EP0084530B1 - Fernsehsteuerung einer kontinuierlichen bergbaumaschine - Google Patents

Fernsehsteuerung einer kontinuierlichen bergbaumaschine Download PDFInfo

- Publication number

- EP0084530B1 EP0084530B1 EP81902200A EP81902200A EP0084530B1 EP 0084530 B1 EP0084530 B1 EP 0084530B1 EP 81902200 A EP81902200 A EP 81902200A EP 81902200 A EP81902200 A EP 81902200A EP 0084530 B1 EP0084530 B1 EP 0084530B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- seam

- working face

- mining machine

- portions

- remote control

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C35/00—Details of, or accessories for, machines for slitting or completely freeing the mineral from the seam, not provided for in groups E21C25/00 - E21C33/00, E21C37/00 or E21C39/00

- E21C35/20—General features of equipment for removal of chippings, e.g. for loading on conveyor

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C35/00—Details of, or accessories for, machines for slitting or completely freeing the mineral from the seam, not provided for in groups E21C25/00 - E21C33/00, E21C37/00 or E21C39/00

- E21C35/24—Remote control specially adapted for machines for slitting or completely freeing the mineral

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21C—MINING OR QUARRYING

- E21C35/00—Details of, or accessories for, machines for slitting or completely freeing the mineral from the seam, not provided for in groups E21C25/00 - E21C33/00, E21C37/00 or E21C39/00

- E21C35/302—Measuring, signaling or indicating specially adapted for machines for slitting or completely freeing the mineral

Definitions

- the invention relates to a method for remotely controlled mining by a remotely guided mining machine within a seam, according to the preamble part of claim 1, and a system for carrying out the method, according to the preamble part of claim 3.

- Remote control mining methods and systems particularly for coal seams, have long been recognized as desirable and many attempts have been made to provide methods and systems having the capability of commercial operation.

- a generic method and system is for example known from US-A-4 023 862.

- This known method for remotely controlled mining by a remotely guided mining machine within a seam comprises the steps of positioning a continuous mining machine in mining relation to the seam with a mining machine having power driven means thereon for moving said machine through successive seam material cutting cycles which include an advancing movement along a mined entry within the seam in a direction toward the working face of the seam.

- this method comprises the step of controlling the cutting cycle of said continuous mining machine from a remote control station by means of a television camera, so that the material cut during the cycle is cut from the seam up to the different material defining the roof and down to the different material defining the floor.

- This known method and respective remotely controlled mining system includes several essential drawbacks that have prevented such methods and systems from achieving successful commercial operation.

- the reason for this is that the generic system consists in the provision of a black and white television camera and black and white television monitor. This set-up was regarded to be all that was required, since what was being pictured was the black and white world of an underground coalmine. The practical experience however showed, that the operation was such that it never produced coal of sufficient quality and quantity. From the standpoint of the quality of the coal produced, the black and white television picture was incapable of providing the operator with the ability to accurately maintain the mining machine within the seam.

- Claims 2 and 4 include preferred embodiments of the method and system according to the invention, respectively.

- the present system provides a means by which the sight and sound of actual operation can be retained for the operator thus rendering the present system suitable not only for short distance remote control but total remote control as well.

- a high wall mining system which embodies the principles of the present invention.

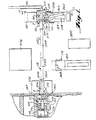

- the system includes three basic component assemblies: (1) a continuous mining machine, generally indicated at 10, for advancing in the high wall seam; (2) a remote control guidance system 12 for controlling the movements of the continuous mining machine within the seam from a position outwardly of the high wall; and (3) an expansible and retractable vacuum air conveying system 14 connectable with the continuous mining machine 10 so as to be advanced in the seam thereby and to effect conveyance of the coal removed from the seam by the continuous mining machine to a position outwardly of the high wall.

- the continuous mining machine 10 utilized in accordance with the principles of the present invention may be any of the known commercially available models.

- a preferred embodiment is the Model #101 Helimatic Miner, manufactured and sold by Dresser Industries, Jeffrey Mining Machine Division.

- Figure 16 illustrates the remote control system schematic of this brochure modified for purposes of the present invention.

- the continuous mining machine 10 includes a track frame 16 having left and right-hand endless track assemblies 18 driven by separate hydraulic motors, indicated schematically at 20 and 22 in Figure 16.

- a sump frame 24 mounted on the track frame 16 for horizontal longitudinal sliding movement is a sump frame 24.

- a pair of sump cylinders, indicated schematically at 26 in Figure 16 is provided for effecting the reciprocating movement of the sump frame 24.

- Pivoted on the sump frame 24 about a transverse horizontal axis is an auger head assembly 28.

- the auger head assembly 28 is moved through raising and lowering movements abouts its pivotal axis with respect to the sump frame 24 by a pair of auger head cylinders, indicated schematically at 30 in Figure 14, extending between the sump frame 24 and the auger head assembly 28.

- two electric motor drives for the auger cutting head are also provided.

- a gathering assembly 34 which includes a laterally extending scraper type pick-up blade 36 for the auger cutters, auger head assembly 28 and a central conveyor 38.

- a pair of gathering cylinders is provided between the sump frame 24 and the gathering assembly 34 for effecting raising and lowering movements of the gathering assembly 34 and permitting a floating movement thereof.

- a hydraulic motor indicated schematically at 42 in Figure 16, is provided for driving the central conveyor 38.

- the mining machine 10 as manufactured and sold is also provided with a chain conveyor assembly carried by the sump frame 24 for receiving the coal from the central conveyor 38 of the gathering assembly 34 and conveying the same rearwardly of the track frame 16.

- this chain conveyor is not utilized in practicing the present invention, as will be more apparent hereinafter.

- a third electric motor 44 which drives the hydraulic pump (not shown) to provide hydraulic fluid under pressure for the various hydraulic motors and cylinders.

- the hydraulic cylinders 26, 30 and 40 and the hydraulic motors 22, 20 and 42 are controlled by pilot operated main valves, indicated schematically at 46, 48, 50, 52, 54 and 56 respectively, and the pilot pressure to the main valves is controlled by solenoid operated valves, indicated schematically at 58, 60, 62, 64, 66 and 68 respectively.

- the electric motor 44 is provided with a starter 70 connected through a transformer 72 and the two auger motors 32 are provided with starters 74 which operate from a time delay relay 76. All of the above electrical components are connected to lines in a main cable 78 of extensive length forming a part of the remote control guide system 12.

- the guidance system includes a control station 80 which preferably embodies a construction similar to that of a conventional house trailer. As shown, the control station is located on the high wall bench adjacent the area of the seam of the high wall where the entry is to be developed. In this way, the control station can be moved along the bench parallel to the high wall as successive entries are developed.

- the remote control guidance system 12 also includes as a component thereof a larger diameter power operated cable reel 82 which is also adapted to be mounted in the area adjacent to and outwardly of the high wall of the seam in which operations are to take place.

- the mounting is one which renders the cable reel 82 portable so that it may also be moved along the seam as successive entries are worked.

- mount the cable reel 82 on a trailer body 84 the trailer body being of a type which forms one part of a conventional tractor- trailer truck assembly.

- the cable reel 82 is such that it can be rotated in either direction by an electric motor so as to either pay out or wind up an electric cable 78 thereon.

- the electric cable 78 handled by the cable reel 82 is of a size such that it will not readily bend and hence the requirement for a large diameter reel.

- the manner in which the length of the cable extending inwardly from the high wall to the continuous miner 10 is handled will be described more fully hereinafter in conjunction with the description of the conveying system.

- the cable reel 82 provides for the capability of continuous electrical connection during the rotating movements thereof.

- the terminal end of the cable 78 wound thereon is preferably connected from the cable reel 82 to a control station 80.

- the control station thus provides for direct remote control operation of all of the functions of the machine 10 through the cable 78 carried by the cable reel 82.

- these functions are effected by eight electrical switches, indicated at 86, 88, 90, 92, 94, 96, 98 and 100 for controlling the respectively electric motors 44 and 32, cylinders 26, 30 and 40 and hydraulic motors 22, 20 and 24.

- An emergency stop switch 102 is also provided.

- the remote control guidance system 12 includes the provision of auxiliary lights 104 and front and rear television monitoring cameras 106 on the continuous mining machine 10 and a television monitoring receiver 108 at the control station 80 (see Figure 17).

- auxiliary lights 104 and front and rear television monitoring cameras 106 on the continuous mining machine 10

- a television monitoring receiver 108 at the control station 80 (see Figure 17).

- a length of coaxial cable 110 which is handled by a power driven cable reel 112, also suitably mounted on the trailer body 84.

- the television cameras and receivers are of the conventional low light cable type well known in the television arts.

- the cable reel 112 is of the type which is adapted to maintain a continuous circuit while the cable is either paid out or wound onto the reel.

- the terminal end of the cable 110 wound on the reel 112 extends to the control station 80.

- the lights 104 provide for a degree of illumination of portions of the space surrounding the mining machine 10 including both toward the working face as well as toward the rear thereof which is sufficiently greater than the lighting normally provided by the mining machine 10 to enable the television cameras 106 to pick up pictures which, when viewed by the operator at the control station 80, enable the operator to distinguish between the coal of the seam and the material (slate or the like) which forms the roof and floor of the entry being mined. While the present invention contemplates the utilization of a single television camera capable of being directed both rearwardly and forwardly, a preferred arrangement is to provide two wide- angled television cameras 106 on the track frame 16 of the mining machine 10 in fixed positions.

- the number of receivers 108 at the control station 80 can be equal to the number of the television cameras 104

- a preferable arrangement is to provide a suitable switch 114 which will enable the operator at the control station 80 to select which of the two television cameras 106 is to be operated and to be viewed.

- the television cameras 106 and lights 104 associated with the face are used during the advancing movements of the mining machine 10 while the television cameras and lights associated with the rear of the machine 10 are used during the restracting movements of the machine 10 from the entry.

- the lights 104 are preferably a full spectrum compact gaseous light source.

- An exemplary embodiment is a 400 watt CSI lamp #99-0201 which is a metal halide lamp manufactured by the Thorn Company.

- 1000 watt CSI Thorn lamps #99-0221 may be utilized.

- Preferably two such lamps may be utilized if desired.

- the compact light source bulbs or lamp are used in conjunction with reflectors and lens which gather, concentrate and project the light at the desired location. While the lights are preferably mounted in fixed position on the continuous mining machine, they can be carried by conventional pan and tilt assemblies if desired.

- An exemplary embodiment of a reflector is the Strand-Century reflector for a 6" fresnel, manufactured by Century Lighting Company.

- a preferred lens is the Strand-Century 6-270602-010 lens for a 6" fresnel manufactured by Century Lighting Company.

- the television cameras 106 are preferably broadcast quality color television cameras.

- Exemplary embodiment is the CEI-310 color television camera system manufactured by Commercial Electronics, Incorporated.

- the camera is provided with a zoom lens and an automatic focus module, for example, Fujinon AI2 x 9 zoom lens and Fujinon servo-focus module.

- the color television camera system is utilized with the audio pick-up, although it is within the contemplation of the invention to utilize the video pick-up of the camera system alone without the audio pick-up.

- the television monitors or receivers 108 are preferably high resolution color television receivers, a specific example being the Ikegami TM-20-8RA monitor S/N 8 x B003.

- the remote control guidance system 12 includes a rotating beam optical laser unit 116.

- the unit 116 may be of any well-known construction, a preferred embodiment is Model 900-1 made by Micro Grade Laser Systems, Inc.

- the laser unit 116 is positioned just outside of the high wall face so that its beam is projected forwardly perpendicular to the face of the seam and parallel to the planned entry to be mined.

- Mounted on the track frame 16 of the mining machine 10 are two laser beam detectors 118 and 120.

- Each detector may be of any suitable construction, a preferred embodiment is a model compatible with the laser unit 116 in which each has three detecting zones or separate laser sensitive areas.

- the two detectors 118 and 120 are mounted on the track frame 16 of the continuous mining machine 10 so that they are aligned in a common vertical plane which is parallel to the center line of the machine 10.

- the two units 118 and 120 are spaced apart in a longitudinal horizontal direction with respect to the axis of the machine 10 and displaced vertically so as to enable the forward- most unit to have a direct line to the laser unit 116.

- the detectors 118 and 120 are provided with readout and light indicator circuitry (not shown).

- the light indicator of the units mounted on the miner 10 are in a position such that they can be picked up by the rearwardly directed television camera 106.

- the indicator circuitry of the detectors 118 and 120 is connected to the control station 80 by a sufficient length of cable 122 controlled by a power driven cable reel assembly 124.

- the cable reel 124 is mounted on the trailer body 84 and the end of the cable 122 on the reel 124 provides for continuous energization during the cable reel movements and connection to the control station 80.

- the projected rotating laser beam from the unit 116 strikes the detectors 188 and 120 which are mounted horizontally on a line which is parallel to the center line of the miner 10, but on different horizontal planes.

- Each detector 118 is connected to its own control readout unit (not shown) which supplies the power to operate the detector circuits and contains the circuitry to receive and translate the signals from each of the three detector zones. These units then transmit these signals to their respective three light indicators and the lines of the cable 122.

- the cable 122 transmits the signals of the eight indicators of the detectors to six lights 126, 128, 120, 132, 134 and 136 (see Figure 17) which are illuminated in exactly the same sequence as the lights on the two three-light indicators of the detectors 118 and 120 located on the mining machine 10.

- lights 126, 128 and 130 represent the left-hand, center and right-hand laser sensitive areas of the detector 118 while lights 132, 134 and 136 represent the comparable areas of detector 120.

- the center zones of both detectors will be energized and the center lights of both three-light detectors and the center lights 128 and 134 at the operator station 80 will be illuminated. Should the machine 10 stray from this straight line (in the horizontal plane) then some other sequence of lights would be illuminated. For example, should the machine 10 start to turn left (as viewed in Figure 1) the right-hand detecting zone of detector 118 and the left-hand zone of detector 120 would be energized, lighting their respective indicating lights 130 and 132. This then instantly informs the operator of the misalignment and he then can take immediate redmedial actions.

- the laser system described above in conjunction with the television system provides the operator with the capability of remotely controlling the advancing movement of the continuous mining machine 10 into the seam both vertically so that the roof and floor of the entry being mined will be defined by the top and bottom of the seam, and horizontally so that the entry being mined will extend inwardly of the high wall along a straight line following the seam. So long as the seam is vertically straight and does not contain vertical undulations, the laser system will provide the capability of maintaining a straight entry through the seam.

- a sonar system is preferably also utilized.

- the sonar system includes four sonic transducers 138, 140, 142 and 144, which may be of any well-known commercial design mounted so that one is provided on each corner of the track frame 16 of the continuous mining machine 10. These sonic transducers are oriented so as to direct their sonic waves toward the adjacent rib or side wall of the entry being mined.

- the transducers may be of any conventional construction and operate in conventional fashion to send out periodic sonic wave pulses in the high frequency zone which strike the rib or side wall toward which they are directed and are reflected back to the transducer.

- the transducers are provided with circuitry which is capable of detecting the length of time that it takes the emitted sonic wave pulses to leave the transducer and be reflected back.

- the sonic waves are emitted on a continuing intermittent pulse basis separated by small fractions of a second. Since the mined or cut rib is not a smooth surface, one pulse may strike a protrusion on the rib and require less time to be reflected than another pulse that may strike a depression. Thus it becomes necessary to continuously average these measured time periods.

- the extensible and retractable vacuum air conveying system 14 includes as a critical component thereof a positive displacement vacuum air pump, generally indicated at 154 in Figure 1, which is preferably mounted on the trailer body 84, outwardly of the high wall.

- the air pump 154 may be of any conventional positive displacement design.

- the pump unit provides on its suction side a vacuum air source for the system 14 which is transmitted to the continuous mining machine 10.

- the inlet of the vacuum air system 14 is provided on the continuous mining machine 10 in lieu of the chain conveyor normally provided on such machine as aforesaid.

- the sump frame 24 of the machine 10 provides a box-like construction on which the components of the chain conveyor are normally mounted.

- the structure is provided by a bottom plate 156, the forward end of which curves upwardly along the radius and terminates at a position just rearwardly of the discharge end of the central conveyor 38 of the gathering assembly 34.

- a top plate 158 normally provides for the movement of the top flight of the chain conveyor thereover also is provided.

- the forward edge of the top plate 158 is spaced rearwardly from the forward upwardly curving edge of the bottom plate 156 so as to provide an inlet opening 160 into which the coal discharging from the central conveyor 38 is deposited.

- the rearward edges of the plates 156 and 158 are welded in sealed relation with the forward edge of a transition duct 162.

- the transition duct 162 is thus fixed to the sump frame and extends rearwardly thereof and terminates in a circular ring flange connector 164.

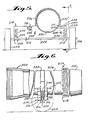

- the pipe 168 forms one component of a slip joint, best shown in Figure 4, which accommodates the sumping horizontal reciprocating movement of the sump frame 24 with respect to the track frame 16 of the mining machine 10.

- the rear end of the pipe 168 has a pair of axially spaced rings 170 fixed to the exterior periphery thereof, the rings having a series of balls 172 mounted therebetween.

- the balls 172 are adapted to engage the interior periphery of an outer pipe 174 which forms the other basic component of the slip joint.

- the outer pipe 174 includes a stop ring 176 fixed on the interior periphery thereof at a position inwardly of the forward end thereof. Disposed in outwardly spaced relation with the stop ring 176 is a garlock type annular seal 178. Disposed outwardly and adjacent the seal 178 is a pair of side-by-side inflatable seals 180.

- a pair of retainer rings 182 similar to the rings 170 previously described which have a series of balls 184 mounted therebetween which engage the outer periphery of the inner pipe 168.

- a preferred arrangement is to provide for the selective pressurization of the inflatable seals so that the friction provided during times when the slip joint is moved can be varied to accommodate such movement.

- a conventional air conditioning unit 186 there is provided in back of the track frame 16 of the machine 10 a conventional air conditioning unit 186.

- the purpose of this unit 186 is to provide for a self-contained source for cooling the various components of the machine in lieu of the cooling system normally provided.

- the compressor of this system is preferably utilized to provide for a source of pressure for the inflatable seals 180.

- the seals 180 have inlets 188 connected together which inlets lead to an electrically operated three-position valve 190.

- the inlet lines 188 to the two inflatable seals are connected through a pressure regulator 192 to the air compressor source (not shown) of the cooling unit 186, the pressure regulator being set to provide an operating pressure of 20 psi when the three-position valve is in a position to communicate the pressure regulator to the inflatable seals.

- the three-position valve 190 serves to communicate the inflatable seals 180 with a second pressure regulator 194, which is likewise connected to the air compressor source of the cooling unit.

- the pressure regulator 194 is set to control the pressure at a reduced value as, for example, 10 psi.

- the three-position valve 190 in its third position is adapted to vent the inflatable seals to atmosphere.

- the electrical controls for the three-position valve can be connected to operate with the sump cylinder 26 and control 58 therefor.

- the control 58 for the sump cylinder 26 is actuated to advance the sump cylinders

- the signal for this movement is connected to move the three-position valve 190 into its second position so that the pressure of the inflatable seals 188 during the sumping action of the machine will be 10 psi.

- the three-position valve 190 is simultaneously actuated to move the three-position valve 190 into its third position, thus venting the inflatable seals 188 to atmosphere during the tramming movement of the machine.

- the arrangement is such that the three-position valve 190 will be spring actuated to retain the same in its first position at all other times, thus providing a 20 psi pressure to the seals 188.

- the rearward end portion of the outer pipe 174 is fixedly secured to the track frame 16 of the machine 10, as by a yoke construction 196, and has a female quick disconnect coupling 198 mounted on the rearward end thereof. Any well-known type of quick disconnect coupling can be utilized. A preferred arrangement is marketed under the registered trademark PRONTO-LOCK II by Ciba-Geigy.

- the female coupling 198 includes an enlarged socket having a series of internal threads 200 in its outer end portion and a frustoconical sealing surface 202 disposed inwardly thereof.

- the female coupling 198 is adapted to cooperate with a male quick disconnect coupling 204 formed on one end of a conduit section 206 having a similar female coupling 208 on the opposite end thereof.

- the male coupling 204 includes an interior frustoconical sealing surface 210 on the end of the conduit 206 and a separate externally threaded sleeve 212 having threads adapted to cooperate with the socket threads 200 previously described.

- the vacuum air conveyor system 14 is made expansible and retractable by the provision of a multiplicity of conduit sections 206 further selectively interconnected in end-to-end relationship so as to provide a conduit string which extends from the high wall inwardly of the seam to the continuous mining machine 10.

- Each of the sections 206 is constructed in the manner previously indicated which includes male and female quick disconnect couplings 204 and 208 on the ends thereof.

- a wheeled carriage assembly is provided for each conduit section 206.

- the wheeled carriage assembly 214 may assume any desired configuration (for example, it may be constructed in the manner suggested in the aforesaid Densmore patent), a preferred construction is illustrated in Figures 5 and 6.

- the carriage assembly 214 includes a pair of frame boards 216 connected together in spaced relation by a pair of inverted U-shaped brackets 218.

- the brackets are open at their bottoms and are provided with vertically elongated transverse slots 220.

- Mounted within the slots 220 is an axle 222 having wheels 224 on the ends thereof.

- Fixedly mounted above the axle 222 within each bracket 218 is a spring seat element 226 on which is seated the bottom end of a coil spring 228.

- the upper end of each coil spring 228 seats on the upper surface of the associated bracket 228. This way the frame boards 216 are resiliently suspended on the axle.

- the upper surfaces of the frame boards 216 are provided with aligned saddle-like recesses 230 of arcuate configuration adapted to receive the lower periphery of a conduit section 206.

- a strap 232 whose ends are suitably anchored to pins 234 carried by the frame boards 216.

- the upper surfaces of the frame boards on one side of the main recesses 230 are provided with aligned recesses 236. These recesses are of a size to receive the main electrical cable 78 extending to the continuous mining machine which is handled by the cable reel 82.

- a telescopic conduit transfer mechanism For purposes of adding conduit sections 206 to the conduit string, and for detaching conduit sections from the conduit string, there is provided a telescopic conduit transfer mechanism, generally indicated at 242.

- the mechanism 242 includes an outer fixed pipe section 244 of a length greater than the length of the conduit sections 206.

- the outer pipe section 244 is mounted on the high wall bench outwardly of the high wall in a fixed position with its axis aligned with the inward direction of extent of the entry to be mined. Any suitable means may be provided for effecting this fixed positioning of the fixed outer pipe section.

- the pipe is fixedly supported on portable strands 246 at each end.

- the conduit transfer mechanism 242 also includes an inner pipe section 248 which likewise has a length which is greater than the length of the conduit sections 206.

- One end of the inner pipe section 248 is telescopically mounted within an adjacent end of the outer pipe section 244 and there is provided between the telescoping ends a slip joint which is similar to the slip joint previously described in connection with Figure 4.

- suitable ball bearings 250 and 252 provided on each section with a stop ring 254, a garlock type of seal 256 and a pair of inflatable seals 258.

- the arrangement with respect to the air circuitry to the inflatable seals 258 is simply and on-off type of circuitry in which air pressure from a suitable compressor 260 mounted on the trailer body 84 is directed through an appropriate pressure regulator 262 so as to provide an available source of 20 psi air.

- a simple two-way valve 264 is provided capable of electrical remote control which in one position communicates the 20 psi regulator with the inflatable seals and in the other position communicates the inflatable seals with atmosphere.

- the arrangement is such that the valve 264 is turned to its second position communicating the seals to atmosphere only during the tramming movement of the continuous mining machine since the sumping movement is not transmitted by the operation of the machine to the conveying system.

- the end of the inner pipe section 248 is provided with a male quick disconnect coupling 266 which mates with the female coupling 208 provided on each conduit section 210.

- the inner pipe section 248 may be provided with a carriage assembly 214 adjacent its outer end and a suitable roller assembly 268 is provided adjacent the end of the outer pipe section 244 to rollingly support the opposite end of the inner pipe section 248 to telescopic movement within the outer pipe section.

- the mode of operation of the conduit transfer mechanism 242 in adding a conduit section 206 to the conduit string is illustrated in the stage views of Figures 7, 8 and 9.

- male coupling 266 is disengaged from the female coupling 208 of the last conduit section 206 of the conduit string.

- the inner pipe section 248 is moved to the left as viewed in Figure 7 until it extends almost entirely telescopically with the outer pipe section 244, as shown in Figure 8, leaving the male coupling 266 on the end thereof spaced from the female coupling 208 of the last conduit section 206 of the conduit string a distance sufficient to move a new conduit section 206 supported at its central portion by a wheeled carriage assembly 214, therebetween.

- the new conduit section is added to the conduit string as shown in Figure 9, by connecting the female coupling 208 thereof with the male coupling 266 and the male coupling 210 thereof with the female coupling 208 of the last conduit section 206 of the conduit string.

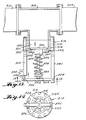

- the opposite end of the outer pipe section 244 has a pipe 270 connected thereto which has a central bend therein so as to extend upwardly and outwardly.

- the end of this pipe section connects with the inlet side of a separator assembly, generally indicated at 272.

- the separator assembly 272 includes a front inclined inlet wall 274 (e.g. 45°) which has an opening therein which receives a flanged connection formed on the end of the pipe section 270.

- Extending upwardly and outwardly from the upper edge of the front wall is an inclined transition top wall 276.

- the inclined transition top wall 276 has a top housing wall 278 connected to the edge thereof which top wall is of generally rectangular configuration.

- the separator assembly 272 also includes a pair of side housing walls 280, extending downwardly from the side edges of the top wall and suitable triangular shaped transition side walls 282 are connected between the leading edges of the side walls 280 and the side edges of the front wall 274. Finally, the rear edges of the top wall 278 and side walls 280 are enclosed by a rear housing wall 284.

- baffle plate 286 Extending between the side walls 280 and in engagement with the topwall 278 is a baffle plate 286. As shown, the upper edge of the baffle plate 28 is spaced inwardly from the forward edge of the top wall 278 in a position such that the particles in the air stream issuing from the pipe section 270 will impinge thereon.

- the baffle plate 286 extends downwardly from its upper edge and in a direction away from the pipe at an angle of approximately 68° with respect to the top wall 278.

- the lower edge of the baffle plate terminates at a point spaced above the lower surfaces of the side walls 280, rear wall 284 and front wall 274. Access to the housing provided by the walls thus far described may be obtained by an openable and closable hatch 288 in the rear wall.

- a sight panel 290 may also be provided in the rear wall, see Figure 12.

- a hopper section 292 Extending downwardly from the lower edges of the housing is a hopper section 292 in the form of an inwardly and downwardly tapering four-sided prism.

- the lower edges of the hopper section 292 feed to the upper opening formed in a cylindrical housing 294 forming a part of a rotary air lock discharge valve or feeder unit, generally indicated at 296.

- Units of this type are well known and a preferred embodiment is the model #24X22SR produced by Sprout Waldren.

- the unit 296 is schematically illustrated in Figures 11 and 12 as including a pocketed rotor 296 which is mounted within the cylindrical housing 294 and driven by the electric motor 300.

- the cylindrical housing 294 includes a lower discharge opening 302, the arrangement being such that as the rotor 298 is rotated by the motor 300, the pockets are filled from the hopper section 292 and are emptied as they pass the outer opening 302.

- any suitable conveyor arrangement may be provided beneath the rotary valve outlet opening for the purpose of receiving the discharged particles and handling them from that point on.

- a belt-type conveyor 304 is shown extending beneath the trailer bed to receive the discharge from the rotary valve which extends through the trailer bed.

- the conveyor 304 serves to discharge the material on a further belt conveyor 306 extending along the bench at the high wall location.

- one of the side walls 280 of the separator housing has an outlet opening 308 flanged to connect with a pipe assembly 310 which extends from the separator housing to a T-pipe connector, indicated at 312.

- the T-pipe connector 312 has the stem outlet thereof provided with a vacuum relief and by-pass valve mechanism, generally indicated at 314.

- the vacuum relief and by-pass valve assembly 314 includes a cylindrical valve body 316 adapted to mate with the flange of the stem connection of the T fitting 312. As shown, the valve body 316 is formed with a plurality of annular spaced apertures for receiving a series of bolts 318 to effect the connection with the stem outlet of the T fitting.

- the central portion of the valve body 316 is provided with a cylindrical recess, as indicated at 320, which forms a relatively thin central end wall 322.

- the end wall has a series of annularly spaced openings 324 formed therein which provide in the end wall a central hub portion 326 and a plurality of spokes 328 as is clearly evident from Figure 14.

- valve seat 330 which is engaged by a disc valve member 332.

- the central portion of the valve member 332 is fixed to one end of a valve stem 334 which slidably engages through a central opening in the hub portion 326 and hence outwardly of the valve body 316.

- the outer end of the valve stem 334 has a fitting 336 fixed thereto which serves to engage one end of a coil spring 338 disposed in surrounding relation to the valve stem 334.

- the opposite end of the coil spring 338 engages a suitable seat formed on the hub portion 326 of the end wall 322.

- Extending from the valve body 316 and fixed thereto by one of the bolts 318 is an elongated standard 340.

- the opposite end of the standard 340 pivotally receives one end of an actuating lever 342 as indicated at 344, the opposite end of which is pivotally connected, as indicated at 346, to the plunger 348 of a solenoid 350.

- the solenoid 350 is carried by the outer end of a standard 352 similar to the standard 340 fixed to the valve body 316 by an opposite bolt 318.

- the central portion of the operating lever 342 is connected to the fitting 336 through a one-way connection bumper 354.

- the valve member 332 is operable to move inwardly from the closed position, as shown, against the bias of the spring 338 when the vacuum pressure conditions within the T fitting 312 reach a predetermined minimal value which is equivalent to that which may cause conduit collapse. This movement will take place without corresponding movement of the operating lever 342 taking place.

- the plunger 348 is moved inwardly which in turn moves the operating lever 342 in a direction to positively engage the valve stem 334 and move the same together with the valve member 332 inwardly so that the valve member 332 is displaced from its seat 330, thus opening the interior of the system to atmosphere irrespective of the vacuum pressure conditions therein.

- the solenoid 350 the system as thus far described is bypassed.

- the opposite branch of the T fitting 312 is communicated by a pipe assembly 356 to a tangential inlet of a filter assembly, generally indicated at 358.

- the filter assembly may be of any known construction.

- a preferred embodiment is the filter assembly Micropul model #109-10-20 manufactured by U.S. Filter Corporation.

- the bottom apex outlet of the hydrocyclone filter assembly 358 is provided with a rotary airlock valve assembly 360 which is similar to the assembly 296 previously described.

- the upper central air outlet of the filter assembly 358 is connected, as by a pipe assembly 362, to the inlet of the main positive displacement vacuum pump 154.

- the rotary airlock valve assembly 360 extends through the floor of the trailer in a manner similar to that previously described in connection with the assembly.

- a separate conveying system (not shown) for receiving the discharge from the filter assembly can be provided. It is contemplated that this discharge is considerably less than that of the feeder rotary airlock valve associated with the separator, hence the discharge can be separately handled.

- the size of the particulate coal material discharged from the filter will be less than that in the separator and consequently maintaining this material separate from the discharge of the separator is considered desirable.

- FIG. 17 there is shown therein a diagrammatic view of a control panel generally indicated at 364, which contains the various instrumentalities enabling an operator at the control station 80 to remotely control the entire system.

- the control panel includes the switches 86-102 by which the operation of the continuous mining machine can be controlled.

- the normal operating cycle of the continuous mining machine 10 is as follows. With the gathering head cylinders 40 set by the switch 94 in a floating position and the auger head cylinders 30 set by the switch 92 in a raised position, sump cylinders 26 are actuated by the switch 90 to effect a forward movement of the sump frame with the auger head assembly 28 and gathering assembly 34 carried thereby into the coal seam.

- the inflatable seal 180 of the slip joint carried by the machine 10 is actuated so as to maintain a 10 psi value thereon.

- the sumping movement takes place with the track frame 16 in a stationary position. Consequently, during this movement the operator should have the selector switch for the television camera in a position to view the forwardly extending camera so that he will have a view of the seam as the cutting head advances therein along the roof. This will enable the operator to raise and lower the auger head if need be.

- the sumping distance is approximately 18 inches so that at the end of this movement the operator then lowers the auger head to the floor again taking care by virtue of the television monitor to insure that the coal in the seam is removed without digging into the floor.

- the operator Simultaneously with this movement the operator also actuates the switch venting the inflatable seals 258 of the mechanism 242.

- the switch 366 in Figure 17.

- switches 368, 370 and 372 for controlling the motors of the cable reels 82, 112 and 124, respectively. It is during this tramming movement that the operator must carefully watch the laser lights 128 and 134 and the sonar readout indicators 146,148,150 and 152 if this system is in use.

- the solenoid switch 374 and inflatable seal switch 366 are again actuated to reestablish the vacuum air circuit to the inlet opening 160 of the continuous mining machine 10.

- an advance of more than a thousand feet may be accomplished in two shifts after which it becomes necessary to retract the machine 10 from the mined entry so that the entire cycle can be commenced at the next entry.

- the vacuum air conveying system 14 described above is the subject of our Divisional European Application No. 85109312.0.

Landscapes

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Geology (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Mechanical Engineering (AREA)

- Drilling And Exploitation, And Mining Machines And Methods (AREA)

- Selective Calling Equipment (AREA)

- Devices That Are Associated With Refrigeration Equipment (AREA)

- Storing, Repeated Paying-Out, And Re-Storing Of Elongated Articles (AREA)

- Details Of Television Systems (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81902200T ATE30758T1 (de) | 1981-08-03 | 1981-08-03 | Fernsehsteuerung einer kontinuierlichen bergbaumaschine. |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/US1981/001030 WO1983000525A1 (en) | 1981-08-03 | 1981-08-03 | Televised remote control of a continuous mining machine |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85109312.0 Division-Into | 1985-07-24 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0084530A1 EP0084530A1 (de) | 1983-08-03 |

| EP0084530A4 EP0084530A4 (de) | 1984-01-09 |

| EP0084530B1 true EP0084530B1 (de) | 1987-11-11 |

Family

ID=22161345

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81902200A Expired EP0084530B1 (de) | 1981-08-03 | 1981-08-03 | Fernsehsteuerung einer kontinuierlichen bergbaumaschine |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0084530B1 (de) |

| JP (1) | JPS58501237A (de) |

| AT (1) | ATE30758T1 (de) |

| AU (1) | AU581932B2 (de) |

| BR (1) | BR8109041A (de) |

| DE (1) | DE3176521D1 (de) |

| WO (1) | WO1983000525A1 (de) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4714681A (en) * | 1981-07-01 | 1987-12-22 | The Board Of Reagents, The University Of Texas System Cancer Center | Quadroma cells and trioma cells and methods for the production of same |

| DE3431148A1 (de) * | 1984-08-24 | 1986-03-06 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Verfahren und vorrichtung zum entfernen von badmaterialresten an anodenresten |

| US5871260A (en) * | 1997-02-11 | 1999-02-16 | Delli-Gatti, Jr.; Frank A. | Mining ultra thin coal seams |

| US7703857B2 (en) * | 2007-09-08 | 2010-04-27 | Joy Mm Delaware, Inc. | Continuous miner having a sumping frame |

| CN115045702B (zh) * | 2022-06-09 | 2025-03-21 | 北京天玛智控科技股份有限公司 | 基于多模态数据的智能放煤控制方法和系统 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1455962A (fr) * | 1965-07-22 | 1966-05-20 | Commissariat Energie Atomique | Procédé et appareil de carottage surveillé par télévision |

| US3333893A (en) * | 1965-07-27 | 1967-08-01 | Union Carbide Corp | Earth strata differentiating device |

| US3362752A (en) * | 1965-08-17 | 1968-01-09 | Joy Mfg Co | Mining apparatus and method |

| US3748248A (en) * | 1968-01-25 | 1973-07-24 | F Wanzenberg | Deep sea mining system |

| US3602551A (en) * | 1968-07-29 | 1971-08-31 | John L Velegol | Underground fluid conveyor transportation method and system |

| US3672725A (en) * | 1970-06-15 | 1972-06-27 | Earl & Wright Ltd | Deep sea mining method and apparatus |

| US3722556A (en) * | 1971-08-19 | 1973-03-27 | W Jeffers | Rolling pipe line assembly, system and method |

| US3892443A (en) * | 1973-11-05 | 1975-07-01 | Dresser Ind | Continuous cutting and gathering apparatus for a continuous mining machine |

| DE2416947B2 (de) * | 1974-04-08 | 1977-07-07 | Gebr. Eickhoff, Maschinenfabrik U. Eisengiesserei Mbh, 4630 Bochum | Verfahren zum begrenzen der verstellbewegung eines an einem allseitig schwenkbaren tragarm einer vortriebsmaschine gelagerten loesewerkzeuges auf den aufzufahrenden streckenquerschnitt und einrichtung zur ausuebung dieses verfahrens |

| US3947980A (en) * | 1975-02-10 | 1976-04-06 | Hawaii Marine Research, Inc. | Process and apparatus for deep-sea particle harvesting |

| US4023862A (en) * | 1975-12-24 | 1977-05-17 | Louis Gold | Hydraulic mining and transportation of coal using hot oil under pressure |

| US4079997A (en) * | 1976-09-10 | 1978-03-21 | Jury Nikolaevich Bienko | Photoelectric method and device for control of a mining machine along a bed of mineral |

| FR2420120A1 (fr) * | 1978-03-17 | 1979-10-12 | Coal Industry Patents Ltd | Systeme de controle permettant de determiner la configuration d'un trajet d'abattage de minerai dont les extremites ne peuvent pas etre reliees par une ligne de visee |

| GB2136857B (en) * | 1983-03-24 | 1986-08-06 | Coaltex | Scoop miner |

-

1981

- 1981-08-03 WO PCT/US1981/001030 patent/WO1983000525A1/en not_active Ceased

- 1981-08-03 DE DE8181902200T patent/DE3176521D1/de not_active Expired

- 1981-08-03 JP JP50271981A patent/JPS58501237A/ja active Pending

- 1981-08-03 EP EP81902200A patent/EP0084530B1/de not_active Expired

- 1981-08-03 AT AT81902200T patent/ATE30758T1/de not_active IP Right Cessation

- 1981-08-03 BR BR8109041A patent/BR8109041A/pt unknown

-

1985

- 1985-10-09 AU AU48446/85A patent/AU581932B2/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| EP0084530A1 (de) | 1983-08-03 |

| AU581932B2 (en) | 1989-03-09 |

| JPS58501237A (ja) | 1983-07-28 |

| DE3176521D1 (en) | 1987-12-17 |

| WO1983000525A1 (en) | 1983-02-17 |

| ATE30758T1 (de) | 1987-11-15 |

| EP0084530A4 (de) | 1984-01-09 |

| AU4844685A (en) | 1986-02-06 |

| BR8109041A (pt) | 1983-08-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4323280A (en) | Remote controlled high wall coal mining system | |

| US4281876A (en) | Televised remote control system of a continuous mining machine | |

| GB2307577A (en) | Communication system | |

| EP0084530B1 (de) | Fernsehsteuerung einer kontinuierlichen bergbaumaschine | |

| CN109823782A (zh) | 一种粮仓作业设备 | |

| US3672725A (en) | Deep sea mining method and apparatus | |

| US5848825A (en) | High wall mining conveying method | |

| RU2682298C1 (ru) | Роботизированный, мобильный, модульный горноспасательный комплекс и способы его применения | |

| US3362752A (en) | Mining apparatus and method | |

| AU644945B2 (en) | Redundant remote control system used on continuous miner | |

| EP0172438A1 (de) | Ein- und ausfahrbare Einrichtung zur pneumatischen Förderung mittels Unterdruck | |

| US5667021A (en) | Apparatus for driving grade stakes | |

| CN213620012U (zh) | 一种煤矿用搜救机器人 | |

| GB2115187A (en) | Automatic control of apparatus for moving a slurry | |

| US8905487B2 (en) | Mine equipment recovery system | |

| CN115822695A (zh) | 多级串联转载运输采煤方法 | |

| CN111483604B (zh) | 一种基于无人机的静态爆破危岩治理装置及方法 | |

| CN115892263B (zh) | 一种多功能无人破障车及多功能无人破障车的控制方法 | |

| CN105672986A (zh) | 水井测调智能操控装置及方法 | |

| JPS6135370Y2 (de) | ||

| CN114949688A (zh) | 一种空地协同智能巡检救灾机器人 | |

| CN213892501U (zh) | 一种火车客车漂移伸展式上水机 | |

| JP4874638B2 (ja) | 安全管理装置 | |

| CN116347029A (zh) | 一种矿用履带巡检侦测机器人 | |

| WO1998046472A1 (en) | Tractor unit and wheeled trailer combination |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19830427 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR GB LI LU NL SE |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19871111 Ref country code: LI Effective date: 19871111 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19871111 Ref country code: CH Effective date: 19871111 Ref country code: AT Effective date: 19871111 |

|

| REF | Corresponds to: |

Ref document number: 30758 Country of ref document: AT Date of ref document: 19871115 Kind code of ref document: T |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19871130 |

|

| REF | Corresponds to: |

Ref document number: 3176521 Country of ref document: DE Date of ref document: 19871217 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EN | Fr: translation not filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19880831 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19900903 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19901020 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19910803 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920501 |