EP0180904A2 - Dispositif de refroidissement - Google Patents

Dispositif de refroidissement Download PDFInfo

- Publication number

- EP0180904A2 EP0180904A2 EP85113773A EP85113773A EP0180904A2 EP 0180904 A2 EP0180904 A2 EP 0180904A2 EP 85113773 A EP85113773 A EP 85113773A EP 85113773 A EP85113773 A EP 85113773A EP 0180904 A2 EP0180904 A2 EP 0180904A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cooling device

- suction

- subcooler

- line

- refrigerant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 25

- 239000007788 liquid Substances 0.000 claims abstract description 22

- 239000002826 coolant Substances 0.000 claims abstract description 12

- 239000003507 refrigerant Substances 0.000 claims description 30

- 238000005192 partition Methods 0.000 claims description 4

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 239000000110 cooling liquid Substances 0.000 abstract description 6

- 238000004781 supercooling Methods 0.000 description 4

- 238000001704 evaporation Methods 0.000 description 3

- 230000008020 evaporation Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 239000003921 oil Substances 0.000 description 2

- 238000005086 pumping Methods 0.000 description 2

- 241000237858 Gastropoda Species 0.000 description 1

- 206010021580 Inadequate lubrication Diseases 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 230000006651 lactation Effects 0.000 description 1

- 239000010687 lubricating oil Substances 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000005057 refrigeration Methods 0.000 description 1

- 238000009420 retrofitting Methods 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B7/00—Compression machines, plants or systems, with cascade operation, i.e. with two or more circuits, the heat from the condenser of one circuit being absorbed by the evaporator of the next circuit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B1/00—Compression machines, plants or systems with non-reversible cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/07—Details of compressors or related parts

- F25B2400/074—Details of compressors or related parts with multiple cylinders

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/13—Economisers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/23—Separators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/25—Control of valves

- F25B2600/2509—Economiser valves

Definitions

- the invention relates to a cooling device with a piston compressor having a plurality of cylinders, a condenser, an expansion element and an evaporator, with a line connecting the piston compressor, the condenser, the expansion element and the evaporator to one another for an evaporable refrigerant liquid, and with an in the line between the condenser and expansion element, provided with a vaporizable coolant subcooler for the refrigerant.

- the object is achieved in that part of the refrigerant is used as the coolant for the subcooler, and an outlet opening of the subcooler for evaporated coolant is connected via an additional suction line to the suction side of part of the cylinders of the piston compressor.

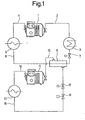

- a multi-cylinder, motor-driven compressor 1 sucks vapor Refrigerant via a so-called suction line 2 from an evaporator 3 at a relatively low pressure and compresses the steam to a relatively high pressure in order to convey it via a so-called compressed gas line 4 into a condenser 5.

- a heat transfer medium for example air, water or the like

- the liquefied (and slightly subcooled) refrigerant is passed via a liquid line 6 to an expansion device 7, the function of which is to feed an amount of refrigerant liquid adapted to the respective operating conditions into the evaporator 3.

- the expansion element 7 is also a throttling point between high and low pressure.

- the liquid refrigerant fed into the evaporator 3 and kept at low pressure evaporates by supplying heat and is then sucked off again by the compressor 1 via the suction line 2, either dry saturated or slightly overheated.

- cooling capacity the amount of heat absorbed in the evaporator 3

- the subcooler 8 has its own coolant circuit with compressor 11, suction line 12, pressure line 14,

- the circuit of the subcooler 8 also contains a solenoid valve 19.

- the refrigerant circuit connected to the compressor 1 is also referred to as the main circuit, the coolant circuit connected to the compressor 11 as a secondary circuit. Both circuits work physically in the same way.

- the delivery volume of the compressor 11 required for the secondary or subcooling circuit need only be approximately 10 to 25% of the delivery volume of the compressor 1 in order to achieve the desired liquid subcooling.

- the core of which is a compressor which combines the functions of the compressors 1 and 11.

- the common piston compressor 21 has six cylinders. Of these six cylinders, only a few (e.g. five cylinders) draw vaporous refrigerant via the suction line 22 from the evaporator 23 and, in the same way as previously described with reference to the main circuit of FIG. 1, convey via the compressed gas line 24 into the common condenser 25. After leaving the condenser 25, the liquefied refrigerant is passed directly through the subcooler 28 to the expansion element 27 via a first line A of the liquid line 26 and is fed by the latter into the evaporator 23 in a controlled manner and, after evaporation, is sucked off again by the piston compressor 21.

- a few e.g. five cylinders

- a partial flow of the liquefied refrigerant is fed into the subcooler 28 in a controlled manner via a further line B of the liquid line 26 via a remotely controlled solenoid valve 29 and through a further expansion element 30.

- the refrigerant evaporates due to this partial stream of the heat supply by the relatively warmer K älteschierikeit of the strand A and is then used as an additional suction vapor, with an outlet opening 31 of the subcooler 28 pumped connected suction line 32.

- This pumping takes place according to the invention via the cylinder or cylinders of the piston compressor 21-, the suction chambers of which are not connected to the line 22 but to the line 32. From the suction side of this or these cylinders, the suction steam is then conveyed to a common pressure chamber of the piston compressor 21 and mixed there with the steam of the main compressor part (originating from the suction line 22). This process causes the refrigerant liquid to be subcooled in the subcooler 8 with the aforementioned increase in performance resulting therefrom.

- FIG. 3 shows a modified arrangement in which the subcooler 38 is designed as an "open liquid collector", ie does not act as a heat exchanger like the subcooler 28 in the case of FIG. 2. Corresponding parts are provided with the same reference numerals in FIGS. 2 and 3.

- the principle of operation of the "open" subcooler 38 is based on the fact that part of the liquid refrigerant contained therein is sucked off in vapor form by the relevant part of the compressor 21 via the additional suction line 32.

- the K included in the sub-cooler 38 älteffentechnik is subcooled thereby.

- the solenoid valve 29 has the task of interrupting the refrigerant flow during the standstill periods and is opened with a certain delay after the start.

- a regulator 39 in the additional suction line 32 controls the pressure and the flowing amount of refrigerant.

- a pressure regulator 4o is provided in the system according to FIG. 3, which is required to maintain a certain condensing pressure.

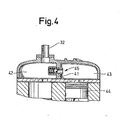

- FIG. 4 shows one of the twin cylinder heads.

- the other cylinder heads of the compressor are designed in the usual way.

- the suction chamber of the cylinder head shown in FIG. 4 is divided into two suction chambers 42 and 43 by a partition 41.

- the chamber 42 is connected to the subcooler via the additional suction line 32 in the manner described.

- the suction chamber 43 like the suction chambers of the other cylinders, is connected to the evaporator 23 via the suction line 22.

- One of the pistons 44 of the compressor is visible in FIG. 3. All cylinders of the arrangement are connected to a common pressure chamber (not shown) in the usual way.

- a valve device 45 is arranged in the partition 41, which is designed either (as shown) as a check valve 46 or as a solenoid valve can be.

- the compressor compressor 21

- the subcooler is first pumped down to a suction pressure that corresponds to that of the other cylinders.

- the check valve opens automatically, the cylinder in question then works in parallel with the other compressor part.

- valve device 41 as a solenoid valve, this must already be opened when the solenoid valve 29 closes.

- the cooling device described offers the following advantages: at the start, the system can initially stabilize by delayed opening of the solenoid valve 29. The risk of refrigerant transfer from the subcooler to the compressor during the Start-up phase is avoided by the aforementioned empty pumping. By switching the supercooling circuit on and off, power control is possible without affecting the application limits. By combining the main circuit with its secondary circuit, there is no need for second compressors and condensers with accessories. This also results in a simplified line assembly. A subsequent retrofitting of the compressor to the embodiment according to FIG. 4 is possible.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

- Surgical Instruments (AREA)

- Encapsulation Of And Coatings For Semiconductor Or Solid State Devices (AREA)

- Sampling And Sample Adjustment (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85113773T ATE46026T1 (de) | 1984-11-03 | 1985-10-29 | Kuehlvorrichtung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19843440253 DE3440253A1 (de) | 1984-11-03 | 1984-11-03 | Kuehlvorrichtung |

| DE3440253 | 1984-11-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0180904A2 true EP0180904A2 (fr) | 1986-05-14 |

| EP0180904A3 EP0180904A3 (en) | 1986-10-08 |

| EP0180904B1 EP0180904B1 (fr) | 1989-08-30 |

Family

ID=6249455

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85113773A Expired EP0180904B1 (fr) | 1984-11-03 | 1985-10-29 | Dispositif de refroidissement |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0180904B1 (fr) |

| AT (1) | ATE46026T1 (fr) |

| DE (2) | DE3440253A1 (fr) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2092424A1 (es) * | 1992-09-16 | 1996-11-16 | Ornaque Carlos Gutierrez | Sistema frigorico de seguridad por bloque mixto. |

| EP0898128A2 (fr) * | 1997-08-22 | 1999-02-24 | Carrier Corporation | Pompe à chaleur à compression internement étagée et à fluide frigorigène variable |

| EP0837291A3 (fr) * | 1996-08-22 | 2000-10-04 | Denso Corporation | Système frigorifique du type à compression de vapeur |

| EP1139039A1 (fr) * | 2000-03-27 | 2001-10-04 | Carrier Corporation | Amélioration d'un circuit d'économiseur |

| EP1498667A2 (fr) * | 2003-07-18 | 2005-01-19 | Star Refrigeration Ltd. | Système de réfrigération améliore a cycle transcritique |

| WO2005008148A1 (fr) * | 2003-07-14 | 2005-01-27 | Carrier Corporation | Systeme de compression de fluide frigorigene a sous-refroidissement selectif |

| WO2006015741A1 (fr) * | 2004-08-09 | 2006-02-16 | Linde Kältetechnik Gmbh | Circuit frigorifique et procede de fonctionnement d'un circuit frigorifique |

| DE102005009173A1 (de) * | 2005-02-17 | 2006-08-24 | Bitzer Kühlmaschinenbau Gmbh | Kälteanlage |

| US8113008B2 (en) | 2004-08-09 | 2012-02-14 | Carrier Corporation | Refrigeration circuit and method for operating a refrigeration circuit |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4702086A (en) * | 1986-06-11 | 1987-10-27 | Turbo Coils Inc. | Refrigeration system with hot gas pre-cooler |

| US5095712A (en) * | 1991-05-03 | 1992-03-17 | Carrier Corporation | Economizer control with variable capacity |

| DE19826291A1 (de) * | 1998-06-12 | 1999-12-16 | Linde Ag | Verfahren zum Betreiben einer Pumpe zur Förderung siedender Kältemittel oder Kälteträger |

| DK3295029T3 (da) | 2015-05-13 | 2019-09-23 | Carrier Corp | Frem- og tilbagegående economiserkompressor |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH101888A (de) * | 1922-06-26 | 1923-10-16 | Sulzer Ag | Verbund-Kompressions-Kältemaschine. |

| US2320097A (en) * | 1941-08-20 | 1943-05-25 | Servel Inc | Refrigeration |

| FR2287666A1 (fr) * | 1974-10-11 | 1976-05-07 | Primore Sales Inc | Soupape automatique munie d'un compresseur de refrigerant |

| FR2304041A1 (fr) * | 1975-03-11 | 1976-10-08 | Kvaerner Brug Kjoleavdelning | Dispositif pour une installation de compression et de condensation de gaz |

| US4197719A (en) * | 1976-01-29 | 1980-04-15 | Dunham-Bush, Inc. | Tri-level multi-cylinder reciprocating compressor heat pump system |

| US4230470A (en) * | 1977-01-21 | 1980-10-28 | Hitachi, Ltd. | Air conditioning system |

| FR2503841A1 (fr) * | 1981-04-09 | 1982-10-15 | Guillemin Georges | Pompe a chaleur pour le chauffage de batiments |

| DE3301304A1 (de) * | 1982-02-26 | 1983-09-15 | Hitachi, Ltd., Tokyo | Kuehlanlage mit einem kompressor in spiralbauweise |

-

1984

- 1984-11-03 DE DE19843440253 patent/DE3440253A1/de not_active Withdrawn

-

1985

- 1985-10-29 AT AT85113773T patent/ATE46026T1/de not_active IP Right Cessation

- 1985-10-29 DE DE8585113773T patent/DE3572721D1/de not_active Expired

- 1985-10-29 EP EP85113773A patent/EP0180904B1/fr not_active Expired

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH101888A (de) * | 1922-06-26 | 1923-10-16 | Sulzer Ag | Verbund-Kompressions-Kältemaschine. |

| US2320097A (en) * | 1941-08-20 | 1943-05-25 | Servel Inc | Refrigeration |

| FR2287666A1 (fr) * | 1974-10-11 | 1976-05-07 | Primore Sales Inc | Soupape automatique munie d'un compresseur de refrigerant |

| FR2304041A1 (fr) * | 1975-03-11 | 1976-10-08 | Kvaerner Brug Kjoleavdelning | Dispositif pour une installation de compression et de condensation de gaz |

| US4197719A (en) * | 1976-01-29 | 1980-04-15 | Dunham-Bush, Inc. | Tri-level multi-cylinder reciprocating compressor heat pump system |

| US4230470A (en) * | 1977-01-21 | 1980-10-28 | Hitachi, Ltd. | Air conditioning system |

| FR2503841A1 (fr) * | 1981-04-09 | 1982-10-15 | Guillemin Georges | Pompe a chaleur pour le chauffage de batiments |

| DE3301304A1 (de) * | 1982-02-26 | 1983-09-15 | Hitachi, Ltd., Tokyo | Kuehlanlage mit einem kompressor in spiralbauweise |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2092424A1 (es) * | 1992-09-16 | 1996-11-16 | Ornaque Carlos Gutierrez | Sistema frigorico de seguridad por bloque mixto. |

| EP0837291A3 (fr) * | 1996-08-22 | 2000-10-04 | Denso Corporation | Système frigorifique du type à compression de vapeur |

| EP0898128A2 (fr) * | 1997-08-22 | 1999-02-24 | Carrier Corporation | Pompe à chaleur à compression internement étagée et à fluide frigorigène variable |

| EP0898128A3 (fr) * | 1997-08-22 | 2001-09-05 | Carrier Corporation | Pompe à chaleur à compression internement étagée et à fluide frigorigène variable |

| EP1139039A1 (fr) * | 2000-03-27 | 2001-10-04 | Carrier Corporation | Amélioration d'un circuit d'économiseur |

| WO2005008148A1 (fr) * | 2003-07-14 | 2005-01-27 | Carrier Corporation | Systeme de compression de fluide frigorigene a sous-refroidissement selectif |

| EP1498667A3 (fr) * | 2003-07-18 | 2006-05-17 | Star Refrigeration Ltd. | Système de réfrigération améliore a cycle transcritique |

| EP1498667A2 (fr) * | 2003-07-18 | 2005-01-19 | Star Refrigeration Ltd. | Système de réfrigération améliore a cycle transcritique |

| US7845190B2 (en) | 2003-07-18 | 2010-12-07 | Star Refrigeration Limited | Transcritical refrigeration cycle |

| WO2006015741A1 (fr) * | 2004-08-09 | 2006-02-16 | Linde Kältetechnik Gmbh | Circuit frigorifique et procede de fonctionnement d'un circuit frigorifique |

| US8113008B2 (en) | 2004-08-09 | 2012-02-14 | Carrier Corporation | Refrigeration circuit and method for operating a refrigeration circuit |

| US8844303B2 (en) | 2004-08-09 | 2014-09-30 | Carrier Corporation | Refrigeration circuit and method for operating a refrigeration circuit |

| US9476614B2 (en) | 2004-08-09 | 2016-10-25 | Carrier Corporation | Refrigeration circuit and method for operating a refrigeration circuit |

| US9494345B2 (en) | 2004-08-09 | 2016-11-15 | Carrier Corporation | Refrigeration circuit and method for operating a refrigeration circuit |

| DE102005009173A1 (de) * | 2005-02-17 | 2006-08-24 | Bitzer Kühlmaschinenbau Gmbh | Kälteanlage |

| WO2006087075A1 (fr) * | 2005-02-17 | 2006-08-24 | Bitzer Kühlmaschinenbau Gmbh | Appareil frigorifique |

| US7451617B2 (en) | 2005-02-17 | 2008-11-18 | Bitzer Kuhlmaschinenbau Gmbh | Refrigeration system |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3572721D1 (en) | 1989-10-05 |

| EP0180904B1 (fr) | 1989-08-30 |

| ATE46026T1 (de) | 1989-09-15 |

| DE3440253A1 (de) | 1986-05-15 |

| EP0180904A3 (en) | 1986-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2508417C2 (de) | Kälteerzeugungssystem | |

| EP1789732B1 (fr) | Circuit frigorifique et procede de fonctionnement d'un circuit frigorifique | |

| DE60011196T2 (de) | Kombinierter Wärmetauscher mit Verdampfer, Akkumulator und Saugleitung | |

| DE69003067T2 (de) | Kälteanlage. | |

| DE3046549C2 (de) | Vorrichtung zum Verflüssigen von Erdgas oder Synthesegas mit niedrigem Siedepunkt | |

| DE60113363T2 (de) | Kälteanlage mit Phasentrennung | |

| EP0855009B1 (fr) | Convertisseur thermique par sorption dote de composants supplementaires | |

| EP0180904A2 (fr) | Dispositif de refroidissement | |

| DE2157079A1 (de) | Zweistufige Kälteanlage | |

| DE112004002189T5 (de) | Kühlsystem mit Verdampfer und Verdichter | |

| WO2006015741A1 (fr) | Circuit frigorifique et procede de fonctionnement d'un circuit frigorifique | |

| DE3521060A1 (de) | Verfahren zum kuehlen und verfluessigen von gasen | |

| DE2709343A1 (de) | Gegenstrom-klimaanlage | |

| EP0190319B1 (fr) | Machine frigorifique ou pompe a chaleur et pompe a jet pour celle-ci | |

| EP0021205A2 (fr) | Procédé de compression-absorption hybride pour pompes à chaleur ou machine frigorifique | |

| EP2215412A1 (fr) | Installation pour le refroidissement, le chauffage ou la climatisation, en particulier installations frigorifiques | |

| DE4122889C1 (fr) | ||

| DE2261091A1 (de) | Anordnung zur oelkuehlung bei kuehlkompressoren des rotationstyps | |

| DE19533755C2 (de) | Vorrichtung und Verfahren zur Erzeugung von Wärme und Kälte | |

| DE3431452A1 (de) | Als waermepumpe genutztes kuehl- oder gefriergeraet | |

| DE2438418A1 (de) | Gaskompressor der verdraengerbauart, insbesondere fuer kaeltemaschinen | |

| DE2837695A1 (de) | Verfahren und vorrichtung zur wirkungsgradverbesserung in einer kuehlanlage | |

| DE2825076A1 (de) | Waermepumpensystem | |

| DE68926533T2 (de) | Doppelverdampferkühlvorrichtung für Haushaltskühlschränke | |

| DE19832682A1 (de) | Abtaueinrichtung für einen Verdampfer einer Wärmepumpe oder eines Klimageräts |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE DE FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19870404 |

|

| 17Q | First examination report despatched |

Effective date: 19880108 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE FR GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19890830 Ref country code: NL Effective date: 19890830 Ref country code: BE Effective date: 19890830 |

|

| REF | Corresponds to: |

Ref document number: 46026 Country of ref document: AT Date of ref document: 19890915 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3572721 Country of ref document: DE Date of ref document: 19891005 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19891029 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19941028 Year of fee payment: 10 Ref country code: FR Payment date: 19941028 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19941121 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19951029 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19951029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960702 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |