EP0060197B1 - Rodoir à granulométrie variable - Google Patents

Rodoir à granulométrie variable Download PDFInfo

- Publication number

- EP0060197B1 EP0060197B1 EP82400395A EP82400395A EP0060197B1 EP 0060197 B1 EP0060197 B1 EP 0060197B1 EP 82400395 A EP82400395 A EP 82400395A EP 82400395 A EP82400395 A EP 82400395A EP 0060197 B1 EP0060197 B1 EP 0060197B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ring

- flutes

- male

- grinder

- female

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000001033 granulometry Methods 0.000 title 1

- 229910003460 diamond Inorganic materials 0.000 description 6

- 239000010432 diamond Substances 0.000 description 6

- 238000010009 beating Methods 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B33/00—Honing machines or devices; Accessories therefor

- B24B33/08—Honing tools

- B24B33/085—Honing tools in which the honing element consists of a deformable body

Definitions

- EP-A-0 005 003 discloses expandable lappers comprising externally grooved abrasive rings which can be deformed by crushing.

- the present invention relates to a lapping machine of the above type in which the abrasive ring deforms while remaining perfectly cylindrical, which results in better lapping precision.

- the lapping according to the invention is characterized in that the pushers are in abutment against male internal grooves of the ring, in that the expansion cone is held from place to place in the axis of the body by centralizers arranged in mortises formed at the periphery of the cone, and in that the ring has external grooves distributed uniformly over its periphery, the external female grooves being arranged opposite the internal male grooves and being deep enough for the wall existing between a female groove outer and an inner male groove is thin enough to give the ring the flexibility it needs to expand.

- the abrasive ring can have twice as many internal male and female grooves as external male and female grooves.

- the lapping may comprise at the right of each ring, as many pushers as there are male grooves or external female grooves, each of them being in contact with an internal male groove situated opposite an external male groove.

- the abrasive ring can also include an equal number of internal grooves and external grooves, each internal male groove being arranged opposite an external female groove.

- the lapping may comprise, in line with the ring, pushers in a number equal to half the number of male grooves or female grooves, each of them being in contact with an internal male groove.

- the lapping comprises on the side of its free end at least one fixing ring coaxial with a ring with ramps which is integral with the expansion cone, has a cylindrical outer surface in contact with the wall of the central bore of the lapping body, and is provided with sloping grooves in which are engaged expansion pushers.

- the lapping according to the invention comprises a body or mandrel 1 having a cylindrical bore 2 inside which can slide an expansion cone 3.

- This cone is held in place in place in the axis of the body 1 by centralizers 4 which are glued in mortises 5 formed at the periphery of the cone.

- centralizers 4 which are glued in mortises 5 formed at the periphery of the cone.

- three series of mortises are provided axially separated from each other, each series comprising four mortises distributed circumferentially around the cone.

- a pin 6 crosses a hole provided axially at one end of the body 1 and is engaged in a groove 7 of the cone 3, which secures in rotation the cone and the body while allowing the cone to move axially in the body .

- the reference 8 designates a nozzle screwed into the end of the large section of the cone and which is intended to be connected to the expansion rod, not shown, of a lapping machine.

- a spacer 9 On the body 1 are mounted a spacer 9 and a series of diamond rings 10.

- Each of the rings 10 is fluted internally and externally. More specifically, it internally comprises 2n male splines alternately 11a and 11b equidistant and separated from each other by female splines 12, slightly narrower than the male splines. Externally, it comprises n female splines 13 arranged opposite the internal male splines 11a and separated from each other by male splines 14. These female splines 13 have a width less than that of the splines 11a and are relatively deep so that the ring has a reduced thickness at the right of these grooves 11a, which gives it a certain flexibility and allows its extension.

- the body 1 of the lapping has on its periphery 2n grooves 16 which extend over practically its entire length. In these grooves open openings. 17 whose length is substantially equal to that of the rings 10 and which are spaced from each other by a distance equal to this same length; these openings 17 are staggered.

- the rings 10 are mounted on the body 1 having their internal male splines 11a and 11b engaged in the splines of the body 1, so that the splines 11 are located opposite the openings 17 of these splines 16.

- Pushers 18 engaged in these openings are arranged between the male splines 11b and the expansion cone 3; the inner face of these pushers has the same slope as the cone; due to the staggered arrangement of the openings 17, the angular positions of the rings 10 differ from one ring to the other by 360 ° / 2n.

- a ring 19 is fitted onto a tie rod 20 fixed to the end of the expansion cone 3 and held in place by a nut 21.

- Finished diamond rings 10a are mounted on the body 1, in line with the ring 19, being separated from the rings 10 by a ring 22; the set of diamond rings 10 and 10a is held on the body by a nut 23.

- the ring 19 has non-opening longitudinal slots 24 and external grooves 25 with a sloping bottom, in which the pushers 18a are engaged, the underside of these pushers having the same slope as the bottom of the grooves 25.

- this lapper To use this lapper, it is engaged deflated in the bore to be machined. During the beating of the spindle, only the rings 10 are in contact with the wall of the bore. When the expansion cylinder controlling the expansion rod of the lapping machine is in abutment, the movement of the spindle is stopped while the latter is in the high position and the lapping rod is extracted from the bore; the rings 10a finish the bore.

- fluted diamond rings 10 comprising twice as many external grooves as internal grooves

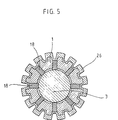

- fluted diamond rings 26 comprising as many internal grooves as external grooves (FIG. 5).

- the pushers are in contact with parts of reduced thickness of the ring.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8105258A FR2501561A1 (fr) | 1981-03-11 | 1981-03-11 | Rodoir a granulometrie variable |

| FR8105258 | 1981-03-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0060197A1 EP0060197A1 (fr) | 1982-09-15 |

| EP0060197B1 true EP0060197B1 (fr) | 1984-07-25 |

Family

ID=9256296

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82400395A Expired EP0060197B1 (fr) | 1981-03-11 | 1982-03-08 | Rodoir à granulométrie variable |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0060197B1 (OSRAM) |

| DE (1) | DE3260429D1 (OSRAM) |

| FR (1) | FR2501561A1 (OSRAM) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5390448A (en) * | 1993-04-22 | 1995-02-21 | Sunnen Products Company | Modular expandable honing tool |

| JP5294945B2 (ja) | 2009-03-31 | 2013-09-18 | 本田技研工業株式会社 | 内径加工工具 |

| CN116237826B (zh) * | 2023-05-11 | 2023-07-14 | 四川省卓辰精密机械制造有限公司 | 一种阀块油孔打磨工具及打磨装置 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0005003A1 (en) * | 1978-04-19 | 1979-10-31 | Ex-Cell-O Corporation | Expandable abrading tool |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2460997C3 (de) * | 1974-12-21 | 1984-01-26 | Nagel Maschinen- und Werkzeugfabrik GmbH, 7440 Nürtingen | Honwerkzeug zur Bearbeitung zylindrischer Werkstückbohrungen |

| FR2356479A1 (fr) * | 1976-06-28 | 1978-01-27 | Citroen Sa | Rodoir a bague deformable |

-

1981

- 1981-03-11 FR FR8105258A patent/FR2501561A1/fr active Granted

-

1982

- 1982-03-08 EP EP82400395A patent/EP0060197B1/fr not_active Expired

- 1982-03-08 DE DE8282400395T patent/DE3260429D1/de not_active Expired

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0005003A1 (en) * | 1978-04-19 | 1979-10-31 | Ex-Cell-O Corporation | Expandable abrading tool |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2501561B1 (OSRAM) | 1985-01-11 |

| FR2501561A1 (fr) | 1982-09-17 |

| EP0060197A1 (fr) | 1982-09-15 |

| DE3260429D1 (en) | 1984-08-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0944765B1 (fr) | Outil de forage et/ou de carottage | |

| FR2929868A1 (fr) | Porte-outil pourvu d'un moyen d'amortissement | |

| FR2538442A1 (fr) | Taillant pour foration rotative assistee par jet | |

| EP1225322A1 (fr) | Dispositif de centrage d'un tube dans un arbre de turbine | |

| FR2620960A1 (fr) | Outil de honage ou de pierrage expansible | |

| EP0063976B1 (fr) | Rodoir à barrettes | |

| FR2704168A1 (fr) | Mandrin de honage expansible modulaire. | |

| EP0130592B1 (fr) | Plaquette de coupe pour usinage par rotation, outil garni de telles plaquettes et procédé d'affûtage de telles plaquettes | |

| EP0060197B1 (fr) | Rodoir à granulométrie variable | |

| FR2607183A1 (fr) | Appareil de forage, notamment elargisseur, et bras de coupe pour un tel appareil | |

| EP3600736B1 (fr) | Mandrin de serrage a coulisseaux inclines | |

| CA2918614C (fr) | Outil de rodage d'une surface externe d'un tube cylindrique droit | |

| FR2704790A1 (fr) | Scie-cloche réglable de diamètre variable. | |

| FR2601276A1 (fr) | Meule, notamment meule sur tige. | |

| FR2628999A1 (fr) | Dispositif pour le montage et le demontage rapide d'outils ou de lames circulaires sur un porte-outil en forme d'arbre | |

| EP0805734A1 (fr) | Meule perfectionnee pour verres ophtalmiques, et machine de meulage correspondante | |

| FR2517576A1 (OSRAM) | ||

| FR2687087A1 (fr) | Tete de honage avec avance en spirale. | |

| EP0661136B1 (fr) | Procédé de rodage de la surface d'une pièce et rodoir pour la mise en oeuvre de ce procédé | |

| US5527214A (en) | Roughing finishing honing tool with push/pull expansion mechanism | |

| FR2515547A1 (fr) | Outil abrasif a une seule passe a diametre fixe pour usinage d'un alesage par rotation et mouvement axial | |

| EP2688703B1 (fr) | Procede et dispositif de fraisage - surfacage | |

| FR2554747A1 (fr) | Outil pour le tronconnage de tubes | |

| FR2632217A1 (fr) | Dispositif et procede de fabrication d'une poulie a gorge a partir d'un disque circulaire en tole | |

| FR2551833A1 (fr) | Appareil destine au montage d'un organe sur une canalisation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT |

|

| 17P | Request for examination filed |

Effective date: 19820920 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT |

|

| REF | Corresponds to: |

Ref document number: 3260429 Country of ref document: DE Date of ref document: 19840830 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| ITPR | It: changes in ownership of a european patent |

Owner name: OFFERTA DI LICENZA AL PUBBLICO |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000322 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000530 Year of fee payment: 19 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20010308 |