EP0000418A1 - Process for glueing materials - Google Patents

Process for glueing materials Download PDFInfo

- Publication number

- EP0000418A1 EP0000418A1 EP78200093A EP78200093A EP0000418A1 EP 0000418 A1 EP0000418 A1 EP 0000418A1 EP 78200093 A EP78200093 A EP 78200093A EP 78200093 A EP78200093 A EP 78200093A EP 0000418 A1 EP0000418 A1 EP 0000418A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- imidazoline

- alkyl

- aryl

- aralkyl

- cycloalkyl

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G59/00—Polycondensates containing more than one epoxy group per molecule; Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups

- C08G59/18—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing

- C08G59/40—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing characterised by the curing agents used

- C08G59/50—Amines

- C08G59/5046—Amines heterocyclic

- C08G59/5053—Amines heterocyclic containing only nitrogen as a heteroatom

- C08G59/5073—Amines heterocyclic containing only nitrogen as a heteroatom having two nitrogen atoms in the ring

Definitions

- epoxy compounds occupy a wide space.

- Epoxy compounds with more than one epoxy group in the molecule are particularly suitable for bonding non-porous materials such as metals. Due to the dense, impermeable metal surface, volatile components cannot escape from the adhesive joints. For the bonding of metals, adhesives are therefore preferred that are free of solvents and dispersants and that do not produce any fission products when they are crosslinked. Epoxy resin-based adhesives meet these requirements.

- Epoxy resins also called ethoxylin resins in literature

- Epoxy resins are reaction products of alkylene oxides with, for example, polyphenols, which are hardened irreversibly with the aid of hardening agents.

- the task of the hardening process is the adhesive layer to make it insoluble and infusible. When these resins are cured, no fission products are released, so that there is no loss of substance and mostly shrink-free curing is achieved.

- epoxy resin adhesives for example polycarboxylic acids and their anhydrides, polyalcohols, amines, amides, amidoamines, but also phenol-formaldehyde and carbamide-formaldehyde precondensates, polyesters, alcoholates of polyvalent metals, metal salts of siccative acids, metal phenolates, complexes Use tin compounds, zinc fluoroborate, polyisocyanates and titanium acid esters.

- the ready-to-use adhesives are either in the form of two-component systems, since the hardening reaction starts immediately when the resin and hardener are combined; or the hardeners are added to the resin as so-called latent hardeners and the hardening reaction only begins at elevated temperatures.

- the former case a pot life must be observed when using this adhesive, after which it cannot be processed further.

- relatively high temperatures and long times are required for hardening, which is not applicable to all materials.

- most of these common hardeners are not physiologically harmless.

- the aim of the present invention was to find suitable epoxy resin hardener systems for bonds which make formulation of two-component systems superfluous and enable the bond to cure even at relatively low temperatures and in short times.

- the imidazoline derivatives described above are used in particular in amounts of in particular 3 to 60% by weight, preferably 4 to 40% by weight, based on the resin weight amounts of hardener. Under certain circumstances, smaller or larger additives can also be advantageous.

- Suitable cyclic amidines for the purposes of the present invention which correspond to the general formula described earlier are, for example: 2-phenylimidazoline, 2-phenyl-4-methylimidazoline, 2- (m-tolyl) -4-methylimidazoline, 2- (m-pyridyl) imidazoline, 1,4-tetramethylene-bis- (4-methyl-imidazoline-2), 2-methyl-imidazoline, 2,4-dimethyl-imidazoline, 2-ethyl-imidazoline, 2-ethyl- 4-methyl-imidazoline, 2-benzyl-imidazoline, 2- (o-tolyl) -imidazoline, 2- (p-tolyl) -imidazoline, tetramethylene-bis-imidazoline, 1,1,3-trimethyl-1,4- tetramethylene-bis-imidazoline, 1,1,3-trimethyl-1,4-tetramethylene-bis-4-methyl-imidazoline, 1,3,3-

- the imidazoline derivatives which can be used according to the invention can be prepared by known processes from optionally substituted geminal diamines and aliphatic or aromatic mono- or dinitriles, optionally in the presence of H 2 S, elemental sulfur or sulfuryl chloride as a catalyst.

- 1,2-epoxy compounds which can be used according to the invention, the following may be mentioned: the epoxides from mono- or polyunsaturated hydrocarbons: ethylene, propylene, butylene, butadiene, cyclohexene, vinylcyclohexene, dicyclopentadiene, cyclododecatriene, polybutadienes, styrene; halogen-containing epoxides, such as epichlorohydrin; Epoxy ether of simple alcohols, methyl, ethyl, butyl, 2-ethylhexyl alcohol; Epoxy ether of polyhydric alcohols: ethylene, propylene, butylene glycol, polyglycol, glycerin, pentaerythritol; Epoxy ethers of mono- and polyhydric phenols: phenol, cresol, resorcinol, hydroquinone, 4,4'-dihydroxidiphenyl,

- the adhesive formulations according to the invention are produced in a very simple manner: First, the epoxy resins, insofar as they are solid resins, are crushed. The two reactants are then intimately mixed with one another, ensuring a uniform distribution of the amidines according to the invention in the epoxy resin. If solid epoxy resins are used, the grain size of the powder obtained in this way should not exceed 500 ⁇ m. It is not necessary to add solvent - the so-called reactive diluents which may be present in liquid or semi-liquid epoxy resins are not considered solvents in this sense.

- the adhesive formulations obtained in this way can, if necessary, be mixed with customary additives such as fillers, pigments, dyes and the like.

- resin - and / or hardener can be dyed, for example, to make visible adhesive joints appear less noticeable or to allow so-called shadow gaps to stand out.

- the method according to the invention can be used for gluing the most diverse materials, e.g. Metals, light metals, but also non-metallic materials such as ceramics, glass, leather, rubber, wood, temperature-resistant plastic, etc. with itself or with other materials. It can also be used to manufacture sandwich constructions from metals and other materials.

- materials e.g. Metals, light metals, but also non-metallic materials such as ceramics, glass, leather, rubber, wood, temperature-resistant plastic, etc.

- non-metallic materials such as ceramics, glass, leather, rubber, wood, temperature-resistant plastic, etc.

- the adhesives formulated with the amidines used according to the invention fully meet the requirement for freedom from solvents, and they are also available as one-component systems. This eliminates the disadvantages described above, such as flash-off and pot life, and shrinkage-free curing takes place without the formation of fission products. These properties make them ideally suited for bonding non-porous materials, e.g. Metals. Due to the relatively low curing temperatures required, it is possible to bond temperature-sensitive materials such as soldered metal parts.

- the adhesive formulations according to the invention can be applied electrostatically if solid epoxy resins are used. This makes it possible to apply precisely metered, thin layers, which is advantageous, for example, when gluing foils.

- the 1,2-epoxy compounds used were intimately mixed with the amidines used according to the invention in the stated weight ratios.

- both components were pre-comminuted, mixed and to a particle size grind to less than 500 ⁇ m.

- liquid resins Examples 4 to 8

- the amidines according to the invention were ground finely and mixed into the resins until they were evenly distributed.

- the adhesive formulations thus obtained were applied to various substrates and these were then bonded at the temperatures and times indicated.

- the dimensions of the test specimens and the overlapped, ie, glued surface corresponded to DIN 53 273.

- DIN 53 273 The dimensions of the test specimens and the overlapped, ie, glued surface corresponded to DIN 53 273.

- the shear strength was determined in accordance with the above standard.

- it must be mentioned that the materials used for these tests have been degreased, but no other pretreatment (such as roughening, etching, etc.) has been carried out.

- Example 1 The resin-hardener formulation of Example 1 was applied electrostatically to test specimens from V 2 A and these were glued:

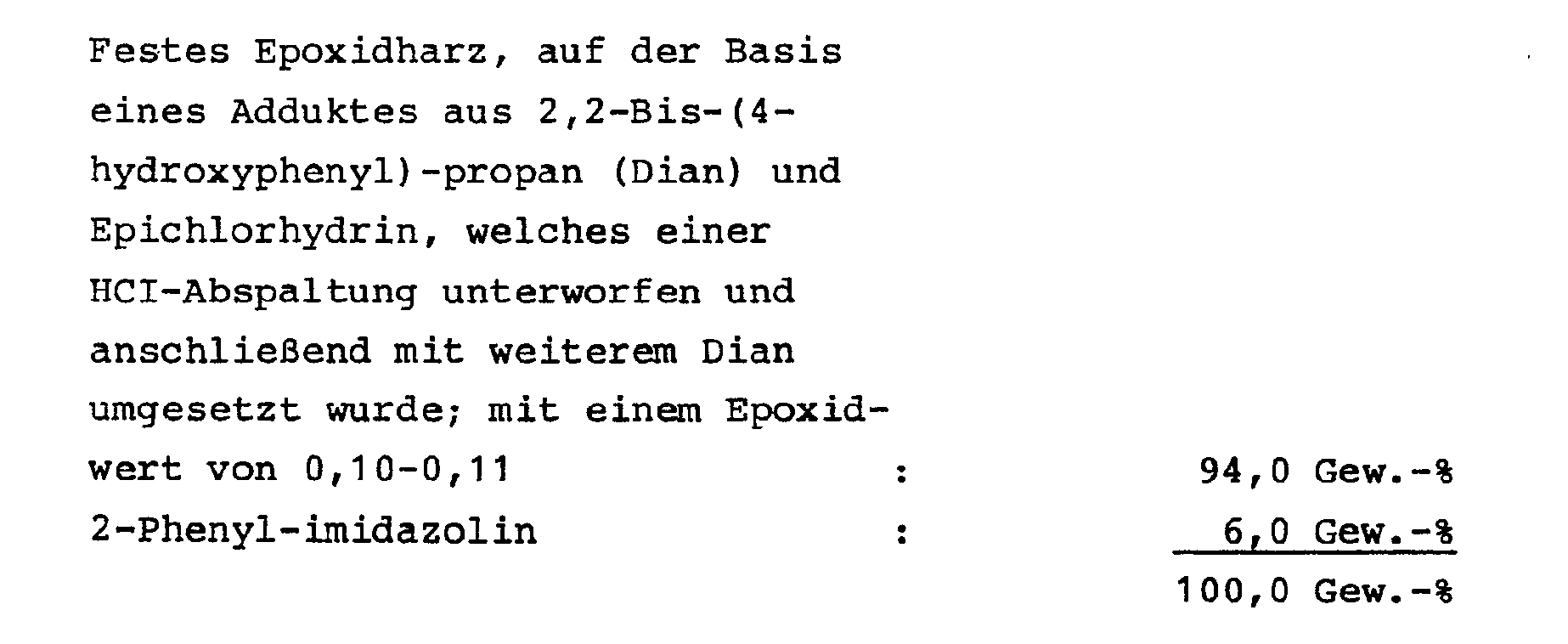

- 2-phenyl-imidazoline was formulated with an epoxy resin as follows:

- This formulation was V 2 O T estMech bonded for 30 minutes at 150 ° C and then a shear strength of 20.7 kgf / cm 2 was measured.

- Test specimens made from V 2 A were bonded with this formulation and the shear strength was then determined at + 0 ° C., 20 ° C. and 80 ° C. In addition, the bonds were exposed to a temperature load of 80 ° C for 3 days and checked again for their shear strength.

- test specimens made of V 2 A were glued on the one hand to those made of test rubber on the other hand for 30 minutes at 100 ° C. and then a shear strength of 11.6 kp / cm 2 was measured.

- Example 5 With the formulation of Example 5, 2 mm thick wooden strips were glued at 50 ° C. for 24 hours. The shear strength could not be measured by this, but the adhesive becomes firm characterized by the fact that it was not possible to pull apart the bonded test specimens by hand.

- V 2 A test specimens were bonded at 150 ° C. for 30 minutes and then a shear strength of 76.0 kp / cm 2 was measured.

Abstract

Description

Unter der Vielzahl der zum Verkleben von Werkstoffen verwendeten Stoffe, wie Vinylpolymerisate, Butadienpolymerisate, Olefinpolymerisate, Ketonharze, Alkydharze, Alkyl-, Terpen- u.a. modifizierte Phenolharze, Phenol-Formaldehydharze, ungesättigte Polyester, Polyurethane und andere, nehmen die Epoxidverbindungen einen breiten Raum ein.Among the multitude of materials used for bonding materials, such as vinyl polymers, butadiene polymers, olefin polymers, ketone resins, alkyd resins, alkyl, terpene and others. modified phenolic resins, phenol-formaldehyde resins, unsaturated polyesters, polyurethanes and others, the epoxy compounds occupy a wide space.

Epoxidverbindungen mit mehr als einer Epoxygruppe im Molekül, gelegentlich auch als Epoxidharze bezeichnet, eignen sich besonders zum Verkleben unporöser Werkstoffe, wie Metalle. Aufgrund der dichten, undurchlässigen Metalloberfläche können flüchtige Bestandteile nicht aus den Klebefugen entweichen. Für die Verklebung von Metallen werden daher Klebstoffe bevorzugt, die lösungs- und dispergiermittelfrei sind und bei deren Vernetzung keine Spaltprodukte entstehen. Diese Voraussetzungen werden von Klebstoffen auf Epoxidharzbasis erfüllt.Epoxy compounds with more than one epoxy group in the molecule, sometimes also referred to as epoxy resins, are particularly suitable for bonding non-porous materials such as metals. Due to the dense, impermeable metal surface, volatile components cannot escape from the adhesive joints. For the bonding of metals, adhesives are therefore preferred that are free of solvents and dispersants and that do not produce any fission products when they are crosslinked. Epoxy resin-based adhesives meet these requirements.

Epoxidharze (im Schrifttum auch Äthoxylinharze genannt) sind Umsetzungsprodukte von Alkylenoxiden mit beispielsweise Polyphenolen, die mit Hilfe von Härtungsmitteln irreversibel gehärtet werden. Der Härtungsprozeß hat die Aufgabe, die Klebstoffschicht unlöslich und unschmelzbar zu machen. Bei der Härtung dieser Harze werden keine Spaltprodukte frei, so daß kein Substanzverlust entsteht und meist eine schrumpffreie Härtung erreicht wird.Epoxy resins (also called ethoxylin resins in literature) are reaction products of alkylene oxides with, for example, polyphenols, which are hardened irreversibly with the aid of hardening agents. The task of the hardening process is the adhesive layer to make it insoluble and infusible. When these resins are cured, no fission products are released, so that there is no loss of substance and mostly shrink-free curing is achieved.

Es ist bekannt, als Härter für Epoxidharz-Klebstoffe beispielsweise Polycarbonsäuren und ihre Anhydride, Polyalkohole, Amine, Amide, Amidoamine, aber auch Phenol-Formaldehyd- und Carbamid-Formaldehyd-Vorkondensate, Polyester, Alkoholate mehrwertiger Metalle, Metallsalze von Sikkativsäuren, Metallphenolate, komplexe Zinnverbindungen, Zinkfluorborat, Polyisocyanate und Titansäureester einzusetzen.It is known as a hardener for epoxy resin adhesives, for example polycarboxylic acids and their anhydrides, polyalcohols, amines, amides, amidoamines, but also phenol-formaldehyde and carbamide-formaldehyde precondensates, polyesters, alcoholates of polyvalent metals, metal salts of siccative acids, metal phenolates, complexes Use tin compounds, zinc fluoroborate, polyisocyanates and titanium acid esters.

Bei der dem Stand der Technik entsprechenden Verwendung dieser gebräuchlichen Härter liegen die gebrauchsfertigen Kleber entweder als Zweikomponenten-Systeme vor, da beim Zusammengeben von Harz und Härter sofort die Härtungsreaktion einsetzt; oder die Härter werden als sog. latente Härter dem Harz beigegeben und die Härtungsreaktion setzt erst bei erhöhten Temperaturen ein. Im ersteren Fall ist beim Gebrauch dieser Kleber eine Topfzeit zu beachten, nach deren Überschreitung eine weitere Verarbeitung nicht mehr erfolgen kann. Im zweiten Fall werden zur Härtung relativ hohe Temperaturen und lange Zeiten benötigt, was nicht bei allen Werkstoffen anwendbar ist. Daneben ist bei den meisten dieser gebräuchlichen Härter eine physiologische Unbedenklichkeit nicht gegeben.When these customary hardeners are used in accordance with the prior art, the ready-to-use adhesives are either in the form of two-component systems, since the hardening reaction starts immediately when the resin and hardener are combined; or the hardeners are added to the resin as so-called latent hardeners and the hardening reaction only begins at elevated temperatures. In the former case, a pot life must be observed when using this adhesive, after which it cannot be processed further. In the second case, relatively high temperatures and long times are required for hardening, which is not applicable to all materials. In addition, most of these common hardeners are not physiologically harmless.

Ziel der vorliegenden Erfindung war es, geeignete Epoxidharz-Härtemittel-Systeme für Verklebungen zu finden, die eine Formulierung von Zweikomponenten-Systemen überflüssig machen und eine Aushärtung der Verklebung schon bei relativ niedrigen Temperaturen und in kurzen Zeiten ermöglichen.The aim of the present invention was to find suitable epoxy resin hardener systems for bonds which make formulation of two-component systems superfluous and enable the bond to cure even at relatively low temperatures and in short times.

Es wurde nun überraschenderweise gefunden, daß man zu Verklebungen von Werkstoffen ohne die beschriebenen Nachteile gelangt, wenn man Epoxidharze mit speziellen Imidazolinen als Härter einsetzt.It has now surprisingly been found that bonding of materials without the disadvantages described can be achieved if epoxy resins with special imidazolines are used as hardeners.

Gegenstand der Erfindung ist daher ein Verfahren zum Verkleben von Werkstoffen unter Verwendung von in der Wärme härtbaren Einkomponenten-Systemen aus 1.2-Epoxidverbindungen mit mindestens einer 1.2-Epoxidgruppen im Molekül und cyclischen Amidinen sowie gegebenenfalls den üblichen Zusätzen, dadurch gekennzeichnet, daß man als cyclische Amidine Imidazolin-Derivate der allgemeinen Formel

Die vorstehend beschriebenen Imidazolin-Derivate gelangen besonders in Mengen von insbesondere 3 - 60 Gew.-%, vorzugsweise 4 - 40 Gew.-%, bezogen auf die Harzgewichtsmengen Härter, zum Einsatz. Es können unter Umständen auch kleinere oder größere Zusätze vorteilhaft sein.The imidazoline derivatives described above are used in particular in amounts of in particular 3 to 60% by weight, preferably 4 to 40% by weight, based on the resin weight amounts of hardener. Under certain circumstances, smaller or larger additives can also be advantageous.

Geeignete cyclische Amidine im Sinne der vorliegenden Erfindung, die der früher beschriebenen allgemeinen Formel entsprechen, sind beispielsweise: 2-Phenylimidazolin, 2-Phenyl-4-methyl-imidazolin, 2-(m-Tolyl)-4-methyl-imidazolin, 2-(m-Pyridyl)-imidazolin, 1,4-Tetramethylen-bis-(4-methyl-imidazolin-2), 2-Methyl-imidazolin, 2,4-Dimethyl-imidazolin, 2-Äthyl-imidazolin, 2-Äthyl-4-methyl-imidazolin, 2-Benzyl-imidazolin, 2-(o-Tolyl)-imidazolin, 2-(p-Tolyl)-imidazolin, Tetramethylen-bis-imidazolin, 1,1,3-Trimethyl-1,4-tetramethylen-bis-imidazolin, 1,1,3-Trimethyl-1,4-tetramethylen-bis-4-methyl-imidazolin, 1,3,3-Trimethyl-1,4-tetramethylen-bis-4-methylimidazolin, 1,2-Phenylen-bis-imidazolin, 1,3-Phenylen-bis-4-methyl-imidazolin u.a.m. Es können auch Gemische der Imidazolin-Derivate erfindungsgemäß eingesetzt werden.Suitable cyclic amidines for the purposes of the present invention which correspond to the general formula described earlier are, for example: 2-phenylimidazoline, 2-phenyl-4-methylimidazoline, 2- (m-tolyl) -4-methylimidazoline, 2- (m-pyridyl) imidazoline, 1,4-tetramethylene-bis- (4-methyl-imidazoline-2), 2-methyl-imidazoline, 2,4-dimethyl-imidazoline, 2-ethyl-imidazoline, 2-ethyl- 4-methyl-imidazoline, 2-benzyl-imidazoline, 2- (o-tolyl) -imidazoline, 2- (p-tolyl) -imidazoline, tetramethylene-bis-imidazoline, 1,1,3-trimethyl-1,4- tetramethylene-bis-imidazoline, 1,1,3-trimethyl-1,4-tetramethylene-bis-4-methyl-imidazoline, 1,3,3-trimethyl-1,4-tetramethylene-bis-4-methylimidazoline, 1, 2-phenylene-bis-imidazoline, 1,3-phenylene-bis-4-methyl-imidazoline and others Mixtures of the imidazoline derivatives can also be used according to the invention.

Die erfindungsgemäß einsetzbaren Imidazolin-Derivate können nach bekannten Verfahren aus gegebenenfalls substituierten geminalen Diaminen und aliphatischen oder aromatischen Mono- bzw. Dinitrilen gegebenenfalls in Gegenwart von H2S, elementarem Schwefel oder Sulfurylchlorid als Katalysator hergestellt werden.The imidazoline derivatives which can be used according to the invention can be prepared by known processes from optionally substituted geminal diamines and aliphatic or aromatic mono- or dinitriles, optionally in the presence of H 2 S, elemental sulfur or sulfuryl chloride as a catalyst.

Aus der großen Zahl der 1,2-Epoxidverbindungen, welche erfindungsgemäß eingesetzt werden können, seien genannt: Die Epoxide aus ein- oder mehrfach ungesättigten Kohlenwasserstoffen: Äthylen, Propylen, Butylen, Butadien, Cyclohexen, Vinylcyclohexen, Dicyclopentadien, Cyclododecatrien, Polybutadiene, Styrol; halogenhaltige Epoxide, wie Epichlorhydrin; Epoxiäther der einfachen Alkohole, Methyl-, Äthyl-, Butyl-, 2-Äthylhexylalkohol; Epoxiäther mehrwertiger Alkohole: Äthylen-, Propylen-, Butylenglykol, Polyglykol, Glycerin, Pentaerythrit; Epoxidäther ein- und mehrwertiger Phenole: Phenol, Kresol, Resorcin, Hydrochinon, 4,4'-Dihydroxidiphenyl, 4,4'-Dihydroxidiphenylmethan, 2,2-Bis-(4-hydroxiphenyl)-propan, 4,4'-Dihydroxidiphenylsulfon, Phenol-Formaldehyd-Kondensationsprodukte; N-haltige Epoxide: das N,N-Diglycidylanilin, N,N'-Dimethyldiglycidyl-4,4'-diaminodiphenylmethan. Bevorzugt werden solche, die mehr als eine Epoxigruppe im Molekül besitzen.From the large number of 1,2-epoxy compounds which can be used according to the invention, the following may be mentioned: the epoxides from mono- or polyunsaturated hydrocarbons: ethylene, propylene, butylene, butadiene, cyclohexene, vinylcyclohexene, dicyclopentadiene, cyclododecatriene, polybutadienes, styrene; halogen-containing epoxides, such as epichlorohydrin; Epoxy ether of simple alcohols, methyl, ethyl, butyl, 2-ethylhexyl alcohol; Epoxy ether of polyhydric alcohols: ethylene, propylene, butylene glycol, polyglycol, glycerin, pentaerythritol; Epoxy ethers of mono- and polyhydric phenols: phenol, cresol, resorcinol, hydroquinone, 4,4'-dihydroxidiphenyl, 4,4'-dihydroxidiphenylmethane, 2,2-bis (4-hydroxiphenyl) propane, 4,4'-dihydroxidiphenyl sulfone, Phenol-formaldehyde condensation products; N-containing epoxies: that N, N-diglycidylaniline, N, N'-dimethyldiglycidyl-4,4'-diaminodiphenylmethane. Preferred are those which have more than one epoxy group in the molecule.

Ebensogut wie die reinen Epoxidverbindungen können auch deren Gemische, beispielsweise solche von Mono- und Polyepoxiden erfindungsgemäß umgesetzt werden.As well as the pure epoxy compounds, their mixtures, for example those of mono- and polyepoxides, can also be reacted according to the invention.

Die Herstellung der erfindungsgemäßen Klebstofformulierungen erfolgt in denkbar einfacher Weise: Zunächst werden die Epoxidharze, soweit es sich um Festharze handelt, zerkleinert. Danach werden beide Reaktionspartner innig miteinander vermischt, wobei für eine gleichmäßige Verteilung der erfindungsgemäßen Amidine im Epoxidharz gesorgt wird. Gelangen feste Epoxidharze zum Einsatz, sollte die Korngröße des so erhaltenen Pulvers nicht über 500 µm betragen. Eine Zugabe von Lösungsmittel ist nicht erforderlich - die bei der Verwendung von flüssigen oder halbflüssigen Epoxidharzen in diesen gegebenenfalls enthaltenen sog. reaktiven Verdünner werden in diesem Sinne nicht als Lösungsmittel verstanden.The adhesive formulations according to the invention are produced in a very simple manner: First, the epoxy resins, insofar as they are solid resins, are crushed. The two reactants are then intimately mixed with one another, ensuring a uniform distribution of the amidines according to the invention in the epoxy resin. If solid epoxy resins are used, the grain size of the powder obtained in this way should not exceed 500 μm. It is not necessary to add solvent - the so-called reactive diluents which may be present in liquid or semi-liquid epoxy resins are not considered solvents in this sense.

Die so erhaltenen Klebstofformulierungen können erforderlichenfalls mit üblichen Zusätzen, wie Füllstoffen, Pigmenten, Farbstoffen u.a. versetzt werden - so können Harz und/oder Härter beispielsweise angefärbt werden, um sichtbare Klebefugen unauffälliger erscheinen oder aber sog. Schattenfugen besonders hervortreten zu lassen.The adhesive formulations obtained in this way can, if necessary, be mixed with customary additives such as fillers, pigments, dyes and the like. resin - and / or hardener can be dyed, for example, to make visible adhesive joints appear less noticeable or to allow so-called shadow gaps to stand out.

Das erfindungsgemäße Verfahren kann Verwendung finden zum Verkleben der mannigfaltigsten Werkstoffe, z.B. Metalle, Leichtmetalle, aber auch nichtmetallische Werkstoffe wie Keramik, Glas, Leder, Gummi, Holz, temperaturbeständiger Kunststoff u.a. mit sich selbst oder mit anderen Werkstoffen. Auch kann es zur Herstellung von Sandwichkonstruktionen aus Metallen und anderen Werkstoffen herangezogen werden.The method according to the invention can be used for gluing the most diverse materials, e.g. Metals, light metals, but also non-metallic materials such as ceramics, glass, leather, rubber, wood, temperature-resistant plastic, etc. with itself or with other materials. It can also be used to manufacture sandwich constructions from metals and other materials.

Die mit den erfindungsgemäß eingesetzten Amidinen formulierten Klebstoffe erfüllen voll die Forderung nach Lösungsmittelfreiheit, außerdem liegen sie als Einkomponenten-Systeme vor. Dadurch entfallen die eingangs geschilderten Nachteile wie Ablüft- und Topfzeit und es erfolgt eine schwundfreie Härtung ohne die Bildung von Spaltprodukten. Durch diese Eigenschaften sind sie u.a. bestens geeignet zum Verkleben unporöser Werkstoffe, wie z.B. Metallen. Durch die benötigten relativ niedrigen Härtungstemperaturen ist u.a. eine Verklebung von temperaturempfindlichen Werkstoffen, wie gelötete Metallteile, möglich.The adhesives formulated with the amidines used according to the invention fully meet the requirement for freedom from solvents, and they are also available as one-component systems. This eliminates the disadvantages described above, such as flash-off and pot life, and shrinkage-free curing takes place without the formation of fission products. These properties make them ideally suited for bonding non-porous materials, e.g. Metals. Due to the relatively low curing temperatures required, it is possible to bond temperature-sensitive materials such as soldered metal parts.

Weiterhin wurde festgestellt, daß als wesentlicher technischer Fortschritt die Applikation der erfindungsgemäßen Klebstoffformulierungen im Falle der Verwendung von festen Epoxidharzen auf elektrostatischem Wege erfolgen kann. Damit ist es möglich, exakt dosierbare, dünne Schichten aufzubringen, was beispielsweise beim Verkleben von Folien von Vorteil ist.Furthermore, it was found that, as a major technical advance, the adhesive formulations according to the invention can be applied electrostatically if solid epoxy resins are used. This makes it possible to apply precisely metered, thin layers, which is advantageous, for example, when gluing foils.

Als weitere Vorteile müssen die gute Temperaturbeständigkeit der Verklebungen, ihre Chemikalienresistenz sowie im besonderen ihre Waschlaugen- und Heißwasserbeständigkeit hervorgehoben werden. Außerdem haben akute orale Toxizitätsprüfungen (ZD50, Ratte) der ausgehärteten Verklebungen, die mit den erfindungsgemäßen Amidinen hergestellt wurden, ergeben, daß diese Formulierungen als nicht toxisch anzusehen sind.The good temperature resistance of the bonds, their chemical resistance and, in particular, their resistance to washing water and hot water must be emphasized as further advantages. In addition, acute oral toxicity tests (ZD 50 , rat) of the cured bonds which were produced with the amidines according to the invention have shown that these formulations are to be regarded as non-toxic.

Das erfindungsgemäße Verfahren wird durch die nachstehenden Beispielle illustriert.The process according to the invention is illustrated by the examples below.

Die verwendeten 1,2-Epoxidverbindungen, in der Praxis als Epoxidharze bezeichnet, wurden mit den erfindungsgemäß eingesetzten Amidinen in den angegebenen Gewichtsverhältnissen innig vermischt. Im Falle der Verwendung von Festharzen (Beispiele 1 bis 3) wurden beide Komponenten vorzerkleinert, gemischt und auf eine Korngröße unter 500 µm vermahlen. Bei der Verwendung von Flüssigharzen (Beispiele 4 bis 8) wurden die erfindungsgemäßen Amidine fein gemahlen und in die Harze eingemischt, bis sie gleichmäßig verteilt waren. Die so erhaltenen Klebstofformulierungen wurden auf verschiedene Substrate aufgebracht und diese anschließend bei den angegebenen Temperaturen und Zeiten verklebt. Die Abmessungen der Probekörper sowie die überlappte, d.h., verklebte Fläche entsprachen DIN 53 273. Zur Charakterisierung der erhaltenen Verklebungen wurde die Scherfestigkeit gemäß obiger Norm ermittelt. Ergänzend muß erwähnt werden, daß die verwendeten Werkstoffe für diese Versuche zwar entfettet wurden, aber sonst keinerlei Vorbehandlung (wie Aufrauhen, Anätzen o.ä.) vorgenommen worden ist.The 1,2-epoxy compounds used, referred to in practice as epoxy resins, were intimately mixed with the amidines used according to the invention in the stated weight ratios. In the case of using solid resins (Examples 1 to 3), both components were pre-comminuted, mixed and to a particle size grind to less than 500 µm. When using liquid resins (Examples 4 to 8), the amidines according to the invention were ground finely and mixed into the resins until they were evenly distributed. The adhesive formulations thus obtained were applied to various substrates and these were then bonded at the temperatures and times indicated. The dimensions of the test specimens and the overlapped, ie, glued surface corresponded to DIN 53 273. To characterize the bonds obtained, the shear strength was determined in accordance with the above standard. In addition, it must be mentioned that the materials used for these tests have been degreased, but no other pretreatment (such as roughening, etching, etc.) has been carried out.

2-Phenyl-imidazolin wurde mit einem Epoxidharz nach folgender Formulierung kombiniert:

Mit dieser Har.; Härter-Formulierung wurden Testkörper aus verschiedenen Werkstoffen verklebt und nach 30- bzw. 60-minütiger Härtung bei 100/120/140°C folgende Scherfestigkeitswerte gemessen:

Die Harz-Härter-Formulierung des Beispiels 1 wurde auf elektrostatischem Wege auf Testkörper aus V2A appliziert und diese verklebt:

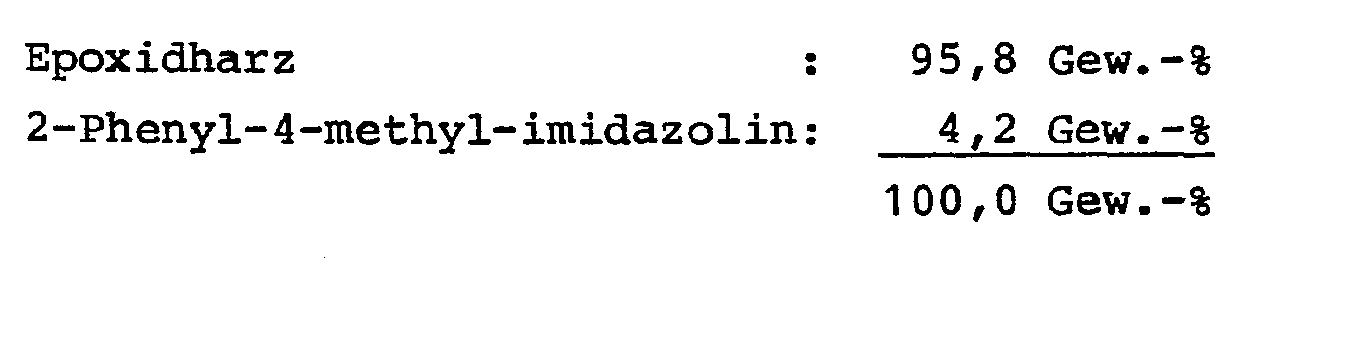

2-Phenyl-4-methyl-imidazolin wurde mit dem Epoxidharz des Beispiels 1 formuliert:

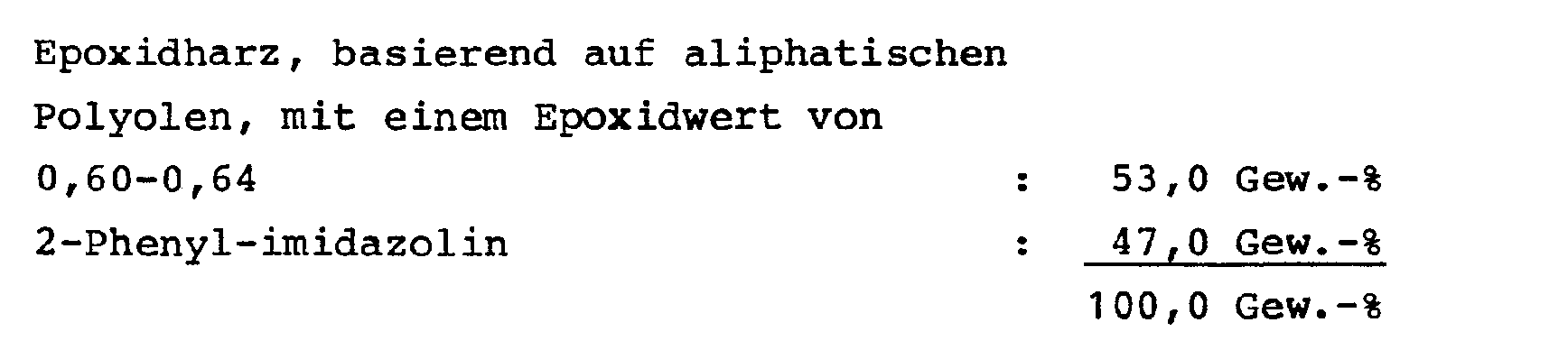

2-Phenyl-imidazolin wurde mit einem Epoxidharz wie folgt formuliert:

Mit dieser Formulierung wurden V2A-Testkörper während 30 Minuten bei 150°C verklebt und anschließend eine Scherfestigkeit von 20,7 kp/cm2 gemessen.This formulation was V 2 O T estkörper bonded for 30 minutes at 150 ° C and then a shear strength of 20.7 kgf / cm 2 was measured.

2-Phenyl-imidazolin wurde mit einem Epoxidharz nach folgender Formulierung kombiniert:

Mit dieser Formulierung wurden Testkörper aus V2A verklebt und anschließend bei + O°C, 20°C und 80°C die Scherfestigkeit ermittelt. Außerdem wurden die Verklebungen 3 Tage einer Temperaturbelastung von 80°C ausgesetzt und erneut auf ihre Scherfestigkeit geprüft.

Mit der Formulierung des Beispiels 5 wurden Testkörper aus V2 A einerseits mit solchen aus Testgummi andererseits während 30 Minuten bei 100°C verklebt und anschließend eine Scherfestigkeit von 11,6 kp/cm2 gemessen.With the formulation of Example 5, test specimens made of V 2 A were glued on the one hand to those made of test rubber on the other hand for 30 minutes at 100 ° C. and then a shear strength of 11.6 kp / cm 2 was measured.

Mit der Formulierung des Beispiels 5 wurden 2 mm starke Holzleisten während 24 Stunden bei 50°C verklebt. Die Scherfestigkeit konnte hieran nicht gemessen werden, jedoch wird die Klebefestigkeit dadurch charakterisiert, daß es nicht möglich war, die verklebten Testkörper von Hand auseinanderzuziehen.With the formulation of Example 5, 2 mm thick wooden strips were glued at 50 ° C. for 24 hours. The shear strength could not be measured by this, but the adhesive becomes firm characterized by the fact that it was not possible to pull apart the bonded test specimens by hand.

2-Phenyl-imidazolin wurde mit einem Epoxidharz nach folgender Formulierung kombiniert:

Mit dieser Formulierung wurden V2A-Testkörper während 30 Minuten bei 150°C verklebt und anschließend eine Scherfestigkeit von 76,0 kp/cm2 gemessen.With this formulation, V 2 A test specimens were bonded at 150 ° C. for 30 minutes and then a shear strength of 76.0 kp / cm 2 was measured.

Claims (3)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2731335 | 1977-07-12 | ||

| DE19772731335 DE2731335A1 (en) | 1977-07-12 | 1977-07-12 | METHOD FOR BONDING MATERIALS |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0000418A1 true EP0000418A1 (en) | 1979-01-24 |

Family

ID=6013687

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP78200093A Withdrawn EP0000418A1 (en) | 1977-07-12 | 1978-07-08 | Process for glueing materials |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0000418A1 (en) |

| DE (1) | DE2731335A1 (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0090238A1 (en) * | 1982-03-26 | 1983-10-05 | Bayer Ag | Cyclic amidines, process for their preparation and the use of cyclic amidines as catalysts in the hardening of epoxy resins |

| EP0175874A1 (en) * | 1984-09-22 | 1986-04-02 | Hüls Aktiengesellschaft | Carboxyl group containing curing agents |

| EP0417043A2 (en) * | 1989-09-07 | 1991-03-13 | Ciba-Geigy Ag | Curing agents and accelerators for epoxy- and isocyanate resins |

| EP0501074A1 (en) * | 1991-02-28 | 1992-09-02 | Texaco Chemical Company | Mixtures of 1-isopropyl-2-aryl imidazole and 1-isopropyl-2-aryl imidazoline as epoxy resin curative compositions |

| EP0525936A1 (en) * | 1991-07-29 | 1993-02-03 | Texaco Chemical Company | Accelerator for curing epoxy resins |

| GB2332202A (en) * | 1997-12-09 | 1999-06-16 | Courtaulds Coatings | Curable epoxy resin compositions |

| EP2113525A1 (en) * | 2008-04-30 | 2009-11-04 | Sika Technology AG | Activator for epoxy resin composites |

| WO2009133168A1 (en) * | 2008-04-30 | 2009-11-05 | Sika Technology Ag | Activator for epoxy resin compositions |

| WO2023235279A1 (en) | 2022-05-30 | 2023-12-07 | Corning Incorporated | Coated articles and methods of making coated articles |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3041834A1 (en) * | 1980-11-06 | 1982-06-09 | Bayer Ag, 5090 Leverkusen | NEW AMIDINE AND AMIDINE / ISOCYANATE ADDUCTS, METHOD FOR THE PRODUCTION THEREOF AND THEIR USE AS CATALYSTS FOR THE CURING OF EPOXY RESINS |

| JPS57185316A (en) * | 1981-05-11 | 1982-11-15 | Sumitomo Metal Mining Co Ltd | Electrically conductive resin paste |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2202138A1 (en) * | 1972-10-05 | 1974-05-03 | Veba Chemie Ag | |

| JPS5243834A (en) * | 1975-10-06 | 1977-04-06 | Matsushita Electric Ind Co Ltd | Electro-conductive adhesive |

-

1977

- 1977-07-12 DE DE19772731335 patent/DE2731335A1/en not_active Withdrawn

-

1978

- 1978-07-08 EP EP78200093A patent/EP0000418A1/en not_active Withdrawn

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2202138A1 (en) * | 1972-10-05 | 1974-05-03 | Veba Chemie Ag | |

| JPS5243834A (en) * | 1975-10-06 | 1977-04-06 | Matsushita Electric Ind Co Ltd | Electro-conductive adhesive |

Non-Patent Citations (1)

| Title |

|---|

| CHEMICAL ABSTRACTS, vol. 87, 24265n (1977) & JP-A-52 043 834 (MATSUSHITA). * |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0090238A1 (en) * | 1982-03-26 | 1983-10-05 | Bayer Ag | Cyclic amidines, process for their preparation and the use of cyclic amidines as catalysts in the hardening of epoxy resins |

| EP0175874A1 (en) * | 1984-09-22 | 1986-04-02 | Hüls Aktiengesellschaft | Carboxyl group containing curing agents |

| EP0417043A2 (en) * | 1989-09-07 | 1991-03-13 | Ciba-Geigy Ag | Curing agents and accelerators for epoxy- and isocyanate resins |

| EP0417043A3 (en) * | 1989-09-07 | 1992-09-30 | Ciba-Geigy Ag | Curing agents and accelerators for epoxy- and isocyanate resins |

| EP0501074A1 (en) * | 1991-02-28 | 1992-09-02 | Texaco Chemical Company | Mixtures of 1-isopropyl-2-aryl imidazole and 1-isopropyl-2-aryl imidazoline as epoxy resin curative compositions |

| US5189118A (en) * | 1991-02-28 | 1993-02-23 | Texaco Chemical Company | Mixtures of 1-isopropyl-2-aryl imidazole and 1-isopropyl-2-aryl imidazoline as epoxy resin curatives |

| EP0525936A1 (en) * | 1991-07-29 | 1993-02-03 | Texaco Chemical Company | Accelerator for curing epoxy resins |

| GB2332202A (en) * | 1997-12-09 | 1999-06-16 | Courtaulds Coatings | Curable epoxy resin compositions |

| EP2113525A1 (en) * | 2008-04-30 | 2009-11-04 | Sika Technology AG | Activator for epoxy resin composites |

| WO2009133168A1 (en) * | 2008-04-30 | 2009-11-05 | Sika Technology Ag | Activator for epoxy resin compositions |

| US8859695B2 (en) | 2008-04-30 | 2014-10-14 | Sika Technology Ag | Activator for epoxy resin compositions |

| WO2023235279A1 (en) | 2022-05-30 | 2023-12-07 | Corning Incorporated | Coated articles and methods of making coated articles |

Also Published As

| Publication number | Publication date |

|---|---|

| DE2731335A1 (en) | 1979-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0354498B1 (en) | Reactive fusible glue | |

| EP0591307B1 (en) | Reactive hot-melt adhesive | |

| EP0658584B1 (en) | Epoxy resin-hardener system having elastic properties | |

| EP0043050B1 (en) | Curable adhesive | |

| EP0133154A1 (en) | Composites impregnated with a hardenable epoxy resin matrix | |

| EP0000418A1 (en) | Process for glueing materials | |

| DE3611158A1 (en) | EPOXY RESIN COATING | |

| EP0054632A1 (en) | Hardenable adhesive | |

| EP0388359B1 (en) | Imidazoline compounds | |

| EP3460019B1 (en) | One-component thermosetting epoxy adhesive with improved adhesion | |

| EP0658583B1 (en) | Epoxy resin-hardener system having elastic properties | |

| DE2717582A1 (en) | PROCESS FOR THE PRODUCTION OF QUICKLY HARDENABLE, STORAGE-STABLE SUBSTRATES COATED WITH EPOXY RESIN / HARDER MIXTURES | |

| DE3803508C2 (en) | Cold-curing, warm, post-crosslinkable resin based on epoxy | |

| EP0781771A1 (en) | Compounds containing cyclic amidine and uretedione groups, a method for their preparation and their use | |

| DE60109696T2 (en) | Thermosetting resin composition and resin-coated metal foil, prepreg and film-type adhesive using this composition | |

| DE102017129487B4 (en) | Epoxy resin mixture, its use and method for producing an epoxy resin mixture | |

| DE2534693C3 (en) | Heat-curable, solid epoxy resin compounds | |

| DE69913075T2 (en) | Adhesive film for semiconductor packages | |

| DE2044720C3 (en) | Process for the production of carbon fiber fabrics pre-impregnated with epoxy casting resins | |

| DE1644832B2 (en) | Manufacture of coatings, bonds and grouting joints based on triglycidyl isocyanurate | |

| EP0061683B1 (en) | Curable adhesive | |

| DE1947873C3 (en) | Process for the production of insoluble polyadducts based on epoxy compounds containing urethane groups | |

| EP0643103B1 (en) | Curable binders | |

| DE4136573A1 (en) | N-AMINOALKYLIMIDAZOLE COMPOUNDS CONTAINING AMID AND CARBOXYL GROUPS AND THE USE THEREOF AS A CURING AGENT FOR EPOXY RESINS | |

| EP0617069A2 (en) | Curable, powdery mixtures |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB LU NL SE |

|

| 17P | Request for examination filed | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19801212 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KULISCH, VOLKER W. Inventor name: OBENDORF, JOHANN, DR. Inventor name: SCHUELDE, FELIX, DR. |