CN114797628A - Device and method for extracting chondroitin from fish bone paste - Google Patents

Device and method for extracting chondroitin from fish bone paste Download PDFInfo

- Publication number

- CN114797628A CN114797628A CN202210453417.8A CN202210453417A CN114797628A CN 114797628 A CN114797628 A CN 114797628A CN 202210453417 A CN202210453417 A CN 202210453417A CN 114797628 A CN114797628 A CN 114797628A

- Authority

- CN

- China

- Prior art keywords

- ring

- grinding

- fish bone

- groups

- bone paste

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F33/00—Other mixers; Mixing plants; Combinations of mixers

- B01F33/80—Mixing plants; Combinations of mixers

- B01F33/83—Mixing plants specially adapted for mixing in combination with disintegrating operations

- B01F33/831—Devices with consecutive working receptacles, e.g. with two intermeshing tools in one of the receptacles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F27/00—Mixers with rotary stirring devices in fixed receptacles; Kneaders

- B01F27/80—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis

- B01F27/90—Mixers with rotary stirring devices in fixed receptacles; Kneaders with stirrers rotating about a substantially vertical axis with paddles or arms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C2/00—Crushing or disintegrating by gyratory or cone crushers

- B02C2/10—Crushing or disintegrating by gyratory or cone crushers concentrically moved; Bell crushers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C23/00—Auxiliary methods or auxiliary devices or accessories specially adapted for crushing or disintegrating not provided for in preceding groups or not specially adapted to apparatus covered by a single preceding group

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08B—POLYSACCHARIDES; DERIVATIVES THEREOF

- C08B37/00—Preparation of polysaccharides not provided for in groups C08B1/00 - C08B35/00; Derivatives thereof

- C08B37/0003—General processes for their isolation or fractionation, e.g. purification or extraction from biomass

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08B—POLYSACCHARIDES; DERIVATIVES THEREOF

- C08B37/00—Preparation of polysaccharides not provided for in groups C08B1/00 - C08B35/00; Derivatives thereof

- C08B37/006—Heteroglycans, i.e. polysaccharides having more than one sugar residue in the main chain in either alternating or less regular sequence; Gellans; Succinoglycans; Arabinogalactans; Tragacanth or gum tragacanth or traganth from Astragalus; Gum Karaya from Sterculia urens; Gum Ghatti from Anogeissus latifolia; Derivatives thereof

- C08B37/0063—Glycosaminoglycans or mucopolysaccharides, e.g. keratan sulfate; Derivatives thereof, e.g. fucoidan

- C08B37/0069—Chondroitin-4-sulfate, i.e. chondroitin sulfate A; Dermatan sulfate, i.e. chondroitin sulfate B or beta-heparin; Chondroitin-6-sulfate, i.e. chondroitin sulfate C; Derivatives thereof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Biochemistry (AREA)

- Molecular Biology (AREA)

- General Health & Medical Sciences (AREA)

- Materials Engineering (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Food Science & Technology (AREA)

- Dermatology (AREA)

- Sustainable Development (AREA)

- Mechanical Engineering (AREA)

- Meat, Egg Or Seafood Products (AREA)

Abstract

The invention relates to the field of chondroitin extraction, in particular to equipment for extracting chondroitin from fish bone paste, which comprises a heating tank, wherein a tank cover is coaxially and fixedly arranged at the upper end of the heating tank, a grinding and pressing piece penetrates through the upper end surface of the tank cover, a valve penetrates through the middle of the lower end surface of the heating tank, a flow piece is arranged inside the heating tank, a drawing piece penetrates through the side surface of the heating tank and is positioned above the flow piece, a support piece is arranged at the lower end edge of the heating tank, and a feed inlet penetrates through and is embedded in the upper end edge of the tank cover.

Description

Technical Field

The invention relates to the field of chondroitin extraction, in particular to equipment and a method for extracting chondroitin from fish bone paste.

Background

In the extraction process of chondroitin extraction, fish bone powder and sodium hydroxide solution are mixed by using equipment, then sodium chloride powder is added on the basis of mixing to prepare required solution again, and then next procedure of chondroitin extraction is carried out, and as massive fish bone is mixed in the fish bone powder and sodium chloride particles are mixed in the sodium chloride powder, the fish bone powder can be dissolved and mixed by stirring for a long time in the mixing process, the time consumption of the process is long, and the mixing efficiency is low.

Disclosure of Invention

The invention aims to solve the defects in the background art and provides equipment and a method for extracting chondroitin from fish bone paste.

In order to achieve the purpose, the invention adopts the technical scheme that: the utility model provides an equipment that fish bone paste drawed chondroitin, includes the heating jar, the coaxial fixed mounting in upper end of heating jar has the cover, the up end of cover runs through to install and grinds the casting die, the lower terminal surface middle part of heating jar runs through to install the valve, the internally mounted of heating jar has a stream spare, the side of heating jar runs through to install and takes out the piece, it is located the top that flows the piece to take out, the lower extreme edge of heating jar installs a piece, the upper end edge of cover runs through to inlay and has the feed inlet.

Preferably, prop up the spare including extending the lower extreme edge multiunit support frame at the heating tank, the multiunit it has the reinforcing ring to inlay between the support frame, the lower extreme of support frame is provided with the callus on the sole, grind the casting die including running through the mill section of thick bamboo of installing at the upper end middle part of cover, the inside coaxial mill platform that is provided with of grinding a section of thick bamboo, the inside central point of grinding the platform puts to run through to inlay and has the drive shaft, the up end of grinding the platform is opened and is established to the conical surface, the upper end fixed mounting of drive shaft has servo motor.

Preferably, the up end of grinding a section of thick bamboo is inlayed and is had the mount, the side of mount extends and has bears the frame, the drive shaft runs through to rotate and inlays in the up end that bears the frame, the side that bears the frame extends and has stretches out the seat, the up end that stretches out the seat is inlayed and is had the motor cabinet, the tip and the servo motor fixed connection of motor cabinet.

Preferably, the tip of mount is rotated and is installed the connecting axle, the outside of connecting axle is close to one end and is provided with the drive ring, the axial lead of connecting axle and the axial lead collineation of drive ring, the surface of drive axle and the other end of connecting axle coaxial mosaic respectively have two sets of gears, two sets of the gear meshes mutually, two sets of guide blocks are installed to the up end symmetry of grinding a section of thick bamboo, the guide block is located the place ahead of mount, and is two sets of the outside of guide block is laminated respectively and is installed two sets of leading truck, and one set of it is one set of edge department extends on the side of leading truck has the post of stretching out, it rotates to be connected with the push rod to stretch out the slope between post and the drive ring.

Preferably, the surface one end annular array of connecting axle extends and has four groups of connecting blocks, four groups the tip of connecting block all is connected with the inside surface fixed connection of drive ring, the side of leading truck is close to the inside of last edge department and has run through and has seted up the spout, the guide block laminates in the inside of spout, the up end symmetry of grinding a section of thick bamboo extends and has two sets of fixing bases, fixing base and guide block fixed connection, the lower extreme of leading truck is inlayed and is had the go-between, the lower terminal surface of go-between extends and has surely encircles, surely encircle to be located and grind the seam crossing between platform and the grinding a section of thick bamboo directly over.

Preferably, the surface of drive shaft extends there is the fixed block, the tip of fixed block is inlayed and is had the V-arrangement piece, the inboard upper portion of heating jar extends there is the tripod, the tip of tripod is inlayed and is had the flange, the axial lead of flange and the axial lead collineation of drive shaft, the lower terminal surface laminating in the up end of flange of V-arrangement piece, the flange is located and grinds under the seam crossing between platform and the grinding barrel.

Preferably, the stream piece includes a stream dish on the inner wall upper portion of fixed mounting at the heating jar, a stream dish is located the below of flange, the inboard annular array of a stream dish extends and has four group's connecting plates, four groups the tip of connecting plate is all inlayed and is had No. two stream dishes, the upper end middle part of No. two stream dishes runs through and has seted up the through-hole, the up end of a stream dish all is the downward sloping setting with the up end of No. two stream dishes, the drive shaft runs through the inboard in the through-hole, the lower extreme annular array of drive shaft extends and has the multiunit stirring leaf, multiunit it has the beaded finish to inlay between the stirring leaf.

Preferably, the extraction piece is including extending the pump seat in the side of heating jar, the upper end fixed mounting of pump seat has the pump body, the fixed intercommunication of one end of the pump body has communicating pipe, communicating pipe runs through in the side of heating jar, the tip of communicating pipe is the downward sloping setting, the fixed intercommunication of the other end of the pump body has the conveyer pipe, the fixed intercommunication of the end of conveyer pipe has a dispersion ring, the fixed intercommunication of the inside annular array of a dispersion ring has the multiunit connecting pipe, the fixed intercommunication of the end of connecting pipe has No. two dispersion rings, a dispersion ring is located the top outer edge of a stream disk, No. two dispersion rings are located the top outer edge of No. two stream disks, the axial lead of an axial lead, No. two dispersion rings of dispersion ring and the axial lead collineation of drive shaft.

Also provides a using method of the device for extracting chondroitin from fish bone paste, which comprises the following steps:

s1: adding a sodium hydroxide solution into a heating tank through a feeding hole, and placing the fishbone powder into a grinding cylinder, grinding the fishbone powder by virtue of a grinding table, and allowing the fishbone powder to fall through the matching of a receiving disc and a V-shaped sheet;

s2: the falling fishbone powder is carried by the first flow plate and the second flow plate, the sodium hydroxide solution is extracted to the first flow plate and the second flow plate by the extracting part to be mixed with the fishbone powder, the fishbone powder falls down and is stirred by the stirring blade to be mixed again, and the heating tank is heated during mixing;

s3: and after the sodium hydroxide solution and the fishbone powder are mixed, adding sodium chloride powder into the grinding cylinder to mix the falling and mixed sodium hydroxide solution and the fishbone powder, and then discharging to perform the next procedure.

Compared with the prior art, the invention has the following beneficial effects:

1. through the grinding and pressing piece that sets up, can add fishbone powder and sodium chloride powder in proper order and grind a section of thick bamboo, grind the cubic fishbone of clamp in the fishbone powder and the sodium chloride granule in the sodium chloride powder with the help of grinding a section of thick bamboo and mill the platform to guarantee the powder purity of fishbone powder and sodium chloride powder, improve mixing efficiency with this.

2. The ground fish bone powder and the sodium chloride powder can continuously fall on the connecting disc, the fish bone powder and the sodium chloride powder are pushed to two sides of the connecting disc by means of the V-shaped sheets to be dispersed and continuously fall on the first flow disc and the second flow disc from two sides of the connecting disc, at the moment, the pump body works to pump the sodium hydroxide solution in the heating tank out and send the sodium hydroxide solution into the first dispersing ring and the second dispersing ring, the sodium hydroxide solution is dispersed and sprayed out through the first dispersing ring and the connecting disc, the sprayed sodium hydroxide solution flows on the first flow disc and the second flow disc to be mixed with the fish bone powder and the sodium chloride powder which continuously fall, and the fish bone powder, the sodium chloride powder and the sodium chloride solution are fully mixed through the continuous adding, so that the mixing quality is improved.

3. Under the action of the driving ring, the extending column can be continuously driven to move through the push rod, the guide frame slides on the guide block in a fit mode to drive the cutting ring on the connecting ring to continuously move up and down, fishbone powder and sodium chloride powder at the joint between the grinding table and the grinding cylinder are continuously pressed down, the fishbone powder and the sodium chloride powder can be fully filled between the grinding table and the grinding cylinder to be ground, the grinding time is shortened, and the blanking efficiency is improved.

Drawings

FIG. 1 is a schematic structural diagram of an apparatus for extracting chondroitin from fish bone paste according to the present invention;

FIG. 2 is a sectional view of an apparatus for extracting chondroitin from fish bone paste according to the present invention;

FIG. 3 is a schematic view of a first tray of an apparatus for extracting chondroitin from fish bone paste according to the present invention;

FIG. 4 is a schematic view of a grinding cylinder of an apparatus for extracting chondroitin from fish bone paste according to the present invention;

FIG. 5 is a cross-sectional view of a grinding cylinder of the device for extracting chondroitin from fish bone paste according to the present invention;

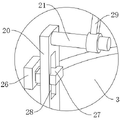

FIG. 6 is a schematic view of a guiding frame of the chondroitin extracting apparatus from fish bone paste according to the present invention;

FIG. 7 is a flow chart of the process for extracting chondroitin from fish bone paste according to the present invention.

In the figure: 1. a heating tank; 2. a can lid; 3. grinding the cylinder; 4. a servo motor; 5. a drive shaft; 6. a pump body; 7. a pump mount; 8. a communicating pipe; 9. a delivery pipe; 10. a support frame; 11. a reinforcing ring; 12. a foot pad; 13. grinding a platform; 14. a valve; 15. stirring blades; 16. a reinforcement ring; 17. a stream tray I; 18. a connecting ring; 19. cutting a ring; 20. a guide frame; 21. extending the column; 22. a connecting shaft; 23. a drive ring; 24. a gear; 25. a carrier; 26. a fixed seat; 27. a guide block; 28. a chute; 29. a push rod; 30. a fixed block; 31. a V-shaped piece; 32. receiving a plate; 33. a first dispersion ring; 34. a connecting pipe; 35. a second dispersing ring; 36. a stream tray II; 37. connecting blocks; 38. a connecting plate; 39. a fixed mount; 40. a projecting seat; 41. a motor base.

Detailed Description

The following description is presented to disclose the invention so as to enable any person skilled in the art to practice the invention. The preferred embodiments in the following description are given by way of example only, and other obvious variations will occur to those skilled in the art.

The device for extracting chondroitin from fish bone paste comprises a heating tank 1, a tank cover 2 is coaxially and fixedly mounted at the upper end of the heating tank 1, a grinding part is mounted on the upper end face of the tank cover 2 in a penetrating manner, a valve 14 is mounted in the middle of the lower end face of the heating tank 1 in a penetrating manner, a flow part is mounted inside the heating tank 1, an extraction part is mounted on the side face of the heating tank 1 in a penetrating manner, the extraction part is located above the flow part, a support part is mounted at the lower end edge of the heating tank 1, and a feed inlet is embedded in the upper end edge of the tank cover 2 in a penetrating manner.

A spare is including extending the lower extreme edge multiunit support frame 10 at heating tank 1, it has reinforcing ring 11 to inlay between the multiunit support frame 10, the lower extreme of support frame 10 is provided with callus on the sole 12, grind the casting die including running through the mill section of thick bamboo 3 of installing at the upper end middle part of cover 2, the inside coaxial grinding platform 13 that is provided with of 3 of grinding a section of thick bamboo, the inside central point that grinds platform 13 puts to run through to inlay and has drive shaft 5, the up end of grinding platform 13 is opened and is established to the conical surface, the upper end fixed mounting of drive shaft 5 has servo motor 4, can drive through the drive shaft 5 that sets up and grind platform 13 and rotate, support frame 10 plays the effect of support, reinforcing ring 11 plays reinforced effect.

Grind the up end of a section of thick bamboo 3 and inlay and have mount 39, the side of mount 39 extends and has bears frame 25, drive shaft 5 runs through to rotate and inlays in the up end of bearing frame 25, the side of bearing frame 25 extends and has stretch out seat 40, the up end that stretches out seat 40 inlays and has motor cabinet 41, the tip and the servo motor 4 fixed connection of motor cabinet 41, motor cabinet 41 plays and carries out the effect of fixing to servo motor 4, bear the effect that frame 25 played restriction drive shaft 5.

The end of the fixed mount 39 is rotatably provided with a connecting shaft 22, one end of the outer side of the connecting shaft 22 is provided with a driving ring 23, the axial lead of the connecting shaft 22 is collinear with the axial lead of the driving ring 23, the outer surface of the driving shaft 5 and the other end of the connecting shaft 22 are respectively and coaxially embedded with two groups of gears 24, the two groups of gears 24 are meshed with each other, two groups of guide blocks 27 are symmetrically arranged on the upper end surface of the grinding cylinder 3, the guide blocks 27 are positioned in front of the fixed mount 39, two groups of guide frames 20 are respectively attached to the outer sides of the two groups of guide blocks 27, the upper edge of the side surface of one group of guide frames 20 extends to form an extending column 21, a push rod 29 is obliquely and rotatably connected between the extending column 21 and the driving ring 23, the gears 24 play a role in transmission, the extending column 21 plays a role in connection, and the role in guiding by matching between the guide blocks 27 and the guide frames 20.

The outer surface one end annular array of connecting axle 22 extends and has four groups of connecting blocks 37, the tip of four groups of connecting blocks 37 all is connected with the inside surface fixed connection of drive ring 23, the side of leading truck 20 is close to upper edge department and has been run through and has been seted up spout 28, guide block 27 laminates in the inside of spout 28, the up end symmetry of grinding drum 3 extends and has two sets of fixing bases 26, fixing base 26 and guide block 27 fixed connection, the lower extreme of leading truck 20 is inlayed and is had go-between 18, the lower terminal surface of go-between 18 extends and has surely encircles 19, surely encircle 19 and be located directly over the seam department between grinding platform 13 and the grinding drum 3, connecting block 37 plays the fixed effect of connecting, spout 28 plays the effect of restriction guide block 27, fixing base 26 plays the effect of fixing guide block 27.

The outer surface of drive shaft 5 extends there is fixed block 30, the tip of fixed block 30 is inlayed and is had V-arrangement piece 31, the inboard upper portion of heating jar 1 extends and has the tripod, the tip of tripod is inlayed and is had flange 32, the axial lead of flange 32 and the axial lead collineation of drive shaft 5, the lower terminal surface laminating of V-arrangement piece 31 is in the up end of flange 32, flange 32 is located and grinds under the seam crossing between platform 13 and the grinding barrel 3, the tripod plays the effect of fixing flange 32, flange 32 plays the effect of carrying on.

The flow piece comprises a first flow disc 17 fixedly mounted on the upper portion of the inner wall of the heating tank 1, the first flow disc 17 is located below the receiving disc 32, four groups of connecting plates 38 extend from the inner side of the first flow disc 17 in an annular array mode, two groups of flow discs 36 are embedded at the end portions of the four groups of connecting plates 38, a through hole is formed in the middle of the upper end of each second flow disc 36 in a penetrating mode, the upper end face of the first flow disc 17 and the upper end face of each second flow disc 36 are arranged in a downward inclined mode, the driving shaft 5 penetrates through the inner side of the through hole, a plurality of groups of stirring blades 15 extend from the lower end of the driving shaft 5 in an annular array mode, reinforcing rings 16 are embedded among the groups of stirring blades 15, the connecting plates 38 play a role in fixing the first flow disc 17 and the second flow disc 36 together, and the reinforcing rings 16 play a role in reinforcing the groups of stirring blades 15.

The drawing part comprises a pump seat 7 extending on the side surface of the heating tank 1, a pump body 6 is fixedly installed at the upper end of the pump seat 7, a communicating pipe 8 is fixedly communicated with one end of the pump body 6, the communicating pipe 8 penetrates through the side surface of the heating tank 1, the end part of the communicating pipe 8 is arranged in a downward inclined manner, the other end of the pump body 6 is fixedly communicated with a conveying pipe 9, a first dispersing ring 33 is fixedly communicated with the end part of the conveying pipe 9, a plurality of groups of connecting pipes 34 are fixedly communicated with the inner annular array of the first dispersing ring 33, the end part of the connecting pipe 34 is fixedly communicated with a second dispersing ring 35, the first dispersing ring 33 is positioned at the upper outer edge of the first flow plate 17, the second dispersing ring 35 is positioned at the upper outer edge of the second flow plate 36, the axial lead of the first dispersing ring 33, the axial lead of the second dispersing ring 35 and the axial lead of the driving shaft 5 are collinear, the communicating pipe 8 plays a role, and the conveying pipe 9 plays a role in communicating and conveying, the connecting pipe 34 functions as a communication, and the pump base 7 functions as a fixing for the pump body 6.

As shown in FIG. 7, the preparation method of chondroitin extracted from fish bone paste is shown, the device of the present invention is used for the pretreatment of fish paste, and the obtained fish paste is further processed by the steps shown in FIG. 7.

Also provides a using method of the device for extracting chondroitin from fish bone paste, which comprises the following steps:

s1: adding a sodium hydroxide solution into the heating tank 1 through a feeding hole, and placing the fishbone powder into a grinding cylinder 3, grinding the fishbone powder by virtue of a grinding table 13, and allowing the fishbone powder to fall through the matching of a receiving disc 32 and a V-shaped sheet 31 in a dispersing manner;

s2: the falling fishbone powder is received by the first flow plate 17 and the second flow plate 36, the sodium hydroxide solution is extracted to the first flow plate 17 and the second flow plate 36 by the extracting part to be mixed with the fishbone powder, and the fishbone powder falls down to be stirred by the stirring blade 15 to be mixed again, and the heating tank 1 is heated during mixing;

s3: after the sodium hydroxide solution and the fishbone powder are mixed, adding sodium chloride powder into the milling drum 3 to mix the falling and mixed sodium hydroxide solution and the fishbone powder, and then discharging to perform the next procedure.

When in use, sodium hydroxide solution is added into the heating tank 1 through the feed inlet, fishbone powder is placed in the grinding cylinder 3, the servo motor 4 works to drive the driving shaft 5 to rotate at the moment, and further drive the grinding table 13, the V-shaped piece 31 and the stirring blade 15 on the driving shaft 5 to rotate, the blocky fishbone mixed in the fishbone powder is driven by the grinding cylinder 3 and the grinding table 13, meanwhile, the connecting shaft 22 is driven by the driving shaft 5 to synchronously rotate through the gear 24, and further drive the driving ring 23 to rotate, so as to continuously drive the extending column 21 to move through the push rod 29, at the moment, the guide frame 20 is attached to the guide block 27 to slide, so as to drive the cutting ring 19 on the connecting ring 18 to continuously move up and down, so as to continuously press down the fishbone powder at the joint between the grinding table 13 and the grinding cylinder 3, the ground fishbone powder can be fully filled between the grinding table 13 and the grinding cylinder 3 to be ground, and the ground fishbone powder can continuously fall on the connecting disc 32, the fish bone powder is pushed to the two sides of the receiving disc 32 by the V-shaped sheets 31 to be dispersed and continuously fall on the first flow disc 17 and the second flow disc 36 from the two sides of the receiving disc 32, at the moment, the pump body 6 works to draw out the sodium hydroxide solution in the heating tank 1 to be sent into the first dispersing ring 33 and the second dispersing ring 35, the sodium hydroxide solution sprayed out is dispersed and sprayed out through the first dispersing ring 33 and the receiving disc 32, the sodium hydroxide solution sprayed out flows on the first flow disc 17 and the second flow disc 36 to be mixed with the fish bone powder which continuously falls, the mixed fish bone powder falls on the lower part of the heating tank 1 and is stirred by the stirring blades 15 to be further mixed, the heating tank 1 works to be heated, after the mixed fish bone powder is added into the grinding cylinder 3 to be mixed with the solution mixed in the heating tank 1, and after the mixed fish bone powder is mixed, the valve 14 is opened to be discharged, and the next process can be carried out.

The foregoing shows and describes the general principles, essential features, and advantages of the invention. It will be understood by those skilled in the art that the present invention is not limited to the embodiments described above, which are merely illustrative of the principles of the invention, but that various changes and modifications may be made without departing from the spirit and scope of the invention, which fall within the scope of the invention as claimed. The scope of the invention is defined by the appended claims and equivalents thereof.

Claims (9)

1. The utility model provides an equipment of chondroitin is drawed to fish bone paste, includes heating jar (1), its characterized in that: the coaxial fixed mounting in upper end of heating jar (1) has cover (2), the up end of cover (2) runs through to install grinds the casting die, the lower terminal surface middle part of heating jar (1) runs through to install valve (14), the internally mounted of heating jar (1) has a class piece, the side of heating jar (1) runs through to install and takes out the piece, it is located the top that flows the piece to take out, the lower extreme edge of heating jar (1) installs a piece, the upper end edge of cover (2) runs through to inlay and has the feed inlet.

2. The device for extracting chondroitin from fish bone paste as claimed in claim 1, wherein: a spare is including extending lower extreme edge multiunit support frame (10), multiunit at heating tank (1) inlay between support frame (10) and have reinforcing ring (11), the lower extreme of support frame (10) is provided with callus on the sole (12), grind the casting die including running through a mill section of thick bamboo (3) of installing in the upper end middle part of cover (2), the inside coaxial of grinding a section of thick bamboo (3) is provided with grinds platform (13), the inside central point of grinding platform (13) puts and runs through and inlays and have drive shaft (5), the up end of grinding platform (13) is opened and is established to the conical surface, the upper end fixed mounting of drive shaft (5) has servo motor (4).

3. The device for extracting chondroitin from fish bone paste as claimed in claim 2, wherein: grind the up end of a section of thick bamboo (3) and inlay and have mount (39), the side of mount (39) extends and has bear frame (25), drive shaft (5) run through to rotate and inlay in the up end that bears frame (25), the side that bears frame (25) extends and has stretch out seat (40), the up end that stretches out seat (40) inlays and has motor cabinet (41), the tip and servo motor (4) fixed connection of motor cabinet (41).

4. The device for extracting chondroitin from fish bone paste as claimed in claim 3, wherein: a connecting shaft (22) is rotatably arranged at the end part of the fixed frame (39), a driving ring (23) is arranged at one end, close to the outer side of the connecting shaft (22), the axial lead of the connecting shaft (22) is collinear with the axial lead of the driving ring (23), two groups of gears (24) are respectively and coaxially embedded in the outer surface of the driving shaft (5) and the other end of the connecting shaft (22), the two groups of gears (24) are meshed, two groups of guide blocks (27) are symmetrically arranged on the upper end surface of the grinding cylinder (3), the guide blocks (27) are positioned in front of the fixed frame (39), two groups of guide frames (20) are respectively attached to the outer sides of the two groups of guide blocks (27), wherein the upper edge of the side surface of one group of the guide frames (20) extends to form a protruding column (21), a push rod (29) is connected between the extending column (21) and the driving ring (23) in an inclined and rotating way.

5. The device for extracting chondroitin from fish bone paste as claimed in claim 4, wherein: the utility model discloses a grinding machine, including grinding cylinder (3), connecting axle (22), the inside fixed surface that the outside surface one end annular array of connecting axle (22) extends and has four groups connecting block (37), four groups the tip of connecting block (37) all is connected with the inside fixed surface of drive ring (23), the side of leading truck (20) is close to the top edge and runs through and has seted up spout (28), inside in spout (28) is laminated in leading truck (27), the up end symmetry of grinding cylinder (3) is extended and is had two sets of fixing bases (26), fixing base (26) and leading truck (27) fixed connection, the lower extreme of leading truck (20) is inlayed and is had go-between ring (18), the lower terminal surface of go-between ring (18) extends and has surely encircles (19), surely encircle (19) and be located directly over the seam crossing between grinding table (13) and grinding cylinder (3).

6. The device for extracting chondroitin from fish bone paste as claimed in claim 5, wherein: the surface of drive shaft (5) extends and has fixed block (30), the tip of fixed block (30) is inlayed and is had V-arrangement piece (31), the inboard upper portion of heating jar (1) extends and has the tripod, the tip of tripod is inlayed and is had flange (32), the axial lead of flange (32) and the axial lead collineation of drive shaft (5), the up end in flange (32) is laminated to the lower terminal surface of V-arrangement piece (31), flange (32) are located and grind under the seam crossing between platform (13) and grinding barrel (3).

7. The device for extracting chondroitin from fish bone paste as claimed in claim 6, wherein: flow a set (17) including a fixed mounting on the inner wall upper portion of heating jar (1), a set (17) is located the below of flange (32) of flowing, the inboard ring array of a set (17) of flowing extends and has four group connecting plate (38), four groups the tip of connecting plate (38) is all inlayed and is had No. two sets of flow dish (36), the upper end middle part of No. two sets of flow dish (36) is run through and has been seted up the through-hole, the up end of a set (17) and the up end of No. two sets of flow dish (36) all are the downward sloping setting, drive shaft (5) run through in the inboard of through-hole, the lower extreme ring array of drive shaft (5) extends and has multiunit stirring leaf (15), multiunit it has beaded finish (16) to inlay between stirring leaf (15).

8. The apparatus for extracting chondroitin from fish bone paste as claimed in claim 7, wherein: the drawing part comprises a pump seat (7) extending to the side face of the heating tank (1), the upper end of the pump seat (7) is fixedly provided with a pump body (6), one end of the pump body (6) is fixedly communicated with a communicating pipe (8), the communicating pipe (8) runs through the side face of the heating tank (1), the end part of the communicating pipe (8) is arranged in a downward inclination mode, the other end of the pump body (6) is fixedly communicated with a conveying pipe (9), the end part of the conveying pipe (9) is fixedly communicated with a first dispersing ring (33), the inner annular array of the first dispersing ring (33) is fixedly communicated with a plurality of groups of connecting pipes (34), the end part of each connecting pipe (34) is fixedly communicated with a second dispersing ring (35), the first dispersing ring (33) is located at the outer edge of the top of the first flow plate (17), and the second dispersing ring (35) is located at the outer edge of the top of the second flow plate (36), the axial lead of the first dispersion ring (33) and the axial lead of the second dispersion ring (35) are collinear with the axial lead of the driving shaft (5).

9. The method for using the device for extracting chondroitin from fish bone paste, which is used in the device for extracting chondroitin from fish bone paste as claimed in claim 8, is characterized by comprising the following steps: s1: adding a sodium hydroxide solution into the heating tank (1) through a feeding hole, and placing the fishbone powder into a grinding cylinder (3) to be ground and fall through a grinding table (13) and dispersed and fall through the matching of a connecting disc (32) and a V-shaped sheet (31);

s2: the falling fishbone powder is received by the first flow plate (17) and the second flow plate (36), the sodium hydroxide solution is extracted to the first flow plate (17) and the second flow plate (36) by the extracting part to be mixed with the fishbone powder, the fishbone powder falls down and is stirred by the stirring blade (15) to be mixed again, and the heating tank (1) is heated during mixing;

s3: after the sodium hydroxide solution and the fishbone powder are mixed, adding sodium chloride powder into the milling drum (3) to mix the falling and mixed sodium hydroxide solution and the fishbone powder, and then discharging to perform the next procedure.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210453417.8A CN114797628B (en) | 2022-04-27 | 2022-04-27 | Equipment and method for extracting chondroitin from fish bone paste |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210453417.8A CN114797628B (en) | 2022-04-27 | 2022-04-27 | Equipment and method for extracting chondroitin from fish bone paste |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114797628A true CN114797628A (en) | 2022-07-29 |

| CN114797628B CN114797628B (en) | 2023-09-05 |

Family

ID=82509783

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210453417.8A Active CN114797628B (en) | 2022-04-27 | 2022-04-27 | Equipment and method for extracting chondroitin from fish bone paste |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114797628B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115031811A (en) * | 2022-08-10 | 2022-09-09 | 常州市金马高分子材料有限公司 | Liquid level measuring device and method for production of ETFE colored particles |

| CN115430338A (en) * | 2022-08-10 | 2022-12-06 | 山东克曼特新能源科技发展有限公司 | New material apparatus for producing based on vacuum technique |

| CN115779761A (en) * | 2022-10-24 | 2023-03-14 | 山东福瑞达生物科技有限公司 | Contain ectoine, careless maintenance essence treatment facility of centella |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20180044441A1 (en) * | 2014-08-12 | 2018-02-15 | Muliang ZHANG | Chondroitin sulfate preparation process and equipment thereof |

| CN210729544U (en) * | 2019-09-25 | 2020-06-12 | 内蒙古清泉生物科技有限公司 | A agitating unit for chondroitin production |

| CN111330717A (en) * | 2018-12-18 | 2020-06-26 | 陈思绮 | Environment-friendly paint secondary grinding and sanding device |

| CN211339357U (en) * | 2019-12-02 | 2020-08-25 | 青岛海伽生物科技有限公司 | Chondroitin sulfate extraction tank with high heat transfer speed |

| CN111701273A (en) * | 2020-07-03 | 2020-09-25 | 山东冰文生物技术有限公司 | Alcohol precipitation device is used in production of acid chondroitin |

| CN211910481U (en) * | 2020-03-11 | 2020-11-13 | 无棣县兴亚生物科技有限公司 | Environment-friendly feather powder additive processing equipment |

| CN113083856A (en) * | 2021-04-02 | 2021-07-09 | 汪亦冬 | Recycling treatment system and treatment method for steel smelting solid waste |

| CN113527541A (en) * | 2021-08-20 | 2021-10-22 | 青岛万图明生物制品有限公司 | Chondroitin sulfate draws equipment |

| CN214974255U (en) * | 2021-06-02 | 2021-12-03 | 南京东纳生物科技有限公司 | Si02 nanoparticle processing equipment |

| CN215655403U (en) * | 2021-08-11 | 2022-01-28 | 山东康源堂中药饮片股份有限公司 | Chinese-medicinal material grinder |

| CN215983725U (en) * | 2021-06-30 | 2022-03-08 | 无棣县兴亚生物科技有限公司 | A apparatus for producing for extracting chondroitin sulfate |

-

2022

- 2022-04-27 CN CN202210453417.8A patent/CN114797628B/en active Active

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20180044441A1 (en) * | 2014-08-12 | 2018-02-15 | Muliang ZHANG | Chondroitin sulfate preparation process and equipment thereof |

| CN111330717A (en) * | 2018-12-18 | 2020-06-26 | 陈思绮 | Environment-friendly paint secondary grinding and sanding device |

| CN210729544U (en) * | 2019-09-25 | 2020-06-12 | 内蒙古清泉生物科技有限公司 | A agitating unit for chondroitin production |

| CN211339357U (en) * | 2019-12-02 | 2020-08-25 | 青岛海伽生物科技有限公司 | Chondroitin sulfate extraction tank with high heat transfer speed |

| CN211910481U (en) * | 2020-03-11 | 2020-11-13 | 无棣县兴亚生物科技有限公司 | Environment-friendly feather powder additive processing equipment |

| CN111701273A (en) * | 2020-07-03 | 2020-09-25 | 山东冰文生物技术有限公司 | Alcohol precipitation device is used in production of acid chondroitin |

| CN113083856A (en) * | 2021-04-02 | 2021-07-09 | 汪亦冬 | Recycling treatment system and treatment method for steel smelting solid waste |

| CN214974255U (en) * | 2021-06-02 | 2021-12-03 | 南京东纳生物科技有限公司 | Si02 nanoparticle processing equipment |

| CN215983725U (en) * | 2021-06-30 | 2022-03-08 | 无棣县兴亚生物科技有限公司 | A apparatus for producing for extracting chondroitin sulfate |

| CN215655403U (en) * | 2021-08-11 | 2022-01-28 | 山东康源堂中药饮片股份有限公司 | Chinese-medicinal material grinder |

| CN113527541A (en) * | 2021-08-20 | 2021-10-22 | 青岛万图明生物制品有限公司 | Chondroitin sulfate draws equipment |

Non-Patent Citations (1)

| Title |

|---|

| 李良铸: "《最新生化药物制备技术》", 北京:中国医药科技出版社, pages: 317 - 320 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115031811A (en) * | 2022-08-10 | 2022-09-09 | 常州市金马高分子材料有限公司 | Liquid level measuring device and method for production of ETFE colored particles |

| CN115430338A (en) * | 2022-08-10 | 2022-12-06 | 山东克曼特新能源科技发展有限公司 | New material apparatus for producing based on vacuum technique |

| CN115779761A (en) * | 2022-10-24 | 2023-03-14 | 山东福瑞达生物科技有限公司 | Contain ectoine, careless maintenance essence treatment facility of centella |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114797628B (en) | 2023-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114797628A (en) | Device and method for extracting chondroitin from fish bone paste | |

| CN210729725U (en) | Navel pastes production with chinese-medicinal material milling equipment | |

| CN208161548U (en) | A kind of chemical fertilizer disc granulation device with flow control function | |

| CN112675571B (en) | Shower gel raw material extraction system | |

| CN115463601A (en) | Compounding device is used in emery wheel preparation | |

| CN208809094U (en) | A kind of manufacturing device of tablet easy to produce | |

| CN220657733U (en) | Grinding device for suspension liquid fertilizer production | |

| CN207544309U (en) | Broiler chickens mixed feed mixing machine blanking sieve | |

| CN216879725U (en) | Pulping equipment is used in preparation of mushroom dried bean | |

| CN220443964U (en) | Uniform and refined tea grinding device | |

| CN216764865U (en) | Vitamin B12 nitrogen source interpolation device for fermentation cylinder | |

| CN219816565U (en) | Peeling soybean dry bean pulping device | |

| CN220294612U (en) | Mixing arrangement is used in beverage production processing | |

| CN217093762U (en) | Probiotics reducing mechanism | |

| CN219615766U (en) | Grinding device for preparing COD remover | |

| CN217006408U (en) | A sampling device for preparing epoxy glue reation kettle | |

| CN109126604A (en) | A kind of tealeaves efficient mixing device | |

| CN220460844U (en) | Fish meal chondroitin refines equipment | |

| CN219596480U (en) | Protein extraction device | |

| CN209772656U (en) | Aquatic products fodder bits and pieces separation sieving mechanism | |

| CN219648037U (en) | Traditional chinese medicine sieve separator that screening efficiency is high | |

| CN213192784U (en) | Front-section feeding filtering structure and filter press thereof | |

| CN114888993B (en) | Pretreatment stirring device for plastic ingredients | |

| CN210786392U (en) | Filter equipment is used in vinegar drink production | |

| CN219923211U (en) | Glossy ganoderma polysaccharide extraction element |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |