CN108860527B - Underwater robot-underwater mechanical arm system - Google Patents

Underwater robot-underwater mechanical arm system Download PDFInfo

- Publication number

- CN108860527B CN108860527B CN201810745727.0A CN201810745727A CN108860527B CN 108860527 B CN108860527 B CN 108860527B CN 201810745727 A CN201810745727 A CN 201810745727A CN 108860527 B CN108860527 B CN 108860527B

- Authority

- CN

- China

- Prior art keywords

- underwater

- mechanical arm

- underwater robot

- robot

- joint

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63C—LAUNCHING, HAULING-OUT, OR DRY-DOCKING OF VESSELS; LIFE-SAVING IN WATER; EQUIPMENT FOR DWELLING OR WORKING UNDER WATER; MEANS FOR SALVAGING OR SEARCHING FOR UNDERWATER OBJECTS

- B63C11/00—Equipment for dwelling or working underwater; Means for searching for underwater objects

- B63C11/52—Tools specially adapted for working underwater, not otherwise provided for

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J9/00—Programme-controlled manipulators

- B25J9/16—Programme controls

- B25J9/1602—Programme controls characterised by the control system, structure, architecture

- B25J9/1605—Simulation of manipulator lay-out, design, modelling of manipulator

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J9/00—Programme-controlled manipulators

- B25J9/16—Programme controls

- B25J9/1612—Programme controls characterised by the hand, wrist, grip control

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63G—OFFENSIVE OR DEFENSIVE ARRANGEMENTS ON VESSELS; MINE-LAYING; MINE-SWEEPING; SUBMARINES; AIRCRAFT CARRIERS

- B63G8/00—Underwater vessels, e.g. submarines; Equipment specially adapted therefor

- B63G8/14—Control of attitude or depth

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Robotics (AREA)

- Aviation & Aerospace Engineering (AREA)

- Automation & Control Theory (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Ocean & Marine Engineering (AREA)

- Manipulator (AREA)

Abstract

The invention relates to an underwater robot-underwater mechanical arm system, which belongs to the field of underwater robots and comprises three parts: the underwater robot comprises an underwater robot body, an underwater mechanical arm and an auxiliary adjusting device; the underwater robot body is a cable-free autonomous underwater robot, the power system of the underwater robot realizes the attitude and motion control of the underwater robot in an underactuated mode, and the driving system of the underwater robot consists of a single propeller and a cross rudder and is arranged at the stern part of the underwater robot; the system adopts an underwater mechanical arm with four degrees of freedom and five functions, the underwater mechanical arm consists of two rotary joints, two swinging joints and a mechanical hand grab, and an auxiliary adjusting device is arranged right below the underwater robot and close to the stern. The device is driven by a lead screw slider mechanism and a servo motor. Through moving the slider, can realize the regulation to underwater robot focus. The device is used for compensating the influence of the longitudinal change of the gravity center of the underwater robot caused by the underwater mechanical arm in the motion process, and realizing the stable posture of the underwater robot.

Description

Technical Field

The invention relates to the technical field of underwater robots, in particular to an underwater robot-underwater mechanical arm system.

Background

As the development degree of the ocean is increasingly deepened, people hope more to complete more tasks and play more important roles, which brings about many new technical challenges. Underwater operation must be completed on the basis of good coordination and cooperation of a working tool and a robot, the technology is not mature at present, and scholars in many related fields at home and abroad are struggling to overcome the difficulty and strive to realize complete autonomous operation of the underwater robot in the morning. It is in this environment that underwater robot-arm systems are born. The system can independently complete all tasks, automatically return, has the advantages of small volume, flexible movement, easy release and recovery, no limitation of armored cables, suitability for various sea conditions and the like, and can play an important role in marine operation.

As a research hotspot in the aspect of current underwater operation, many domestic and foreign universities, scientific research institutions, enterprises and the like are actively involved in the development of the underwater robot-mechanical arm system, and a plurality of research institutions with excellent results lead the research and development directions of the underwater robot-mechanical arm system in the future, and some early research results are confidential and are not published to the outside. Some research data and related simulation results were not published until the beginning of the 80's of the 20 th century.

Under the layout and planning of national development strategy, the underwater robot-mechanical arm system in China starts to be explored earlier, but compared with some European and American old-fashioned marine engineering devices, the underwater robot-mechanical arm system is slightly thinner in research results. Shenyang automation of Chinese academy of sciences is an early preloader and seeker in the field of domestic underwater robots. When domestic resources are limited and international resources and products are blocked, sinking engineering researchers can overcome a plurality of technical difficulties in sequence by means of inflexible spirit and tenacious spirits, and a lot of force is contributed to the development of the underwater robot-mechanical arm system in China. The underwater robot-arm system research topic developed by the inventor of zhongqifeng, but was limited by the sensors and other related hardware resources at that time, the inventor of zhongqifeng performed only some exploratory studies in terms of attitude control. The university of science and technology in Huazhong bears the research and development work of four types of underwater robot-mechanical arm systems in front and at the back under the support of related national departments, the research results are applied to an underwater robot platform 'intelligent water' cooperatively researched and developed by units such as Harbin engineering university and the like, the related work is carried out, and the three-degree-of-freedom mechanical arm arranged on an AUV body successfully completes the cable shearing task in still water.

Disclosure of Invention

Aiming at the defects in the prior art, the invention aims to provide an underwater robot and an underwater mechanical arm system, which have the advantages of high adaptation ratio, flexible movement, strong operation capability, higher intelligence and the like, can finish submarine intelligent exploration, and can grab and sample submarine targets.

An underwater robot-underwater mechanical arm system is composed of an underwater robot body, an underwater mechanical arm (5), an auxiliary adjusting system (6), a motion planning and control system, a navigation system, a vision system and a power supply system; the underwater robot comprises a cross rudder (1), a stern (2), an AUV main body (3), a bow (4), an underwater mechanical arm (5), an auxiliary adjusting device (6) and a propeller (7); the power supply system is powered by a battery pack, the vision system comprises a camera, the navigation system comprises a strapdown inertial navigation Doppler log, and the motion planning and control system comprises a propeller (7) and a cross rudder; the control system of the underwater mechanical arm (5) is composed of a communication system, a mechanical arm controller, a servo motor driver, a mechanical arm body and a speed measuring sensor; the underwater mechanical arm (5) consists of four joints, including a rotary joint at the bottom, a swing joint of a large arm, a swing joint of a small arm and a rotary joint of a wrist; the single propeller (7) is arranged on the horizontal direction of the stern (2) of the underwater robot; the cross rudder is arranged at the stern (2) part of the underwater robot and in front of the propeller (7); the underwater mechanical arm (5) is arranged right below the underwater robot and close to the bow (4); the tail end of the underwater robot is provided with a mechanical gripper, each joint is driven by a servo motor, an auxiliary adjusting system is composed of a lead screw slider mechanism, the sliders are driven by the servo motor to move, and an auxiliary adjusting device (6) is arranged right below the underwater robot and close to the stern (2).

The underwater mechanical arm (5) control system specifically comprises: the communication bus is started by the master control center, establishes communication contact between the master control center and each module, and transmits instructions and data; the mechanical arm controller receives and decodes the instruction sent by the main control center, and drives and controls the mechanical arm joint according to the decoding result; the servo motor driver drives each joint servo motor; and the rotating speed measuring sensor is used for measuring the rotating condition of the real-time feedback servo motor.

The underwater mechanical arm (5) specifically comprises: the underwater mechanical arm (5) is made of corrosion-resistant and light-weight materials, and navy brass containing 1% of tin is selected as a gear manufacturing raw material; when the underwater mechanical arm (5) is in a zero-position state, the underwater mechanical arm can be completely recovered to the bottom of the underwater robot; the underwater mechanical arm (5) has four degrees of freedom, namely two rotary joints and two swing joints, the rotary joint (5.2) at the bottom is connected with a base (5.1) through a bearing, one end of the swing joint (5.3) of the large arm is connected with the rotary joint (5.2) at the bottom, the other end of the swing joint is connected with a mechanical rod, the other end of the mechanical rod is connected with the swing joint (5.4) of the small arm through a bearing, the tail end of the swing joint (5.4) of the small arm is connected with the rotary joint (5.5) of the wrist, and the tail end of the rotary joint (5.5) of the wrist is provided with a mechanical gripper (5.6) which is driven by a servo; the kinematics model of the underwater robot-underwater mechanical arm (5) system is as follows:

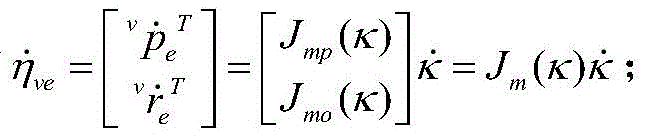

wherein the pose vector of the end effector of the robot-underwater mechanical arm (5) system under an inertial coordinate system and a motion coordinate system is ηe=[ipe T ire T]T∈R6×1And ηve=[vpe T vre T]T∈R6×1(ii) a The motion equation of the underwater mechanical arm (5) under the motion coordinate system is written asJtaskIs a Jacobian matrix of the task space of the underwater robot-underwater mechanical arm (5) system.

The auxiliary adjusting device (6) specifically comprises: the mass of a sliding block and the length of a sliding rod of the auxiliary adjusting device (6) are determined according to the mass ratio relationship between the underwater robot and the underwater mechanical arm (5); the auxiliary adjusting device (6) is single-degree-of-freedom and moves in the direction parallel to the bow (4) and the stern (2) of the underwater robot, and the auxiliary adjusting device (6) can adjust and compensate disturbance in the trim direction.

The AUV main body (3) specifically comprises: the maximum diameter of AUV is 0.26m, the whole length is 1.6m, and a whole body carbon fiber structure is adopted.

Compared with the prior art, the invention has the following outstanding advantages and beneficial effects:

(1) the invention determines an underwater robot-underwater mechanical arm system which has the advantages of high adaptation ratio, flexible movement, strong operation capability and higher intellectualization, can complete seabed intelligent exploration and can grab and sample seabed targets.

(2) The auxiliary adjusting device is added, so that the interference and influence on the posture and the motion of the underwater robot body in the motion process of the underwater mechanical arm can be compensated, and the working reliability of the system can be effectively ensured.

(3) The mechanical arm adopts a four-degree-of-freedom form, can perform underwater operation tasks in a three-dimensional space, can make up for the defect of insufficient lateral movement capability of the underwater robot under the condition of large lateral ocean current, and can assist in posture adjustment of the underwater robot.

(4) The invention fully considers the complexity of the underwater robot-underwater mechanical arm system, carries out system modeling and lays a foundation for intelligent control.

Drawings

FIG. 1 is a diagram of an overall system of an underwater robot-robotic arm system;

FIG. 2 is a design structure diagram of an underwater robot;

FIG. 3 is a block diagram of a control system of the underwater robot;

FIG. 4 is a schematic design view of a robotic arm;

FIG. 5 is a diagram of the robot arm control system;

FIG. 6 is a layout diagram of an auxiliary adjustment device of the underwater robot-boom system;

FIG. 7 is a diagram of a motion model of the underwater robot-mechanical arm system;

fig. 8 shows the function of each joint of the mechanical arm.

Detailed Description

The invention consists of three parts: the underwater robot comprises an underwater robot body, an underwater mechanical arm (5) and an auxiliary adjusting device (6). The underwater robot adopted by the system is an autonomous underwater robot AUV, and the power is supplied by a battery pack. In order to improve the cruising ability, the underwater robot adopts an under-actuated system to complete the attitude and position control of the underwater robot. The single propeller (7) is arranged on the horizontal direction of the stern (2) of the underwater robot to realize the displacement control of the underwater robot in the forward and backward directions. The cross rudder is arranged at the stern (2) of the underwater robot and in front of the propeller (7), so that the course angle and the pitch angle of the underwater robot are controlled. The underwater mechanical arm (5) is arranged right below the underwater robot and close to the bow (4), and the underwater mechanical arm (5) has four degrees of freedom which are two rotary joints and two swing joints respectively; a mechanical gripper (5.6) is arranged at the tail end of the underwater robot, and each joint is driven by a servo motor, so that five-function underwater operation tasks can be realized. When the underwater mechanical arm (5) is in a zero-position state, the underwater mechanical arm can be completely recovered to the bottom of the underwater robot, and the water flow resistance of the underwater robot-mechanical arm system can be reduced. The auxiliary adjusting device (6) is composed of a lead screw sliding block mechanism, and the servo motor drives the sliding block to move so as to adjust the change of the gravity center of the underwater robot in the longitudinal direction. The auxiliary adjusting device (6) is arranged right below the underwater robot and close to the stern (2). When the underwater robot performs underwater operation, the underwater robot can generate great interference on the body of the underwater robot, so that the posture of the underwater robot fluctuates. However, the attitude fluctuation of the underwater robot can generate certain interference on the underwater operation precision of the underwater mechanical arm (5). The device is mainly used for compensating the longitudinal posture of the underwater robot, and realizing the stable posture of the underwater robot so as to improve the operation precision of the underwater mechanical arm (5).

1. Underwater robot

The maximum diameter of the underwater robot body is 0.26m, the overall length is 1.6m, and the strength and the corrosion resistance of the body are improved by adopting a whole-body carbon fiber structure, so that higher stability is maintained in a severe environment. The underwater robot is longer in appearance and round and smooth in whole, and aims to reduce water resistance of the underwater robot in water. The underwater robot designed by the method can complete the operation task within 200m underwater, and can meet the requirement of the conventional operation task.

The underwater robot system is divided into the following four subsystems.

Motion planning and control system: according to the information of the sensor on the underwater robot and the mechanical arm (5), the information perception of the seabed working environment is completed, so that the real-time task planning and path planning of the system are performed, and then the mechanical arm and the underwater robot are coordinately controlled according to the planning result, so that the system can complete tasks smoothly and safely. In the aspect of power driving, the underwater robot adopts an under-actuated mode, and the mode can save energy and improve the duration of the underwater robot due to the fact that the number of the propellers (7) is small. A propeller (7) is arranged at the stern (2) of the underwater robot and is responsible for providing the propelling power of the underwater robot in the forward and backward directions, and a tail cross rudder is arranged in front of the propeller (7) and is used for carrying out attitude control of a course angle and a pitch angle.

A navigation system: the navigation system provides relevant information such as position, speed, attitude angle and the like in navigation and operation processes for the system, and as one of important system measurement mechanisms, the precision, stability and environment adaptability of the navigation system can have great influence on the system.

A vision system: in the operation process of the autonomous underwater robot, the image transmitted back by the camera is subjected to visual image processing to obtain image information within a visual angle range, so that the work of analyzing object type information, judging obstacles and the like can be performed, and the safety guarantee of the underwater robot is improved.

A power supply system: the underwater robot is powered by the battery pack, and the maximum endurance time is 5 hours.

2. Underwater mechanical arm (5)

The underwater mechanical arm (5) consists of four joints, and comprises a rotary joint (5.2) at the bottom, a swinging joint (5.3) of a big arm, a swinging joint (5.4) of a small arm and a wrist rotary joint (5.5); the rotary joint (5.2) at the bottom is connected with the base (5.1) through a bearing, one end of the swing joint (5.3) of the large arm is connected with the rotary joint (5.2) at the bottom, the other end of the swing joint is connected with the mechanical rod, the other end of the mechanical rod is connected with the swing joint (5.4) of the small arm through a bearing, the tail end of the swing joint (5.4) of the small arm is connected with the rotary joint (5.5) of the wrist, and the tail end of the rotary joint (5.5) of the wrist is provided with a mechanical gripper (5.6) driven by a servo.

The manufacturing material of the mechanical arm selects a material capable of resisting corrosion as a manufacturing raw material, the invention selects 2A12 high-strength aluminum alloy as the manufacturing material of the mechanical arm, and selects navy brass containing 1% of tin as the best gear manufacturing raw material. The high-strength aluminum alloy can reduce the weight of the connecting rod by a certain amount on the premise of meeting the requirements of the strength and the corrosion resistance of the connecting rod of the mechanical arm.

The control system of the underwater mechanical arm (5) is composed of a communication system, a mechanical arm controller, a servo motor driver, a mechanical arm body and a speed measuring sensor. The communication bus is started by the main control center and is responsible for establishing communication contact between the main control center and each module and transmitting instructions and data. And the mechanical arm controller is used for receiving and decoding the command sent by the main control center and performing drive control on the mechanical arm joint according to a decoding result. The servo motor driver is responsible for driving each joint servo motor to complete the planning task. The rotating speed measuring sensor is used for feeding back the rotation condition of the servo motor in real time and providing feedback information for the motor controller so as to better control the motor.

3. Auxiliary adjusting device (6)

And determining the slide block mass and the slide bar length of the auxiliary adjusting device (6) according to the mass ratio relationship between the underwater robot and the underwater mechanical arm (5). Because the main working surface of the underwater mechanical arm (5) is in the vertical plane of the underwater robot, the area of the underwater robot in the heave direction is relatively large, and the self inertia is also large, the auxiliary adjusting device (6) designed by the invention is single-degree-of-freedom and can only move in the direction parallel to the bow (4) and the stern (2) of the underwater robot. Therefore, when the underwater mechanical arm (5) is in motion operation, the auxiliary adjusting device (6) can adjust and compensate disturbance in the pitching direction.

The invention will now be described in more detail by way of example with reference to the accompanying drawings in which:

as shown in fig. 1, the system consists of three parts: the underwater robot comprises an underwater robot, an underwater mechanical arm (5) and an auxiliary adjusting device (6). The underwater robot is an independent underwater robot without cables, the attitude and the motion of the underwater robot are controlled by combining a single propeller (7) and a cross rudder, and the propeller (7) is not arranged in the vertical direction and the lateral direction, so that the underwater robot is an under-actuated system. The underwater mechanical arm (5) is a four-degree-of-freedom five-function underwater mechanical arm (5) and consists of two rotary joints, two swinging joints and a mechanical hand (5.6), and when the underwater mechanical arm (5) is not used, the underwater mechanical arm can be completely recovered to the bottom of the underwater robot, so that the resistance borne by the body is minimum. The auxiliary adjusting device (6) is arranged on a screw slider mechanism below the rear side of the underwater robot and driven by a servo motor, a heavy object is arranged on a slider and can reciprocate, so that the influence of longitudinal change of the gravity center of the underwater robot caused by the underwater mechanical arm (5) in the motion process is compensated, and the posture of the underwater robot is stabilized.

Mounting holes are formed in two ends of the bottom of the underwater mechanical arm (5), the mounting holes are connected with a framework placed on the underwater mechanical arm (5) inside the underwater robot, the mounting holes are located in the front space in the underwater robot cabin, other joints can be unfolded from the bottom end of the underwater robot through control, and the underwater robot can be hidden in the bottom cabin of the underwater robot when not in work. The auxiliary adjusting system is installed in the rear cabin of the underwater robot body, and a motor and a lead screw of the adjusting system are fixedly connected with the underwater robot framework through screws, as shown in figure 1.

As shown in FIG. 2, the underwater robot has a longer shape and is round and smooth as a whole, so as to reduce the water resistance in water. In the aspect of power driving, the underwater robot is provided with a propeller (7) at the tail part, which is responsible for providing integral propulsion power, and a tail cross rudder is designed for controlling the attitude, the steering motion and the like. The purpose of doing so can practice thrift the energy, improves underwater robot's duration of endurance. The robot body has the maximum diameter of 0.26m and the whole length of 1.6m, and adopts a whole-body carbon fiber structure, so that the strength and the corrosion resistance of the body are improved, and higher stability is kept in a severe environment. The underwater robot designed by the invention can complete an operation task within 200m underwater, the maximum duration is 5 hours, and the requirements of conventional operation tasks can be met.

As shown in fig. 3, the underwater robot system is divided into several subsystems as follows.

Motion planning and control system: and according to the information of the sensor on the underwater robot and the mechanical arm, the information sensing of the seabed working environment is completed, so that the real-time task planning and path planning of the system are performed, and then the mechanical arm and the underwater robot are coordinately controlled according to the planning result, so that the system can smoothly and safely complete tasks.

A navigation system: the navigation system provides relevant information such as position, speed, attitude angle and the like in navigation and operation processes for the system, and as one of important system measurement mechanisms, the precision, stability and environment adaptability of the navigation system can have great influence on the system.

A vision system: in the operation process of the autonomous underwater robot, the image transmitted back by the camera is subjected to visual image processing to obtain image information within a visual angle range, so that the work of analyzing object type information, judging obstacles and the like can be performed, and the safety guarantee of the underwater robot is improved.

A power supply system: the underwater robot is powered by the battery pack, and the maximum endurance time is 5 hours.

The other systems are mechanical arms and auxiliary adjusting systems.

As shown in fig. 4, the underwater robot arm (5) is composed of 4 joints, including a bottom revolute joint, a large arm revolute joint, a small arm revolute joint, and a wrist revolute joint. The base is installed in an underwater robot cabin, the rotary joint is placed in the base and is connected with the large arm swing joint, the large arm swing joint is connected with the small arm swing joint through the connecting rod, the small arm swing joint is connected with the wrist joint through the connecting rod, and the wrist joint is connected with the paw. The electric connecting line of the mechanical arm joint is connected with a cable through an oil filling pipe in a cable-laying mode, and the function of the mechanical arm joint is shown in figure 8. The manufacturing material of the mechanical arm selects a material capable of resisting corrosion as a manufacturing raw material, the invention selects 2A12 high-strength aluminum alloy as the manufacturing material of the mechanical arm, and selects navy brass containing 1% of tin as the best gear manufacturing raw material. The high-strength aluminum alloy can reduce the weight of the connecting rod by a certain amount on the premise of meeting the requirements of the strength and the corrosion resistance of the connecting rod of the mechanical arm.

As shown in fig. 5, the underwater robot arm (5) is composed of a communication system, a robot arm controller, a servo motor driver, a robot arm body, and a speed measurement sensor. The communication bus is started by the main control center and is responsible for establishing communication contact between the main control center and each module and transmitting instructions and data. And the mechanical arm controller is used for receiving and decoding the command sent by the main control center and performing drive control on the mechanical arm joint according to a decoding result. The servo motor driver is responsible for driving each joint servo motor to complete the planning task. The rotating speed measuring sensor is used for feeding back the rotation condition of the servo motor in real time and providing feedback information for the motor controller so as to better control the motor.

As shown in fig. 6, the mass of the slide block and the length of the slide rod of the auxiliary adjusting device (6) are determined according to the mass ratio relationship between the underwater robot and the underwater mechanical arm (5). Because the main working surface of the underwater mechanical arm (5) is in the vertical plane of the underwater robot, the area of the underwater robot in the heave direction is relatively large, and the self inertia is also large, the auxiliary adjusting device (6) designed by the invention is single-degree-of-freedom and can only move in the direction parallel to the bow (4) and the stern (2) of the underwater robot. Therefore, when the underwater mechanical arm (5) is in motion operation, the auxiliary adjusting device (6) can adjust and compensate disturbance in the pitching direction.

As shown in fig. 7, the respective joint position vectors of the underwater robot-underwater robot arm (5) system in the inertial coordinate system are defined as [ x, y, z, phi, theta, psi, theta ═ x1,θ2,θ3,θ4]TThe joint speed of the underwater robot-underwater mechanical arm (5) system under the motion coordinate system isThe kinematic model of the joint space of the underwater robot-underwater mechanical arm (5) system can be obtained as follows:

wherein I4×4Is an identity matrix, 06×4And 04×6Is a zero matrix.

Further defining the position vector of the end effector of the underwater robot-underwater mechanical arm (5) system under an inertial coordinate system and a motion coordinate system to be ηe=[ipe T ire T]T∈R6×1And ηve=[vpe T vre T]T∈R6×1。

The motion equation describing the underwater mechanical arm (5) in the motion coordinate system is written as follows:

the transformation matrix of the end effector of the underwater robot-underwater mechanical arm (5) system to the fixed system is as follows:

in the formula (I), the compound is shown in the specification,iRvis a transformation matrix between the dynamic system and the static system,vRea conversion relationship matrix between the end effector and the body of the mechanical arm,ipva position vector representing the body under the fixed system,vpeis the position vector of the end of the arm under the tether.

Underwater robot-underwater robot arm (5) system the arm tip position in the alignment can be expressed as:

ipe=ipv+iRv vpe(5)

the above formula is derived:

Whereiniwv×]Is a diagonally symmetric matrix, i.e. foriwv=[wxwywz[TIs provided with

Meanwhile, two properties are used in formula (7), namely, [ X × ] Y ═ Y × ] X and X × Y ═ Y × X for X, Y is a matrix.

The attitude matrix is derived:

in the derivation process of the above equation, the equation is usedvRi=iRv -1=iRv T,iRv[vwe×]iRv T=[iRv vwe×]. At the same time for the pivoting movementiRv=J2(η2)。

Obtained by the formula (9):

the kinematic model of the underwater robot-underwater mechanical arm (5) system obtained by combining the formula (7) and the formula (10) is as follows:

wherein JtaskIs a Jacobian matrix of the task space of the underwater robot-underwater mechanical arm (5) system.

Claims (1)

1. An underwater robot-underwater mechanical arm system is composed of an underwater robot body, an underwater mechanical arm, an auxiliary adjusting system, a motion planning and control system, a navigation system, a vision system and a power supply system; the underwater propeller specifically comprises a cross rudder, a stern, an AUV main body, a bow, an underwater mechanical arm, an auxiliary adjusting device and a propeller; the power supply system is powered by a battery pack, the vision system comprises a camera, the navigation system comprises a strapdown inertial navigation Doppler log, and the motion planning and control system comprises a propeller and a cross rudder; the underwater mechanical arm control system is composed of a communication system, a mechanical arm controller, a servo motor driver, a mechanical arm body and a speed measuring sensor; the underwater mechanical arm consists of four joints, including a rotary joint at the bottom, a swing joint of a large arm, a swing joint of a small arm and a rotary joint of a wrist; the single propeller is arranged in the horizontal direction of the stern of the underwater robot; the cross rudder is arranged at the stern part of the underwater robot and in front of the propeller; the underwater mechanical arm is arranged right below the underwater robot and close to the bow part; the tail end of the underwater robot is provided with a mechanical gripper, each joint is driven by a servo motor, an auxiliary adjusting system consists of a lead screw slider mechanism, the servo motor drives a slider to move, and an auxiliary adjusting device is arranged right below the underwater robot and close to the stern;

the underwater mechanical arm control system specifically comprises:

the communication bus is established by the master control center to communicate with each module and transmit instructions and data; the mechanical arm controller receives and decodes the instruction sent by the main control center, and drives and controls the mechanical arm joint according to a decoding result; the servo motor driver drives each joint servo motor; the speed measurement sensor measures the rotation condition of the real-time feedback servo motor;

the underwater mechanical arm specifically comprises:

the manufacturing material of the underwater mechanical arm selects a corrosion-resistant and light-weight material as a manufacturing raw material, and selects admiralty brass containing 1% of tin as a gear manufacturing raw material; when the underwater mechanical arm is in a zero position state, the underwater mechanical arm can be completely recovered to the bottom of the underwater robot; the underwater mechanical arm has four degrees of freedom, namely two rotary joints and two swinging joints, the rotary joint at the bottom is connected with the base through a bearing, one end of the swinging joint of the large arm is connected with the rotary joint at the bottom, the other end of the swinging joint is connected with the mechanical rod, the other end of the mechanical rod is connected with the swinging joint of the small arm through a bearing, the tail end of the swinging joint of the small arm is connected with the rotary joint of the wrist, and the tail end of the rotating joint of the wrist is connected with a mechanical gripper driven by a servo; the kinematics model of the underwater robot-underwater mechanical arm system is as follows:

wherein the end effector of the robot-underwater mechanical arm system is under an inertial coordinate system and a motion coordinate systemPose vector at position ηe=[ipe Tire T]T∈R6×1And ηve=[vpe Tvre T]T∈R6×1(ii) a The motion equation of the underwater mechanical arm under the motion coordinate system is written asJtaskIs a Jacobian matrix of a task space of an underwater robot-underwater mechanical arm system;

the auxiliary adjusting device specifically comprises:

the mass of a sliding block and the length of a sliding rod of the auxiliary adjusting device are determined according to the mass ratio relationship between the underwater robot and the underwater mechanical arm; the auxiliary adjusting device is single-degree-of-freedom and moves in the direction parallel to the fore and aft directions of the underwater robot, and the auxiliary adjusting device can adjust and compensate disturbance in the trim direction;

the AUV main body specifically comprises:

the maximum diameter of the AUV is 0.26m, the overall length is 1.6m, and a whole-body carbon fiber structure is adopted.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810745727.0A CN108860527B (en) | 2018-07-09 | 2018-07-09 | Underwater robot-underwater mechanical arm system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201810745727.0A CN108860527B (en) | 2018-07-09 | 2018-07-09 | Underwater robot-underwater mechanical arm system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN108860527A CN108860527A (en) | 2018-11-23 |

| CN108860527B true CN108860527B (en) | 2020-07-14 |

Family

ID=64300249

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201810745727.0A Active CN108860527B (en) | 2018-07-09 | 2018-07-09 | Underwater robot-underwater mechanical arm system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN108860527B (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110763228B (en) * | 2019-10-08 | 2022-12-13 | 哈尔滨工程大学 | Error correction method of integrated navigation system based on seabed oil and gas pipe node position |

| CN110816793B (en) * | 2019-12-10 | 2023-11-17 | 大连海事大学 | Underwater robot and working method thereof |

| CN111136687B (en) * | 2019-12-31 | 2023-06-20 | 哈尔滨工程大学 | Underwater robot vision control target grabbing test system and method |

| CN111319734A (en) * | 2020-04-15 | 2020-06-23 | 浙江大学 | Modularized reconfigurable underwater robot |

| CN113277034B (en) * | 2021-05-18 | 2022-12-30 | 江苏科技大学 | Underwater robot for marine product fishing |

| CN113844627A (en) * | 2021-10-22 | 2021-12-28 | 杭州电子科技大学 | Unmanned no cable operation type robot under water |

| CN113879494A (en) * | 2021-10-26 | 2022-01-04 | 蓓伟机器人科技(上海)有限公司 | Intelligent underwater robot and motion control method thereof |

| CN116160435A (en) * | 2023-04-24 | 2023-05-26 | 海南坤联科技有限公司 | Somatosensory-control bionic mechanical arm mounted on submarine |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07214484A (en) * | 1994-01-31 | 1995-08-15 | Mitsubishi Heavy Ind Ltd | Manipulator for submarine boat |

| CN1876485A (en) * | 2006-07-04 | 2006-12-13 | 浙江大学 | Underwater gliding detector |

| CN201938094U (en) * | 2010-11-15 | 2011-08-24 | 聊城大学 | Four-freedom fruit-picking manipulator system |

| CN203510208U (en) * | 2013-10-17 | 2014-04-02 | 上海海洋大学 | Multi-degree of freedom underwater operation mechanical arm |

| CN104084947A (en) * | 2014-06-27 | 2014-10-08 | 哈尔滨工程大学 | Seven-functional underwater mechanical arm system |

| CN106477008A (en) * | 2016-11-25 | 2017-03-08 | 哈尔滨工程大学 | A kind of three bodies streamlined AUTONOMOUS TASK underwater robot platform |

| CN206480306U (en) * | 2016-12-06 | 2017-09-08 | 昆明理工大学 | A kind of four-degree-of-freedom teaching robot |

-

2018

- 2018-07-09 CN CN201810745727.0A patent/CN108860527B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07214484A (en) * | 1994-01-31 | 1995-08-15 | Mitsubishi Heavy Ind Ltd | Manipulator for submarine boat |

| CN1876485A (en) * | 2006-07-04 | 2006-12-13 | 浙江大学 | Underwater gliding detector |

| CN201938094U (en) * | 2010-11-15 | 2011-08-24 | 聊城大学 | Four-freedom fruit-picking manipulator system |

| CN203510208U (en) * | 2013-10-17 | 2014-04-02 | 上海海洋大学 | Multi-degree of freedom underwater operation mechanical arm |

| CN104084947A (en) * | 2014-06-27 | 2014-10-08 | 哈尔滨工程大学 | Seven-functional underwater mechanical arm system |

| CN106477008A (en) * | 2016-11-25 | 2017-03-08 | 哈尔滨工程大学 | A kind of three bodies streamlined AUTONOMOUS TASK underwater robot platform |

| CN206480306U (en) * | 2016-12-06 | 2017-09-08 | 昆明理工大学 | A kind of four-degree-of-freedom teaching robot |

Non-Patent Citations (3)

| Title |

|---|

| 《4自由度示教机械手构型设计与运动分析》;高蕾娜等;《实验室研究与探索》;20160731;第44-47页 * |

| 《水下机器人-机械手姿态调节系统研究》;杨超等;《哈尔滨工程大学学报》;20180228;第377-383页 * |

| 《水下机器人-机械手系统构建与研究》;张奇峰等;《海洋技术》;20070331;第10-15页 * |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108860527A (en) | 2018-11-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108860527B (en) | Underwater robot-underwater mechanical arm system | |

| CN108313241B (en) | Electromagnetic adsorption underwater operation robot based on ROV platform | |

| CN108045532B (en) | Underwater electric mechanical arm operation nacelle and use method thereof | |

| AU2016212374B2 (en) | Underwater manipulator arm robot | |

| Jun et al. | A new concept and technologies of multi-legged underwater robot for high tidal current environment | |

| CN111137419B (en) | Deformable autonomous underwater robot | |

| CN211592892U (en) | Center-of-gravity shifting type amphibious sampling robot | |

| KR20190108353A (en) | Moving apparatus in water | |

| Sverdrup-Thygeson et al. | A control framework for biologically inspired underwater swimming manipulators equipped with thrusters | |

| CN110641660B (en) | Underwater operation robot for marine product fishing | |

| CN115535195B (en) | Underwater robot based on hybrid driving of bionic swing and propeller and working method thereof | |

| CN113561178A (en) | Intelligent grabbing device and method for underwater robot | |

| CN112666983B (en) | AUV stable hovering device based on flow field speed decomposition method | |

| CN113968326A (en) | Vector frame type underwater robot | |

| Ai et al. | System design and experiment of the hybrid underwater vehicle | |

| CN106904258A (en) | Bi-motor is multidirectional to advance autonomous robot under water | |

| CN109866902B (en) | Single-propeller vector propulsion device | |

| CN113022822B (en) | Underwater outer limb and application thereof | |

| CN116062130A (en) | Shallow water underwater robot based on full degree of freedom | |

| Liang et al. | Experiment of robofish aided underwater archaeology | |

| CN114313168A (en) | Chain type multi-body autonomous underwater robot | |

| Su et al. | A closed-loop method to generate fast C-start for a robotic fish | |

| CN214397164U (en) | Humanoid underwater operation robot | |

| CN112660345A (en) | Six-degree-of-freedom underwater detection robot | |

| CN115125923B (en) | Small-size waters rubbish clearance robot |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |