Fertilizer powdery process for processing device

Technical field

The utility model belongs to agricultural fertilizer production unit technical field, relates to a kind of have construction period weak point, investment repayment profit height and the little fertilizer powdery process for processing device of the market risk.

Background technology

Fertilizer is meant microorganisms with specific functions and serve as one type of fertilizer that has microbial fertilizer and fertilizer effect concurrently of originating and being composited through harmless treatment, the organic materials that becomes thoroughly decomposed with plant and animal residues (like feces of livestock and poultry, agricultural crop straw etc.) mainly; The ecological organic fertilier nutritive element is complete; Can improve the soil, improve the soil compaction that uses chemical fertilizer to cause.Improve soil physical and chemical property, strengthen soil water-retaining, protect fertile, as to supply fertilizer ability.Useful microbe in the fertilizer get into behind the soil with soil in mikrobe form mutual symbiosis propagation relation, suppress harmful bacteria growing and also be converted into probiotics, interact; Mutually promote; Play the synergy of colony, probiotics produces a large amount of meta-bolitess in the growth and breeding process, impel organic decomposition and inversion; Can promote and the regulation and control plant growth directly or indirectly for crop provides multiple nutrients and pungent.Improve soil porosity, penetrating exchangeability and plant survival rate, increase probiotics and soil microorganisms and population.Simultaneously, the advantage probiotics group energy that forms at crop root suppresses harmful pathogenic bacteria procreation, and the degeneration-resistant resistance against diseases of enhancing crop reduces the disease index of continuous cropping crop, uses year after year and can alleviate continuous cropping obstacle greatly.Reducing environmental pollution, to people, animal, environmental safety, nontoxic, is a kind of environment-friendly type fertilizer.

The utility model content

In order to overcome the above-mentioned shortcoming of prior art

,The utility model provides a kind of fertilizer powdery process for processing device with construction period weak point, investment repayment profit height and the little characteristics of the market risk.

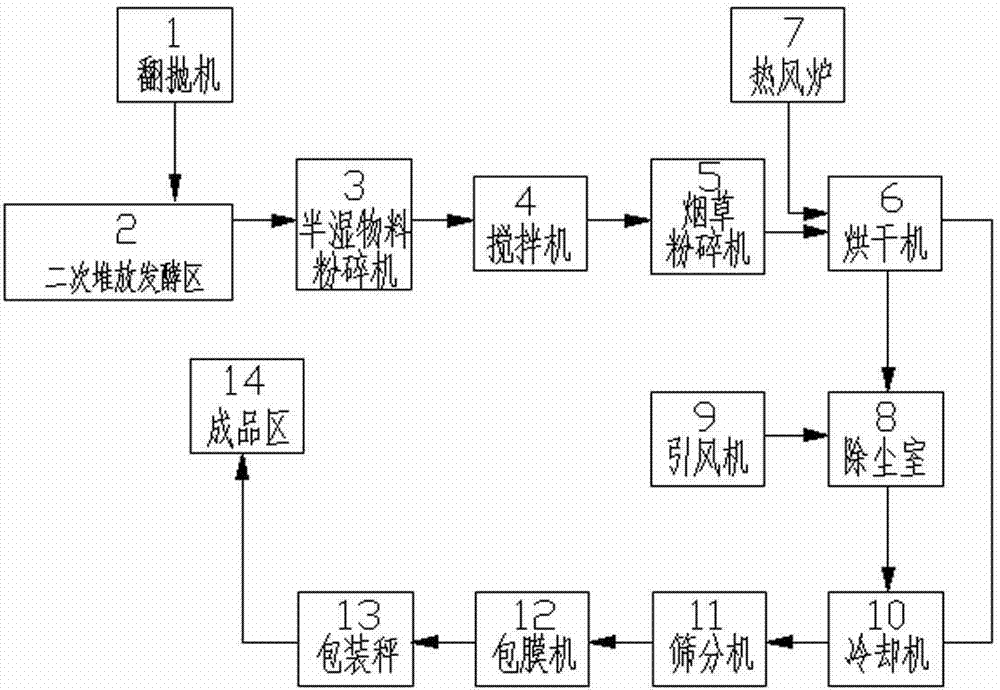

The utility model solves the technical scheme that its technical problem adopted: a kind of fertilizer powdery process for processing device, comprise turnover throwing machine, and turnover throwing machine is stacked fermentation zone with secondary and is connected; Secondary is stacked fermentation zone and is connected with half wet stock kibbler; Half wet stock kibbler connects stirrer, and stirrer links to each other with the tobacco kibbler, and the tobacco kibbler connects dryer; Be provided with hotblast stove in the dryer; Dryer is connected with dust settling chamber respectively with induced draft fan, and dust settling chamber links to each other with coating machine with sieve apparatus through cooler, and coating machine connects packing scale.

The beneficial effect of the utility model is: can rationally accomplish the powdery treating processes to raw material up hill and dale, the whole production course of processing is smooth, simple, environmental protection, has practiced thrift production cost; Improved working efficiency; Dwindled man-hour, had construction period weak point, investment repayment profit height and the little characteristics of the market risk, fertilizer reduces environmental pollution; To people, animal, environmental safety, nontoxic, be a kind of environment-friendly type fertilizer.

Description of drawings

Fig. 1 is the structure block diagram of the utility model.

Among the figure: the 1-turnover throwing machine, the 2-secondary is stacked fermentation zone, 3-half wet stock kibbler, 4-stirrer, 5-tobacco kibbler, 6-dryer, 7-hotblast stove, 8-dust settling chamber, 9-induced draft fan, 10-cooler, 11-sieve apparatus, 12-coating machine, 13-packing scale, 14-finished product district.

Embodiment

Below in conjunction with accompanying drawing the utility model is further specified.

Referring to Fig. 1; A kind of fertilizer powdery process for processing device comprises turnover throwing machine 1, and turnover throwing machine 1 connects secondary stacking fermentation zone 2 and the raw materials that secondary is stacked in the fermentation zone 2 are handled; Secondary is stacked fermentation zone 2 raw material is sent into half wet stock kibbler 3; The raw material that half wet stock kibbler 3 will be handled is sent into stirrer 4 and is stirred, and again raw material is sent into tobacco kibbler 5 after stirrer 4 is handled, and tobacco kibbler 5 carries out sending into dryer 6 again after particulate state is handled with raw material and toasts; Be provided with hotblast stove 7 in the dryer 6; After the oven dry raw material is sent into dust settling chamber 8 and handle, carry out step process through cooler 10 and sieve apparatus 11 again after dust settling chamber 8 is handled, produce good product and pack through coating machine 12 and packing scale 13 through induced draft fan 9; Send into finished product district 14 after the packing and store, promptly accomplished the work of fertilizer powdery process for processing.

The utility model can rationally be accomplished the powdery treating processes to raw material up hill and dale, and the whole production course of processing is smooth, simple, environmental protection, has practiced thrift production cost; Improved working efficiency; Dwindled man-hour, had construction period weak point, investment repayment profit height and the little characteristics of the market risk, fertilizer reduces environmental pollution; To people, animal, environmental safety, nontoxic, be a kind of environment-friendly type fertilizer.