EP0096485A2 - Automatic dispenser for flexible discs - Google Patents

Automatic dispenser for flexible discs Download PDFInfo

- Publication number

- EP0096485A2 EP0096485A2 EP83302806A EP83302806A EP0096485A2 EP 0096485 A2 EP0096485 A2 EP 0096485A2 EP 83302806 A EP83302806 A EP 83302806A EP 83302806 A EP83302806 A EP 83302806A EP 0096485 A2 EP0096485 A2 EP 0096485A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- carrier

- disc

- plunger

- dispenser according

- piston

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B13/00—Apparatus or processes specially adapted for manufacturing conductors or cables

- H01B13/012—Apparatus or processes specially adapted for manufacturing conductors or cables for manufacturing wire harnesses

Definitions

- This invention relates to the dispensing of flexible discs and particularly to an automatic dispenser which is capable of dispensing flexible discs one at a time so as to fit or force each disc over a spigot or, preferably, a shouldered pin such as may be used in the production of a wiring loom for electrical harnesses.

- a loom table or pins used in conjunction with it or a method of using such a table is not part of the present invention, a preferred form of the present invention is intended to be suitable for use in a technique of producing wiring harnesses as is described, for example, in our European Patent Application No. 82301173.9 (published 13 October 1982 under No. 0062413).

- a loom table includes, among other things, a multiplicity of layers of which one is a mesh that can receive the ends of shouldered pins but which prevents the complete passage of the pins.

- the pins are inserted in predetermined positions so as to define a multiplicity of paths for the wires which are to be laid down to form the wiring harness.

- an automatic robot manipulator for the insertion of the pins in the table and to lay the wires using the same manipulator which may have a wrist coupled to a pneumatic line and adapted for the reception of a multiplicity of different devices such as a pin insertion tool and a wire laying tool.

- the pins may be disposed in pairs, the path or paths of the wires extending between the pairs.

- the pins are preferably double ended, having a central portion of larger diameter and two similar end portions of reduced diameter. Accordingly, a collar may be inserted over the upper end of the pin and be supported by the shoulder at one end of the central portion. It is one object of the present invention to provide an automatic dispenser which can place a collar on such a pin.

- the dispenser is adapted for coupling to a pneumatic line and is intended for use as a detachable accessory tool for a robot; for this purpose the coupling by means of which the dispenser is attachable to a robot head may be of a convenient standard form.

- other forms of coupling may be used if the circumstances permit.

- the automatic manipulator may use a head which is in the form of a tube of annular cross-section, this tube being coupled when in place on the manipulator to a source of vacuum suction so that it can pick-up a collar and deposit it over the head of a pin.

- a source of vacuum suction so that it can pick-up a collar and deposit it over the head of a pin.

- British Patent Specification No. 1252355 illustrates a mechanism for transferring punched cards one at a time from one stack to another by means of a slider and a plunger.

- British Patent Specification No. 1481996 illustrates a machine in which metal fasteners are fed in single file, though not in a stack, to a transfer position whence one can be engaged by a plunger while a second fastener is held away from the pa:h of the plunger.

- Neither specification is concerned with the dispensing of discs onto pins or spigots.

- a further more specific object of the invention is to provide a dispenser which is capable of dispensing a flexible collar over a pin or spigot.

- a dispenser comprises a magazine for a stack of discs and a carrier which is.adapted to receive a single disc from one end of the stack and capable of releasing such a disc on the application of axial force thereto.

- the dispenser further comprises means for moving the carrier so as to align the disc with a plunger, preferably a hollow plunger if the discs are in the form of collars for disposition over pins or spigots. Means are provided for advancing the plunger to apply the required axial force to release the disc from the carrier.

- the carrier includes an aperture for accommodating a disc and means,such as a partial shoulder, for engaging the disc at the rim thereof in order to resist but not prevent axial movement of the disc relative to the carrier.

- the carrier comprises a plate positioned to cover the.said one end of the stack and being movable between a position for receiving the disc and a position generally aligning the disc with respect to the plunger.

- the means for moving the carrier is largely dependent upon the nature of the carrier and the movement thereof.

- the carrier might be a slidable plate, it is preferable to provide a carrier which rotates between the aforementioned positions.

- the means for moving the carrier may include a piston or plunger keyed to prevent its rotation and including means such as a pin adapted to engage a helical groove in a spigot which is secured to the carrier for conjoint rotation therewith.

- the means for moving the carrier and the means for advancing the hollow plunger may be constituted by resettable actuators.

- the actuator for moving the carrier may be constituted by a piston movable against a restoring force provided by a spring.

- the actuator for the hollow plunger may likewise comprise a piston which may be movable against a restoring force provided by a spring. It is convenient to provide sequencing of the operation of the actuators so that the actuator for the carrier completes the movement of the carrier and such that the movement of the hollow plunger is inhibited until the carrier's movement is completed.

- the piston for effecting movement of the carrier may be arranged to inhibit the communication of the piston for moving the hollow plunger with a source of fluid pressure until the stroke of the piston for moving the carrier is substantially completed.

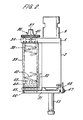

- the drawings illustrate a dispenser 1 which has a metal body 2 which may be made of aluminium. With reference particularly to Figure l,within the body are two passageways 3 and 4 which may be formed by boring or reaming whichever is convenient.

- the body 2 has a top plate 5 which closes off the top end of the passageway 3, which at its upper end is slightly enlarged for the accommodation of an O-ring 6.

- the plate 5 has an aperture 7 aligned with the passageway 4, which is slightly enlarged at its upper end for the accommodation of an O-ring 8.

- Fitting within the aperture 7 is a coupling 9 having an internal passageway 10 and a bayonet fitting 11 by means of which the coupling 9 may be connected to a standard pneumatic hand or wrist of a robot manipulator.

- the passageway 10 can receive pneumatic pressure at times determined by the programming of the manipulator. This form of manipulator is well-known and will not be described further.

- the entrance to this passage from the passageway 3 is normally below the head of the piston 14 and thus until the piston substantially completes its stroke the chamber constituted by the passageway 4 is cut-off from communication with the source of pneumatic pressure.

- a pivot bearing 20 Within a lower, reduced section, part 19 of the passageway 3 is fitted a pivot bearing 20 .

- the bearing 20 has an external screw threading 21 for engagement with a threading in the part 19.

- the upper part of the bearing is formed as a tube 22 which receives the stem 15 of the piston.

- a compression spring 23 Within the annular well formed between the tube 22 and the wall of the passageway 3 is a compression spring 23 which provides restoring force for the piston.

- an air hole 24 formed in the body 2. This air hole permits the escape of air from that part of the chamber 3 which is below the head of the piston 14.

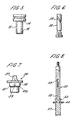

- the upper tubular part 22 of the bearing includes a slot 25 which is arranged so as to extend lengthwise of the stem 15 of the piston. This slot is engaged by one end of a pin 26 carried in the aperture 16 in the stem 15 of the piston 14.

- the pin 26 and the slot 25 provide a means of keying the piston and thereby preventing rotation thereof.

- a spigot 28 which extends upwardly so as to be accommodated within the hollow stem 15 of the piston.

- the spigot 28, which is shown in detail in Figure 6, is formed with a helical groove 29 engaged by the inner end of the pin 26.

- a carrier 31 is attached to the spigot 28.

- This carrier 31 is in the form of a plate arranged in a plane generally transverse the direction of movement and the longitudinal axis of the piston.

- the piston and the components associated therewith constitute a resettable actuator for moving the carrier constituted by the plate 31.

- Downward movement of the piston in response to the application of fluid pressure to the passageway 10 causes the spigot 28 to rotate and thereby causes the plate 31 to rotate to the position shown in Figure 1.

- the carrier moves to this position from a position which it can receive a disc from a stack of discs.

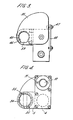

- Figure 2 illustrates the dispenser when the carrier is in a position to receive a disc, and the features of Figure 2 will be for convenience described before the remainder of Figure 1.

- a bracket 32 supporting the bottom end of a magazine 33 constituted by a metal tube.

- the upper end of the magazine 33 is aligned with an aperture 34 in the top plate and this aperture is provided with recesses 35 constituting part of a bayonet fitting for a closure 36.

- the closure has an external grip 37 and a cylindrical body 38 which has a lateral bore 39 supporting a nylon pin 40 ( Figure 2) which can engage the recesses 35.

- the body 38 has an annular shoulder 41 and associated groove 41a supporting one end of a compression spring 42 of which the other end engages a metal pressure pad 43. This pad bears on the upper end of a stack of rubber collars 44, and together with the spring constitutes means for urging the stack towards the lower end of the magazine.

- the magazine may readily be loaded with a stack of discs by removing the closure 36 together with the spring 42 and pad 43.

- the carrier 31 includes a shallow recess 45 which is of depth approximately corresponding to the depth of a collar and of diameter slightly larger than that of a collar 44.

- the recess is formed with a peripheral shoulder 46. Other forms of shoulder could be used instead.

- the lowermost disc in the stack is received by the recess 45.

- the recess 45 and shoulder 46 provide a means by which a collar or disc can be received and they inhibit but, owing to the slightness of the shoulder, do not prevent the passage of the disc through the carrier 31 if sufficient axial force is applied to the collar which is in the recess 45.

- the force of the spring 42 must be sufficient to maintain the stack of discs but should be insufficient to force the lowermost collar through the carrier plate 31. Xowever, quite a strong . spring 42 can be used because in the arrangement shown it is difficult for the lowermost disc to flex as is required for its passage through the aperture defined by the shoulder 46.

- the return position of the carrier 34 is set by an adjustable stop 47 carried on a bracket 48 . attached to the body 2.

- the head 50 is secured to the top of a stem 51 of which the lower part 52 constitutes a hollow plunger, there being a bore 53 extending from the lower end of the stem 51 towards the upper end thereof.

- the lower end of the stem 51 is enlarged, having a head 54. This provides an end stop for the upward movement of the piston head 50.

- the head 50 is urged upwardly by means of a compression spring 55 engaging the head 50 and encircling the stem 51.

- the passageway 4 is provided with an air relief hole 56.

- the pistons retract automatically when the fluid pressure is relieved, and it will be noted that the recess 45 is open at one side (shown by the reference 59) so that the carrier can return without fouling the plunger 52.

- dispenser in its preferred form, intended for use as particularly described, it may have a more general utility.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Manipulator (AREA)

- Coating Apparatus (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- De-Stacking Of Articles (AREA)

Abstract

An automatic dispenser for dispensing a flexible rubber collar over a shouldered pin comprises a magazine 33 for holding a stack of collars. A carrier 31 has a recess 45 provided with a shoulder 46 which resists movement of a disc but does not prevent movement of a disc through the carrier plate 31 on the application of sufficient axial force. An actuator constituted by a piston 14 is coupled to the carrier 31 to effect rotation thereof so as to align the disc held in the recess 42 with a hollow plunger 52. Advancement of the piston causes the hollow plunger 52 to force the disc through the aperture defined by the shoulder 46, the disc flexing under the action of the plunger. The plunger can receive the spigot or head of the pin so that the collar may be inserted on the spigot or pin as far as a shoulder thereon.

Description

- This invention relates to the dispensing of flexible discs and particularly to an automatic dispenser which is capable of dispensing flexible discs one at a time so as to fit or force each disc over a spigot or, preferably, a shouldered pin such as may be used in the production of a wiring loom for electrical harnesses.

- Although the construction of a loom table or pins used in conjunction with it or a method of using such a table is not part of the present invention, a preferred form of the present invention is intended to be suitable for use in a technique of producing wiring harnesses as is described, for example, in our European Patent Application No. 82301173.9 (published 13 October 1982 under No. 0062413). In that technique a loom table includes, among other things, a multiplicity of layers of which one is a mesh that can receive the ends of shouldered pins but which prevents the complete passage of the pins. The pins are inserted in predetermined positions so as to define a multiplicity of paths for the wires which are to be laid down to form the wiring harness. It is preferable to use an automatic robot manipulator for the insertion of the pins in the table and to lay the wires using the same manipulator which may have a wrist coupled to a pneumatic line and adapted for the reception of a multiplicity of different devices such as a pin insertion tool and a wire laying tool. The pins may be disposed in pairs, the path or paths of the wires extending between the pairs.

- In such a technique and as suggested in the aforementioned patent application, it would be convenient to use flexible discs in the form of collars which can be supported by the pins so as to provide spaced platforms for supporting the wires of the harness clear of the loom table. It will be understood that, as disclosed in the aforementioned application, the pins are preferably double ended, having a central portion of larger diameter and two similar end portions of reduced diameter. Accordingly, a collar may be inserted over the upper end of the pin and be supported by the shoulder at one end of the central portion. It is one object of the present invention to provide an automatic dispenser which can place a collar on such a pin.

- As is briefly indicated in the foregoing, it is known to use a robot manipulator which can carry a selected one of a plurality of different tools according to the particular task which the manipulator is to perform. In a preferred embodiment of the present invention the dispenser is adapted for coupling to a pneumatic line and is intended for use as a detachable accessory tool for a robot; for this purpose the coupling by means of which the dispenser is attachable to a robot head may be of a convenient standard form. However, other forms of coupling may be used if the circumstances permit.

- In the aforementioned application it is suggested that for disposing collars over selected pins the automatic manipulator may use a head which is in the form of a tube of annular cross-section, this tube being coupled when in place on the manipulator to a source of vacuum suction so that it can pick-up a collar and deposit it over the head of a pin. Such a proposal is feasible though has the practical disadvantage of requiring a source of vacuum suction. Moreover, though such a proposal is satisfactory for use in dispensing solid discs, it is less suitable for dispensing collars and other apertured discs.

- British Patent Specification No. 1252355 illustrates a mechanism for transferring punched cards one at a time from one stack to another by means of a slider and a plunger.

- British Patent Specification No. 1481996 illustrates a machine in which metal fasteners are fed in single file, though not in a stack, to a transfer position whence one can be engaged by a plunger while a second fastener is held away from the pa:h of the plunger. Neither specification is concerned with the dispensing of discs onto pins or spigots.

- It is accordingly a general object of the invention to provide an.improved dispenser for dispensing flexible discs and particularly flexible apertured discs such as collars. A further more specific object of the invention is to provide a dispenser which is capable of dispensing a flexible collar over a pin or spigot.

- According to a preferred embodiment of the invention a dispenser comprises a magazine for a stack of discs and a carrier which is.adapted to receive a single disc from one end of the stack and capable of releasing such a disc on the application of axial force thereto. The dispenser further comprises means for moving the carrier so as to align the disc with a plunger, preferably a hollow plunger if the discs are in the form of collars for disposition over pins or spigots. Means are provided for advancing the plunger to apply the required axial force to release the disc from the carrier.

- Preferably the carrier includes an aperture for accommodating a disc and means,such as a partial shoulder, for engaging the disc at the rim thereof in order to resist but not prevent axial movement of the disc relative to the carrier. In a preferred form, the carrier comprises a plate positioned to cover the.said one end of the stack and being movable between a position for receiving the disc and a position generally aligning the disc with respect to the plunger.

- The construction of the means for moving the carrier is largely dependent upon the nature of the carrier and the movement thereof. Although the carrier might be a slidable plate, it is preferable to provide a carrier which rotates between the aforementioned positions. In order to effect the required movement of the carrier, the means for moving the carrier may include a piston or plunger keyed to prevent its rotation and including means such as a pin adapted to engage a helical groove in a spigot which is secured to the carrier for conjoint rotation therewith.

- In order to facilitate the automatic operation of the dispenser, the means for moving the carrier and the means for advancing the hollow plunger may be constituted by resettable actuators. The actuator for moving the carrier may be constituted by a piston movable against a restoring force provided by a spring. The actuator for the hollow plunger may likewise comprise a piston which may be movable against a restoring force provided by a spring. It is convenient to provide sequencing of the operation of the actuators so that the actuator for the carrier completes the movement of the carrier and such that the movement of the hollow plunger is inhibited until the carrier's movement is completed. For this purpose, if the actuators are constituted by pneumatically or hydraulically operated pistons, the piston for effecting movement of the carrier may be arranged to inhibit the communication of the piston for moving the hollow plunger with a source of fluid pressure until the stroke of the piston for moving the carrier is substantially completed.

- The accompanying drawings, which illustrate by way of example a preferred embodiment of the invention, are as follows:

- Figure 1 is a sectional view of one embodiment of a dispenser according to the invention;

- Figure 2 is another view of the dispenser;

- Figure 3 is an underneath view of the dispenser illustrated by Figures 1 and 2;

- Figure 4 is a top view of the dispenser;

- Figures 5,6 and 7 illustrate three components of the dispenser; and

- Figure 8 illustrates the operation of the dispenser.

- The drawings illustrate a dispenser 1 which has a

metal body 2 which may be made of aluminium. With reference particularly to Figure l,within the body are twopassageways body 2 has a top plate 5 which closes off the top end of thepassageway 3, which at its upper end is slightly enlarged for the accommodation of an O-ring 6. The plate 5 has an aperture 7 aligned with thepassageway 4, which is slightly enlarged at its upper end for the accommodation of an O-ring 8. Fitting within the aperture 7 is a coupling 9 having aninternal passageway 10 and a bayonet fitting 11 by means of which the coupling 9 may be connected to a standard pneumatic hand or wrist of a robot manipulator. When the coupling 9 is in position on the robot manipulator, thepassageway 10 can receive pneumatic pressure at times determined by the programming of the manipulator. This form of manipulator is well-known and will not be described further. - From the bottom of the

internal passageway 10 of the coupling 9 extends an oblique narrow passage 12 which is aligned with andin communication with apassage 13 leading to the chamber constituted by the upper part of thepassageway 3 in thebody 2. Within this chamber-is apiston 14 of which the head is a sealing but slidable fit in thepassageway 3 and of which thestem 15 is formed as a hollow tube. The piston is illustrated in Figure 5. In the wall of the stem is a small aperture 16: its significance will become apparent. Above the head of the piston is anylon buffer 17. There is a small clearance between thebuffer 17 and the wall of thepassageway 3... - Extending from the

passageway 3 obliquely to the upper part of thepassageway 4 is anarrow passage 18. The entrance to this passage from thepassageway 3 is normally below the head of thepiston 14 and thus until the piston substantially completes its stroke the chamber constituted by thepassageway 4 is cut-off from communication with the source of pneumatic pressure. - Within a lower, reduced section,

part 19 of thepassageway 3 is fitted a pivot bearing 20. Thebearing 20 has anexternal screw threading 21 for engagement with a threading in thepart 19. The upper part of the bearing is formed as atube 22 which receives thestem 15 of the piston. Within the annular well formed between thetube 22 and the wall of thepassageway 3 is acompression spring 23 which provides restoring force for the piston. Near the bottom of this well is anair hole 24 formed in thebody 2. This air hole permits the escape of air from that part of thechamber 3 which is below the head of thepiston 14. - The upper

tubular part 22 of the bearing includes aslot 25 which is arranged so as to extend lengthwise of thestem 15 of the piston. This slot is engaged by one end of apin 26 carried in theaperture 16 in thestem 15 of thepiston 14. Thepin 26 and theslot 25 provide a means of keying the piston and thereby preventing rotation thereof. - Fitted within the bearing is a

spigot 28 which extends upwardly so as to be accommodated within thehollow stem 15 of the piston. Thespigot 28, which is shown in detail in Figure 6, is formed with ahelical groove 29 engaged by the inner end of thepin 26. By means of a screw 30 acarrier 31 is attached to thespigot 28. Thiscarrier 31 is in the form of a plate arranged in a plane generally transverse the direction of movement and the longitudinal axis of the piston. - The piston and the components associated therewith constitute a resettable actuator for moving the carrier constituted by the

plate 31. Downward movement of the piston in response to the application of fluid pressure to thepassageway 10 causes thespigot 28 to rotate and thereby causes theplate 31 to rotate to the position shown in Figure 1. The carrier moves to this position from a position which it can receive a disc from a stack of discs. - Figure 2 illustrates the dispenser when the carrier is in a position to receive a disc, and the features of Figure 2 will be for convenience described before the remainder of Figure 1.

- Secured to the side of the

body 2 is a bracket 32 supporting the bottom end of amagazine 33 constituted by a metal tube. The upper end of themagazine 33 is aligned with anaperture 34 in the top plate and this aperture is provided withrecesses 35 constituting part of a bayonet fitting for aclosure 36. As is shown in detail in Figure 7, the closure has anexternal grip 37 and acylindrical body 38 which has a lateral bore 39 supporting a nylon pin 40 (Figure 2) which can engage therecesses 35. Thebody 38 has anannular shoulder 41 and associatedgroove 41a supporting one end of acompression spring 42 of which the other end engages ametal pressure pad 43. This pad bears on the upper end of a stack ofrubber collars 44, and together with the spring constitutes means for urging the stack towards the lower end of the magazine. - The magazine may readily be loaded with a stack of discs by removing the

closure 36 together with thespring 42 andpad 43. - The

carrier 31 includes ashallow recess 45 which is of depth approximately corresponding to the depth of a collar and of diameter slightly larger than that of acollar 44. The recess is formed with aperipheral shoulder 46. Other forms of shoulder could be used instead. - When the

carrier 31 is in the position shown in Figure 2, the lowermost disc in the stack is received by therecess 45. Therecess 45 andshoulder 46 provide a means by which a collar or disc can be received and they inhibit but, owing to the slightness of the shoulder, do not prevent the passage of the disc through thecarrier 31 if sufficient axial force is applied to the collar which is in therecess 45. Of course, the force of thespring 42 must be sufficient to maintain the stack of discs but should be insufficient to force the lowermost collar through thecarrier plate 31. Xowever, quite a strong .spring 42 can be used because in the arrangement shown it is difficult for the lowermost disc to flex as is required for its passage through the aperture defined by theshoulder 46. As is shown in Figures 2 and 4, the return position of thecarrier 34 is set by an adjustable stop 47 carried on abracket 48 . attached to thebody 2. - Reverting now to Figure 1: within the chamber constituted by the-

passageway 4 is apiston 49 of which thehead 50 is a sliding fit within the chamber. Thehead 50 is secured to the top of astem 51 of which thelower part 52 constitutes a hollow plunger, there being abore 53 extending from the lower end of thestem 51 towards the upper end thereof. The lower end of thestem 51 is enlarged, having ahead 54. This provides an end stop for the upward movement of thepiston head 50. Thehead 50 is urged upwardly by means of acompression spring 55 engaging thehead 50 and encircling thestem 51. Thepassageway 4 is provided with anair relief hole 56. - The downward movement of the

piston 14 under the action of the applied fluid pressure causes thecarrier 31 to move and as thepiston 14 completes its stroke, so that thecarrier 31 is moved into position such that the collar held within therecess 45 is aligned with theplunger 52, thepassageway 18 is uncovered by thepiston 14 and thepiston head 50 is subject to fluid pressure which moves theplunger 52 downwardly. The movement of the plunger forces thecollar 44 through thecarrier 31 and, as shown in Figure 8, over a shoulderedpin 57. Thebore 53 in the plunger accommodates thespigot 58 at the end of the pin. - For further details of the

pin 57, reference may be made to the aforementioned application. - The pistons retract automatically when the fluid pressure is relieved, and it will be noted that the

recess 45 is open at one side (shown by the reference 59) so that the carrier can return without fouling theplunger 52. - It will be understood that although the dispenser is, in its preferred form, intended for use as particularly described, it may have a more general utility.

Claims (13)

1. A dispenser for dispensing flexible discs over pins or spigots, comprising a magazine (33) for a . stack of discs, a carrier (31) adapted to receive a single disc (44) from one end of the stack and being capable of releasing the disc on the application of axial force thereto, a plunger (52) adapted for fitting or forcing the disc over a pin or spigot, means (14,15,26, 28) for moving the carrier so as to align the disc with the plunger and means (50) for advancing the plunger to apply said axial force.

2. An automatic dispenser for dispensing flexible apertured discs over pins or spigots, comprising a magazine (33) for a stack of said discs, a carrier (31) adapted to receive a single disc (44) from one end of the stack and being capable of releasing the disc on the application of axial force thereto, a hollow plunger (52), a resettable actuator (3,14,15,23,26,27,28) for moving the carrier so as to align the disc with the said plunger, and a resettable actuator (4,50,55) for advancing the hollow plunger to apply said axial force.

3. A dispenser according to claim 1 or claim 2 in which the carrier includes a recess (45) for accommodating the disc and means (46) for engaging the disc at the rim thereof, to resist but not prevent axial . movement of the disc through the carrier.

4. A dispenser according to claim 3 in which the means (46) for engaging comprises a partial shoulder.

5. A dispenser according to claim 4 in which the carrier (31) comprises a plate positioned to cover said one end of the stack and being movable between a position for receiving the disc and a position aligning a disc with respect to the hollow plunger.

6. A dispenser according to any foregoing claim in which the carrier rotates to move the single disc into alignment with the plunger.

7. A dispenser according to any of claims 1 to 6 in which the means or actuator for moving the carrier comprises a fluid-operated piston (14).

8. A dispenser according to claim 7 in which the piston (14) is keyed to prevent the rotation thereof and includes a part (26) adapted to engage a helical groove (20) in a spigot (28) which is secured to the carrier for conjoint rotation therewith.

9. A dispenser according to any of claims 1 to 8 in which the plunger (52) comprises part of a fluid-operated piston (50,51).

10. A dispenser according to any of claims 1 to 8 in which the means or actuator for moving the carrier is arranged to complete the movement of the carrier and to inhibit earlier movement of the hollow plunger .

11. A dispenser according to claims 7, 9 and 10 in which the piston forming part of the means or actuator for moving the carrier is disposed to receive fluid pressure and to delay the communication of that pressure to the piston (50), which forms part of the means or actuator for moving the hollow plunger.

12. A dispenser according to any foregoing claim in which the magazine (33) comprises a tube of which one end is adjacent to the carrier and of which the other end receives a releasable closure.

13. A dispenser according to claim 12, further comprising means (42) carried by the closure for urging the stack towards the said one end thereof.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB8216577 | 1982-06-08 | ||

| GB8216577 | 1982-06-08 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0096485A2 true EP0096485A2 (en) | 1983-12-21 |

| EP0096485A3 EP0096485A3 (en) | 1985-10-23 |

Family

ID=10530885

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83302806A Withdrawn EP0096485A3 (en) | 1982-06-08 | 1983-05-17 | Automatic dispenser for flexible discs |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0096485A3 (en) |

| JP (1) | JPS5957829A (en) |

| GB (1) | GB2121387A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR888151A (en) * | 1942-07-17 | 1943-12-06 | Pour Liaisons Telephoniques & | Automatic machine for manufacturing cable elements with concentric conductors |

| GB641037A (en) * | 1948-05-07 | 1950-08-02 | Telecommunications Sa | Machines for making high frequency cables |

| FR1024537A (en) * | 1950-09-13 | 1953-04-02 | Telecommunications Sa | Improvements to the construction of concentric pairs |

| EP0062413A2 (en) * | 1981-03-25 | 1982-10-13 | British Aerospace Public Limited Company | Apparatus and method for the production of wiring harnesses |

-

1983

- 1983-05-17 GB GB08313601A patent/GB2121387A/en not_active Withdrawn

- 1983-05-17 EP EP83302806A patent/EP0096485A3/en not_active Withdrawn

- 1983-06-08 JP JP10251383A patent/JPS5957829A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR888151A (en) * | 1942-07-17 | 1943-12-06 | Pour Liaisons Telephoniques & | Automatic machine for manufacturing cable elements with concentric conductors |

| GB641037A (en) * | 1948-05-07 | 1950-08-02 | Telecommunications Sa | Machines for making high frequency cables |

| FR1024537A (en) * | 1950-09-13 | 1953-04-02 | Telecommunications Sa | Improvements to the construction of concentric pairs |

| EP0062413A2 (en) * | 1981-03-25 | 1982-10-13 | British Aerospace Public Limited Company | Apparatus and method for the production of wiring harnesses |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0096485A3 (en) | 1985-10-23 |

| JPS5957829A (en) | 1984-04-03 |

| GB2121387A (en) | 1983-12-21 |

| GB8313601D0 (en) | 1983-06-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0491193B1 (en) | Automatic rivet feed apparatus | |

| CA1283635C (en) | Apparatus for installing fasteners | |

| EP0092967A2 (en) | An automatic hand changing device for industrial robots | |

| AU681026B2 (en) | Screw strip with overlapping washers, and method and apparatus for installation | |

| US4396318A (en) | Collet-type drill | |

| US5375754A (en) | Automatic riveting machine | |

| US4571804A (en) | O-Ring insertion tool | |

| EP0201293B1 (en) | Breakstem fastener installation tool | |

| WO1989002798A1 (en) | Lockbolt installation tool with cartridge feed | |

| US4442738A (en) | Automatic push-to-start screwdriver | |

| US7255667B2 (en) | Carrier for tool holders | |

| US4630344A (en) | Apparatus and method for assembling parts | |

| EP0096485A2 (en) | Automatic dispenser for flexible discs | |

| US4352615A (en) | Feeder for automatic lathe | |

| EP0039188A1 (en) | Pneumatically operated applicator and method of applying adhesive tape | |

| JP2023538719A (en) | coating device | |

| US4365400A (en) | Apparatus for installing sleeves on substrates | |

| JPH0250819B2 (en) | ||

| US5297417A (en) | Portable collet crimping apparatus | |

| US5647111A (en) | Automatic sealant application apparatus and method | |

| US4451965A (en) | Method for installing a sleeve on a substrate | |

| EP1479462A1 (en) | Remote fastener presenter | |

| US20230356287A1 (en) | Device for Setting a Temporary Fastener | |

| JP2023538484A (en) | rivet setting device | |

| EP0178117B1 (en) | Stud welding device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR IT LI LU NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19851202 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: GIBBONS, RALPH DAVID |