EP0103429A2 - Verriegelungsvorrichtung - Google Patents

Verriegelungsvorrichtung Download PDFInfo

- Publication number

- EP0103429A2 EP0103429A2 EP83304874A EP83304874A EP0103429A2 EP 0103429 A2 EP0103429 A2 EP 0103429A2 EP 83304874 A EP83304874 A EP 83304874A EP 83304874 A EP83304874 A EP 83304874A EP 0103429 A2 EP0103429 A2 EP 0103429A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- locking mechanism

- spindle

- locking device

- gear wheel

- lock

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B65/00—Locks or fastenings for special use

- E05B65/0075—Locks or fastenings for special use for safes, strongrooms, vaults, fire-resisting cabinets or the like

Definitions

- the present invention relates to locking devices which are particularly but not exclusively suitable for use in the lid or door of an underfloor safe.

- a locking device comprising at least two bolts, each rotatable between an open and a closed position by a first locking mechanism, and a second locking mechanism adapted to lock the first locking mechanism against movement to retract the bolts, the second locking mechanism beingreleasable by a sequence of at least two operations.

- the second locking mechanism is actuable to disengage by an unlocking action of an externally accessible lock, followed by a relocking action of the same lock.

- the first locking mechanism comprises a first gear wheel on each of the bolts, which gear wheels mesh with a single second gear wheel.

- the second locking mechanism may include a blind gear wheel which is moveable into engagement with the said first gear wheels to prevent the said first gear wheels turning to retract the bolts.

- the blind gear has sufficient cogs to mesh with the first gear wheels, but insufficient cogs to enable the wheels to be rotated to retract the bolts.

- the second locking mechanism includes means for locking the blind gear in engagement with the said first gear wheels including at least one externally accessible lock, in such a way that if an external lock is broken the blind gear remains in engagement with the first gears and the bolts cannot be retracted.

- Each accessible lock is advantageously connected to rotate an inclined cam face which is adapted to be located above or below a disk mounted co-axially with the second gear.

- the inclined cam may have a gap so that it can be rotated out of the path of the said disk to enable the disk to move freely along its axis.

- the disk is spring biassed towards the upward position by a limited amount.

- the inclined cam face can be part of a large screw so that it can move the disk by itself up and down the axis.

- the locking device illustrated in the drawings comprises three bolts 11 shaped as shown in the drawings and each being rotatable on its own spindle 12 through approximately 90°. Each of these bolts 11 has attached thereto on its upper surface concentric with the gear wheel a multi-toothed gear wheel 13. The three bolts 11 when extended engage under a flange on the safe body and prevent the removal of the door or lid 10.

- the three gear wheels 13 are engageable with a central gear 14 which is mounted on a central spindle 15.

- the outer end of the spindle 15 is provided with a head 16 which is indented at 17 so that the spindle can be turned from the outside of the safe by a screw driver or by a special key or device.

- each spindle 12 on which a gear wheel 13 is mounted has a layer of tungsten carbide 18.

- the system of co-operating gear wheels 13, 14 forms the first locking mechanism for the bolts.

- a second locking mechanism which locks the first locking mechanism.

- This second locking mechanism involves a limited axial movement of the spindle 15 inwardly against an outward bias from a coiled spring 19.

- the spring 19 sits in a bore 20 at the inner end of the spindle -15 and engages in a seating 21 in the bottom of the bore 22 of the safe lid 10 which contains the central spindle and its appendages.

- a disk 24 which is flat on top and chamfered on the underside which is inward of the lid. All three items, the driving gear 14 , the blind gear 23 and the disk 24 are concentric on the central spindle 15 and of equal diameter.

- the lid adjacent to the disk 24 there is at least one ramped cam 25, in essence rather like part of a helter-skelter, but mounted on a spindle to be rotateable.

- a portion of the upper surface is flat and the under surface is flat.

- the ramp portion of the cam 25 extends from the top to the bottom over an angle of approximately 180°. Part of the cam is cut-away to allow clearance for vertical movement of the chamfered disk 24.

- the ramped cam engages the upper

- the ramped cam is rotated by a key which engages in a multi-lever lock,the key hole 26 for which is on the outside of the lid.

- the ramped cam is clear of the disk 24 and allows the spring bias of the coiled spring 19 to push the spindle 15 outwardly by a limited amount, say about 8 inch, (see Figure 3).

- the edge of the chamfered disk 24 is now higher than the bottom of the ramp on the cam but the blind gear is still engaged so that the lid is still firmly secured to the safe.

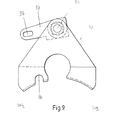

- FIG. 6 to 9 An embodiment including such a mechanism is illustrated in Figures 6 to 9.

- the disk 24 is replaced by a disk 24a to the top of which is fixed a small peg 31 which protrudes 1.5mm from the top surface of the disk 24a.

- the ramped cam 25 is replaced by an escapement member 32 which pivots about a spindle 33.

- This member 32 is shown in detail in Figure 9 , from which it will be seen that the member 32 has a generally triangular shape, the pivotal axis 33 for which is near the vertex. At the other side from the axis the member is cut away centrally to reduce weight and also to leave two peninsulars 34 which are further away from the axis 33 than any other part of the member 32. The peninsulars are further cut away.

- the head 16 must first be depressed against the resilience of the spring 19 by about 2mm to release the peg 31 so that the member 32 can be pivoted clockwise by a relocking action of the lock 26.

- the upper peninsular 34b then moves out of the way of the disk 24a to enable the disk to rise to the maximum height permitted by the spring 19 so that the gears 13 and 14 are engaged to enable rotation to the spindle 15 to unlock the bolts 11.

- the lower peninsular 34a does not obstruct the disk 24a in its upward movement on the re-locking action as it moves into a position which is underneath the disk.

Landscapes

- Lock And Its Accessories (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB8225934 | 1982-09-10 | ||

| GB8225934 | 1982-09-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0103429A2 true EP0103429A2 (de) | 1984-03-21 |

| EP0103429A3 EP0103429A3 (de) | 1984-09-05 |

Family

ID=10532842

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83304874A Ceased EP0103429A3 (de) | 1982-09-10 | 1983-08-24 | Verriegelungsvorrichtung |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0103429A3 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITGE20090025A1 (it) * | 2009-04-27 | 2009-07-27 | Carpenteria Bozzano Di Bozzano Nico Lo G B E C | Meccanismo di apertura/chiusura di un portello tagliafuoco |

| CN112951644A (zh) * | 2021-02-25 | 2021-06-11 | 星凯电气有限公司 | 配电柜隔离开关闭锁装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE115625C (de) * | ||||

| GB191401910A (en) * | 1913-02-22 | 1914-08-27 | Pierre Reynier | Improvements in and relating to Fastening Devices. |

| GB2084238A (en) * | 1980-09-26 | 1982-04-07 | Secure Safes Coventry Ltd | Fastening for safe door |

-

1983

- 1983-08-24 EP EP83304874A patent/EP0103429A3/de not_active Ceased

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITGE20090025A1 (it) * | 2009-04-27 | 2009-07-27 | Carpenteria Bozzano Di Bozzano Nico Lo G B E C | Meccanismo di apertura/chiusura di un portello tagliafuoco |

| CN112951644A (zh) * | 2021-02-25 | 2021-06-11 | 星凯电气有限公司 | 配电柜隔离开关闭锁装置 |

| CN112951644B (zh) * | 2021-02-25 | 2023-02-28 | 星凯电气有限公司 | 配电柜隔离开关闭锁装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0103429A3 (de) | 1984-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4831851A (en) | Combination/electronic lock system | |

| US20020178771A1 (en) | Storage compartment security system | |

| CA2163292C (en) | Interconnected lock | |

| EP2084350B1 (de) | Eine drehsperrvorichtung und einen manipulationssicheren mechanismus enthaltende verriegelungsanordung | |

| CN101351608A (zh) | 用于入口屏障的安全防护系统 | |

| WO2015065508A1 (en) | Improved rotary blocking device | |

| US4233913A (en) | Safe door | |

| US7984630B2 (en) | Locker lock | |

| US5484177A (en) | Dual function lock mechanism | |

| EP0103429A2 (de) | Verriegelungsvorrichtung | |

| US5651568A (en) | Privacy snib mechanism | |

| CA1227941A (en) | Locks | |

| US132936A (en) | Improvement in permutation locks | |

| US197683A (en) | Improvement in drawer-locks | |

| JP4147331B2 (ja) | カム送り防止機構 | |

| US1170481A (en) | Lock. | |

| JPS5811875Y2 (ja) | 掛け忘れ防止錠 | |

| US681838A (en) | Combination-lock. | |

| US1227425A (en) | Lock. | |

| US677363A (en) | Combined time and combination lock. | |

| WO2006033566A3 (en) | Basic mechanical automatic door's lock with central gearbox | |

| USRE5131E (en) | Improvement in locks | |

| JPH01203578A (ja) | 扉錠 | |

| EP1552091B1 (de) | Zweiteilige schlossanordnung | |

| US283644A (en) | Heset f |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19841030 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: LIONWELD LIMITED |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19861026 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: FRASER, JAMES EDWARD |