CN107112172B - Solder sheet, solder, fuse unit, fuse element, protective element, short-circuit element, and switching element - Google Patents

Solder sheet, solder, fuse unit, fuse element, protective element, short-circuit element, and switching element Download PDFInfo

- Publication number

- CN107112172B CN107112172B CN201580059143.2A CN201580059143A CN107112172B CN 107112172 B CN107112172 B CN 107112172B CN 201580059143 A CN201580059143 A CN 201580059143A CN 107112172 B CN107112172 B CN 107112172B

- Authority

- CN

- China

- Prior art keywords

- flux

- conductor

- electrode

- fusible conductor

- sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H37/00—Thermally-actuated switches

- H01H37/74—Switches in which only the opening movement or only the closing movement of a contact is effected by heating or cooling

- H01H37/76—Contact member actuated by melting of fusible material, actuated due to burning of combustible material or due to explosion of explosive material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/02—Details

- H01H85/04—Fuses, i.e. expendable parts of the protective device, e.g. cartridges

- H01H85/041—Fuses, i.e. expendable parts of the protective device, e.g. cartridges characterised by the type

- H01H85/044—General constructions or structure of low voltage fuses, i.e. below 1000 V, or of fuses where the applicable voltage is not specified

- H01H85/0445—General constructions or structure of low voltage fuses, i.e. below 1000 V, or of fuses where the applicable voltage is not specified fast or slow type

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/02—Details

- H01H85/04—Fuses, i.e. expendable parts of the protective device, e.g. cartridges

- H01H85/05—Component parts thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H85/00—Protective devices in which the current flows through a part of fusible material and this current is interrupted by displacement of the fusible material when this current becomes excessive

- H01H85/02—Details

- H01H85/04—Fuses, i.e. expendable parts of the protective device, e.g. cartridges

- H01H85/05—Component parts thereof

- H01H85/165—Casings

Abstract

The flux is appropriately retained in the fusible conductor, while achieving both an improvement in the rating of the fuse element and the like and a quick fusing property. The fuse unit 1 includes a fusible conductor 6 and a solder piece 5 in which solder 7 is impregnated into an insulator, the solder piece 5 is mounted on the fusible conductor 6 and/or under the fusible conductor 6, and the fusible conductor 6 is fused by an overcurrent flowing through the fusible conductor 6. Alternatively, the fuse unit 1 has a fusible conductor 6, and a flux 9 containing an insulator sheet that contains a flowing body or semi-flowing body of the insulator sheet that retains a liquid is coated on the fusible conductor 6 and/or below the fusible conductor 6.

Description

Technical Field

The present invention relates to a fuse unit (fuse element) which is attached to a current path and which interrupts the current path by self-heating when a current exceeding a rated value flows or by heat generation and fusion of a heating element, and particularly relates to a fuse unit having excellent quick-break characteristics, a fuse element, a protective element, a short-circuit element, a switching element, and a flux sheet (flux) and a flux used for them.

The present application claims priority based on japanese patent application No. 2014-229359, filed 11/2014 in japan, which is incorporated herein by reference.

Background

Conventionally, a fuse unit is used which fuses due to self-heating when a current exceeding a rated current flows, and interrupts the current path. As the fuse unit, for example, a clip-fixed fuse in which solder is sealed in a glass tube, a chip fuse in which an Ag electrode is printed on a surface of a ceramic substrate, a screw-fixed fuse in which a part of a copper electrode is thinned and incorporated in a plastic case, an insertion-type fuse, or the like is widely used.

Prior art documents

Patent document

Patent document 1: japanese patent laid-open publication No. 2011-82064.

Disclosure of Invention

Problems to be solved by the invention

However, the conventional fuse unit described above has a problem that surface mounting by reflow is not possible, the current rating is low, and quick-break performance is deteriorated if the rating is increased due to an increase in size.

In the case of a quick-break fuse element for reflow mounting, it is generally preferable that the fuse unit is a high-melting-point solder containing lead and having a melting point of 300 ℃ or higher so as not to be melted by the heat of reflow. However, the use of lead-containing solder is only limitedly recognized in RoHS directive and the like, and it is considered that the demand for lead-free solder will increase in the future.

That is, as the fuse unit, it is required to be capable of surface mounting by reflow and excellent in mountability to the fuse element; the rated value is improved so as to correspond to large current; the fuse has a quick fusing property of quickly cutting off a current path when a rated overcurrent is exceeded.

Accordingly, an object of the present invention is to provide a fuse unit, a fuse element, a protection element, a short-circuit element, and a switching element, which can be surface-mounted and can achieve both of an improvement in rating of the fuse element and a quick fusing property, and a solder pad and a solder used for them.

Means for solving the problems

In order to solve the above-mentioned problems, a solder piece according to the present invention is mounted on a fusible conductor of a fuse element, wherein a solder is impregnated into an insulator, and a specific gravity of the insulator is equal to or less than a specific gravity of the fusible conductor.

The flux according to the present invention is applied to the fusible conductor of the fuse element or to the fusible conductor, and is a fluid or semi-fluid to which an insulator sheet having liquid retentivity is added and which has a specific gravity equal to or lower than that of the fusible conductor.

Further, a fuse unit according to the present invention includes: a fusible conductor; and a flux sheet for dipping the flux into an insulator having a specific gravity equal to or lower than that of the fusible conductor, and mounting the flux sheet on the fusible conductor and/or under the fusible conductor.

Further, a fuse unit according to the present invention includes: a fusible conductor; and adding a flux of a fluid or semi-fluid of an insulator sheet having a specific gravity equal to or lower than that of the fusible conductor and having liquid retentivity, and applying the flux onto and/or under the fusible conductor.

Further, a fuse element according to the present invention includes: a fusible conductor; and a flux piece for dipping the flux into an insulator having a specific gravity equal to or lower than that of the fusible conductor, and mounting the flux piece on the fusible conductor and/or under the fusible conductor, wherein the fusible conductor is fused by an overcurrent flowing through the fusible conductor.

The fuse element according to the present invention includes a fusible conductor, and a flux containing a fluid or semi-fluid of an insulator sheet having a specific gravity equal to or lower than that of the fusible conductor and having liquid retentivity is applied to the fusible conductor and/or below the fusible conductor, and the fusible conductor is fused by an overcurrent flowing through the fusible conductor.

In addition, the protection element according to the present invention includes: an insulating substrate; a heating element formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate; a 3 rd electrode electrically connected to the heating element; a fusible conductor connected across from the 1 st electrode to the 2 nd electrode via the 3 rd electrode; and a flux piece for dipping the flux into the insulator having a specific gravity equal to or less than that of the soluble conductor, wherein the flux piece is mounted on the soluble conductor and/or under the soluble conductor, and the soluble conductor is fused by heat generated by energization of the heating element, thereby blocking the electrodes between the 1 st and 2 nd electrodes.

In addition, the protection element according to the present invention includes: an insulating substrate; a heating element formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate; a 3 rd electrode electrically connected to the heating element; and a fusible conductor connected across from the 1 st electrode to the 2 nd electrode via the 3 rd electrode, wherein a flux containing a fluid or semi-fluid of an insulator sheet having a specific gravity equal to or lower than that of the fusible conductor and having liquid retentivity is applied on the fusible conductor and/or below the fusible conductor, and the fusible conductor is fused by heat generated by energization of the heating element to block the gap between the 1 st and 2 nd electrodes.

Further, a short-circuit element according to the present invention includes: an insulating substrate; a heating element formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate in proximity thereto; a 3 rd electrode electrically connected to the heating element; a fusible conductor connected across from the 1 st electrode to the 3 rd electrode; and a flux piece for dipping flux into the insulator having a specific gravity equal to or less than that of the soluble conductor, wherein the flux piece is mounted on the soluble conductor and/or under the soluble conductor, and the soluble conductor is fused by heat generated by energization of the heating element, thereby performing short-circuiting between the 1 st and 2 nd electrodes and blocking between the 1 st and 3 rd electrodes.

Further, a short-circuit element according to the present invention includes: an insulating substrate; a heating element formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate in proximity thereto; a 3 rd electrode electrically connected to the heating element; and a fusible conductor connected across from the 1 st electrode to the 3 rd electrode, wherein a flux containing a fluid or semi-fluid of an insulator sheet having a specific gravity equal to or lower than that of the fusible conductor and having liquid retentivity is applied on the fusible conductor and/or under the fusible conductor, and the fusible conductor is fused by heat generated by energization of the heating element, thereby performing short-circuiting between the 1 st and 2 nd electrodes and blocking between the 1 st and 3 rd electrodes.

Further, a switching element according to the present invention includes: an insulating substrate; 1 st and 2 nd heating elements formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate in proximity thereto; a 3 rd electrode formed adjacent to the 1 st electrode and electrically connected to the 1 st heating element; a 1 st fusible conductor connected across from the 1 st electrode to the 3 rd electrode; a 4 th electrode electrically connected to the 2 nd heating element and formed adjacent to the 2 nd electrode; a 5 th electrode formed adjacent to the 4 th electrode; a 2 nd fusible conductor connected from the 2 nd electrode through the 4 th electrode and across to the 5 th electrode; and a flux piece for dipping flux into the insulator having a specific gravity equal to or less than that of the 1 st and 2 nd soluble conductors, wherein the flux piece is mounted on the 1 st and 2 nd soluble conductors and/or under the 1 st and 2 nd soluble conductors, the 2 nd soluble conductor is fused by heat generated by energization of the 2 nd heating element, the 2 nd and 5 th electrodes are cut off, the 1 st soluble conductor is fused by heat generated by energization of the 1 st heating element, and the 1 st and 2 nd electrodes are short-circuited.

Further, a switching element according to the present invention includes: an insulating substrate; 1 st and 2 nd heating elements formed on or in the insulating substrate; 1 st and 2 nd electrodes formed on the insulating substrate in proximity thereto; a 3 rd electrode formed adjacent to the 1 st electrode and electrically connected to the 1 st heating element; a 1 st fusible conductor connected across from the 1 st electrode to the 3 rd electrode; a 4 th electrode electrically connected to the 2 nd heating element and formed adjacent to the 2 nd electrode; a 5 th electrode formed adjacent to the 4 th electrode; and a 2 nd fusible conductor connected from the 2 nd electrode to the 5 th electrode via the 4 th electrode, wherein a flux of a fluid or semi-fluid containing an insulator sheet having a specific gravity equal to or lower than that of the 1 st and 2 nd fusible conductors is applied on the 1 st and 2 nd fusible conductors and/or under the 1 st and 2 nd fusible conductors, the 2 nd fusible conductor is fused by heat generated by energization of the 2 nd heating element, the 2 nd and 5 th electrodes are cut, and the 1 st fusible conductor is fused by heat generated by energization of the 1 st heating element, thereby short-circuiting the 1 st and 2 nd electrodes.

Effects of the invention

The flux sheet according to the present invention is configured to hold the flux on the fusible conductor and/or under the fusible conductor by impregnating the flux into the insulator, thereby suppressing flux flowing out and unevenness.

Further, the flux according to the present invention contains the insulator sheet having liquid retainability, and thus can retain the flux on the fusible conductor and/or under the fusible conductor, and can suppress flux flowing out or unevenness.

In the fuse unit according to the present invention, the flux is impregnated into the insulator, whereby the flux can be held on the fusible conductor and/or under the fusible conductor, and the flux can be prevented from flowing out or being unevenly distributed.

In the fuse unit according to the present invention, the flux is held on the fusible conductor and/or under the fusible conductor by including the insulator sheet having liquid retainability in the flux, and the flux can be prevented from flowing out or being unevenly distributed.

In the fuse element according to the present invention, the flux is impregnated into the insulator, whereby the flux can be held on the fusible conductor and/or under the fusible conductor, and the flux can be prevented from flowing out or being unevenly distributed.

In the fuse element according to the present invention, the flux is held on the fusible conductor and/or under the fusible conductor by including the insulator sheet having liquid retainability in the flux, and the flux can be prevented from flowing out or being unevenly distributed.

In the protective element according to the present invention, the flux is impregnated into the insulator, whereby the flux can be held on the fusible conductor and/or under the fusible conductor, and the flux can be prevented from flowing out or being unevenly distributed.

In the protective element according to the present invention, the flux is held on the fusible conductor and/or under the fusible conductor by including the insulator sheet having liquid retainability in the flux, and the flux can be prevented from flowing out or being unevenly distributed.

In the short-circuit element according to the present invention, the flux is impregnated into the insulator, whereby the flux can be held above and/or below the fusible conductor, and the flux can be prevented from flowing out or being unevenly distributed.

In the short-circuit element according to the present invention, the flux is held on the fusible conductor and/or under the fusible conductor by including the insulator sheet having liquid retainability in the flux, and the flux is prevented from flowing out or being unevenly distributed.

In the switching element according to the present invention, the flux is impregnated into the insulator, whereby the flux can be held above and/or below the fusible conductor, and the flux can be prevented from flowing out or being unevenly distributed.

In the switching element according to the present invention, the flux is held on the fusible conductor and/or under the fusible conductor by including the insulator sheet having liquid retainability in the flux, and the flux is prevented from flowing out or being unevenly distributed.

Drawings

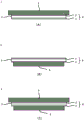

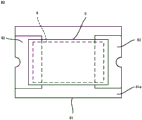

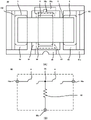

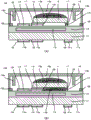

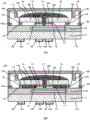

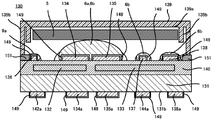

Fig. 1 is a sectional view of a fuse unit to which the present invention is applied, fig. 1 (a) is a sectional view illustrating a case where a solder piece is provided on a soluble conductor, fig. 1 (B) is a sectional view illustrating a case where a solder piece is provided under a soluble conductor, and fig. 1 (C) is a sectional view illustrating a case where a solder piece is provided on each of upper and lower sides of a soluble conductor.

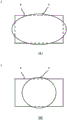

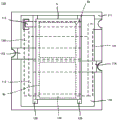

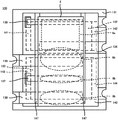

Fig. 2 is a plan view of a fuse unit to which the present invention is applied.

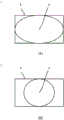

Fig. 3 (a) is a sectional view showing an example of a flux sheet to which the present invention is applied, fig. 3 (B) is a sectional view showing a modification of the flux sheet, and fig. 3 (C) is a sectional view showing another modification of the flux sheet.

Fig. 4 (a) is a plan view showing a case where a solder piece is elliptical as a modified example of the fuse unit to which the present invention is applied, and fig. 4 (B) is a plan view showing a case where the solder piece is circular as a modified example of the fuse unit to which the present invention is applied.

Fig. 5 is a cross-sectional view showing a modification of the fuse unit to which the present invention is applied, fig. 5 (a) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to a soluble conductor, fig. 5 (B) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to a lower portion of a soluble conductor, and fig. 5 (C) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to upper and lower portions of a soluble conductor, respectively.

Fig. 6 (a) is a plan view showing a case where a flux containing an insulator sheet is applied in an elliptical shape as a modification of the fuse unit to which the present invention is applied, and fig. 6 (B) is a plan view showing a case where a flux containing an insulator sheet is applied in a circular shape as a modification of the fuse unit to which the present invention is applied.

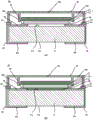

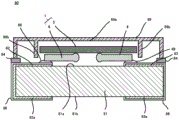

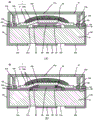

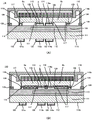

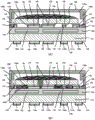

Fig. 7 is a sectional view showing a fuse element to which the present invention is applied, fig. 7 (a) is a sectional view illustrating a case where a solder piece is mounted on a fusible conductor, and fig. 7 (B) is a sectional view illustrating a case where a solder piece is mounted on each of the fusible conductor and the fusible conductor.

Fig. 8 is a plan view showing a fuse element to which the present invention is applied, with a cover member removed.

Fig. 9 is a cross-sectional view showing a state in which a fusible conductor of a fuse element to which the present invention is applied is melted.

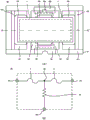

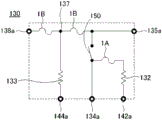

Fig. 10 (a) is a circuit diagram before the fusible conductor of the fuse element to which the present invention is applied is blown, and fig. 10 (B) is a circuit diagram after the fusible conductor of the fuse element to which the present invention is applied is blown.

Fig. 11 is a sectional view showing a modification of the fuse element to which the present invention is applied, fig. 11 (a) is a sectional view for explaining a case where a solder piece is mounted on a soluble conductor, and fig. 11 (B) is a sectional view for explaining a case where a solder piece is mounted on each of the soluble conductor and the soluble conductor.

Fig. 12 is a cross-sectional view showing another modification of the fuse element to which the present invention is applied, fig. 12 (a) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to a soluble conductor, and fig. 12 (B) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to each of the upper and lower soluble conductors.

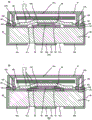

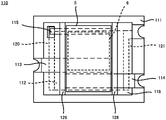

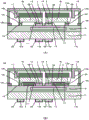

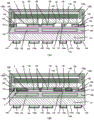

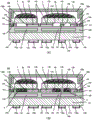

Fig. 13 is a sectional view of a protective element to which the present invention is applied, fig. 13 (a) is a sectional view illustrating a case where a solder chip is mounted on a soluble conductor, and fig. 13 (B) is a sectional view illustrating a case where a solder chip is mounted on a soluble conductor and a solder chip is mounted under a soluble conductor, respectively.

Fig. 14 is a plan view showing a protection element to which the present invention is applied by removing a cover member, and fig. 14 (B) is a circuit diagram before a fusible conductor of the protection element to which the present invention is applied is fused.

Fig. 15 is a sectional view showing a state where a fusible conductor of a protection element to which the present invention is applied is melted.

Fig. 16 is a plan view showing the cap member removed in a state where the fusible conductor of the protection element to which the present invention is applied is blown, and fig. 16 (B) is a circuit diagram after the fusible conductor of the protection element to which the present invention is applied is blown.

Fig. 17 is a sectional view showing a modified example of the protective element to which the present invention is applied, fig. 17 (a) is a sectional view for explaining a case where a flux chip is mounted on a soluble conductor, and fig. 17 (B) is a sectional view for explaining a case where a flux chip is mounted on each of the soluble conductor and the soluble conductor.

Fig. 18 is a sectional view showing another modification of the protective element to which the present invention is applied, fig. 18 (a) is a sectional view illustrating a case where a flux containing an insulator sheet is applied to a soluble conductor, and fig. 18 (B) is a sectional view illustrating a case where a flux containing an insulator sheet is applied to each of the upper and lower soluble conductors.

Fig. 19 is a plan view showing a short-circuit element to which the present invention is applied, with a cover member removed.

Fig. 20 is a sectional view of a short-circuit element to which the present invention is applied, fig. 20 (a) is a sectional view illustrating a case where a solder chip is mounted on a soluble conductor, and fig. 20 (B) is a sectional view illustrating a case where a solder chip is mounted on a soluble conductor and a solder chip is mounted under a soluble conductor, respectively.

Fig. 21 is a sectional view showing a state where a fusible conductor of a short-circuit element to which the present invention is applied is melted.

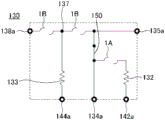

Fig. 22 (a) is a circuit diagram before the fusible conductor of the short-circuit element to which the present invention is applied is blown, and fig. 22 (B) is a circuit diagram after the fusible conductor of the short-circuit element to which the present invention is applied is blown.

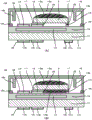

Fig. 23 is a sectional view showing a modified example of the short-circuit element to which the present invention is applied, fig. 23 (a) is a sectional view for explaining a case where a flux chip is mounted on a soluble conductor, and fig. 23 (B) is a sectional view for explaining a case where a flux chip is mounted on each of the soluble conductor and the soluble conductor.

Fig. 24 is a cross-sectional view showing another modification of the short-circuit device to which the present invention is applied, fig. 24 (a) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to a soluble conductor, and fig. 24 (B) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to each of the upper and lower soluble conductors.

Fig. 25 is a plan view showing another modification of the short-circuit element to which the present invention is applied.

Fig. 26 is a cross-sectional view showing another modification of the short-circuit element to which the present invention is applied, fig. 26 (a) is a cross-sectional view for explaining a case where a solder piece is mounted on a soluble conductor, and fig. 26 (B) is a cross-sectional view for explaining a case where a solder piece is mounted on each of the soluble conductor and the soluble conductor.

Fig. 27 is a cross-sectional view showing another modification of the short-circuit element to which the present invention is applied, fig. 27 (a) is a cross-sectional view for explaining a case where a solder piece is mounted on each of two fusible conductors, and fig. 27 (B) is a cross-sectional view for explaining a case where a solder piece is mounted on each of two fusible conductors and under each of two fusible conductors.

Fig. 28 is a cross-sectional view showing another modification of the short-circuit device to which the present invention is applied, fig. 28 (a) is a cross-sectional view for explaining a case where a solder piece is mounted on a soluble conductor, and fig. 28 (B) is a cross-sectional view for explaining a case where a solder piece is mounted on each of the soluble conductor and the soluble conductor.

Fig. 29 is a cross-sectional view showing another modification of the short-circuit element to which the present invention is applied, fig. 29 (a) is a cross-sectional view for explaining a case where a solder piece is mounted on each of two fusible conductors, and fig. 29 (B) is a cross-sectional view for explaining a case where a solder piece is mounted on each of two fusible conductors and under each of two fusible conductors.

Fig. 30 is a cross-sectional view showing another modification of the short-circuit device to which the present invention is applied, fig. 30 (a) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to a soluble conductor, and fig. 30 (B) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to each of the upper and lower soluble conductors.

Fig. 31 is a plan view showing a switching element to which the present invention is applied with a cover member removed.

Fig. 32 is a sectional view of a switching element to which the present invention is applied, fig. 32 (a) is a sectional view illustrating a case where a solder chip is mounted on a fusible conductor, and fig. 32 (B) is a sectional view illustrating a case where a solder chip is mounted on a fusible conductor and a solder chip is mounted under a fusible conductor, respectively.

Fig. 33 is a circuit diagram before a fusible conductor of a switching element to which the present invention is applied is blown.

Fig. 34 is a circuit diagram after a fusible conductor of a switching element to which the present invention is applied is blown.

Fig. 35 is a sectional view showing a state in which a fusible conductor of a switching element to which the present invention is applied is melted.

Fig. 36 is a plan view of the switching element to which the present invention is applied, with the cover member removed, showing a state in which the 2 nd fusible conductor is melted faster than the 1 st fusible conductor.

Fig. 37 is a plan view of a switching element to which the present invention is applied, with a cover member removed, and illustrates a state in which both the 1 st fusible conductor and the 2 nd fusible conductor are melted.

Fig. 38 is a sectional view showing a modified example of the switching element to which the present invention is applied, fig. 38 (a) is a sectional view for explaining a case where a solder piece is mounted on a fusible conductor, and fig. 38 (B) is a sectional view for explaining a case where a solder piece is mounted on each of the fusible conductor and the fusible conductor.

Fig. 39 is a sectional view showing another modification of the switching element to which the present invention is applied, fig. 39 (a) is a sectional view illustrating a case where a flux containing an insulator sheet is collectively applied to two fusible conductors, and fig. 39 (B) is a sectional view illustrating a case where a flux containing an insulator sheet is collectively applied to two fusible conductors and below two fusible conductors, respectively.

Fig. 40 is a sectional view showing another modification of the switching element to which the present invention is applied, fig. 40 (a) is a sectional view for explaining a case where a solder piece is individually mounted on each of two fusible conductors, and fig. 40 (B) is a sectional view for explaining a case where a solder piece is individually mounted on each of two fusible conductors and under each of two fusible conductors.

Fig. 41 is a sectional view showing another modification of the switching element to which the present invention is applied, fig. 41 (a) is a sectional view for explaining a case where a solder piece is individually mounted on each of two fusible conductors, and fig. 41 (B) is a sectional view for explaining a case where a solder piece is individually mounted on each of two fusible conductors and under each of two fusible conductors.

Fig. 42 is a cross-sectional view showing another modification of the switching element to which the present invention is applied, fig. 42 (a) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to each of two soluble conductors, and fig. 42 (B) is a cross-sectional view illustrating a case where a flux containing an insulator sheet is applied to each of two soluble conductors and below two soluble conductors.

Detailed Description

Hereinafter, a fuse unit, a fuse element, a protective element, a short-circuit element, and a switching element to which the present invention is applied, and a solder piece and solder used for these will be described in detail with reference to the drawings. The present invention is not limited to the following embodiments, and it is apparent that various modifications can be made without departing from the scope of the present invention. The drawings are schematic, and the proportions of the dimensions and the like may be different from those in reality. Specific dimensions and the like should be determined with reference to the following description. It is to be noted that even the drawings include portions having different dimensional relationships or ratios from each other.

[ fuse Unit ]

First, a fuse unit to which the present invention is applied will be described. The fuse unit 1 to which the present invention is applied is also used for a fuse element, a protection element, a short-circuit element, and a switching element described later, and is fused by self-heating (joule heat) or fused by heating of a heating element when a current exceeding a rated value is applied. The fuse unit 1 is a high melting point solder containing lead as a main component or a member in which 3 or more metal layers having different melting points are laminated. For example, in the case of a metal laminate having 3 or more layers having different melting points, as shown in fig. 1 (a), 1 (B), and 1 (C), the solder sheet 5 has a high-melting-point metal layer 2, a low-melting-point metal layer 3 having a lower melting point than the high-melting-point metal layer 2, and is formed in a substantially rectangular plate shape as shown in fig. 2, for example. The high melting point metal layer 2 and the low melting point metal layer 3 constitute a fusible conductor 6.

[ fusible conductor ]

For example, Ag, Cu, or an alloy containing Ag or Cu as a main component is suitably used for the high-melting-point metal layer 2, and has a high melting point that does not melt even when the fuse unit 1 is mounted on an insulating substrate in a reflow furnace.

For example, Sn or an alloy containing Sn as a main component, which is generally called "lead-free solder", is suitably used for the low melting point metal layer 3. The melting point of the low-melting-point metal layer 3 does not necessarily need to be higher than the temperature of the reflow furnace, and may be about 200 ℃.

The fuse unit 1 is formed by laminating 3 or more metal layers having different melting points, and thus has excellent mountability to an insulating substrate of a fuse element, a protection element, a short-circuit element, and a switching element, and also can improve mountability to an external circuit substrate of each element using the fuse unit 1. In addition, the fuse unit 1 can achieve an improvement in rating and quick fusing property in each element.

That is, even when the fuse unit 1 is exposed to a high-temperature environment of the melting point or higher of the low-melting-point metal layer 3 for a short time by an external heat source such as a reflow furnace, the fuse unit 1 is provided with the high-melting-point metal layer 2, and can prevent the fuse unit from being fused or deformed, and prevent the initial disconnection, the initial short circuit, or the degradation of fusing characteristics due to the rated fluctuation. Therefore, the fuse unit 1 can efficiently mount each element such as a fuse element on an insulating substrate or each element such as a fuse element on an external circuit substrate by reflow mounting, and can improve mountability.

Further, since the fuse unit 1 is configured by laminating the high melting point metal layer 2 having a low resistance, the conductor resistance can be significantly reduced as compared with a conventional fusible conductor using a lead-based high melting point solder. Further, by laminating the low melting point metal layer 3 and the high melting point metal layer 2, the melting temperature of the fuse unit 1 can be reduced to about 300 to 400 ℃, and the current rating can be remarkably improved as compared with a conventional chip fuse or the like having the same size and comprising a dumbbell-shaped copper foil unit having a melting point of 1085 ℃. Further, the fuse can be made thinner than a conventional chip fuse having the same current rating, and is excellent in quick fusing property.

[ flux sheet ]

In order to prevent oxidation of the high melting point metal layer 2 or the low melting point metal layer 3 of the soluble conductor 6, remove an oxide at the time of fusing, and improve solder fluidity, the fuse unit 1 is mounted with a flux sheet 5 over the entire outermost layer of the soluble conductor 6, as shown in fig. 2.

The solder piece 5 may be mounted under the fusible conductor 6 as shown in fig. 1 (B), that is, may be configured to contact the lower surface of the fusible conductor 6, in addition to being mounted on the fusible conductor 6 as shown in fig. 1 (a). When the solder piece 5 is mounted on the soluble conductor 6, it is necessary to secure a connection margin on the lower surface of the soluble conductor 6 when the fuse unit 1 is connected to the substrate of each element with the fuse unit facing downward. Therefore, the solder sheet 5 is preferably smaller in area than the lower surface of the soluble conductor 6, and may be a sheet-like body having an opening at the connection portion.

In addition to the solder pieces described with reference to fig. 1 (a) and 1 (B), the solder pieces 5 may be mounted on the fusible conductors 6 and under the fusible conductors 6, respectively, as shown in fig. 1 (C). By mounting the flux chip 5 on each of the upper and lower surfaces of the soluble conductor 6, it is expected that the oxide at the time of fusing can be removed more stably and the solder fluidity can be improved. Note that the upper and lower portions of the fusible conductor 6 of the solder chip 5 shown in fig. 1 (C) are the same as those described with reference to fig. 1 (a) and 1 (B), and therefore, the description thereof is omitted.

As shown in fig. 3 (a), 3 (B), and 3 (C), the flux sheet 5 is obtained by immersing and holding the flux 7 in a fluid or semi-fluid state in the sheet-like support 8, for example, by immersing the flux 7 in a nonwoven fabric or a mesh-like state, or by disposing a nonwoven fabric or a mesh-like state on the flux 7 applied to the outermost layer of the fuse unit 1, and immersing the flux 7. The flux sheet 5 can hold the flux 7 of a fluid or semi-fluid by a support 8 having liquid retainability.

Here, since the flux chip 5 is mounted on the fusible conductor 6 and/or under the fusible conductor 6 and used, the supporting body 8 uses an insulator so that the electrical characteristics are not affected by the fusion of the fusible conductor 6 or the like. As a material forming the support 8, various materials can be used depending on the structure thereof, and for example, an insulator such as resin or glass is suitable.

As an example of a specific structure, the flux sheet 5 is a member in which the flux 7 is impregnated in the porous support 8 in fig. 3 (a). The porous structure may be a structure having many holes penetrating in the vertical direction of the sheet as shown in fig. 3 (a), or a sponge-like structure. That is, by providing the flux chip 5 as a structure having many voids such as a porous body or a sponge, the liquid retainability is improved, and the flux 7 can be retained at a desired position on the fusible conductor 6 and/or below the fusible conductor 6.

In fig. 3 (B), the flux sheet 5 is formed by impregnating the flux 7 into a support 8, which is a nonwoven fabric or a mesh-like material. The texture is a fibrous structure as shown in fig. 3 (B). That is, the flux chip 5 can hold the flux 7 at a desired position on the fusible conductor 6 and/or under the fusible conductor 6 by improving the liquid holding property with the fibrous structure.

In fig. 3 (C), the flux sheet 5 is formed by mixing and drying a needle-like or short-fiber-like support 8 and flux 7. The needle-like shape and the short-fiber shape are described in detail in the description of the flux to be described later. The flux sheet 5 has a needle-like or short-fiber structure, and can improve liquid holding properties and hold the flux 7 at a desired position on the fusible conductor 6 and/or below the fusible conductor 6.

Here, various insulators having liquid retentivity that retain the flux 7 can be used for the support body 8, but the flux 7 needs to be retained on the fusible conductor 6 at least up to the mounting temperature of the wire unit 1 or each component using it. Therefore, the support 8 needs to have heat resistance enough to maintain its shape, and can be made of a material that deforms or melts at a temperature exceeding the mounting temperature of the fuse unit 1 or the elements using the fuse unit to have fluidity. That is, at a temperature at which the fusible conductor 6 is fused, such as exceeding the mounting temperature, it is not necessary to hold the flux 7 on the fusible conductor 6, and therefore the supporting body 8 melts and flows together with the flux 7. By melting or having fluidity of the support 8, the support 8 is not left when the fusible conductor 6 is melted, and the insulating property can be improved.

More specifically, a material that deforms or melts at a temperature of 300 ℃ or higher and has fluidity is preferably used for the support body 8.

The specific gravity of the support 8 is preferably equal to or less than the specific gravity of the soluble conductor 6. This is because the support body 8 needs to be made light to converge the fusible conductors 6 when they are fused. That is, if the specific gravity of the support 8 is larger than that of the soluble conductor 6, the support 8 presses the soluble conductor, and therefore the soluble conductor is less likely to be gathered, and the fusing characteristics as the fuse unit 1 may be deteriorated.

In the volume of the fusible conductor 6, the low melting point metal layer 3 occupies most of the volume, and therefore, the specific gravity of the support 8 is preferably set to be equal to or less than the specific gravity of the low melting point metal layer 3, and more specifically, the specific gravity is preferably set to 5g/cm3The following materials.

As shown in fig. 2, the solder pellet 5 has an area larger than the surface area of the fusible conductor 6. Thus, the fusible conductor 6 is completely covered with the solder piece 5, and even when the volume expands due to melting, rapid fusing due to the removal of oxidation of the solder 7 and the improvement of wettability can be reliably achieved. As shown in fig. 1 (B) and 1 (C), when the flux chip 5 is mounted on the lower surface of the soluble conductor 6, the area is smaller than the surface area of the soluble conductor 6. Thus, the lower surface of the fusible conductor 6 is covered with the solder piece 5, and a connection margin of each element to the substrate can be secured.

As shown in fig. 4 (a) and 4 (B), the flux chip 5 may have a circular or elliptical shape. Such a solder sheet 5 can be formed into a circular or elliptical shape by punching or the like of a sheet having a sufficiently larger surface area than the fusible conductor 6.

When the solder piece 5 is formed in a circular or elliptical shape, it is preferable that at least the diameter of the circle or ellipse is larger than the short side of the rectangular fusible conductor 6. The position for mounting the flux chip 5 is preferably a position where the center of the circle or ellipse overlaps the fusion-cut portion of the soluble conductor 6.

By mounting the flux sheet 5 on the fusible conductor 6 and/or under the fusible conductor 6, it is possible to retain the flux over the entire surface of the fusible conductor 6 even in the heat treatment step when the fuse unit 1 is mounted, to improve the wettability of the fusible conductor 6 to the low-melting-point metal layer 3 (e.g., solder), to remove the oxide during melting of the low-melting-point metal layer 3, and to improve the quick fusing property using the corrosive action to the high-melting-point metal (e.g., Ag).

Further, even when the flux chip 5 is mounted on the fusible conductor 6 and/or under the fusible conductor 6 and an oxidation preventing film such as lead-free solder containing Sn as a main component is formed on the surface of the high melting point metal layer 2 of the outermost layer of the fusible conductor 6, the oxide of the oxidation preventing film can be removed, thereby effectively preventing the oxidation of the high melting point metal layer 2 and maintaining and improving the quick fusing property.

[ flux containing insulator sheet ]

In order to obtain substantially the same effect as that of the flux sheet 5, the flux 9 containing an insulator sheet, which is contained in the needle-like or short-fiber insulator sheet 10 mixed with the flux 7 of the fluid or semi-fluid, may be applied to the fusible conductor 6 and/or under the fusible conductor 6 without immersing the fluid or semi-fluid flux 7 in the sheet-like support 8.

As shown in fig. 5 (a), the flux 9 including an insulator sheet is composed of a fluid or semi-fluid flux 7 and an insulator sheet 10 of needle-like or short fibers.

The flux 7 may be the same as the flux impregnated into the flux sheet 5.

The insulator sheet 10 is an insulator of needle-like or short fibers. For example, glass fibers or a material obtained by finely dividing a nonwoven fabric into short fibers can be used for the insulator sheet 10. The insulator sheet 10 is formed to have a length within a range not affecting the fluidity of the flux 7, and is entangled with each other when mixed with the flux 7, or has a structure having a predetermined surface area so that the flux 7 can be held between each other by surface tension.

The shape of the insulator sheet 10 is not limited to the needle shape or the short fiber, and may have a hook-like structure, for example, and may be entangled with each other by the hook-like structure. The insulator sheet 10 is not limited to a single shape, and may be different in shape or length.

The flux 9 including the insulator sheet may be applied under the soluble conductor 6, that is, applied to the lower surface of the soluble conductor 6 as shown in fig. 5 (B), in addition to being applied on the soluble conductor 6 as shown in fig. 5 (a). In addition, when the flux 9 including the insulator sheet is applied to the fusible conductor 6, and when the fuse unit 1 is connected to the substrate of each element in a downward direction, it is necessary to secure a connection margin on the lower surface of the fusible conductor 6. Therefore, the flux 9 including the insulator sheet is preferably applied so as to be smaller than the area of the lower surface of the soluble conductor 6, and is preferably applied so as to avoid the connection portion.

The flux 9 including the insulator sheet may be applied on the soluble conductor 6 and under the soluble conductor 6 as shown in fig. 5 (C), in addition to the description of fig. 5 (a) and 5 (B). By applying the flux 9 containing the insulator sheet on the upper and lower sides of the soluble conductor 6, it is expected that the oxide at the time of fusing can be removed more stably and the fluidity of the solder can be improved. Note that the flux 9 including the insulator sheet shown in fig. 5 (C) is the same as the flux described with reference to fig. 5 (a) and 5 (B) above and below the soluble conductor 6, and therefore, the description thereof is omitted.

The flux 9 including the insulator sheet 10 can be applied to the soluble conductor 6 in a circular or elliptical shape as shown in fig. 6 (a) or 6 (B), thereby holding the flux 7 in the same manner as the flux sheet 5, simplifying the sheet manufacturing and sheet mounting steps as compared with the flux sheet 5, and being implemented without changing the previous manufacturing step of applying the flux to the soluble conductor.

In addition, the flux 9 containing the insulator sheet is more preferably applied in a rectangular shape over the fusible conductor 6 and/or over the entire surface below the fusible conductor 6, from the viewpoint of removing an oxide at the time of fusing and improving solder fluidity. However, it is needless to say that the flux 9 including the insulator sheet is not applied to the connection portion of each element under the soluble conductor 6, and a connection margin needs to be kept, which is the same as the case described with reference to fig. 1 (B) and 1 (C).

[ stacked Structure of fuse units ]

The fuse unit 1 can improve the resistance (pulse resistance) to surge of an abnormally high voltage instantaneously applied to an electric system in which each element such as a fuse element is incorporated, by forming the inner layer provided between the pair of high-melting-point metal layers 2 as the low-melting-point metal layer 3 and forming the outer layer as the high-melting-point metal layer 2. That is, with the fuse unit 1, the fusible conductor 6 cannot be blown, for example, in a case where a current of, for example, 100A flows for several megaseconds (msec). Here, since a large current flowing for a very short time flows on the surface layer of the conductor (skin effect), the fuse unit 1 is provided with the high-melting-point metal layer 2 such as Ag plating having a low resistance value as the outer layer of the fusible conductor 6, and therefore, the current applied by the surge is easily flowed, and the fuse unit can be prevented from being fused by the self-heating. Therefore, the fuse unit 1 can significantly improve the resistance to surge as compared with a conventional fuse made of a solder alloy.

In the fuse unit 1, the volume of the low melting point metal layer 3 of the fusible conductor 6 is preferably larger than the volume of the high melting point metal layer 2. By making the volume of the low melting point metal layer 3 large, the fuse unit 1 can efficiently perform the short-time fusing due to the erosion of the high melting point metal layer 2.

[ production method ]

The fuse unit 1 can be manufactured by forming the high melting point metal 2 on the surface of the low melting point metal layer 3 by using a plating technique to form the fusible conductor 6, and mounting the solder piece 5 on the fusible conductor 6 and/or under the fusible conductor 6.

The soluble conductor 6 can be efficiently manufactured by, for example, Ag plating on the surface of a long solder foil, and can be easily used by cutting the solder foil according to the size when used.

The fusible conductor 6 may be produced by bonding a low-melting-point metal foil constituting the low-melting-point metal layer 3 and a high-melting-point metal foil constituting the high-melting-point metal layer 2. The soluble conductor 6 can be manufactured by, for example, laminating and pressing (press) 2 pieces of rolled Cu foil or Ag foil with a similarly rolled solder foil constituting the low melting point metal layer 3 interposed therebetween. In this case, the low melting point metal foil is preferably selected to be softer than the high melting point metal foil. This makes it possible to absorb variations in thickness and to bond the low-melting-point metal foil and the high-melting-point metal foil without a gap. Since the low melting point metal foil is reduced in thickness by pressing, it is only necessary to set the thickness to be thick. When the low melting point metal foil protrudes from the end face of the soluble conductor by the pressing, the low melting point metal foil is preferably cut and finished into a shape.

The soluble conductor 6 can be formed by laminating the low melting point metal layer 3 and the high melting point metal layer 2 by a thin film forming technique using vapor deposition or the like or other known laminating technique.

In the case where one high-melting-point metal layer 2 is used as the outermost layer of the fusible conductor 6, an oxidation preventing film, not shown, may be formed on the surface of the outermost high-melting-point metal layer 2. The outermost high-melting-point metal layer 2 of the fusible conductor 6 is further covered with an oxidation-preventing film, and thus, for example, even when Cu plating or Cu foil is formed as the high-melting-point metal layer 2, oxidation of Cu can be prevented. Therefore, the soluble conductor 6 can be prevented from being fused for a long time due to oxidation of Cu, and can be fused in a short time.

The soluble conductor 6 can be formed using an inexpensive metal such as Cu, which is easily oxidized, as the high melting point metal layer 2, without using an expensive material such as Ag.

The oxidation preventing film of the high melting point metal can be made of the same material as the low melting point metal layer 3, and for example, lead-free solder containing Sn as a main component can be used. The oxidation preventing film can be formed by plating tin on the surface of the high melting point metal layer 2. The oxidation preventing film can be formed by Au plating or pre-solder.

Next, a process of mounting the flux chip 5 on the soluble conductor 6 will be described. First, the flux sheet 5 is prepared by dipping the flux 7 into the support 8 having an area sufficiently larger than that of the soluble conductor 6, heating the resultant in an oven or the like to dry and solidify the solvent portion of the flux 7, thereby preparing a mother sheet (mother sheet), and cutting the mother sheet into desired sizes. Further, the flux sheet 5 may be directly manufactured without manufacturing a master. In this case, the step of cutting out the flux sheet 5 can be omitted.

Next, the cut-out solder piece 5 is mounted on the soluble conductor 6 so as to completely cover and hide the soluble conductor 6. Further, as a fixing agent for temporarily fixing the flux chip 5 to the soluble conductor 6, a small amount of liquid flux 7 is dropped or applied, and the flux chip 5 is mounted on the soluble conductor 6 by being dried while being carried on the flux chip 5. When the solder piece 5 is mounted under the soluble conductor 6, the solder piece 5 having a smaller surface area than the lower surface of the soluble conductor 6 is mounted in a state where the lower surface of the soluble conductor 6 faces upward. Further, as a fixing agent for temporarily fixing the flux chip 5 under the soluble conductor 6, a small amount of liquid flux 7 is dropped or applied, and the flux chip 5 is mounted on the soluble conductor 6 by being dried while being carried on the flux chip 5. Further, in the case where the flux pieces 5 are mounted on the upper and lower fusible conductors 6 and 6, the flux pieces 5 may be mounted on one surface of each fusible conductor 6, but one or both of the two flux pieces 5 may be temporarily fixed, and the fixing agent may be dried by heating when bonding the cover members of the respective elements, which will be described later.

Another example in which the flux chip 5 is mounted on the soluble conductor 6 will be described. The support 8 corresponding to the size of the solder piece 5 is cut out from the mother support which is sufficiently larger than the area of the fusible conductor 6. Next, after the flux 7 is applied or dropped onto the soluble conductor 6, the cut support 8 is carried before the flux 7 is dried. The support 8 absorbs the flux 7 and is integrated with the flux 7 because of its liquid-retaining property. Thereafter, the solvent portion of the flux 7 is dried and solidified through a drying process, thereby forming the flux sheet 5. When the solder piece 5 is mounted under the soluble conductor 6, the support 8 cut out to have a smaller surface area than the lower surface of the soluble conductor 6 is carried after the flux 7 is applied or dropped onto the lower surface of the soluble conductor 6 in a state where the lower surface of the soluble conductor 6 is directed upward and before the flux is dried 7. The support 8 absorbs the flux 7 and is integrated with the flux 7 because of its liquid-retaining property. Thereafter, the solvent portion of the flux 7 is dried and solidified through the drying process, so that the flux piece 5 is formed on the lower surface of the soluble conductor 6.

By using this step, the step of manufacturing the solder sheet 5 in advance can be omitted, and the fuse unit 1 can be manufactured by simply carrying the support 8 after the ordinary step of applying the solder 7, without requiring a complicated manufacturing step.

An example of a case where the flux chip 5 is not mounted on the soluble conductor 6, that is, a case where the flux 9 including an insulator chip is used will be described. The flux 9 containing the insulator sheet on the soluble conductor 6 spreads by applying or dropping the flux 9 containing the insulator sheet having fluidity or semi-fluidity on the soluble conductor 6, and the configuration and the effect substantially equal to those of the flux sheet 5 can be obtained. In addition, when the flux 9 including the insulator sheet is applied under the soluble conductor 6, the flux 9 including the insulator sheet is applied or dropped onto the lower surface of the soluble conductor 6 in a state where the lower surface of the soluble conductor 6 faces upward, and the flux 9 including the insulator sheet spreads on the lower surface of the soluble conductor 6, whereby a structure and an effect substantially equivalent to those of the flux sheet 5 can be obtained.

By using this step, the step of manufacturing the solder sheet 5 in advance can be omitted, and the fuse unit 1 can be manufactured by applying the solder 9 containing the insulator sheet only in the same step as the ordinary step of applying the solder 7, without requiring a complicated manufacturing step.

Next, a fuse element, a protection element, a short-circuit element, and a switching element using the fuse unit 1 will be described. In the following description, each element using the fuse unit 1 will be described, but it is obvious that the fuse unit 1 and its modified examples may be used for each element. In the following, elements substantially identical to those described with reference to the fuse unit 1 are denoted by the same reference numerals, and description thereof is omitted.

[ fuse element (self-heating cutoff) ]

As shown in fig. 7 (a), a fuse element 80 to which the present invention is applied includes: an insulating substrate 81; a 1 st electrode 82 and a 2 nd electrode 83 provided on the insulating substrate 81; a fuse unit 1 which is installed between the 1 st and 2 nd electrodes 82, 83, and which cuts off a current path between the 1 st and 2 nd electrodes 82, 83 by applying a current exceeding a rated current and fusing by self-heating; and a cover member 89 covering the fuse unit 1 on the insulating substrate 81. The fuse unit 1 is constituted by a fusible conductor 6 and a solder piece 5 mounted on the fusible conductor 6 and/or below the fusible conductor 6.

The insulating substrate 81 is formed in a rectangular shape using an insulating member such as alumina, glass ceramic, mullite, or zirconia. In addition, a material for a printed wiring board such as an epoxy glass substrate or a phenol substrate may be used for the insulating substrate 81.

The 1 st and 2 nd electrodes 82 and 83 are formed on opposite ends of the insulating substrate 81. The 1 st and 2 nd electrodes 82 and 83 are formed by a conductive pattern such as Ag or Cu wiring, and a protective layer 86 such as Sn plating, Ni/Au plating, Ni/Pd/Au plating, or the like is provided on the surface as appropriate as a measure against oxidation. The 1 st and 2 nd electrodes 82 and 83 are continuous with the 1 st and 2 nd external connection electrodes 82a and 83a formed on the rear surface 81b from the front surface 81a of the insulating substrate 81 via a castellation (casting). The fuse element 80 is mounted on a current path of the circuit board via the 1 st and 2 nd external connection electrodes 82a and 83a formed on the rear surface 81 b.

The 1 st and 2 nd electrodes 82 and 83 are connected to the fusible conductor 6 of the fuse unit 1 via a connecting material 88 such as solder. As described above, since the fusible conductor 6 includes the high-melting-point metal layer 2, the fuse unit 1 has high mountability and can be easily connected by reflow soldering or the like after being mounted between the 1 st and 2 nd electrodes 82 and 83 via the connecting material 88.

[ fusible conductor ]

As the fusible conductor 6, a fusible conductor substantially equivalent to the fusible conductor described in the fuse unit 1 is used, and therefore, the description and the layer structure are omitted. The same applies to all the embodiments described below.

[ flux sheet ]

The fuse element 80 is mounted with a flux sheet 5 over the entire outermost layer on the soluble conductor 6, as shown in fig. 7 (a), in order to prevent oxidation of the high melting point metal layer 2 or the low melting point metal layer 3, remove oxides at the time of fusing, and improve solder fluidity. Since the solder sheet 5 is substantially the same as the solder sheet described in the fuse unit 1, the description and the internal structure are omitted. In addition, when the solder piece 5 is mounted on the fusible conductor 6, as shown in fig. 7 (B), the above-described case of the fuse unit 1 can be applied, and only an example in which the solder piece 5 is mounted on the fusible conductor 6 will be described, and detailed illustration and description will be omitted. The same applies to all the embodiments described below.

The flux sheet 5 is a sheet-shaped support 8 into which a fluid or semi-fluid flux 7 is impregnated and held, and the flux 7 is impregnated into a nonwoven fabric or a mesh, for example, or the flux 7 is impregnated by arranging a nonwoven fabric or a mesh on the flux 7 applied to the outermost layer of the soluble conductor 6.

As shown in fig. 8, the solder pellet 5 preferably has an area larger than the surface area of the fusible conductor 6. Thus, the fusible conductor 6 is completely covered with the solder piece 5, and even when the volume expands due to melting, oxidation removal by the solder 7 and rapid fusing due to improvement of wettability can be reliably achieved.

By mounting the solder piece 5 on the fusible conductor 6, the solder 7 can be held over the entire surface of the fusible conductor 6 even in the heat treatment step at the time of mounting the fuse unit 1 or at the time of mounting the fuse element 80, and when the fuse element 80 is actually used, the wettability of the low melting point metal layer 3 (e.g., solder) is improved, and the oxide during melting of the 1 st and 2 nd low melting point metals is removed, and the corrosive action on the high melting point metal (e.g., Ag) is used, whereby the quick fusing property can be improved.

Further, even when an oxidation preventing film such as a lead-free solder mainly containing Sn is formed on the surface of the high melting point metal layer 2 of the outermost layer of the soluble conductor 6 by disposing the flux chip 5, the oxide of the oxidation preventing film can be removed, so that the oxidation of the high melting point metal layer 2 can be effectively prevented, and the quick fusing property can be maintained and improved.

[ cover Member ]

The fuse element 80 is provided with a lid member 89 which protects the inside and prevents the melted fuse unit 1 from scattering, on a surface 81a of an insulating substrate 81 on which the fuse unit 1 is provided.

The lid member 89 can be formed of an insulating member such as various engineering plastics or ceramics. Since the fuse element 80 is covered with the cover member 89, even when self-heating cutoff is performed due to generation of arc discharge caused by overcurrent, the molten metal is captured by the cover member 89, and scattering to the surroundings can be prevented.

The cover member 89 has a protruding portion 89b extending from the top surface 89a toward the insulating substrate 81 to at least the side surface of the solder piece 5. Since the lid member 89 restricts the movement of the side surface of the flux chip 5 by the projection 89b, the position shift of the flux chip 5 can be prevented. That is, the projection 89b is provided at a position corresponding to the position at which the solder piece 5 is to be held, so as to have a size that maintains a predetermined gap with respect to the size of the solder piece 5. The protruding portion 89b may be a wall surface covering around the side surface of the flux pad 5, or may be a member partially protruding.

The lid member 89 is configured to have a predetermined space between the solder sheet 5 and the top surface 89 a. This is because, as shown in fig. 9, when the fusible conductor 6 is melted, the melted conductor is required to push up the gap for the solder piece 5.

Therefore, the lid member 89 is configured to: the height of the internal space of the cover member 89 (the height up to the top surface 89 a) is made larger than the sum of the height of the fused fusible conductor 6 on the surface 81a of the insulating substrate 81 (the height that becomes the highest among the fused conductors in the case of breaking into a plurality of fused conductors) and the thickness of the solder piece 5.

[ mounting state ]

Next, the mounting state of the fuse element 80 will be described. As shown in fig. 7, the fusible element 80 is mounted with the fusible conductor 6 separated from the surface 81a of the insulating substrate 81.

On the other hand, in a fuse element in which a fusible conductor or the like is formed on the surface of an insulating substrate by printing and the fusible conductor is in contact with the surface of the insulating substrate, a fusible metal of the fusible conductor adheres to the insulating substrate between electrodes 1 and 2, and leakage occurs. For example, in a fuse element in which a fusible conductor is formed by printing Ag paste on a ceramic substrate, the ceramic and Ag are sintered and cut into the fuse element, and the sintered fuse element remains between the 1 st and 2 nd electrodes. Therefore, a leakage current flows between the 1 st and 2 nd electrodes due to the residue, and the current path cannot be completely blocked.

Here, in the fuse element 80, the fusible conductor 6 is formed as a single body separately from the insulating substrate 81, and is mounted separately from the surface 81a of the insulating substrate 81. Therefore, the fuse element 80 is drawn to the 1 st and 2 nd electrodes 82 and 83 without causing the fusible metal to cut into the insulating substrate 81 even when the fusible conductor 6 is fused, and the 1 st and 2 nd electrodes 82 and 83 can be reliably insulated from each other.

The fuse element 80 can be connected to the 1 st and 2 nd electrodes 82 and 83 with the fusible conductor 6 by reflow soldering as described above, but in addition to this, the fuse element 80 may be connected to the 1 st and 2 nd electrodes 82 and 83 with the fusible conductor 6 by ultrasonic soldering.

Next, as shown in fig. 8, the fuse element 80 is mounted on the fusible conductor 6 so that the solder sheet 5 completely covers the hidden fusible conductor 6. Further, as a fixing agent for temporarily fixing the flux 5 to the soluble conductor 6, a small amount of liquid flux 7 is dropped or applied to carry the flux piece 5, thereby fixing the flux piece 5 to the soluble conductor 6.

Next, the lid member 89 is bonded to the insulating substrate 81 via the adhesive 84. The protruding portion 89b of the cover member 89 has a predetermined gap with respect to the mounting position of the flux chip 5, and therefore does not interfere with the flux chip 5.

[ Circuit diagram ]

Such a fuse element 80 has a circuit configuration shown in fig. 10 (a). The fuse element 80 is mounted on an external circuit via the 1 st and 2 nd external connection electrodes 82a and 83a, and is incorporated in a current path of the external circuit. The fuse element 80 does not blow even by self-heating while a predetermined rated current flows through the fusible conductor 6. When the fuse element 80 is energized with an overcurrent exceeding the rated current, the fusible conductor 6 is fused by self-heating, and cuts off the interval between the 1 st and 2 nd electrodes 82 and 83, thereby cutting off the current path of the external circuit (fig. 10B).

At this time, since the fusible conductor 6 is laminated with the low-melting-point metal layer 3 having a lower melting point than the high-melting-point metal layer 2 as described above, the fuse element 80 starts to erode the high-melting-point metal layer 2 by self-heating due to overcurrent. Therefore, the fuse element 80 can be melted at a temperature lower than the melting temperature of the high-melting-point metal layer 2 by the action of the low-melting-point metal layer 3 of the fusible conductor 6 on the high-melting-point metal layer 2, and can be melted quickly.

Further, as shown in fig. 9, the molten metal of the soluble conductor 6 is left-right opened by the physical drawing action of the 1 st and 2 nd electrodes 82 and 83, and thus the current path between the 1 st and 2 nd electrodes 82 and 83 can be quickly and reliably cut off.

[ production method ]

The manufacturing method of the fuse element 80 can be the manufacturing method of the fuse unit 1 described above. Thus, the explanation of the manufacturing method related to the fuse unit 1 is omitted.

First, Ag or Cu wiring or the like is patterned by screen printing or the like on the 1 st and 2 nd electrodes 82 and 83, respectively, at opposite ends of the insulating substrate 81, and a protective layer 86 of Sn, Ni/Au, Ni/Pd/Au or the like is formed on the surface by electroplating as appropriate as a countermeasure against oxidation and electrode corrosion, thereby manufacturing a base portion.

Next, on the front surface 81a side of the insulating substrate 81, a connecting material 88 such as solder paste is applied to the 1 st and 2 nd electrodes 82 and 83, and the fusible conductor 6 portion of the fuse unit 1 is connected to the 1 st and 2 nd electrodes 82 and 83. Thus, the fusible conductor 6, which is the fuse unit 1, is mounted on the 1 st and 2 nd electrodes 82 and 83.

Next, the adhesive 84 is applied to the surface 81a side of the insulating substrate 81 in a predetermined range, and then the lid member 89 is adhered to cover the fuse unit 1, thereby completing the fuse element 80.

Here, as for the method of mounting the fuse unit 1 in the fuse element 80, the manufacturing process of the fuse unit 1 may be divided and employed inside the manufacturing process of the fuse element 80.

Specifically, before the solder piece 5 of the fuse unit 1 is bonded to the soluble conductor 6, or before the solder 9 containing an insulator sheet is applied to the surface of the soluble conductor 6, after the individual soluble conductor 6 is mounted on the 1 st and 2 nd electrodes 82 and 83 and connected, the solder piece 5 may be temporarily fixed to the soluble conductor 6 with a fixing agent such as a solder 7, or after the individual soluble conductor 6 is mounted on the 1 st and 2 nd electrodes 82 and 83 and connected, the solder 9 containing an insulator sheet may be applied. In this case, the flux sheet 5 can be fixed while the adhesive 84 is cured by heating in the step of bonding the cover member 89.

By adopting the method for manufacturing the fuse unit 1 in the method for manufacturing the fuse element 80, it is possible to integrate the manufacturing process of the fuse element 80 and the manufacturing process of the fuse unit 1 without manufacturing the fuse unit 1 in advance, and therefore, improvement in productivity can be expected.

Note that, even when the method for manufacturing the fuse unit 1 is adopted as the method for manufacturing the fuse element 80, the step of bonding the lid member 89 is finally unnecessary.

[ modification 1 of fuse element ]

Next, modification 1 of the fuse element 80 will be described. As shown in fig. 11 (a), the fuse element 80 may be one in which the solder piece 5 is replaced with a solder piece 85 a. The fuse element 80 shown in fig. 11 (a) is not particularly modified in portions other than the solder bumps 85 a.

The flux sheet 85a is formed by immersing and holding the flux 7 in a fluid or semi-fluid state in the sheet-like support 8, for example, by immersing the flux 7 in a nonwoven fabric or a mesh-like state, or by disposing a nonwoven fabric or a mesh-like state on the flux 7 applied to the outermost layer of the soluble conductor 6 and immersing the flux 7. The flux sheet 85a can hold the flux 7 of the fluid or semi-fluid by the support 8 having liquid retainability.

When the structure shown in modification 1 of the fuse element 80 is used, the fuse element 80 can be manufactured by mounting and connecting the single soluble conductor 6 to the 1 st and 2 nd electrodes 82 and 83, applying or dropping the flux 7 of the fluid or semi-fluid to the soluble conductor 6, and then mounting the sheet-like support 8 on the flux 7 in the manufacturing method of the fuse element 80 described above.

In addition, when the structure shown in modification 1 of the fuse element 80 is used, the solder piece 85a can be mounted under the soluble conductor 6 as shown in fig. 11 (B). It is needless to describe that the solder piece 85a may be mounted only under the fusible conductor 6.

[ modification 2 of fuse element ]

Next, a modification of the fuse element 80 will be described. As shown in fig. 12 (a), the fuse element 80 may be one in which the solder sheet 5 is replaced with solder 85b containing an insulator sheet. The fuse element 80 shown in fig. 12 (a) is not particularly modified in portions other than the solder 85b containing the insulator sheet.

The flux 85b containing the insulator sheet is contained in the insulator sheet 10 of needle-like or short fiber mixed with the flux 7 of the fluid or semi-fluid and applied to the soluble conductor 6 without immersing the fluid or semi-fluid flux 7 in the sheet-like support 8. The flux 85b including the insulator sheet can hold the fluid or semi-fluid flux 7 on the soluble conductor 6 by the insulator sheet 10 having liquid retainability.

When the structure shown in modification 2 of the fuse element 80 is used, the fuse element 80 can be manufactured by mounting and connecting the individual fusible conductors 6 to the 1 st and 2 nd electrodes 82 and 83, and then applying the flux 9 containing the insulator sheet, which is contained by mixing the needle-shaped or short-fiber insulator sheet 10, to the fusible conductors 6 in the above-described method for manufacturing the fuse element 80.

In addition, when the structure shown in modification 2 of the fuse element 80 is used, as shown in fig. 12 (B), the flux 85B containing the insulator sheet can be applied under the soluble conductor 6. It is needless to say that the flux 85b including the insulator sheet may be applied only under the fusible conductor 6.

[ protective element (heating block and self-heating block by heating element) ]

Next, a protection element using the fuse unit 1 will be described. In the following description, the same components as those of the fuse unit 1 and the fuse element 80 are denoted by the same reference numerals, and the details thereof are omitted.

As shown in fig. 13 (a) and 14 (a), a protection element 90 to which the present invention is applied includes: an insulating substrate 91; a heating element 93 laminated on the insulating substrate 91 and covered with the insulating member 92; a 1 st electrode 94 and a 2 nd electrode 95 formed at both ends of the insulating substrate 91; a heating element extraction electrode 96 laminated on the insulating substrate 91 so as to overlap the heating element 93 and electrically connected to the heating element 93; a fuse unit 1 having both ends connected to the 1 st and 2 nd electrodes 94 and 95, respectively, and a central portion connected to a heating element extraction electrode 96; and a cover member 97 covering the fuse unit 1 on the insulating substrate 91. The fuse unit 1 is composed of a fusible conductor 6 and a solder piece 5 mounted on the fusible conductor 6 and/or under the fusible conductor 6. Fig. 13 (B) illustrates the solder piece 5 mounted under the soluble conductor 6.

The insulating substrate 91 is formed in a rectangular shape using an insulating member such as alumina, glass ceramic, mullite, or zirconia, as in the insulating substrate 81. In addition, a material for a printed wiring board such as an epoxy glass substrate or a phenol substrate may be used for the insulating substrate 91.

The 1 st and 2 nd electrodes 94 and 95 are formed at opposite ends of the insulating substrate 91. The 1 st and 2 nd electrodes 94 and 95 are formed by conductive patterns such as Ag or Cu wirings. The 1 st and 2 nd electrodes 94 and 95 are continuous with the 1 st and 2 nd external connection electrodes 94a and 95a formed on the rear surface 91b from the front surface 91a of the insulating substrate 91 via the castellation structure. The protection element 90 is incorporated in a part of a current path formed on the circuit board by connecting the 1 st and 2 nd external connection electrodes 94b and 95b formed on the rear surface 91b to connection electrodes provided on the circuit board on which the protection element 90 is mounted.

The heating element 93 is a conductive member that generates heat when energized, and is made of, for example, nichrome, W, Mo, Ru, or a material containing these. The heating element 93 can be formed by mixing a powder of these alloys, compositions, or compounds with a resin binder or the like to form a paste-like mixture, patterning the paste on the insulating substrate 91 by a screen printing technique, and then firing the paste.

In the protection element 90, the heating element 93 is covered with the insulating member 92, and the heating element extraction electrode 96 is formed so as to face the heating element 93 through the insulating member 92. The fusible conductor 6 of the fuse unit 1 is connected to the heating element-drawing electrode 96, and thus the heating element 93 is overlapped with the fusible conductor 6 via the insulating member 92 and the heating element-drawing electrode 96. The insulating member 92 is provided to protect and insulate the heating element 93 and to transmit the heat efficiency of the heating element 93 to the soluble conductor 6, and is made of, for example, a glass layer.