EP0113278A1 - Submersible pump device, especially for the fuel supply of a burner - Google Patents

Submersible pump device, especially for the fuel supply of a burner Download PDFInfo

- Publication number

- EP0113278A1 EP0113278A1 EP83402462A EP83402462A EP0113278A1 EP 0113278 A1 EP0113278 A1 EP 0113278A1 EP 83402462 A EP83402462 A EP 83402462A EP 83402462 A EP83402462 A EP 83402462A EP 0113278 A1 EP0113278 A1 EP 0113278A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shaft

- chamber

- supply

- orifice

- supply chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000000446 fuel Substances 0.000 title claims description 9

- 239000007788 liquid Substances 0.000 claims abstract description 22

- 230000007246 mechanism Effects 0.000 claims abstract description 9

- 238000005086 pumping Methods 0.000 claims abstract description 8

- 230000004044 response Effects 0.000 claims abstract description 3

- 238000007872 degassing Methods 0.000 claims description 7

- 230000000694 effects Effects 0.000 claims description 3

- 230000008030 elimination Effects 0.000 claims description 2

- 238000003379 elimination reaction Methods 0.000 claims description 2

- 208000031968 Cadaver Diseases 0.000 description 5

- 230000008859 change Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 241000287107 Passer Species 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 235000021183 entrée Nutrition 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000000750 progressive effect Effects 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B7/00—Piston machines or pumps characterised by having positively-driven valving

- F04B7/04—Piston machines or pumps characterised by having positively-driven valving in which the valving is performed by pistons and cylinders coacting to open and close intake or outlet ports

- F04B7/06—Piston machines or pumps characterised by having positively-driven valving in which the valving is performed by pistons and cylinders coacting to open and close intake or outlet ports the pistons and cylinders being relatively reciprocated and rotated

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M37/00—Apparatus or systems for feeding liquid fuel from storage containers to carburettors or fuel-injection apparatus; Arrangements for purifying liquid fuel specially adapted for, or arranged on, internal-combustion engines

- F02M37/04—Feeding by means of driven pumps

- F02M37/043—Arrangements for driving reciprocating piston-type pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23K—FEEDING FUEL TO COMBUSTION APPARATUS

- F23K5/00—Feeding or distributing other fuel to combustion apparatus

- F23K5/02—Liquid fuel

- F23K5/14—Details thereof

- F23K5/142—Fuel pumps

Definitions

- the present invention relates to a device for supplying liquid to a receiving member, comprising a submerged pump and intended in particular but not exclusively for supplying a burner with liquid fuel.

- Patent FR 2 448 054 describes a pump, in particular for liquid fuel, comprising a blind body immobilized in rotation and mounted so as to be able to slide back and forth on a rotary shaft, for example directly on the shaft of an engine.

- a cam mechanism arranged between the body and the shaft for example constituted by the machined end of the shaft, produces the alternating rectilinear movement of the body along the axis of the shaft and therefore the cyclic variation of the volume of a pumping chamber defined by the end of the shaft and the interior of the blind body.

- the object of the invention is in particular to remedy the aforementioned drawbacks of pumps of the type described and to create a liquidc supply device which is reliable, inexpensive and compact.

- the device according to the invention comprises a supply chamber, connected to the suction orifice and in which is housed the blind body, while a seal is mounted between the rotary shaft and a fixed wall of the supply chamber, and that the discharge orifice is connected to a tube terminating outside of the latter.

- the life of the seal is thus improved by the fact that it is only subjected to the low load of the liquid in the supply chamber and that it does not have to bear stresses due to the alternating sliding of the body. on the rotating shaft.

- the immersion of the vibrating body in the chamber allows wide manufacturing tolerances especially for the body since the leak fluid between the body and the shaft is no longer a nuisance and contributes to the lubrication of the body-shaft bearing.

- the supply chamber is mounted on the drive shaft in the form of a supply sub-assembly including the blind body and a degassing device.

- the latter may advantageously comprise a rigid or flexible tube connecting the suction orifice of the blind body to the interior space of the chamber, the tube having a liquid drawing orifice and at an upper level an opening allowing progressive elimination air bubbles reaching the room.

- This degassing device constitutes another important aspect of the present invention, and can moreover be used in a supply chamber which would not contain the pumping device internally, a pump of a different kind would be used.

- the chamber may be formed in one piece with a flange or with the motor or fan casing. It can of course be engaged with the seal on the motor shaft to be removably attached to the flange or to the casing. In both cases, it is desirable to provide access to the interior of the room.

- the pump body can be immobilized in rotation by the discharge hose connecting the body discharge orifice to an outlet connector of the chamber and / or by a suction hose connecting the body suction orifice to the 'interior space of the room; the suction hose can of course constitute the degassing tube envisaged previously.

- the design of the supply device is thus simplified.

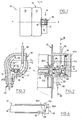

- FIG. 1 shows a burner 10 comprising a device 11 for supplying liquid fuel, a fan 12 of known type with an outer casing 13, a combustion head 14 and regulating and control members 15.

- An electric motor of axis X-X of which only the shaft 16 and its ball bearing 13A has been indicated makes it possible to actuate the fan 12 and a pump 17 of the supply device 11.

- the device 11 has a fuel chamber 18 and - a - blind body 19 slidably mounted on the end of the shaft 16.

- the body 19 can be immobilized in rotation by cooperation of a post and a complementary mortise provided on the body and on a fixed part of the chamber 18; however, it is preferably prevented from rotating by connection hoses and by a return spring which will be described later.

- the body 19 is movable on the shaft 16 in an alternating translation of small amplitude by means of a cam mechanism constituted either by a cam flange formed on the shaft, or by a cam machined at the end shaft and cooperating with an eccentric stop provided inside the body.

- a cam mechanism constituted either by a cam flange formed on the shaft, or by a cam machined at the end shaft and cooperating with an eccentric stop provided inside the body.

- FIG. 4 a stop machined at the end of the shaft 16A, which cooperates with an inclined cam surface 19A provided internally at the bottom of the blind body 19, during its molding. made of synthetic material.

- the cam mechanism When the drive shaft 16 rotates, the cam mechanism produces the comings and goings of the blind body 19 on the shaft in cooperation with a weak return spring 20 interposed between the body and a fixed wall 18A of the supply chamber.

- the blind body 19 has (FIG. 3) a suction hole 21 and a discharge hole 22 which are substantially opposite; these orifices are connected alternately during rotation of the shaft with a lumen 23 of the shaft itself open on a pumping cavity 24 of cyclically variable volume, formed between the body and the shaft.

- the blind body 19 is housed in the supply chamber 18 and its suction orifice 21 communicates with the volume of liquid contained in the chamber under normal pumping conditions while a seal ( O-ring 25 and / or lip seal 25A) is disposed between the rotary shaft 16 and a fixed wall 26 of the supply chamber.

- a seal O-ring 25 and / or lip seal 25A

- the seal 25 only supports the stresses due to the rotation of the shaft, as well as the low pressure of the liquid in the chamber.

- the body 19 can now be manufactured with a wide tolerance since leaks from liquid return to the chamber while lubricating the bearing; finally, the spring 20 can be lightened as a result of the reduction in the weight of the body freed from the seal, the stop 17A (FIG. 4) of the spring therefore also being able to be lightened.

- a flexible tube 27 located in the chamber 18 is connected to the suction nozzle 21. It has an opening 29 at its free end.

- a calibrated orifice 28 is provided in the tube 27 or better in the suction nozzle 21.

- the normal level of liquid in the chamber is designated by h 1 .

- the opening 29 is located higher than the calibrated orifice 28, and higher than the level h 1 .

- Chamber 18 has an inlet connection 30, fitted with a filter 30A. whose opening is above the level of the pump.

- An at least partly flexible tube 31 is connected on the one hand to the discharge orifice 22 of the blind body, on the other hand to an outlet connector 32 of the chamber 18.

- the hoses 27, 31 help to immobilize the blind body 19 in rotation while allowing its alternating sliding of small amplitude on the shaft.

- the hoses are for example in abutment against the inner wall of the supply chamber. It should be noted that the rupture of one of the hoses does not have the effect of an external leakage of the liquid.

- this degassing device can be used with a pump 17 different from that described above, submerged or not.

- the blind body 19 constitutes (where appropriate with the flexible 27 and the flexible 31) an interchangeable component allowing a change of flow. Indeed, to change the flow rate, it will suffice to replace a component provided with a body 19 with cavity 24 and calibrated orifice 28 by a component with cavity, inclined cam surface and calibrated orifice dimensioned differently. This can be done easily after opening the cover 18A of the chamber 18.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Feeding And Controlling Fuel (AREA)

- Reciprocating Pumps (AREA)

Abstract

Description

La présente invention concerne un dispositif d'alimentation en liquide d'un organe récepteur, comprenant une pompe immergée et destiné notamment mais non exclusivement à alimenter un brûleur en combustible liquide.The present invention relates to a device for supplying liquid to a receiving member, comprising a submerged pump and intended in particular but not exclusively for supplying a burner with liquid fuel.

Le brevet FR 2 448 054 décrit une pompe notamment pour combustible liquide comprenant un corps borgne immobilisé en rotation et monté de manière à pouvoir coulisser en va et vient sur un arbre rotatif, par exemple directement sur l'arbre d'un moteur. Un mécanisme à came disposé entre le corps et l'arbre, par exemple constitué par l'extrémité usinée de l'arbre, produit le mouvement rectiligne alterné du corps selon l'axe de l'arbre et donc la variation cyclique du volume d'une chambre de pompage définie par l'extrémité de l'arbre et l'intérieur du corps borgne.Patent FR 2 448 054 describes a pump, in particular for liquid fuel, comprising a blind body immobilized in rotation and mounted so as to be able to slide back and forth on a rotary shaft, for example directly on the shaft of an engine. A cam mechanism arranged between the body and the shaft, for example constituted by the machined end of the shaft, produces the alternating rectilinear movement of the body along the axis of the shaft and therefore the cyclic variation of the volume of a pumping chamber defined by the end of the shaft and the interior of the blind body.

Cette pompe extrêmement simple est bien adaptée aux faibles débits de liquide vers lesquels s'orientent les utilisateurs par raison d'économie.This extremely simple pump is well suited to the low liquid flow rates to which users are oriented for reasons of economy.

Elle présente toutefois pour inconvénient de nécessiter entre l'arbre moteur et l'extrémité ouverte du corps borgne un joint d'étanchéité de type dynamique soumis non seulement aux contraintes résultant de la rotation de l'arbre, mais également aux contraintes alternées produites--par le glissement du corps en va et vient sur l'arbre. On comprend que la fatigue du joint est importante et induit un risque de fuite non négligeable.However, it has the drawback of requiring between the drive shaft and the open end of the blind body a dynamic type seal subject not only to the stresses resulting from the rotation of the shaft, but also to the alternating stresses produced-- by the sliding of the body back and forth on the tree. It is understood that the fatigue of the seal is high and induces a non-negligible risk of leakage.

De plus, une telle pompe déplace de très faibles débits de combustible, au contraire des pompes habituelles à débit surdimensionné et à recyclage ; l'adduction de bulles d'air à la pompe est par conséquent plus gênante et peut causer l'extinction du brûleur.In addition, such a pump displaces very low fuel flow rates, unlike conventional pumps with oversized flow and recycling; the supply of air bubbles to the pump is therefore more troublesome and can cause the burner to go out.

L'invention a notamment pour but de remédier aux inconvénients cités des pompes du type décrit et de créer un dispositif d'alimentation en liquidc qui soit fiable, peu onéreux et de faible encombrement.The object of the invention is in particular to remedy the aforementioned drawbacks of pumps of the type described and to create a liquidc supply device which is reliable, inexpensive and compact.

Elle concerne un dispositif servant à alimenter en liquide un organe récepteur à partir d'une chambre d'alimentation et comprenant :

- - un corps borgne immobilisé en rotation et monté de manière à pouvoir coulisser sur un arbre moteur rotatif,

- - un mécanisme à came disposé entre le corps et l'arbre pour produire en coopération avec un ressort agissant sur le corps un mouvement de va et vient de celui-ci sur l'arbre en réponse à la rotation de l'arbre,

- - le corps borgne et l'arbre définissant entre eux une cavité de pompage dont le volume varie sous l'effet du mécanisme à came quand l'arbre tourne et qui communique avec une lumière prévue sur l'arbre et mise elle-même en relation alternée, quand l'arbre tourne, avec un orifice d'aspiration et un orifice de refoulement ménagés dans le corps borgne.

- - a blind body immobilized in rotation and mounted so as to be able to slide on a rotary motor shaft,

- - a cam mechanism arranged between the body and the shaft to produce, in cooperation with a spring acting on the body, a movement back and forth thereof on the shaft in response to the rotation of the shaft,

- - the blind body and the shaft defining between them a pumping cavity whose volume varies under the effect of the cam mechanism when the shaft rotates and which communicates with a light provided on the shaft and put itself in relation alternating, when the shaft rotates, with a suction port and a discharge port formed in the blind body.

Le dispositif selon l'invention comprend une chambre d'alimentation, reliée à l'orifice d'aspiration et dans laquelle est logé le corps borgne, tandis qu'un joint d'étanchéité est monté entre l'arbre rotatif et une paroi fixe de la chambre d'alimentation, et que l'orifice de refoulement est relié à une tubulure aboutissant à l'extérieur de celle-ci.The device according to the invention comprises a supply chamber, connected to the suction orifice and in which is housed the blind body, while a seal is mounted between the rotary shaft and a fixed wall of the supply chamber, and that the discharge orifice is connected to a tube terminating outside of the latter.

La durée de vie du joint est ainsi améliorée du fait qu'il n'est soumis qu'à la faible charge du liquide de la chambre d'alimentation et qu'il n'a pas à supporter de contraintes dues au glissement alterné du corps sur l'arbre tournant. De plus, l'immersion du corps vibrant dans la chambre permet de larges tolérances de fabrication notamment pour le corps puisque la fuite du liquide entre le corps et l'arbre n'est plus une gêne et contribue à la lubrification du palier corps- arbre.The life of the seal is thus improved by the fact that it is only subjected to the low load of the liquid in the supply chamber and that it does not have to bear stresses due to the alternating sliding of the body. on the rotating shaft. In addition, the immersion of the vibrating body in the chamber allows wide manufacturing tolerances especially for the body since the leak fluid between the body and the shaft is no longer a nuisance and contributes to the lubrication of the body-shaft bearing.

De préférence la chambre d'alimentation est montée sur l'arbre moteur sous forme de sous-ensemble d'alimentation incluant le corps borgne et un dispositif de dégazage. Ce dernier peut avantageusement comprendre un tube rigide ou flexible reliant l'orifice d'aspiration du corps borgne à l'espace intérieur de la chambre, le tube présentant un orifice de puisage de liquide et à un niveau supérieur une ouverture permettant l'élimination progressive des bulles d'air parvenant à la chambre.Preferably the supply chamber is mounted on the drive shaft in the form of a supply sub-assembly including the blind body and a degassing device. The latter may advantageously comprise a rigid or flexible tube connecting the suction orifice of the blind body to the interior space of the chamber, the tube having a liquid drawing orifice and at an upper level an opening allowing progressive elimination air bubbles reaching the room.

Ce dispositif de dégazage constitue un autre aspect important de la présente invention, et peut d'ailleurs être utilisé dans une chambre d'alimentation qui ne contiendrait pas intérieurement le dispositif de pompage, on utiliserait une pompe d'un genre différent.This degassing device constitutes another important aspect of the present invention, and can moreover be used in a supply chamber which would not contain the pumping device internally, a pump of a different kind would be used.

Dans le cas particulier de l'alimentation d'un brûleur en combustible, la chambre peut être formée d'une pièce avec un flasque ou avec l'enveloppe du moteur ou du ventilateur. Elle peut bien entendu être engagée avec le joint d'étanchéité sur l'arbre moteur pour être fixée de manière amovible au flasque ou à l'enveloppe. Dans les deux cas, il est souhaitable de prévoir un accès à l'intérieur de la chambre.In the particular case of supplying fuel to a burner, the chamber may be formed in one piece with a flange or with the motor or fan casing. It can of course be engaged with the seal on the motor shaft to be removably attached to the flange or to the casing. In both cases, it is desirable to provide access to the interior of the room.

Le corps de pompe peut être immobilisé en rotation par le flexible de refoulement reliant l'orifice de refoulement du corps à un raccord de sortie de la chambre et/ou par un flexible d'aspiration reliant l'orifice d'aspiration du corps à l'espace intérieur de la chambre ; le flexible d'aspiration peut bien sûr constituer le tube de dégazage envisagé précédemment. La conception du dispositif d'alimentation se trouve de la sorte simplifiée.The pump body can be immobilized in rotation by the discharge hose connecting the body discharge orifice to an outlet connector of the chamber and / or by a suction hose connecting the body suction orifice to the 'interior space of the room; the suction hose can of course constitute the degassing tube envisaged previously. The design of the supply device is thus simplified.

D'autres caractéristiques et avantages de l'invention apparaîtront à l'examen de la description détaillée qui va suivre et des dessins annexés, sur lesquels :

- - la figure 1 représente schématiquement une coupe axiale d'un brûleur équipé du dispositif d'alimentation conforme à l'invention ;

- - la figure 2 montre une coupe schématique agrandie du dispositif de la figure 1 ;

- - la figure 3 représente le dispositif en coupe transversale selon le plan III-III de la figure 2, et

- - la figure 4 représente en vue agrandie les éléments de la pompe des figures 2 et 3.

- - Figure 1 schematically shows an axial section of a burner equipped with the supply device according to the invention;

- - Figure 2 shows an enlarged schematic section of the device of Figure 1;

- FIG. 3 represents the device in cross section along the plane III-III of FIG. 2, and

- - Figure 4 shows in enlarged view the elements of the pump of Figures 2 and 3.

On voit sur la figure 1 un brûleur 10 comprenant un dispositif d'alimentation 11 en combustible liquide, un ventilateur 12 de type connu à enveloppe extérieure 13, une tête de combustion 14 et des organes de régulation et de commande 15.FIG. 1 shows a

Un moteur électrique d'axe X-X dont seul a été indiqué l'arbre 16 et son palier à billes 13A permet d'actionner le ventilateur 12 et une pompe 17 du dispositif d'alimentation 11.An electric motor of axis X-X of which only the

Comme le montrent mieux les figures 2 et 3, le dispositif 11 présente une chambre à combustible 18 et--un--corps borgne 19 monté à glissement sur l'extrémité de l'arbre 16. Le corps 19 peut être immobilisé en rotation par coopération d'un tenon et d'une mortaise complémentaire prévus sur le corps et sur une partie- fixe de la chambre 18 ; il est cependant de préférence empêché de tourner par des flexibles de raccordement et par un ressort de rappel qui seront décrits plus loin.As best shown in Figures 2 and 3, the

Le corps 19 est déplaçable sur l'arbre 16 selon une translation alternée de faible amplitude grâce à un mécanisme à came constitué soit par une collerette à came ménagée sur l'arbre, soit par une came usinée en bout d'arbre et coopérant avec une butée excentrée prévue à l'intérieur du corps. De telles dispositions ont été décrites dans le brevet FR 2 448 054.The

Cependant dans le mode de réalisation préférentiel de la présente invention, on prévoit (figure 4) une butée usinée en bout d'arbre 16A, qui coopère avec une surface de came inclinée 19A prévue intérieurement au fond du corps borgne 19, lors de son moulage en matière synthétique.However, in the preferred embodiment of the present invention, there is provided (FIG. 4) a stop machined at the end of the

De la sorte, on peut adapter très simplement le débit de la pompe par échange du corps borgne 19, l'arbre 16 demeurant le même.In this way, the flow rate of the pump can be very simply adapted by exchange of the

Lorsque l'arbre moteur 16 tourne, le mécanisme à came produit le va et vient du corps borgne 19 sur l'arbre en coopération avec un faible ressort de rappel 20 interposé entre le corps et une paroi fixe 18A de la chambre d'alimentation.When the

Le corps borgne 19 présente (figure 3) un orifice d'aspiration 21 et un orifice de refoulement 22 sensiblement opposés ; ces orifices sont mis alternativement en liaison lors de la rotation de l'arbre avec une lumière 23 de l'arbre elle-même ouverte sur une cavité de pompage 24 de volume cycliquement variable, ménagée entre le corps et l'arbre.The

Selon l'invention, le corps borgne 19 est logé dans la chambre d'alimentation 18 et son orifice d'aspiration 21 communique avec le volume de liquide contenu dans la chambre dans les conditions normales de pompage tandis qu'un joint d'étanchéité (joint torique 25 et/ou joint à lèvre 25A) est disposé entre l'arbre rotatif 16 et une paroi fixe 26 de la chambre d'alimentation. On comprendra aisément que le joint 25 ne supporte que les contraintes dues à la rotation de l'arbre, ainsi que la faible pression du liquide dans la chambre. De plus, le corps l9 peut désormais être fabriqué avec une large tolérance puisque les fuites de liquide reviennent à la chambre tout en lubrifiant le palier ; enfin, le ressort 20 peut être allégé par suite de la réduction du poids du corps débarrassé du joint, la butée 17A (figure 4) du ressort pouvant donc également être allégée.According to the invention, the

Un tube flexible 27 situé dans la chambre 18 est relié à l'embout d'aspiration 21. Il présente une ouverture 29 à son extrémité libre. Un orifice calibré de puisage 28 est prévu dans le tube 27 ou mieux dans l'embout d'aspiration 21. Le niveau normal de liquide dans la chambre est désigné par h1. L'ouverture 29 se situe plus haut que l'orifice calibré 28, et plus haut que le niveau h1. La chambre 18 présente un raccord d'entrée 30, muni d'un filtre 30A. dont l'ouverture est au-dessus du niveau de la pompe.A

Un tube au moins en partie flexible 31 est relié d'une part à l'orifice de refoulement 22 du corps borgne, d'autre part à un raccord de sortie 32 de la chambre 18.An at least partly

Il convient de remarquer que les flexibles 27, 31, concourent à immobiliser en rotation le corps borgne 19 tout en autorisant son coulissement alterné de faible amplitude sur l'arbre. Les flexibles sont par exemple en appui contre la paroi intérieure de la chambre d'alimentation. On notera que la rupture de l'un des flexibles n'a pas pour effet de fuite externe du liquide.It should be noted that the

Le dispositif d'alimentation avec dégazage décrit fonctionne de la manière suivante :

- En régime établi et lorsqu'il n'y a pas d'arrivée d'air au raccord d'entrée 30, la pompe volumétrique 17 assure le même débit de liquide d au

raccord 30, à l'orifice calibré depuisage 28, à l'orifice d'aspiration 21 ; l'orifice 28 est calibré de sorte que le niveau du liquide dans la chambre se stabilise à la hauteur h1 assurant une charge suffisante pour faire passer le débit.

- In steady state and when there is no air supply to the

inlet connection 30, thepositive displacement pump 17 ensures the same flow of liquid d at theconnection 30, at thecalibrated orifice 28, thesuction port 21; theorifice 28 is calibrated so that the level of the liquid in the chamber stabilizes at the height h 1 ensuring a sufficient charge to pass the flow.

Lorsqu'une certaine quantité d'air arrive brusquement au raccord 30, le niveau du liquide baisse jusqu'à un niveau h2 indiqué en tirets sur la figure 2 ce niveau étant insuffisant pour assurer le débit d à l'orifice 28. Le débit à l'orifice d'aspiration 21 étant inchangé, la compensation volumétrique s'effectue par aspiration d'air par l'ouverture 29 et le tube 27. L'air est dès lors associé au liquide sous forme de micro- bulles aspirées à l'orifice 21 à chaque cycle de pompage. Le volume compris entre l'orifice calibré 28 et la lumière 23 est inférieur à la cylindrée de la pompe et assure ainsi une parfaite régularité.When a certain quantity of air suddenly arrives at the

L'excès d'air dans la chambre d'alimentation 18 est alors progressivement annulé par envoi de micro- bulles d'air avec le combustible, vers le brûleur, et ce sans provoquer l'extinction intempestive de celui-ci. Comme précédemment indiqué, ce dispositif de dégazage peut être utilisé avec une pompe 17 différente de celle décrite plus haut, immergée ou non.The excess air in the

Par ailleurs, on constate que la présence du joint d'étanchéité 25 dans une paroi fixe 26 de la chambre 18 permet d'assurer un mouillage constant de la pompe 17. Le corps borgne 19 constitue (le cas échéant avec le flexible 27 et le flexible 31) un composant interchangeable autorisant un changement de débit. En effet, pour changer le débit il suffira de remplacer un composant muni d'un corps 19 à cavité 24 et à orifice calibré 28 par un composant à cavité, surface de came inclinée et orifice calibré dimensionnés différemment. Cela peut se faire aisément après ouverture du couvercle 18A de la chambre 18.Furthermore, it can be seen that the presence of the

Il va de soi que l'on peut apporter des modifications au mode de réalisation décrit sans pour autant sortir du cadre de l'invention.It goes without saying that modifications can be made to the embodiment described without departing from the scope of the invention.

Claims (9)

caractérisé par le fait qu'il comprend une chambre d'alimentation (18), reliée à l'orifice d'aspiration (21), et dans laquelle est logé le corps borgne (19), tandis qu'un joint d'étanchéité (25) est monté entre l'arbre rotatif et une paroi fixe (26) de la chambre d'alimentation, et que l'orifice de refoulement (22) est relié à une tubulure (31, 32) aboutissant à l'extérieur de la chambre d'alimentation.1. Device for supplying liquid to a receiving member from a supply chamber comprising:

characterized by the fact that it comprises a supply chamber (18), connected to the suction orifice (21), and in which the blind body (19) is housed, while a seal ( 25) is mounted between the rotary shaft and a fixed wall (26) of the supply chamber, and that the discharge orifice (22) is connected to a tube (31, 32) terminating outside the feed chamber.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83402462T ATE22968T1 (en) | 1982-12-30 | 1983-12-19 | LIQUID PUMP DEVICE, ESPECIALLY FOR THE FUEL SUPPLY OF A BURNER. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8222104A FR2538861A1 (en) | 1982-12-30 | 1982-12-30 | SUBMERSIBLE PUMP DEVICE, PARTICULARLY FOR SUPPLYING A FUEL BURNER |

| FR8222104 | 1982-12-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0113278A1 true EP0113278A1 (en) | 1984-07-11 |

| EP0113278B1 EP0113278B1 (en) | 1986-10-15 |

Family

ID=9280710

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83402462A Expired EP0113278B1 (en) | 1982-12-30 | 1983-12-19 | Submersible pump device, especially for the fuel supply of a burner |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0113278B1 (en) |

| AT (1) | ATE22968T1 (en) |

| DE (1) | DE3367000D1 (en) |

| FR (1) | FR2538861A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2616209B1 (en) * | 1987-06-05 | 1990-12-14 | Cie Int Du Chauffage | LIQUID SUPPLY DEVICE, PARTICULARLY FOR FUEL SUPPLY OF A BURNER, AND LIQUID FUEL BURNER ASSOCIATED WITH SAID DEVICE |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1577622A (en) * | 1924-01-02 | 1926-03-23 | Wayne Tank & Pump Company | Liquid-fuel burner |

| DE559650C (en) * | 1932-09-22 | Charles Perdrisat | Feed device for liquid burner | |

| FR1579801A (en) * | 1967-09-06 | 1969-08-29 | ||

| DE1528395A1 (en) * | 1965-03-10 | 1970-07-02 | Borg-Warner Corp., Chicago, Hl. (V.St.A.) | Fuel pump |

| FR2448054A1 (en) * | 1979-02-05 | 1980-08-29 | Fonderie Soc Gen De | Pump assembly for liq. fuelled domestic burner - comprises rotating piston with position adjustment for low flow rate |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1047406A (en) * | 1951-12-29 | 1953-12-14 | Lorraine De Travaux Ferroviair | Advanced pump |

| US2869467A (en) * | 1956-05-15 | 1959-01-20 | Alexander S Limpert | Liquid proportioning pump |

-

1982

- 1982-12-30 FR FR8222104A patent/FR2538861A1/en active Granted

-

1983

- 1983-12-19 EP EP83402462A patent/EP0113278B1/en not_active Expired

- 1983-12-19 DE DE8383402462T patent/DE3367000D1/en not_active Expired

- 1983-12-19 AT AT83402462T patent/ATE22968T1/en not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE559650C (en) * | 1932-09-22 | Charles Perdrisat | Feed device for liquid burner | |

| US1577622A (en) * | 1924-01-02 | 1926-03-23 | Wayne Tank & Pump Company | Liquid-fuel burner |

| DE1528395A1 (en) * | 1965-03-10 | 1970-07-02 | Borg-Warner Corp., Chicago, Hl. (V.St.A.) | Fuel pump |

| FR1579801A (en) * | 1967-09-06 | 1969-08-29 | ||

| FR2448054A1 (en) * | 1979-02-05 | 1980-08-29 | Fonderie Soc Gen De | Pump assembly for liq. fuelled domestic burner - comprises rotating piston with position adjustment for low flow rate |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0113278B1 (en) | 1986-10-15 |

| ATE22968T1 (en) | 1986-11-15 |

| DE3367000D1 (en) | 1986-11-20 |

| FR2538861A1 (en) | 1984-07-06 |

| FR2538861B1 (en) | 1985-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0006045B1 (en) | Control device for an hydraulic circuit and hydraulic motor unit incorporating such a circuit | |

| FR2758372A1 (en) | COMPRESSOR FOR VEHICLE INTERIOR AIR CONDITIONING SYSTEM | |

| FR2698664A1 (en) | Fuel distribution circuit for an internal combustion engine. | |

| FR2739419A1 (en) | WATER PUMP | |

| FR2595766A1 (en) | OIL DISPENSING DEVICE FOR LUBRICATING THE BEARINGS OF A VOLUTE MACHINE | |

| FR2808308A1 (en) | Spiral compressor has inlet pipe feeding towards deflector, which directs inlet gas into zone of inlet chamber, where oil mist is generated | |

| FR2919688A1 (en) | SPIRAL REFRIGERATOR COMPRESSOR WITH VARIABLE SPEED | |

| FR2834016A1 (en) | Jet pump for transferring fuel between different compartments in multi-compartment fuel tanks, has sealing elements each adapted to open when pressure of injected fluid exceeds predetermined level | |

| FR2736399A1 (en) | COMPRESSOR WITH VOLUTES, PROVIDED WITH A SUCTION RETAINING VALVE | |

| FR2641338A1 (en) | LOW FLOW PUMP, PARTICULARLY FOR LUBRICATING A TWO-STROKE ENGINE | |

| FR2538457A1 (en) | FUEL SYSTEM FOR INTERNAL COMBUSTION ENGINE | |

| FR2736688A3 (en) | Swashplate pump for water jet cleaning unit | |

| EP0113278B1 (en) | Submersible pump device, especially for the fuel supply of a burner | |

| EP1135589B1 (en) | Liquid transferring assembly, in particular for fuel additive | |

| FR2608224A1 (en) | AXIAL PISTON PUMP | |

| EP0798458A1 (en) | Pumping device immerged in motor vehicle tank | |

| FR2667361A1 (en) | FUEL SUPPLY MANIFOLD WITH A VIBRATION DAMPING ACTION, FOR A FUEL SUPPLY LINE OF AN INTERNAL COMBUSTION ENGINE. | |

| WO1987007352A1 (en) | Liquid distribution valve | |

| FR2818321A1 (en) | Fuel delivery system, for vehicles, has brushless suction pump fitted with fine filter, upstream of pump. | |

| FR2792620A1 (en) | Dispensing unit and flexible support, for flexible pouch containing liquid, has bush for connection to pump and has two internal nozzles which may be connected to tube extending into pouch | |

| FR2636098A1 (en) | VACUUM DEVICE FOR FUEL PUMP RESERVE | |

| EP1083004B1 (en) | Pump for a container | |

| FR2781528A1 (en) | Flow unit for providing fuel flow from fuel tank has degassing valve fitted into flow unit breathing cover, which is integral with the rotor case; it has rotor blade annular channel connected to degassing valve | |

| FR2594897A1 (en) | ROTARY PUMP FOR LIQUIDS | |

| FR2621562A1 (en) | Oil tank with internal partition. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19841015 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 22968 Country of ref document: AT Date of ref document: 19861115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3367000 Country of ref document: DE Date of ref document: 19861120 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: COMPAGNIE INTERNATIONALE DE CHAUFFAGE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: COMPAGNIE INTERNATIONALE DU CHAUFFAGE |

|

| BECN | Be: change of holder's name |

Effective date: 19861015 |

|

| ITF | It: translation for a ep patent filed | ||

| NLXE | Nl: other communications concerning ep-patents (part 3 heading xe) |

Free format text: IN PAT.BUL.24/86,PAGES 3052 AND 3083:SHOULD BE MODIFIED INTO:COMPAGNIE INTERNATIONALE DE CHAUFFAGE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| ITTA | It: last paid annual fee | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 83402462.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19991214 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19991217 Year of fee payment: 17 Ref country code: CH Payment date: 19991217 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19991218 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20000106 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20001117 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20001120 Year of fee payment: 18 Ref country code: AT Payment date: 20001120 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001219 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001219 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20001228 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 |

|

| BERE | Be: lapsed |

Owner name: CIE INTERNATIONALE DE CHAUFFAGE Effective date: 20001231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20001219 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20010701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011220 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83402462.2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020830 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |