CN112535109A - Forage feeding device for goat breeding - Google Patents

Forage feeding device for goat breeding Download PDFInfo

- Publication number

- CN112535109A CN112535109A CN202011409991.0A CN202011409991A CN112535109A CN 112535109 A CN112535109 A CN 112535109A CN 202011409991 A CN202011409991 A CN 202011409991A CN 112535109 A CN112535109 A CN 112535109A

- Authority

- CN

- China

- Prior art keywords

- fixedly connected

- side wall

- forage

- plate

- feeding device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 241000283707 Capra Species 0.000 title claims abstract description 43

- 239000004459 forage Substances 0.000 title claims abstract description 40

- 238000009395 breeding Methods 0.000 title claims abstract description 24

- 230000001488 breeding effect Effects 0.000 title claims abstract description 24

- 230000007246 mechanism Effects 0.000 claims abstract description 22

- 238000009434 installation Methods 0.000 claims abstract description 14

- 230000000712 assembly Effects 0.000 claims abstract description 3

- 238000000429 assembly Methods 0.000 claims abstract description 3

- 244000025254 Cannabis sativa Species 0.000 claims description 11

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 10

- 239000007921 spray Substances 0.000 claims description 8

- 230000005540 biological transmission Effects 0.000 claims description 6

- 238000005192 partition Methods 0.000 claims description 6

- 239000000463 material Substances 0.000 claims description 3

- 238000000034 method Methods 0.000 description 8

- 241000254032 Acrididae Species 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000009286 beneficial effect Effects 0.000 description 2

- 239000010865 sewage Substances 0.000 description 2

- 241001494479 Pecora Species 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 208000002925 dental caries Diseases 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000007726 management method Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; AVICULTURE; APICULTURE; PISCICULTURE; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K5/00—Feeding devices for stock or game ; Feeding wagons; Feeding stacks

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01F—PROCESSING OF HARVESTED PRODUCE; HAY OR STRAW PRESSES; DEVICES FOR STORING AGRICULTURAL OR HORTICULTURAL PRODUCE

- A01F29/00—Cutting apparatus specially adapted for cutting hay, straw or the like

- A01F29/02—Cutting apparatus specially adapted for cutting hay, straw or the like having rotating knives with their cutting edges in a plane perpendicular to their rotational axis

- A01F29/04—Cutting apparatus specially adapted for cutting hay, straw or the like having rotating knives with their cutting edges in a plane perpendicular to their rotational axis with feeding direction transverse to axis

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01F—PROCESSING OF HARVESTED PRODUCE; HAY OR STRAW PRESSES; DEVICES FOR STORING AGRICULTURAL OR HORTICULTURAL PRODUCE

- A01F29/00—Cutting apparatus specially adapted for cutting hay, straw or the like

- A01F29/09—Details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Environmental Sciences (AREA)

- Birds (AREA)

- Animal Husbandry (AREA)

- Biodiversity & Conservation Biology (AREA)

- Threshing Machine Elements (AREA)

Abstract

The invention provides a forage feeding device for goat breeding, and relates to the field of goat breeding. The forage feeding device for goat breeding comprises a bottom base, wherein a U-shaped vertical plate is fixedly connected to the upper surface of the bottom base, an installation rod is rotatably connected to the inner side wall of the top of the U-shaped vertical plate through a rotating rod, a driving mechanism for driving the rotating rod to rotate is connected to the side wall of the U-shaped vertical plate, and a plurality of feeding assemblies are rotatably connected to the outer side wall of the installation rod; the top of the U-shaped vertical plate is fixedly connected with two mounting upright posts. Through mutually supporting between U type riser, forage case, broken case, baffle, U type striker plate and the feed cylinder, when the feed, can drop into forage in the feeder hopper that corresponds and broken in batches, forage after the breakage drops to the hopper that the below corresponds through the feed cylinder, and goat detachable feed avoids between each other the angle fill to lead to the unable feed of part goat and influence the normal growth of goat.

Description

Technical Field

The invention relates to the technical field of goat breeding, in particular to a forage feeding device for goat breeding.

Background

The production of the goats has the characteristics of high reproduction rate, strong adaptability, easy management and the like, the goats are widely raised in vast agricultural and pastoral areas in China so far, the development is rapid after the reform is opened, and the goats naturally raised in a scattered mode have long growth period and are inconvenient to manage, so that most of the existing goat breeding is centralized breeding.

Present sheep hurdle relies on the manual work to take on time mostly to the feed of goat when breeding and feeds, and the forage is concentrated in same trough, and the goat can be concentrated together at the feed in-process, easily because of striving for food and the corner fill, can lead to the unable feed of partial goat and influence the normal growth of goat, and simultaneously, after the goat feed is ended, can remain the crushed aggregates in the trough, need artifical manual cleaning and take the water washing, the cleaning efficiency is low, and the labor intensity is increased, and the human cost is big.

Disclosure of Invention

Technical problem to be solved

Aiming at the defects of the prior art, the invention provides a forage feeding device for goat breeding, which solves the problems that in the prior art, goats are easy to take food intensively, the horns and hoppers are not beneficial to the growth of the goats, and the eating grooves are not easy to clean after the goats take food.

(II) technical scheme

In order to achieve the purpose, the invention is realized by the following technical scheme: a forage feeding device for goat breeding comprises a bottom base, wherein a U-shaped vertical plate is fixedly connected to the upper surface of the bottom base, an installation rod is rotatably connected to the inner side wall of the top of the U-shaped vertical plate through a rotating rod, a driving mechanism for driving the rotating rod to rotate is connected to the side wall of the U-shaped vertical plate, and a plurality of feeding assemblies are rotatably connected to the outer side wall of the installation rod; the top of the U-shaped vertical plate is fixedly connected with two mounting upright posts, the top of the two mounting upright posts is fixedly connected with the same forage box, the inner side wall of the forage box is fixedly connected with a crushing box, the inner side wall of the crushing box is fixedly connected with a plurality of partition plates, the crushing box is divided into a plurality of crushing cavities by the plurality of partition plates, a crushing mechanism is arranged in each crushing cavity, the inner side wall of each crushing cavity is provided with a discharge hole, the outer side wall of the crushing box, which is close to the discharge hole, is rotatably connected with a U-shaped striker plate, the outer side of the U-shaped striker plate is provided with a feeding barrel; the U-shaped vertical plate is characterized in that a plurality of mounting plates are fixedly connected to the bottom of the U-shaped vertical plate, the outer side wall of each mounting plate is rotatably connected with a rotating plate, and the outer side wall of each rotating plate is provided with a spray head and a water supply mechanism matched with the spray head.

Preferably, the feeding assembly comprises two feeding hoppers, the two feeding hoppers are connected with the mounting rod through connecting blocks, the openings of the two feeding hoppers are opposite in direction and symmetrically arranged relative to the mounting rod, and the feeding hopper with the upward opening is positioned right below the lower charging barrel.

Preferably, the bottom base is arranged in a hollow mode, the inner side wall of the bottom base penetrates through the bottom base and is fixedly connected with a drain pipe, a large mounting opening is formed in the upper surface of the bottom base, a large grid plate is fixedly connected to the inner side wall of the large mounting opening, and the large grid plate is located below the plurality of spray heads.

Preferably, the upper surface of the bottom base is fixedly connected with a plurality of side baffles, the positions of the side baffles correspond to the positions of the partition plates one by one, a plurality of small grid plates are arranged on the outer sides of the side baffles, a plurality of small mounting openings are formed in the upper surface of the bottom base, and the small grid plates are fixedly connected with the inner side walls of the corresponding small mounting openings.

Preferably, broken mechanism is including setting up a plurality of annular broken swoves in broken cavity, forage case lateral wall fixedly connected with driving motor, driving motor output fixedly connected with pivot, the pivot end runs through a plurality of baffles in proper order and rotates with forage case inner wall to be connected, and is a plurality of annular broken sword is all fixed cup joint on the pivot lateral wall.

Preferably, the crushing cavity inside wall fixedly connected with feeder hopper, the feeder hopper runs through the grass case and outwards extends.

Preferably, the grass workbin lateral wall rotates through the movable rod to be connected with and rotates the wheel, the movable rod is connected with the pivot transmission through first belt, it is connected with the actuating lever, a plurality of to rotate the wheel lateral wall and rotate the equal fixedly connected with installation piece in U type striker plate bottom, and is a plurality of installation piece lateral wall runs through and the swivelling joint has same movable rod, the movable rod runs through the grass workbin and outwards extends, the actuating lever is kept away from and is rotated wheel one end and the movable rod and outwards extends one end and rotate and be connected.

Preferably, mounting panel lateral wall fixedly connected with is the mounting bracket of U type setting, the mounting bracket inside wall rotates and is connected with the montant, the fixed cover of rotor plate connects on the montant lateral wall.

Preferably, water supply mechanism including run through and with rotor plate fixed connection's hose, shower nozzle and hose top fixed connection, many the same delivery pipe of shower nozzle one end fixedly connected with is kept away from to the hose, the delivery pipe lateral wall cover is equipped with spacing, spacing and mounting panel lateral wall fixed connection.

Preferably, the driving mechanism comprises a servo motor fixedly connected with the outer side wall of the U-shaped vertical plate, one end of the rotating rod is fixedly connected with a cross rod, and the cross rod penetrates through the U-shaped vertical plate and is in transmission connection with an output shaft of the servo motor through a second belt.

The working principle is as follows: during the use, drop into each feeder hopper with the forage in proper order, start driving motor, driving motor drives the pivot and rotates, the pivot drives each annular broken sword with the forage breakage and through the discharge gate entering corresponding U type striker plate in, finally in the feed cylinder landing to the hopper that corresponds of below, drive the movable rod rotation through first belt when the pivot rotates, the movable rod drives and rotates the wheel rotation, the rotation wheel in the rotation passes through the actuating lever and drives the carriage release lever round trip movement, thereby make each U type striker plate shake, accelerate dropping of forage.

At this moment, each goat can be independently from feeding in the feeding hopper, avoid each other the angle fill lead to the unable feed of part goat and influence the normal growth of goat, after the feed, can start servo motor and rotate, servo motor drives horizontal pole and dwang rotation through the second belt this moment, make the feeding hopper position change of both sides, clean feeding hopper shifts to feed cylinder below, feeding hopper after the feed then shifts to the shower nozzle top, open the shower nozzle and can begin to wash feeding hopper, so that use next time, wherein need notice, before starting servo motor work, at first need rotate the rotor plate and misplace with feeding hopper, avoid rotor plate influence feeding hopper to rotate, after feeding hopper position shifts, rotate the rotor plate to treat abluent feeding hopper below again, so that the hopper after feeding washes.

(III) advantageous effects

The invention provides a forage feeding device for goat breeding. The method has the following beneficial effects:

1. through mutually supporting between U type riser, forage case, broken case, baffle, U type striker plate and the feed cylinder, when the feed, can drop into forage in the feeder hopper that corresponds and broken in batches, forage after the breakage drops to the hopper that the below corresponds through the feed cylinder, and goat detachable feed avoids between each other the angle fill to lead to the unable feed of part goat and influence the normal growth of goat.

2. Through mutually supporting between U type riser, dwang, installation pole, shower nozzle, actuating mechanism and the water spray mechanism, utilize actuating mechanism to drive the dwang and rotate to make the magazine rotate, the magazine opening that is located the shower nozzle top this moment is down, opens the shower nozzle and can directly wash the magazine, and the cleaning efficiency is high and has reduced artifical intensity of labour, has reduced the human cost.

3. Through the mutual matching among the bottom base, the large grid plate and the small grid plate, the bottom base is convenient to wash, and the washed sewage and the sewage washed by the feeding hopper can flow into the bottom base through the large grid plate and the small grid plate and are discharged outwards through the drain pipe, so that the cleanliness of the bottom base is ensured.

Drawings

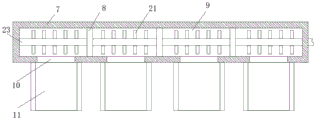

FIG. 1 is a schematic structural view of the present invention;

FIG. 2 is an enlarged view of FIG. 1 at A;

FIG. 3 is a top view of the bottom base of the present invention;

FIG. 4 is a schematic view of a connecting structure of a U-shaped vertical plate and a side baffle plate in the invention;

FIG. 5 is a schematic view of a connecting structure of a U-shaped vertical plate and a mounting plate according to the present invention;

FIG. 6 is a cross-sectional view of the forage tank of the present invention;

fig. 7 is a cross-sectional view of a crushing box according to the present invention.

Wherein, 1, a bottom base; 2. a U-shaped vertical plate; 3. rotating the rod; 4. mounting a rod; 5. mounting the upright post; 6. a grass box; 7. a crushing box; 8. a partition plate; 9. crushing the cavity; 10. a discharge port; 11. a U-shaped striker plate; 12. feeding the material barrel; 13. mounting a plate; 14. a rotating plate; 15. a spray head; 16. a feeding hopper; 17. a drain pipe; 18. a large grid plate; 19. a side dam; 20. a small grid plate; 21. an annular crushing knife; 22. a drive motor; 23. a rotating shaft; 24. a feed hopper; 25. a movable rod; 26. a rotating wheel; 27. a drive rod; 28. a travel bar; 29. a mounting frame; 30. a vertical rod; 31. a flexible water pipe; 32. a water supply pipe; 33. a limiting frame; 34. a servo motor; 35. a cross bar.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

As shown in fig. 1-7, an embodiment of the invention provides a forage feeding device for goat breeding, which comprises a bottom base 1, wherein a U-shaped vertical plate 2 is fixedly connected to the upper surface of the bottom base 1, an inner side wall of the top of the U-shaped vertical plate 2 is rotatably connected with an installation rod 4 through a rotating rod 3, a driving mechanism for driving the rotating rod 3 to rotate is connected to the side wall of the U-shaped vertical plate 2, the driving mechanism comprises a servo motor 34 fixedly connected to the outer side wall of the U-shaped vertical plate 2, a cross rod 35 is fixedly connected to one end of the rotating rod 3, the cross rod 35 penetrates through the U-shaped vertical plate 2 and is in transmission connection with an output shaft of the servo motor 34 through a second belt.

Specifically, the feeding assembly comprises two feeding hoppers 16, the two feeding hoppers 16 are connected with the mounting rod 4 through connecting blocks, the two feeding hoppers 16 are oppositely opened and symmetrically arranged about the mounting rod 4, and the feeding hopper 16 with the upward opening is positioned right below the lower charging barrel 12.

Wherein, bottom base 1 is hollow setting and inside wall runs through and fixedly connected with drain pipe 17, big installing port has been seted up to 1 upper surface of bottom base, big grid plate 18 of big installing port interior lateral wall fixedly connected with, big grid plate 18 is located a plurality of shower nozzles 15 below, a plurality of side shields 19 of 1 last fixed surface of bottom base connected with, the one-to-one in 19 positions of side shield and 8 positions of baffle, a plurality of side shields 19 outside all is equipped with little grid plate 20, a plurality of little installing ports have been seted up to 1 upper surface of bottom base, little grid plate 20 and the interior lateral wall fixed connection of little installing port that corresponds.

Wherein, two installation stands 5 of 2 top fixedly connected with of U type riser, the same grass hopper 6 of 5 top fixedly connected with of two installation stands, the broken case 7 of 6 inside wall fixedly connected with of grass hopper, a plurality of baffles 8 of 7 inside wall fixedly connected with of broken case, a plurality of baffles 8 separate broken case 7 for a plurality of broken cavitys 9, be equipped with broken mechanism in broken cavity 9, broken mechanism is including setting up a plurality of annular broken sword 21 in broken cavity 9, 6 lateral wall fixedly connected with driving motor 22 of grass hopper, driving motor 22 output end fixedly connected with pivot 23, the pivot 23 end runs through a plurality of baffles 8 in proper order and is connected with the rotation of 6 inner walls of grass hopper, a plurality of annular broken sword 21 are all fixed cup joint on 23 lateral walls of pivot, utilize annular broken sword 21 to carry out the fodder breakage in the broken cavity 9 that corresponds, be convenient for the goat to eat.

Wherein, discharge gate 10 has been seted up to broken cavity 9 inside wall, 7 lateral walls of broken case and being close to discharge gate 10 and locating to rotate and be connected with U type striker plate 11, the U type striker plate 11 outside is equipped with feed cylinder 12 down, feed cylinder 12 run through and with 6 inside wall fixed connection of forage case, 9 inside wall fixedly connected with feeder hopper 24 of broken cavity, feeder hopper 24 runs through forage case 6 and outwards extends, the setting of feeder hopper 24, the people of being convenient for put in the forage.

Further, the outer side wall of the forage tank 6 is rotatably connected with a rotating wheel 26 through a movable rod 25, the movable rod 25 is in transmission connection with a rotating shaft 23 through a first belt, the outer side wall of the rotating wheel 26 is rotatably connected with a driving rod 27, the bottoms of the U-shaped striker plates 11 are fixedly connected with mounting blocks, the outer side walls of the mounting blocks are penetrated and rotatably connected with a same movable rod 28, the movable rod 28 penetrates through the forage tank 6 and extends outwards, one end of the driving rod 27, far away from the rotating wheel 26, is rotatably connected with one end of the movable rod 28, which extends outwards, the driving rod 27 is eccentrically installed on the rotating wheel 26, the outer side wall of the forage tank 6 is provided with an arc-shaped movable opening matched with the movable rod 28, so that the movable rod 28 can move under the driving of the driving rod 27, when the driving motor 22 drives the rotating shaft 23 to rotate, the movable rod 25 drives the corresponding rotating wheel, the quick shaking and blanking are convenient.

Wherein, a plurality of mounting panels 13 of bottom fixedly connected with in U type riser 2, 13 lateral walls of mounting panel rotate and are connected with rotor plate 14, 13 lateral walls fixedly connected with of mounting panel is the mounting bracket 29 that the U type set up, 29 inside walls of mounting bracket rotate and are connected with montant 30, 14 fixed cup joints on 30 lateral walls of montant of rotor plate, 14 lateral walls of rotor plate are equipped with shower nozzle 15 and the water supply mechanism with 15 looks adaptations of shower nozzle, water supply mechanism is including running through and with 14 fixed connection's of rotor plate hose 31, shower nozzle 15 and 31 top fixed connection of hose, the same root delivery pipe 32 of 15 one end fixedly connected with of shower nozzle is kept away from to many hose 31, 32 lateral wall cover of delivery pipe is equipped with spacing 33, spacing 33 and 13 lateral wall fixed connection of mounting panel, delivery pipe 32 is connected with external tap.

It is noted that, herein, relational terms such as first and second, and the like may be used solely to distinguish one entity or action from another entity or action without necessarily requiring or implying any actual such relationship or order between such entities or actions. Also, the terms "comprises," "comprising," or any other variation thereof, are intended to cover a non-exclusive inclusion, such that a process, method, article, or apparatus that comprises a list of elements does not include only those elements but may include other elements not expressly listed or inherent to such process, method, article, or apparatus. Without further limitation, an element defined by the phrase "comprising a reference structure" does not exclude the presence of other identical elements in a process, method, article, or apparatus that comprises the element.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (10)

1. The utility model provides a goat breeding is with forage feeding device, includes bottom base (1), its characterized in that: the feeding device comprises a bottom base (1), a U-shaped vertical plate (2) is fixedly connected to the upper surface of the bottom base (1), an installation rod (4) is rotatably connected to the inner side wall of the top of the U-shaped vertical plate (2) through a rotating rod (3), a driving mechanism for driving the rotating rod (3) to rotate is connected to the side wall of the U-shaped vertical plate (2), and a plurality of feeding assemblies are rotatably connected to the outer side wall of the installation rod (4);

the top of the U-shaped vertical plate (2) is fixedly connected with two mounting upright columns (5), the top of the two mounting upright columns (5) is fixedly connected with the same grass box (6), the inner side wall of the grass box (6) is fixedly connected with a crushing box (7), the inner side wall of the crushing box (7) is fixedly connected with a plurality of partition plates (8), the crushing box (7) is divided into a plurality of crushing cavities (9) by the plurality of partition plates (8), a crushing mechanism is arranged in each crushing cavity (9), a discharge hole (10) is formed in the inner side wall of each crushing cavity (9), a U-shaped material baffle plate (11) is rotatably connected to the outer side wall of each crushing box (7) and close to the discharge hole (10), a feeding cylinder (12) is arranged on the outer side of each U-shaped material baffle plate (11), and each feeding cylinder (12);

a plurality of mounting plates (13) are fixedly connected to the bottom in the U-shaped vertical plate (2), the outer side wall of each mounting plate (13) is rotatably connected with a rotating plate (14), and the outer side wall of each rotating plate (14) is provided with a spray head (15) and a water supply mechanism matched with the spray head (15).

2. The forage feeding device for goat breeding according to claim 1, wherein: the feeding assembly comprises two feeding hoppers (16), the two feeding hoppers (16) are connected with the mounting rod (4) through connecting blocks, the openings of the two feeding hoppers (16) are opposite in direction and symmetrically arranged relative to the mounting rod (4), and the feeding hopper (16) with the upward opening is positioned right below the lower charging barrel (12).

3. The forage feeding device for goat breeding according to claim 1, wherein: the bottom base (1) is hollow, the inner side wall of the bottom base (1) penetrates through the bottom base and is fixedly connected with a drain pipe (17), a large mounting opening is formed in the upper surface of the bottom base (1), a large grid plate (18) is fixedly connected to the inner side wall of the large mounting opening, and the large grid plate (18) is located below the spray heads (15).

4. The forage feeding device for goat breeding according to claim 3, wherein: the bottom base (1) upper surface fixed connection has a plurality of side dams (19), side dam (19) position and baffle (8) position one-to-one, and is a plurality of the side dam (19) outside all is equipped with little grid plate (20), a plurality of little installing ports have been seted up to bottom base (1) upper surface, little grid plate (20) and the interior lateral wall fixed connection of little installing port that corresponds.

5. The forage feeding device for goat breeding according to claim 1, wherein: broken mechanism is including setting up a plurality of annular broken sword (21) in broken cavity (9), grass workbin (6) lateral wall fixedly connected with driving motor (22), driving motor (22) output fixedly connected with pivot (23), pivot (23) end runs through a plurality of baffles (8) in proper order and rotates with grass workbin (6) inner wall and be connected, and is a plurality of annular broken sword (21) is all fixed cup joints on pivot (23) lateral wall.

6. The forage feeding device for goat breeding according to claim 1, wherein: broken cavity (9) inside wall fixedly connected with feeder hopper (24), feeder hopper (24) run through grass workbin (6) and outwards extend.

7. The forage feeding device for goat breeding according to claim 1, wherein: grass workbin (6) lateral wall is rotated through movable rod (25) and is connected with rotation wheel (26), movable rod (25) are connected with pivot (23) transmission through first belt, it is connected with actuating lever (27) to rotate wheel (26) lateral wall rotation, and is a plurality of the equal fixedly connected with installation piece in U type striker plate (11) bottom, it is a plurality of the installation piece lateral wall runs through and rotates and be connected with same root carriage release lever (28), carriage release lever (28) run through grass workbin (6) and outwards extend, actuating lever (27) are kept away from and are rotated wheel (26) one end and outside extension one end rotation connection of carriage release lever (28).

8. The forage feeding device for goat breeding according to claim 1, wherein: mounting panel (13) lateral wall fixedly connected with is mounting bracket (29) that the U type set up, mounting bracket (29) inside wall rotates and is connected with montant (30), the fixed cover of rotor plate (14) is connected on montant (30) lateral wall.

9. The forage feeding device for goat breeding according to claim 1, wherein: the water supply mechanism is including running through and with rotor plate (14) fixed connection's hose (31), shower nozzle (15) and hose (31) top fixed connection, many the same root delivery pipe (32) of shower nozzle (15) one end fixedly connected with are kept away from in hose (31), delivery pipe (32) lateral wall cover is equipped with spacing (33), spacing (33) and mounting panel (13) lateral wall fixed connection.

10. The forage feeding device for goat breeding according to claim 1, wherein: the driving mechanism comprises a servo motor (34) fixedly connected with the outer side wall of the U-shaped vertical plate (2), one end of the rotating rod (3) is fixedly connected with a cross rod (35), and the cross rod (35) penetrates through the U-shaped vertical plate (2) and is in transmission connection with an output shaft of the servo motor (34) through a second belt.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011409991.0A CN112535109A (en) | 2020-12-04 | 2020-12-04 | Forage feeding device for goat breeding |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011409991.0A CN112535109A (en) | 2020-12-04 | 2020-12-04 | Forage feeding device for goat breeding |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112535109A true CN112535109A (en) | 2021-03-23 |

Family

ID=75016039

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011409991.0A Withdrawn CN112535109A (en) | 2020-12-04 | 2020-12-04 | Forage feeding device for goat breeding |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112535109A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113350191A (en) * | 2021-05-13 | 2021-09-07 | 山西医科大学第一医院 | Intelligent severe patient feeding device capable of avoiding overflowing liquid food |

-

2020

- 2020-12-04 CN CN202011409991.0A patent/CN112535109A/en not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113350191A (en) * | 2021-05-13 | 2021-09-07 | 山西医科大学第一医院 | Intelligent severe patient feeding device capable of avoiding overflowing liquid food |

| CN113350191B (en) * | 2021-05-13 | 2022-10-04 | 山西医科大学第一医院 | Intelligent severe patient feeding device capable of avoiding overflowing liquid food |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111715090A (en) | Mixing device and mixing method for poultry breeding | |

| CN111185435A (en) | Fresh tea leaf cleaning device for processing small-leaf melon slices | |

| CN112535109A (en) | Forage feeding device for goat breeding | |

| CN211636173U (en) | Self-cleaning mixing and stirring processing equipment | |

| CN209002859U (en) | Cabbage is washed, cuts all-in-one machine | |

| CN210965090U (en) | Reation kettle is used in chemical fertilizer production | |

| CN210233431U (en) | A storage device for concrete curing | |

| CN208956735U (en) | A kind of aquaculture tank with automatic cleaning function | |

| CN112999915A (en) | Self-cleaning mixing and stirring processing equipment | |

| CN217196353U (en) | Silica gel particle cleaning and spraying equipment | |

| CN215466393U (en) | Belt cleaning device is used in stable white duck fine hair processing of feeding | |

| CN213728094U (en) | Solid beverage raw material cleaning device | |

| CN110809974A (en) | Automatic chemical fertilizer spreading device | |

| CN219593331U (en) | Poultry trough | |

| CN218072962U (en) | Automatic throw edible device | |

| CN214918546U (en) | Intelligence bevel machine shaves face sword washing tank | |

| CN215121896U (en) | Agricultural is with seed device of scribbling medicine | |

| CN213198197U (en) | Improved mixer tank for aerated concrete block production line | |

| CN214131292U (en) | Building agitating unit for waterproof material | |

| CN217850164U (en) | Automatic water and fertilizer mixing device for irrigation | |

| CN220987064U (en) | Excrement and urine collection device is used in live pig breeding | |

| CN216314863U (en) | Automatic feeder of aquaculture suitable for pond is supported crucian | |

| CN111328791B (en) | Agricultural pesticide spraying device | |

| CN108901992A (en) | A kind of aquaculture tank with automatic cleaning function | |

| CN214829820U (en) | Farm excrement and sewage pretreatment equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication | ||

| WW01 | Invention patent application withdrawn after publication |

Application publication date: 20210323 |