CN1082891C - 可分层的包装层压材料及其生产方法 - Google Patents

可分层的包装层压材料及其生产方法 Download PDFInfo

- Publication number

- CN1082891C CN1082891C CN96199285A CN96199285A CN1082891C CN 1082891 C CN1082891 C CN 1082891C CN 96199285 A CN96199285 A CN 96199285A CN 96199285 A CN96199285 A CN 96199285A CN 1082891 C CN1082891 C CN 1082891C

- Authority

- CN

- China

- Prior art keywords

- layer

- package lamina

- starch

- lamina material

- paper

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 10

- 238000004806 packaging method and process Methods 0.000 title description 3

- 239000000463 material Substances 0.000 claims abstract description 103

- 239000010410 layer Substances 0.000 claims abstract description 77

- 229920003023 plastic Polymers 0.000 claims abstract description 34

- 239000004033 plastic Substances 0.000 claims abstract description 34

- 239000011087 paperboard Substances 0.000 claims abstract description 22

- 229920002472 Starch Polymers 0.000 claims abstract description 15

- 235000019698 starch Nutrition 0.000 claims abstract description 15

- 239000008107 starch Substances 0.000 claims abstract description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 5

- 230000004888 barrier function Effects 0.000 claims description 18

- 239000011111 cardboard Substances 0.000 claims description 16

- 229920001684 low density polyethylene Polymers 0.000 claims description 13

- 239000004702 low-density polyethylene Substances 0.000 claims description 13

- 238000000034 method Methods 0.000 claims description 13

- 229920000881 Modified starch Polymers 0.000 claims description 11

- 235000019426 modified starch Nutrition 0.000 claims description 11

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 10

- 239000001301 oxygen Substances 0.000 claims description 10

- 229910052760 oxygen Inorganic materials 0.000 claims description 10

- 238000001125 extrusion Methods 0.000 claims description 9

- 239000007789 gas Substances 0.000 claims description 8

- 239000011248 coating agent Substances 0.000 claims description 7

- 238000000576 coating method Methods 0.000 claims description 7

- 210000000498 stratum granulosum Anatomy 0.000 claims description 5

- 239000006185 dispersion Substances 0.000 claims description 4

- 239000011229 interlayer Substances 0.000 claims description 4

- 239000002985 plastic film Substances 0.000 claims description 4

- 229920006255 plastic film Polymers 0.000 claims description 4

- 229920001169 thermoplastic Polymers 0.000 claims description 4

- 230000004927 fusion Effects 0.000 claims description 2

- 239000004416 thermosoftening plastic Substances 0.000 claims description 2

- 239000000123 paper Substances 0.000 abstract description 18

- 239000000853 adhesive Substances 0.000 abstract description 9

- 230000001070 adhesive effect Effects 0.000 abstract description 7

- 229920003169 water-soluble polymer Polymers 0.000 abstract description 4

- 239000012790 adhesive layer Substances 0.000 abstract description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 abstract description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 abstract description 2

- 239000005022 packaging material Substances 0.000 abstract 5

- 239000011230 binding agent Substances 0.000 abstract 1

- 229920001222 biopolymer Polymers 0.000 abstract 1

- 239000006223 plastic coating Substances 0.000 abstract 1

- 238000004064 recycling Methods 0.000 abstract 1

- 238000012856 packing Methods 0.000 description 27

- 239000000835 fiber Substances 0.000 description 11

- 238000007789 sealing Methods 0.000 description 11

- 239000007788 liquid Substances 0.000 description 8

- 238000001035 drying Methods 0.000 description 7

- 239000004698 Polyethylene Substances 0.000 description 5

- 238000005516 engineering process Methods 0.000 description 5

- 229920000573 polyethylene Polymers 0.000 description 5

- 230000008859 change Effects 0.000 description 4

- -1 polyethylene Polymers 0.000 description 4

- 239000013047 polymeric layer Substances 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 description 2

- 239000004411 aluminium Substances 0.000 description 2

- 230000003190 augmentative effect Effects 0.000 description 2

- UFRKOOWSQGXVKV-UHFFFAOYSA-N ethene;ethenol Chemical group C=C.OC=C UFRKOOWSQGXVKV-UHFFFAOYSA-N 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 239000002648 laminated material Substances 0.000 description 2

- 238000011068 loading method Methods 0.000 description 2

- 229920000642 polymer Polymers 0.000 description 2

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- IMROMDMJAWUWLK-UHFFFAOYSA-N Ethenol Chemical compound OC=C IMROMDMJAWUWLK-UHFFFAOYSA-N 0.000 description 1

- 230000003321 amplification Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000012792 core layer Substances 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 239000004715 ethylene vinyl alcohol Substances 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 230000008595 infiltration Effects 0.000 description 1

- 238000001764 infiltration Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 235000021056 liquid food Nutrition 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000003199 nucleic acid amplification method Methods 0.000 description 1

- 238000012858 packaging process Methods 0.000 description 1

- 238000000053 physical method Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/10—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of paper or cardboard

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B17/00—Recovery of plastics or other constituents of waste material containing plastics

- B29B17/02—Separating plastics from other materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B17/00—Recovery of plastics or other constituents of waste material containing plastics

- B29B17/04—Disintegrating plastics, e.g. by milling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/0038—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding involving application of liquid to the layers prior to lamination, e.g. wet laminating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B43/00—Operations specially adapted for layered products and not otherwise provided for, e.g. repairing; Apparatus therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D65/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D65/38—Packaging materials of special type or form

- B65D65/40—Applications of laminates for particular packaging purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/26—Scrap or recycled material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2705/00—Use of metals, their alloys or their compounds, for preformed parts, e.g. for inserts

- B29K2705/02—Aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2009/00—Layered products

- B29L2009/003—Layered products comprising a metal layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2317/00—Animal or vegetable based

- B32B2317/12—Paper, e.g. cardboard

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2553/00—Packaging equipment or accessories not otherwise provided for

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/62—Plastics recycling; Rubber recycling

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/80—Packaging reuse or recycling, e.g. of multilayer packaging

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Environmental & Geological Engineering (AREA)

- Laminated Bodies (AREA)

- Wrappers (AREA)

- Packages (AREA)

Abstract

本发明涉及由纸或纸板层(11)和在低或纸板卷材(11)的两侧面上的外部、不透液体的塑料层(12,13)组成的层压包装材料(10)。为了有利于层压包装材料(10)使用后材料的回收,使包装材料(10)在纸或纸板层(11)和各个外部塑料涂层(12,13)之间有水溶性聚合物层(14,15),所述层(14,15)是起粘合剂的作用。由于粘合剂层(14,15)以可靠的粘合力把各层粘接在一起形成充分整体化的包装材料的同时,也有了能使包装材料在使用后通过材料处理,优选分割成小片,在约40-60℃的热水下,易于分离或分层,借此粘合剂层(14,15)溶解而留下分别为纸或纸板和塑料易分离部分。粘合剂的实例可以是生物聚合物或合成的,水溶性聚合物,例如淀粉或聚乙烯醇,其涂覆量介于0.1和5g/m2(干重)。

Description

技术领域

本发明涉及由纸或纸板和塑料多层组成的可分层包装材料,还涉及生产所述可分层包装层压材料的方法。

背景技术

在包装工业中,使用的经常是单一用途类型的包装,并且这些所谓单一用途、易处置的一大类包装是由纸或纸板层和外部、不透液体的聚乙烯层组成的层压包装材料(包装层压材料)生产的。

层压包装材料(包装层压材料)组成的出发点是能为被包装的产品提供最佳的可能保护,同时作为包装必须有足够的机械强度和稳定性以便安全和方便的装卸。

仅由纸或纸板和聚乙烯组成的包装虽在构型上稳定且不透液体,但缺少气体阻挡层性能。为了用对气体,尤其是氧气的气密性增补包装,通常是在包装层压材料中装上一层铝(通常所说的Al箔)。除Al箔以外其它具有相应所要求的不透气性的材料也以商品化、单一用途易处置型的包装,如乙烯与乙烯醇共聚物的EVOH形式出现。

上述类型的包装层压材料常规生产方法是简单挤塑法,其中在纸或纸板卷材的两个侧面上涂上挤塑的聚乙烯的薄层,为的是形成包装层压材料外部、不透液体的塑料层。生产具有增补的气体不透性的包装层压材料,例如使用一卷纸或纸板与一卷预制的铝,借助于密封层(粘合剂)粘合在一起,铝在优良的粘合强度下与纸或纸板卷材粘结,密封层被挤塑在所述两种卷材的当中。之后使卷材涂上被挤塑在卷材两个侧面上的聚乙烯薄层,用于形成所述包装层压材料的外部,不透液体的塑料层。

借助于这种方法,前面已描述过的这类包装层压材料可以给出优良的整体性和优良的内部粘合(结合)强度,这是由包装层压材料能生产出机械强度高和构型稳定的包装的极其重要的先决条件。

尽管包装层压材料优良的整体性和内部粘合强度对于能生产具有优良机械强度和构型稳定性来说是理想的和必须的,但是还存在着一些重要和决定性的因素,如果希望能从废包装层压材料中尽可能再循环单个材料,和能通过以尽可能纯的形式回收和循环它们来重新利用这些单个材料。例如,长期以来在本技术领域内一直存在着要求回收包装层压材料(其纸或纸板部分)的纤维含量,但是由于纸或纸板层与邻近的密封层(或聚乙烯层)间强有力的粘合连接,已经证实在分离处理后不发生与塑料粘合的纤维的损失,而使这些层被此分离是困难的。

本发明的目的

因此本发明的一个目的是为了克服与前述现有技术包装层压材料有关的缺点。

本发明进一步的目的是实现包装层压材料易于分层,尽管该包装层压材料各层间有优良的整体性和优良的内部粘合力,由此易于回收和再次使用,而不会有如用现有技术包装层压材料的情况一样的过量的材料损失。

本发明还有一个目的是实现由纸或纸板和塑料层组成的包装层压材料,从该包装层压材料,其中所含纤维(纸或纸板)易于以最大可能的程度和可能的最纯形式被回收和重新使用。

本发明还有一个目的是提供一种易于分层并具有氧气阻挡层性能的包装层压材料。解决方案

本发明的第一方面提供了一种具有氧气阻挡层性能的包装层压材料,它包括纸或纸板的芯层和一层或多层塑料,其特征在于芯层和所述塑料层通过包括淀粉或淀粉衍生物的中间粘合层的中介而相互粘合,并且该粘合层还可提供所述气体阻挡层性能。

所述的塑料层可以通过表面熔合与淀粉层结合,或被挤塑在淀粉层上。

粘合层优选存在量介于0.1和5g/m2(干重)之间,更优选介于0.5和1g/m2(干重)之间。

所述的塑料优选是热塑性聚合物,更优选是低密度聚乙烯(LDPE)。

所述的包装层压材料优选在24小时,1atm,提供289cm3/m2或以下的氧气阻挡层。

本发明的另一方面提供了一种生产按权利要求1所述包装层压材料(10)的方法,其特征在于在芯层卷材(11)至少一个侧面上涂有淀粉或淀粉衍生物水溶液的薄层(14,15),干燥所述卷材以便除去所涂覆的含水淀粉或淀粉衍生物层(14,15)中的水;和使干燥过的卷材与塑料膜(12,13)结合,该塑料膜通过与淀粉或淀粉衍生物的中间层(14,15)的表面熔合而与卷材结合。

淀粉水溶液优选通过分散体涂复操作施加。

淀粉水溶液的施加量优选使淀粉或淀粉衍生物涂层(14,15)干燥后的存在量介于0.1和5g/m2。

本发明的第三方面提供了淀粉或淀粉衍生物在包装层压材料中作为中间粘合层的应用,以使塑料层与纸或纸板的芯层相结合而提供气体阻挡层性能。

使用施加于纸或纸板和塑料层(和各自的多个塑料层)间的水溶性聚合物的粘合层,按本发明将会获得一种包装层压材料,该材料一方面能显示纸或纸板层与上述塑料层间的优良整体性和优良的内部粘合力(粘合强度),另一方面,该材料易于分层,即该包装层压材料在使用后,能分成其单个材料层。更确切地说,已证明由本发明包装层压材料有可能生产一种包装,该包装具有气体阻挡层性能、足够的机械强度和耐外界应力的构型坚固性,该应力是在通常装卸和使用时发生的,但不会造成变形或别的损坏,并且包装中来自包装层压材料中所含的纤维(纸或纸板)采用简单有效的方法即可容易地被回收和再次使用,纤维不会由于分离和粘在分离的塑料部分而造成过量的损失。

在根据本发明已完成的切合实际的实验中,已经证明处在中间的层,即使在量非常少时如低至约0.1g(干重)/m2,一方面有很好的整体性同时又是易于可分层的包装层压材料。根据本发明,对于处于中间粘合剂层的实际数量范围大约为0.1g(干重)/m2-约5g(干重)/m2,优选约0.5-1g(干重)/m2。

附图的简述

本发明将借助本发明一个优选实施方案的包装层压材料的非限制性实施例,并参考附图在下文予以更详细地描述,其中:

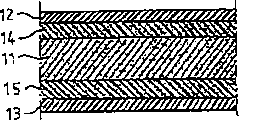

图1示意说明按照本发明一个实施方案的包装层压材料的截面图。

图2示意说明图1包装层压材料的生产方法。

最佳实施方案的描述

参见附图1,由此示意说明本发明简单实施方案的包装层压材料截面图,用通用的参考号数10表示。为了以尽可能明了的方式说明原理,在本文中采用“简单实施方案”一词表明包装层压材料10,仅用非常有限数目的单个层来表示。然而在实践中,包装层压材料可能含有比附图所示的层数多许多倍。尽管举例说明的包装层压材料具有五个独立层,但对于本技术领域的一般技术人员来说很明显这个数目是可以改变的,由此下面的描述不应视为对本发明的限制。

包装层压材料10具有构型上坚固,但可折叠的纸或纸板芯层11,其主要功能是给予包装层压材料10以机械强度和稳定性,以便适合由包装层压材料10生产构型稳定的包装。芯层11是包装层压材料10中显示较大厚度的一层,对于与本发明特别有关的包装层压材料类型来说,其厚度可从约100μm变化到约300-400μm。然而芯层11的厚度对本发明而言并非严格的参数,在其最宽的范围内,使本发明用于包装层压材料的芯层厚度对比本发明具体规定的可小些也可大些。

在芯层11的两侧,有塑料外层12、13,借助于它们的帮助保护内部能吸收液体的纤维层11(纸或纸板)免遭来自两个方向上的水分和湿气渗透否则它们将很容易渗透并使纤维层湿透而变得无用。所述两外层12和13中的塑料选择是可变的,但优选由与例示说明过的实施方案相同塑料组成的层,最好是可挤塑的热塑性塑料,例如低密度聚乙烯(LDPE)。用LDPE层作为本发明包装层压材料10中外部不透液体层12和13的优点之一是,它们通过通常所说的热封就能相互和本身易于被密封,这是一种供应包装的有效方法,正如下文将要进行的详细说明,在包装层压材料10转变成为构型稳定的包装过程中,所述包装是通过折痕成形为包装预定不变几何构型产生的。优先选择相应各外部塑料层12和13的厚度以便使纤维层达到所要求的水分和防潮,同时有可能在两层互相面对的表面之间进行有效的热封。实际上,相应各塑料层12和13的厚度介于约10和40μm。

从图1可见,在所述简单实施方案中,外塑料层12和外塑料层13借助各自的粘结剂或粘合剂的中间层14和15的中介而与内部纸或纸板粘结,该粘结剂或粘合剂具有这样一种性质,即它可以以良好的粘合强度与纸或纸板层11以及与各自的外塑料层12和13连接。

在分层时能起“脱离剂层”作用处在中间的粘合剂层14,15的厚度为从约0.1g(干重)/m2和0.1g(干重)/m2以上,如0.1-5g(干重)/m2。优选的是,厚度约为0.5-1g(干重)/m2。

意外地发现所涂淀粉层具有氧气阻挡层的性能。十分惊奇的是,在工业可接受的气体阻挡层性能仅通过很少量的含水淀粉聚合物就可获得。

通过实施例,发现使用各具有0.5和1g/m2厚度的淀粉聚合物层14、15,在24小时和1atm下可提供氧气阻挡层为289cm3/m2。

进一步发现使用厚度各为1g和1.5g/m2的聚合物层14、15,在24小时和1atm下可提供141cm3/m2的氧气阻挡层。

上述阻挡层性能应与常规的纸板-聚乙烯层压材料但无常规阻挡层(如EVOH-层或Al-箔)作一比较,这种常规层压材料具有的氧气阻挡层在24小时和1atm下为3000cm3/m2。

本发明的包装层压材料10可按图2示意说明的方法生产,其中与图1相同的参考数字用于相同或相应的部分,以便有利于两幅附图的对比。

使纸或纸板卷材11沿着箭头方向从卷片轴(未画出)引向图2左边的涂覆台20,在涂覆场所处卷材11的两个侧面,用常规的涂覆装置21涂上一层所选的水性聚合物例如淀粉或聚乙烯醇的水溶液或分散液的薄层。涂于卷材11两个侧面上的水溶液或分散液的数量以这样的一种方式选择,以便各个涂覆过的聚合物层具有介于0.1和5g(干重)/m2,优选约0.5-1g(干重)/m2的厚度。

双面涂覆过的卷材11被进一步引到干燥台30处,在该处卷材的双侧面借助于干燥设备31除去原先涂覆的含水聚合物层中的水(干燥)而得到干燥。干燥后,各个聚合物层的厚度,如早已提到的,优选在0.1-5g(干重)/m2之间。理想地约为0.5-1g(干重)/m2。

来自干燥台30、干燥过的卷材11经转向辊40进一步引入挤塑机台50,在该处在双面涂上薄塑料外层的卷材11,借助于合适的挤塑机51,在干燥过的聚合物层上被挤塑,同时把卷材引过两个旋转冷却辊52,52中间的压辊间隙,为的是制成成品的包装层压材料10,正如环形区A内以放大方式表示。如前所述,挤塑的塑料优选热塑性的,最好是低密度聚乙烯(LDPE),它适合通过所谓的热封有效转化包装层压材料10成为不透液体,尺寸稳定的包装。

从板或卷材,优选预先弄有拆缝和装饰过颜色的包装层压材料10的坯料,采用常规“成形-装填-密封”技术可生产单一用途易处置的、不透液体,尺寸稳定的包装,按此技术通过新式的、合理的包装和填充机即可使包装成形、装料和密封。例如,用一种包装层压材料的卷材,生产这样的包装,其方法是首先把卷材做成管子,沿该管的两个纵向边缘通过热封纵向搭接接合密封处使管的边缘相互结合。在该管中注满适当的内含物,例如液体食品,再于管中内含物水平之下,横切管的纵轴,通过重复横向密封管子把管分成多个独立的包装。最后沿纵向封口处纵向切开使包装相互分开,采用本质上是已知的方法借助于附加成形和热封操作产生所要求的几何形状,通常是平行六面体。

使用后,采用普通的方法和使用有效技术及装置时,用作包装的材料很容易被分成其各个组成部分,并且以非常纯的形式被回收和再次使用。根据本发明,尤其是包装(在包装层压材料的芯层中的纸或纸板)中所含的纤维大量地被回收且以极纯的形式被再次使用,在这种情况下首先把空的、用过的包装机械分割成小片或小条。把粉碎的材料送入常规的搅碎机中再于40-60℃的热水中搅拌进行机械加工处理以便溶解起“脱离剂”作用的水溶性聚合物层,由此纤维能有效地与塑料分离而不含有任何纤维粘附和伴随塑料表面。之后用物理方法把这样分离的纤维和塑料部分相互分开,借此使大量分离出来的纤维得到回收并以极纯的形式再次使用,例如供重新生产纸或纸板用。

显而易见的是根据前面的描述本发明的包装层压材料有可能生产出不透液体、尺寸稳定的包装,同时作为相应的包装层压材料,和由该包装层压材料制造的包装,很容易分成薄层,结果,采用普通的技术和早已现成的设备,就能容易地回收和再次使用。尤其是,本发明有利于作为包装层压材料的纸或纸板,由此使该包装层压材料所含的全部纤维(纸或纸板)实际上都能被回收并以极纯净的形式得到再次使用。

许多上述予以专门描述过的包装层压材料的改进和变更方案对本技术领域内的技术人员来说是显而易见的,没有偏离在本发明中公开的本发明基本原理。例如,包装层压材料除了有上面提到的那些层以外,还可能含有许多相同或不同材料的其它层,例如另外的阻挡层材料(如Al-箔或EVOH)。在这样的情况下,本发明包装层压材料还可能在上面提到的附加层中间含有能起脱离剂层作用的附加粘合剂层,为的是使包装层压材料可能简便分层,致使这些附加层能被回收和再次使用。由此这些改进和变更方案落入了如附加权利要求中定义的本发明原理的精神和范围之内。

Claims (10)

1.一种具有氧气阻挡层性能的包装层压材料,它包括纸或纸板的芯层(11)和一层或多层塑料(12,13),其特征在于芯层(11)和所述塑料层(12,13)通过包括淀粉或淀粉衍生物的中间粘合层(14,15)的中介而相互粘合,并且该粘合层还可提供所述气体阻挡层性能,并且粘合层(14,15)存在量介于0.1和5g/m2(干重)之间。

2.按权利要求1所述的包装层压材料,其特征在于塑料层(12,13)通过表面熔合与淀粉层结合。

3.按权利要求1所述包装层压材料,其特征在于塑料层(12,13)挤塑在淀粉层上。

4.按权利要求1所述的包装层压材料,其特征在于粘合层(14,15)存在量介于0.5和1g/m2(干重)之间。

5.按权利要求1-3中任一项所述包装层压材料,其特征在于塑料是热塑性的聚合物。

6.按权利要求1-3中任一项所述包装层压材料,其特征在于塑料是低密度聚乙烯(LDPE)。

7.按权利要求1-3中任一项所述包装层压材料,其特征在于它在24小时,1atm,提供289cm3/m2或以下的氧气阻挡层。

8.一种生产按权利要求1所述包装层压材料(10)的方法,其特征在于在芯层卷材(11)至少一个侧面上涂有淀粉或淀粉衍生物水溶液的薄层(14,15),干燥所述卷材以便除去所涂覆的含水淀粉或淀粉衍生物层(14,15)中的水;和使干燥过的卷材与塑料膜(12,13)结合,该塑料膜通过与淀粉或淀粉衍生物的中间层(14,15)的表面熔合而与卷材结合,并且粘合层(14,15)存在量介于0.1和5g/m2(干重)之间。

9.按权利要求8所述方法,其特征在于淀粉水溶液是通过分散体涂复操作施加。

10.按权利要求8或9所述方法,其特征在于淀粉水溶液的施加量应使淀粉或淀粉衍生物涂层(14,15)干燥后的存在量介于0.1和5g/m2。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE9503817-0 | 1995-10-30 | ||

| SE95038170 | 1995-10-30 | ||

| SE9503817A SE9503817D0 (sv) | 1995-10-30 | 1995-10-30 | Delaminerbart förpackningslaminat samt sätt att framställa detta |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1205670A CN1205670A (zh) | 1999-01-20 |

| CN1082891C true CN1082891C (zh) | 2002-04-17 |

Family

ID=20400013

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN96199285A Expired - Fee Related CN1082891C (zh) | 1995-10-30 | 1996-10-30 | 可分层的包装层压材料及其生产方法 |

Country Status (12)

| Country | Link |

|---|---|

| EP (1) | EP0934160B1 (zh) |

| JP (1) | JPH11514595A (zh) |

| KR (1) | KR100338659B1 (zh) |

| CN (1) | CN1082891C (zh) |

| AT (1) | ATE273794T1 (zh) |

| AU (1) | AU729024B2 (zh) |

| BR (1) | BR9611221A (zh) |

| CA (1) | CA2236424A1 (zh) |

| DE (1) | DE69633200T2 (zh) |

| ES (1) | ES2224181T3 (zh) |

| SE (1) | SE9503817D0 (zh) |

| WO (1) | WO1997016312A1 (zh) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE9801675D0 (sv) | 1998-05-13 | 1998-05-13 | Tetra Laval Holdings & Finance | Gas barrier packaging laminate, method for production thereof and packaging containers |

| US6569539B2 (en) | 1996-10-30 | 2003-05-27 | Tetra Level Holdings & Finance S.A. | Gas barrier packaging laminate method for production thereof and packaging containers |

| DE19721704A1 (de) * | 1997-05-23 | 1998-11-26 | Becker Preservotec Gmbh | Verfahren und Vorrichtung zum Ablösen von Kaschierungen |

| EP1097041B1 (en) * | 1998-03-10 | 2004-02-11 | Tetra Laval Holdings & Finance S.A. | Process for laminated packaging materials and packaging containers produced therefrom |

| SE516817C2 (sv) * | 1999-09-07 | 2002-03-05 | Tetra Laval Holdings & Finance | Förfarande för framställning av ett laminerat förpackningsmaterial, förpackningsmaterial som framställts enligt detta förfartande, samt förpackningar framställda av detta förpackningsmaterial |

| FI123420B (fi) * | 2006-09-25 | 2013-04-30 | Teknologian Tutkimuskeskus Vtt | Päällystetty paperi- tai kartonkituote ja menetelmä sen valmistamiseksi |

| GB0708327D0 (en) * | 2006-12-11 | 2007-06-06 | Twist Cyril | Polymeric films |

| RU2487881C1 (ru) | 2009-07-07 | 2013-07-20 | Тетра Лаваль Холдингз Энд Файнэнс С.А. | Барьерный слой для упаковочного ламината и упаковочный ламинат, включающий такой барьерный слой |

| DE202012102550U1 (de) | 2012-07-11 | 2012-10-17 | Kobusch-Sengewald Gmbh | Verpackungslaminat und Verpackungsbehälter |

| US8865296B2 (en) | 2013-03-14 | 2014-10-21 | Cal Poly Corporation | Designed defects in laminate composites |

| PL3126134T3 (pl) * | 2014-04-03 | 2022-04-19 | Gimsa S.R.L. | Materiał nadający się do recyklingu |

| EP3795355A1 (en) * | 2015-11-27 | 2021-03-24 | Tetra Laval Holdings & Finance S.A. | Method of manufacturing a laminated packaging material, the packaging material obtained by the method and packaging containers manufactured therefrom |

| ES2922983T3 (es) * | 2015-11-27 | 2022-09-22 | Tetra Laval Holdings & Finance | Método para fabricar un material de envasado laminado |

| CN105416838B (zh) * | 2015-12-30 | 2017-12-22 | 桑春龙 | 用于氧化聚合型油墨的可回收包装物 |

| CN105383134B (zh) * | 2015-12-30 | 2017-10-20 | 桑春龙 | 用于紫外线固化型油墨的可回收包装物 |

| CN108657592A (zh) * | 2017-04-01 | 2018-10-16 | 南京光谷数据处理有限公司 | 用于紫外线uv固化型油墨的环保回收包装物 |

| SE543190C2 (en) * | 2018-06-12 | 2020-10-20 | Stora Enso Oyj | Re-pulpable packaging material |

| SE543572C2 (en) * | 2018-12-10 | 2021-03-30 | Stora Enso Oyj | Repulpable and heat-sealable packaging material |

| DE102019123558A1 (de) * | 2019-09-03 | 2021-03-04 | Constantia Pirk Gmbh & Co. Kg | Resuspendierbares Papierlaminat und Verfahren zu dessen Herstellung |

| AT522884B1 (de) * | 2020-02-18 | 2021-03-15 | Constantia Pirk Gmbh & Co Kg | Recyclebare Papierverpackung mit hoher Barriere gegen Wasserdampf und Sauerstoff |

| SE545982C2 (en) * | 2020-05-18 | 2024-04-02 | Stora Enso Oyj | A paperboard based material comprising a dispersion coated latex layer and an extrusion coated barrier polyolefin layer for packaging of liquid and food |

| EP4302638A1 (en) | 2021-03-02 | 2024-01-10 | Kolmar Korea Co., Ltd. | Container for contents |

| KR102279627B1 (ko) * | 2021-03-02 | 2021-07-21 | 한국콜마주식회사 | 내용물 용기 |

| DE102021122296A1 (de) | 2021-08-27 | 2023-03-02 | Huhtamaki Flexible Packaging Germany Gmbh & Co. Kg | Papierlagenhaltiger Lagenverbund mit einer dextrinhaltigen Trennschicht |

| DE102021125007A1 (de) * | 2021-09-28 | 2023-03-30 | Constantia Pirk Gmbh & Co. Kg | Beschichtetes Papier zu Verpackungszwecken und Verfahren zu dessen Herstellung |

| WO2024133242A1 (de) | 2022-12-19 | 2024-06-27 | Loparex Germany Gmbh & Co. Kg | Recyclingfähige kunststofffolie |

| WO2024133243A1 (de) | 2022-12-19 | 2024-06-27 | Loparex Germany Gmbh & Co. Kg | Recyclingfähige oberflächenbeschichtete kunststofffolie |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0085919A1 (en) * | 1982-02-10 | 1983-08-17 | Ab Tetra Pak | A method for the manufacture of a packing material with good gas-tightness properties |

| EP0530662A1 (en) * | 1991-09-04 | 1993-03-10 | AB Tetra Pak | Easy-to-Recycle laminated material for packaging use |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FI920703A (fi) * | 1992-02-19 | 1993-08-20 | Neste Oy | Foerfarande foer framstaellning av en laminat |

| EP0615838B1 (fr) * | 1993-02-12 | 2001-06-13 | Cofradec S.A. | Produit composite stratifié |

-

1995

- 1995-10-30 SE SE9503817A patent/SE9503817D0/xx unknown

-

1996

- 1996-10-30 JP JP51727897A patent/JPH11514595A/ja not_active Ceased

- 1996-10-30 EP EP19960937630 patent/EP0934160B1/en not_active Expired - Lifetime

- 1996-10-30 DE DE1996633200 patent/DE69633200T2/de not_active Expired - Lifetime

- 1996-10-30 AU AU75124/96A patent/AU729024B2/en not_active Ceased

- 1996-10-30 BR BR9611221A patent/BR9611221A/pt not_active IP Right Cessation

- 1996-10-30 CA CA 2236424 patent/CA2236424A1/en not_active Abandoned

- 1996-10-30 WO PCT/SE1996/001403 patent/WO1997016312A1/en active IP Right Grant

- 1996-10-30 ES ES96937630T patent/ES2224181T3/es not_active Expired - Lifetime

- 1996-10-30 CN CN96199285A patent/CN1082891C/zh not_active Expired - Fee Related

- 1996-10-30 KR KR10-1998-0703203A patent/KR100338659B1/ko not_active IP Right Cessation

- 1996-10-30 AT AT96937630T patent/ATE273794T1/de active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0085919A1 (en) * | 1982-02-10 | 1983-08-17 | Ab Tetra Pak | A method for the manufacture of a packing material with good gas-tightness properties |

| EP0530662A1 (en) * | 1991-09-04 | 1993-03-10 | AB Tetra Pak | Easy-to-Recycle laminated material for packaging use |

Also Published As

| Publication number | Publication date |

|---|---|

| DE69633200T2 (de) | 2005-09-08 |

| WO1997016312A1 (en) | 1997-05-09 |

| BR9611221A (pt) | 1999-05-25 |

| DE69633200D1 (de) | 2004-09-23 |

| SE9503817D0 (sv) | 1995-10-30 |

| CA2236424A1 (en) | 1997-05-09 |

| EP0934160A1 (en) | 1999-08-11 |

| EP0934160B1 (en) | 2004-08-18 |

| CN1205670A (zh) | 1999-01-20 |

| KR100338659B1 (ko) | 2003-03-04 |

| KR19990067244A (ko) | 1999-08-16 |

| ES2224181T3 (es) | 2005-03-01 |

| AU7512496A (en) | 1997-05-22 |

| JPH11514595A (ja) | 1999-12-14 |

| ATE273794T1 (de) | 2004-09-15 |

| AU729024B2 (en) | 2001-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1082891C (zh) | 可分层的包装层压材料及其生产方法 | |

| US11732418B2 (en) | Composite structures for packaging articles and related methods | |

| US5700586A (en) | Laminate and production method thereof | |

| JP5785498B2 (ja) | パッケージ用積層体、パッケージ用積層体の製造方法、及びパッケージ用積層体によって作られた包装容器 | |

| JP5442613B2 (ja) | 軟質包装複合材料 | |

| US20050148759A1 (en) | Ream wrap comprising PLA resin | |

| RU2236943C2 (ru) | Способ производства ламинированного упаковочного материала и упаковочные контейнеры, изготовленные из этого упаковочного материала | |

| EP1361044A2 (en) | Ream wrap comprising PLA resin | |

| EP0820412B1 (en) | A method for producing a packaging laminate | |

| CN1204281A (zh) | 包装用层压制品和生产此包装用层压制品的方法,以及用此包装用层压制品制造并具有优越氧气阻隔性能的全装容器 | |

| EP0665785B1 (en) | Laminating method | |

| CA2428320C (en) | Ream wrap comprising pla resin | |

| SE467926B (sv) | Flexibelt, ark- eller banformigt foerpackningsmaterial |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20020417 Termination date: 20141030 |

|

| EXPY | Termination of patent right or utility model |