EP0053370B1 - Method to control a hydraulic mechanism, and hydraulic mechanism suited to carry out said method - Google Patents

Method to control a hydraulic mechanism, and hydraulic mechanism suited to carry out said method Download PDFInfo

- Publication number

- EP0053370B1 EP0053370B1 EP81109942A EP81109942A EP0053370B1 EP 0053370 B1 EP0053370 B1 EP 0053370B1 EP 81109942 A EP81109942 A EP 81109942A EP 81109942 A EP81109942 A EP 81109942A EP 0053370 B1 EP0053370 B1 EP 0053370B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- hydraulic

- pressure

- low

- pressure accumulator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims description 15

- 230000001133 acceleration Effects 0.000 claims description 13

- 239000012530 fluid Substances 0.000 claims description 6

- 230000007704 transition Effects 0.000 claims description 2

- 230000003467 diminishing effect Effects 0.000 claims 2

- 230000000694 effects Effects 0.000 claims 1

- 238000010586 diagram Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B11/00—Servomotor systems without provision for follow-up action; Circuits therefor

- F15B11/02—Systems essentially incorporating special features for controlling the speed or actuating force of an output member

- F15B11/04—Systems essentially incorporating special features for controlling the speed or actuating force of an output member for controlling the speed

- F15B11/046—Systems essentially incorporating special features for controlling the speed or actuating force of an output member for controlling the speed depending on the position of the working member

- F15B11/048—Systems essentially incorporating special features for controlling the speed or actuating force of an output member for controlling the speed depending on the position of the working member with deceleration control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/20—Fluid pressure source, e.g. accumulator or variable axial piston pump

- F15B2211/21—Systems with pressure sources other than pumps, e.g. with a pyrotechnical charge

- F15B2211/212—Systems with pressure sources other than pumps, e.g. with a pyrotechnical charge the pressure sources being accumulators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/30—Directional control

- F15B2211/305—Directional control characterised by the type of valves

- F15B2211/3056—Assemblies of multiple valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/30—Directional control

- F15B2211/315—Directional control characterised by the connections of the valve or valves in the circuit

- F15B2211/31523—Directional control characterised by the connections of the valve or valves in the circuit being connected to a pressure source and an output member

- F15B2211/31535—Directional control characterised by the connections of the valve or valves in the circuit being connected to a pressure source and an output member having multiple pressure sources and a single output member

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/30—Directional control

- F15B2211/32—Directional control characterised by the type of actuation

- F15B2211/327—Directional control characterised by the type of actuation electrically or electronically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/405—Flow control characterised by the type of flow control means or valve

- F15B2211/40576—Assemblies of multiple valves

- F15B2211/40584—Assemblies of multiple valves the flow control means arranged in parallel with a check valve

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/415—Flow control characterised by the connections of the flow control means in the circuit

- F15B2211/41581—Flow control characterised by the connections of the flow control means in the circuit being connected to an output member and a return line

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/42—Flow control characterised by the type of actuation

- F15B2211/426—Flow control characterised by the type of actuation electrically or electronically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/40—Flow control

- F15B2211/46—Control of flow in the return line, i.e. meter-out control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/60—Circuit components or control therefor

- F15B2211/625—Accumulators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/60—Circuit components or control therefor

- F15B2211/665—Methods of control using electronic components

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/60—Circuit components or control therefor

- F15B2211/665—Methods of control using electronic components

- F15B2211/6654—Flow rate control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F15—FLUID-PRESSURE ACTUATORS; HYDRAULICS OR PNEUMATICS IN GENERAL

- F15B—SYSTEMS ACTING BY MEANS OF FLUIDS IN GENERAL; FLUID-PRESSURE ACTUATORS, e.g. SERVOMOTORS; DETAILS OF FLUID-PRESSURE SYSTEMS, NOT OTHERWISE PROVIDED FOR

- F15B2211/00—Circuits for servomotor systems

- F15B2211/70—Output members, e.g. hydraulic motors or cylinders or control therefor

- F15B2211/755—Control of acceleration or deceleration of the output member

Definitions

- the invention relates to a method for controlling a hydraulic actuator with a hydraulic cylinder, a hydraulic piston, a high-pressure source and a low-pressure accumulator for the pressure medium and with lines opening into the hydraulic cylinder for connecting the cylinder space sections separated from the piston to the high-pressure source or the low-pressure accumulator which during a first phase of movement of the piston from its one end position to its other, the enlarging space section of the hydraulic cylinder is connected to the high pressure source to accelerate the piston, while the shrinking space section is connected to the low pressure accumulator, and during a second Movement phase of the piston, the enlarging cylinder chamber is connected to the low-pressure accumulator and a braking of the piston by an increase in pressure in the decreasing cylinder chamber section by interrupting the connection m it is caused by the low pressure accumulator.

- a control method of this type is known from DE-B-16 50 330.

- the speed of the piston during its movement from one end position to the other is essentially uniform and is determined or limited by the amount of pressure medium delivered or by two throttles, one of which is arranged in the pressure medium supply line and one in the pressure medium discharge line.

- the end position is braked by shutting off the unhindered pressure medium outflow from the reducing space shortly before the end of the piston movement.

- the present invention is based on the object of proposing a control method of the type mentioned at the outset, in which the pressure of the pressure medium becomes fully effective unhindered by throttles in order to achieve the fastest possible sequence of the actuating process.

- this object is achieved in that the deceleration phase immediately follows the acceleration phase, that the reversal takes place for the purpose of the transition from the acceleration phase to the deceleration phase at a time in which the piston has traveled about half its way and that for reversing the acceleration phase into the deceleration phase the pressure medium supply from the pressure medium source to the enlarging cylinder chamber section is blocked, and that during the deceleration phase pressure medium is displaced from the shrinking cylinder chamber section due to the inertia of the masses to be braked into a high-pressure accumulator.

- the pressure of the pressure medium is effective unhindered during the acceleration phase, so that an optimal acceleration of the piston with its actuating mass can be achieved.

- the deceleration phase begins, in that a connection is established between the space that is shrinking and the high-pressure source designed as a high-pressure accumulator.

- the pressure of the high-pressure accumulator is thus also used for braking, so that the acceleration force is equal to the deceleration force.

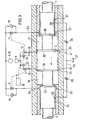

- the hydraulic cylinder is denoted by 1, the hydraulic piston displaceably arranged therein by 2 and the actuating mass connected by a piston rod 3 to the piston 2 by 4.

- 4 can e.g. B. the closure member of a slide or a valve.

- the left side of the cylinder 1 is connected to a high-pressure accumulator 6 via a valve 5 and to the low-pressure accumulator 8 via a valve 7.

- the valve 7 is bridged by a check valve 9, which is installed in such a way that the pressure of the accumulator 6 does not occur in the low-pressure accumulator 8.

- the right side of the cylinder 1 is connected to a further high-pressure accumulator 12 via a valve 11 and to the low-pressure accumulator 8 via the valve 13.

- the check valve bridging the valve 13 is designated by 14.

- the Valves 5, 7, 11 and 13 can be actuated automatically, with the aid of the control unit 15 shown as a block.

- the check valves 18 and 19 which can be opened in the direction of the respective high-pressure accumulators 6 and 12 intended.

- the movement of the piston 2 with the mass 4 from its left end position into its right end position takes place as follows: from the initially closed valves, the valve 5 to the high-pressure accumulator 6 and the valve 13 to the low-pressure accumulator 8 are opened at the time t o . This increases the pressure in the cylinder space 16 to the left of the piston 2, so that the piston 2 is accelerated with the mass 4 to the right.

- the hydraulic fluid located in the cylinder chamber 17 to the right of the piston 2 flows through the valve 13 into the low-pressure accumulator.

- the high-pressure accumulator 6 and the low-pressure accumulator 8 are separated from one another by the check valve 9.

- the piston 2 reaches its right-hand end position (shown in broken lines and denoted by 2 '). In a corresponding manner, the piston 2 can be moved from right to left.

- the valves 11 and 7 are first opened, whereby the acceleration phase begins.

- the delay phase is initiated by closing these two valves and opening valve 13.

- FIGS. 2a to 2c show a movement sequence in which the pressure reversal is carried out half way of the piston 2 or after half the time of the entire movement sequence. In such a case, the acceleration and deceleration values can be chosen to be the same. In practice, this means that the pressure in the accumulators 6 and 12 can be the same or only a high-pressure accumulator is required.

- control valves for reversing the pressures during the piston movement can lead to disadvantages if a control valve z. B. does not switch at the right time due to stiffness. This can be avoided if the oil flows control themselves depending on the path, as is shown, for example, in FIG. 3.

- the sections 20 and 21 of the piston rod 3 fastened on both sides to the piston 2 are designed as control pistons.

- the oil supply and discharge channels are formed by bores 31 and 32 in the cylinder jacket; they can be expanded on the cylinder inner wall to form ring channels or control grooves 22, 23, 24, 25. These control grooves correspond to chamfered control edges 27, 28, 29, 30 on the piston and on sections 20 and 21 of the piston rod.

- valves 11 and 13 are opened at the start by the control member; Valves 5 and 7 remain closed.

- the pressure oil flows from the high-pressure accumulator 6 via valve 11, line 32 into the annular channel 23 and further into the cylinder space 17.

- the oil to be displaced from the cylinder space 16 flows via the annular channel 24 into the line 31 and via the check valve 33 into the low-pressure accumulator 8

- the control edge 28 of the control piston 21 closes the ring channel 23; the high-pressure oil inflow is shut off.

- the control edge 30 of the piston 2 now opens the annular channel 25, which is connected to the low-pressure accumulator 8 via the already opened valve 13.

- the previous oil flow via ring channel 24 and check valve 33 into the low-pressure accumulator 8 is interrupted by the control edge 29 of the piston 2 and the ring channel 22 is opened by the control edge 27 of the control piston 20, so that the oil to be displaced via check valve 18 in the High-pressure accumulator 6 must be promoted.

- the desired deceleration pressure now prevails in the cylinder space 16, while only the pressure of the low-pressure accumulator 8 required for refilling acts in the annular space 17.

- a line system 26 with adjustable throttles 35 and 36 is provided, which in the amount of Control piston 20 and 21 opens and communicates with a storage tank 37.

- the position of the orifices 38 and 39 is selected so that they are only released by the associated control piston shortly before it reaches its one end position (the left control piston has its left end position and the right piston has its right end position).

- a small amount of oil is then discharged into the storage tank 37 via the line system 26 and via the associated throttle, as a result of which the piston safely reaches its end position.

- the check valves 33 and 34 bridging the valves 7 and 13 are arranged in the opposite direction to the check valves 9 and 13.

- the check valves in the object of FIG. 1 fulfill the task of keeping the low-pressure accumulator constantly separate from the high-pressure accumulator.

- this task is already fulfilled by the special position of the control edges and channels.

- the valves 7 and 13 could be omitted if oil to be refilled from the storage tank 37 were replaced. This is possible if the storage tank 37 is operated at atmospheric pressure and the control grooves 24, 25 are connected to the storage tank 37 (indicated by the lines 40 and 41 shown in broken lines).

- a certain refill pressure pressure of the low-pressure accumulator

- a suitable pressure in the high-pressure accumulator is 200 bar.

- the pressure in the low-pressure accumulator is expediently 20 bar.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fluid-Pressure Circuits (AREA)

Description

Die Erfindung bezieht sich auf ein Verfahren zur Steuerung eines hydraulischen Stellantriebs mit einem Hydraulikzylinder, einem Hydraulikkolben, einer Hochdruckquelle sowie einem Niederdruckspeicher für das Druckmittel und mit in den Hydraulikzylinder mündenden Leitungen zur Verbindung der vom Kolben getrennten Zylinderraumabschnitte mit der Hochdruckquelle bzw. dem Niederdruckspeicher, bei dem während einer ersten Phase der Bewegung des Kolbens von seiner einen Endlage in seine andere der sich vergrößernde Raumabschnitt des Hydraulikzylinders zur Beschleunigung des Kolbens an die Hochdruckquelle angeschlossen wird, während der sich verkleinernde Raumabschnitt mit dem Niederdruckspeicher in Verbindung steht, und bei dem während einer zweiten Bewegungsphase des Kolbens der sich vergrößernde Zylinderraum mit dem Niederdruckspeicher in Verbindung steht und eine Abbremsung des Kolbens durch einen Druckanstieg im sich verkleinernden Zylinderraumabschnitt durch Unterbrechung der Verbindung mit dem Niederdruckspeicher bewirkt wird.The invention relates to a method for controlling a hydraulic actuator with a hydraulic cylinder, a hydraulic piston, a high-pressure source and a low-pressure accumulator for the pressure medium and with lines opening into the hydraulic cylinder for connecting the cylinder space sections separated from the piston to the high-pressure source or the low-pressure accumulator which during a first phase of movement of the piston from its one end position to its other, the enlarging space section of the hydraulic cylinder is connected to the high pressure source to accelerate the piston, while the shrinking space section is connected to the low pressure accumulator, and during a second Movement phase of the piston, the enlarging cylinder chamber is connected to the low-pressure accumulator and a braking of the piston by an increase in pressure in the decreasing cylinder chamber section by interrupting the connection m it is caused by the low pressure accumulator.

Ein Steuerungsverfahren dieser Art ist aus der DE-B-16 50 330 bekannt. Die Geschwindigkeit des Kolbens während seiner Bewegung von seiner einen Endlage in die andere ist im wesentlichen gleichförmig und bestimmt bzw. begrenzt durch die Menge des geförderten Druckmittels bzw. durch zwei Drosseln, von denen je eine in der Druckmittelzuführungsleitung und Druckmittelabführungsleitung angeordnet sind. In der Endphase der Kolbenbewegung erfolgt eine Endlagenabbremsung, indem kurz vor dem Ende der Kolbenbewegung der ungehinderte Druckmittelabfluß aus dem sich verkleinernden Raum abgesperrt wird.A control method of this type is known from DE-B-16 50 330. The speed of the piston during its movement from one end position to the other is essentially uniform and is determined or limited by the amount of pressure medium delivered or by two throttles, one of which is arranged in the pressure medium supply line and one in the pressure medium discharge line. In the final phase of the piston movement, the end position is braked by shutting off the unhindered pressure medium outflow from the reducing space shortly before the end of the piston movement.

Der vorliegenden Erfindung liegt die Aufgabe zugrunde, ein Steuerungsverfahren der eingangs genannten Art vorzuschlagen, bei dem der Druck des Druckmittels ungehindert von Drosseln voll wirksam wird, um einen möglichst schnellen Ablauf des Stellvorganges zu erreichen.The present invention is based on the object of proposing a control method of the type mentioned at the outset, in which the pressure of the pressure medium becomes fully effective unhindered by throttles in order to achieve the fastest possible sequence of the actuating process.

Erfindungsgemäß wird diese Aufgabe dadurch gelöst, daß sich die Verzögerungsphase unmittelbar an die Beschleunigungsphase anschließt, daß die Umsteuerung zum Zwecke des Überganges von der Beschleunigungsphase in die Verzögerungsphase zu einem Zeitpunkt erfolgt, in dem der Kolben etwa seinen halben Weg zurückgelegt hat und daß zur Umsteuerung von der Beschleunigungsphase in die Verzögerungsphase die Druckmittelzufuhr von der Druckmittelquelle zum sich vergrößernden Zylinderraumabschnitt gesperrt wird, und daß während der Verzögerungsphase Druckmittel aus dem sich verkleinernden Zylinderraumabschnitt infolge der Trägheit der abzubremsenden Massen in einen Hochdruckspeicher verdrängt wird.According to the invention, this object is achieved in that the deceleration phase immediately follows the acceleration phase, that the reversal takes place for the purpose of the transition from the acceleration phase to the deceleration phase at a time in which the piston has traveled about half its way and that for reversing the acceleration phase into the deceleration phase the pressure medium supply from the pressure medium source to the enlarging cylinder chamber section is blocked, and that during the deceleration phase pressure medium is displaced from the shrinking cylinder chamber section due to the inertia of the masses to be braked into a high-pressure accumulator.

Bei einem insbesondere zur Verstellung großer Massen geeigneten Steuerungsverfahren dieser Art ist während der Beschleunigungsphase der Druck des Druckmittels ungehindert wirksam, so daß eine optimale Beschleunigung des Kolbens mit seiner Stellmasse erreicht werden kann. Unmittelbar nach der Beschleunigungsphase beginnt bereits die Verzögerungsphase, indem zwischen dem sich verkleinernden Raum und der als Hochdruckspeicher ausgebildeten Hochdruckquelle eine Verbindung hergestellt wird. Damit wird der Druck des Hochdruckspeichers auch für die Abbremsung eingesetzt, so daß die Beschleunigungskraft gleich der Verzögerungskraft ist. Ein besonderer Vörteil ist darin zu sehen, daß infolge des Einsatzes des Druckmediums auch zur Verzögerung der zu verstellenden Masse der größte Teil der zur Beschleunigung der Masse aufgewendeten Energie zurückgewonnen werden kann. Selbst bei schweren und schnell zu verstellenden Massen ist deshalb der Energieverbrauch gering.In a control method of this type, which is particularly suitable for adjusting large masses, the pressure of the pressure medium is effective unhindered during the acceleration phase, so that an optimal acceleration of the piston with its actuating mass can be achieved. Immediately after the acceleration phase, the deceleration phase begins, in that a connection is established between the space that is shrinking and the high-pressure source designed as a high-pressure accumulator. The pressure of the high-pressure accumulator is thus also used for braking, so that the acceleration force is equal to the deceleration force. A particular advantage can be seen in the fact that, as a result of the use of the pressure medium, the majority of the energy expended to accelerate the mass can also be recovered in order to delay the mass to be adjusted. Therefore, even with heavy and quickly adjustable masses, the energy consumption is low.

Der Ablauf des Stellvorganges kann dadurch beschleunigt und in seiner Wirkungsweise besonders günstig, störungssicher und zeitgenau ausgeführt werden, daß die Umsteuerung selbsttätig abläuft und das Umsteuerungsorgan durch den Kolben selbst gebildet wird. Wegaufnehmer zur Erfassung von Positionen und z. B. dadurch betätigte Magnetventile mit unvermeidlichen Totzeiten können dann entfallen.The course of the actuating process can be accelerated and its mode of operation can be carried out particularly cheaply, reliably and in a timely manner in that the reversal takes place automatically and the reversing element is formed by the piston itself. Position transducer for the detection of positions and z. B. actuated solenoid valves with inevitable dead times can then be omitted.

Weitere Vorteile und Einzelheiten der Erfindung sollen anhand der Figuren 1 bis 4 erläutert werden. Es zeigen:

Figur 1 eine schematische Darstellung, anhand der das Prinzip erläutert wird,- Figuren 2a bis c Diagramme über Bewegungsabläufe, die mit Hilfe des erfindungsgemäßen Verfahrens bewirkt werden können, und

Figur 3 ein spezielles Ausführungsbeispiel für einen für die Durchführung des erfindungsgemäßen Steuerungsverfahrens geeigneten hydraulischen Antrieb.

- FIG. 1 shows a schematic illustration, on the basis of which the principle is explained,

- Figures 2a to c diagrams of motion sequences that can be effected with the help of the method according to the invention, and

- Figure 3 shows a special embodiment for a hydraulic drive suitable for performing the control method according to the invention.

Bei der Prinzip-Darstellung nach Figur 1 sind der Hydraulikzylinder mit 1, der darin verschiebbar angeordnete Hydraulikkolben mit 2 und die über eine Kolbenstange 3 mit dem Kolben 2 verbundene Stellmasse mit 4 bezeichnet. 4 kann z. B. das Verschlußglied eines Schiebers oder eines Ventiles sein. Die linke Seite des Zylinders 1 ist über ein Ventil 5 mit einem Hochdruckspeicher 6 und über ein Ventil 7 mit dem Niederdruckspeicher 8 verbunden. Das Ventil 7 ist mittels eines Rückschlagventils 9 überbrückt, das derart eingebaut ist, daß der Druck des Speichers 6 nicht im Niederdruckspeicher 8 auftritt.In the basic illustration according to FIG. 1, the hydraulic cylinder is denoted by 1, the hydraulic piston displaceably arranged therein by 2 and the actuating mass connected by a

In entsprechender Weise ist die rechte Seite des Zylinders 1 über ein Ventil 11 mit einem weiteren Hochdruckspeicher 12 und über das Ventil 13 mit dem Niederdruckspeicher 8 verbunden. Das das Ventil 13 überbrückende Rückschlagventil ist mit 14 bezeichnet. Die Ventile 5, 7, 11 und 13 sind automatisch betätigbar, und zwar mit Hilfe des als Block dargestellten Steuergerätes 15. Parallel zu den Ventilen 5 und 11 sind schließlich noch die in Richtung zu den jeweiligen Hochdruckspeichern 6 bzw. 12 zu öffnenden Rückschlagventile 18 und 19 vorgesehen.In a corresponding manner, the right side of the

Die Bewegung des Kolbens 2 mit der Masse 4 aus seiner linken Endlage in seine rechte Endlage geschieht folgendermaßen: Von den zunächst geschlossenen Ventilen werden zur Zeit to das Ventil 5 zum Hochdruckspeicher 6 und das Ventil 13 zum Niederdruckspeicher 8 geöffnet. Dadurch erhöht sich der Druck im links vom Kolben 2 gelegenen Zylinderraum 16, so daß der Kolben 2 mit der Masse 4 nach rechts beschleunigt wird. Die im rechts vom Kolben 2 gelegenen Zylinderraum 17 befindliche Hydraulikflüssigkeit strömt über das Ventil 13 in den Niederdruckspeicher ab. Durch das Rückschlagventil 9 sind der Hochdruckspeicher 6 und der Niederdruckspeicher 8 voneinander getrennt. Während der Bewegung des Kolbens 2 mit der Masse 4 von links nach rechts wird zum Zeitpunkt t1 eine Umsteuerung des Druckes vorgenommen, und zwar derart, daß die Beschleunigungsphase beendet und die Verzögerungsphase begonnen wird. Dazu werden zum Zeitpunkt t1 die Ventile 5 und 13 geschlossen. Der Zylinderteilraum 16 wird dadurch druckentlastet. Das infolge der Weiterbewegung des Kolbens 2 im Raum 17 verdrängte Ölvolumen fließt über das Rückschlagventil 19 in den Hochdruckspeicher 12. Der dadurch erzeugte Hochdruck im Zylinderraum 17 bewirkt die gewünschte Verzögerung des Kolbens 2 mit der Masse 4. Infolge des Rückschlagventils 9 ist sichergestellt, daß im Teilraum 16 keine störenden Kavitationen auftreten. Über das Rückschlagventil 9 füllt sich der Teilraum 16 mit Hydraulikflüssigkeit aus dem Niederdruckspeicher 8. Zum Zeitpunkt t2 gelangt der Kolben 2 in seine rechte Endlage (gestrichelt dargestellt und mit 2' bezeichnet). In entsprechender Weise kann eine Bewegung des Kolbens 2 von rechts nach links bewirkt werden. Dazu werden zunächst die Ventile 11 und 7 geöffnet, wodurch die Beschleunigungsphase beginnt. Durch Schließen dieser beiden Ventile und Öffnung des Ventils 13 wird die Verzögerungsphase eingeleitet. In den Diagrammen nach den Figuren 2a bis 2c ist ein Bewegungsablauf dargestellt, bei dem die Druckumsteuerung auf halbem Weg des Kolbens 2 bzw. nach der halben Zeit des gesamten Bewegungsablaufs vorgenommen wird. In einem solchen Fall können Beschleunigungs- und Verzögerungswert gleich gewählt werden. Für die Praxis bedeutet das, daß der Druck in den Speichern 6 und 12 gleich sein kann oder nur ein Hochdruckspeicher erforderlich ist. Geschwindigkeit und Weg s in Abhängigkeit von der Zeit sind für einen solchen Fall in Figur 2b und Figur 2c dargestellt. Der Vorteil eines in dieser Weise ablaufenden Stellvorganges liegt darin, daß - wegen der Symmetrie der Kurven - die Bewegungen in beiden Richtungen gleichförmig ablaufen. Voraussetzung für einen gleichförmig ablaufenden Bewegungsvorgang sind noch gleich große Wirkflächen. Beim Gegenstand der Figur 1 kann das z. B. dadurch erreicht werden, daß der Kolben 2 auch auf seiner rechten Seite mit einer Kolbenstange ausgerüstet ist.The movement of the

Die Betätigung von Steuerventilen zur Umsteuerung der Drücke während der Kolbenbewegung kann zu Nachteilen führen, wenn ein Steuerventil z. B. durch Schwergängigkeit nicht im richtigen Zeitpunkt schaltet. Dies läßt sich vermeiden, wenn die Ölströme sich wegeabhängig selbst steuern, wie dies beispielsweise in Figur 3 gezeigt wird. Bei diesem Ausführungsbeispiel sind die Abschnitte 20 und 21 der beidseitig am Kolben 2 befestigten Kolbenstange 3 als Steuerkolben ausgebildet.The actuation of control valves for reversing the pressures during the piston movement can lead to disadvantages if a control valve z. B. does not switch at the right time due to stiffness. This can be avoided if the oil flows control themselves depending on the path, as is shown, for example, in FIG. 3. In this exemplary embodiment, the

Die Öl-Zu- und -Abfuhrkanäle werden durch Bohrungen 31 und 32 im Zylindermantel gebildet; sie können an der Zylinderinnenwand zu Ringkanälen bzw. Steuernuten 22, 23, 24, 25 erweitert sein. Diese Steuernuten korrespondieren mit abgeschrägten Steuerkanten 27, 28, 29, 30 am Kolben und an den Abschnitten 20 und 21 der Kolbenstange.The oil supply and discharge channels are formed by

Soll beispielsweise der (in seiner Mittelstellung dargestellte) Kolben 2 in der gezeichneten Pfeilrichtung von seiner rechten Endstellung nach links laufen, so werden zum Start vom Steuerorgan 15 Ventil 11 und 13 geöffnet; Ventile 5 und 7 bleiben geschlossen. Aus dem Hochdruckspeicher 6 fließt das Drucköl über Ventil 11, Leitung 32 in den Ringkanal 23 und weiter in den Zylinderraum 17. Das aus dem Zylinderraum 16 zu verdrängende Öl fließt über den Ringkanal 24 in die Leitung 31 und über das Rückschlagventil 33 in den Niederdruckspeicher 8. Im (dargestellten) Umsteuerzeitpunkt schließt die Steuerkante 28 des Steuerkolbens 21 den Ringkanal 23; damit ist der Hochdruckölzufluß abgesperrt. Zum Nachfüllen des Zylinderraums 17 öffnet nun die Steuerkante 30 des Kolbens 2 den Ringkanal 25, der über das schon geöffnete Ventil 13 mit dem Niederdruckspeicher 8 in Verbindung steht. Im Zylinderraum 16 wird gleichzeitig durch die Steuerkante 29 des Kolbens 2 der bisherige Ölabfluß über Ringkanal 24 und Rückschlagventil 33 in den Niederdruckspeicher 8 unterbrochen und durch die Steuerkante 27 des Steuerkolbens 20 der Ringkanal 22 geöffnet, so daß das zu verdrängende Öl über Rückschlagventil 18 in den Hochdruckspeicher 6 gefördert werden muß. Nunmehr herrscht im Zylinderraum 16 der gewünschte Verzögerungsdruck, während im Ringraum 17 nur der zum Nachfüllen nötige Druck des Niederdruckspeichers 8 wirkt.If, for example, the piston 2 (shown in its central position) is to run from its right end position to the left in the direction of the arrow, 15

Gegen Hubende kann die zu verzögernde Energie so weit aufgebraucht sein, daß das Rückschlagventil 18 nicht mehr überwunden werden kann. Zu diesem Zweck ist ein Leitungssystem 26 mit einstellbaren Drosseln 35 und 36 vorgesehen, das in Höhe der Steuerkolben 20 und 21 mündet und mit einem Speichertank 37 in Verbindung steht. Die Lage der Mündungen 38 und 39 ist so gewählt, daß sie vom zugehörigen Steuerkolben nur dann freigegeben werden, kurz bevor dieser seine eine Endstellung (der linke Steuerkolben seine linke Endstellung und der rechte Kolben seine rechte Endstellung) erreicht. In der jeweiligen Endphase der Bewegungen des Steuerkolbens wird dann eine geringe Ölmenge über das Leitungssystem 26 und über die jeweils zugehörige Drossel in den Speichertank 37 abgeführt, wodurch der Kolben seine Endlage sicher erreicht.Towards the end of the stroke, the energy to be decelerated can be used up to such an extent that the

Gegenüber dem Ausführungsbeispiel nach Figur 1 sind beim Ausführungsbeispiel nach Figur 3 die die Ventile 7 und 13 überbrückenden Rückschlagventile 33 und 34 in umgekehrter Richtung als die Rückschlagventile 9 und 13 angeordnet. Der Grund dafür liegt darin, daß die Rückschlagventile beim Gegenstand der Figur 1 die Aufgabe erfüllen, den Niederdruckspeicher vom Hochdruckspeicher ständig getrennt zu halten. Beim Gegenstan der Figur 3 ist diese Aufgabe bereits durch die besondere Lage der Steuerkanten und -kanäle erfüllt. Die Ventile 7 und 13 könnten entfallen, wenn nachzufüllendes Öl aus dem Speichertank 37 ersetzt würde. Das ist möglich, wenn der Speichertank 37 bei Atmosphärendruck betrieben wird und die Steuernuten 24, 25 mit dem Speichertank 37 in Verbindung stehen (angedeutet durch die gestrichelt dargestellten Leitungen 40 und 41). Die Kolbenbewegung ist dann allerdings nicht optimal schnell. Für schnellere Bewegungen des Kolbens und auch zum Zweck des sicheren Erreichens der Endlage des Kolbens ist ein bestimmter Nachfülldruck (Druck des Niederdruckspeichers) erforderlich. Ein zweckmäßiger Druck im Hochdruckspeicher ist 200 bar. Bei schnellen Bewegungen ist der Druck im Niederdruckspeicher zweckmäßigerweise 20 bar.Compared to the exemplary embodiment according to FIG. 1, in the exemplary embodiment according to FIG. 3, the

Claims (8)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3044675 | 1980-11-27 | ||

| DE19803044675 DE3044675A1 (en) | 1980-11-27 | 1980-11-27 | METHOD FOR CONTROLLING A HYDRAULIC DRIVE AND HYDRAULIC DRIVE SUITABLE FOR CARRYING OUT THIS CONTROL METHOD |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0053370A2 EP0053370A2 (en) | 1982-06-09 |

| EP0053370A3 EP0053370A3 (en) | 1983-05-04 |

| EP0053370B1 true EP0053370B1 (en) | 1986-10-15 |

Family

ID=6117710

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81109942A Expired EP0053370B1 (en) | 1980-11-27 | 1981-11-27 | Method to control a hydraulic mechanism, and hydraulic mechanism suited to carry out said method |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0053370B1 (en) |

| DE (1) | DE3044675A1 (en) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3206162A1 (en) * | 1982-02-20 | 1983-09-01 | Hartmann & Lämmle GmbH & Co KG, 7255 Rutesheim | DRIVE FOR A MOVABLE DIMENSION BY MEANS OF A HYDROMOTOR |

| SE437861B (en) * | 1983-02-03 | 1985-03-18 | Goran Palmers | DEVICE FOR MEDIUM HYDRAULIC CYLINDER OPERATED MACHINERY WITH ONE OF A DRIVE CELL THROUGH AN ENERGY CUMULATOR DRIVE PUMP |

| DE3583147D1 (en) * | 1985-12-13 | 1991-07-11 | Schenck Ag Carl | METHOD AND DEVICE FOR GENERATING IMPACTING LOADS ON A TESTING PART. |

| DE4439667C2 (en) * | 1994-11-07 | 1998-07-02 | Festo Ag & Co | Working cylinder |

| DE102014212129A1 (en) * | 2014-06-25 | 2015-12-31 | Robert Bosch Gmbh | Hydraulic arrangement |

| KR102092481B1 (en) * | 2018-12-19 | 2020-04-20 | 주식회사 두산 | Reversing prevention valve for a construction vehicle |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1650330B2 (en) * | 1966-11-30 | 1978-07-06 | The Cessna Aircraft Co., Wichita, Kan. (V.St.A.) | Device for braking a double-acting hydraulic actuator at the end of the stroke |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1263514B (en) * | 1961-07-27 | 1968-03-14 | Siemens Ag | Hydraulic drive |

| FR1563208A (en) * | 1968-03-01 | 1969-04-11 | ||

| CH473319A (en) * | 1968-06-19 | 1969-05-31 | Hydrel Ag Maschf | Fully hydraulic device on the machine or apparatus with a straight back and forth moving part, for largely load and speed independent reversal of the accuracy of the movement of the part between two adjustable reversing points |

| US3563273A (en) * | 1968-10-28 | 1971-02-16 | Carl R Mills | Actuator valve |

| FR2129156A5 (en) * | 1971-03-17 | 1972-10-27 | Citroen Sa | |

| DE2245129A1 (en) * | 1972-09-14 | 1974-03-21 | Bosch Gmbh Robert | WORK CYLINDER |

| NL7214004A (en) * | 1972-10-17 | 1974-04-19 | ||

| CH568495A5 (en) * | 1974-03-11 | 1975-10-31 | Haeny & Cie Ag | |

| NL182162C (en) * | 1977-01-10 | 1988-01-18 | Hydraudyne Bv | DEVICE FOR HYDRAULIC OR PNEUMATIC DRIVING AND BRAKING OF A TOOL. |

| DE2821489C3 (en) * | 1978-05-17 | 1981-03-19 | Danfoss A/S, 6430 Nordborg | Valve arrangement with two valve parts sliding one on top of the other |

| GB2035464B (en) * | 1978-11-28 | 1982-12-15 | Dartec Ltd | Actuator protection assemblies |

| DE2851478A1 (en) * | 1978-11-28 | 1980-06-04 | Mts Systems Gmbh | Quick-action HV switching mechanism - has two energy stores connected via holes to chamber containing drive piston |

-

1980

- 1980-11-27 DE DE19803044675 patent/DE3044675A1/en not_active Withdrawn

-

1981

- 1981-11-27 EP EP81109942A patent/EP0053370B1/en not_active Expired

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1650330B2 (en) * | 1966-11-30 | 1978-07-06 | The Cessna Aircraft Co., Wichita, Kan. (V.St.A.) | Device for braking a double-acting hydraulic actuator at the end of the stroke |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0053370A3 (en) | 1983-05-04 |

| EP0053370A2 (en) | 1982-06-09 |

| DE3044675A1 (en) | 1982-07-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3323363C2 (en) | ||

| DE112005002529B4 (en) | Hydraulically operated casting unit | |

| EP2644903B1 (en) | Method and hydraulic control device for controlling a consumer | |

| DE2516810B2 (en) | Impact device operated with hydraulic fluid | |

| DE19734966B4 (en) | hydraulic hammer | |

| DE2512480B2 (en) | Valve device for a hydraulically operated electrical circuit breaker | |

| DE2102591A1 (en) | Hydraulic pump | |

| EP0053370B1 (en) | Method to control a hydraulic mechanism, and hydraulic mechanism suited to carry out said method | |

| DE3818068A1 (en) | SPEED REDUCER FOR PNEUMATIC DRIVES | |

| DE2649775A1 (en) | Servo assisted fluid spool valve - has control piston movable against spring and contg. servo piston assisting spring movement | |

| DE3341641C2 (en) | ||

| DE2003584A1 (en) | Device for pressure medium distribution | |

| DE112005002551B4 (en) | Hydraulically operated casting unit | |

| DE2647372A1 (en) | DEVICE FOR A LOAD MOVING HYDRAULIC MOTOR TO PREVENT UNCONTROLLED LOAD MOVEMENT IN THE EVENT OF A PIPE BREAKAGE | |

| DE624868C (en) | Device for achieving a controllable downtime of hydraulically moving tool parts, in particular grinding machine parts, when reversing | |

| DE2647140A1 (en) | Non-reversing hydraulic valve system - has slider with two pistons for load control and has return line | |

| DE69420713T2 (en) | DEVICE DRIVEN BY PRESSURE MEANS A LINEAR MOVEMENT | |

| DE873209C (en) | Equipment for pressurized systems | |

| DE3016929C2 (en) | ||

| EP3447313A1 (en) | Fluid-powered actuator with an intermediate position and method for actuating such an actuator | |

| DE2524949C3 (en) | Hydraulic pile hammer | |

| DE549480C (en) | Hydraulic drive for work tools, especially machine tools with long strokes and high speeds of the moving part | |

| DE856393C (en) | Piston slide control for central lubrication systems | |

| EP0152937B1 (en) | Hydraulic drive element for weaving shuttles | |

| DE1675438B1 (en) | Pilot operated valve with short switching time |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19811208 |

|

| AK | Designated contracting states |

Designated state(s): CH FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): CH FR GB IT LI |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH FR GB IT LI |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19881127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19881130 Ref country code: CH Effective date: 19881130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19890731 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| ITTA | It: last paid annual fee |