CN113083865A - Kitchen waste desalting device - Google Patents

Kitchen waste desalting device Download PDFInfo

- Publication number

- CN113083865A CN113083865A CN202110440445.1A CN202110440445A CN113083865A CN 113083865 A CN113083865 A CN 113083865A CN 202110440445 A CN202110440445 A CN 202110440445A CN 113083865 A CN113083865 A CN 113083865A

- Authority

- CN

- China

- Prior art keywords

- draining

- box body

- stirring

- kitchen waste

- feeding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000010806 kitchen waste Substances 0.000 title claims abstract description 63

- 238000011033 desalting Methods 0.000 title claims abstract description 20

- 238000003756 stirring Methods 0.000 claims abstract description 43

- 238000004062 sedimentation Methods 0.000 claims abstract description 20

- 239000007921 spray Substances 0.000 claims abstract description 15

- 239000002351 wastewater Substances 0.000 claims abstract description 13

- 238000007599 discharging Methods 0.000 claims abstract description 12

- 230000007246 mechanism Effects 0.000 claims abstract description 9

- 239000010813 municipal solid waste Substances 0.000 claims abstract description 8

- 238000010612 desalination reaction Methods 0.000 claims abstract description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 36

- 239000000463 material Substances 0.000 claims description 20

- 238000011068 loading method Methods 0.000 claims description 14

- 239000007788 liquid Substances 0.000 claims description 8

- 230000008676 import Effects 0.000 claims description 4

- 239000007787 solid Substances 0.000 abstract description 6

- 150000003839 salts Chemical class 0.000 description 12

- 238000010586 diagram Methods 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 239000000126 substance Substances 0.000 description 4

- 239000002699 waste material Substances 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- 235000013305 food Nutrition 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000003763 carbonization Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 235000012054 meals Nutrition 0.000 description 2

- 239000010865 sewage Substances 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 231100000678 Mycotoxin Toxicity 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 239000010775 animal oil Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 210000000988 bone and bone Anatomy 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000010791 domestic waste Substances 0.000 description 1

- 235000013312 flour Nutrition 0.000 description 1

- 239000010794 food waste Substances 0.000 description 1

- 239000004519 grease Substances 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910017053 inorganic salt Inorganic materials 0.000 description 1

- 150000002632 lipids Chemical class 0.000 description 1

- 235000013372 meat Nutrition 0.000 description 1

- 244000000010 microbial pathogen Species 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000002636 mycotoxin Substances 0.000 description 1

- 235000015097 nutrients Nutrition 0.000 description 1

- 239000003895 organic fertilizer Substances 0.000 description 1

- 239000005416 organic matter Substances 0.000 description 1

- 102000004169 proteins and genes Human genes 0.000 description 1

- 108090000623 proteins and genes Proteins 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000002689 soil Substances 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 235000015112 vegetable and seed oil Nutrition 0.000 description 1

- 239000008158 vegetable oil Substances 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B3/00—Destroying solid waste or transforming solid waste into something useful or harmless

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

- B08B3/022—Cleaning travelling work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B5/00—Operations not covered by a single other subclass or by a single other group in this subclass

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B2101/00—Type of solid waste

- B09B2101/02—Gases or liquids enclosed in discarded articles, e.g. aerosol cans or cooling systems of refrigerators

Landscapes

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Processing Of Solid Wastes (AREA)

Abstract

The invention relates to a kitchen waste desalting device which comprises a feeding machine, a stirrer, a draining machine and a sedimentation tank, wherein the feeding machine comprises a feeding hopper, a feeding conveyor and a discharging pipe, a filter screen plate is arranged at the lower half part of the lower end part of the feeding conveyor, a waste water hopper is arranged below the filter screen plate, the stirrer comprises a box body, a stirring shaft, a conveying shaft and a stirring conveyor, the middle part of the box body is provided with the stirring shaft, the bottom of the box body is provided with the conveying shaft, the stirring shaft and the conveying shaft are connected with a driving mechanism, and the draining machine comprises a draining box body, a spray nozzle and a draining plate; this kitchen garbage desalination device adopts screw conveyer to carry kitchen garbage to the agitator in, dilutes and dissolves the salinity in the kitchen garbage, and the solid kitchen garbage who separates after reusing the waterlogging caused by excessive rainfall machine to the stirring carries out the waterlogging caused by excessive rainfall, the salinity in the surplus rubbish of detach that can be effectively quick.

Description

Technical Field

The invention relates to the technical field of kitchen waste treatment, in particular to a kitchen waste desalting device.

Background

In recent years, with the improvement of living standard of people, the catering industry develops rapidly, the proportion of kitchen waste in urban household waste is increasing, the kitchen waste refers to waste generated in activities such as daily life of residents, food processing, food service and unit meal supply, the main sources of the kitchen waste are household kitchens, restaurants, dining halls, markets and other industries related to food processing, the main components of the kitchen waste comprise rice and flour food residues, vegetables, animal and vegetable oil, meat and bones and the like, and the kitchen waste comprises starch, cellulose, protein, lipid and inorganic salt in terms of chemical composition; because the kitchen waste is rich in organic matter content and high in water content and is very easy to rot, the properties and the smell of the kitchen waste can generate bad influence on environmental sanitation, harmful substances such as pathogenic microorganisms and mycotoxin can be easily generated, and a large amount of kitchen waste can generate great harm to the environment and human health if being treated improperly.

In the prior art, the kitchen waste is generally treated by adopting a carbonization and landfill mode, but the kitchen waste contains substances such as grease, water, salt and the like besides solid residues, salt in the kitchen waste cannot be thoroughly decomposed even through high-temperature carbonization, and the waste with high salt content can cause bad influence on soil quality if being directly filled.

The kitchen waste contains rich nutrient substances, if the kitchen waste is required to be recycled, salt which cannot be decomposed in the kitchen waste needs to be removed, and the kitchen waste with the salt removed can be used as a raw material for preparing an organic fertilizer, so that the aims of protecting the environment and utilizing waste are fulfilled; therefore, how to overcome the above technical problems and disadvantages is a problem to be solved.

Disclosure of Invention

The invention aims to overcome the defects described in the background art, and therefore the kitchen waste desalting device is realized.

In order to achieve the purpose, the technical scheme of the invention is as follows: a kitchen waste desalting device comprises a feeding machine, a stirring machine, a draining machine and a sedimentation tank, wherein an outlet of the feeding machine is communicated with an inlet of the stirring machine, an outlet of the stirring machine is communicated with an inlet of the draining machine, the feeding machine comprises a feeding hopper, a feeding conveyor and a discharging pipe, the feeding hopper is arranged above the lower end part of the feeding conveyor, the discharging pipe is arranged below the upper end part of the feeding conveyor, a filter screen plate is arranged on the lower half part of the lower end part of the feeding conveyor, a waste water hopper is arranged below the filter screen plate, and a waste water pipe communicated with the sedimentation tank is arranged on the side part of the waste water hopper and used for discharging water filtered out of the feeding conveyor into the sedimentation tank; the stirring machine comprises a box body, a stirring shaft, a conveying shaft and a stirring conveyor, wherein the top of the box body is provided with a stirring feed hopper, the middle of the box body is provided with the stirring shaft, the bottom of the box body is provided with the conveying shaft, the stirring shaft and the conveying shaft are connected with a driving mechanism, the bottom of the box body at the end part of the conveying shaft is provided with a material leakage opening, a buffer pipe is arranged below the material leakage opening, and the lower end of the buffer pipe is connected; the draining machine comprises a draining box body, a spray head and a draining plate, wherein a draining feed hopper is arranged at the top of the draining box body, the spray head is installed in a water spray cavity at the top of the draining box body, the draining plate is installed at the lower part of the draining box body, a vibrating motor is installed on the side surface of the draining box body, the draining box body is installed on the bottom frame through a pressure spring, vibration is carried out in the draining process, kitchen waste is in full contact with spray water, and a better desalting effect is achieved.

Further, the material loading conveyer is screw conveyer, and the material loading conveyer top is provided with the motor, the access hole has all been seted up on material loading conveyer middle part and upper portion, is convenient for dredge when material loading conveyer blocks up, and access hole department is provided with middle part apron and upper portion apron respectively, and material loading conveyer upper portion below is fixed with the mounting bracket.

Further, the top of the box body is provided with a box cover, the box cover is provided with a stirring feed hopper, and the box cover is fixedly connected with the box body through a bolt lock.

Further, actuating mechanism includes motor, chain one and chain two, the motor is installed at the box top, and chain wheel one and chain wheel two are installed respectively to motor and stirring shaft tip, are connected through chain one between chain wheel one and the chain wheel two, and chain wheel three and chain wheel four are installed respectively to the other end of (mixing) shaft and the tip of carrying the axle, connect through chain two between chain wheel three and the chain wheel four, adopt a motor to provide power for (mixing) shaft and transport axle, can effective energy saving.

Further, carry the axle to be the auger delivery axle, the side-mounting of buffer tube has the drain pipe, drain pipe and sedimentation tank intercommunication, the stirring conveyer is provided with the stirring discharging pipe for auger delivery machine and upper end below, be provided with liquid level float switch on the lateral wall on box upper portion, be provided with the inlet tube on the lateral wall before the box.

Furthermore, a water outlet is formed in the bottom of the water storage cavity at the lower part of the draining plate and is communicated with the sedimentation tank through a water outlet pipe, and a draining discharge hopper is arranged at the end part of the draining cavity in the middle of the draining box body.

The kitchen waste desalting device has the beneficial effects that:

1. according to the kitchen waste desalting device, the kitchen waste is conveyed into the stirrer by using the feeding machine, sewage in the kitchen waste is primarily filtered by using the filter screen plate at the lower part of the feeding conveyor, and a large amount of salt contained in the sewage in the kitchen waste is removed;

2. according to the kitchen waste desalting device, the kitchen waste with most of moisture filtered out is conveyed into the stirrer, quantitative water is added into the stirrer, the motor is started to stir, the salt in the kitchen waste is dissolved and diluted, the water and the solid kitchen waste are separated through the drain pipe on the side surface of the buffer pipe, and sixty percent of salt in the kitchen waste can be effectively removed;

3. according to the kitchen waste desalination device, the spray head is used for spraying solid kitchen waste, the vibration motor is used for vibrating the draining plate, the kitchen waste can be fully contacted with spray water, the spray water is discharged from the water storage cavity below the draining plate, eighty five percent of salinity in the kitchen waste can be effectively removed, and the purpose of removing the salinity is achieved.

Drawings

FIG. 1 is a schematic structural diagram of a kitchen waste desalting device according to the present invention;

FIG. 2 is a schematic diagram of a top view mechanism of the kitchen waste desalination apparatus according to the present invention;

FIG. 3 is a schematic diagram of the mechanism of the feeding machine in the kitchen waste desalting device according to the present invention;

FIG. 4 is a schematic cross-sectional view A-A of FIG. 3;

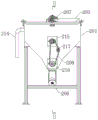

FIG. 5 is a schematic structural diagram of a stirrer in the kitchen waste desalting device of the invention;

FIG. 6 is a schematic cross-sectional view B-B of FIG. 5;

FIG. 7 is a schematic diagram of a draining device of the kitchen waste desalting device according to the present invention;

FIG. 8 is a schematic top view of FIG. 7;

in the figure: 1-feeding machine, 101-feeding hopper, 102-discharging pipe, 103-feeding conveyor, 104-filter screen plate, 105-waste water hopper, 106-waste water pipe, 107-middle cover plate, 108-upper cover plate, 109-motor, 110-mounting rack, 111-maintenance opening, 2-stirrer, 201-box, 202-box cover, 203-stirring feed hopper, 204-stirring shaft, 205-conveying shaft, 206-stirring conveyor, 207-stirring motor, 208-chain I, 209-chain II, 210-leakage opening, 211-buffer pipe, 212-drainage pipe, 213-liquid level float switch, 214-water inlet pipe, 215-chain wheel III, 216-chain wheel IV, 217-tension wheel, 218-chain wheel I, 219-a second chain wheel, 220-a bolt lock, 221-a stirring discharge pipe, 3-a water draining machine, 301 a draining box body, 302-a draining feed hopper, 303-a draining discharge hopper, 304-a water spraying cavity, 305-a spray head, 306-a draining cavity, 307-a draining plate, 308-a water storage cavity, 309-a water outlet, 310-a water outlet pipe, 311-a bottom frame, 312-a pressure spring, 313-a vibration motor and 4-a sedimentation tank.

Detailed Description

The kitchen waste desalting device of the invention is described in more detail by the specific embodiment with reference to the attached drawings.

In the description of the present invention, it is to be understood that the terms "upper", "lower", "front", "rear", "left", "right", "top", "bottom", "inner", "outer", and the like, indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, are merely for convenience in describing the present invention and simplifying the description, and do not indicate or imply that the device or element being referred to must have a particular orientation, be constructed and operated in a particular orientation, and thus, should not be construed as limiting the present invention.

Referring to fig. 1-8, the kitchen waste desalination device of this embodiment adopts screw conveyer to convey kitchen waste to the mixer, dilutes and dissolves the salt in the kitchen waste, and then uses the waterlogging caused by excessive rainfall machine to carry out the waterlogging caused by excessive rainfall to the solid kitchen waste that separates after the stirring, can effectively quick detach the salt in the surplus rubbish of meal, and it mainly includes material loading machine 1, mixer 2, waterlogging caused by excessive rainfall machine 3 and sedimentation tank 4, the export of material loading machine 1 and the import of mixer 2 communicate, and the export of mixer 2 and the import of waterlogging caused by excessive rainfall machine 3 communicate, and the water that filters out among material loading machine 1, mixer 2 and waterlogging caused by excessive rainfall machine 3 discharges into sedimentation tank 4 through the pipeline, concentrates the water and then does further processing.

In detail, as shown in fig. 3-4, the feeding machine comprises a feeding hopper 101, a feeding conveyor 103 and a discharging pipe 102, the feeding hopper 101 is arranged above the lower end part of the feeding conveyor 103, the discharging pipe 102 is arranged below the upper end part of the feeding conveyor 103, a filter screen plate 104 is arranged at the lower half part of the lower end part of the feeding conveyor 103, a waste water hopper 105 is arranged below the filter screen plate 104, a waste water pipe 106 communicated with the sedimentation tank 4 is arranged at the side part of the waste water hopper 105 and used for discharging water filtered out of the feeding conveyor into the sedimentation tank, the feeding conveyor 103 is a screw conveyor, a motor 109 is arranged at the top end of the feeding conveyor 103, maintenance ports 111 are respectively arranged at the middle part and the upper part of the feeding conveyor 103 and are convenient for dredging when the feeding conveyor is blocked, a middle cover plate 107 and an upper cover plate 108 are respectively arranged at the maintenance ports 111, a mounting frame 110 is fixed below the upper part of the feeding conveyor 103, used for installing the feeding machine.

Referring to fig. 5-6 in detail, the agitator comprises a box 201, an agitator shaft 204, a conveying shaft 205 and an agitator conveyer 206, wherein a box cover 202 is arranged on the top of the box 201, an agitator hopper 203 is arranged on the box cover 202, the box cover 202 is fixedly connected with the box 201 through a bolt lock 220, a liquid level float switch 213 is arranged on the side wall of the upper part of the box 201, a water inlet pipe 214 is arranged on the front side wall of the box 201, the agitator shaft 204 is arranged in the middle of the box 201, the conveying shaft 205 is arranged at the bottom of the box 201, the conveying shaft 205 is a spiral conveying shaft, the agitator shaft 204 is connected with the conveying shaft 205 through a driving mechanism, the driving mechanism comprises an agitator motor 207, a first chain 208 and a second chain 209, the agitator motor 207 is arranged on the top of the box 201, a first chain wheel 218 and a second chain wheel 219 are respectively arranged at, three sprockets 215 and four sprockets 216 are installed respectively to the other end of (mixing) shaft 204 and the tip of carrying axle 205, connect through two 209 chains between three sprockets 215 and the four sprockets 216, adopt a motor to provide power for (mixing) shaft and carrying axle, can effective energy saving, the drain hole 210 has been seted up to the box 201 bottom of carrying axle 205 tip, and the drain hole 210 below is provided with buffer tube 211, the side-mounting of buffer tube 211 has drain pipe 212, and drain pipe 212 and sedimentation tank 4 intercommunication, and buffer tube 211 lower extreme are connected with stirring conveyer 206, stirring conveyer 206 is provided with stirring discharging pipe 211 for screw conveyer and upper end below.

7-8, the waterlogging caused by excessive rainfall machine includes waterlogging caused by excessive rainfall box 301, shower nozzle 305 and draining board 307, draining box 301 top is provided with waterlogging caused by excessive rainfall feeder hopper 302, and shower nozzle 305 installs in the water spray chamber 304 at draining box 301 top, and draining board 307 installs the lower part at draining box 301, delivery port 309 has been seted up to water storage chamber 308 bottom of draining board 307 lower part, and delivery port 309 passes through outlet pipe 310 and 4 intercommunications of sedimentation tank, draining chamber 306 tip at draining box 301 middle part is provided with waterlogging caused by excessive rainfall play fill 303, draining box 301 side-mounting has shock dynamo 313, and draining box 301 installs on chassis 311 through pressure spring 312, shakes at the waterlogging caused by excessive rainfall in-process, makes kitchen garbage and shower water fully contact, reaches better desalination effect.

When the kitchen waste treatment device is used, the kitchen waste is conveyed into a feeding hopper of a feeding machine, liquid in the kitchen waste is separated from the liquid fixed at a filter screen plate, the liquid enters a sedimentation tank through a pipeline for further treatment, the kitchen waste is conveyed into a stirrer through a feeding conveyor, a proper amount of water is injected into the stirrer through a water inlet pipe, meanwhile, a stirring motor is started for stirring, the salt content in the kitchen waste is dissolved and diluted, a conveying shaft conveys the kitchen waste to a material leakage port and enters a buffer pipe, the liquid enters the sedimentation tank through a water discharge pipe, solids are conveyed into a draining machine through the stirring conveyor, the kitchen waste flows downwards along a draining plate through a vibration motor, a high-pressure spray head sprays water to clean the kitchen waste, waste water is discharged into the sedimentation tank through the draining plate, the residual drained kitchen waste flows to a next process from a material discharge port and is treated through a three process, and about eighty five percent of salt content in the kitchen waste can be effectively removed, after subsequent treatment, the kitchen waste reaches the standard of recycling, and the purposes of waste utilization and environmental protection are achieved.

Unless defined otherwise, technical or scientific terms used herein shall have the ordinary meaning as understood by one of ordinary skill in the art to which this invention belongs. The word "comprising" or "comprises", and the like, means that the element or item listed before the word covers the element or item listed after the word and its equivalents, but does not exclude other elements or items. The terms "connected" or "coupled" and the like are not restricted to physical or mechanical connections, whether direct or indirect.

Exemplary embodiments of the present invention have been described in detail with reference to the preferred embodiments, however, it will be understood by those skilled in the art that various changes and modifications may be made to the specific embodiments described above, and various combinations of the technical features and structures proposed by the present invention may be made without departing from the concept of the present invention.

Claims (6)

1. The utility model provides a kitchen garbage desalination device, includes material loading machine, mixer, draining machine and sedimentation tank, the export of material loading machine and the import intercommunication of mixer, the export of mixer and the import intercommunication of draining machine, its characterized in that: the feeding machine comprises a feeding hopper, a feeding conveyor and a discharging pipe, the feeding hopper is arranged above the lower end part of the feeding conveyor, the discharging pipe is arranged below the upper end part of the feeding conveyor, a filter screen plate is arranged at the lower half part of the lower end part of the feeding conveyor, a waste water hopper is arranged below the filter screen plate, and a waste water pipe communicated with the sedimentation tank is arranged at the side part of the waste water hopper; the stirring machine comprises a box body, a stirring shaft, a conveying shaft and a stirring conveyor, wherein the top of the box body is provided with a stirring feed hopper, the middle of the box body is provided with the stirring shaft, the bottom of the box body is provided with the conveying shaft, the stirring shaft and the conveying shaft are connected with a driving mechanism, the bottom of the box body at the end part of the conveying shaft is provided with a material leakage opening, a buffer pipe is arranged below the material leakage opening, and the lower end of the buffer pipe is connected; the draining machine comprises a draining box body, a spray head and a draining plate, wherein a draining feed hopper is arranged at the top of the draining box body, the spray head is installed in a water spray cavity at the top of the draining box body, the draining plate is installed at the lower part of the draining box body, a vibration motor is installed on the side surface of the draining box body, and the draining box body is installed on the bottom frame through a pressure spring.

2. The kitchen waste desalting device according to claim 1, characterized in that: the material loading conveyer is screw conveyer, and material loading conveyer top is provided with the motor, the access hole has all been seted up on material loading conveyer middle part and upper portion, and access hole department is provided with middle part apron and upper portion apron respectively, and material loading conveyer upper portion below is fixed with the mounting bracket.

3. The kitchen waste desalting device according to claim 1, characterized in that: the top of the box body is provided with a box cover, the box cover is provided with a stirring feed hopper, and the box cover is fixedly connected with the box body through a bolt lock.

4. The kitchen waste desalting device according to claim 1, characterized in that: the driving mechanism comprises a motor, a first chain and a second chain, the motor is installed at the top of the box body, a first chain wheel and a second chain wheel are installed on the end portion of the motor and the end portion of the stirring shaft respectively, the first chain wheel and the second chain wheel are connected through the first chain, a third chain wheel and a fourth chain wheel are installed on the other end of the stirring shaft and the end portion of the conveying shaft respectively, and the fourth chain wheel are connected through the second chain.

5. The kitchen waste desalting device according to claim 1, characterized in that: the conveying shaft is a spiral conveying shaft, a drain pipe is arranged on the side face of the buffer pipe and communicated with the sedimentation tank, the stirring conveyor is a spiral conveyor, a stirring discharge pipe is arranged below the upper end of the stirring conveyor, a liquid level float switch is arranged on the side wall of the upper portion of the box body, and a water inlet pipe is arranged on the front side wall of the box body.

6. The kitchen waste desalting device according to claim 1, characterized in that: the water draining device is characterized in that a water outlet is formed in the bottom of a water storage cavity at the lower part of the draining plate and is communicated with the sedimentation tank through a water outlet pipe, and a draining discharge hopper is arranged at the end part of a draining cavity in the middle of the draining box body.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110440445.1A CN113083865A (en) | 2021-04-23 | 2021-04-23 | Kitchen waste desalting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110440445.1A CN113083865A (en) | 2021-04-23 | 2021-04-23 | Kitchen waste desalting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113083865A true CN113083865A (en) | 2021-07-09 |

Family

ID=76679700

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110440445.1A Pending CN113083865A (en) | 2021-04-23 | 2021-04-23 | Kitchen waste desalting device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113083865A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115156250A (en) * | 2022-06-17 | 2022-10-11 | 四川琳宸生物能源科技有限公司 | Kitchen waste salt reducing device |

Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN202238856U (en) * | 2011-03-21 | 2012-05-30 | 焦社杰 | Combined modular kitchen waste recycling treatment system |

| CN102553892A (en) * | 2012-01-20 | 2012-07-11 | 宁波开诚生态技术有限公司 | Sorting, cleaning screening, smashing and screening discharging process of kitchen waste processing system |

| CN102690134A (en) * | 2011-03-21 | 2012-09-26 | 焦社杰 | Processing method and processing system for kitchen garbage resourcilization |

| CN105478441A (en) * | 2015-12-02 | 2016-04-13 | 合肥合大环境工程研究院有限公司 | Food waste treatment device |

| CN205188152U (en) * | 2015-12-07 | 2016-04-27 | 中船重工(西安)东仪环保科技有限公司 | Kitchen garbage's biological processing device |

| CN207435329U (en) * | 2017-11-08 | 2018-06-01 | 浙江华再环境技术有限公司 | Food waste treatment device |

| CN109821864A (en) * | 2019-04-04 | 2019-05-31 | 四川深蓝环保科技有限公司 | A kind of pretreatment system and method for kitchen garbage |

| CN210112869U (en) * | 2019-01-29 | 2020-02-25 | 枝江市鹏达机械有限责任公司 | Solid-liquid separation device for kitchen waste |

| CN111360037A (en) * | 2020-04-09 | 2020-07-03 | 山东宇康环保工程有限公司 | Kitchen waste wet-heat hydrolysis pretreatment system and wet-heat hydrolysis pretreatment process |

| CN211100723U (en) * | 2019-08-07 | 2020-07-28 | 崇州杨明电子产品有限公司 | Kitchen garbage thermal cycle sprays deoiling demineralizer |

| CN211217985U (en) * | 2019-10-22 | 2020-08-11 | 江苏明轩环保科技有限公司 | High-salinity kitchen waste pretreatment equipment |

| CN211839521U (en) * | 2020-01-14 | 2020-11-03 | 湖南震宇环保设备有限公司 | Kitchen waste desalination and degreasing treatment system |

| CN111922040A (en) * | 2020-08-04 | 2020-11-13 | 云南天斧环保科技有限公司 | Kitchen waste treatment equipment |

| CN212285254U (en) * | 2020-03-04 | 2021-01-05 | 深圳市君颂自动化科技有限公司 | Oil and salt removing equipment and kitchen waste recycling equipment |

| CN212682002U (en) * | 2020-06-22 | 2021-03-12 | 浙江顺联智能设备有限公司 | Three-phase separation system for kitchen waste |

-

2021

- 2021-04-23 CN CN202110440445.1A patent/CN113083865A/en active Pending

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102690134A (en) * | 2011-03-21 | 2012-09-26 | 焦社杰 | Processing method and processing system for kitchen garbage resourcilization |

| CN202238856U (en) * | 2011-03-21 | 2012-05-30 | 焦社杰 | Combined modular kitchen waste recycling treatment system |

| CN102553892A (en) * | 2012-01-20 | 2012-07-11 | 宁波开诚生态技术有限公司 | Sorting, cleaning screening, smashing and screening discharging process of kitchen waste processing system |

| CN105478441A (en) * | 2015-12-02 | 2016-04-13 | 合肥合大环境工程研究院有限公司 | Food waste treatment device |

| CN205188152U (en) * | 2015-12-07 | 2016-04-27 | 中船重工(西安)东仪环保科技有限公司 | Kitchen garbage's biological processing device |

| CN207435329U (en) * | 2017-11-08 | 2018-06-01 | 浙江华再环境技术有限公司 | Food waste treatment device |

| CN210112869U (en) * | 2019-01-29 | 2020-02-25 | 枝江市鹏达机械有限责任公司 | Solid-liquid separation device for kitchen waste |

| CN109821864A (en) * | 2019-04-04 | 2019-05-31 | 四川深蓝环保科技有限公司 | A kind of pretreatment system and method for kitchen garbage |

| CN211100723U (en) * | 2019-08-07 | 2020-07-28 | 崇州杨明电子产品有限公司 | Kitchen garbage thermal cycle sprays deoiling demineralizer |

| CN211217985U (en) * | 2019-10-22 | 2020-08-11 | 江苏明轩环保科技有限公司 | High-salinity kitchen waste pretreatment equipment |

| CN211839521U (en) * | 2020-01-14 | 2020-11-03 | 湖南震宇环保设备有限公司 | Kitchen waste desalination and degreasing treatment system |

| CN212285254U (en) * | 2020-03-04 | 2021-01-05 | 深圳市君颂自动化科技有限公司 | Oil and salt removing equipment and kitchen waste recycling equipment |

| CN111360037A (en) * | 2020-04-09 | 2020-07-03 | 山东宇康环保工程有限公司 | Kitchen waste wet-heat hydrolysis pretreatment system and wet-heat hydrolysis pretreatment process |

| CN212682002U (en) * | 2020-06-22 | 2021-03-12 | 浙江顺联智能设备有限公司 | Three-phase separation system for kitchen waste |

| CN111922040A (en) * | 2020-08-04 | 2020-11-13 | 云南天斧环保科技有限公司 | Kitchen waste treatment equipment |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115156250A (en) * | 2022-06-17 | 2022-10-11 | 四川琳宸生物能源科技有限公司 | Kitchen waste salt reducing device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN209773033U (en) | Kitchen waste processor | |

| US8927266B2 (en) | Garbage separating apparatus and food waste disposal system including the same | |

| CN206264208U (en) | A kind of technics of reclaim of plastic waste reproduces pipeline system | |

| JP2006272312A (en) | High-speed treatment apparatus for organic waste | |

| CN210261769U (en) | Novel integrated kitchen waste degradation device | |

| CN110918622A (en) | Surplus rubbish recycle treater of meal | |

| CN110079444B (en) | Novel kitchen waste anaerobic fermentation treatment device and method | |

| KR20140012816A (en) | Food waste receiving canister having a discharge apparatus of sludge | |

| CN108715504A (en) | Changing food waste into resources disposes integrated system | |

| CN107721064A (en) | A kind of processing method of food and drink waste water and food garbage | |

| CN113578935A (en) | Resourceful treatment method for kitchen waste | |

| KR200384812Y1 (en) | Food wastes treater | |

| CN113083865A (en) | Kitchen waste desalting device | |

| CN110216131A (en) | A kind of kitchen garbage decomposition apparatus and method | |

| CN210332825U (en) | Urban wet garbage treatment device | |

| CN220127149U (en) | Kitchen waste recycling treatment system and treatment vehicle thereof | |

| CN115958051B (en) | Cooperative treatment system and treatment method for food wastes and kitchen wastes | |

| CN209602336U (en) | A kind of dedicated sewage-treatment plant of animal epidemic prevention | |

| CN208146642U (en) | A kind of kitchen and fruits and vegetables rubbish and integrated waste water treatment system | |

| CN215032235U (en) | Kitchen waste treatment device with cleaning function | |

| CN212419075U (en) | Kitchen waste environment-friendly treatment equipment | |

| CN211965339U (en) | Oil refining pretreatment device for kitchen waste | |

| CN207958165U (en) | The system that kitchen garbage makes organic fertilizer | |

| CN209989389U (en) | Novel anaerobic fermentation treatment device for kitchen waste | |

| CN210385075U (en) | Cow dung lignin screening separator |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20210709 |