CN212949076U - Feeding device of film recycling extruder - Google Patents

Feeding device of film recycling extruder Download PDFInfo

- Publication number

- CN212949076U CN212949076U CN202021175684.6U CN202021175684U CN212949076U CN 212949076 U CN212949076 U CN 212949076U CN 202021175684 U CN202021175684 U CN 202021175684U CN 212949076 U CN212949076 U CN 212949076U

- Authority

- CN

- China

- Prior art keywords

- extruder

- feeding machine

- compaction

- bin

- film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model relates to a feed arrangement of extruder is retrieved to film, the device include the feed bin and compaction feeding machine feed bin that link together with the extruder. A screw conveyor is arranged at the bottom of the bin, and a compaction feeding machine bin is arranged below the discharge end of the screw conveyor; an outlet is arranged on the compaction feeding machine bin, and a cutter head is arranged in the outlet; the cutter head is provided with a central shaft, and the central shaft is connected with a compaction feeding machine motor; the compaction feeding machine motor is fixed on a support of the extruder, and the extruder is connected with a compaction feeding machine bin. The utility model discloses can realize the continuous production of high yield and the feeding of ultra-thin film and thick film, can retrieve long, wide being less than 20mm, the film that thickness is 12~200 mu m, its output is greater than 400 kg/h.

Description

Technical Field

The utility model relates to a film is retrieved and is recycled technical field, especially relates to a film is retrieved feed arrangement of extruder.

Background

The film is a product required by people in daily life. With the rapid development of the plastic industry, the yield of the film is increased, but the waste plastic is increased, and the problems of environmental pollution, energy consumption and the like are also caused. The recycling of waste films has become a hot point of research in various countries around the world.

The film recovery granulation is to utilize a crusher to crush the film, then to enter an extruder to melt and granulate, and then to produce a new film or other plastic products. Due to the low bulk density and large difference of the films, the materials are easy to block at the feed inlet of the conventional extruder, and industrial continuous extrusion granulation is difficult to realize.

SUMMERY OF THE UTILITY MODEL

The utility model aims to solve the technical problem that a film that realizes high output continuous production retrieves extruder's feed arrangement is provided.

In order to solve the above problem, the utility model relates to a film recycling extruder's feed arrangement, its characterized in that: the device comprises a bin connected with an extruder and a compaction feeding machine bin; a screw conveyor is arranged at the bottom of the bin, and a compaction feeding machine bin is arranged below the discharge end of the screw conveyor; an outlet is arranged on the compaction feeding machine bin, and a cutter head is arranged in the outlet; the cutter head is provided with a central shaft, and the central shaft is connected with a compaction feeding machine motor; the compaction feeding machine motor is fixed on a support of the extruder, and the extruder is connected with a compaction feeding machine bin.

The central shaft is connected with an output shaft of the compaction feeder motor through a belt pulley.

And a feed inlet is arranged on the side surface of the extruder and is connected with an outlet of a bin of the compaction feeding machine.

The diameter of the cutter head is 1000mm, the thickness is 40mm, the rotating speed is 400 r/min-600 r/min, and a crescent-shaped lug is arranged on the upper surface of the cutter head.

The diameter of a screw of the spiral conveyer is 300mm, and the constant rotating speed is 30 r/min.

The diameter of the compaction feeding machine bin is 1100mm, and the height of the compaction feeding machine bin is 1200 mm.

The diameter of a screw of the extruder is 120mm, and the length-diameter ratio is 32: 1, the highest rotating speed is 120 r/min.

Compared with the prior art, the utility model has the following advantage:

1. the utility model discloses be equipped with the blade disc in the well compaction feeding machine feed bin, consequently, can in time effectively with the film rolling, reduce the volume of film, make it steadily get into the extruder by controlled, product that can the continuous production steady quality.

2. The utility model discloses a control of compaction feed motor electric current can control the dwell time of film in the feed bin effectively to obtain stable in quality's recovery product.

3. Adopt the utility model discloses can retrieve the film that length, width are less than 20mm, and thickness are 12~200 mu m, its output is greater than 400kg/h, can realize the continuous production of high yield and the feeding of ultra-thin film and thick film.

Drawings

The following describes embodiments of the present invention in further detail with reference to the accompanying drawings.

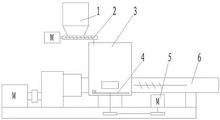

Fig. 1 is a schematic view of the vertical structure of the present invention.

Fig. 2 is a schematic view of the top view structure of the present invention.

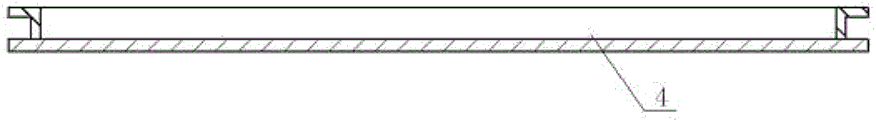

Fig. 3 is a schematic structural diagram of the middle cutter head of the present invention.

Fig. 4 is a top view of the cutter head of the present invention.

In the figure: 1, a storage bin; 2-a screw conveyor; 3-compacting a feeder bin; 4, a cutter head; 5-compacting feeder motor; 6-extruder.

Detailed Description

As shown in figures 1-4, the feeding device of the film recycling extruder comprises a bin 1 connected with an extruder 6 and a compaction feeding machine bin 3. A screw conveyor 2 is arranged at the bottom of the bin 1, and a compaction feeding machine bin 3 is arranged below the discharge end of the screw conveyor 2; an outlet is arranged on the compaction feeding machine bin 3, and a cutter head 4 is arranged in the outlet; the cutter head 4 is provided with a central shaft which is connected with a compaction feeding machine motor 5; a compactor feed motor 5 is fixed to the support of an extruder 6, which extruder 6 is connected to a compactor feed bin 3.

Wherein: the central shaft is connected with an output shaft of a motor 5 of the compaction feeding machine through a belt pulley to drive the cutter head 4 to rotate at a high speed.

The side of the extruder 6 is provided with a feed inlet which is connected with the outlet of the compaction feeder bin 3.

The diameter of the cutter head 4 is 1000mm, the thickness is 40mm, the rotating speed is 400 r/min-600 r/min, and a crescent-shaped convex block is arranged on the upper surface of the cutter head.

The screw diameter of the screw conveyor 2 was 300mm and the constant rotational speed was 30 r/min.

The diameter of the compaction feeding machine bin 3 is 1100mm, and the height is 1200 mm.

The diameter of a screw of the extruder 6 is 120mm, and the length-diameter ratio is 32: 1, the highest rotating speed is 120 r/min.

The working principle is as follows: the opening or the stopping of the motor of the screw conveyor 2 is controlled by setting the current of the motor 5 of the compaction feeding machine, so that the material quantity in the bin 3 of the compaction feeding machine is controlled. When the current of the motor 5 of the compaction feeding machine exceeds a set value, the material in the bin 3 of the compaction feeding machine is excessive, the motor of the screw conveyor 2 is stopped, and the material is not conveyed; when the current of the motor 5 of the compaction feeding machine is lower than a set value, the compaction feeding machine indicates that the material in the bin 3 of the compaction feeding machine is less, and the motor of the screw conveyor 2 is started to convey the material.

The shape of the recycling film of the utility model is that the length and the width are less than 20mm, and the thickness is 12 to 200 μm.

When the device works, a thin film in the hopper 1 passes through the low-speed rotating screw conveyor 2 to the compaction feeding machine bin 3, is compacted into a roll shape by the high-speed rotating cutter head 4, and enters the extruder 6 from the side surface of the barrel of the extruder 6. An output shaft of a motor 5 of the compaction feeding machine is connected with a central shaft of the cutter head 4 through a belt pulley to drive the cutter head 4 to rotate at a high speed. The opening or the stopping of the motor of the screw conveyor 2 is controlled by setting the current of the motor 5 of the compaction feeder, so that the material amount in the bin 3 of the compaction feeder is controlled. When the current of the motor 5 of the compaction feeding machine exceeds a set value, the material in the bin 3 of the compaction feeding machine is excessive, the motor of the screw conveyor 2 is stopped, and the material is not conveyed; when the current of the motor 5 of the compaction feeding machine is lower than a set value, the compaction feeding machine indicates that the material in the bin 3 of the compaction feeding machine is less, and the motor of the screw conveyor 2 is started to convey the material.

Claims (7)

1. The utility model provides a feed arrangement of extruder is retrieved to film which characterized in that: the device comprises a bin (1) connected with an extruder (6) and a compaction feeding machine bin (3); a screw conveyor (2) is arranged at the bottom of the bin (1), and a compaction feeding machine bin (3) is arranged below the discharge end of the screw conveyor (2); an outlet is arranged on the compaction feeding machine bin (3), and a cutter head (4) is arranged in the outlet; the cutter head (4) is provided with a central shaft, and the central shaft is connected with a compaction feeding machine motor (5); the compaction feeding machine motor (5) is fixed on a support of the extruder (6), and the extruder (6) is connected with the compaction feeding machine bin (3).

2. A feeding device of a film recycling extruder as claimed in claim 1, wherein: the central shaft is connected with an output shaft of the compaction feeding machine motor (5) through a belt pulley.

3. A feeding device of a film recycling extruder as claimed in claim 1, wherein: and a feed inlet is formed in the side surface of the extruder (6), and is connected with an outlet of the compaction feeding machine bin (3).

4. A feeding device of a film recycling extruder as claimed in claim 1, wherein: the diameter of the cutter head (4) is 1000mm, the thickness is 40mm, the rotating speed is 400 r/min-600 r/min, and a crescent-shaped convex block is arranged on the upper surface of the cutter head.

5. A feeding device of a film recycling extruder as claimed in claim 1, wherein: the diameter of a screw of the spiral conveyor (2) is 300mm, and the constant rotating speed is 30 r/min.

6. A feeding device of a film recycling extruder as claimed in claim 1, wherein: the diameter of the compaction feeding machine bin (3) is 1100mm, and the height is 1200 mm.

7. A feeding device of a film recycling extruder as claimed in claim 1, wherein: the diameter of a screw of the extruder (6) is 120mm, and the length-diameter ratio is 32: 1, the highest rotating speed is 120 r/min.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021175684.6U CN212949076U (en) | 2020-06-23 | 2020-06-23 | Feeding device of film recycling extruder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202021175684.6U CN212949076U (en) | 2020-06-23 | 2020-06-23 | Feeding device of film recycling extruder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN212949076U true CN212949076U (en) | 2021-04-13 |

Family

ID=75386512

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202021175684.6U Active CN212949076U (en) | 2020-06-23 | 2020-06-23 | Feeding device of film recycling extruder |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN212949076U (en) |

-

2020

- 2020-06-23 CN CN202021175684.6U patent/CN212949076U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111438837A (en) | Method for regenerating and granulating waste EPS cold pressing material and control system | |

| CN206748816U (en) | A kind of plastic strip pelleter | |

| CN111438838A (en) | Method for regenerating and granulating waste EPS hot melt material and control system | |

| US4189291A (en) | Apparatus and process for recovering scraps of thermoplastic material, even of heterogeneous shapes, by gradual melting and compression through one or more orifices | |

| CN203990525U (en) | Fish meal Flat die granulating machine | |

| CN212949076U (en) | Feeding device of film recycling extruder | |

| CN214288380U (en) | Environment-friendly efficient plastic flour mill | |

| CN204566436U (en) | A kind of wood is moulded to process raw material and is pulverized and mixed system | |

| CN215312176U (en) | Ring die feed granulator | |

| CN115771213A (en) | Rubbing crusher with dustproof function is used in plastic production | |

| CN213222555U (en) | Waste recovery device for machining in mechanical field | |

| CN212288257U (en) | Control system for regeneration granulation of waste EPS cold pressing material | |

| CN110696226B (en) | Wood-plastic composite material crushing and recycling device | |

| CN2200527Y (en) | Regeneration device for waste foamed plastics | |

| CN212266332U (en) | Control system for regeneration granulation of waste EPS hot melt material | |

| CN209580185U (en) | A kind of crushing feeding device of polyurethane ingredient production | |

| CN210906488U (en) | Plastic woven sack raw materials for production's crushing mesh screen device | |

| CN201082578Y (en) | Feeding device of extruding machine | |

| CN212920052U (en) | Plastic crushing device for recycling waste plastic | |

| CN201070847Y (en) | Ring mould rolling wheel extrusion molding machine with novel structure | |

| CN2296765Y (en) | Crusher | |

| CN207877261U (en) | A kind of mono-roller type comminutor | |

| CN206642845U (en) | A kind of stalk crasher | |

| CN111330515A (en) | Biomass granulator | |

| CN216756673U (en) | Steel shaving shredder convenient for discharging |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |