EP0165334B1 - Trigger mechanism for small arms - Google Patents

Trigger mechanism for small arms Download PDFInfo

- Publication number

- EP0165334B1 EP0165334B1 EP84107194A EP84107194A EP0165334B1 EP 0165334 B1 EP0165334 B1 EP 0165334B1 EP 84107194 A EP84107194 A EP 84107194A EP 84107194 A EP84107194 A EP 84107194A EP 0165334 B1 EP0165334 B1 EP 0165334B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- trigger

- pin

- sear

- pivot

- rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000010304 firing Methods 0.000 claims abstract description 30

- 230000000903 blocking effect Effects 0.000 claims abstract description 9

- 230000000452 restraining effect Effects 0.000 claims abstract 2

- 230000033001 locomotion Effects 0.000 description 8

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000001960 triggered effect Effects 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 206010027175 memory impairment Diseases 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A17/00—Safety arrangements, e.g. safeties

- F41A17/56—Sear safeties, i.e. means for rendering ineffective an intermediate lever transmitting trigger movement to firing pin, hammer, bolt or sear

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A19/00—Firing or trigger mechanisms; Cocking mechanisms

- F41A19/06—Mechanical firing mechanisms, e.g. counterrecoil firing, recoil actuated firing mechanisms

- F41A19/17—Hair-trigger mechanisms

Definitions

- the invention relates to a trigger device with a trigger for handguns, in which a trigger lug pivotably in a housing, which locks the cocked firing pin in its one pivot position, a trigger rod which supports the trigger gun in its one pivot position and thereby holds the trigger bar in its pivot position blocking the firing pin Actuation in the trigger direction, the trigger rod is arranged in its other pivot position, which releases the trigger studs, and a trigger tensioner which can be tensioned by the trigger when it is actuated against the trigger direction, with a securing element in its securing position preventing the trigger from being actuated in the trigger direction.

- the geometry of the trigger devices of small arms is usually designed such that a force of at least 1.5 kg, preferably 2 kg, must be exerted on the trigger to trigger a shot.

- this high trigger weight often leads to the shot getting torn, especially with less experienced shooters.

- the so-called pricking devices which is an additional device installed in the direction of the trigger, with which the trigger weight can be reduced to up to approximately one hundred grams. Even a very slight vibration or movement of the weapon is then sufficient to trigger a shot. Therefore, it is only permitted under certain circumstances and under observation of special safety measures and regulations to bring about this dangerous and critical condition of the weapon.

- the trigger should only be tensioned shortly before the shot is fired, i.e. , only when the weapon is already aimed at the target to be shot. It is also a requirement that the piercer must be released immediately if the planned shot could not be fired for any reason.

- the object of the present invention is now to further increase the safety of such trigger devices, namely to prevent the trigger from being triggered unintentionally even when the shooter is acting against the regulations and has been there for a long time before the shot, namely when the trigger device is secured , the piercer wants to cock and / or forgets to release the piercer by opening the breech if the intended shot is not fired.

- the trigger gallery is loaded into its pivot position blocking the strained firing pin by a spring and is forced into its other pivot position by the untensioned firing pin, and in the latter pivot position it locks the plunger clamp in its untensioned pivot position that the trigger attacks when actuating against the trigger direction on the plunger clamping piece, pivots it into the clamping position and holds it in an unstable equilibrium

- the securing element is a slide which relaxes the tensioned plunger clamping piece during the transfer from the unlocked to the securing position and which in its securing position locks the trigger rod against a release of the trigger gallery and the trigger against actuation also in the direction of the trigger direction.

- the trigger device In the trigger device according to the invention, it is therefore not possible to cock the set as long as the weapon is secured. The shooter is thus forced to tighten the trigger only after the weapon has been unlocked, i.e. when it is already in the firing position. If the intended shot is not fired for any reason, the gun is automatically released from the safety by securing the weapon, so that the previously usual additional process, namely the opening of the breech or the separate manual relaxation of the stick after the safety is avoided.

- a trigger gallery 2 a trigger rod 3 and a trigger 4 are each rotatably mounted in a trigger housing 1.

- 5 with a plunger clamping piece 5 is also rotatably mounted in the trigger housing 1.

- a safety slide 6 is slidably mounted in the trigger housing 1.

- the take-off lug 2 can be rotated to a limited extent about an axis 7 and is loaded into an upper position by a spring 8, which ensures its coupling with a firing pin nut 9.

- the trigger rod 3 is rotatable about an axis 10 and is loaded by a spring-loaded pin 11 in the direction of the trigger gallery 2.

- the trigger 4 is also rotatably mounted on this axis 10 and is supported by a spring 12 with its contact surface 13 against the trigger rod 3 pressed.

- the engraver clamping piece 5 is double-armed and has a tensioning roller 14 and an adjusting screw 15 on the arm facing the trigger 4, while a spring 16 acts on the other arm.

- the adjusting screw 15 is used to compensate for manufacturing-related tolerances and allows the tensioning roller 14 to be optimally positioned with respect to the upper arm 17 of the trigger 14.

- the safety slide 6 has a lower securing position (FIG. 1) and an upper unlocked position (FIG. 2),

- the firing pin nut 9 passes behind a hook 18 of the trigger stud 2.

- the trigger stud 2 cannot escape the force exerted on it by the firing pin nut 9, i. H. do not swivel downward because its surface 19 is supported against the surface 20 of the trigger rod 3.

- the take-off gallery 2 has two cams 21 and 22, the height difference between the lower cam 21 and the upper cam 22 determining the catch entry, that is to say the degree of overlap between the support surfaces 19 and 20.

- the end faces the cams 21 and 22 are expediently formed parallel to the direction of movement of the safety slide 6.

- the distance between the surface 23 of the safety slide 6 and the upper cam 22 of the trigger lug 2 must be less than the distance between the surface 23 and the lower cam 21 of the trigger lug 2; in practice the difference in distance is advantageously between 0.2 and 0.4 mm.

- the width of the head 24 of the trigger rod 3 must correspond to the distance between the cam 21 and the surface 23.

- the head 24 of the trigger rod 3 should also have parallel surfaces. This enables economical manufacturing of very tight tolerances by means of simple grinding processes.

- the trigger rod 3 is pivoted out of the support latch of the trigger block 2 for the purpose of firing the shot by pressure on the lower arm 26 of the trigger 4.

- the geometry of the trigger support latches is designed such that a force of at least 1.5 kg, preferably 2 kg , must be applied to the lower arm 26 of the trigger 4 to trigger a shot

- the trigger weight mentioned can be reduced to a few 100 g, in extreme cases even to 50 g and less, by means of the piercing device explained below. With such a low trigger weight, a very slight vibration or movement of the interacting parts can be sufficient to trigger a shot. That's why it is only permitted under certain circumstances and with special safety measures and regulations, to bring about this dangerous and critical condition of the weapon.

- this state is produced by advancing the lower arm 26 of the trigger 4, that is to say by advancing the lever 26 in the direction of the arrow in FIG. 3.

- the trigger 4 rotates about the axis 10 so that its upper arm 27 counterclockwise towards

- Plunger clamping piece 5 pivots.

- the contact surface 28 of the arm 27 then presses against the roller 14, as a result of which the arm of the plunger 5 connected to the roller 14 is pivoted upward against the pressure of the spring 16.

- the arm 27 of the trigger 4 is pivoted so far in the direction of the chuck 5, until its edge 29 engages under the roller 14 and a balance of forces between the force of the spring 16, the force of the spring 12 and the frictional force of the moving parts arises; this position can be called the dead center position. In this position, the engraver is cocked. In order to be able to carry out this tensioning of the piercer, however, it is a prerequisite that - as drawn in FIG. 3 - the safety slide 6 is in the unlocked state, as will be explained later.

- the reduction ratio and thus the trigger weight can be varied in a simple manner by means of an adjusting screw 30, with which the amount by which the arm 27 with its edge 29 can be pivoted behind the actual dead center position of the roller 14 can be determined. If the balance of forces is destroyed by a force acting on the lever arm 26 of the trigger 4 in the direction of the arrow (FIG. 4), then it suddenly collapses under the action of the strong spring 16. The spring 16 now presses the pretensioner 5 back into its rest position (FIG. 1), the roller 14 throwing the arm 27 of the trigger 4 forward over the inclined surface 28 in the direction of the trigger rod 3. The arm 27 strikes with its surface 13 against the trigger rod 3 and knocks it out of the support latch 19 of the trigger gallery 2. The trigger gallery 2 thus pivots, as already described for the case of the stab-free firing, under the influence of the firing pin spring and gives the firing pin free.

- the measures are to be explained which lead to the fact that, in the secured state, as mentioned, the piercer cannot be tensioned and that the tensioned piercer is relaxed when the weapon is secured.

- the trigger device is shown with the cock under tension.

- the safety slide 6 has at its lower end a recess 31 into which the cam 32 of the trigger 4 can enter. In the secured state (FIG. 1), this recess 31 lies below the cam 32, so that the trigger 4 or its lever 26 cannot be moved in the direction of the arrow of FIG. 3. So if the weapon is secured, ie if the safety slide 6 is in its lower position, then a "piercing" is not possible.

- the edge 33 will slide after only a few tenths of a millimeter the surface 23 over the surface 34 of the trigger rod 3 and prevents the trigger rod 3 from being pivoted out of the catch 19 of the trigger gallery 2 by pressure or impact.

- the inserted trigger device is already secured after a minimal displacement of the safety slide 6, so that, as is generally customary in the previously known repeating rifles, the piercer could be stabbed by manual actuation of the trigger arm 26 without a shot being triggered thereby .

- the safety slide 6 automatically performs the stabbing in the further course of its downward movement into the secured end position, thereby that with its paragraph 35 hits the cam 32 of the trigger 4 and thereby inevitably relaxes the cocked prick.

- the safety slide 6 jumps into one or the other end position by a suitable spring element and thereby the pulse gets to knock the trigger 4 out of its cocked position via its cam 32, this operation of the slide 6 is known per se.

- cocking the trigger and triggering a shot by the trigger are only possible with the trigger device fully cocked and fully unlocked. If the cocked prick is to be relaxed again without triggering a shot, this can be done by actuating the safety device of the trigger device, with an - unintentional - firing of the shot being prevented even with the slightest displacement of the safety slide into the safety position.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Toys (AREA)

Abstract

Description

Die Erfindung betrifft eine Abzugseinrichtung mit Rückstecher für Handfeuerwaffen, bei der in einem Gehäuse schwenkbar ein Abzugsstollen, der in seiner einen Schwenkstellung den gespannten Schlagbolzen sperrt, eine in ihrer einen Schwenkstellung den Abzugsstollen abstützende und dabei in seiner den Schlagbolzen sperrenden Schwenkstellung haltenden Abzugsstange, ein bei Betätigung in Abzugsrichtung die Abzugsstange in ihre andere, den Abzugsstollen freigebenden Schwenkstellung schwenkenden Abzug und ein vom Abzug bei dessen Betätigung entgegen der Abzugsrichtung spannbares Stecherspannstück angeordnet sind, wobei ein Sicherungselement in seiner sichernden Stellung das Betätigen des Abzugs in Abzugsrichtung verhindert.The invention relates to a trigger device with a trigger for handguns, in which a trigger lug pivotably in a housing, which locks the cocked firing pin in its one pivot position, a trigger rod which supports the trigger gun in its one pivot position and thereby holds the trigger bar in its pivot position blocking the firing pin Actuation in the trigger direction, the trigger rod is arranged in its other pivot position, which releases the trigger studs, and a trigger tensioner which can be tensioned by the trigger when it is actuated against the trigger direction, with a securing element in its securing position preventing the trigger from being actuated in the trigger direction.

Aus Sicherheitsgründen ist die Geometrie der Abzugseinrichtungen von Handfeuerwaffen üblicherweise so ausgelegt, daß eine Kraft von mindestens 1,5 kg, vorzugsweise 2 kg, auf den Abzug ausgeübt werden muß, um einen Schuß auszulösen. Dieses hohe Abzugsgewicht führt aber, insbesondere bei weniger geübten Schützen, vielfach zu einem Verreißen des Schusses. Abhilfe schaffen hier die sogenannten Stechereinrichtungen, wobei es sich um eine in die Abzugsrichtung eingebaute Zusatzvorrichtung handelt, mit der das Abzugsgewicht auf bis ca. hundert Gramm, reduziert werden kann. Schon eine sehr geringe Erschütterung oder Bewegung der Waffe genügt dann aber, um einen Schuß auszulösen. Deshalb ist es auch nur unter bestimmten Umständen und unter Beobachtung besonderer Sicherheitsmaßnahmen und -vorschriften erlaubt, diesen gefährlichen und kritischen Zustand der Waffe herbeizuführen. So ist es beispielsweise vorgeschrieben, daß erst im Anschlag kurz vor Abgabe des Schusses der Stecher gespannt werden darf, d.h. , erst dann, wenn die Waffe bereits auf das zu beschießende Ziel gerichtet ist. Weiterhin ist Vorschrift, daß der Stecher sofort wieder entspannt werden muß, wenn der geplante Schuß aus irgendwelchen Gründen nicht abgegeben werden konnte.For safety reasons, the geometry of the trigger devices of small arms is usually designed such that a force of at least 1.5 kg, preferably 2 kg, must be exerted on the trigger to trigger a shot. However, this high trigger weight often leads to the shot getting torn, especially with less experienced shooters. This is remedied by the so-called pricking devices, which is an additional device installed in the direction of the trigger, with which the trigger weight can be reduced to up to approximately one hundred grams. Even a very slight vibration or movement of the weapon is then sufficient to trigger a shot. Therefore, it is only permitted under certain circumstances and under observation of special safety measures and regulations to bring about this dangerous and critical condition of the weapon. For example, it is stipulated that the trigger should only be tensioned shortly before the shot is fired, i.e. , only when the weapon is already aimed at the target to be shot. It is also a requirement that the piercer must be released immediately if the planned shot could not be fired for any reason.

Bei der eingangs erwähnten Abzugseinrichtung mit Rückstecher, wie sie in der DE-PS-22 53 199 offenbart ist, sind deshalb Maßnahmen getroffen, die dafür Sorge tragen, daß bei geöffneter Kammer oder entspanntem Schloß der Stecher nicht gespannt werden kann und daß beim öffnen des Verschlusses sich der gespannte Stecher selbsttätig entspannt. Ännliche Sicherheitsmaßnahmen sind bei einer konstruktiv etwas anders gestalteten Abzugseinrichtung nach der DE-PS-29 33 107 getroffen; auch hier kann der Stecher nur bei gespanntem Schloß und geschlossener Kammer gespannt werden und wird beim Öffnen des Verschlusses selbsttätig entspannt.In the trigger device with backstitch mentioned at the outset, as disclosed in DE-PS-22 53 199, measures are therefore taken to ensure that when the chamber is open or the lock is relaxed, the setter cannot be tensioned and that when the The tensioned setter automatically relaxes. Similar security measures are taken with a structurally somewhat different extraction device according to DE-PS-29 33 107; here too, the set can only be tightened when the lock and chamber are closed and is automatically released when the lock is opened.

Aufgabe der vorliegenden Erfindung ist es nun, die Sicherheit derartiger Abzugseinrichtungen noch weiter zu erhöhen, nämlich ein ungewolltes Auslösen des Schusses durch den Stecher auch dann zu verhindern, wenn der Schütze gegen die Vorschriften handelt und bereits längere Zeit vor dem Schuß, nämlich bei gesicherter Abzugseinrichtung, den Stecher spannen will und/oder bei Nichtabgabe des beabsichtigten Schusses vergißt, den Stecher durch Öffnen des Verschlusses zu entspannen. Die Lösung dieser Aufgabe erfolgt dadurch, daß der Abzugsstollen in seine den gespannten Schlagbolzen sperrende Schwenkstellung durch eine Feder belastet und in seine andere Schwenkstellung durch den ungespannten Schlagbolzen gezwungen ist, wobei er in der letzteren Schwenkstellung das Stecherspannstuck in dessen ungespannter Schwenkstellung arretiert, daß der Abzug bei seiner Betätigung entgegen der Abzugsrichtung am Stecherspannstück angreift, dieses in die Spannstellung verschwenkt und in dieser in einem labilen Gleichgewicht festhält, und daß das Sicherungselement ein Schieber ist, der bei Überführung von der entsicherten in die sichernde Stellung das gespannte Stecherspannstück entspannt und der in seiner sichernden Stellung die Abzugsstange gegen eine Freigabe des Abzugsstollens und den Abzug gegen eine Betätigung auch in Richtung gegen die Abzugsrichtung sperrt.The object of the present invention is now to further increase the safety of such trigger devices, namely to prevent the trigger from being triggered unintentionally even when the shooter is acting against the regulations and has been there for a long time before the shot, namely when the trigger device is secured , the piercer wants to cock and / or forgets to release the piercer by opening the breech if the intended shot is not fired. This object is achieved in that the trigger gallery is loaded into its pivot position blocking the strained firing pin by a spring and is forced into its other pivot position by the untensioned firing pin, and in the latter pivot position it locks the plunger clamp in its untensioned pivot position that the trigger attacks when actuating against the trigger direction on the plunger clamping piece, pivots it into the clamping position and holds it in an unstable equilibrium, and that the securing element is a slide which relaxes the tensioned plunger clamping piece during the transfer from the unlocked to the securing position and which in its securing position locks the trigger rod against a release of the trigger gallery and the trigger against actuation also in the direction of the trigger direction.

Bei der erfindungsgemäßen Abzugseinrichtung ist es also nicht möglich, den Stecher zu spannen, solange die Waffe gesichert ist. Der Schütze wird damit gezwungen, das Spannen des Stechers erst nach dem Entsichern der Waffe, also wenn diese sich bereits im Anschlag befindet, vorzunehmen. Wird der beabsichtigte Schuß aus irgendwelchen Gründen nicht abgegeben, dann erfolgt durch das Sichern der Waffe ein selbsttätiges Entspannen des Stechers, so daß sich der bisher übliche zusätzliche Vorgang, nämlich das Öffnen des Verschlusses oder das separate manuelle Entspannen des Stechers nach dem Sichern erübigt.In the trigger device according to the invention, it is therefore not possible to cock the set as long as the weapon is secured. The shooter is thus forced to tighten the trigger only after the weapon has been unlocked, i.e. when it is already in the firing position. If the intended shot is not fired for any reason, the gun is automatically released from the safety by securing the weapon, so that the previously usual additional process, namely the opening of the breech or the separate manual relaxation of the stick after the safety is avoided.

Zweckmäßige Ausgestaltungen der Erfindung sind in den Unteransprüchen gekennzeichnet.Advantageous embodiments of the invention are characterized in the subclaims.

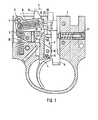

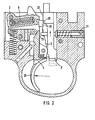

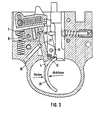

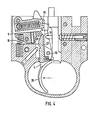

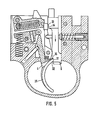

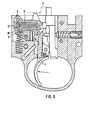

Auf der Zeichnung ist eine Ausführungsform der Erfindung beispielsweise dargestellt. Es zeigen;

- Fig. 1 eine Seitenansicht der Abzugseinrichtung, und zwar im gespannten und gesicherten Zustand, wobei jedoch der Stecher ungespannt ist,

- Fig. 2 eine Seitenansicht der Abzugseinrichtung gemäß Fig. 1, und zwar in gespannten und entsichertem Zustand, wobei der Stecher ungespannt ist,

- Fig. 3 eine Seitenansicht der Abzugseinrichtung gemäß Fig. 1, und zwar in gespanntem und entsichertem Zustand, wobei der Stecher gespannt ist,

- Fig. 4 eine Seitenansicht der Abzugseinrichtung gemäß Fig. 1, und zwar in gespannten und entsichertem Zustand, wobei der Stecher ausgelöst ist und sich in seiner Vorwärtsbewegung befindet, Fig. 5 eine Seitenansicht der Abzugseinrichtung gemäß Fig. 1, und zwar in gespanntem Zustand, wobei der Stecher gespannt ist und der Sicherungsschieber sich in Bewegung aus seiner entsicherten in seine sichernde Stellung befindet, und

- Fig. 6 eine Seitenansicht der Abzugseinrichtung gemäß Fig. 1, und zwar in entspanntem und entsichertem Zustand, wobei sich der Abzug in Auslösestellung befindet.

- 1 is a side view of the trigger device, namely in the tensioned and secured state, but with the lug untensioned,

- FIG. 2 shows a side view of the trigger device according to FIG. 1, namely in a tensioned and unlocked state, the piercer being untensioned,

- 3 shows a side view of the trigger device according to FIG. 1, namely in a tensioned and unlocked state, with the piercer being tensioned,

- 4 shows a side view of the trigger device according to FIG. 1, namely in a tensioned and unlocked state, the trigger being triggered and in its forward movement, 5 is a side view of the trigger device according to FIG. 1, namely in the tensioned state, the piercer being tensioned and the safety slide being in motion from its unlocked position to its securing position, and

- 6 shows a side view of the trigger device according to FIG. 1, in a relaxed and unlocked state, the trigger being in the release position.

Zunächst werden anhand der Fig. 1 und 2 der Aufbau und die Funktionsweise des Abzugs und der Sicherung beschrieben, und zwar ohne Berücksichtigung der - ungespannten - Stechereinrichtung.First of all, the structure and the mode of operation of the trigger and the fuse are described with reference to FIGS. 1 and 2, without taking into account the - unstressed - pricking device.

Gemäß Fig. 1 sind in einem Abzugsgehäuse 1 ein Abzugsstollen 2, eine Abzugsstange 3 und ein Abzug 4 jeweils drehbar gelagert. Mit 5 ist ein im Abzugsgehäuse 1 ebenfalls drehbar gelagertes Stecherspannstücke 5 bezeichnet. Weiterhin ist im Abzugsgehäuse 1 ein Sicherungsschiebar 6 gleitbar gelagert.1, a

Der Abzugsstollen 2 ist um eine Achse 7 begrenzt drehbar und wird durch eine Feder 8 in eine obere Stellung belastet, die seine Kopplung mit einer Schlagbolzenmutter 9 sicherstellt. Die Abzugsstange 3 ist um eine Achse 10 drehbar und wird von einem federbelasteten Bolzen 11 in Richtung auf den Abzugsstollen 2 hin belastet, Der Abzug 4 ist ebenfalls drehbar auf dieser Achse 10 gelagert und wird durch eine Feder 12 mit seiner Anlagefläche 13 gegen die Abzugsstange 3 gedrückt. Das StecherSpannstück 5 ist doppelarmig ausgebildet und weist auf den dem Abzug 4 zugewandten Arm eine Spannrolle 14 und eine Justierschraube 15 auf, während an dem anderen Arm eine Feder 16 angreift. Die Justierschraube 15 dient zum Ausgleich von fertigungsbedingten Toleranzen und erlaubt die optimale Positionierung der Spannrolle 14 gegenüber dem oberen Arm 17 des Abzugs 14. Der Sicherungsschiebbar 6 weist eine untere Sicherungsstellung (Fig. 1) und eine obere entsicherte Stellung (Fig.2) auf,The take-

Im gespannten Zustand der Waffe tritt die Schlagbolzenmutter 9 hinter einen Haken 18 des Abzugsstollens 2. Dabei kann der Abzugsstollen 2 der von der Schlagbolzenmutter 9 auf ihn ausgeübten Kraft nicht ausweichen, d. h. nicht nach unten schwenken, weil er sich mit seiner Fläche 19 gegen die Fläche 20 der Abzugsstange 3 abstützt. Wie aus der Zeichnung ersichtlich ist, weist dabei der Abzugsstollen 2 zwei Nocken 21 und 22 auf, wobei die Höhendifferenz zwischen unterem Nocken 21 und oberem Nocken 22 den Rasteneintritt bestimmt, das heißt, den Grad der Überschneidung zwischen den Stützflächen 19 und 20. Die Stirnflächen der Nocken 21 und 22 sind zweckmäßigerweise parallel zur Bewegungsrichtung des Sicherungsschiebers 6 ausgebildet. Der Abstand zwischen der Fläche 23 des Sicherungsschiebers 6 und dem oberen Nocken 22 des Abzugsstollens 2 muß geringer sein als der Abstand zwischen der Fläche 23 und dem unteren Nocken 21 des Abzugsstollens 2; in der Praxis liegt der Abstandsunterschied zweckmäßigerweise zwischen 0,2 und 0,4 mm. Die Breite des Kopfes 24 der Abzugsstange 3 muß dem Abstand zwischen Nocken 21 und Fläche 23 entsprechen. Wie die Stirnfläche der Nocken 21 und 22 des Abzugsstollens 2 parallel zur Fläche 23 des Sicherungsschiebers 3 soll auch der Kopf 24 der Abzugsstange 3 dazu parallele Flächen aufweisen. Dies ermöglicht eine wirtschaftliche Fertigung sehr enger Toleranzen mittels einfacher Schleifvorgänge. Die Wahl einfacher, leicht zu fertigender und zu kontrollierender Formen im Bereich der Abzugsrasten darstellenden Bauelemente garantiert ein sehr hohes Maß an Sicherheit, weil der Abzugsstollen 2 im gesicherten Zustand wegen der vorgeschriebenen Abstandsdifferenz zwischen Nocken 22 und Fläche 23 einerseits und zwischen Nocken 21 und Fläche 23 andererseits auch dann nicht ungewollt freigegeben werden kann, wenn die Stützflächen 19 und 20 durch unsachgemäße Behandlung beschädigt oder abgenutzt sein sollten.In the cocked state of the weapon, the

In der in Fig. 1 dargestellten gesicherten Lage kann kein Schuß abgegeben werden, weil die Anlagefläche 23 des Sicherungsschiebers 6 eine Verschwenkung der Abzugsstange im Uhrzeigersinn verhindert und die Abzugsstange 3 damit den Abzugsstollen 2 nicht freigeben kann, deren Haken 18 also die Schlagbolzenmutter 9 festhält. Zum Abgeben eines Schusses muß deshalb zunächst der Sicherungsschieber 6 in Pfeilrichtung (Fig. 2) nach oben verschoben werden, mit der Folge, daß der Kopf 24 nicht mehr an der Fläche 23 anliegt und die Ausnehmung 25 des Sicherungsschiebers 6 es erlaubt, daß die Abzugsstange 3 beim Betätigen des Abzugs 4 eine begrenzte Bewegung im Uhrzeiger sinn gegen den Druck des federbelasteten Bolzens 11 aus der Stützrast des Abzugsstollens 2 ausführt. Der Abzugsstollen 2 kann dann unter der Wirkung der von der Schlagbolzenfeder über die Schlagbolzenmutter 9 auf ihn ausgeübten Kraft nach unten gegen den Druck der Feder 8 wegschwenken und den Schlagbolzen unter der Wirkung der Schlagbolzenfeder nach vorne schnellen lassen (Fig. 6).In the secured position shown in FIG. 1, no shot can be fired because the

Das Verschwenken der Abzugsstange 3 aus der Stützrast des Abzugsstollens 2 zum Zweck der Schußabgabe erfolgt durch Druck auf den unteren Arm 26 des Abzuges 4. Aus Sicherheitsgründen ist die Geometrie der Abzugsstützrasten so ausgelegt, daß eine Kraft von mindestens 1,5 kg, vorzugsweise 2 kg, auf den unteren Arm 26 des Abzugs 4 ausgeübt werden muß, um einen Schuß auszulösenThe

Mittels der nachfolgend erläuterten Stechereinrichtung kann das erwähnte Abzugsgewicht auf einige 100 g, im Extremfall sogar auf 50 g und weniger, reduziert werden. Bei einem derart niedrigen Abzugsgewicht kann schon eine sehr geringe Erschütterung oder Bewegung der zusammenwirkenden Teile genügen, um einen Schuß auszulösen. Deshalb ist es auch nur unter bestimmten Umständen bei Beachtung besonderer Sicherheitsmaßnahmen und -vorschriften erlaubt, diesen gefährlichen und kritischen Zustand der Waffe herbeizuführen. Bei der erfindungsgemäßen Abzugseinrichtung wird dieser Zustand durch Vordrücken des unteren Armes 26 des Abzuges 4 hergestellt, also durch Vordrücken des Hebels 26 in Richtung des Pfeils von Fig. 3. Der Abzug 4 dreht sich dabei um die Achse 10, so daß sein oberer Arm 27 gegen den Uhrzeigersinn in Richtung zumThe trigger weight mentioned can be reduced to a few 100 g, in extreme cases even to 50 g and less, by means of the piercing device explained below. With such a low trigger weight, a very slight vibration or movement of the interacting parts can be sufficient to trigger a shot. That's why it is only permitted under certain circumstances and with special safety measures and regulations, to bring about this dangerous and critical condition of the weapon. In the trigger device according to the invention, this state is produced by advancing the

Stecherspannstück 5 hin schwenkt. Die Anlagefläche 28 des Armes 27 drückt dann gegen die Rolle, 14, wodurch der mit der Rolle 14 verbundene Arm des Stecherspannstucks 5 gegen den Druck der Feder 16 nach oben verschwenkt wird. Der Arm 27 des Abzuges 4 wird dabei soweit in Richtung Stecherspannstück 5 weitergeschwenkt, bis seine Kante 29 unter die Rolle 14 greift und ein Kräftegleichgewicht zwischen der Kraft der Feder 16, der Kraft der Feder 12 und der Reibkraft der bewegten Teile entsteht; diese Lage kann als Totpunktlage bezeichnet werden. In dieser Lage ist also der Stecher gespannt. Um dieses Spannen des Stechers durchführen zu können, ist aber Voraussetzung, daß sich - wie in Fig. 3 gezeichnet - der Sicherungsschieber 6 im entsicherten Zustand befindet, wie später noch erläutert werden wird.Plunger

Zum Auslösen eines Schusses mittels des Stechers ist es nun erforderlich, das erwähnte Kräftegleichgewicht aufzuheben, was dadurch geschieht, daß auf den unteren Arm 26 des Abzugs 4 mit einer bestimmten Kraft in Gegenrichtung zum Stecherspannen eingewirkt wird. Aufgrund der besonderen Kräfteverhältnisse, die sich bei einer in der Totpunktlage abgestützten Rolle ergeben, genügt dabei eine im Verhältnis zu der von der Feder 16 auf die Kante 29 des Armes 27 erzeugten großen Stützkraft sehr geringe Auslenkkraft, um das Kräftegleichgewicht aufzuheben, d.h. es liegt ein großes Untersetzungsverhältnis vor, mittels dessen sich das Abdrückgewicht auf 100 g und weniger reduzieren läßt. Das Untersetzungsverhältnis und damit das Abzugsgewicht kann auf einfache Weise mittels einer Stellschraube 30 variiert werden, mit der sich das Maß festlegen läßt, um welches der Arm 27 mit seiner Kante 29 hinter die eigentliche Totpunktlage der Rolle 14 geschwenkt werden kann. Wird das Kräftegleichgewicht durch eine auf den Hebelarm 26 des Abzugs 4 in Pfeilrichtung (Fig.4) wirkende Kraft zerstört, dann bricht es unter der Wirkung der starken Feder 16 schlagartig zusammen. Die Feder 16 drückt das Stecherspannstück 5 jetzt in seine Ruhelage (Fig. 1) zurück, wobei die Rolle 14 den Arm 27 des Abzuges 4 über die schräge Fläche 28 nach vorne in Richtung auf die Abzugsstange 3 schleudert. Der Arm 27 prallt mit seiner Fläche 13 gegen die Abzugsstange 3 und schlägt diese aus der Stützrast 19 des Abzugsstollens 2. Der Abzugsstollen 2 schwenkt somit, wie bereits für den Fall der stecherlosen Schußauslösung beschrieben, unter dem Einfluß der Schlagbolzenfeder nach unten und gibt den Schlagbolzen frei.To trigger a shot by means of the piercer, it is now necessary to break the aforementioned balance of forces, which is done by acting on the

Anhand von Fig. 5 sollen nun die Maßnahmen erläutert werden, die dazu führen, daß im gesicherten Zustand wie erwähnt der Stecher nicht gespannt werden kann, und daß der gespannte Stecher beim Sichern der Waffe entspannt wird. Dabei ist in Fig. 5 nochmals, wie schon in Fig. 3, die Abzugseinrichtung bei gespanntem Stecher dargestellt, Ersichtlicherweise besitzt der Sicherungsschiebbar 6 an seinem unteren Ende eine Ausnehmung 31, in die der Nocken 32 des Abzugs 4 eintreten kann. Im gesicherten Zustand (Fig. 1) liegt diese Ausnehmung 31 unterhalb des Nockens 32, so daß der Abzug 4 bzw. dessen Hebel 26 nicht in Richtung des Pfeils von Fig. 3 verschoben werden kann. Ist also die Waffe gesichert, d. h., befindet sich der Sicherungsschiebbar 6 in seiner unteren Position, dann ist ein "Einstechen" nicht möglich. Wird nun aber bei ungesicheter Waffe (Sicherungsschiebbar 6) in seiner oberen Position und gespanntem Stecher, die Waffe gesichert, also der Sicherungsschieber 6 nach unten geschoben (Fig. 5), dann schiebt sich schon nach einem Weg von wenigen Zehnteln eines Millimeters die Kante 33 der Fläche 23 über die Fläche 34 der Abzugsstange 3 und verhindert, daß die Abzugsstange 3 durch Druck oder Schlag aus der Rast 19 des Abzugsstollen 2 herausgeschwenkt werden kann. Das bedeutet, daß die eingestochene Abzugseinrichtung schon nach einer minimalen Verschiebung des Sicherungsschiebers 6 gesichert ist, so daß der Stecher nun, wie bei den bisher bekannten Repetierbüchsen allgemein üblich, durch manuelle Betätigung des Abzugsarmes 26 entstochen werden könnte, ohne daß dadurch ein Schuß ausgelöst wird. Um nun aber zu verhindern, daß dieses äußerst wichtige Entstechen durch Betätigen des Abzugarmes 26 aus Vergeßlichkeit oder Leichtsinn unterlassen wird, ist erfindungsgemäß vorgesehen, daß der Sicherungsschieber 6 im weiteren Verlauf seiner Bewegung nach unten in die gesicherte Endstellung selbsttätig das Entstechen vornimmt, und zwar dadurch, daß der mit seinem Absatz 35 auf den Nocken 32 des Abzugs 4 trifft und dadurch den gespannten Stecher zwangsläufig entspannt. Beim Sichern der Waffe wird also zunächst sichergestellt, daß das gespannte Stecherspannstück nicht mehr in der Lage ist, einen Schuß auszulösen, worauf dann während des weiteren Bewegungsweges des Schiebers 6 eine selbsttätige Entspannung des Stecherspannstücks 5 erfolgt, und zwar ohne daß der Schütze den Stecher manuell durch Verschieben des Abzugs 4 entstechen müßte. In diesem Zusammenhang ist darauf hinzuweisen, daß der Sicherungsschieber 6 durch ein geeignetes Federelement in die eine oder andere Endlage springt und dadurch den Impuls bekommt, um den Abzug 4 über seinen Nocken 32 aus seiner gespannten Stellung herauszuschlagen, wobei diese Funktionsweise des Schiebers 6 an sich bekannt ist.5, the measures are to be explained which lead to the fact that, in the secured state, as mentioned, the piercer cannot be tensioned and that the tensioned piercer is relaxed when the weapon is secured. 5, as already shown in FIG. 3, the trigger device is shown with the cock under tension. Obviously, the

Fig. 6 schließlich zeigt die Abzugseinrichtung im abgeschossenen Zustand der Waffe. Der Abzugsstollen 2 ist durch die Unterkante der Schlagbolzenmutter 9 gegen den Druck der Feder 8 nach unten geschwenkt, so daß seine Unterkante 36 mit geringem Zwischenraum parallel zur Oberkante 37 des Stecherspannstücks 5 liegt. Bedingt durch diesen geringen Abstand ist es nicht möglich, den Stecher durch Verschwenken des Abzugs 4 zu spannen, da der dem Abzug 4 zugewandte, mit der Rolle 14 versehene Arm des Stecherspannstücks 5 durch die Unterkante 36 des Abzugsstollens 2 an einer Aufwärtsbewegung gehindert ist.6 finally shows the trigger device in the fired state of the weapon. The take-

Zusammenfassend ist also zu sagen: Ein Spannen des Stechers und ein Auslösen eines Schusses durch den Stecher sind nur bei gespannter und völlig entsicherter Abzugseinrichtung möglich. Soll der gespannte Stecher ohne Auslösen eines Schusses wieder entspannt werden, dann kann dies durch Betätigung der Sicherung der Abzugseinrichtung erfolgen, wobei bereits bei geringster Verschiebung des Sicherungsschiebers in die Sicherungsposition eine - ungewollte - Schußabgabe verhindert wird.In summary, it can be said that cocking the trigger and triggering a shot by the trigger are only possible with the trigger device fully cocked and fully unlocked. If the cocked prick is to be relaxed again without triggering a shot, this can be done by actuating the safety device of the trigger device, with an - unintentional - firing of the shot being prevented even with the slightest displacement of the safety slide into the safety position.

Claims (13)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP84107194A EP0165334B1 (en) | 1984-06-22 | 1984-06-22 | Trigger mechanism for small arms |

| AT84107194T ATE33899T1 (en) | 1984-06-22 | 1984-06-22 | TRIGGER DEVICE FOR SMALL ARMS. |

| DE8484107194T DE3470801D1 (en) | 1984-06-22 | 1984-06-22 | Trigger mechanism for small arms |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP84107194A EP0165334B1 (en) | 1984-06-22 | 1984-06-22 | Trigger mechanism for small arms |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0165334A1 EP0165334A1 (en) | 1985-12-27 |

| EP0165334B1 true EP0165334B1 (en) | 1988-04-27 |

Family

ID=8192009

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84107194A Expired EP0165334B1 (en) | 1984-06-22 | 1984-06-22 | Trigger mechanism for small arms |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0165334B1 (en) |

| AT (1) | ATE33899T1 (en) |

| DE (1) | DE3470801D1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11015894B1 (en) * | 2019-12-06 | 2021-05-25 | Ceska Zbrojovka A.S. | Trigger resistance setting mechanism |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE58903470D1 (en) * | 1989-07-21 | 1993-03-18 | Krieghoff Gmbh H | TENSIONING DEVICE FOR HANDGUNS WITH PISTON REMOVAL. |

| EP0428292A3 (en) * | 1989-11-14 | 1992-09-16 | Ram-Line, Inc. | Firearm with plastic material |

| JP2988743B2 (en) * | 1991-05-30 | 1999-12-13 | 株式会社ミロク製作所 | Set trigger release mechanism |

| BE1005385A3 (en) * | 1991-09-16 | 1993-07-13 | Browning Sa | Device for reducing the weight of departure of relaxation of a rifle. |

| BE1005388A3 (en) * | 1991-09-17 | 1993-07-13 | Browning Sa | Clutch device for relaxation weight starting reduced rifles. |

| IT201900007983A1 (en) * | 2019-06-04 | 2020-12-04 | Benelli Armi Spa | RELEASE GROUP FOR WEAPON |

| CN114688917A (en) * | 2020-12-29 | 2022-07-01 | 保联企业股份有限公司 | Bow and arrow trigger switch device |

| CN113804051B (en) * | 2021-11-12 | 2023-06-06 | 重庆建设工业(集团)有限责任公司 | Method for assembling trigger component of submachine gun |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2856717A (en) * | 1957-04-01 | 1958-10-21 | William R Parke | Rifle trigger and safety mechanism |

| DE2253199C2 (en) * | 1972-10-30 | 1981-09-17 | J.P. Sauer & Sohn GmbH gegründet 1751, 2330 Eckernförde | Trigger mechanism for handguns with set trigger |

| DE2933107C2 (en) * | 1979-08-16 | 1983-01-13 | Johann Ing. Kufstein Kepplinger | Trigger device with set trigger |

-

1984

- 1984-06-22 EP EP84107194A patent/EP0165334B1/en not_active Expired

- 1984-06-22 DE DE8484107194T patent/DE3470801D1/en not_active Expired

- 1984-06-22 AT AT84107194T patent/ATE33899T1/en active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11015894B1 (en) * | 2019-12-06 | 2021-05-25 | Ceska Zbrojovka A.S. | Trigger resistance setting mechanism |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0165334A1 (en) | 1985-12-27 |

| ATE33899T1 (en) | 1988-05-15 |

| DE3470801D1 (en) | 1988-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2845471C2 (en) | Safety device for a semi-automatic pistol | |

| DE2059396A1 (en) | Trigger mechanism with shock protection for hunting and sporting firearms | |

| DE1553916C3 (en) | Rifle with latch bolt | |

| EP0165334B1 (en) | Trigger mechanism for small arms | |

| DE2253199C2 (en) | Trigger mechanism for handguns with set trigger | |

| EP1456597B1 (en) | Trigger device for a rapid fire handgun | |

| DE2754761C2 (en) | "Trigger device for a semi-automatic firearm" | |

| DE3120024C2 (en) | Automatic safety device for handguns | |

| CH620763A5 (en) | ||

| DE1428774C3 (en) | Trigger device for automatic firearms for triggering single and continuous fire | |

| DE3436401C2 (en) | Trigger device with auxiliary trigger | |

| DE2332273C3 (en) | Safety catch for automatic firearm | |

| CH641271A5 (en) | Firing pin safety for handguns, especially self-loading pistols. | |

| DE2250650A1 (en) | SAFETY DEVICE FOR FIRE ARMS | |

| EP0185786B1 (en) | Forward-set trigger mechanism for small arms | |

| DE4207252A1 (en) | Breech head for gun with locking bolts to hold breech in position - has mechanism which prevents firing of gun unless both locking bolts are in place | |

| EP0253797B1 (en) | Trigger mechanism for firing an automatic gun | |

| DE2162260C3 (en) | ||

| DE2240878B2 (en) | revolver | |

| CH338381A (en) | Firing pin lock on a handgun | |

| EP0603455A2 (en) | Gear safety for preventing an unwanted second shot after the firing of the first shot in a multichannel rifle | |

| DE69513449T2 (en) | Firing device for gun by the strike of an igniter and gun with such a device | |

| DE3808102A1 (en) | Safety device for shooting weapons, especially self-loading pistols (semi-automatic pistols) | |

| DE69211424T2 (en) | Loosening device for joggers | |

| DE2252204C3 (en) | Firearm with external, pivotable hammer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19860303 |

|

| 17Q | First examination report despatched |

Effective date: 19871007 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 33899 Country of ref document: AT Date of ref document: 19880515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3470801 Country of ref document: DE Date of ref document: 19880601 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940609 Year of fee payment: 11 Ref country code: DE Payment date: 19940609 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19940614 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940615 Year of fee payment: 11 Ref country code: GB Payment date: 19940615 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940624 Year of fee payment: 11 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 84107194.7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950622 Ref country code: AT Effective date: 19950622 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950623 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19950630 Ref country code: CH Effective date: 19950630 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950622 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960229 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960301 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84107194.7 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |