EP0015992B1 - Low profile crushing apparatus - Google Patents

Low profile crushing apparatus Download PDFInfo

- Publication number

- EP0015992B1 EP0015992B1 EP79900517A EP79900517A EP0015992B1 EP 0015992 B1 EP0015992 B1 EP 0015992B1 EP 79900517 A EP79900517 A EP 79900517A EP 79900517 A EP79900517 A EP 79900517A EP 0015992 B1 EP0015992 B1 EP 0015992B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- crusher

- jaw

- crushing

- chamber

- crusher chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000463 material Substances 0.000 claims abstract description 26

- 239000011435 rock Substances 0.000 claims abstract description 15

- 238000000034 method Methods 0.000 claims description 7

- 230000003252 repetitive effect Effects 0.000 claims description 2

- 238000005065 mining Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 2

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000011572 manganese Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C1/00—Crushing or disintegrating by reciprocating members

- B02C1/02—Jaw crushers or pulverisers

- B02C1/04—Jaw crushers or pulverisers with single-acting jaws

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C21/00—Disintegrating plant with or without drying of the material

- B02C21/02—Transportable disintegrating plant

Definitions

- This invention relates to a low profile crusher apparatus suitable for crushing mine ore or hard rock, or any other suitable material.

- One preferred example of the crusher apparatus is a portable, low head room or low profile, crusher for primary reduction of ore or hard rock, close to the active working areas in underground mining operations.

- a Blake type crusher is disclosed in US-A-2,127,027 as comprising: a main frame; a stationary, vertically inclined, first crusher jaw; a movable, vertically inclined, second crusher jaw, pivoted at the lower end thereof, the upper end of that jaw being connected to a pitman; an eccentric drive connected to said pitman so as to drive said second crusher jaw; and conveyor means mounted adjacent the lower end of said second crusher jaw so as to collect and transport the crushed material.

- a low profile crusher apparatus suitable for crushing mine or hard rock, comprising:

- feeder and collector means comprises: feeder means (28) mounted adjacent said crusher chamber (84), for feeding material into an upper portion of said crusher chamber; and collector means (30) mounted adjacent the lower end of said crusher chamber (84), for collecting and transporting material passing through said crusher chamber.

- said preferred embodiment is characterized in that the uppermost portion of said second crusher jaw (60) is disposed lower than the uppermost portion of said first crusher jaw (39) so as to define an inlet (82) of crusher chamber (84); and the upper portion of said feeder means (28) is disposed at a height not substantially higher than the uppermost portion of said first crusher jaw (39).

- a method of crushing hard material with crusher apparatus said method being characterized by the use of a crusher apparatus according to said first aspect of the present invention.

- said material to be crushed comprises mine ore and/or hard rock.

- the crusher jaws (39, 60) are vertically inclined to form an inclined crusher chamber (84) which slopes downwardly from inlet to outlet thereof, with the lower jaw (60) being movable to impart crushing action between it and a stationary upper jaw (39).

- This arrangement of jaws (39, 60) in combination with features a) and b) of claim 1 provides a powerful and most efficient crushing of material while maintaining very adequate feeding of the material through the crusher chamber.

- the arrangement of the crusher jaws in this manner permits the attendant eccentric shaft, drive means (66, 68), and support means (62, 64) to be positioned in a lower profile manner on the main frame (20), as well as reduce the height at which feeder (28) feeds the inlet of the crusher chamber (84) so as to permit the feeding and collecting system (28, 30) to be mounted at a lower position on the main frame (20).

- the present invention enables a portable, low head room, crusher to be provided which has significantly reduced profile compared to prior art apparatus suitable for use in underground mine applications, and has a crusher chamber capacity comparably equal to prior art crushers which require significantly greater head room than required by apparatus according to said first aspect of the present invention.

- a crusher of the present invention can be more easily and efficiently transported from site to site compared to prior art, hard rock crushers.

- a crusher of the present invention is of comparable ease to manufacture and maintain relative to prior art, hard rock crushers.

- a crusher of the present invention can be advantageously utilized more closer to the working areas of undergound mines, for greatly improving ore handling and production in those mines. It will be appreciated that the disposition of the lower crusher jaw (60) and the eccentric drive means (66, 68) not only contributes to providing lower head room but also ensures efficient transport of crushed material from the inlet of the crusher chamber (84) to the outlet thereof.

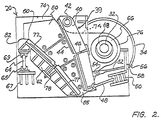

- a portable, low profile, crusher apparatus includes a main frame 20, which is supported for movement by several pairs of conventional wheel means 22, 24.

- a crusher portion 26 is centrally located on the main frame 20 so as to be adjacent a conventional feed conveyor system 28 and above a discharge conveyor system 30.

- feed and discharge conveyor systems are of conventional nature, and a variety of standard types thereof could be employed within the context of the present invention.

- a typical scalping mechanism is usually included to remove fine or the like before entry to the crusher chamber 84.

- An eccentrically mounted shaft means 32 is connected to a pair of fly wheels such as at 34, which in turn is driven via a belt drive 36 connected to a conventional motor 38.

- Each of these components can be mounted on the main frame 20 in any conventional suitable manner.

- the crusher portion 26 is shown in greater detail and includes a stationary first jaw 39, together with supporting frame 40 mounted for pivoted movement at its upper end via a shaft 42, which in turn is supported at each end to main frame .20 in a conventional manner.

- a replaceable jaw liner 44 comprising highly wear resistant material (e.g. manganese) is releasably fixed to supporting frame 40 by means of threaded wedgelike member 46.

- the lower end of stationary jaw 39 is releasably fixed in position by a toggle arrangement 48 provided with a series of shims 50.

- the toggle arrangement 48 is easily used to adjust the position of frame 40 pivoted about shaft 42 so as to vary the discharge opening between the jaws 39, 60.

- Toggle arrangement 48 is held in place by means of rods 52 pivotally mounted to flanges 54 carried by supporting frame 40, and provided with threaded ends 56 respectively carrying a nut 58 and extended through suitable respective holes in main frame 20.

- the jaw 39 can be pivoted and locked into a new position.

- the jaw 39 is inclined relative to the horizontal, and slopes downwardly from the feed inlet 82 of the crusher chamber 84 to the outlet 85 thereof.

- a moveable jaw 60 has a supporting frame or pitman 62.

- the upper end of pitman 62 is supported by a toggle arrangement 64 located beneath the feeder end.

- the upper and lower ends of pitman 62 are attached to a tubelike support 66 provided with eccentric bearings 68 mounted on eccentric shaft 32.

- a pair of bearings 70 are mounted on the main frame 20 and connected to eccentric shaft 32.

- Each end of the shaft 32 is mounted to a fly wheel 34 provided with counter weights to offset the unbalanced weight of pitman 62.

- One of fly wheels 34 is connected to a conventional electric motor 38 via belt drive 36 to provide rotary power to eccentric shaft 32.

- the pitman 62 includes side plates 74 and the extended collar-like portion 76 which is connected to tubelike support 66, such that the eccentric motion of shaft 32 is imparted to pitman 62, and a replaceable jaw liner 77 is mounted thereon by a removable threaded wedgelike member 78. It is desirable to provide detachable wear plates 80 respectively to each of the side plates 74 of pitman 62, because of abuse normally encountered in the crusher chamber 84 during operation.

- the jaw 60 is disposed in an inclined position with the upper end thereof adjacent the feed inlet 82 of crusher chamber 84 defined between the respective jaws 39, 60 and the pitman's side plates 74.

- the lower end of crusher chamber 84 includes a discharge outlet 85 for the processed material which falls to the discharge conveyor 30.

- the toggle arrangement 64 supporting pitman 62 includes an adjustable and replaceable toggle seat 65 mounted on a cross member 67 fixed to the main frame 20. Another replaceable toggle seat 69 is provided at the top end of pitman 62 where it is connected to pitman 62. It may be desirable to provide for positive retention of toggle arrangement 64 in seat 69 by means of a releasably mounted spring or the like to prevent inadvertent unseating of toggle arrangement 64 during adverse operation conditions. By adjustment of the position of toggle arrangement 64, the motion of the feed end of crusher jaw 60 can be varied according to the most desirable action for a given crushing application.

- toggle arrangements 48, 64 serve as safety mechanism because they can be designed to break should uncrushable material enter crusher chamber 84.

- toggle arrangements 48, 64 are easily replaceable and relatively inexpensive, their breakability provides a safety factor for preventing more serious damage to the other components which represent more difficult and expensive repair or replacement.

- the crusher apparatus shown in the drawings can be used for crushing mine ore and/or hard rock, in e.g. underground mining operations.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Disintegrating Or Milling (AREA)

- Crushing And Grinding (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US90490678A | 1978-05-11 | 1978-05-11 | |

| US904906 | 1978-05-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0015992A1 EP0015992A1 (en) | 1980-10-01 |

| EP0015992B1 true EP0015992B1 (en) | 1983-02-09 |

Family

ID=25419949

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP79900517A Expired EP0015992B1 (en) | 1978-05-11 | 1979-12-17 | Low profile crushing apparatus |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0015992B1 (enExample) |

| JP (1) | JPS55500290A (enExample) |

| AT (1) | ATE2398T1 (enExample) |

| CA (1) | CA1132512A (enExample) |

| DE (1) | DE2964699D1 (enExample) |

| WO (1) | WO1979001060A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6084166A (ja) * | 1983-06-02 | 1985-05-13 | 株式会社栗本鉄工所 | 可搬式破砕装置 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2566588A (en) * | 1946-03-02 | 1951-09-04 | Bastian Blessing Co | Beverage dispenser with control setting indicator |

| US2873922A (en) * | 1954-11-22 | 1959-02-17 | Arthur W Fahrenwald | Jaw crusher |

| US3386667A (en) * | 1965-10-22 | 1968-06-04 | Clinton E. May | High frequency hydraulic actuated jaw crusher |

| US3804345A (en) * | 1972-09-15 | 1974-04-16 | Barber Greene Co | Jaw crusher die mounting |

| US3946955A (en) * | 1974-08-01 | 1976-03-30 | Rock Industries Machinery Corporation | Multiple section wear plate for a rock crusher |

-

1979

- 1979-02-09 CA CA321,139A patent/CA1132512A/en not_active Expired

- 1979-05-11 JP JP50079079A patent/JPS55500290A/ja active Pending

- 1979-05-11 WO PCT/US1979/000315 patent/WO1979001060A1/en not_active Ceased

- 1979-05-11 AT AT79900517T patent/ATE2398T1/de not_active IP Right Cessation

- 1979-05-11 DE DE7979900517T patent/DE2964699D1/de not_active Expired

- 1979-12-17 EP EP79900517A patent/EP0015992B1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| DE2964699D1 (en) | 1983-03-17 |

| WO1979001060A1 (en) | 1979-12-13 |

| EP0015992A1 (en) | 1980-10-01 |

| ATE2398T1 (de) | 1983-03-15 |

| CA1132512A (en) | 1982-09-28 |

| JPS55500290A (enExample) | 1980-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4815667A (en) | System and method for recovery of salvageable ferrous and non-ferrous metal components from incinerated waste materials, and a selective crusher therefor | |

| US2005758A (en) | Crusher | |

| US4288040A (en) | Low profile crushing apparatus | |

| CN111013736A (zh) | 井工煤矿顺槽用移动式筛分破碎一体机 | |

| CN208436911U (zh) | 一种用于矿石粉碎的安全保护式对辊破碎机 | |

| EP0015992B1 (en) | Low profile crushing apparatus | |

| US2097906A (en) | Crusher for stone and like materials | |

| US3933316A (en) | Mill for comminuting ore material | |

| CN209222209U (zh) | 一种液压复合辊式破碎机 | |

| US3853274A (en) | Impact crusher | |

| US3556415A (en) | Jaw crusher and method of operation thereof | |

| CN102430457A (zh) | 多功能卧式旋回破碎机 | |

| US3503563A (en) | Gyratory rock crusher | |

| US1877121A (en) | Hammer crusher | |

| CN210994447U (zh) | 一种对硅料尺寸进行控制的装置 | |

| US3848818A (en) | Mobile crusher unit | |

| US2962229A (en) | Material crushing and grinding means and method | |

| CN115814945B (zh) | 一种多条板除铁器 | |

| CN107597265B (zh) | 单辊破碎机 | |

| US2885157A (en) | Material crushing and sizing means cooperable with reciprocating conveyor | |

| RU2061590C1 (ru) | Способ производства дробленки из различных материалов и установка для его осуществления | |

| WO2023089332A1 (en) | An improved jaw crusher | |

| KR102776558B1 (ko) | 철제류 이물질 선별 장치 및 이를 포함하는 괴탄 파쇄 시설 | |

| US55181A (en) | Improvement in quartz-mills | |

| CN116140029B (zh) | 一种采场和选厂分置的非磁性矿加工系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed | ||

| AK | Designated contracting states |

Designated state(s): AT DE FR GB SE |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT DE FR GB SE |

|

| REF | Corresponds to: |

Ref document number: 2398 Country of ref document: AT Date of ref document: 19830315 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 2964699 Country of ref document: DE Date of ref document: 19830317 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910411 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19910412 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19910418 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19910426 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19910430 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19920511 Ref country code: AT Effective date: 19920511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19920512 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19920511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19930129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930202 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 79900517.8 Effective date: 19921204 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |