CN202493679U - Anti-collision quick-open fire hydrant - Google Patents

Anti-collision quick-open fire hydrant Download PDFInfo

- Publication number

- CN202493679U CN202493679U CN2012200112198U CN201220011219U CN202493679U CN 202493679 U CN202493679 U CN 202493679U CN 2012200112198 U CN2012200112198 U CN 2012200112198U CN 201220011219 U CN201220011219 U CN 201220011219U CN 202493679 U CN202493679 U CN 202493679U

- Authority

- CN

- China

- Prior art keywords

- valve clack

- water outlet

- main

- main valve

- fire hydrant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Lift Valve (AREA)

- Taps Or Cocks (AREA)

Abstract

The utility model discloses an anti-collision quick-open fire hydrant, which is manually opened and closed, is designed to have a double-valve-clack self-sealing structure, is opened step by step in a 90-degree rotation manner, has a crotch-shaped appearance and belongs to the fields of fire fighting and water supply and drainage. The anti-collision quick-open fire hydrant is composed of a slant slider, a water outlet joint pipe, a main body, a water inlet joint pipe, a pressure rod, a middle rod, a main shaft rod, a drainage valve, a main valve clack, an auxiliary valve clack, a spring and a guide sleeve; the water inlet joint pipe is arranged at a water inlet side, a water outlet joint pipe is arranged at a water outlet side, the valve seat is embedded in the main body, and the drainage valve is screwed in the main body; the slant slider is fixed in the water outlet joint pipe; the pressure rod is provided with a steel ball, the lower part of the pressure rod butts against the middle rod, the lower part of the middle rod butts against the main shaft rod, and the spring is sleeved on the main shaft rod; a main seal ring is fixed in the main valve clack through a main pressure plate, and the auxiliary seal ring is fixed in the auxiliary valve clack through an auxiliary pressure plate; and the main valve clack and the auxiliary valve clack are sleeved on the main shaft rod. According to the utility model, the problems of long opening and closing time, large operation torque, unavailability for self-discharge and freezing prevention, and collision-induced water jet of the conventional fire hydrant are solved; the main valve clack is maintained in a seal state under the action of the pressure of supplied water, and water supply is started by rotating the slant slider and pressing down the main valve clack; and the anti-collision quick-open fire hydrant has a wide application prospect in the fields of electric power, petrochemical industry and urban fire control.

Description

Technical field

The utility model relates to a kind of fire protection sector of being used for; Rated working pressure reaches 1.6MPa, and nominal diameter is DN150mm, and water supply flow reaches 5000L/min; Be designed to bivalve lobe self sealing structure, rotate 90 ° of substep opening ways; Profile is branching shape, is the core control valve-crashproof fire hydrant of opening soon in the hydrant system, belongs to fire-fighting, plumbing field.

Background technique

Existing fire hydrant, rated working pressure is on the low side, is 1.2MPa; Unlatching, closing operation need the full-time staff could be competent at bigger power.

Traditional fire hydrant opens, cuts out and need rotate a few, has stopped over the fire extinguishing water supply time; Existing fire hydrant does not have automatic drain valve, can't get rid of ponding in the fire hydrant automatically, causes the freezing accident that can't open water supply once more even cause the fire hydrant bursting by freezing of fire hydrant, application places such as the incompatible north is antifreeze, town water supply in cold season.

Present fire hydrant, receive object accidental impact such as automobile, forklift after, fire hydrant water flow jet and going out, up to more than ten meters, the significant wastage water resources causes surface gathered water to hinder urban highway traffic.

Summary of the invention

In order to fill up the domestic crashproof blank of driving fire hydrant soon; In order to solve fire hydrant rapid operation, open and close fast, prevent the automobile impacting water outlet, to prevent the problem that the bolt ice freeze-up is frozen; Satisfy the 5000L/min water output, the utility model provides a kind of crashproof fire hydrant of opening soon, and its rated working pressure is 1.6MPa; Nominal diameter 150mm, opening time<10s; The utility model adopts bivalve lobe self sealing structure, rotates 90 ° of substep opening ways, and profile is branching shape; Adopt main valve clack, secondary flap self sealing structure, suffer object strikes water outlet such as automobile to take over fracture at fire hydrant after, intrinsic main valve clack, secondary flap can keep sealing state; Rotate 90 ° and just can open water supply; Angled-lift splits has all adopted steel ball up and down, elder generation's open auxiliary flap small flow water outlet during unlatching, and the water outlet of main valve clack full flow is opened in 3 the pressure release elder generations via water outlet on main valve clack again, reduces roof pressure power down, operates light; The body cavity lowest part has assembled drain valve, releases automatically to prevent freezing except that ponding.Be with a wide range of applications at electric power, metallurgy, urban fire protection.

The utility model be achieved in that crashproof open soon fire hydrant by: angled-lift splits, trim ring, screw, O RunddichtringO, water outlet adapter, lining, depression bar, intermediate bar, spring, spindle rod, body, drain valve, main valve clack, secondary flap, steel ball, valve seat, primary seal circle, main pressing plate, secondary pressing plate, secondary seal ring, cotter pin, bolt, water inlet adapter, guide sleeve are formed; Influent side is equipped with into water adapter, and water outlet side is connected to water outlet and takes over, and valve seat is set in the body, and drain valve is threaded onto in the body; Angled-lift splits by trim ring, screw in water outlet is taken over; Steel ball is equipped with on depression bar top, and the depression bar bottom props up intermediate bar, and the intermediate bar bottom props up spindle rod, and spindle rod is with spring, and intermediate bar is with guide sleeve; The primary seal circle is fixed in the main valve clack by main pressing plate, and secondary seal ring is fixed in the secondary flap by secondary pressing plate; Secondary flap, main valve clack are placed on the spindle rod, by the cotter pin screens.

Main valve clack, secondary flap receive water source thrust to close sealing at ordinary times.Counterclockwise switching angled-lift splits is 90 ° during unlatching, following compression bar, intermediate bar, spindle rod, and the water outlet of first open auxiliary flap small flow, the water outlet of main valve clack full flow is opened in 3 the pressure release elder generations via water outlet on main valve clack again, has reduced time top steering force; When closing, clockwise rotate 90 ° of angled-lift splitses, main valve clack, secondary flap move to water outlet side and to close sealing under source pressure promotes.

The beneficial effect of the utility model is: adopt bivalve lobe self sealing structure, rotate 90 ° of substep opening ways; After suffering the object strikes water outlet to take over fracture, intrinsic main valve clack and secondary flap keep sealing automatically under hydraulic pressure thrust, solve conventional fire hydrant and are severed the accident of splitting casual Kingsoft of water, back; Angled-lift splits adopts steel ball up and down, and frictional force is little, elder generation's open auxiliary flap small flow water outlet during unlatching, and the water outlet of main valve clack full flow is opened in 3 the pressure release elder generations via water outlet on main valve clack again, operates light; The body cavity lowest part is provided with drain valve, gets rid of ponding in the fire hydrant automatically, plays preventing freezing effect.

Description of drawings

Below in conjunction with accompanying drawing and embodiment the utility model is further specified.

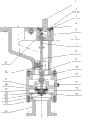

Fig. 1 is the sectional drawing of the utility model closed condition.

Fig. 2 is the outline drawing of the utility model.

Fig. 3 is the vital part in the utility model: sectional drawing is taken in water outlet.

Fig. 4 is the vital part in the utility model: part sectioned view is taken in water outlet.

Fig. 5 is the vital part in the utility model: the body sectional drawing.

Water outlet is taken over: water outlet is taken over water inlet neck neck section and is adopted thin-walled and reinforcing rib design, plays the safety fuse cutout effect of rupturing when receiving the object accidental impact.

Body: adopt Cuprum alloy, lowest part is equipped with drain valve in the body cavity, and water intake studs with valve seat, and water outlet is designed to the clear opening of several circle-shaped equal portions.

Main valve clack: be designed to play with spindle rod and cooperate, circle-shaped 3 pressure release guide clear openings, main valve clack and the primary seal circle employing setting-in clamping mode of being evenly equipped with.

Angled-lift splits: adopt 45 ° of oblique angles, rotate 90 ° of following compression bars, substep is pushed secondary flap, main valve clack water outlet open; Plane and lower inclined plane are designed to the steel ball rolling friction on the angled-lift splits, play the effect that reduces steering force.

The technological scheme that its technical problem of the utility model solution is taked is:

Adopt bivalve lobe self sealing structure, rotate 90 ° of substep opening ways through design in the utility model; After being clashed into water outlet adapter fracture, intrinsic main valve clack and secondary flap keep sealing automatically under water source thrust; Angled-lift splits adopts steel ball up and down, and frictional force is little, elder generation's open auxiliary flap small flow water outlet during unlatching, and the water outlet of main valve clack full flow is opened in 3 the pressure release elder generations via water outlet on main valve clack again, operates light; The body cavity lowest part is provided with drain valve, gets rid of ponding in the fire hydrant automatically.

Embodiment

Crashproof open soon fire hydrant by: angled-lift splits (1), trim ring (2), screw (3), O RunddichtringO (4), water outlet take over (5), lining (6), depression bar (7), intermediate bar (8), spring (9), spindle rod (10), body (11), drain valve (12), main valve clack (13), secondary flap (14), steel ball (15), guide sleeve (16), valve seat (17), primary seal circle (18), main pressing plate (19), secondary pressing plate (20), secondary seal ring (21), cotter pin (22), bolt (23), water inlet is taken over (24) and is formed; Influent side is equipped with into water adapter, and water outlet side is connected to water outlet and takes over, and valve seat is set in the body, and drain valve is threaded onto in the body; Angled-lift splits by trim ring, screw in water outlet is taken over; Steel ball is equipped with on depression bar top, and the depression bar bottom props up intermediate bar, and the intermediate bar bottom props up spindle rod, and spindle rod is with spring, and intermediate bar is with guide collar; The primary seal circle is fixed in the main valve clack by main pressing plate, and secondary seal ring is fixed in the secondary flap by secondary pressing plate; Secondary flap, main valve clack are placed on the spindle rod, by the cotter pin screens.Main valve clack, secondary flap receive water source thrust to close sealing at ordinary times.Counterclockwise switching angled-lift splits is 90 ° during unlatching, following compression bar, intermediate bar, spindle rod, and the water outlet of first open auxiliary flap small flow, the water outlet of main valve clack full flow is opened in 3 the pressure release elder generations via water outlet on main valve clack again; When closing, clockwise rotate 90 ° of angled-lift splitses, main valve clack, secondary flap move to water outlet side and to close sealing under source pressure promotes.

1) material: water inlet is taken over and is adopted spheroidal graphite cast iron, water outlet to take over the employing grey cast iron; Body, lining, drain valve, angled-lift splits, valve seat adopt Cuprum alloy; Stainless steel is adopted in steel ball, depression bar, intermediate bar, spindle rod, main valve seat, secondary flap, main pressing plate, secondary pressing plate, trim ring, spring, screw, bolt, cotter pin; Primary seal circle, secondary seal ring and O RunddichtringO adopt nitrile butadiene rubber; Guide sleeve adopts nylon.

2) rated working pressure: 1.6MPa.

3) opening time :≤10S.

4) water supply flow: >=5000L/min.

5) rotation angled-lift splits On/Off moment :≤5N.m.

The utility model is with a wide range of applications at electric power, metallurgy, urban fire protection.

Claims (3)

1. crashproof fire hydrant of opening soon, it is characterized in that by: (5), lining (6), depression bar (7), intermediate bar (8), spring (9), spindle rod (10), body (11), drain valve (12), main valve clack (13), secondary flap (14), steel ball (15), guide sleeve (16), valve seat (17), primary seal circle (18), main pressing plate (19), secondary pressing plate (20), secondary seal ring (21), cotter pin (22), bolt (23) are taken in angled-lift splits (1), trim ring (2), screw (3), O RunddichtringO (4), water outlet, water inlet is taken over (24) and formed; Adopt bivalve lobe self sealing structure, rotate 90 ° of substep opening ways; Influent side is equipped with into water adapter, and water outlet side is connected to water outlet and takes over, and valve seat is set in the body, and drain valve is threaded onto in the body; Angled-lift splits is fixed in the water outlet adapter by trim ring; Steel ball is equipped with on depression bar top, and the depression bar bottom props up intermediate bar, and the intermediate bar bottom props up spindle rod, and spindle rod is with spring, and intermediate bar is with guide sleeve; The primary seal circle is fixed in the main valve clack by main pressing plate, and secondary seal ring is fixed in the secondary flap by secondary pressing plate; Secondary flap, main valve clack are placed on the spindle rod, by the cotter pin screens; Main valve clack, secondary flap receive water source thrust to close sealing at ordinary times; The switching angled-lift splits is 90 ° counterclockwise, and following compression bar, secondary flap, main valve clack are opened water outlet.

2. the crashproof fire hydrant of opening soon according to claim 1 is characterized in that water outlet adapter water inlet neck neck section adopts thin-walled and reinforcing rib design.

3. the crashproof fire hydrant of opening soon according to claim 1 is characterized in that main valve clack and spindle rod are designed to play and cooperate, and is evenly equipped with 3 pressure release elder generation vias, and main valve clack and primary seal circle adopt the setting-in clamping mode.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200112198U CN202493679U (en) | 2012-01-10 | 2012-01-10 | Anti-collision quick-open fire hydrant |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200112198U CN202493679U (en) | 2012-01-10 | 2012-01-10 | Anti-collision quick-open fire hydrant |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202493679U true CN202493679U (en) | 2012-10-17 |

Family

ID=46999911

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200112198U Expired - Fee Related CN202493679U (en) | 2012-01-10 | 2012-01-10 | Anti-collision quick-open fire hydrant |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202493679U (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103363125A (en) * | 2013-05-23 | 2013-10-23 | 金卡高科技股份有限公司 | Multistage-opening valve driven by slowdown motor |

| CN106382369A (en) * | 2015-12-29 | 2017-02-08 | 安徽红星阀门有限公司 | Water supply hydrant |

| CN109488775A (en) * | 2019-01-10 | 2019-03-19 | 成都国光电气股份有限公司 | Balanced disc structure |

-

2012

- 2012-01-10 CN CN2012200112198U patent/CN202493679U/en not_active Expired - Fee Related

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103363125A (en) * | 2013-05-23 | 2013-10-23 | 金卡高科技股份有限公司 | Multistage-opening valve driven by slowdown motor |

| CN103363125B (en) * | 2013-05-23 | 2016-02-10 | 金卡高科技股份有限公司 | The multistage valve opening door driven by reducing motor |

| CN106382369A (en) * | 2015-12-29 | 2017-02-08 | 安徽红星阀门有限公司 | Water supply hydrant |

| CN106382369B (en) * | 2015-12-29 | 2018-08-10 | 安徽红星阀门有限公司 | A kind of turncock |

| CN109488775A (en) * | 2019-01-10 | 2019-03-19 | 成都国光电气股份有限公司 | Balanced disc structure |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202493679U (en) | Anti-collision quick-open fire hydrant | |

| CN102587456A (en) | Two-stage pressure-adjusting multifunctional outdoor fire hydrant | |

| CN205503998U (en) | Fire hydrant bottom valve | |

| CN201710863U (en) | Large-diameter pressurizing drive deluge alarm valve | |

| CN101694215B (en) | Hemispherical control valve of slurry pump | |

| CN103055461B (en) | Low-torque linkage double-open fire hydrant | |

| CN203264132U (en) | Raining alarm valve | |

| CN202347584U (en) | Anti-colliding fire hydrant | |

| CN213994687U (en) | Anti-reset device | |

| CN208472846U (en) | A kind of antifreeze anticollision pressure-regulating type outdoor fire hydrant | |

| CN202538217U (en) | Subarea control valve | |

| CN201739577U (en) | Fire-fighting check valve | |

| CN201136053Y (en) | Gas-liquid control system for tundish emergency shutter | |

| CN201581440U (en) | Anti-collision type water supply hydrant | |

| CN105179329A (en) | Efficient hydraulic ram | |

| CN2523953Y (en) | Flying and water entering protector for steam turbine | |

| CN103388489A (en) | Strong karst tunnel permanent draining structure and construction method thereof | |

| CN204328164U (en) | Deluge alarm valve | |

| CN102698397A (en) | Pressurization-driven rainwater control valve for water mist fire-extinguishing system | |

| CN212835672U (en) | Anticollision pressure regulating bolt | |

| CN221798591U (en) | Energy-saving and consumption-reducing fire-fighting water supply equipment | |

| CN101839008A (en) | Anti-collision integrated outdoor fire hydrant | |

| CN220134669U (en) | Antifreezing rotary ball valve | |

| CN201232224Y (en) | Hydrant capable of automatic turning off water | |

| CN2683955Y (en) | Antifreezing water tap valve cock |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20140110 |