EP0099825B1 - Electric gas heater - Google Patents

Electric gas heater Download PDFInfo

- Publication number

- EP0099825B1 EP0099825B1 EP19830401459 EP83401459A EP0099825B1 EP 0099825 B1 EP0099825 B1 EP 0099825B1 EP 19830401459 EP19830401459 EP 19830401459 EP 83401459 A EP83401459 A EP 83401459A EP 0099825 B1 EP0099825 B1 EP 0099825B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- resistors

- gas heater

- heater according

- electric gas

- group

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/18—Arrangement or mounting of grates or heating means

- F24H9/1854—Arrangement or mounting of grates or heating means for air heaters

- F24H9/1863—Arrangement or mounting of electric heating means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H3/00—Air heaters

- F24H3/02—Air heaters with forced circulation

- F24H3/04—Air heaters with forced circulation the air being in direct contact with the heating medium, e.g. electric heating element

- F24H3/0405—Air heaters with forced circulation the air being in direct contact with the heating medium, e.g. electric heating element using electric energy supply, e.g. the heating medium being a resistive element; Heating by direct contact, i.e. with resistive elements, electrodes and fins being bonded together without additional element in-between

Definitions

- the present invention relates to an electric hot gas generator of the type comprising an elongated refractory insulating jacket provided at one end with an inlet opening for the gas to be heated, and at the other end with an opening hot gas outlet, and a plurality of electrical heating resistors arranged inside the envelope in a transverse direction thereof.

- the main object of the invention is to remedy the aforementioned drawbacks.

- the invention more specifically relates to an electric hot gas generator comprising an elongated refractory insulating jacket provided at one of its ends with an inlet opening for the gas to be heated, and at the other end with a hot gas outlet opening, and a plurality of electrical heating resistors arranged inside the envelope in a transverse direction thereof, characterized in that each resistance is surrounded by a plurality of dead tubes heated by radiation.

- the resistors are divided into several groups, the resistors of the same group being supplied electrically in parallel, and the number of resistors of each group increasing from one group to the next in the direction of gas flow.

- the dead tubes are preferably arranged parallel to the resistors.

- the resistors can be mounted vertically suspended inside the envelope, the latter being arranged horizontally.

- the resistors can be formed by double silicon carbide spirals, in one piece.

- Dead tubes can also be made of silicon carbide.

- two dead tubes are arranged on either side of each resistor in the transverse plane containing said resistor with which they define a first row, and a second row formed of three dead tubes is arranged in another transverse plane separated from the previous one by a distance substantially equal to the difference existing between each dead tube of the first row and the resistance of said first row and at half the interval separating two successive resistances of the same group.

- the generator of the invention comprises a system for regulating the outlet temperature of the hot gas comprising a plurality of thyristors, ie one thyristor per group of resistors, each thyristor controlling the supply of the group of resistors with which it is associated. It also includes a safety system which interrupts heating when the power difference between the supply of two groups of resistors exceeds a predetermined value.

- each group may be supplied by one phase from a three-phase source, the regulation system comprising three thyristors with phase-shifted angle control and the security system being provided for detecting the power difference between phases.

- the reference 1 designates the envelope of the hot gas generator.

- This envelope has the shape of a rectangular parallelepiped whose walls, formed of two layers of refractory and insulating concrete, delimit the passage of gas between an inlet opening 2 and an outlet opening 3, respectively fitted at the two ends of the casing 1.

- the above-mentioned rectangular parallelepiped has the following dimensions: 5 m long, 1 m wide and 1.20 m high.

- the dimensions of the gas passage are as follows: 5 m long, 0.30 m wide and 0.60 m high. These dimensions do not take into account the end portions connecting the body of the envelope to the openings 2 and 3.

- each resistor 4 made of silicon carbide, has the shape of a double spiral in one piece.

- Each resistor 4 is surrounded by dead tubes, such as 5, also made of silicon carbide whose function consists in transmitting to the gas the heat received by radiation from the resistors 4.

- the ballast tubes 5 are advantageously embedded at their ends in the lower walls and top of the casing 1 arranged horizontally.

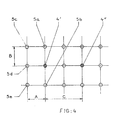

- FIG. 4 shows the relative arrangements of two neighboring resistors 4 and of dead tubes 5 which surround them.

- Two dead tubes 5a and 5b are arranged on either side of the resistor 4 ', parallel to the latter, in the same transverse plane of the casing 1 containing said resistor with which they define a first row.

- a second row formed by three dead tubes 5c, 5d and 5e is arranged in another transverse plane.

- the tube 5c is arranged opposite the tube 5a, the tube 5e opposite the tube 5b, while the tube 5d is arranged opposite the resistor 4 'to which all these tubes are parallel.

- the distance A separating the two aforementioned transverse planes is substantially equal to the difference B existing between each dead tube 5a and 5b and the resistor 4 '. It is of course equal to the difference existing between the tubes 5c, 5d and 5e of the second row.

- the distance A is moreover substantially equal to half of the interval C separating the two successive resistors 4 ′ and 4 ".

- the arrangement which has just been described is, of course, repetitive.

- the resistors 4 are divided into several groups, the resistors of the same group being electrically supplied in parallel.

- the number of resistors in the same group increases from one group to the next in the direction of gas circulation between the openings 2 and 3 of the casing 1.

- each group there are provided three groups Gi, G 2 , G 3 having respectively 5, 7, 9 resistors arranged as previously indicated.

- the resistors 4 are supplied in parallel, while the groups G i , G 2 , G 3 , are also supplied in parallel, for example by a three-phase electrical source.

- variable number of resistors 4 per group takes into account the fact that the temperature of the gas increases from the inlet to the outlet, and that consequently the power which each resistor 4 can dissipate decreases from upstream to downstream, counts given the maximum admissible temperature for resistors 4 (approximately 1650 ° C in an oxidizing atmosphere). It should also be noted that this maximum temperature depends on the value of each resistance which can vary over time.

- a bundle F only constituted by dead tubes 5.

- This bundle which comprises for example 18 dead tubes is arranged in a way analogous to the preceding groups, ie six rows of three tubes 5 parallel to the tubes 5 which surround the resistors 4. The function of the tubes 5 of this bundle is to ensure perfect homogenization of the outlet temperature.

- resistors 4 The power is ultimately delivered by 21 resistors 4.

- FIG. 5 schematically represents the system for regulating the outlet temperature.

- This system comprises a plurality of thyristors, namely one thyristor per group of resistors 4, each thyristor controlling the supply of the group of resistors with which it is associated.

- the thyristors T 1 , T 2 and T 3 respectively control the resistors 4 of the groups G “G 2 and Gs.

- the thyristors are supplied in parallel, for example by a phase from a three-phase source, as previously indicated. Thyristors with phase shift angle control are then used.

- a thermometer T measures the temperature of the gas at the generator outlet, and sends a signal representative of this temperature to a comparator.

- the comparator CT which compares the value of said temperature with a set value

- the comparator CT delivers a difference signal to each thyristor T i , T 2 , T 3 respectively connected to the groups Gi, G 2 , G 3 of resistors 4 of which the supply is regulated in a conventional manner.

- a security system S known per se, and designed to interrupt heating when the power difference between the supply of two groups of resistors exceeds a predetermined value.

- This system S is connected to the thyristors Ti, T 2 , T 3 by means of a wattmeter, respectively W i , W 2 , W 3 .

- the security system S compares the powers measured by said wattmeters and emits, if necessary, a security signal capable of acting on a switch (not shown) in order to cut off the electrical supply.

- the safety system S compares the power differences between the different phases (discrepancy detection).

- Each group Gi, G 2 , G 3 can be supplied separately.

- the group Gi can also be supplied directly with a signal from the processing of the measurement difference - temperature setpoint.

- the groups G 2 and G 3 can then be controlled indirectly by said signal by means of a potentiometer which makes it possible to obtain equal power on the three phases of the three-phase source.

- the dimensions given by way of example may be modified in order to correspondingly modify the power required.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Resistance Heating (AREA)

Description

La présente invention concerne un générateur électrique de gaz chaud du type comprenant une enveloppe réfractaire isolante de forme allongée munie à l'une de ses extrémités d'une ouverture d'entrée du gaz à chauffer, et à l'autre extrémité d'une ouverture de sortie du gaz chaud, et une pluralité de résistances électriques de chauffage disposées à l'intérieur de l'enveloppe suivant une direction transversale de celle-ci.The present invention relates to an electric hot gas generator of the type comprising an elongated refractory insulating jacket provided at one end with an inlet opening for the gas to be heated, and at the other end with an opening hot gas outlet, and a plurality of electrical heating resistors arranged inside the envelope in a transverse direction thereof.

Un générateur électrique de gaz chaud du type précité est connu depuis longtemps, notamment dans les installations de chauffage domestique. L'extension de son domaine d'utilisation à des applications industrielles a rencontré un certain nombre de difficultés.An electric generator of hot gas of the aforementioned type has been known for a long time, in particular in domestic heating installations. The extension of its field of use to industrial applications encountered a certain number of difficulties.

Le rendement d'un tel générateur s'est révélé très médiocre. Cet inconvénient résulte du fait que le chauffage n'est pas homogène dans une même section transversale de l'enveloppe. Cela résulte également du fait que le gaz circulant à l'intérieur de l'enveloppe voit sa température augmenter au fur et à mesure de son écoulement tandis que les résistances qu'il balaie sont chauffées de manière uniforme. Les transferts thermiques ne s'effectuent pas de manière rationnelle. Il devient alors impossible d'atteindre des températures élevées.The performance of such a generator has been found to be very poor. This drawback results from the fact that the heating is not homogeneous in the same cross section of the envelope. This also results from the fact that the gas circulating inside the envelope sees its temperature increase as it flows while the resistances which it sweeps are heated uniformly. Heat transfers are not carried out rationally. It then becomes impossible to reach high temperatures.

L'invention a surtout pour but de remédier aux inconvénients précités.The main object of the invention is to remedy the aforementioned drawbacks.

Elle consiste essentiellement à prévoir autour de chaque résistance, une pluralité de tubes morts que ladite résistance chauffe par rayonnement, tandis que le gaz balayant le surface desdits tubes morts est chauffé par convection, de la même façon qu'il est chauffé lorsqu'il balaye les parois internes de l'enveloppe. Elle consiste en outre à réaliser un agencement des résistances suivant une disposition permettant d'assurer une chauffe rationelle.It essentially consists in providing around each resistance, a plurality of dead tubes that said resistance heats by radiation, while the gas sweeping the surface of said dead tubes is heated by convection, in the same way as it is heated when it sweeps the inner walls of the envelope. It also consists in making an arrangement of the resistors according to a provision making it possible to ensure rational heating.

L'invention a plus précisément pour objet un générateur électrique de gaz chaud comprenant une enveloppe réfractaire isolante de forme allongée munie à l'une de ses extrémités d'une ouverture d'entrée du gaz à chauffer, et à l'autre extrémité d'une ouverture de sortie du gaz chaud, et une pluralité de résistances électriques de chauffage disposées à l'intérieur de l'enveloppe suivant une direction transversale de celle-ci, caractérisé en ce que chaque résistance est entourée par une pluralité de tubes morts chauffés par rayonnement.The invention more specifically relates to an electric hot gas generator comprising an elongated refractory insulating jacket provided at one of its ends with an inlet opening for the gas to be heated, and at the other end with a hot gas outlet opening, and a plurality of electrical heating resistors arranged inside the envelope in a transverse direction thereof, characterized in that each resistance is surrounded by a plurality of dead tubes heated by radiation.

Les résistances sont répartis en plusieurs groupes, les résistances d'un même groupe étant alimentées électriquement en parallèle, et le nombre de résistances de chaque groupe augmentant d'un groupe au suivant dans le sens de circulation du gaz. On peut, par exemple prévoir trois groupes de résistances ayant respectivement cinq, sept et neuf résistances.The resistors are divided into several groups, the resistors of the same group being supplied electrically in parallel, and the number of resistors of each group increasing from one group to the next in the direction of gas flow. One can, for example provide three groups of resistors having respectively five, seven and nine resistors.

Avantageusement, il sera prévu, entre le groupe comprenant le plus grand nombre de résistances et l'ouverture de sortie de gaz chaud, un faisceau de tubes morts disposés suivant une direction transversale de l'enveloppe.Advantageously, there will be provided, between the group comprising the greatest number of resistances and the hot gas outlet opening, a bundle of dead tubes arranged in a transverse direction of the envelope.

Les tubes morts sont disposés, de préférence, parallèlement aux résistances. Les résistances pourront être montées verticalement suspendues à l'intérieur de l'enveloppe, cette dernière étant disposée horizontalement.The dead tubes are preferably arranged parallel to the resistors. The resistors can be mounted vertically suspended inside the envelope, the latter being arranged horizontally.

Les résistances peuvent être constituées par des spirales doubles en carbure de silicium, d'une seule pièce. Les tubes morts peuvent aussi être réalisés en carbure de silicium.The resistors can be formed by double silicon carbide spirals, in one piece. Dead tubes can also be made of silicon carbide.

Suivant un mode de réalisation particulier, deux tubes morts sont disposés de part et d'autre de chaque résistance dans le plan transversal contenant ladite résistance avec laquelle ils définissent une première rangée, et une deuxième rangée formée de trois tubes morts est disposée dans un autre plan transversal séparé du précédent d'une distance sensiblement égale à l'écart existant entre chaque tube mort de la première rangée et la résistance de ladite première rangée et à la moitié de l'intervalle séparant deux résistances successives du même groupe.According to a particular embodiment, two dead tubes are arranged on either side of each resistor in the transverse plane containing said resistor with which they define a first row, and a second row formed of three dead tubes is arranged in another transverse plane separated from the previous one by a distance substantially equal to the difference existing between each dead tube of the first row and the resistance of said first row and at half the interval separating two successive resistances of the same group.

Le générateur de l'invention comporte un système de régulation de la température de sortie du gaz chaud comprenant une pluralité de thyristors, soit un thyristor par groupes de résistances, chaque thyristor contrôlant l'alimentation du groupe de résistances auquel il est associé. Il comporte, en outre, un système de sécurité qui interrompt le chauffage lorsque l'écart de puissance entre l'alimentation de deux groupes de résistances dépasse une valeur prédéterminée.The generator of the invention comprises a system for regulating the outlet temperature of the hot gas comprising a plurality of thyristors, ie one thyristor per group of resistors, each thyristor controlling the supply of the group of resistors with which it is associated. It also includes a safety system which interrupts heating when the power difference between the supply of two groups of resistors exceeds a predetermined value.

Dans le cas où le générateur comprend trois groupes de résistances, chaque groupe pourra être alimenté par une phase d'une source triphasée, le système de régulation comportant trois thyristors à commande d'angle déphasée et le système de sécurité étant prévu pour détecter l'écart de puissance entre les phases.In the case where the generator comprises three groups of resistors, each group may be supplied by one phase from a three-phase source, the regulation system comprising three thyristors with phase-shifted angle control and the security system being provided for detecting the power difference between phases.

L'invention sera mieux comprise en se référant à la description qui suit, faite en regard des dessins annexés, concernant une forme de réalisation particulière de l'invention donnée à titre d'exemple non limitatif.

- La figure 1 représente le générateur en élévation suivant une coupe axiale.

- La figure 2 représente le générateur en plan suivant une coupe axiale.

- La figure 3 en est une coupe transversale.

- La figure 4 est un schéma illustrant l'agencement des tubes morts autour de deux résistances voisines.

- La figure 5 est un schéma électronique du système de régulation de la température de sortie du gaz chaud.

- Figure 1 shows the generator in elevation in an axial section.

- Figure 2 shows the generator in plan along an axial section.

- Figure 3 is a cross section.

- FIG. 4 is a diagram illustrating the arrangement of the dead tubes around two neighboring resistors.

- Figure 5 is an electronic diagram of the regulation system of the hot gas outlet temperature.

Sur les figures 1 à 3, le repère 1 désigne l'enveloppe du générateur de gaz chaud. Cette enveloppe présente la forme d'un parallèlépipède rectangle dont les parois, formées de deux couches de béton réfractaire et isolant, délimitent le passage du gaz entre une ouverture d'entrée 2 et une ouverture de sortie 3, respectivement aménagées aux deux extrémités de l'enveloppe 1.In Figures 1 to 3, the

Suivant une forme particulière de réalisation, le parallèlépipède rectangle précité a les dimensions suivantes: 5 m de long, 1 m de large et 1,20 m de haut. Les dimensions du passage des gaz sont les suivantes: 5 m de long, 0,30 m de large et 0,60 m de haut. Ces dimensions ne prennent pas en compte les parties d'extrémités raccordant le corps de l'enveloppe aux ouvertures 2 et 3.According to a particular embodiment, the above-mentioned rectangular parallelepiped has the following dimensions: 5 m long, 1 m wide and 1.20 m high. The dimensions of the gas passage are as follows: 5 m long, 0.30 m wide and 0.60 m high. These dimensions do not take into account the end portions connecting the body of the envelope to the

A l'intérieur de l'enveloppe 1, des résistances électriques, telles que 4, sont disposées suivant une direction transversale, de préférence dans le plan vertical médian de ladite enveloppe. Ces résistances sont alors montées verticalement suspendues. Chaque résistance 4 réalisée en carbure de silicium, présente la forme d'une spirale double en une seule pièce. Chaque résistance 4 est entourée de tubes morts, tels que 5, également réalisés en carbure de silicium dont la fonction consiste à transmettre au gaz la chaleur reçue par rayonnement des résistances 4. Lest tubes 5 sont avantageusement encastrés à leurs extrémités dans les parois inférieure et supérieure de l'enveloppe 1 disposée horizontalement.Inside the

La figure 4 montre les dispositions relatives de deux résistances 4 voisines et de tubes morts 5 qui les entourent.FIG. 4 shows the relative arrangements of two neighboring

Deux tubes morts 5a et 5b sont disposés de part et d'autre de la résistance 4', parallèlement à celle-ci, dans le même plan transversal de l'enveloppe 1 contenant ladite résistance avec laquelle ils définissent une première rangée. Une deuxième rangée formée de trois tubes morts 5c, 5d et 5e est aménagée dans un autre plan transversal. Le tube 5c est disposé en regard du tube 5a, le tube 5e en regard du tube 5b, tandis que le tube 5d est disposé en regard de la résistance 4' à laquelle tous ces tubes sont parallèles. La distance A séparant les deux plans transversaux précités est sensiblement égale à l'écart B existant entre chaque tube mort 5a et 5b et la résistance 4'. Elle est bien entendu égale à l'écart existant entre les tubes 5c, 5d et 5e de la deuxième rangée. La distance A est par ailleurs sensiblement égale à la moitié de l'intervalle C séparant les deux résistances successives 4' et 4". La disposition que l'on vient de décrire est, bien entendu, répétitive.Two

Dans le cas de la forme de réalisation précitée, chaque tube 5a un diamètre de 54 mm et une longueur de 710 mm, tandis que les dimensions de chaque résistances 5 sont les suivantes:

- - diamètre: 54 mm

- - longueur totale: 1092 mm

- - longueur de la partie chauffante: 610 mm

- - diameter: 54 mm

- - total length: 1092 mm

- - length of the heating part: 610 mm

Suivant une caractéristique particulièrement importante de l'invention, les résistances 4 sont réparties en plusieurs groupes, les résistances d'un même groupe étant électriquement alimentées en parallèle. Le nombre de résistances d'un même groupe augmente d'un groupe au suivant dans le sens de la circulation du gaz entre les ouvertures 2 et 3 de l'enveloppe 1.According to a particularly important characteristic of the invention, the

Dans le cas de l'exemple représenté, il est prévu trois groupes Gi, G2, G3 ayant respectivement 5, 7, 9 résistances agencées comme précédemment indiqué. Dans chaque groupe les résistances 4 sont alimentées en parallèle, tandis que les groupes Gi, G2, G3, sont également alimentés en parallèle, par exemple par une source électrique triphasée.In the case of the example shown, there are provided three groups Gi, G 2 , G 3 having respectively 5, 7, 9 resistors arranged as previously indicated. In each group the

Le nombre variable de résistances 4 par groupe prend en compte le fait que la température du gaz augmente de l'entrée vers la sortie, et que par conséquent la puissance que peut dissiper chaque résistance 4 diminue de l'amont vers l'aval, compte tenu de la température maximale admissible pour les résistances 4 (environ 1650° C en atmosphère oxydante). On doit également remarquer que cette température maximale dépend de la valeur de chaque résistance qui peut varier dans le temps.The variable number of

Il est prévu par ailleurs, entre le groupe G3 et 9 résistances et l'ouverture de sortie 3 du gaz, un faisceau F uniquement constitué par des tubes morts 5. Ce faisceau qui comprend par exemple 18 tubes morts est agencé d'une manière analogue aux groupes précédents, soit six rangées de trois tubes 5 parallèles aux tubes 5 qui entourent les résistances 4. La fonction des tubes 5 de ce faisceau est d'assurer une parfaite homogénéisation de la température de sortie.There is also provided, between group G 3 and 9 resistors and the

La puissance est en définitive délivrée par 21 résistances 4. Ces résistances, les tubes morts, ainsi que les parois du passage de l'enveloppe 1, définissent la totalité de la surface de transfert de chaleur sur laquelle le gaz vient s'échauffer par convection. On voit que cette surface est considérablement augmentée par rapport à l'art antérieur. Il en résulte une augmentation de la puissance fournie par les résistances 4.The power is ultimately delivered by 21

La figure 5 représente, de façon schématique, le système de régulation de la température de sortie. Ce système comprend une pluralité de thyristors, à savoir un thyristor par groupe de résistances 4, chaque thyristor contrôlant l'alimentation du groupe de résistances auquel il est associé.FIG. 5 schematically represents the system for regulating the outlet temperature. This system comprises a plurality of thyristors, namely one thyristor per group of

En référence à l'exemple que l'on vient de décrire, les thyristors T1, T2et T3 contrôlent respectivement les résistances 4 des groupes G" G2 et Gs. Les thyristors sont alimentés en parallèle, par exemple par une phase d'une source triphasée, comme précédemment indiqué. On fait alors appel à des thyristors à commande d'angle déphasée. Un thermomètre T mesure la température du gaz à la sortie du générateur, et il envoie un signal représentatif de cette température à un comparateur CT, lequel compare la valeur de ladite température à une valeur de consigne. Le comparateur CT délivre un signal d'écart à chaque thyristor Ti, T2, T3 respectivement relié aux groupes Gi, G2, G3 de résistances 4 dont l'alimentation est régulée de façon classique.With reference to the example which has just been described, the thyristors T 1 , T 2 and T 3 respectively control the

Un système de sécurité S, connu en soi, et prévu pour interrompre le chauffage lorsque l'écart de puissance entre l'alimentation de deux groupes de résistances dépasse une valeur prédéterminée. Ce système S est relié aux thyristors Ti, T2, T3 par l'intermédiaire d'un wattmètre, respectivement Wi, W2, W3. Le système de sécurité S compare les puissances mesurées par lesdits wattmètres et émet, le cas échéant, un signal de sécurité apte à agir sur un interrupteur (non représenté) en vue de couper l'alimentation électrique. Dans le cas d'une alimentation par les trois phases d'une source triphasée, le système de sécurité S compare les écarts de puissance entre les différentes phases (détection de discordance).A security system S, known per se, and designed to interrupt heating when the power difference between the supply of two groups of resistors exceeds a predetermined value. This system S is connected to the thyristors Ti, T 2 , T 3 by means of a wattmeter, respectively W i , W 2 , W 3 . The security system S compares the powers measured by said wattmeters and emits, if necessary, a security signal capable of acting on a switch (not shown) in order to cut off the electrical supply. In the case of a three-phase supply from a three-phase source, the safety system S compares the power differences between the different phases (discrepancy detection).

On peut alimenter séparément chaque groupe Gi, G2, G3. On peut aussi alimenter le groupe Gi directement par un signal provenant du traitement de l'écart mesure - consigne de la température. Les groupes G2 et G3 peuvent alors être pilotés indirectement par ledit signal par l'intermédiaire d'un potentiomètre qui permet d'obtenir l'égalité de puissance sur les trois phases de la source triphasée.Each group Gi, G 2 , G 3 can be supplied separately. The group Gi can also be supplied directly with a signal from the processing of the measurement difference - temperature setpoint. The groups G 2 and G 3 can then be controlled indirectly by said signal by means of a potentiometer which makes it possible to obtain equal power on the three phases of the three-phase source.

Bien que l'invention ait été décrite en référence à une forme particulière de réalisation, il va de soi qu'elle n'y est en rien limitée, et que des modifications peuvent lui être apportées sans sortir de son domaine.Although the invention has been described with reference to a particular embodiment, it goes without saying that it is in no way limited thereto, and that modifications can be made to it without departing from its field.

On pourra modifier les dimensions données à titre d'exemple en vue de modifier corrélative- ment la puissance requise. On pourra pour des dimensions données modifier le nombre de résistances et de tubes morts ainsi que le nombre de groupes.The dimensions given by way of example may be modified in order to correspondingly modify the power required. We can for given dimensions modify the number of resistors and dead tubes as well as the number of groups.

Il est également possible de répartir les tubes morts autour des résistances d'une façon autre que celle décrite.It is also possible to distribute the dead tubes around the resistors in a manner other than that described.

Il va de soi que l'on pourra remplacer l'un quelconque des moyens décrits par un moyen techniquement équivalent. L'invention couvre donc, outre l'exemple représenté, ses différentes variantes d'exécution.It goes without saying that any of the means described can be replaced by a technically equivalent means. The invention therefore covers, in addition to the example shown, its various alternative embodiments.

Claims (14)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8212561A FR2530320B1 (en) | 1982-07-19 | 1982-07-19 | |

| FR8212561 | 1982-07-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0099825A1 EP0099825A1 (en) | 1984-02-01 |

| EP0099825B1 true EP0099825B1 (en) | 1985-10-02 |

Family

ID=9276076

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19830401459 Expired EP0099825B1 (en) | 1982-07-19 | 1983-07-13 | Electric gas heater |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0099825B1 (en) |

| DE (1) | DE3360932D1 (en) |

| FR (1) | FR2530320B1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2568672B1 (en) * | 1984-08-06 | 1988-12-09 | Bertin & Cie | METHOD AND DEVICE FOR HEATING GAS BY JOUL EFFECT. |

| FR2579055B1 (en) * | 1985-03-15 | 1990-09-07 | Metanic Sa | ELECTRIC HEATING DEVICE FOR GASEOUS FLUID |

| NO157640C (en) * | 1985-07-09 | 1988-04-20 | Nielsen Ingenioer Og Handelsak | HEATING UNIT. |

| AT395268B (en) * | 1988-04-15 | 1992-11-10 | Vaillant Gmbh | WATER HEATER |

| FR2636770B1 (en) * | 1988-09-19 | 1990-12-28 | Sgn Soc Gen Tech Nouvelle | DEVICE FOR HEATING CONTAMINATED WET GAS |

| DE102005053731A1 (en) | 2005-11-10 | 2007-05-24 | Linde Ag | Apparatus for high pressure gas heating |

| JP6033261B2 (en) * | 2013-06-28 | 2016-11-30 | 貞徳舎株式会社 | Hot air generator |

| CN109140786A (en) * | 2018-07-23 | 2019-01-04 | 珠海格力电器股份有限公司 | Electricity-proof wall and water heater |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE489379C (en) * | 1927-11-25 | 1930-01-17 | Siemens Schuckertwerke Akt Ges | Electric stove |

| DE735982C (en) * | 1937-03-03 | 1943-06-04 | Dr Walter Schottky | Arrangement for the electrical heating of flowing air or gases to high temperatures |

-

1982

- 1982-07-19 FR FR8212561A patent/FR2530320B1/fr not_active Expired

-

1983

- 1983-07-13 DE DE8383401459T patent/DE3360932D1/en not_active Expired

- 1983-07-13 EP EP19830401459 patent/EP0099825B1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| DE3360932D1 (en) | 1985-11-07 |

| FR2530320A1 (en) | 1984-01-20 |

| FR2530320B1 (en) | 1984-12-21 |

| EP0099825A1 (en) | 1984-02-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0099825B1 (en) | Electric gas heater | |

| EP0481858B1 (en) | Self-heating collecting aerosol filter for pyrolysis | |

| FR3065027A1 (en) | VEHICLE EXHAUST GAS PURIFYING DEVICE AND CORRESPONDING DRIVING METHOD | |

| EP3942165B1 (en) | Durable heating member for a vehicle exhaust gas purifying device | |

| FR3077330A1 (en) | FACILITATED HANDLING HEATING DEVICE FOR A VEHICLE EXHAUST GAS PURIFYING DEVICE | |

| FR2695203A1 (en) | Thermistor liquid detector. | |

| EP0076759B1 (en) | Apparatus for continuously determining the heating value of gases | |

| WO2020065165A1 (en) | Electric radiator of a ventilation, heating and/or air-conditioning system of a motor vehicle | |

| FR2641794A1 (en) | MEASURING AND HEATING PROBE FOR THE HEAT TREATMENT OF METAL CONDUITS, ESPECIALLY HEAT EXCHANGER TUBES | |

| FR2463564A1 (en) | JULY HEATING ELEMENT FOR HIGH TEMPERATURE FURNACE | |

| EP0105770A1 (en) | Industrial electric heating enclosure | |

| FR2632475A1 (en) | Device for the homogeneous heating of fluids by the Joule effect | |

| EP0117201A1 (en) | Electric resistance heater for heating a gaseous mixture | |

| WO2017032821A1 (en) | Thermally transparent thermoelectric converter | |

| FR2570475A1 (en) | Very high yield condensation boiler | |

| FR2627658A1 (en) | Carbon fibre heating element - has graphite terminals and carbon fibre screws for high temp. operation | |

| FR2579055A1 (en) | ELECTRICAL HEATING DEVICE FOR GASEOUS FLUID | |

| FR3086209A1 (en) | ELECTRIC RADIATOR OF A VENTILATION, HEATING AND / OR AIR CONDITIONING SYSTEM OF A MOTOR VEHICLE | |

| FR2568672A1 (en) | Method and device for heating a gas by the Joule effect | |

| FR2494676A1 (en) | MOBILE CRANE FOR OPERATING IN COLD REGIONS | |

| CH361647A (en) | Gas heating device | |

| CA1325235C (en) | Porous electric heating element incorporating perforated and/or notched metal plates | |

| FR2765671A1 (en) | BI-ENERGY HEATER BLOCK, PARTICULARLY FOR THE PRODUCTION OF DOMESTIC HOT WATER AND BALLOON EQUIPPED WITH SUCH A BLOCK | |

| FR3028033A1 (en) | METHOD FOR DETECTING AN INSUFFICIENT LEVEL OF LIQUID IN A HEATED ENCLOSURE OF AN ELECTRIC HEATER | |

| FR2590005A1 (en) | System of power semiconductor components cooled by circulation of a liquid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19840319 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 3360932 Country of ref document: DE Date of ref document: 19851107 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19870714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19870731 Ref country code: CH Effective date: 19870731 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19880401 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881122 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83401459.9 Effective date: 19880901 |