwa 60 Gewichtsprozent, vorzugsweise zwischen etwa 20 und etwa 50 Gewichtsprozent, jeweils bezogen auf Aktivsubstanz.In the fatliquoring agents which are suitable for the process according to the invention and which contain further components in addition to sulfosuccinic acid monoamides (fatliquor mixtures), the proportion of sulfosuccinic acid monoamides is between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, in each case based on active substance.

Die für das erfindungsgemäße Verfahren geeigneten Fettungsmittel liegen beispielsweise in Form von Pasten, wäßrigen Emulsionen oder Mikroemulsionen vor.The lubricants suitable for the process according to the invention are present, for example, in the form of pastes, aqueous emulsions or microemulsions.

Nach dem erfindungsgemäßen Verfahren werden gegebenenfalls gefärbte Leder und Pelze in wäßriger Flotte bei etwa 35 bis 70 °C, vorzugsweise bei etwa 40 bis 55 °C mit Fettungsmitteln auf Basis von Sulfobernsteinsäure monoamiden gefettet. In Abhängigkeit von den zu behandelnden Leder- und Pelztypen werden etwa 3 bis 15 Gewichtsprozent - bezogen auf Aktivsubstanz sowie auf Falz- oder Fellgewicht - an Fettungsmitteln eingesetzt. Der pH- Wert der Lickerflotte liegt zwischen etwa 4 und 8, vorzugsweise zwischen etwa 4 und 6. Der Lickerfettung kann sich eine an sich bekannte Behandlung mit einem Polyacrylatgerbstoff anschließen, bevor mit Säure, beispielsweise Ameisensäre ein pH-Wert zwischen etwa 3,8 und 4,2 eingestellt wird. Danach werden die Fettungsmittel auf Basis von Sulfobernsteinsäuremonoamiden in an sich bekannter Weise mit polyvalenten Metallsalzen, insbesondere mit Aluminium-, Chrom-, Titan- und/oder Zirkonsalzen in wäßriger Form fixiert. Die Einsatzmengen der Salze liegen zwischen etwa ein und zehn Gewichtsprozent bezogen auf Falz- oder Fellgewicht.In the process according to the invention, colored leather and furs are optionally dipped in an aqueous liquor at about 35 to 70 ° C., preferably at about 40 to 55 ° C., with degreasing agents based on sulfosuccinic acid greased monoamides. Depending on the types of leather and fur to be treated, about 3 to 15 percent by weight - based on the active substance as well as the weight of the fold or fur - is used in fatliquoring agents. The pH of the liquor liquor is between about 4 and 8, preferably between about 4 and 6. The licker lubrication can be followed by a treatment with a polyacrylate tanning agent known per se, before a pH between about 3.8 and with acid, for example formic acids 4.2 is set. Thereafter, the fatliquoring agents based on sulfosuccinic acid monoamides are fixed in a known manner with polyvalent metal salts, in particular with aluminum, chromium, titanium and / or zirconium salts in aqueous form. The amounts of salts used are between about one and ten percent by weight based on the weight of the fold or skin.

Im Rahmen des erfindungsgemäßen Verfahrens können Leder und Pelze mit Fettungsmitteln auf Basis von Sulfobernsteinsäuremonoamiden behandelt werden, indem alle Fettungsmittelbestandteile zusammen der Flotte zugesetzt werden. In manchen Fällen erweist es sich jedoch als vorteilhaft, die einzelnen Fettungsmittelbestandteile nacheinander der Flotte zuzusetzen. In Abhängigkeit vom Anteil der hydrophobierenden und/oder imprägnierenden Fettungsmittel wird eine mehr oder weniger stark ausgeprägte Wasserdichtigkeit erzielt.In the process according to the invention, leather and furs can be treated with fatliquoring agents based on sulfosuccinic acid monoamides by adding all the fatliquoring constituents together to the liquor. In some cases, however, it proves to be advantageous to add the individual fatliquor components to the liquor one after the other. Depending on the proportion of the hydrophobizing and / or impregnating greasing agents, a more or less pronounced water resistance is achieved.

Die Verwendung von Fettungsmitteln auf Basis von Sulfobernsteinsäuremonoamiden zur Hydrophobierung von Leder und Pelzen ist ein weiterer Gegenstand der Erfindung.The use of fatliquors based on sulfosuccinic acid monoamides for the hydrophobization of leather and furs is a further subject of the invention.

Vorzugsweise verwendete Fettungsmittel enthalten Sulfobernsteinsäuremonoamide in Form ihrer Alkali- und/oder Ammoniumsalze.Fatting agents preferably used contain sulfosuccinic acid monoamides in the form of their alkali and / or ammonium salts.

Fettungsmittel, die Salze der Sulfobernsteinsäuremonoamide mit ein oder zwei 12 bis 24 C-Atome, vorzugsweise mit ein oder zwei 14 bis 22 C-Atome enthaltenden gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Alkylresten in den Aminkomponenten enthalten, werden besonders bevorzugt verwendet.Fatting agents which contain salts of sulfosuccinic acid monoamides with one or two 12 to 24 C atoms, preferably with one or two 14 to 22 C atoms containing straight and / or branched chain, saturated and / or unsaturated alkyl radicals in the amine components are particularly preferred used.

Im Rahmen der Erfindung können Fettungsmittel, die als einzige Komponente Sulfobernsteinsäuremonoamide enthalten, verwendet werden.In the context of the invention, fatliquoring agents which contain sulfosuccinic acid monoamides as the only component can be used.

Vorzugsweise werden jedoch Fettungsmittel verwendet, die neben Sulfobernsteinsäuremonoamiden als weitere Komponenten hydrophobierende und/oder imprägnierende Fettungsmittel und/oder Neutralöle enthalten.However, fatliquoring agents are preferably used which, in addition to sulfosuccinic acid monoamides, contain hydrophobing and / or impregnating fatliquoring agents and / or neutral oils as further components.

Geeignete hydrophobierende und/oder imprägnierende Fettungsmittel sind beispielsweise oxidierte und/oder sulfoxidierte C16-30-Kohlenwasserstoffe und/oder C32-40-Wachse, Alkylphosphate mit 12 bis 24 C-Atomen in den gerad- und/oder verzweigtkettigen,gesättigten und/oder ungesättigten Alkylresten, Polycarbonsäurepartialester wie Citronensäurepartialalkylester mit 12 bis 24 C-Atomen in den gerad- und/oder verzweigtkettigen,gesättigten und/oder ungesättigten Veresterungskomponenten und/oder Partialester von Polyalkoholen beispielsweise Sorbitan-, Glycerin- und/oder Pentaerythritfettsäureester mit 12 bis 24 C-Atomen in den gerad- und/oder verzweigtkettigen, gesättigten und/oder ungesättigten Fettsäureresten.Suitable hydrophobicizing and / or impregnating lubricants are, for example, oxidized and / or sulfoxidized C 16-30 hydrocarbons and / or C 32-40 waxes, alkyl phosphates with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated alkyl radicals, polycarboxylic acid partial esters such as partial citric acid partial alkyl esters with 12 to 24 C atoms in the straight and / or branched chain, saturated and / or unsaturated esterification components and / or partial esters of polyalcohols, for example sorbitan, glycerol and / or pentaerythritol fatty acid esters with 12 to 24 C. -Atoms in the straight and / or branched chain, saturated and / or unsaturated fatty acid residues.

Als Neutralöle eignen sich insbesondere tierische und/oder pflanzliche Fette und Öle beispielsweise Klauenöl, Fischöl, Talge, Sojaöl, Sonnenblumenöl, Palmöl und/oder Kokosöl, chlorierte und/oder nicht chlorierte Fettsäuremethylester wie chlorierter Talgfettsäuremethylester, langkettige Kohlenwasserstoffe und /oder Chlorparaffine.Suitable neutral oils are in particular animal and / or vegetable fats and oils, for example claw oil, fish oil, tallow, soybean oil, sunflower oil, palm oil and / or coconut oil, chlorinated and / or non-chlorinated fatty acid methyl esters such as chlorinated tallow fatty acid methyl ester, long-chain hydrocarbons and / or chlorinated paraffins.

Als weitere Bestandteile können die erfindungsgemäß zu verwendenden Fettungsmittel durch Sulfatierung, Sulfonierung, Sulfitierung, Sulfochlorierung oder Phosphatierung von Fetten und/oder Ölen hergestellte Fettstoffe sowie deren Mischungen enthalten. Der Anteil dieser Fettstoffe in Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln kann bis zu etwa 40 Gew.-% - bezogen auf Aktivsubstanz - betragen. Leder und Pelze, die mit solchen Fettungsmittelgemischen behandelt werden, zeichnen sich im Vergleich zu Leder und Pelzen, die mit Sulfobernsteinsäuremonoamid-haltigen Fettungsmitteln ohne sulfatierte, sulfonierte, sulfitierte, sulfochlorierte und/oder phosphatierte Fettstoffe behandelt werden, durch gegebenenfalls weniger gute Hydrophobierungseigenschaften, jedoch durch sehr hohe Weichheit aus.The fatliquors to be used according to the invention may contain, as further constituents, fat substances and mixtures thereof produced by sulfation, sulfonation, sulfitination, sulfochlorination or phosphatization of fats and / or oils. The proportion of these fatty substances in fat-releasing agents containing sulfosuccinic acid monoamide can be up to about 40% by weight, based on the active substance. Leather and furs, which are treated with such fatliquor mixtures, are distinguished by possibly less good hydrophobing properties in comparison to leather and fur, which are treated with fatliquors containing sulfosuccinic acid monoamide without sulfated, sulfonated, sulfited, sulfochlorinated and / or phosphated fat substances very high softness.

In den erfindungsgemäß zu verwendenden Fettungsmitteln, die neben Sulfobernsteinsäuremonoamiden weitere Komponenten enthalten, liegt der Anteil an Sulfobernsteinsäuremonoamiden zwischen etwa 10 und etwa 60 Gewichtsprozent, vorzugsweise zwischen etwa 20 und etwa 50 Gewichtsprozent, jeweils bezogen auf Aktivsubstanz.In the fatliquors to be used according to the invention, which contain further components in addition to sulfosuccinic acid monoamides, the proportion of sulfosuccinic acid monoamides is between about 10 and about 60 percent by weight, preferably between about 20 and about 50 percent by weight, based in each case on the active substance.

Die erfindungsgemäß zu verwendenden Fettungsmittel liegen beispielsweise in Form von Pasten, wäßrigen Emulsionen oder Mikroemulsionen vor.The fatliquors to be used according to the invention are, for example, in the form of pastes, aqueous emulsions or microemulsions.

Die erfindungsgemäßen Fettungsmittel werden von Leder und Pelzen gut aufgenommen und verteilen sich sehr gleichmäßig über den gesamten Lederquerschnitt. Des weiteren wird mit diesen eine ausgeprägte Wasserdichtigkeit der Leder und Pelze erzielt. Im Vergleich zu Leder und Pelzen, die mit Fettungsmitteln enthaltend Sulfobernsteinsäureester gefettet werden, weisen Leder und Pelze, die mit den erfindungsgemäßen Fettungsmitteln behandelt wurden, einen deutlich verzögerten Wasserdurchtritt sowie eine verringerte Wasseraufnahme auf. Die Färbung der mit den erfindungsgemäßen Fettungsmitteln behandelten Leder und Pelze ist im Vergleich zu Leder und Pelzen, die mit Fettungsmitteln enthaltend Sulfobernsteinsäuremonoester behandelt wurden, gleichmäßiger und brillanter.The fatliquoring agents according to the invention are well absorbed by leather and furs and are distributed very evenly over the entire leather cross section. Furthermore, the leather and furs have a pronounced waterproofness. Compared to leather and furs, which are greased with fatty agents containing sulfosuccinic acid esters, leather and furs, which have been treated with the greasing agents according to the invention, have a significantly delayed passage of water and a reduced water absorption. The coloration of the leather and furs treated with the fatliquoring agents according to the invention is more uniform and brilliant than that of leather and fur that has been treated with fatliquoring agents containing sulfosuccinic acid monoesters.

JZ = Jodzahl, AZ = Aminzahl, AS = Aktivsubstanz, Min. = Minuten, h = Stunden.

Die Angabe "%" bedeutet "Gewichtsprozent".JZ = iodine number, AZ = amine number, AS = active substance, min. = Minutes, h = hours.

The indication "%" means "percent by weight".

In einem beheizbaren 2 1-Dreihalskolben, versehen mit Rührer, Thermometer und heizbarem Tropftrichter wurden 98,1 g(1 Mol) Maleinsäureanhydrid vorgelegt und bei 55 bis 60 °C geschmolzen. Nach vollständigem Schmelzen wurden 270 g (1 Mol) Talgamin (Tropfpunkt: 30 °C) unter langsamem Rühren so schnell zugetropft, daß eine Reaktionstemperatur von 55 bis 60 °C nicht überschritten wurde. Anschließend ließ man noch eine halbe Stunde bei 95 bis 100 °C nachreagieren und gab dann zu dem Halbamid 126 g (1 Mol) wasserfreies Natriumsulfit, das in 900 g Wasser gelöst worden war. Nach zweistündigem Rühren bei 85 bis 90 °C wurde eine gut fließende Dispersion mit etwa 35 % Aktivsubstanz erhalten.98.1 g (1 mol) of maleic anhydride were placed in a heated 2 1 three-necked flask equipped with a stirrer, thermometer and heatable dropping funnel and melted at 55 to 60 ° C. After complete melting, 270 g (1 mol) of tallow amine (dropping point: 30 ° C.) were added dropwise so quickly with slow stirring that a reaction temperature of 55 to 60 ° C. was not exceeded. The mixture was then left to react for a further half hour at 95 to 100 ° C. and then 126 g (1 mol) of anhydrous sodium sulfite, which had been dissolved in 900 g of water, was added to the half-amide. After stirring for two hours at 85 to 90 ° C., a well flowing dispersion with about 35% active substance was obtained.

C-Kette des zugrundeliegenden Talgamins: ca. 5 % C₁₄, ca. 30 % C₁₆, ca. 65 % C₁₈.C chain of the underlying tallowamine: approx. 5% C₁₄, approx. 30% C₁₆, approx. 65% C₁₈.

Weitere Kennzahlen des eingesetzten Talgamins:

JZ = 43,5 AZ = 207,8Further key figures of the tallow amine used:

JZ = 43.5 AZ = 207.8

Die Herstellung erfolgte analog Beispiel 1.The preparation was carried out analogously to Example 1.

C-Kette des zugrundeliegenden Behenylamins: 15 % C₁₆, 31 % C₁₈, 10 % C₂₀, 40 % C₂₂.C chain of the underlying behenylamine: 15% C₁₆, 31% C₁₈, 10% C₂₀, 40% C₂₂.

Weitere Kennzahlen des eingesetzten Behenylamins:

JZ = 1, AZ = 188.Other key figures of the behenylamine used:

JZ = 1, AZ = 188.

Analog Beispiel 1 wurde aus 98,1 g (1 Mol) Maleinsäureanhydrid und 270 g (1 Mol) Talgamin das entsprechende Monoamid hergestellt. Anschließend wurde das Monoamid bei 20 bis 40 °C in eine wäßrige Ammoniumhydrogensulfithaltige Lösung, hergestellt durch Einleiten von 64 g (1 Mol) Schwefeldioxid in eine Lösung aus 700 g Wasser und 200 g 20 %iger Ammoniaklösung (ca. 1,1 Mol Ammoniak) bei 20 °C, gegeben. Nach einstündigem Rühren bei 40 °C und zweistündigem Rühren bei 80 °C wurde eine gut fließende Dispersion mit etwa 35 Gew.-% Aktivsubstanz erhalten.Analogously to Example 1, the corresponding monoamide was prepared from 98.1 g (1 mol) of maleic anhydride and 270 g (1 mol) of tallow amine. The monoamide was then at 20 to 40 ° C in an aqueous solution containing ammonium bisulfite, prepared by introducing 64 g (1 mol) of sulfur dioxide into a solution of 700 g of water and 200 g of 20% ammonia solution (about 1.1 mol of ammonia) at 20 ° C. After stirring for one hour at 40 ° C. and for two hours at 80 ° C., a well flowing dispersion with about 35% by weight of active substance was obtained.

Rindoberleder: In üblicher Weise, jedoch ohne Zusätze anionischer Tenside werden chromgegerbte Rind-wet-blue - pH 3,8, Falzstärke 1,8 mm - wie folgt weiterbehandelt:

Die Leder A und C wiesen im Vergleich zu den Ledern B und E einen deutlich verzögerten Wasserdurchtritt und eine verringerte Wasseraufnahme auf.Compared to leathers B and E, leathers A and C had a significantly delayed water penetration and reduced water absorption.

Die Färbung der Leder A und C war im Vergleich zu den Ledern B und E gleichmäßiger und brillanter. Bei einem optischen Vergleich erhielten die Leder A, C, D und F die Stufe 5 und die Leder B und E die Stufe 4 in einer 6-stufigen Bewertungsskala. In dieser bedeutet Stufe 1 schlechte Färbung und Stufe 6 ausgezeichnete Färbung.The coloring of leather A and C was more uniform and brilliant compared to leather B and E. In an optical comparison, leathers A, C, D and F were rated 5 and leathers B and E were rated 4 on a 6-point rating scale. In this level 1 means bad coloring and level 6 excellent coloring.

Claims (12)

und anschließend folgende an sich bekannte Maßnahmen durchgeführt werden:

and then the following known measures are carried out:

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3620780 | 1986-06-20 | ||

| DE19863620780 DE3620780A1 (en) | 1986-06-20 | 1986-06-20 | LUBRICANTS BASED ON SULPHONIC ACID MONOAMIDES |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0249908A2 true EP0249908A2 (en) | 1987-12-23 |

| EP0249908A3 EP0249908A3 (en) | 1989-09-13 |

Family

ID=6303384

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87108533A Withdrawn EP0249908A3 (en) | 1986-06-20 | 1987-06-12 | Fat liquoring agent based on sulphosuccinic-acid monoamide |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US4799932A (en) |

| EP (1) | EP0249908A3 (en) |

| JP (1) | JPS633100A (en) |

| BR (1) | BR8703082A (en) |

| CA (1) | CA1273754A (en) |

| DE (1) | DE3620780A1 (en) |

| SU (1) | SU1547712A3 (en) |

| TR (1) | TR23855A (en) |

| ZA (1) | ZA874447B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1993022464A1 (en) * | 1992-04-29 | 1993-11-11 | Chemische Fabrik Stockhausen Gmbh | Process and agents for waterproofing materials having a fibrous structure |

| WO1996035815A3 (en) * | 1995-05-12 | 1996-12-12 | Stockhausen Chem Fab Gmbh | Process for water-proofing leather at low ph values and thus water-proofed leather |

| CN101633965B (en) * | 2009-08-20 | 2012-12-26 | 陕西科技大学 | Preparation method of flame-retardant polymer/montmorillonite nano fat liquoring complex agent |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19609960C2 (en) * | 1996-03-14 | 2000-07-13 | Zschimmer & Schwarz Gmbh & Co | Process for the production of electrolyte-stable degreasing agents for leather and furs |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE535863A (en) * | 1954-04-06 | 1958-12-19 | ||

| US2968580A (en) * | 1958-06-25 | 1961-01-17 | Bohme Fettchemie Gmbh | Process for increasing the waterresistance of leather |

| US3668124A (en) * | 1970-05-13 | 1972-06-06 | Pennwalt Corp | Composition and method for treating dry-cleanable soil-resistant leathers |

| US3749669A (en) * | 1971-06-21 | 1973-07-31 | Us Agriculture | Lubricants for hides and leather |

| PL85071B1 (en) * | 1972-08-02 | 1977-02-26 | Instytut Przemysłu Organicznego | Leather greasing agent and the method of its production |

| DE2939741A1 (en) * | 1979-10-01 | 1981-04-16 | Henkel KGaA, 4000 Düsseldorf | METHOD FOR GREATENING AND IMPREGNATING LEATHER AND FURS |

| DE3419405A1 (en) * | 1984-05-24 | 1985-11-28 | Henkel KGaA, 4000 Düsseldorf | METHOD FOR PRODUCING LEATHER AND FURS |

| DE3507241A1 (en) * | 1985-03-01 | 1986-09-04 | Henkel KGaA, 4000 Düsseldorf | METHOD FOR PRODUCING WATERPROOF LEATHER OR FUR |

-

1986

- 1986-06-20 DE DE19863620780 patent/DE3620780A1/en not_active Withdrawn

-

1987

- 1987-05-29 SU SU874202646A patent/SU1547712A3/en active

- 1987-06-12 EP EP87108533A patent/EP0249908A3/en not_active Withdrawn

- 1987-06-17 TR TR42287A patent/TR23855A/en unknown

- 1987-06-19 US US07/064,894 patent/US4799932A/en not_active Expired - Fee Related

- 1987-06-19 ZA ZA874447A patent/ZA874447B/en unknown

- 1987-06-19 BR BR8703082A patent/BR8703082A/en unknown

- 1987-06-20 JP JP62154264A patent/JPS633100A/en active Pending

- 1987-06-22 CA CA000540201A patent/CA1273754A/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1993022464A1 (en) * | 1992-04-29 | 1993-11-11 | Chemische Fabrik Stockhausen Gmbh | Process and agents for waterproofing materials having a fibrous structure |

| WO1996035815A3 (en) * | 1995-05-12 | 1996-12-12 | Stockhausen Chem Fab Gmbh | Process for water-proofing leather at low ph values and thus water-proofed leather |

| CN101633965B (en) * | 2009-08-20 | 2012-12-26 | 陕西科技大学 | Preparation method of flame-retardant polymer/montmorillonite nano fat liquoring complex agent |

Also Published As

| Publication number | Publication date |

|---|---|

| BR8703082A (en) | 1988-03-08 |

| US4799932A (en) | 1989-01-24 |

| DE3620780A1 (en) | 1987-12-23 |

| JPS633100A (en) | 1988-01-08 |

| ZA874447B (en) | 1987-12-21 |

| TR23855A (en) | 1990-10-15 |

| EP0249908A3 (en) | 1989-09-13 |

| SU1547712A3 (en) | 1990-02-28 |

| CA1273754A (en) | 1990-09-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0193832B1 (en) | Method for the manufacture of waterproof leather or fur | |

| EP0178557B1 (en) | Process for the production of greasing agents for leather and furs | |

| DE3617657C2 (en) | Room temperature liquid derivatives of natural fats or oils, process for their preparation, and their use | |

| EP0118023B1 (en) | Process for water-proofing leather and furs | |

| EP0247490B1 (en) | Sulphited fatty materials | |

| EP0165481B1 (en) | Method for the manufacture of leather and pelts | |

| DE1669347A1 (en) | Process for greasing leather | |

| EP0249908A2 (en) | Fat liquoring agent based on sulphosuccinic-acid monoamide | |

| DE3909614C2 (en) | ||

| EP0184741B1 (en) | Method of greasing leather and skins | |

| EP0564980B1 (en) | Fat liquoring agent for leather | |

| EP0026423B1 (en) | Method of greasing and impregnating leather and furs | |

| DE4102545A1 (en) | METHOD FOR GELING, PRELIMINATING AND GIVING BARE AND FUR BLOSSES AND FOR LEAVING LEATHER AND FUR | |

| DE4142318C2 (en) | Use of fatty acid conversion products in leather and fur greasing agents and agents for greasing leather and fur skins | |

| DE3317422A1 (en) | Fat-liquoring agent for leather | |

| DE3717961C2 (en) | Process for the preparation of mixtures of N, N-disubstituted ß-aminopropionic acid derivatives, certain mixtures of N-alkyl-N (2-carboxyethyl) sulfonamides and N-alkyl-N (2-carboxyethyl) ureas and use of the compounds mentioned | |

| DE844784C (en) | Fatliquor for materials with a fibrous structure such as leather | |

| EP0763139B1 (en) | Stuffing agents for leathers and fur-skins | |

| EP0763138B1 (en) | Use of sulphated compounds for stuffing leather | |

| EP0752010B1 (en) | Use of alkylene diamine tetrapropionic acids for the oiling off of leathers | |

| AT226356B (en) | Fur and leather fatliquors | |

| DE2355503C3 (en) | Process for the production of a fatty chrome tanning agent and its use for tanning and retanning | |

| DE1768548A1 (en) | Process for the preparation of sulfonation products | |

| EP0746629B1 (en) | Use of sulfonated substances for stuffing leather | |

| EP0670828A1 (en) | Sulphited fats with a reduced free-bisulphite content. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19891012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19910126 |

|

| R18W | Application withdrawn (corrected) |

Effective date: 19910126 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PLOOG, UWE, DR. Inventor name: PRINZ, WOLFGANG Inventor name: FRIESE, HANS-HERBERT, DR. |