EP0020246B1 - Vorrichtung zum Kühlen langer laminierter Wärmwalzprodukte - Google Patents

Vorrichtung zum Kühlen langer laminierter Wärmwalzprodukte Download PDFInfo

- Publication number

- EP0020246B1 EP0020246B1 EP19800400715 EP80400715A EP0020246B1 EP 0020246 B1 EP0020246 B1 EP 0020246B1 EP 19800400715 EP19800400715 EP 19800400715 EP 80400715 A EP80400715 A EP 80400715A EP 0020246 B1 EP0020246 B1 EP 0020246B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- water

- tube

- product

- cooling

- outer part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000001816 cooling Methods 0.000 title claims description 27

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 31

- 238000011144 upstream manufacturing Methods 0.000 claims description 16

- 238000002347 injection Methods 0.000 claims description 14

- 239000007924 injection Substances 0.000 claims description 14

- 239000000498 cooling water Substances 0.000 description 5

- 238000009434 installation Methods 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 230000003313 weakening effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C21D9/54—Furnaces for treating strips or wire

- C21D9/56—Continuous furnaces for strip or wire

- C21D9/573—Continuous furnaces for strip or wire with cooling

- C21D9/5732—Continuous furnaces for strip or wire with cooling of wires; of rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/02—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for lubricating, cooling, or cleaning

- B21B45/0203—Cooling

- B21B45/0209—Cooling devices, e.g. using gaseous coolants

- B21B45/0215—Cooling devices, e.g. using gaseous coolants using liquid coolants, e.g. for sections, for tubes

- B21B45/0224—Cooling devices, e.g. using gaseous coolants using liquid coolants, e.g. for sections, for tubes for wire, rods, rounds, bars

Definitions

- the invention relates to the field of heat treatments of rolled products and relates more particularly to a device for cooling long products in movement, in particular bars and concrete bars.

- Such devices generally consist of a tube inside which the product and the coolant circulate, and the two ends of which are respectively equipped with a water supply, or injection head, and with a separator allowing avoid cooling water being entrained with the product at the outlet of the tube (FR-A-1584095).

- a water supply, or injection head and with a separator allowing avoid cooling water being entrained with the product at the outlet of the tube (FR-A-1584095).

- the product to be cooled is also driven at a high speed, the circulation of water is usually carried out in co-current, with the passage of the product, in order to avoid entrainment of water by the latter, quickly leading to stagnation of the liquid and therefore a deterioration of the heat exchanges by the formation of a vapor film.

- This phenomenon is particularly marked with concrete bars because of their high running speed and the fact that they are generally crenellated.

- the efficiency of the heat exchanges is less good than in that of a counter-current circulation and that it is therefore necessary to longer tube length or higher water flow for the same cooling.

- These known supply tubes generally consist of two coaxial tubular parts with conical fitting each comprising a central passage for the product in movement and delimiting between them an annular chamber for introducing the water, extended by a slot also annular formed between two frustoconical bearing surfaces provided respectively on the inner and outer tubular pieces, this slot being adjustable by axial sliding of the inner tubular piece, forming a socket, in the main body constituted by the outer tubular piece.

- supply heads of this type the movable sleeve of which is floating, therefore remote and independent of the cooling tube, do not appear to be able to be retained for cooling devices using a sheet of water in which any discontinuity in the passage of water would go against the establishment of a laminar flow at high speed.

- the flat cam mechanism mounted at the top of a rotary control axis perpendicular to the displacement of the sleeve may be suitable when the sleeve is floating.

- such a solution is hardly suitable for a device according to the invention in which the sleeve is integral with the cooling tube of which it constitutes the terminal part, since the control axis would work in torsion under a very high torque for manage to set in motion the socket-tube assembly which can reach several meters in length, or even beyond.

- the object of the present invention is to provide improvements to the aforementioned cooling devices, in order to improve their performance as well as to facilitate, in the supply head, the sliding of the internal tubular part for adjusting the slot, when this part constitutes the end part of one of the two cooling tubes.

- the subject of the invention is a device for cooling long rolled products in movement comprising a water injection head interposed between two aligned cooling tubes traversed by a blade of water and through which said product travels.

- device according to which the injection head, ensuring the sealed connection between these two tubes at one of their ends consists of two coaxial tubular pieces with conical interlocking each comprising a central passage for the product in movement and delimiting between them an annular water introduction chamber extended by an annular slot formed between two frustoconical bearing surfaces of the two tubular parts, respectively male and female and provided respectively on the inner tubular part and in the outer tubular part, said slot being adjustable in length and width by axial sliding of the internal part in the external part, and in which, relative in the given direction of travel of the product to be cooled, the outer part provided with the tapered female seat is connected to the downstream tube, the inner piece provided with the tapered male seat being connected to the upstream tube so as to ensure, on the one hand, a main water flow in the downstream tube

- the depth of engagement of the interior part in the exterior part and defining the length and the width of the slot is adjusted by interposing thickness shims between the annular crown of the part inner and the corresponding shoulder of the outer part.

- the device according to the invention may furthermore include means for separating the moving product and the water layer arranged at the free end of each of two tubes.

- the device according to the invention comprises the features according to claim 4.

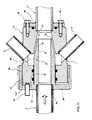

- FIG 1 we can see at 1 the injection head, at 2 the downstream cooling tube, tightly connected to the latter and at the free end of which is disposed a separator 3.

- the upstream cooling tube 4 also comprises a separator 5 arranged at its free end, the other end being connected in leaktight manner to the injection head 1.

- the cooling water enters the injection head 1 through the supply lines 6. Three of them are visible in this figure, but the supply could be carried out using a single line, or four or six, etc ... to ensure a better distribution, the arrivals can be balanced or voluntarily unbalanced to give the water a helical movement.

- the water separates into two streams in opposite directions: a main stream downstream, a secondary stream with a lower flow rate, which is usually set at around 10-20% of the main flow, upstream.

- the downstream current passes through the downstream tube at high speed and arrives in the separator 3 which ensures its evacuation.

- This separator 3 is identical to that described in FR-A-4 455 499 which will be referred to for more details, if necessary. It is essentially constituted by a box comprising two opposite lateral openings in the extension of the tube 2 through which the product surrounded and its liquid envelope and the dried product arrive and exit respectively.

- a water inlet 7 makes it possible to produce in the box a jet perpendicular to the downstream current, so as to cause its shearing. The latter is facilitated by weakening of the current using deflectors arranged in the box. The water is discharged through the collector 8.

- the upstream current passes through the tube 4, then is separated from the product and evacuated by means of the separator 5 and the collector 10.

- the separator 5 is identical to the separator 3, although of smaller dimensions, but the product enters there through the upstream orifice and leaves it through the downstream orifice to engage in the tube 4.

- the latter are provided with one or more centering devices 11, only one of which has been shown on the downstream tube in order to do not overload the figure unnecessarily.

- These devices are identical to those described in FR-A-2 446 861 to which reference will be made if necessary. They essentially consist of a tubular element, coaxial with the cooling tube and of smaller internal diameter, having peripheral channels formed in its thickness.

- the injection head 1 essentially consists of two coaxial parts 12 and 13 fitted one inside the other and cooperating together to ensure the circulation and the adjustment of the cooling water flow rates.

- the part or socket 12 is pierced with a central cylindrical channel 14 for the passage of the product and the cooling water, and has an internal diameter slightly smaller than the internal diameter of the cooling tube 4, so as to be connected to the latter, at its upstream end, forming a funnel.

- Its opposite end has a frustoconical bearing 15 to which corresponds a frustoconical recess 16 of the body 13, of substantially equal taper.

- the frustoconical recess 16 is extended downstream by a cylindrical duct 17, of the same internal diameter as that of the cooling tube 2 and secured to the latter by means of a flange 18 fixed to the body 13 by the screws 19. Upstream, the recess 16 is extended by an annular recess 33 inside which open the conduits 6 for introducing the cooling water.

- the frustoconical bearing surface 15 of the frustoconical sleeve 12 is extended, upstream, by a bearing surface 21 which cooperates with a corresponding bearing surface 22 of the body 13 to ensure the longitudinal sliding of the sleeve 12 in the body 13.

- the bearing surfaces 15 and 21 according to the relative position of the parts 12 and 13, define with the annular recess 33 a chamber 20 for introducing water, opening downstream in an equally annular slot 23 delimited by the bearing surfaces 15 and 16. This slot communicates at its other end with the circular channels 14 and 17.

- the flow rate of the downstream current is determined by the pressure drop between the introduction chamber 20 and the downstream end of the tube 2 which is at atmospheric pressure. Only the water "in excess” compared to the flow rate thus determined, goes upstream, therefore towards the cooling tube 4.

- This pressure drop can be varied by increasing or decreasing the internal diameter of the tube 2, but this requires significant modifications to the installation. It is therefore preferable to keep this diameter constant and to act upstream of the tube.

- the depth of engagement of the frustoconical sleeve 12 inside the body 13 is adjusted by means of shims such as 24, of different thicknesses, interposed between the internal wall of an annular ring 25, adjacent to the bearing 21, provided on the sleeve 12 and a corresponding shoulder 26 of the body 13.

- the assembly is held in position by tightening by means of an external flange 27 fixed to the body 13 by the screws 28. O-rings are provided wherever necessary to seal the assembly.

- This embodiment is of very simple design, but it has the disadvantage of requiring disassembly and a change of shim each time that one wants to modify the dimensions of the slot.

- the tube 4 consists of two parts fitted one inside the other, a short length portion 34 secured to the frustoconical sleeve 16 and able to slide inside the rest of the tube, so as to be able to make vary the dimensions of the slot by acting only on the frustoconical sleeve 12, without affecting the rest of the installation.

- the invention is not limited in its scope to the examples described, in particular as regards the adjustment means and the means for maintaining the relative position of the frustoconical sleeve relative to the body. It is of general application to any long product running, but is particularly advantageous for concrete bars and rods whose final metallographic structure must be well controlled to give them the desired mechanical characteristics.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Heat Treatment Of Articles (AREA)

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR7914383A FR2457724A1 (fr) | 1979-06-01 | 1979-06-01 | Dispositif de refroidissement de produits longs lamines en defilement |

| FR7914383 | 1979-06-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0020246A1 EP0020246A1 (de) | 1980-12-10 |

| EP0020246B1 true EP0020246B1 (de) | 1985-02-13 |

Family

ID=9226250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19800400715 Expired EP0020246B1 (de) | 1979-06-01 | 1980-05-21 | Vorrichtung zum Kühlen langer laminierter Wärmwalzprodukte |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0020246B1 (de) |

| DE (1) | DE3070144D1 (de) |

| FR (1) | FR2457724A1 (de) |

| MY (1) | MY8600748A (de) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2522688B1 (fr) * | 1982-03-03 | 1990-09-14 | Siderurgie Fse Inst Rech | Procede et installation de traitement thermique de barres en acier allie pretes a l'emploi, notamment pour la construction mecanique |

| DD239805B1 (de) * | 1985-07-29 | 1988-06-22 | Thaelmann Schwermaschbau Veb | Verfahren zur herstellung eines betonstahles |

| US5329779A (en) * | 1993-02-09 | 1994-07-19 | C.V.G. Siderurgica Del Orinoco, C.A. | Method and apparatus for cooling workpieces |

| CN104088910B (zh) * | 2014-07-15 | 2016-08-24 | 中冶南方(武汉)威仕工业炉有限公司 | 冷轧退火炉炉辊轴承用组合密封装置 |

| CN109237046A (zh) * | 2018-11-01 | 2019-01-18 | 江铜华北(天津)铜业有限公司 | 一种铜线生产线冷却箱用密封结构 |

| CN115076249B (zh) * | 2022-07-18 | 2023-06-20 | 安徽百通达科技医疗用品有限公司 | 一种耐用型联轴器 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1051511A (de) * | 1964-01-13 | 1966-12-14 | ||

| US3395560A (en) * | 1964-06-15 | 1968-08-06 | Southwire Co | Apparatus for and process of coiling rods |

| BE672269A (de) * | 1964-11-12 | 1900-01-01 | ||

| DE1925416C3 (de) * | 1968-03-12 | 1979-08-02 | Walter 4330 Muelheim Krenn | Kühlstrecke für Walzdraht oder Stabmaterial |

| GB1226416A (de) * | 1968-07-10 | 1971-03-31 | ||

| DD110774A1 (de) * | 1974-04-10 | 1975-01-12 | ||

| US3991986A (en) * | 1975-01-27 | 1976-11-16 | Southwire Company | Fluid quench housing assembly with external flow adjustment |

| JPS5329212A (en) * | 1976-08-31 | 1978-03-18 | Showa Electric Wire & Cable Co Ltd | Cooling pipe for wire rod |

| FR2445499B1 (de) * | 1978-12-26 | 1983-11-10 | Siderurgie Fse Inst Rech | |

| FR2446861A1 (fr) * | 1979-01-19 | 1980-08-14 | Siderurgie Fse Inst Rech | Dispositif pour refroidir un produit long en defilement |

-

1979

- 1979-06-01 FR FR7914383A patent/FR2457724A1/fr active Granted

-

1980

- 1980-05-21 EP EP19800400715 patent/EP0020246B1/de not_active Expired

- 1980-05-21 DE DE8080400715T patent/DE3070144D1/de not_active Expired

-

1986

- 1986-12-30 MY MY8600748A patent/MY8600748A/xx unknown

Also Published As

| Publication number | Publication date |

|---|---|

| EP0020246A1 (de) | 1980-12-10 |

| MY8600748A (en) | 1986-12-31 |

| DE3070144D1 (en) | 1985-03-28 |

| FR2457724B1 (de) | 1983-05-13 |

| FR2457724A1 (fr) | 1980-12-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA1256822A (fr) | Dispositif de conditionnement de l'eau contenant ou carbonate de calcium et installation realisee avec ce dispositif | |

| EP0481869B1 (de) | Düse für Oberflächenbehandlung durch einen Laser mit Pulverzufuhr | |

| FR2467067A1 (fr) | Dispositif pour la fabrication de corps a structure alveolaire par extrusion d'une matiere ceramique, et procede d'obtention dudit dispositif | |

| FR2726964A1 (fr) | Buse pour tete de bruleur d'un appareil de pulverisation de plasma | |

| FR2550469A1 (fr) | Injecteur de microbulles | |

| EP1817955A1 (de) | Anlage und Verfahren zur Herstellung von Röhren zur tropfenweisen Bewässerung | |

| EP0020246B1 (de) | Vorrichtung zum Kühlen langer laminierter Wärmwalzprodukte | |

| CA1290529C (fr) | Appareillage pour l'extrusion de tubes plastiques a parois composites -procede de fabrication de tubes au moyen de l'appareillage | |

| EP1132625B1 (de) | Strahlpumpe für Flüssigkeit und Dampf mit verstellbarer Düse | |

| CA1233393A (fr) | Valve d'alimentation et de decharge brutale munie d'un piston | |

| WO1987000457A1 (fr) | Outil d'expansion hydraulique pour element tubulaire | |

| EP0013230B1 (de) | Vorrichtung zum Entfernen einer Flüssigkeit von der Oberfläche eines langen, sich kontinuierlich bewegenden Produktes | |

| WO2005072051A2 (fr) | Systeme de dosage de matiere plastique pour dispositif de production d'articles en matiere plastique | |

| FR2588779A1 (fr) | Separateur a vortex pour liquide heterogene a debit variable | |

| FR2846263A1 (fr) | Mandrin refroidi pour l'enroulement d'un produit en bande | |

| EP0014140B1 (de) | Vorrichtung zum Abkühlen eines sich longitudinal fortbewegenden länglichen Gegenstandes | |

| WO2020011969A1 (fr) | Turbine pour dispositif de projection de fluide, dispositif de projection de fluide, ainsi qu'ensemble comprenant un tel dispositif et un outil | |

| EP0397561A1 (de) | Schneidkopf mit Sauerstoffstrahl | |

| FR2532031A3 (fr) | Soupape de passage ou a melanges comportant un guidage rectiligne precis a glissement de la tige de soupape | |

| FR2671511A1 (fr) | Profile a structure alveolaire en resine thermoplastique - appareillage d'extrusion pour l'obtention du profile et son procede de fabrication. | |

| EP0652097B1 (de) | Vorrichtung zur Vereinigung von mindestens zwei Materialströmen in einer Koextrusionslaminierungsmaschine | |

| EP0327526A1 (de) | Vorrichtung zum Kühlen eines Metalls während des Giessens | |

| FR2704176A1 (fr) | Dispositif pour extruder des couches de matière concentriquement autour d'une âme centrale, notamment d'un câble électrique haute tension. | |

| EP0595737A1 (de) | Vorrichtung zum Beschichten von Folien oder Schichten auf einer Kühltrommel | |

| FR2532582A1 (fr) | Outillage rotatif de soufflage de films avec une alimentation centrale en matiere fondue et un refroidissement interne du film |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT LU NL |

|

| 17P | Request for examination filed |

Effective date: 19810610 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT LU NL |

|

| REF | Corresponds to: |

Ref document number: 3070144 Country of ref document: DE Date of ref document: 19850328 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19880129 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19910424 Year of fee payment: 12 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19910531 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19910605 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19910607 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910612 Year of fee payment: 12 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19920521 Ref country code: GB Effective date: 19920521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19920531 |

|

| BERE | Be: lapsed |

Owner name: INSTITUT DE RECHERCHES DE LA SIDERURGIE FRANCAISE Effective date: 19920531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19921201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19920521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930202 |