EP0242500B1 - Assembly for accelerating projectiles by means of an electrically heated plasma - Google Patents

Assembly for accelerating projectiles by means of an electrically heated plasma Download PDFInfo

- Publication number

- EP0242500B1 EP0242500B1 EP87100186A EP87100186A EP0242500B1 EP 0242500 B1 EP0242500 B1 EP 0242500B1 EP 87100186 A EP87100186 A EP 87100186A EP 87100186 A EP87100186 A EP 87100186A EP 0242500 B1 EP0242500 B1 EP 0242500B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- projectile

- electrode

- plasma

- electrodes

- fact

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41B—WEAPONS FOR PROJECTING MISSILES WITHOUT USE OF EXPLOSIVE OR COMBUSTIBLE PROPELLANT CHARGE; WEAPONS NOT OTHERWISE PROVIDED FOR

- F41B6/00—Electromagnetic launchers ; Plasma-actuated launchers

Definitions

- the present invention relates to a device for accelerating projectiles located in a tube closed on one side by an electrically heated plasma with the features of the preamble of claim 1.

- the present invention was therefore based on the object of further developing a device of the type mentioned at the outset in such a way that the corresponding tube parts are subject to only slight wear, even with a high weft sequence.

- the invention is therefore essentially based on the fact that the spread of the plasma is no longer initiated by parts of the accelerator itself, as in the known devices, but rather that both the initiation of the gas discharge and the subsequent heating processes in easily replaceable separate units in which the projectile is also located. Therefore, not only the projectiles but rather the entire cartridge are preferably fed to the tube.

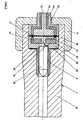

- a known acceleration device is shown again, such as that in the report by Goldstein et. al. is described in more detail.

- Fig. 1 denotes a tube which is closed on one side and on the tube bottom of which the closure is located a first electrode 2 is arranged.

- a second electrode (ring electrode) 3 is connected to the first electrode 2 via a voltage source 4 and a switch.

- the two electrodes 2 and 3 define a plasma chamber designated 6 in the tube 1, which is initially closed in the area of the ring electrode 3 by a projectile 7 to be accelerated.

- this device has the disadvantage that the part of the tube forming the plasma space is subject to extremely high wear due to the material evaporation and heating processes.

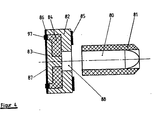

- FIG. 2 The cartridge 8 shown in FIG. 2 and then its function in connection with a gun (FIG. 3) will be described in more detail below.

- the cartridge 8 essentially consists of the projectile 80, a sleeve 81 surrounding the projectile, a second electrode 82 designed as a contact ring and a first electrode 83 designed as a contact piece.

- the first electrode 83 and the second electrode 82 are separated by an insulating piece 84.

- the second electrode 82 has a contact plate ring 85 on its front side and a contact plate ring 86 on its rear side.

- the first electrode 83 has a contact lamella 87 on its side facing away from the projectile 80.

- a splat-shaped discharge space 88 is located between the projectile 80 and the first electrode 83.

- the sleeve 81 can preferably consist of a combustible, light-gas material, for example polyethylene, and the insulating body 84 can be made of polycarbonate.

- light-gassing materials are substances that break down into molecules (gases) with a low molecular weight (molecular weight ⁇ 30) under the effect of the arc discharge.

- aluminum was used as the material for the electrodes 82 and 83.

- Fig. 3 shows how the cartridge 8 is arranged in a plasma gun.

- Lichen parts, such as the closure were only shown schematically.

- a base piece 91 is screwed onto the tube 90, for example.

- Both an inner conductor 92 and an outer conductor 93, which is electrically separated from the inner conductor 92 by insulating means 94, are guided through an opening 95 of the base piece 91 into the sealing space of the tube 90, which is not specifically designated.

- the inner conductor 92 is then contacted in the sealing space via the contact lamella disk 87 with the first electrode 83.

- the outer conductor 93 is correspondingly connected to the ring electrode 82 via the contact lamella ring 86.

- the contacts 85, 86 and 87 of the cartridge are pressed firmly against the tube 90 and against the coaxial first electrode by the pressure of the base piece 91.

- An elastic silicone rubber seal 97 is arranged between the insulating means 94 and the insulating piece 84 for electrical sealing.

- a voltage is applied between the inner conductor 92 and the outer conductor 93.

- the acceleration process is then initiated by a gas discharge which forms between the first electrode 83 and the coaxial electrode 82 in the narrow gap 88 and which is indicated by 96 in FIG. 3.

- a gas discharge which forms between the first electrode 83 and the coaxial electrode 82 in the narrow gap 88 and which is indicated by 96 in FIG. 3.

- material is vaporized and predominantly in the base areas of the hot arc heated up.

- further material is evaporated by the close contact of the arc with the walls of the gap 88. The resulting pressure drives the projectile 80 towards the pipe end.

- a plasma forms behind the projectile 80 in the increasing combustion chamber.

- the plasma consists of a current-carrying stem in the axis of the accelerator and (if a sleeve 81 made of plastic is used) a current-carrying sleeve which is pressed against the sleeve 81 by the current forces that occur. Due to the close contact of the plasma shell with the sleeve 81, the latter is vaporized on the surface and thus further material is supplied to the plasma.

- FIG. 4 shows a further exemplary embodiment according to the invention.

- the same parts as in Fig. 2 have been given the same reference numerals.

- the projectile 80 with the sleeve 81 on the one hand and on the other hand the electrodes 82, 83 provided with the contact blades 85, 86, 87 with the insulating piece 84 are each combined to form a unit.

- Such a division into separate structural units makes it possible first to introduce the projectile 80 with the sleeve 81 and in a subsequent period of time the unit consisting of electrodes 82, 83 and insulating piece 84 into the gun barrel. Such a division and loading into two time periods is often necessary, especially for large-caliber weapons.

- FIG. 5 shows a simplified circuit diagram for operating the plasma cannon according to the invention.

- the schematically illustrated plasma cannon was designated by 10 and the simplified circuit diagram by 11. Only a projectile 100 was shown in the plasma gun 10 instead of a cartridge. 101 denotes the first electrode and 102 denotes the second electrode, which is connected to the tube.

- a drive for. B. a motor powered by a liquid fuel

- 111 denotes a DC generator.

- the voltage generated by the direct current generator is fed via switch 112 to a capacitance 113, which acts as a capacitive energy store.

- the capacitance 113 is connected on the one hand to the first electrode 101 via a switch 114 and on the other hand to the second electrode 102 via an inductance 116.

- the capacitance 113 can be short-circuited via a switch 115.

- the capacitive energy store 113 is charged to the voltage Uo.

- the gap-shaped space 88 can also be filled with a slightly gassing substance (e.g. polyethylene). Because the additional material evaporation of this substance increases the plasma pressure, so that the projectile leaves the tube 90 at a higher speed.

- a slightly gassing substance e.g. polyethylene

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Plasma & Fusion (AREA)

- General Engineering & Computer Science (AREA)

- Plasma Technology (AREA)

- Generation Of Surge Voltage And Current (AREA)

- Magnetic Treatment Devices (AREA)

- Buildings Adapted To Withstand Abnormal External Influences (AREA)

- Vending Machines For Individual Products (AREA)

Description

Die vorliegende Erfindung betrifft eine Vorrichtung zur Beschleunigung von in einem einseitig verschlossenem Rohr befindlichen Projektilen durch ein elektrisch aufgeheiztes Plasma mit den Merkmalen des Oberbegriffs des Anspruchs 1.The present invention relates to a device for accelerating projectiles located in a tube closed on one side by an electrically heated plasma with the features of the preamble of

Es ist bekannt, daß mit elektrisch aufgeheizten Plasmen Projektile in metallischen Rohren auf hohe Geschwindigkeiten beschleunigt werden können (vgl. Goldstein S.A. et. al. Final Report on Research and Development of a Plasma Jet Mass Accelerator as a Driver for Impact Fusion; GT-Devices, Alexandria, VA, USA, Contract DE-AC05-81-ER10846, May 1984). Bei diesen bekannten Vorrichtungen werden in engen Isolierstoffkapilaren Plasmastrahlen erzeugt, die auf den Projektilboden einwirken. Durch Kontakt der Gasentladung mit den Kapillarwänden kommt es zur Ablation von Isolierstoff und zur Aufheizung des Plasmas. Die Folge sind Plasmastrahlen, die aus den Kapillaröffnungen austreten.It is known that projectiles in metallic tubes can be accelerated to high speeds with electrically heated plasmas (cf.Goldstein SA et. Al. Final Report on Research and Development of a Plasma Jet Mass Accelerator as a Driver for Impact Fusion; GT-Devices , Alexandria, VA, USA, Contract DE-AC05-81-ER10846, May 1984). In these known devices, plasma jets are generated in narrow insulating capillaries, which act on the projectile floor. Contact of the gas discharge with the capillary walls leads to ablation of the insulating material and heating of the plasma. The result is plasma jets that emerge from the capillary openings.

Besonders nachteilig ist bei diesen bekannten Vorrichtungen, daß durch die Materilaverdampfung und Auifheizungsvorgänge die kapillaren Teile des Beschleunigers einem großen Verschleiß unterliegen.It is particularly disadvantageous in these known devices that the capillary parts of the accelerator are subject to great wear due to material evaporation and heating processes.

Die Rohre entsprechender Waffen, die nach diesem Prinzip arbeiten, müssen daher sehr häufig ausgewechselt werden. Dieses gilt insbesondere dann, wenn mit diesen Waffen eine hohe Schußfolge erreicht werden soll.The tubes of corresponding weapons that work according to this principle must therefore be replaced very often. This is especially true if a high shot order is to be achieved with these weapons.

Der vorliegenden Erfindung lag daher die Aufgabe zugrunde, eine Vorrichtung der eingangs erwähnten Art so weiterzuentwickeln, daß die entsprechenden Rohrteile nur einem geringen Verschleiß, selbst bei hoher Schußfolge, unterliegen.The present invention was therefore based on the object of further developing a device of the type mentioned at the outset in such a way that the corresponding tube parts are subject to only slight wear, even with a high weft sequence.

Erfindungsgemäß wird diese Aufgabe durch die Merkmale des kennzeichnenden Teils des Anspruchs 1 gelöst.According to the invention, this object is achieved by the features of the characterizing part of

Die Unteransprüche geben besonders vorteilhafte Ausgestaltungen der Erfindung wieder.The subclaims represent particularly advantageous embodiments of the invention.

Die Erfindung beruht also im wesentlichen darauf, daß die Ausbreitung des Plasmas nicht mehr - wie bei den bekannten Vorrichtungen - durch Teile des Beschleunigers selbst eingeleitet wird, sondern daß sowohl die Einleitung der Gasentladung als auch die anschließenden Aufheizvorgänge in leicht auswechselbaren separaten Einheiten, in der sich auch das Projektil befindet, erfolgen. Es werden daher vorzugsweise dem Rohr nicht nur die Projektile, sondern die gesamte Kartusche jeweils zugeführt.The invention is therefore essentially based on the fact that the spread of the plasma is no longer initiated by parts of the accelerator itself, as in the known devices, but rather that both the initiation of the gas discharge and the subsequent heating processes in easily replaceable separate units in which the projectile is also located. Therefore, not only the projectiles but rather the entire cartridge are preferably fed to the tube.

Weitere Vorteile der Erfindung werden im folgenden anhand von Ausführungsbeispielen, welche mit Hilfe von Figuren erläutert werden, beschrieben.Further advantages of the invention are described below on the basis of exemplary embodiments, which are explained with the aid of figures.

Es zeigen:

- Fig. 1 eine bekannte Vorrichtung zur Beschleunigung von Projektilen mittels eines elektrisch aufgeheizten Plasmas;

- Fig. 2 den Schnitt eines ersten Ausführungsbeispiels einer erfindungsgemäßen Kartusche;

- Fig. 3 den Schnitt einer erfindungsgemäßen Plasmakanone mit Kartusche gemäß Fig. 2;

- Fig. 4 den Schnitt eines zweiten erfindungsgemäßen Ausführungsbeispiels;

- Fig. 5 einen vereinfachten Schaltplan zum Betrieb der erfindungsgemäßen Plasmakanone;

- Fig. 6 den zeitlichen Verlauf des Stromes in der Plasmakanone.

- 1 shows a known device for accelerating projectiles by means of an electrically heated plasma;

- 2 shows the section of a first exemplary embodiment of a cartridge according to the invention;

- 3 shows the section of a plasma cannon according to the invention with a cartridge according to FIG. 2;

- 4 shows the section of a second exemplary embodiment according to the invention;

- 5 shows a simplified circuit diagram for operating the plasma cannon according to the invention;

- Fig. 6 shows the time course of the current in the plasma gun.

In Fig. 1 ist noch einmal eine bekannte Beschleunigungsvorrichtung dargestellt, wie sie etwa in dem eingangs zitierten Bericht von Goldstein et. al. näher beschrieben wird.In Fig. 1, a known acceleration device is shown again, such as that in the report by Goldstein et. al. is described in more detail.

In Fig. 1 ist mit 1 ein einseitig verschlossenes Rohr bezeichnet, an dessen verschlußseitigem Rohrboden eine erste Elektrode 2 angeordnet ist. Eine zweite Elektrode (Ringelektrode) 3 ist über eine Spannungsquelle 4 und einen Schalter mit der ersten Elektrode 2 verbunden. Durch die beiden Elektroden 2 und 3 wird in dem Rohr 1 eine mit 6 bezeichnete Plasmakammer definiert, die im Bereich der Ringelektrode 3 zunächst durch ein zu beschleunigendes Projektil 7 abgeschlossen ist.In Fig. 1, 1 denotes a tube which is closed on one side and on the tube bottom of which the closure is located a first electrode 2 is arranged. A second electrode (ring electrode) 3 is connected to the first electrode 2 via a voltage source 4 and a switch. The two

Nach dem Schließen des Schalters 5 wird zwischen den Elektroden 2 und 3 ein Lichtbogen gezündet und daß Projektil 7 durch den Druck des Lichtbogenplasmas beschleunigt.After closing switch 5, an arc is ignited between

Wie bereits eingangs erwähnt, weist diese Vorrichtung den Nachteil auf, daß durch die Materialverdampfungs- und Aufheizungsvorgänge der den Plasmaraum bildende Teil des Rohres einem außerordentlich starkem Verschleiß unterliegt.As already mentioned at the beginning, this device has the disadvantage that the part of the tube forming the plasma space is subject to extremely high wear due to the material evaporation and heating processes.

Erfindungsgemäß werden daher einer entsprechenden Plasmakanone nicht mehr nur das Projektil 7 allein, sondern alle einem starken Verschleiß unterliegenden Teile einschließlich der Elektroden, in Form einer Kartusche zugeführt.According to the invention, therefore, not only the

Im folgenden wird zunächst die in Fig. 2 dargestellte Kartusche 8 und anschließend ihre Funktion in Verbindung mit einem Geschütz (Fig. 3) näher beschrieben.The

Die Kartusche 8 besteht im wesentlichen aus dem Projektil 80, einer das Projektil umgebenden Hülse 81, einer als Kontaktring ausgebildeten zweiten Elektrode 82 und einer als Kontaktstück ausgebildeten ersten Elektrode 83. Die erste Elektrode 83 und die zweite Elektrode 82 sind durch ein Isolierstück 84 getrennt. Außerdem weist die zweite Elektrode 82 auf ihrer vorderen Seite einen Kontaktlamellenring 85 und auf ihrer Rückseite einen Kontaktlamellenring 86 auf. Die erste Elektrode 83 besitzt auf ihrer dem Projektil 80 abgewandten Seite eine Kontaktlamellenscheibe 87. Zwischem dem Projektil 80 und der ersten Elektrode 83 befindet sich ein splatförmiger Entladungsraum 88.The

Die Hülse 81 kann vorzugsweise aus einem verbrennbaren leichtgasenden Material, beispielsweise Polyäthylen und der Isolierkörper 84 aus Polycarbonat bestehen. Als leichtgasendes Material werden dabei solche Stoffe bezeichnet, die unter der Wirkung der Lichtbogenentladung in Moleküle (Gase) mit niedrigem Molekulargewicht (Molekulargewicht <30) zerfallen.The

Als Material für die Elektroden 82 und 83 wurde im einem Ausführungsbeispiel Aluminium verwendet.In one embodiment, aluminum was used as the material for the

Fig. 3 zeigt, wie die Kartusche 8 in einer Plasmakanone angeordnet ist. Die nicht erfindungswesentlichen Teile, wie der Verschluß, wurden nur schematisch dargestellt. Mit 9 wurde der verschlußseitige Teil des Rohres 90 bezeichnet. Auf dem Rohr 90 ist ein Bodenstück 91 beispielsweise aufgeschraubt. Durch eine Öffnung 95 des Bodenstückes 91 werden sowohl ein Innenleiter 92 als auch ein Außenleiter 93, der durch Isoliermittel 94 von dem Innenleiter 92 elektrisch getrennt ist, in den nicht extra bezeichneten Verschlußraum des Rohres 90 geführt. In dem Verschlußraum erfolgt dann die Kontaktierung des Innenleiters 92 über die Kontaktlamellenscheibe 87 mit der ersten Elektrode 83. Entsprechend wird der Außenleiter 93 über den Kontaktlamellenring 86 mit der Ringelektrode 82 verbunden.Fig. 3 shows how the

Die Kontakte 85, 86 und 87 der Kartusche werden durch den Druck des Bodenstückes 91 fest gegen das Rohr 90 und gegen die koaxiale erste Elektrode gepreßt.The

Zwischen den Isoliermitteln 94 und dem Isolierstück 84 ist zur elektrischen Abdichtung eine elastische Silikonkautschukdichtung 97 angeordnet.An elastic

Zur Auslösung des Beschleunigungsvorganges wird zwischen den Inneleiter 92 und den Außenleiter 93 eine Spannung angelegt. Der Beschleunigungsvorgang wird dann durch eine Gasentladung eingeleitet, die sich zwischen der ersten Elektrode 83 und der koaxialen Elektrode 82 in dem engen Spalt 88 ausbildet und die in Fig. 3 mit 96 angedeutet ist. Während des raschen Anstieges des Stromes i, der von der Außenelektrode 93 über die Kontaktlamelle 86, die Ringelektrode 82, die Gasentladung 96, die koaxiale Innenelektrode 83 und die Kontaktlamellenscheibe 87 in den Innenleiter fließt, wird überwiegend in den Fußpunktsgebieten des heißen Lichtbogens Material verdampft und aufgeheizt. Zusätzlich wird durch den engen Kontakt des Lichtbogens mit den Wänden des Spaltes 88 weiteres Material verdampft. Der dabei entstehende Druck treibt das Projektil 80 in Richtung des Rohrendes.To initiate the acceleration process, a voltage is applied between the

Während der Beschleunigung bildet sich in dem größerwerdenden Brennraum hinter dem Projektil 80 ein Plasma aus. Das Plasma besteht aus einem stromführenden Stiel in der Achse des Beschleunigers und (bei Verwendung einer aus Kunststoff bestehenden Hülse 81) einer stromführenden Hülle, die durch die auftretenden Strokräfte gegen die Hülse 81 gedrückt wird. Durch den engen Kontakt der Plasmahülle mit der Hülse 81 wird diese oberflächlich verdampft und somit dem Plasma weiteres Material zugeführt.During acceleration, a plasma forms behind the

In Fig. 4 ist ein weiteres Ausführungsbeispiel gemäß der Erfindung dargestellt. Dabei sind die gleichen Teile wie in Fig. 2 mit den gleichen Bezugszeichen versehen worden. Im Unterschied zu Fig. 2 sind in diesem Ausführungsbeispiel einerseits das Projektil 80 mit der Hülse 81 und andererseits die mit den Kontaktlamellen 85, 86, 87 versehenen Elektroden 82, 83 mit dem Isolierstück 84 jeweils zu einer Einheit zusammengefaßt.4 shows a further exemplary embodiment according to the invention. The same parts as in Fig. 2 have been given the same reference numerals. In contrast to FIG. 2, in this exemplary embodiment the projectile 80 with the

Durch eine derartige Aufteilung in getrennte Baueinheiten ist es möglich, zunächst das Projektil 80 mit Hülse 81 und in einem nachfolgenden Zeitabschnitt die aus Elektroden 82, 83 und Isolierstück 84 bestehende Einheit in das Geschützrohr einzuführen. Eine derartige Aufteilund des Ladens in zwei Zeitabschnitte ist häufig insbesondere bei großkalibrigen Waffen erforderlich.Such a division into separate structural units makes it possible first to introduce the projectile 80 with the

Fig. 5 zeigt einen vereinfachten Schaltplan zum Betrieb der erfindungsgemäßen Plasmakanone. Mit 10 wurde dabei die schematisch dargestellte Plasmakanone und mit 11 der vereinfachte Schaltplan bezeichnet. Dabei wurde in der Plasmakanone 10 statt einer Kartusche lediglich ein Projektil 100 dargestellt. Mit 101 ist die erste Elektrode und mit 102 die zweite Elektrode, die mit dem Rohr verbunden ist, bezeichnet.5 shows a simplified circuit diagram for operating the plasma cannon according to the invention. The schematically illustrated plasma cannon was designated by 10 and the simplified circuit diagram by 11. Only a projectile 100 was shown in the

In dem Schaltplan 11 wird mit 110 ein Antrieb, z. B. ein mit einem Flüssigtreibstoff gespeister Motor, und mit 111 ein Gleichstromgenenrator bezeichnet. Die von dem Gleichstromgenerator erzeugte Spannung wird über den Schalter 112 eine Kapazität 113 zugeführt, die als kapazitiver Energiespeicher wirkt. Die Kapazität 113 ist einerseits über einen Schalter 114 mit der ersten Elektrode 101 und andererseits über eine Induktivität 116 mit der zweiten Elektrode 102 verbunden.In the circuit diagram 11 with 110 a drive, for. B. a motor powered by a liquid fuel, and 111 denotes a DC generator. The voltage generated by the direct current generator is fed via

Außerdem kann die Kapazität 113 über einen Schalter 115 kurzgeschlossen werden.In addition, the

Zu Beginn des Beschleunigungsvorganges ist der kapazitive Energiespeicher 113 auf die Spannung Uo aufgeladen. Nach Einlegen des Schalters 114 zum Zeitpunkt t = 0 (vgl. auch Fig. 6), entlädt sich der Energiespeicher über die Induktivität 116 und über das Plasma im Beschleuniger. Wenn zum Zeitpunkt t = t1 der Strom sein imax erreicht hat, wird der Kurzschlußschalter 115 geschlossen. Der abnehmende Stromfluß über das Beschleunigerplasma wird danach durch die Induktivität der Spule 116 aufrechterhalten.At the beginning of the acceleration process, the

Um die Abmessungen der Kartusche 8 (Fig. 2) möglichst klein zu gestalten, kann das Projektil 80 auch direkt an die koaxiale Innenelektrode 83 anschließen (Abstand zwischen Innenelektrode und Projektil = 0).In order to make the dimensions of the cartridge 8 (FIG. 2) as small as possible, the projectile 80 can also connect directly to the coaxial inner electrode 83 (distance between inner electrode and projectile = 0).

Vorzugsweise kann der spaltförmige Zwischenraum 88 aber auch mit einem leicht gasenden Stoff (z. B. Polyäthylen) gefüllt werden. Denn durch die zusätzliche Materialverdampfung dieses Stoffes erhöht sich der Plasmadruck, so daß das Projektil mit höherer Geschwindigkeit das Rohr 90 verläßt.Preferably, the gap-shaped

Claims (5)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863613259 DE3613259A1 (en) | 1986-04-19 | 1986-04-19 | DEVICE FOR ACCELERATING PROJECTILES THROUGH AN ELECTRICALLY HEATED PLASMA |

| DE3613259 | 1986-04-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0242500A1 EP0242500A1 (en) | 1987-10-28 |

| EP0242500B1 true EP0242500B1 (en) | 1990-04-04 |

Family

ID=6299057

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87100186A Expired - Lifetime EP0242500B1 (en) | 1986-04-19 | 1987-01-09 | Assembly for accelerating projectiles by means of an electrically heated plasma |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0242500B1 (en) |

| JP (1) | JPS62248999A (en) |

| DE (2) | DE3613259A1 (en) |

| ES (1) | ES2013729B3 (en) |

| NO (1) | NO870473L (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH067040B2 (en) * | 1988-03-29 | 1994-01-26 | 防衛庁技術研究本部長 | Electromagnetic accelerator |

| DE3814332C2 (en) * | 1988-04-28 | 1997-05-15 | Rheinmetall Ind Ag | Device for accelerating projectiles |

| DE3814330C2 (en) * | 1988-04-28 | 1997-05-15 | Rheinmetall Ind Ag | Electrothermal accelerator |

| DE3814331A1 (en) * | 1988-04-28 | 1989-11-09 | Rheinmetall Gmbh | DEVICE FOR ACCELERATING PROJECTILE |

| US5042359A (en) * | 1988-04-28 | 1991-08-27 | Rheinmetall Gmbh | Projectile accelerating device |

| DE3816300A1 (en) * | 1988-05-13 | 1989-11-23 | Tzn Forschung & Entwicklung | CARTRIDGE FOR ELECTROTHERMAL LOCKING DEVICES |

| DE3830902C1 (en) * | 1988-09-10 | 1992-04-09 | Diehl Gmbh & Co, 8500 Nuernberg, De | |

| DE3910566A1 (en) * | 1989-04-01 | 1990-10-04 | Diehl Gmbh & Co | DEVICE FOR ACCELERATING A PROJECT BY MEANS OF A PLASMA |

| DE3921400C2 (en) * | 1989-06-29 | 1997-03-27 | Deutsch Franz Forsch Inst | Cannon arrangement |

| DE3924056A1 (en) * | 1989-07-21 | 1991-01-24 | Diehl Gmbh & Co | Projectile launching device using electrically heated plasma - uses two or more pairs of electrodes generating discharge arcs at rear of projectile |

| DE4028874A1 (en) * | 1990-09-12 | 1992-03-19 | Diehl Gmbh & Co | Electrothermal gun with pressure vessel and frangible diaphragm - expels projectile by rupture of diaphragm under pressure produced by arc discharge in highly compressed gas |

| DE4132657C2 (en) * | 1991-10-01 | 1996-02-08 | Tzn Forschung & Entwicklung | Electrothermal launcher and cartridge for use in such devices |

| DE19617895C2 (en) * | 1996-05-04 | 1998-02-26 | Rheinmetall Ind Ag | Plasma injection device |

| CN113916050B (en) * | 2021-10-19 | 2023-06-20 | 西南科技大学 | Arc discharge energized gas driven secondary light gas gun |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3431816A (en) * | 1967-07-21 | 1969-03-11 | John R Dale | Mobile gas-operated electrically-actuated projectile firing system |

| US4170922A (en) * | 1977-09-16 | 1979-10-16 | The United States Of America As Represented By The Secretary Of The Navy | Ignitor |

| US4534263A (en) * | 1982-07-19 | 1985-08-13 | Westinghouse Electric Corp. | Electromagnetic launcher with high repetition rate switch |

| DE3321034A1 (en) * | 1983-06-10 | 1984-12-13 | Messerschmitt-Bölkow-Blohm GmbH, 8012 Ottobrunn | ELECTROMAGNETIC CANNON |

-

1986

- 1986-04-19 DE DE19863613259 patent/DE3613259A1/en active Granted

-

1987

- 1987-01-09 ES ES87100186T patent/ES2013729B3/en not_active Expired - Lifetime

- 1987-01-09 DE DE8787100186T patent/DE3762165D1/en not_active Expired - Fee Related

- 1987-01-09 EP EP87100186A patent/EP0242500B1/en not_active Expired - Lifetime

- 1987-02-02 JP JP62020605A patent/JPS62248999A/en active Pending

- 1987-02-06 NO NO870473A patent/NO870473L/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| DE3613259C2 (en) | 1989-12-21 |

| JPS62248999A (en) | 1987-10-29 |

| DE3613259A1 (en) | 1987-10-29 |

| NO870473L (en) | 1987-10-20 |

| DE3762165D1 (en) | 1990-05-10 |

| EP0242500A1 (en) | 1987-10-28 |

| NO870473D0 (en) | 1987-02-06 |

| ES2013729B3 (en) | 1990-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0242500B1 (en) | Assembly for accelerating projectiles by means of an electrically heated plasma | |

| EP1348929B1 (en) | Ammunition cartridge with electrically ignited propellant charge | |

| DE3413728C3 (en) | ||

| DE3814331C2 (en) | ||

| EP0242501B1 (en) | Assembly for accelerating projectiles by means of an electrically heated plasma | |

| CH656400A5 (en) | PLASMA ARC DEVICE FOR APPLYING COVERS. | |

| DE3814330C2 (en) | Electrothermal accelerator | |

| DE1514402A1 (en) | Touch-safe ionizing air nozzle | |

| DE19617895C2 (en) | Plasma injection device | |

| DE4132657C2 (en) | Electrothermal launcher and cartridge for use in such devices | |

| DE3615585C1 (en) | Projectile for firing from an electromagnetic projectile acceleration device | |

| DE3012497A1 (en) | METHOD FOR PRODUCING A IGNITION ELECTRODE | |

| DE4410325C2 (en) | Gun barrel with an erosion-reducing insert and use of the gun barrel in electrical cannons | |

| DE19757443C2 (en) | Plasma torch device for electrothermal and electrothermal chemical cannon systems | |

| DE2209388A1 (en) | PROCEDURE FOR INTERRUPTING AN ARC AND ARRANGEMENT FOR CARRYING OUT THE PROCEDURE | |

| EP0899356B1 (en) | Method and apparatus for coating the inside of a metal tube | |

| DE3814332C2 (en) | Device for accelerating projectiles | |

| DE4003320C2 (en) | Projectile for electrothermal accelerators | |

| DE3910566C2 (en) | ||

| EP1148313B1 (en) | Electrothermal ignition device for an ammunition cartridge and its manufacturing process | |

| DE3716078A1 (en) | Gun barrel for acceleration of projectiles - has pairs of electrodes spaced along length connected to electrical source for preventing gas pressure redn. | |

| DE102008028166A1 (en) | Device for producing atmospheric cold plasma jet, has discharge tube, which has wall made up of dielectric material and central electrode, which is arranged centrically inside discharge tube in longitudinal direction | |

| DE4337964C2 (en) | Electric hybrid accelerator for a special ammunition | |

| EP0080690B1 (en) | Method of extinguishing the arc in high-voltage high-power circuit breakers | |

| DE3708910C2 (en) | Electromagnetic rail accelerator and use of the rail accelerator for accelerating floors with several plasma-forming zones arranged one behind the other |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19870424 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19880705 |

|

| ITF | It: translation for a ep patent filed |

Owner name: CALVANI SALVI E VERONELLI S.R.L. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI NL SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3762165 Country of ref document: DE Date of ref document: 19900510 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19910110 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19910110 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19910131 Ref country code: CH Effective date: 19910131 |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19910801 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 87100186.3 Effective date: 19910910 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19971211 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19971231 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980107 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990109 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991103 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050109 |