EP0053510A2 - Extrusion method - Google Patents

Extrusion method Download PDFInfo

- Publication number

- EP0053510A2 EP0053510A2 EP81305652A EP81305652A EP0053510A2 EP 0053510 A2 EP0053510 A2 EP 0053510A2 EP 81305652 A EP81305652 A EP 81305652A EP 81305652 A EP81305652 A EP 81305652A EP 0053510 A2 EP0053510 A2 EP 0053510A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- extruded

- combustion improver

- extrusion

- billet

- mandrel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/007—Hydrostatic extrusion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/32—Lubrication of metal being extruded or of dies, or the like, e.g. physical state of lubricant, location where lubricant is applied

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C43/00—Devices for cleaning metal products combined with or specially adapted for use with machines or apparatus provided for in this subclass

Definitions

- This invention relates to a method for extruding solid or tubular products using a lubricant, including. removing the deposit of carbonized lubricant produced on the surface of each extruded product thereby to improve the quality of the extruded products and facilitate their aftertreatment.

- non-lubricated extrusion which is widely used for non-ferrous materials (e.g., aluminium and copper alloys)

- extrusion with a glass lubricant and extrusion with a carbon-base lubricant which are used mainly for steel materials

- hydrostatic extrusion which is applicable to a wide variety of metallic materials.

- a lubricated extruding process in which a billet precoated with a carbon-base lubricant is loaded into a container after heating and extruded through a die and/or a mandrel or in which the container as well as the die and/or mandrel is coated with a carbonbase lubricant prior to loading a heated billet in to the container for extrusion and the hydrostatic extrusion process in which a hot billet loaded in a container is extruded by the pressure medium applied to the surface of the billet (with the forced lubricating effect of the pressure medium) each have a common problem in that the surfaces of the extruded tubular product are darkened due to depositions of a carbide formed from the used lubricant, which is formed by the extrusion at a high temperature.

- the carbide deposit on the extruded product not only lowers its value but-also can cause corrosion when the tubular product is used as a condensor tube of a heat exchanger or the like.

- the deposit of carbonized lubricant gives rise to a similar problem even when an iron-base material is extruded with the use of a carbon-base lubricant.

- the present invention provides a method of hot lubricated metal extrusion in which a billet is extruded by means of a die and/or mandrel with an organic lubricant interposed between said billet and die and/or mandrel, said method comprising feeding a combustion improver or a mixture of a combustion improver and water to a surface of the extruded product to burn off the carbide of said lubricant deposited on the surface of said extruded product.

- the billet is extruded into a tubular form by means of a die and a mandrel, said method further . comprising feeding the combustion improver or a mixture of the combustion improver and water into the extruded tubular product through a feed passage in said mandrel to burn off the carbide of said lubricant deposited on the inner surface, of said extruded tubular product.

- said combustion improver may be air and is preferably fed at a rate of Q falling in the range of 1.8d.R.V ⁇ Q ⁇ 14.2d.R.V (where d is the inner diameter of the product in cm, R is the extrustion ratio, and V is the billet extruding speed in cm/sec.)

- combustion improver is fed to an outer surface of the extruded material at a combustion improver feed zone located downstream of an extrusion die to burn off the carbide of said lubricant deposited on the outer surface of said extruded material, and water is fed to the outer surface of the extruded material at a water cooling zone to prevent oxidation on the outer surface and suppress grain growth of said extruded material.

- the feeding rate of the air is controlled to satisfy the following condition; 0.3D ⁇ R ⁇ v ⁇ Q ⁇ 0.7D ⁇ R ⁇ v wherein Q is rate of feed of air (1/min), D is the outer diameter of extruded material (cm), R is the extrusion ratio, and v is the extrusion speed (stem speed) (cm/sec).

- the invention also provides an extrusion apparatus for hot lubricated metal extrusion comprising a die and/or mandrel, a container into which a billet to be extruded, in use, is loaded with an organic lubricant interposed between said billet and die and/or mandrel, and means for feeding a combustion improver or a mixture of a combustion improver and water to a surface of the extruded-product to burn off the carbide of said lubricant deposited on the surface of said extruded product.

- said mandrel may include a feed passage to feed said combustion improver or a mixture of combustion improver and water into the extruded tubular product to burn off the carbide of said lubricant deposited on the inner surfaces of said extruded tubular product.

- Said feeding means may be adapted to feed the combustion improver to the outer surface of the extruded material at a combustion improver feed zone located downstream of the extrusion die to burn off the carbide of said lubricant deposited on the outer surface of said extruded material, and water feed means may be provided to feed water to the outer surface of the extruded material at a water cooling zone located downstream of said combustion improver feed zone to prevent oxidation of the outer surface and to suppress grain growth of said extruded material.

- the invention also provides an extruded product manufactured by any of the above methods of the invention.

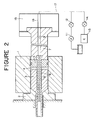

- FIGURES 1 and 2 illustrate a conventional hydrostatic extrusion and a similar hydrostatic extrusion incorporating the method of the present inverition. respectively.

- a hot hollow billet 3 which is heated to a high temperature of 500 0 C or more is loaded into a container 1 and a pressure medium 4 such as a commercially available non-soap type grease, liquid polymer or the like is spread on a mandrel 6 which projects from the front end of a press stem 7 through a seal piston 5, a pressure medium 4 surrounding hollow billet 3 which is extruded by displacement of the stem 7 into a tubular product 3a through a space defined between the mandrel 6 and a press die 2, as shown in FIGURE 1.

- a pressure medium 4 such as a commercially available non-soap type grease, liquid polymer or the like

- the pressure medium 4 sticks to the extruded billet and forms carbide deposits on the inner and outer surfaces of the tubular product 3a which is extruded at a high temperature.

- the hollow billet 3 is precoated with a carbon-base lubricant and heated before charging into the container 1, and then extruded into a tubular form 3a through the mandrel 6 and die 2.

- a heated hollow billet 3 is charged into the container 1 after precoating the container 1, mandrel 6 and die 2 with carbon-base lubricant and similarly extruded into a tubular form 3a through the mandrel 6 and die 2.

- carbide of the lubricant is deposited onto the surfaces of the extruded tubular product in a manner similar to the hydrostatic extrusion.

- the carbonized lubricant or pressure medium deposit lowers the quality of the product and will cause corrosive degradation. Thus as mentioned before the deposit should be removed completely.

- the present invention succeeded in completely burning off the lubricant-and pressure medium which is extruded along with the tubular product through the gap between the mandrel 6 and billet 3, by injecting a combustion improver or a mixture of a combustion improver and water into the tubular product being extruded.

- FIGURE 2 depicts a hot lubricated extrusion incorporating the method of the present invention, in which a container 1, die 2, hollow billet 3, pressure medium 4, seal piston 5, mandrel 6 and stem 7 are arranged substantially in the same manner as in FIGURE 1.

- an axial bore 8 is provided centrally through the mandrel 6 to feed a combustion improver or a mixture of a combustion improver and water as shown in FIGURE 2.

- bores 9 and 16 are provided through the stem 7 in communication with the bore 8.

- the stem 7 holds the mandrel 6 and is held in a crosshead 16 which is movable back and forth together with the stem 7.

- air is referred to as an example of a combustion improver which is fed to a supply passage 17 alone through a valve 14 or together with water which is fed from a pump 11 through a valve 12.

- combustion improver in the present invention, it is preferred to employ a combustion improver in the form of a gas in view of the ease of control of the feeding of the improver continuously from outside into the extruded tubular product through the axial through bores in the mandrel 6 and stem 7 or other components of the press. It is particularly preferred to use atmospheric air which is easily available and advantageous from the standpoint of cost and safety.

- combustion improver alone can attain the purpose of the present invention

- its combined use with water serves to cool the mandrel by forming a mist when the combustion improver is in the form of a gas like air.

- the combustion improver is fed in a mist form to cool off the tube, the carbide deposits on the inner surface of the tubular product are burned off immediately upon extrusion thereof so that the temperature drop of the tube does not hinder the removal of the carbide.

- the required air in compressed form is fed from an air compressor 13 into the extruded tube through the air supply passage 17 and axial bores 16, 9 and 8.

- the air is slightly heated during its passage through the mandrel 6, by absorbing heat from the latter, to a level higher than 50°C, while the hollow billet 3 is heated to 500 to 1150 0 C prior to loading it into the container 1 and extruding it at a stem speed of 40 to 50 mm/sec.

- the air which is supplied in this manner reacts with the lubricant or pressure medium 4 which is extruded with the tubular product 3a through the gap between the mandrel 6 and billet 3, to completely burn off the lubricant or pressure medium by virtue of the heat of the extruded tubular product 3. If the tubular product is extruded at a low temperature, it is necessary to select a suitable lubricant or pressure medium which will be burnt off at the lower temperature.

- a billet heated similarly to a temperature above 500°C may be charged into the container and extruded by means of a commercially available pressure medium such as a non-soap type grease containing an inorganic compound as a tackifier in a mineral oil or a viscous liquid polymer.

- a commercially available pressure medium such as a non-soap type grease containing an inorganic compound as a tackifier in a mineral oil or a viscous liquid polymer.

- a viscous liquid polymer it is preferred to employ a viscous liquid polymer as a pressure medium for hydrostatic extrusion.

- the complete burn-off of the lubricant or pressure medium by air or another combustion improver which is fed into the extuded tubular product through the axial bore 8 in the mandrel in accordance with the method of the present invention can be applied to billets in a very wide temperature range.

- the combustion improver is in the form of a gas like air as in the above-described embodiment, it should be fed at such a rate that the oxygen content in the gas is sufficient for completely burning off the lubricant or pressure medium which is extruded.along with the billet 3 through the gap between the mandrel 6 and billet 3.

- the extruded tubular product 3a may bear on its inner surface closely deposited amorphous carbon particles to a thickness of 0.3 to 0.5 microns. Therefore, it is sufficient to feed oxygen in sufficient quantity to completely burn off the 0.5 micron thick amorphous carbon deposit but desirably more than the minimum amount of oxygen should be supplied for reliable and stable operation.

- the combustion improver is used in a mist form

- water in a reservoir or tank 10 is fed by a pump 11 through a valve 12 as shown in FIGURE 2 and mixed under increased pressure with the compressed air from the air compressor 13, the mist being fed to the axial bore 8 of the mandrel 6 through the supply passage 17 and axial bores 16 and 9.

- the misty combustion improver gas is fed also into the tubular product being extruded as mentioned hereinbefore but its acceleration of the cooling effect on the extruded tube causes no problems since the carbide on the inner surfaces of the extrudate is burned off immediately upon extrustion by the die 2 and mandrel 6.

- the existence of a slight oxidation film or a thin drawable film of Cu 2 O is permissible, which however turns into CuO if oxygen is supplied in an excess amount.

- the production of the oxidation film of Cu0 causes deteriorations in the surface properties in the drawing stage, and it is difficult to remove it by reduction by bright annealing which is usually effected subsequent to the drawing. Therefore, the feed rate of the combustion improver should be so controlled as not to produce an oxidation film of CuO.

- the present invention has succeeded in establishing effective and reliable principles common to ferrous or non-ferrous metal billets, as a result of repeated experiments and studies. More particularly, the carbide (of the lubricant or pressure medium) which deposits on the inner surfaces of the tubular extrudate 3a through the gap between the mandrel 6 and billet 3 is complete burned off in the region to which the combustion improver such as oxygen and air is blown in from the inner end of the axial bore -8 of the mandrel 6.

- the combustion improver should not remain, even in a small amount in the tube after it has passed from the region where combustion takes place if a sound tubular product3a is to be manufactured in which the inner surfaces are completely free of combustible carbide and in which the base metal is not oxidised.

- the combustion improver still remains in the tube which has passed the combustion region and reacts with the base metal to form an objectionable oxidation film, the oxidation reaction terminating when the combustion improver becomes scarce because of the formation of the oxidation film.

- the feed rate Q of the combustion improver for good extrusion is commonly in the range defined below, which is effectively applicable no matter whether the billet is a non-ferrous metal like a cuprous metal or a ferrous metal like carbon steel (S45C) or the like. It has been experimentally confirmed that this method is effective especially for the extrusion of a billet of copper or a copper alloy using air as the combustion improver.

- the abovementioned suitable range of the combustion improver feed rate Q is where the feed rate Q is in the unit of 1/min.

- the feed of the combustion improver should be cut off when the extruding speed becomes zero upon completion of extrusion.of the tubular product 3a. If the feed is cut off with a time delay at the time of completion of extrusion localized oxidation takes place due to the presence of excess oxygen as mentioned before and the oxidized area extends toward the front end of the tubular product 3a. However, a slight time delay should desirably be allowed in the actual operation.

- the time point for stopping the feed of combustion improver if it is cut off before the extrusion: is complete, the combustion of the carbide in the extruded tubular product 3a becomes incomplete and deposits of combustible carbide appear at the rear end of the extruded product.

- the feed of the combustion improver is stopped after a delay, an oxidation film is formed at the rear end of the product to a conspicuous degree due to the supply of excess oxygen.

- the feed of the combustion improver should be controlled in a suitable time range which does not lower the production yield, and in actual operations should suitably be stopped within a time range from one second before to five seconds after the termination of the extrusion of the tubular product 3a.

- the billet may be extruded under a condition in which a slight oxidation film is formed on the inner surface of the extruded tube by residual oxygen, and reducing the oxidation film by feeding through the mandrel 6 a DX gas (2.85%CO, 1.99%H, 11.9%CO and the balance.of N) in the succeeding cooling phase of the tubular product 3a. Since the DX gas is fed after termination of the extrusion, it is necessary to maintain the tubular product 3a in a temperature range suitable for the reduction reaction.

- the residual gas in the extruded tube may be replaced by a non-oxidative gas such as an inert gas or reduction gas to improve the quality of the product.

- Tables 1 to 3 illustrate the results of more specific extrusion experiments according to the method of the present invention in comparison with corresponding conventional methods.

- the subject of the experiment is captioned on each table.

- deposited carbonized lubricant on the outer surface of extruded material can also be removed by feeding combustion improver to the outer surface of the extruded material which leaves the extrustion die, and bringing coolant liquid into contact with the outer surface of the material after the carbonized lubricant is burned off.

- carbonized lubricant remaining on the outer surface can be completely removed, oxidation film formation can be prevented, and crystal grain growth of the extruded product can also be suppressed.

- the thickness of the carbonized lubricant retained on the outer surface of the extruded tube is at most 1.4 ⁇ m.

- the optimum amount of combustion improver is fed to the extruded material while the material is still hot. If the amount of combustion improver is insufficient, carbide will remain on the outer surface, but if the amount of combustion improver is too much, an oxidized film is formed on the outer surface of the extruded material.

- FIGURE 3 is a diagram of an apparatus for carrying out the method of the invention.

- An air feeding zone A is provided downstream of the extrusion die 2 so that air is brought into contact with the outer circumference of the extruded material.

- a water cooling zone w is , provided downstream of said air feeding zone A, so as to prevent oxidation and to suppress cyrstal grain growth of the extruded material.

- the amount of air feed should be proportional to the surface area of the extruded material that passes through the combustion zone (air feeding zone) per unit time period. Therefore, the air feeding rate Q (1/m) can be obtained by the following formula; where K is a constant, D is the outer diameter of extruded material, (cm), R is the extrusion ration, and v is the extrusion speed (stem speed) (cm/sec).

- FIGURE 4 is a graph showing the relationship between the surface quality of the extruded material and the extrusion conditions. More specifically there is shown a relationship between the amount of air feed (Q) and the outer diameter of the extruded material (D). As can be seen from this graph, an excess of air feed causes formation of an oxidation film on the outer surface of the extruded material. In order to completely remove the carbonized lubricant and to prevent the oxidation on the outer surface of the extruded material, the following condition should be satisfied:

- FIGURE 5 shows the relationship between the period of time for the material to pass through the air feeding zone and the amount of air fed.

- the desired period for the material to pass through the air feeding zone varies depending on the amount of air fed, but if the amount of air fed is 140 1/m, the period shall preferably be shorter than 0.13 second. If the amount of air fed is 70 1/min, the period should preferably be shorter than 0.35 second. Generally as the amount of air fed becomes less, the period should be longer, but then the extruded material will cool resulting in coarse grains within the extruded material.

- Crystal grains of extruded cupro-nickel tube do not grow even if the tube is slowly cooled in the atmosphere.

- aluminium brass crystal grains grow rapidly and the surface gets rough when it is drawn.

- the length of air feeding zone is considered for aluminium brass.

- the extrusion conditions are;

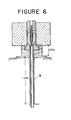

- FIGURE 6 The extrusion took place with an apparatus shown in FIGURE 6.

- a 0.7 m long air feeding zone A is provided at the outlet side of the extrusion die, and a 1.2 m long water cooling zone W is provided downstream of said air feeding zone.

- the amount of water.feed was varied from 0 to 36 1/min.

- the relationship between the amount of coolant water and the crystal grain size of the extruded aluminium brass is shown in FIGURE 7.

- mean grain size of the extruded tube was 0.07 mm.

- the grain size becomes smaller, and when the amount of water is 20 1/min, the grain size becomes finer than 0.04mm.

- the period of time for the material to pass through the air feeding zone is 0.41 second, which is a sufficient period for the carbonized lubricant to completely burn off judging from FIGURE 5.

- the outer surface of the extruded material can be cleared and grain growth can be suppressed by the provision of an air feeding zone which is followed by a water cooling zone at the downstream side of a hot hydrostatic extrusion die.

- the present invention is particularly excellent at completely removing the combustible carbide of the lubricant or pressure medium which tends to deposit on the surfaces of the solid or tubular product, permitting production of solid or tubular products with clean and defect-free surfaces in a simple manner.

- the combustion improver which may mainly consist of a combustion improver gas such as oxygen and air or a mixture of a combusion improver and water is fed to the initial billet extruding point of the die and/or mandrel to cause complete combustion of the combustible carbide under the high extruding temperature.

- the outer surface of the extruded material can by cleaned by removing carbonized lubricant by means of applying combustion improver. Oxidation and undesirable grain growth of the extruded material can be prevented by bringing coolant into direct contact with the outer surface.

Abstract

Description

- This invention relates to a method for extruding solid or tubular products using a lubricant, including. removing the deposit of carbonized lubricant produced on the surface of each extruded product thereby to improve the quality of the extruded products and facilitate their aftertreatment.

- There are known in the art various methods for producing solid or tubular bodies by metal extrusion. including non-lubricated extrusion which is widely used for non-ferrous materials (e.g., aluminium and copper alloys), extrusion with a glass lubricant and extrusion with a carbon-base lubricant which are used mainly for steel materials, or hydrostatic extrusion which is applicable to a wide variety of metallic materials.

- It is also known that the extrudability of a non-ferrous metal material can be improved to a significant degree by the use of a carbon-base lubricant in the extrusion or the hydrostatic extrusion method. For example, with a given press power, it becomes possible to work a billet at a higher reduction rate or to work a billet of a lower temperature. In the case of an aluminium alloy material, it is possible to enhance productivity by speeding up the extrusion without incurring defects. However, these extrusion methods invariably have a problem that the quality of the products is greatly impaired by the carbonized lubricant which deposits on the surfaces of the extruded products. For instance. the use of a lubricated extruding process in which a billet precoated with a carbon-base lubricant is loaded into a container after heating and extruded through a die and/or a mandrel or in which the container as well as the die and/or mandrel is coated with a carbonbase lubricant prior to loading a heated billet in to the container for extrusion and the hydrostatic extrusion process in which a hot billet loaded in a container is extruded by the pressure medium applied to the surface of the billet (with the forced lubricating effect of the pressure medium) each have a common problem in that the surfaces of the extruded tubular product are darkened due to depositions of a carbide formed from the used lubricant, which is formed by the extrusion at a high temperature. The carbide deposit on the extruded product not only lowers its value but-also can cause corrosion when the tubular product is used as a condensor tube of a heat exchanger or the like. The deposit of carbonized lubricant gives rise to a similar problem even when an iron-base material is extruded with the use of a carbon-base lubricant.

- Although the carbide deposit on the surfaces of the solid or tubular extrudate are removed where the extruded tube or rod is drawn through a drawing die in a subsequent stage, it is particularly difficult to wash off by a pickling or like process the carbide deposit from the inner surfaces of the tube. In addition, as the diameter has been reduced in the drawing stage, the pickling operation which is troublesome in itself and requires complicated arrangements for the disposal of the spent liquor becomes even more difficult and should be avoided if possible to improve productivity and economy. Where, for example, a narrow tube of about, say 10 to 30 mm in diameter and in excess of 700 mmin length is extruded, it is practically impossible to remove the deposits on the inner surface of the extruded tube completely by a pickling or similar treatment. Therefore, long and thin tubes should have clean inner surfaces formed during extrusion. However, this has hitherto been difficult or impossible.

- The present invention provides a method of hot lubricated metal extrusion in which a billet is extruded by means of a die and/or mandrel with an organic lubricant interposed between said billet and die and/or mandrel, said method comprising feeding a combustion improver or a mixture of a combustion improver and water to a surface of the extruded product to burn off the carbide of said lubricant deposited on the surface of said extruded product.

- Preferably, the billet is extruded into a tubular form by means of a die and a mandrel, said method further . comprising feeding the combustion improver or a mixture of the combustion improver and water into the extruded tubular product through a feed passage in said mandrel to burn off the carbide of said lubricant deposited on the inner surface, of said extruded tubular product. In this case if the billet is of copper or a copper alloy, said combustion improver may be air and is preferably fed at a rate of Q falling in the range of 1.8d.R.V≦Q≦14.2d.R.V (where d is the inner diameter of the product in cm, R is the extrustion ratio, and V is the billet extruding speed in cm/sec.)

- Preferably said combustion improver is fed to an outer surface of the extruded material at a combustion improver feed zone located downstream of an extrusion die to burn off the carbide of said lubricant deposited on the outer surface of said extruded material, and water is fed to the outer surface of the extruded material at a water cooling zone to prevent oxidation on the outer surface and suppress grain growth of said extruded material.

- When air is the combusion improver the feeding rate of the air is controlled to satisfy the following condition;

0.3D·R·v≦Q≦0.7D·R·v

wherein Q is rate of feed of air (1/min), D is the outer diameter of extruded material (cm), R is the extrusion ratio, and v is the extrusion speed (stem speed) (cm/sec). - The invention also provides an extrusion apparatus for hot lubricated metal extrusion comprising a die and/or mandrel, a container into which a billet to be extruded, in use, is loaded with an organic lubricant interposed between said billet and die and/or mandrel, and means for feeding a combustion improver or a mixture of a combustion improver and water to a surface of the extruded-product to burn off the carbide of said lubricant deposited on the surface of said extruded product.

- Where the apparatus includes a die and mandrel to extrude the billet into a tubular form, said mandrel may include a feed passage to feed said combustion improver or a mixture of combustion improver and water into the extruded tubular product to burn off the carbide of said lubricant deposited on the inner surfaces of said extruded tubular product.

- Said feeding means may be adapted to feed the combustion improver to the outer surface of the extruded material at a combustion improver feed zone located downstream of the extrusion die to burn off the carbide of said lubricant deposited on the outer surface of said extruded material, and water feed means may be provided to feed water to the outer surface of the extruded material at a water cooling zone located downstream of said combustion improver feed zone to prevent oxidation of the outer surface and to suppress grain growth of said extruded material.

- The invention also provides an extruded product manufactured by any of the above methods of the invention.

- Preferred embodiments of the invention will now be described by way of an example only and with reference to the accompanying drawings in which:

- FIGURE 1 is a diagrammatic illustration of one example of conventional hydrostatic pressure extrusion,

- FIGURE 2 is a diagrammatic illustration of one embodiment of the invention as applied to a similar hydrostatic extrusion,

- FIGURE 3 is a diagrammatic illustration of another embodiment of the invention as applied to hydrostatic extrusion,

- FIGURE 4 is a graph showing relationship between the surface quality of the extruded material and the extrusion conditions,

- FIGURE 5 is a graph showing the influence of air fed to the surface quality of the extruded material,

- FIGURE 6 is a diagrammatic illustration of a hydrostatic extrusion according to the invention for experimental operation,

- FIGURE 7 is a graph showing the influence of cooling water on the crystal grain size of extruded tube, and,

- FIGURE 8 is a graph showing the relationship between the crystal grain size of the extruded material and the cold working rate.

- Referring now to the accompanying drawings. FIGURES 1 and 2 illustrate a conventional hydrostatic extrusion and a similar hydrostatic extrusion incorporating the method of the present inverition. respectively. In the hydrostatic extrusion, a hot

hollow billet 3 which is heated to a high temperature of 5000C or more is loaded into acontainer 1 and apressure medium 4 such as a commercially available non-soap type grease, liquid polymer or the like is spread on amandrel 6 which projects from the front end of apress stem 7 through aseal piston 5, apressure medium 4 surroundinghollow billet 3 which is extruded by displacement of thestem 7 into atubular product 3a through a space defined between themandrel 6 and apress die 2, as shown in FIGURE 1. In this instance, thepressure medium 4 sticks to the extruded billet and forms carbide deposits on the inner and outer surfaces of thetubular product 3a which is extruded at a high temperature. In the case of ordinary hot lubricated extrusion which does not employ thepressure medium 4, thehollow billet 3 is precoated with a carbon-base lubricant and heated before charging into thecontainer 1, and then extruded into atubular form 3a through themandrel 6 and die 2. Alternatively, a heatedhollow billet 3 is charged into thecontainer 1 after precoating thecontainer 1,mandrel 6 and die 2 with carbon-base lubricant and similarly extruded into atubular form 3a through themandrel 6 and die 2. In either case, carbide of the lubricant is deposited onto the surfaces of the extruded tubular product in a manner similar to the hydrostatic extrusion. The carbonized lubricant or pressure medium deposit lowers the quality of the product and will cause corrosive degradation. Thus as mentioned before the deposit should be removed completely. - In a hot lubricated extrusion where an organic lubricant and pressure medium are interposed between the

mandrel 6 andbillet 3 and thetubular product 3a is extruded through the space defined by thedie 2 andmandrel 6, the present invention succeeded in completely burning off the lubricant-and pressure medium which is extruded along with the tubular product through the gap between themandrel 6 andbillet 3, by injecting a combustion improver or a mixture of a combustion improver and water into the tubular product being extruded. FIGURE 2 depicts a hot lubricated extrusion incorporating the method of the present invention, in which acontainer 1,die 2,hollow billet 3,pressure medium 4,seal piston 5,mandrel 6 andstem 7 are arranged substantially in the same manner as in FIGURE 1. However, according to the present invention, anaxial bore 8 is provided centrally through themandrel 6 to feed a combustion improver or a mixture of a combustion improver and water as shown in FIGURE 2. To supply the combustion improver or mixture of a combustion improver and water, to thebore 8,bores stem 7 in communication with thebore 8. Thestem 7 holds themandrel 6 and is held in acrosshead 16 which is movable back and forth together with thestem 7. In the following description air is referred to as an example of a combustion improver which is fed to asupply passage 17 alone through avalve 14 or together with water which is fed from a pump 11 through avalve 12. - Although various kinds of materials can be used as combustion improver in the present invention, it is preferred to employ a combustion improver in the form of a gas in view of the ease of control of the feeding of the improver continuously from outside into the extruded tubular product through the axial through bores in the

mandrel 6 andstem 7 or other components of the press. It is particularly preferred to use atmospheric air which is easily available and advantageous from the standpoint of cost and safety. - Although the use of a combustion improver alone can attain the purpose of the present invention, its combined use with water serves to cool the mandrel by forming a mist when the combustion improver is in the form of a gas like air. Even where the combustion improver is fed in a mist form to cool off the tube, the carbide deposits on the inner surface of the tubular product are burned off immediately upon extrusion thereof so that the temperature drop of the tube does not hinder the removal of the carbide. In the embodiment depicted in FIGURE 2, the required air in compressed form is fed from an

air compressor 13 into the extruded tube through theair supply passage 17 andaxial bores mandrel 6, by absorbing heat from the latter, to a level higher than 50°C, while thehollow billet 3 is heated to 500 to 11500C prior to loading it into thecontainer 1 and extruding it at a stem speed of 40 to 50 mm/sec. The air which is supplied in this manner reacts with the lubricant orpressure medium 4 which is extruded with thetubular product 3a through the gap between themandrel 6 andbillet 3, to completely burn off the lubricant or pressure medium by virtue of the heat of the extrudedtubular product 3. If the tubular product is extruded at a low temperature, it is necessary to select a suitable lubricant or pressure medium which will be burnt off at the lower temperature. - Both in the hydrostatic extrusion shown in FIGURE 1' and in the ordinary hot lubricated extrusion using a die and a mandrel alone without use of a pressure medium, it is possible to obtain

tubular products 3a with inner surfaces free of carbide deposits by feeding compressed air into the extruded tube from theair compressor 13 through themandrel 6. More specifically, in the case of the ordinary hot lubricated extrusion, a hollow billet of pure copper, for example, may be extruded under a condition in which carbide deposition appears on the inner surfaces of the tube, if the copper billet is precoated with an organic solvent type carbon lubricant and heated to a temperature over 500°C before charging it into the container. On the other hand, in the case of hydrostatic extrusion, a billet heated similarly to a temperature above 500°C may be charged into the container and extruded by means of a commercially available pressure medium such as a non-soap type grease containing an inorganic compound as a tackifier in a mineral oil or a viscous liquid polymer. In metal extrusion where the temperature of the billet is lower than 500°C, it is preferred to employ a viscous liquid polymer as a pressure medium for hydrostatic extrusion. However, whichever extruding method may be resorted to, the complete burn-off of the lubricant or pressure medium by air or another combustion improver which is fed into the extuded tubular product through theaxial bore 8 in the mandrel in accordance with the method of the present invention can be applied to billets in a very wide temperature range. - Where the combustion improver is in the form of a gas like air as in the above-described embodiment, it should be fed at such a rate that the oxygen content in the gas is sufficient for completely burning off the lubricant or pressure medium which is extruded.along with the

billet 3 through the gap between themandrel 6 andbillet 3. In this connection, it has been experimentally confirmed that the extrudedtubular product 3a may bear on its inner surface closely deposited amorphous carbon particles to a thickness of 0.3 to 0.5 microns. Therefore, it is sufficient to feed oxygen in sufficient quantity to completely burn off the 0.5 micron thick amorphous carbon deposit but desirably more than the minimum amount of oxygen should be supplied for reliable and stable operation. - If the combustion improver is used in a mist form, water in a reservoir or tank 10 is fed by a pump 11 through a

valve 12 as shown in FIGURE 2 and mixed under increased pressure with the compressed air from theair compressor 13, the mist being fed to theaxial bore 8 of themandrel 6 through thesupply passage 17 andaxial bores die 2 andmandrel 6. - For burning off the carbide deposits on the inner surfaces of the tubular extrudate by feeding a combustion improver like oxygen or air or a mixture of a combustion improver and water in accordance with the present invention, it is necessary to take into consideration the oxidation phenomenon of the metal material which constitutes the hollow billet. For example, where the extruding metal is aluminium brass or other metals which are less susceptible to oxidation, there are no problems even if a greater than predetermined minimum amount of combustion improver gas (e.g., oxygen, air) is supplied for complete combustion of the carbide deposits and excess oxygen remains in the tubular extrudate after the complete combustion of the carbide deposits. In contrast, copper-base materials, above all, pure copper and cupro-nickel are very susceptible-to oxidation although brass is relatively immune from oxidation. In the case of brass, oxygen which is fed in an excess amount remains in the tube after complete combustion of the carbide deposits without reacting with the metal or is released from the front end of the extruded

tube 3a, so that the inner surfaces retain a clean brass colour. However, with pure copper or cupro-nickel, use of excess oxygen supply causes production of an oxide film on the base metal by reaction with the residual oxygen which lingers in the tube after complete combustion of the carbide deposits . This also occurs in brass if oxygen is supplied in an extremely excessive amount. In actual operations, the existence of a slight oxidation film or a thin drawable film of Cu2O is permissible, which however turns into CuO if oxygen is supplied in an excess amount. In the extrusion of copper or copper alloy tubes, the production of the oxidation film of Cu0 causes deteriorations in the surface properties in the drawing stage, and it is difficult to remove it by reduction by bright annealing which is usually effected subsequent to the drawing. Therefore, the feed rate of the combustion improver should be so controlled as not to produce an oxidation film of CuO. - With regard to the feed rate of the combustion improver or the mixture of the combustion improver and water, the present invention has succeeded in establishing effective and reliable principles common to ferrous or non-ferrous metal billets, as a result of repeated experiments and studies. More particularly, the carbide (of the lubricant or pressure medium) which deposits on the inner surfaces of the

tubular extrudate 3a through the gap between themandrel 6 andbillet 3 is complete burned off in the region to which the combustion improver such as oxygen and air is blown in from the inner end of the axial bore -8 of themandrel 6. Ideally, the combustion improver should not remain, even in a small amount in the tube after it has passed from the region where combustion takes place if a sound tubular product3a is to be manufactured in which the inner surfaces are completely free of combustible carbide and in which the base metal is not oxidised. However, in actual operation, the combustion improver still remains in the tube which has passed the combustion region and reacts with the base metal to form an objectionable oxidation film, the oxidation reaction terminating when the combustion improver becomes scarce because of the formation of the oxidation film. After passage through the oxidation region where such oxidation reaction takes place, no further oxidation of the base metal occurs, that is to say, the combustion and oxidation regions extend over limited lengths from the extruding position (the outlet of the die), irrespective of the length of the extrudedproduct 3a. Thus, it is possible to effect the complete combustion of the combustible carbide as intended by the present invention and to permit the oxidation reaction only to an unobjectionable degree by controlling the feed rate of the combustion improver to the outlet of theaxial bore 8 of themandrel 6. If the billet extruding speed (cm/sec) is V and the inner diameter (cm) of the extruded product is.d, the feed rate Q of the combustion improver for good extrusion is commonly in the range defined below, which is effectively applicable no matter whether the billet is a non-ferrous metal like a cuprous metal or a ferrous metal like carbon steel (S45C) or the like. It has been experimentally confirmed that this method is effective especially for the extrusion of a billet of copper or a copper alloy using air as the combustion improver. The abovementioned suitable range of the combustion improver feed rate Q is - Further, in actual operations, it is necessary to control suitably the time at which the feed of the combustion improver is started and stopped in a manner to be described hereinafter. The feed of the combustion improver should be cut off when the extruding speed becomes zero upon completion of extrusion.of the

tubular product 3a. If the feed is cut off with a time delay at the time of completion of extrusion localized oxidation takes place due to the presence of excess oxygen as mentioned before and the oxidized area extends toward the front end of thetubular product 3a. However, a slight time delay should desirably be allowed in the actual operation. In order to meet this requirement, we conducted experiments on the feed periods of the combustion improver in the extruding operations, and found that, if the feed is started after the start of actual extrusion of thetubular product 3a, deposits of combustible carbide occur at the front end of the extrudedtubular product 3a due to the delay, although if the feed of combustion improver is started earlier than the initiation of the extrusion no effect is observed. Therefore, it is possible to open the valve. 14 in thefeed passage 17 orvalves tubular product 3a is initiated. With regard to the time point for stopping the feed of combustion improver, if it is cut off before the extrusion: is complete, the combustion of the carbide in the extrudedtubular product 3a becomes incomplete and deposits of combustible carbide appear at the rear end of the extruded product. On the other hand, if the feed of the combustion improver is stopped after a delay, an oxidation film is formed at the rear end of the product to a conspicuous degree due to the supply of excess oxygen. The feed of the combustion improver should be controlled in a suitable time range which does not lower the production yield, and in actual operations should suitably be stopped within a time range from one second before to five seconds after the termination of the extrusion of thetubular product 3a. - In the extrusion of a billet of a metal which is less susceptible to oxidation like aluminium brass as mentioned hereinbefore, there is no possibility of impairing the quality of the extruded product even if the time for stopping the feed of the combustion improver is long after termination of the extrusion, and a suitable feed time range should be determined in connection with the time period of the press cycle.

- Alternatively, for completely burning off the combustible carbide using feed air as a combustion improver fed through the

mandrel 6, the billet may be extruded under a condition in which a slight oxidation film is formed on the inner surface of the extruded tube by residual oxygen, and reducing the oxidation film by feeding through the mandrel 6 a DX gas (2.85%CO, 1.99%H, 11.9%CO and the balance.of N) in the succeeding cooling phase of thetubular product 3a. Since the DX gas is fed after termination of the extrusion, it is necessary to maintain thetubular product 3a in a temperature range suitable for the reduction reaction. In the case of extrusion of an elongated product, it is necessary to study the cooling characteristics of the tubular product and control its temperature accordingly. Further, when it is expected that there is the possibility of residual oxygen existing in thetubular product 3a after its extrusion which would case the oxidation reaction upon a drop in the temperature of the tubular product due to the peculiar characteristics of the oxidation reaction, the residual gas in the extruded tube may be replaced by a non-oxidative gas such as an inert gas or reduction gas to improve the quality of the product. -

- The invention in which carbide on the inner surface of the tubular extruded material is burned off has been discussed.

- However, deposited carbonized lubricant on the outer surface of extruded material (whether solid or tubular) can also be removed by feeding combustion improver to the outer surface of the extruded material which leaves the extrustion die, and bringing coolant liquid into contact with the outer surface of the material after the carbonized lubricant is burned off. Thus carbonized lubricant remaining on the outer surface can be completely removed, oxidation film formation can be prevented, and crystal grain growth of the extruded product can also be suppressed.

- When a copper alloy billet is extruded with heat resisting lubricant, the thickness of the carbonized lubricant retained on the outer surface of the extruded tube is at most 1.4 µm.

- In order to burn off the carbonized lubricant, the optimum amount of combustion improver is fed to the extruded material while the material is still hot. If the amount of combustion improver is insufficient, carbide will remain on the outer surface, but if the amount of combustion improver is too much, an oxidized film is formed on the outer surface of the extruded material.

- In order to obtain the limits of the conditions for feeding the combustion improver, i.e. the amount of combustion improver and the period of feeding the, same, various experiments were made with the following extrusion conditions.

-

- Billet --- Cupro-nickel (68mm in diameter, 200mm in length

- Heating temperature of a Billet --- 9000C

- Extrusion Speed --- 2 m/sec and 4.4 m/sec (product)

- Extrusion Ratio --- 40 and 113

- Combustion Improver --- Air (Atmosphere)

- FIGURE 3 is a diagram of an apparatus for carrying out the method of the invention. An air feeding zone A is provided downstream of the extrusion die 2 so that air is brought into contact with the outer circumference of the extruded material. A water cooling zone w is , provided downstream of said air feeding zone A, so as to prevent oxidation and to suppress cyrstal grain growth of the extruded material.

- According to the experiments with the abovementioned apparatus under the abovementioned conditions, the amount of air feed should be proportional to the surface area of the extruded material that passes through the combustion zone (air feeding zone) per unit time period. Therefore, the air feeding rate Q (1/m) can be obtained by the following formula;

- FIGURE 4 is a graph showing the relationship between the surface quality of the extruded material and the extrusion conditions. More specifically there is shown a relationship between the amount of air feed (Q) and the outer diameter of the extruded material (D). As can be seen from this graph, an excess of air feed causes formation of an oxidation film on the outer surface of the extruded material. In order to completely remove the carbonized lubricant and to prevent the oxidation on the outer surface of the extruded material, the following condition should be satisfied:

- Thus constant K should be from 0.3 to 0.7.

- FIGURE 5 shows the relationship between the period of time for the material to pass through the air feeding zone and the amount of air fed. The desired period for the material to pass through the air feeding zone varies depending on the amount of air fed, but if the amount of air fed is 140 1/m, the period shall preferably be shorter than 0.13 second. If the amount of air fed is 70 1/min, the period should preferably be shorter than 0.35 second. Generally as the amount of air fed becomes less, the period should be longer, but then the extruded material will cool resulting in coarse grains within the extruded material.

- Crystal grains of extruded cupro-nickel tube do not grow even if the tube is slowly cooled in the atmosphere.

- However, aluminium brass crystal grains grow rapidly and the surface gets rough when it is drawn. Thus, the length of air feeding zone is considered for aluminium brass.

- The extrusion conditions are;

- Billet: Aluminium brass (68mm in outer dia, 200mm in length)

- Billet Heating Temperature: 800°C

- Extrusion Speed (extruded product): 1.7 m/s

- Extrusion Ratio: 40

- Extruded Material Size: 22mm in outer dia. 1.5mm thick

- Combustion Improver:

Atmospehric Air 20 1/min. - The extrusion took place with an apparatus shown in FIGURE 6. In this FIGURE 6, a 0.7 m long air feeding zone A is provided at the outlet side of the extrusion die, and a 1.2 m long water cooling zone W is provided downstream of said air feeding zone. In order to examine the water cooling effect, the amount of water.feed was varied from 0 to 36 1/min. The relationship between the amount of coolant water and the crystal grain size of the extruded aluminium brass is shown in FIGURE 7. When the amount of coolant water is 0 1/min,, mean grain size of the extruded tube was 0.07 mm. As the amount of water is increased, the grain size becomes smaller, and when the amount of water is 20 1/min, the grain size becomes finer than 0.04mm.

- If the extruded tube is subsequently drawn, a smoother surface is obtained where the grain size is smaller, as can be seen from FIGURE 8. Thus, a smooth enough surface can be obtained even after one or two drawing passes if the grain size is smaller than 0.04 mm. Therefore, a 0.7 m long air feeding zone is important.

- If the extrusion speed in terms of the extruded material speed is 1.7 m/s, the period of time for the material to pass through the air feeding zone is 0.41 second, which is a sufficient period for the carbonized lubricant to completely burn off judging from FIGURE 5.

- As can be seen from the foregoing description, the outer surface of the extruded material can be cleared and grain growth can be suppressed by the provision of an air feeding zone which is followed by a water cooling zone at the downstream side of a hot hydrostatic extrusion die.

- As is clear from the foregoing description and the results of experiments, in conventional hot lubricated extrusion using an organic lubricant in the usual manner between the container and the billet to be extruded, the present invention is particularly excellent at completely removing the combustible carbide of the lubricant or pressure medium which tends to deposit on the surfaces of the solid or tubular product, permitting production of solid or tubular products with clean and defect-free surfaces in a simple manner. The combustion improver which may mainly consist of a combustion improver gas such as oxygen and air or a mixture of a combusion improver and water is fed to the initial billet extruding point of the die and/or mandrel to cause complete combustion of the combustible carbide under the high extruding temperature. It has become possible to remove the carbide completely and clean the inner surfaces of a tubular product with high reliability. In addition, there can now be obtained tubular products with perfect internal surface shapes irrespective of the length of the products extruded, and the oxidation of the extruded material can be effectively prevented by adjusting the feed rate of the combustion improver even in the case of a material which is normally susceptible to oxidation, thereby precluding formation of an objectionable oxidation film which is produced by the oxidation reaction. Further this can be attained simply by controlling the feed rate and period of time of feed of the combustion improver, without requiring drastic changes in the conventional hot lubricated extrusion system. More specifically, it is possible to produce tubes with good inner surfaces simply by adding a combustion improver feed passage to the mandrel and providing an associated combustion improver feed means.

- Moreover, the outer surface of the extruded material can by cleaned by removing carbonized lubricant by means of applying combustion improver. Oxidation and undesirable grain growth of the extruded material can be prevented by bringing coolant into direct contact with the outer surface.

Claims (9)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP169918/80 | 1980-11-29 | ||

| JP16991880A JPS5791822A (en) | 1980-11-29 | 1980-11-29 | High-temperature lubrication extrusion method for tubular product |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0053510A2 true EP0053510A2 (en) | 1982-06-09 |

| EP0053510A3 EP0053510A3 (en) | 1982-07-14 |

| EP0053510B1 EP0053510B1 (en) | 1985-05-22 |

Family

ID=15895361

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19810305652 Expired EP0053510B1 (en) | 1980-11-29 | 1981-11-30 | Extrusion method |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0053510B1 (en) |

| JP (1) | JPS5791822A (en) |

| CA (1) | CA1191480A (en) |

| DE (1) | DE3170645D1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002085560A1 (en) * | 2001-04-19 | 2002-10-31 | Alcoa Inc. | Injector for molten metal supply system |

| WO2003055626A1 (en) * | 2001-12-28 | 2003-07-10 | Bbs-Riva S.P.A. | Hydraulic device for pumping molten metal and/or controlling a molten metal flow |

| US7934627B2 (en) | 2005-10-13 | 2011-05-03 | Alcoa Inc. | Apparatus and method for high pressure extrusion with molten aluminum |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5919769B2 (en) * | 1981-11-04 | 1984-05-08 | 昭和アルミニウム株式会社 | Manufacturing method for hollow extruded aluminum sections for vacuum use |

| US6505674B1 (en) | 2001-04-19 | 2003-01-14 | Alcoa Inc. | Injector for molten metal supply system |

| EP1714718B1 (en) | 2001-04-19 | 2008-07-09 | Alcoa Inc. | Continuous pressure molten metal supply system and method |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1182193B (en) * | 1960-04-07 | 1964-11-26 | Hydraulik Gmbh | Cooling device on metal pipe presses |

| AT279310B (en) * | 1967-05-12 | 1970-03-10 | Mannesmann Ag | Method and apparatus for removing lubricant coatings from the surfaces of extruded articles |

| DE2739800A1 (en) * | 1977-09-03 | 1979-03-22 | Schloemann Siemag Ag | PROCESS AND EQUIPMENT FOR MANUFACTURING COPPER PIPES, IN PARTICULAR BY INDIRECT METAL EXTRUSION PRESSES |

-

1980

- 1980-11-29 JP JP16991880A patent/JPS5791822A/en active Granted

-

1981

- 1981-11-25 CA CA000390886A patent/CA1191480A/en not_active Expired

- 1981-11-30 DE DE8181305652T patent/DE3170645D1/en not_active Expired

- 1981-11-30 EP EP19810305652 patent/EP0053510B1/en not_active Expired

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1182193B (en) * | 1960-04-07 | 1964-11-26 | Hydraulik Gmbh | Cooling device on metal pipe presses |

| AT279310B (en) * | 1967-05-12 | 1970-03-10 | Mannesmann Ag | Method and apparatus for removing lubricant coatings from the surfaces of extruded articles |

| DE2739800A1 (en) * | 1977-09-03 | 1979-03-22 | Schloemann Siemag Ag | PROCESS AND EQUIPMENT FOR MANUFACTURING COPPER PIPES, IN PARTICULAR BY INDIRECT METAL EXTRUSION PRESSES |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002085560A1 (en) * | 2001-04-19 | 2002-10-31 | Alcoa Inc. | Injector for molten metal supply system |

| WO2003055626A1 (en) * | 2001-12-28 | 2003-07-10 | Bbs-Riva S.P.A. | Hydraulic device for pumping molten metal and/or controlling a molten metal flow |

| US7427190B2 (en) | 2001-12-28 | 2008-09-23 | Bbs-Riva S.P.A. | Hydraulic device for pumping molten metal and/or controlling a molten metal flow |

| US7934627B2 (en) | 2005-10-13 | 2011-05-03 | Alcoa Inc. | Apparatus and method for high pressure extrusion with molten aluminum |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0053510A3 (en) | 1982-07-14 |

| EP0053510B1 (en) | 1985-05-22 |

| CA1191480A (en) | 1985-08-06 |

| JPS6144563B2 (en) | 1986-10-03 |

| JPS5791822A (en) | 1982-06-08 |

| DE3170645D1 (en) | 1985-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0042814B1 (en) | Rapid extrusion of hot-short-sensitive alloys | |

| US4224978A (en) | Method of manufacturing composite strips by continuous casting | |

| US4445350A (en) | Extrusion method using hot lubricant | |

| EP0053510B1 (en) | Extrusion method | |

| US3386161A (en) | Method of making bearing material | |

| EP0848760B1 (en) | Process for manufacturing cylinder liners for internal combustion engines | |

| JPS60114508A (en) | Production of spherical metallic particle | |

| US4365995A (en) | Method of producing multi-layer sliding material | |

| US2974790A (en) | Cross-extrusion process | |

| US3088195A (en) | Cladding with powdered metal to form bimetallic products | |

| JP2006315059A (en) | Copper-plated solid wire for arc welding | |

| US3135623A (en) | Surface treatment of steel billets to be extruded, and of extrusion tools | |

| US3350907A (en) | Method for extruding molybdenum and tungsten | |

| US4030328A (en) | Device for continuous lubrication of an extrusion die | |

| US2773593A (en) | Methods of extruding high copper alloys | |

| JPH0141408B2 (en) | ||

| JPS594204B2 (en) | High-temperature isostatic extrusion method for aluminum alloy containing Mg and Cu as alloying elements | |

| JPS60108497A (en) | Solid lubricant for preparation of seamless steel pipe | |

| US3199331A (en) | Process for the extrusion of ultra-fine wires | |

| JPS63215308A (en) | Rolling method for sizing tube | |

| MAGIE | MOLYBDENUM DISULPHIDE: as an Additive to Wire Drawing Compounds | |

| SU1018733A1 (en) | Method of longitudinal rolling of tubes | |

| JPH05261427A (en) | Manufacture of hot extrusion tube | |

| Nishihara et al. | Hot hydrostatic extrusion of steel | |

| Jefferson | Quarterly Progress Summary: January to March, 1964 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| 17P | Request for examination filed |

Effective date: 19811208 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB |

|

| REF | Corresponds to: |

Ref document number: 3170645 Country of ref document: DE Date of ref document: 19850627 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19900731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19911120 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19911230 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19921130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19921130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930803 |