EP0110683B1 - Determining the degree of cooking in a sulphite digester delignification - Google Patents

Determining the degree of cooking in a sulphite digester delignification Download PDFInfo

- Publication number

- EP0110683B1 EP0110683B1 EP83307188A EP83307188A EP0110683B1 EP 0110683 B1 EP0110683 B1 EP 0110683B1 EP 83307188 A EP83307188 A EP 83307188A EP 83307188 A EP83307188 A EP 83307188A EP 0110683 B1 EP0110683 B1 EP 0110683B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- digester

- delignification

- pressure

- value

- controller module

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000010411 cooking Methods 0.000 title claims description 28

- LSNNMFCWUKXFEE-UHFFFAOYSA-L sulfite Chemical compound [O-]S([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-L 0.000 title claims description 16

- RAHZWNYVWXNFOC-UHFFFAOYSA-N Sulphur dioxide Chemical compound O=S=O RAHZWNYVWXNFOC-UHFFFAOYSA-N 0.000 claims description 26

- 238000006243 chemical reaction Methods 0.000 claims description 24

- 238000000034 method Methods 0.000 claims description 14

- 235000010269 sulphur dioxide Nutrition 0.000 claims description 11

- 239000004291 sulphur dioxide Substances 0.000 claims description 11

- 230000000694 effects Effects 0.000 claims description 6

- 239000002253 acid Substances 0.000 description 7

- 238000004537 pulping Methods 0.000 description 6

- 239000003513 alkali Substances 0.000 description 5

- 239000002023 wood Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- QAOWNCQODCNURD-UHFFFAOYSA-L Sulfate Chemical compound [O-]S([O-])(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-L 0.000 description 2

- 229920005610 lignin Polymers 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229910021653 sulphate ion Inorganic materials 0.000 description 2

- 229920003043 Cellulose fiber Polymers 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 238000009529 body temperature measurement Methods 0.000 description 1

- 238000007705 chemical test Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000014509 gene expression Effects 0.000 description 1

- 239000003265 pulping liquor Substances 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21C—PRODUCTION OF CELLULOSE BY REMOVING NON-CELLULOSE SUBSTANCES FROM CELLULOSE-CONTAINING MATERIALS; REGENERATION OF PULPING LIQUORS; APPARATUS THEREFOR

- D21C3/00—Pulping cellulose-containing materials

- D21C3/22—Other features of pulping processes

- D21C3/228—Automation of the pulping processes

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21C—PRODUCTION OF CELLULOSE BY REMOVING NON-CELLULOSE SUBSTANCES FROM CELLULOSE-CONTAINING MATERIALS; REGENERATION OF PULPING LIQUORS; APPARATUS THEREFOR

- D21C3/00—Pulping cellulose-containing materials

- D21C3/04—Pulping cellulose-containing materials with acids, acid salts or acid anhydrides

- D21C3/06—Pulping cellulose-containing materials with acids, acid salts or acid anhydrides sulfur dioxide; sulfurous acid; bisulfites sulfites

Definitions

- This invention relates to methods of and apparatus for determining the degree of cooking in a sulphite digester for delignification.

- the invention can be used, for example, in the pulp industry.

- Lignin is the major noncarbohydrate constituent of wood. It functions as a natural plastic binder for the cellulose fibres. Its exact formula is unknown. Lignin is removed from wood by both the sulphite and sulphate pulp processes.

- the rate of delignification is a function of cooking liquor composition and cooking temperature, and that this rate increases rapidly with temperature and is affected by acid concentration. It is further known that the rate of deliginification for acid pulping varies with temperature in accordance with the known Arrhenius equation.

- the velocity factor reaction rate (k) can be determined from this equation and subsequently substituted in the standard rate of delignification equation to determine this latter rate.

- US Patent No. US-A-3 941 649 (Wallin) describes a method of obtaining a predetermined Kappa number (a measure of the degree of cooking) in a sulphate pulping process by taking a sample of the pulping liquor at a stage when the preliminary alkali-consuming reactions are substantially complete but before any substantial delignification has taken place, and analysing the sample to establish the alkali content.

- the alkali content is then adjusted by addition of alkali until a predetermined alkali content per unit mass of wood is achieved. This additional alkali content can then be used to calculate the pulping conditions necessary to obtain the required Kappa number.

- the pulping time and temperature are then controlled on the basis of this information during delignification.

- the invention also provides apparatus for accomplishing the foregoing method including individual function blocks which are connected together to achieve the various calculations.

- apparatus for determining the degree of cooking in a sulphite batch digester for delignification the apparatus being characterised by:

- a preferred embodiment of the present invention described hereineblow provides a method and apparatus for calculating sulphite digester rate of delignification and determining the completion of cooking, utilising function blocks to continuously solve the so-called Arrhenius equation for the velocity factor reaction.

- This calculation takes place in the first controller module with the second controller module being provided with function blocks to obtain a value corresponding to the rate of delignification.

- the delignification rate is continuously computed and monitored, and when the cook has been brought up to a desired set point, an indication, such as an alarm, is provided to an operator to terminate the cooking process.

- the preferred apparatus for and methods of determining the degree of cooking in a sulphite digester are simple in design, rugged in construction, and economical to manufacture.

- the drawings show apparatus embodying the invention for determining the degree of cooking in a delignification sulphite digester.

- the rate of delignification is primarily a function of the cooking liquor composition and cooking temperature. Since there are established mathematical expressions for the rate of delignification, it is possible to determine how much cooking time is required based upon the cooking temperature for a particular pulp quality. See Pulp and Paper Manufacture, 2nd Ed., Volume I, The Pulping of Wood, pp 282 to 285.

- the rate of reaction is a little more than doubled by an increase of 10°C in temperature. Cooking is extremely slow at temperatures below 100°C.

- Figure 1 illustrates how calculation of the digester rate of delignification and Kappa (K) Number can be implemented in a Bailey Network 90 (Trade Mark) system. The entire delignification rate and K-number calculation can be accomplished using two Network 90 controller modules 10, 30 for a particular digester. Information concerning the Network 90 can be found in Bailey Controls Company Application Guide 260-2 and Bailey Controls Company Product Specification E93-906.

- the Arrhenius equation can be continuously solved for the velocity factor reaction rate (k), by means of a calculator unit or module 23 shown in greater detail in Figure 2.

- the calculation is based upon digester temperature measurement as determined by a digester temperature transmitter 12 which provides one of a plurality of inputs to the unit 23.

- the partial pressure of sulphur dioxide in the digester is approximated by measuring the difference between steam pressure at the digester temperature and the actual digester pressure. This partial pressure is linearised and corrected for the assumption that the digester pressure is that of only steam and sulphur dioxide in equilibrium with the digester acid. Steam pressure is calculated as a function of temperature in a unit 14 and the actual pressure is supplied by a digester pressure transmitter 15. The difference between the steam pressure and digester pressure is taken in a comparator unit 16. The n power factor in Equation (2) is provided by a function generator 17 and provides a means for compensating for the foregoing assumption.

- the constants A, E, 2.303 and R of Equation (1) are provided to the unit 23 by units 18,19,20 and 21, respectively.

- An output (log k) from the unit 23 is integrated to provide k and multiplied by the partial pressure output value from the function generator 17 to provide an output from the controller module 10 which represents the rate of delignification at any instant for the sulphite digester, in accordance with Equation (2), and is directed to the second controller module 30.

- the digester cook operator manually enters total S0 2 and free S0 2 acid strength chemical tests as inputs to the controller module 30 over units 32 and 33, respectively.

- the controller automatically subtracts the difference, which become the combined S0 2 content, in a comparator unit 34.

- the delignification rate can then have acid strength S0 2 correction applied over a function generator 35 and multipliers 36, 37.

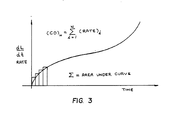

- the delignification rate will be integrated for each cook, in a unit 38, with respect to time, for totalising the area under the reaction curve of Figure 3.

- This area totalisation is related to a degree of cooking (Kappa Number) set point for the particular grade.

- Kappa Number degree of cooking

- the degree of cooking (CD) is derived as follows:

Landscapes

- Paper (AREA)

- Investigating Or Analyzing Non-Biological Materials By The Use Of Chemical Means (AREA)

- Investigating Or Analysing Materials By The Use Of Chemical Reactions (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US44427282A | 1982-11-24 | 1982-11-24 | |

| US444272 | 1982-11-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0110683A1 EP0110683A1 (en) | 1984-06-13 |

| EP0110683B1 true EP0110683B1 (en) | 1987-04-08 |

Family

ID=23764204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83307188A Expired EP0110683B1 (en) | 1982-11-24 | 1983-11-24 | Determining the degree of cooking in a sulphite digester delignification |

Country Status (11)

| Country | Link |

|---|---|

| EP (1) | EP0110683B1 (OSRAM) |

| JP (1) | JPS59137584A (OSRAM) |

| KR (1) | KR880000744B1 (OSRAM) |

| AU (1) | AU2149983A (OSRAM) |

| BR (1) | BR8306460A (OSRAM) |

| CA (1) | CA1198858A (OSRAM) |

| DE (1) | DE3370840D1 (OSRAM) |

| ES (1) | ES8505479A1 (OSRAM) |

| HK (1) | HK95287A (OSRAM) |

| IN (1) | IN159330B (OSRAM) |

| SG (1) | SG60987G (OSRAM) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4990219A (en) * | 1989-06-13 | 1991-02-05 | Elsag International B.V. | Apparatus for controlling the degree of cooking in a digester |

| US4978425A (en) * | 1989-06-13 | 1990-12-18 | Elsag International B.V. | Method for controlling the degree of cooking in a digester |

| EP0445321B1 (de) * | 1990-03-05 | 1994-06-01 | Siemens Aktiengesellschaft | Verfahren zur Herstellung von Zellstoff in einem kontinuierlichen Kocher |

| CN1064096C (zh) * | 1994-04-28 | 2001-04-04 | 东芝株式会社 | 蒸煮锅温度分布控制系统 |

| ATE189715T1 (de) * | 1995-10-09 | 2000-02-15 | Siemens Ag | Verfahren zur bestimmung des endpunktes der zellstoffkochung und anordnung zum steuern der kochzeit bei der zellstoffkochung in einem reaktor |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3941649A (en) * | 1972-07-14 | 1976-03-02 | Mo Och Domsjo Aktiebolag | Process for obtaining a predetermined Kappa number in sulfate pulping |

-

1983

- 1983-11-01 KR KR1019830005175A patent/KR880000744B1/ko not_active Expired

- 1983-11-16 JP JP58214236A patent/JPS59137584A/ja active Pending

- 1983-11-16 ES ES527326A patent/ES8505479A1/es not_active Expired

- 1983-11-18 AU AU21499/83A patent/AU2149983A/en not_active Abandoned

- 1983-11-23 CA CA000441793A patent/CA1198858A/en not_active Expired

- 1983-11-23 IN IN1441/CAL/83A patent/IN159330B/en unknown

- 1983-11-24 BR BR8306460A patent/BR8306460A/pt unknown

- 1983-11-24 DE DE8383307188T patent/DE3370840D1/de not_active Expired

- 1983-11-24 EP EP83307188A patent/EP0110683B1/en not_active Expired

-

1987

- 1987-07-27 SG SG609/87A patent/SG60987G/en unknown

- 1987-12-17 HK HK952/87A patent/HK95287A/xx unknown

Also Published As

| Publication number | Publication date |

|---|---|

| ES527326A0 (es) | 1985-05-16 |

| EP0110683A1 (en) | 1984-06-13 |

| IN159330B (OSRAM) | 1987-05-02 |

| KR840006688A (ko) | 1984-12-01 |

| SG60987G (en) | 1987-10-23 |

| BR8306460A (pt) | 1984-06-26 |

| JPS59137584A (ja) | 1984-08-07 |

| HK95287A (en) | 1987-12-24 |

| DE3370840D1 (en) | 1987-05-14 |

| CA1198858A (en) | 1986-01-07 |

| ES8505479A1 (es) | 1985-05-16 |

| KR880000744B1 (ko) | 1988-05-04 |

| AU2149983A (en) | 1984-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0469771B1 (en) | Method and apparatus for process control | |

| US5156974A (en) | Method for determining the fibrinogen level of a blood sample | |

| EP0110683B1 (en) | Determining the degree of cooking in a sulphite digester delignification | |

| US4353118A (en) | Apparatus for determining the throughflow in pipe conduits | |

| US3941649A (en) | Process for obtaining a predetermined Kappa number in sulfate pulping | |

| US3465550A (en) | Chromatic control of bleaching process | |

| US4104028A (en) | Method of titrating liquor | |

| EP0276477B1 (en) | Apparatus for measuring the change in the concentration of a pigment in blood | |

| US4218734A (en) | Process quantity display apparatus | |

| Allison et al. | Adaptive‐predictive control of kamyr digester chip level | |

| RU2123190C1 (ru) | Способ определения метрологических характеристик однотипных средств измерений в группе | |

| CN106360802A (zh) | 一种烟草浆料制浆过程打浆度的修正方法 | |

| JPS571927A (en) | Measuring apparatus for coefficient of correlation | |

| JPS591707A (ja) | 繭糸の解じよ張力による繭の煮熟状態計測方法 | |

| CA1057906A (en) | Method for automatic control of the dosageing of two chemicals | |

| Haataja et al. | Kappa-number estimation with neural networks | |

| SU729504A1 (ru) | Способ контрол содержани нафталина в коксовом газе | |

| SU870928A2 (ru) | Многоканальный измерительный прибор | |

| SE8505285D0 (sv) | Forfarande for styrning av alkalisk cellulosakokning medelst en snabb analysator som meter organiska eller oorganiska komponenter i kokvetskan | |

| SU985751A1 (ru) | Цифровой анализатор сто чей волны | |

| NO981172L (no) | FremgangsmÕte og anordning til overvÕking av cellulosekoking | |

| SU877407A1 (ru) | Устройство дл контрол процесса растворени | |

| SU1072006A1 (ru) | Устройство дл регулировани толщины ковра древесноволокнистых плит | |

| KR830001225B1 (ko) | 원자로 안전시스템(system) | |

| JPS6097410A (ja) | 多変数系プロセスの同定方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19841116 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 3370840 Country of ref document: DE Date of ref document: 19870514 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19921021 Year of fee payment: 10 Ref country code: DE Payment date: 19921021 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921030 Year of fee payment: 10 |

|

| ITTA | It: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931124 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940802 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |