EP0018912B2 - Dispositif de refroidissement et purification des gaz de sortie d'une installation d'électrolyse de l'eau - Google Patents

Dispositif de refroidissement et purification des gaz de sortie d'une installation d'électrolyse de l'eau Download PDFInfo

- Publication number

- EP0018912B2 EP0018912B2 EP80400592A EP80400592A EP0018912B2 EP 0018912 B2 EP0018912 B2 EP 0018912B2 EP 80400592 A EP80400592 A EP 80400592A EP 80400592 A EP80400592 A EP 80400592A EP 0018912 B2 EP0018912 B2 EP 0018912B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- liquid

- gas

- water

- cooling

- inlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B15/00—Operating or servicing cells

- C25B15/08—Supplying or removing reactants or electrolytes; Regeneration of electrolytes

Definitions

- the present invention relates to the cooling and purification of the gases leaving an electrolysis installation, such as an installation intended for the industrial production of hydrogen and oxygen by electrolysis of water under high pressure and high temperature.

- the gases extracted such as hydrogen and oxygen in the case of the electrolysis of water, leave gas-liquid separators, or "degassers", at temperature high, often above 100 ° C, and charged with water vapor and impurities in the form of aerosols constituted for example by traces of potash.

- degassers gas-liquid separators, or "degassers”

- These gases must therefore, at the outlet of the degasser, be cooled, so as to condense the water vapor that they contain, and purified.

- German application DE-B-1 006 401 describes an installation for the electrolysis of pressurized water provided, above each degasser, with a tower for washing the extracted gases.

- a gas washing tower is an empty tower equipped with sprayers.

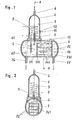

- the reference 7 designates a degasser for electrolysis installation, of the gravity type and in the example considers as described in the French patent application n ° 79-03550 of the plaintiff.

- the degasser 7 is provided with an inlet 76 for mixing a liquid electrolyte, anolyte or catholyte as the case may be, and gas, oxygen or hydrogen respectively, of at least one upper pipe 5 for outlet from gas alone, an outlet 77 of degassed liquid electrolyte, and complementary separation cells 72, three in number in the example considered.

- the hot, gas-charged electrolyte enters the degasser 7 via line 76, through cells 72, via passages 711 of the inlet plate 71 and passages 731 of the outlet plate 73, then spring degassed through line 77 to the electrolyte return circuit.

- the bubbles of coalesced gas on the internal faces of the cells 72 escape through the lateral orifices 741, and come to accumulate at the upper part of the degasser 7 from which they leave via the outlet pipe 5.

- the pipe 5 opens into an enclosure 1 placed above the separator 7, and containing a volume 3 of pure or demineralized water.

- the volume of water 3 is moreover traversed by a cooling circuit constituted by a coil 2 in which circulates cold water, at a temperature of around 20 ° C. to fix ideas, which helps to give the volume of water 3 a temperature of around 30 ° C in the example considered, sufficient to cause the condensation of the water vapor contained in the gas bubbles escaping through the upper outlet 52 of the pipe 5.

- the gas bubbles passing from the outlet 51 of the degasser 7 to the enclosure 1 therefore pass through the volume 3 of pure and refrigerated water. At the time of this crossing, they are washed of their impurities and cooled so as to condense the water vapor which they contain, the condensate obtained being added to the pure water already constituting volume 3. They then leave perfectly purified by an outlet pipe 4 located at the top of the enclosure 1.

- the level of pure water in enclosure 1 is kept more or less constant thanks to a pressure regulator, not shown, located on the circuit 4 of the outlet gases, and acting on a valve, not shown, controlling an inlet 11 demineralized water in the enclosure 1. Furthermore, the return of the condensation water to the electrolysis circuit is effected by at least one pipe 6 connecting the interior of the enclosure 1 to the interior of the degasser 7, from the upper inlet 61 to the lower outlet 62 of the said pipe, which moreover ensures a good pressure balance between the enclosures 1 and 7.

- the invention finds its main use in the industrial production of hydrogen and oxygen by electrolysis of water under pressure.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electrolytic Production Of Non-Metals, Compounds, Apparatuses Therefor (AREA)

- Water Treatment By Electricity Or Magnetism (AREA)

- Physical Water Treatments (AREA)

- Treating Waste Gases (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT80400592T ATE1391T1 (de) | 1979-05-04 | 1980-04-29 | Vorrichtung zum kuehlen und reinigen der abgase einer wasserelektrolyseanlage. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR7911940A FR2455638A1 (fr) | 1979-05-04 | 1979-05-04 | Procede de refroidissement et purification des gaz de sortie d'une installation d'electrolyse, et installation mettant en oeuvre ce procede |

| FR7911940 | 1979-05-04 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0018912A1 EP0018912A1 (fr) | 1980-11-12 |

| EP0018912B1 EP0018912B1 (fr) | 1982-07-28 |

| EP0018912B2 true EP0018912B2 (fr) | 1985-07-10 |

Family

ID=9225317

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP80400592A Expired EP0018912B2 (fr) | 1979-05-04 | 1980-04-29 | Dispositif de refroidissement et purification des gaz de sortie d'une installation d'électrolyse de l'eau |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0018912B2 (cg-RX-API-DMAC7.html) |

| JP (1) | JPS55154591A (cg-RX-API-DMAC7.html) |

| AT (1) | ATE1391T1 (cg-RX-API-DMAC7.html) |

| DE (1) | DE3060696D1 (cg-RX-API-DMAC7.html) |

| FR (1) | FR2455638A1 (cg-RX-API-DMAC7.html) |

| NO (1) | NO152422C (cg-RX-API-DMAC7.html) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10058542B1 (en) | 2014-09-12 | 2018-08-28 | Thioredoxin Systems Ab | Composition comprising selenazol or thiazolone derivatives and silver and method of treatment therewith |

| CN116899359A (zh) * | 2023-06-27 | 2023-10-20 | 中能(江苏苏州)氢能源科技有限公司 | 一种集成超声波的卧式制氢分离装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR715801A (fr) * | 1930-04-22 | 1931-12-10 | Procédé et appareil perfectionnés pour purifier l'oxygène et l'hydrogène résultant de la décomposition électrolytique de l'eau | |

| CH282081A (de) * | 1950-03-10 | 1952-04-15 | Lonza Ag | Verfahren zum Betrieb von druckfesten Wasserelektrolyseuren. |

| GB1415336A (en) * | 1972-11-29 | 1975-11-26 | Mess & Regelungst Veb K | Apparatus for the treatment of gas samples |

-

1979

- 1979-05-04 FR FR7911940A patent/FR2455638A1/fr active Granted

-

1980

- 1980-04-28 NO NO801230A patent/NO152422C/no unknown

- 1980-04-29 AT AT80400592T patent/ATE1391T1/de not_active IP Right Cessation

- 1980-04-29 DE DE8080400592T patent/DE3060696D1/de not_active Expired

- 1980-04-29 EP EP80400592A patent/EP0018912B2/fr not_active Expired

- 1980-05-02 JP JP5935480A patent/JPS55154591A/ja active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| NO801230L (no) | 1980-11-05 |

| NO152422B (no) | 1985-06-17 |

| JPS55154591A (en) | 1980-12-02 |

| EP0018912B1 (fr) | 1982-07-28 |

| JPS6327431B2 (cg-RX-API-DMAC7.html) | 1988-06-02 |

| FR2455638A1 (fr) | 1980-11-28 |

| ATE1391T1 (de) | 1982-08-15 |

| EP0018912A1 (fr) | 1980-11-12 |

| NO152422C (no) | 1985-09-25 |

| FR2455638B1 (cg-RX-API-DMAC7.html) | 1983-09-23 |

| DE3060696D1 (en) | 1982-09-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0181248B1 (fr) | Procédé de chauffage d'un liquide par combustion submergée et dispositif pour la mise en oeuvre du procédé | |

| EP0271556B1 (fr) | Procede et dispositif pour la desacidification d'un gaz renfermant h 2?s ou/et co 2? ainsi que des mercaptans | |

| EP0129854B1 (fr) | Procédé et appareil pour la production de produits gazeux par décomposition de liquides | |

| SE461873B (sv) | Foerfarande foer vakuumrening av oljefyllningar och anordning foer utfoerande av detta foerfarande | |

| RU2704220C2 (ru) | Аппарат для дегазации системы охлаждения ядерного реактора | |

| US4511376A (en) | Method of separating a noncondensable gas from a condensable vapor | |

| CA1256016A (fr) | Procede de desaeration d'eau | |

| EP0018912B2 (fr) | Dispositif de refroidissement et purification des gaz de sortie d'une installation d'électrolyse de l'eau | |

| EP0238592B1 (fr) | Procede pour l'extraction selective de l'h2s d'un gaz en contenant | |

| JPH0555761B2 (cg-RX-API-DMAC7.html) | ||

| US4330307A (en) | Method of separating a noncondensable gas from a condensable vapor | |

| KR910003109B1 (ko) | 전기발전 설비를 순환하는 응축물의 가스제거장치 | |

| EP0239603B1 (fr) | Procede et dispositif pour l'extraction selective de l'h 2?s d'un gaz en contenant | |

| FR2573185A1 (fr) | Echangeur de chaleur a chauffage direct | |

| US4138468A (en) | Method and apparatus for producing or recovering alkanolamine from a mixture containing oxazolidone | |

| CA1339242C (fr) | Procede et dispositif pour l'elimination de l'h s present a faible concentration dans un gaz renfermant egalement une quantite importante de vapeur d'eau | |

| SU1454781A1 (ru) | Деаэрационна установка | |

| BE1006843A3 (fr) | Procede et dispositif pour eliminer les composes d'ammonium contenus dans des eaux usees. | |

| EP0318342B1 (fr) | Procédé de reformage de méthanol impur et dispositif de mise en oeuvre | |

| SU1134842A1 (ru) | Деаэратор | |

| JPH0778628A (ja) | 燃料電池発電装置の生成水回収装置 | |

| NO345441B1 (en) | System and method for removal of oxygen from water | |

| FR2721919A1 (fr) | Procede et installation de recuperation du brome dans un effluent liquide | |

| WO2025242820A1 (fr) | Procédé et système pour traiter un gaz effluent d'un réacteur nucléaire à sels fondus | |

| CH521148A (fr) | Procédé et installation de distillation de solutions salines |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19801211 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 1391 Country of ref document: AT Date of ref document: 19820815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3060696 Country of ref document: DE Date of ref document: 19820916 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: METALLGESELLSCHAFT AG Effective date: 19830422 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19840329 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19840430 Year of fee payment: 5 |

|

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19850429 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form | ||

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE GB IT NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19850710 |

|

| NLR2 | Nl: decision of opposition | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940314 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940318 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940418 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940422 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940427 Year of fee payment: 15 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 80400592.4 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950430 Ref country code: LI Effective date: 19950430 Ref country code: CH Effective date: 19950430 Ref country code: BE Effective date: 19950430 |

|

| BERE | Be: lapsed |

Owner name: CREUSOT-LOIRE Effective date: 19950430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960201 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 80400592.4 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AUV Free format text: LE BREVET CI-DESSUS EST TOMBE EN DECHEANCE FAUTE DE PAIEMENT, DE LA 16E ANNUITE. |