CN102620982A - Concrete beam reverse loading test device - Google Patents

Concrete beam reverse loading test device Download PDFInfo

- Publication number

- CN102620982A CN102620982A CN201210086048XA CN201210086048A CN102620982A CN 102620982 A CN102620982 A CN 102620982A CN 201210086048X A CN201210086048X A CN 201210086048XA CN 201210086048 A CN201210086048 A CN 201210086048A CN 102620982 A CN102620982 A CN 102620982A

- Authority

- CN

- China

- Prior art keywords

- support

- base

- chute

- beams

- support rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000012360 testing method Methods 0.000 title claims abstract description 45

- 238000000034 method Methods 0.000 abstract description 3

- 230000009286 beneficial effect Effects 0.000 abstract description 2

- 238000005096 rolling process Methods 0.000 description 5

- 230000003068 static effect Effects 0.000 description 5

- 238000002474 experimental method Methods 0.000 description 4

- 230000007774 longterm Effects 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000005452 bending Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

Images

Landscapes

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

一种混凝土梁反向加载试验装置,包括底座,底座两端设有滑槽,支座拉杆通过螺母安装在滑槽内;支座拉杆与支座框架连接,两个支座框架之间通过横向拉杆连接;底座上位于滑槽内侧设有支撑杆,支撑杆与分配横梁活动连接;分配横梁下设有千斤顶和力传感器。本发明提供的一种混凝土梁反向加载试验装置,通过采用反向加载的方式,利于观测试件裂缝的走势及测量裂缝的宽度,从而易于获取试验数据,且采用了支座转轴配合扣环的结构,利于加载试件。设置在底座上的滑槽、横向拉杆和扣环结构的配合,可以方便地调整长度,以和试件的长度相适应。

A concrete beam reverse loading test device, including a base, chute is provided at both ends of the base, the support rod is installed in the chute through a nut; the support rod is connected with the support frame, and the two support frames are connected by a transverse The pull rod is connected; the base is provided with a support rod inside the chute, and the support rod is movably connected with the distribution beam; a jack and a force sensor are provided under the distribution beam. A concrete beam reverse loading test device provided by the present invention adopts the method of reverse loading, which is beneficial to observe the trend of cracks in the test piece and measure the width of cracks, so that it is easy to obtain test data, and adopts the support shaft to cooperate with the buckle The structure is conducive to loading the specimen. The cooperation of the chute arranged on the base, the transverse pull rod and the buckle structure can conveniently adjust the length to match the length of the test piece.

Description

技术领域 technical field

本发明涉及混凝土载荷实验领域,特别是一种长期荷载作用下构件能够不卸载并完成破坏实验的混凝土梁反向加载试验装置。 The invention relates to the field of concrete load experiments, in particular to a concrete beam reverse loading test device which can complete damage experiments without unloading components under long-term loads.

背景技术 Background technique

目前研究长期恒定荷载对结构的影响的实验,基本上是通过重物加载的方式进行的,在进行破坏试验时会先卸载后再进行加载破坏,与实际构件在持续荷载发生破坏不同,由于重物加载体积大,占地面积广,加载后移动或调整很不方便,导致实验效率低,并且得到的结果也会与实际结果有一定的差距,不利于研究构件在长期荷载作用下破坏的一般规律。 At present, experiments to study the influence of long-term constant loads on structures are basically carried out by loading heavy objects. During the damage test, they will be unloaded first and then loaded and damaged. This is different from the actual component that is damaged under continuous load. The loaded object has a large volume and covers a large area, and it is very inconvenient to move or adjust after loading, resulting in low experimental efficiency, and there will be a certain gap between the obtained results and the actual results, which is not conducive to the study of the general failure of components under long-term loads. law.

中国专利201120125585.1提供了一种预制梁应力静荷载试验装置,多根反力锚杆一端与基础体连接,另一端与反力钢梁连接,反力钢梁下方设有传力装置,基础体上方设有支承装置。本实用新型提供的一种预制梁应力静荷载试验装置,通过采用上述结构,以较少的设备实现预制梁应力静荷载试验,采用千斤顶进行应力加载,从而不需要配重和起吊设施。该装置存在的问题是观察梁底裂缝的走势及测量裂缝的宽度不便,不利于实验数据的获得。 Chinese patent 201120125585.1 provides a stress static load test device for prefabricated beams. One end of multiple reaction force anchors is connected to the foundation body, and the other end is connected to the reaction force steel beam. There is a supporting device. The utility model provides a stress static load test device for prefabricated beams. By adopting the above structure, the stress static load test of prefabricated beams can be realized with less equipment, and a jack is used for stress loading, thereby eliminating the need for counterweights and lifting facilities. The problem with this device is that it is inconvenient to observe the trend of the cracks at the bottom of the beam and measure the width of the cracks, which is not conducive to the acquisition of experimental data.

发明内容 Contents of the invention

本发明所要解决的技术问题是提供一种混凝土梁反向加载试验装置,可以方便的获取试验数据,且便于试件的加载。 The technical problem to be solved by the present invention is to provide a concrete beam reverse loading test device, which can conveniently obtain test data and facilitate loading of test pieces.

为解决上述技术问题,本发明所采用的技术方案是:一种混凝土梁反向加载试验装置,包括底座,底座两端设有滑槽,支座拉杆通过螺母安装在滑槽内; In order to solve the above technical problems, the technical solution adopted in the present invention is: a concrete beam reverse loading test device, including a base, the two ends of the base are provided with chutes, and the support rods are installed in the chutes through nuts;

支座拉杆与支座框架连接,两个支座框架之间通过横向拉杆连接; The support rod is connected with the support frame, and the two support frames are connected by a transverse tie rod;

底座上位于滑槽内侧设有支撑杆,支撑杆与分配横梁活动连接; There is a support rod on the inside of the chute on the base, and the support rod is movably connected with the distribution beam;

分配横梁下设有千斤顶和力传感器。 There are jacks and force sensors under the distribution beam.

支座拉杆与支座框架的下端之间通过支座转轴连接。 The support rod is connected with the lower end of the support frame through the support rotating shaft.

所述的支座转轴通过固定盘锁定。 The rotating shaft of the support is locked by the fixed disk.

横向拉杆通过扣环与支座框架连接。 The transverse tie rod is connected with the support frame through a buckle.

横向拉杆两端通过螺纹与扣环连接。 The two ends of the transverse pull rod are connected with the buckle through threads.

分配横梁底部设有支撑槽,支撑杆活动地位于支撑槽内。 A support groove is provided at the bottom of the distribution beam, and the support rod is movably located in the support groove.

本发明提供的一种混凝土梁反向加载试验装置,通过采用反向加载的方式,利于观测试件裂缝的走势及测量裂缝的宽度,从而易于获取试验数据,且采用了支座转轴配合扣环的结构,利于加载试件。设置在底座上的滑槽、横向拉杆和扣环结构的配合,可以方便地调整长度,以和试件的长度相适应。 A concrete beam reverse loading test device provided by the present invention adopts the method of reverse loading, which is beneficial to observe the trend of cracks in the test piece and measure the width of cracks, so that it is easy to obtain test data, and adopts the support shaft to cooperate with the buckle The structure is conducive to loading the specimen. The cooperation of the chute arranged on the base, the transverse pull rod and the buckle structure can conveniently adjust the length to match the length of the test piece.

本发明的装置,可以对混凝土梁及类似梁体构件的试件进行长期静力加载和持续荷载作用下模拟钢筋锈蚀试验研究,整个加载装置结构简单,占地面积小,可以任意移动,并可以重复利用,加载控制方便准确,检测数据能更好的贴近实际;可以满足各个学校教学试验梁的实验装置,也可以用于各科研机构对受弯和受剪构件各项性能的检测试验。 The device of the present invention can carry out long-term static loading and simulated steel corrosion test research on concrete beams and similar beam members under the action of continuous load. Reuse, convenient and accurate loading control, and test data can be closer to reality; it can be used as an experimental device for teaching test beams in various schools, and can also be used for various performance testing tests of bending and shearing components in various scientific research institutions.

附图说明 Description of drawings

下面结合附图和实施例对本发明作进一步说明: Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

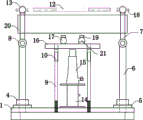

图1为本发明的主视结构示意图。 Fig. 1 is a schematic diagram of the front view structure of the present invention.

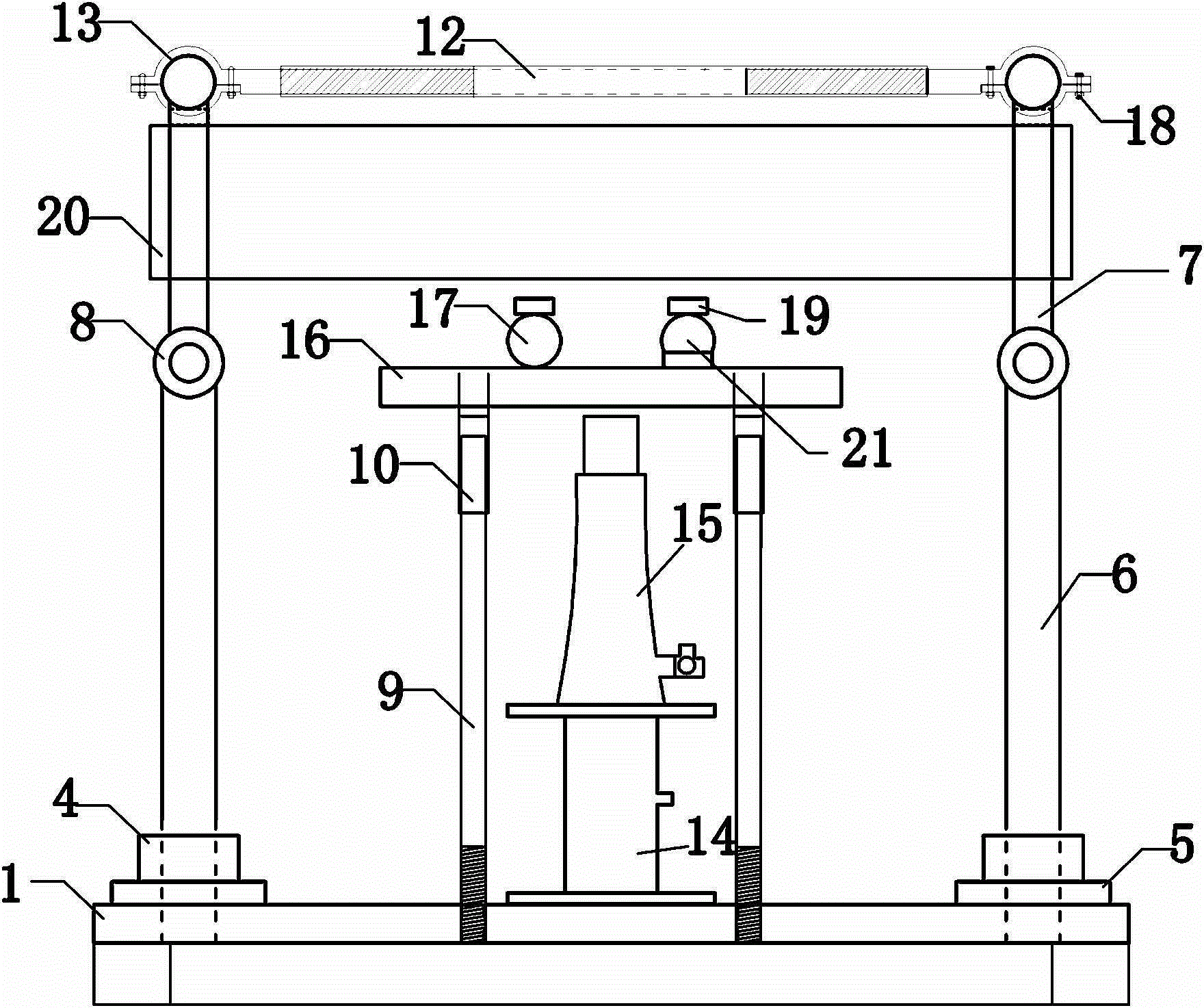

图2为本发明的侧视结构示意图。 Fig. 2 is a schematic side view of the structure of the present invention.

图3为本发明中底座的俯视示意图。 Fig. 3 is a schematic top view of the base of the present invention.

图中:底座1,滑槽2,固定孔3,螺母4,强化垫板5,支座拉杆6,支座框架7,支座转轴8,支撑杆9,支撑槽10,固定盘11,横向拉杆12,扣环13,力传感器14,千斤顶15,分配横梁16,滚动支承17,紧固螺栓18,垫板19,试件20,固定支承21。

In the figure: base 1, chute 2, fixing hole 3,

具体实施方式 Detailed ways

如图1、图3中,一种混凝土梁反向加载试验装置,包括底座1,底座1两端设有滑槽2,支座拉杆6通过螺母4安装在滑槽2内;底座1侧视成“Ω”形,下方的螺母4位于“Ω”形内凹的部位中。在上方的螺母4的下方还设有强化垫板5,用于确保支座拉杆6受力可靠。

As shown in Fig. 1 and Fig. 3, a concrete beam reverse loading test device includes a base 1, a chute 2 is provided at both ends of the base 1, and a

支座拉杆6与支座框架7连接,两个支座框架7之间通过横向拉杆12连接;

The

如图1中,底座1上位于滑槽2内侧设有支撑杆9,支撑杆9通过螺纹与底座1上的固定孔3连接,从而可以调节支撑杆9的高度,以适应不同的试件20。

As shown in Figure 1, a

支撑杆9与分配横梁16活动连接,优选的方案中分配横梁16底部设有支撑槽10,支撑杆9活动地位于支撑槽10内。分配横梁16下设有千斤顶15和力传感器14。由此结构,当千斤顶15顶升时,分配横梁16可以随之运动。

The

分配横梁16上设有滚动支承17和固定支承21。滚动支承17和固定支承21上设有垫板19,试件20安装在垫板19上,在支座框架7与试件20之间也设有垫板19。

The distribution beam 16 is provided with a rolling support 17 and a

如图1中,支座拉杆6与支座框架7的下端之间通过支座转轴8连接,其中,支座拉杆6与支座转轴8焊接连接,支座框架7的下端与支座转轴8铰接。所述的支座转轴8通过固定盘11锁定。由此结构,支座框架7可以向两侧旋转,从而便于加载试件20至支座转轴8上,加载完成后再旋转使支座框架7与试件20垂直。

As shown in Figure 1, the lower end of the

横向拉杆12通过扣环13与支座框架7连接。横向拉杆12两端通过螺纹与扣环13连接。扣环13的结构见图1中所示,由此结构,一是便于从环扣处与支座框架7分离,从而便于加载试件,二是可以通过螺纹调节扣环13和横向拉杆12的整体长度,同时支座拉杆6通过螺母4紧固在滑槽2不同的位置与横向拉杆12的长度相配合,从而适应不同长度的试件。

The

使用时,通过螺母4将支座拉杆6安装在滑槽2内,根据试件20的长度调整至合适的位置。

When in use, the

在底座1上放置力传感器14,在力传感器14上方放置千斤顶15。

A

安装支撑杆9到底座1的固定孔3,通过螺纹调节支撑杆9的高度,将支撑槽10放置在支撑杆9上,本例中的支撑槽10采用“U”形支撑槽,再将分配横梁16放置在支撑槽10上。

Install the

将试件20放置在支座转轴8上,确保试件对中。旋转使支座框架7与试件20垂直,安装固定盘11,利用螺栓锁定支座转轴8,再通过横向拉杆12上的扣环13连接支座框架7,上紧紧固螺栓18固定扣环13。具体如图2中所示。

Place the

在试件下方根据实验要求放置滚动支承17、固定支承21和垫板19,开启千斤顶15即可开始静力加载实验。

Place the rolling bearing 17, the fixed bearing 21 and the

本发明的装置是通过千斤顶15提供的作用力,一方面通过分配横梁16上的滚动支承17和固定支承21,传给试件22作为加载力,试件22端部通过支座框架7提供反向拉力,支座框架7的反向拉力通过支座转轴8和支座拉杆6传给底座1,另一方面利用力传感器14直接作用在底座1上,从而使整个发明的装置成为一个内部自平衡状态。

The device of the present invention uses the active force provided by the

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210086048XA CN102620982A (en) | 2012-03-28 | 2012-03-28 | Concrete beam reverse loading test device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210086048XA CN102620982A (en) | 2012-03-28 | 2012-03-28 | Concrete beam reverse loading test device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102620982A true CN102620982A (en) | 2012-08-01 |

Family

ID=46561030

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210086048XA Pending CN102620982A (en) | 2012-03-28 | 2012-03-28 | Concrete beam reverse loading test device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102620982A (en) |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102818729A (en) * | 2012-09-07 | 2012-12-12 | 广州市建筑材料工业研究所有限公司 | Apparatus and method for detecting flexural bearing capacity of building wallboard |

| CN103175707A (en) * | 2013-03-25 | 2013-06-26 | 同济大学 | Testing apparatus suitable for substructure robustness of beam-column joints of planar frames |

| CN103207096A (en) * | 2013-03-21 | 2013-07-17 | 河海大学 | Vertical load loading device for shear wall |

| CN104142270A (en) * | 2014-07-31 | 2014-11-12 | 桂林理工大学 | Large reverse loading device |

| CN104198360A (en) * | 2014-08-28 | 2014-12-10 | 华东交通大学 | Simulation experiment device for coupling effect of acid rain, dampness heat and mechanical load |

| CN104237010A (en) * | 2014-08-14 | 2014-12-24 | 贵州长通电力线路器材有限公司 | Multifunctional concrete electric pole mechanical property detection platform |

| CN104330276A (en) * | 2014-11-11 | 2015-02-04 | 青岛建安建设集团有限公司 | Test method for measuring ultimate bearing capacity of ceiling support system |

| CN104458257A (en) * | 2014-11-26 | 2015-03-25 | 西北工业大学 | Bearing reaction simulating device for rotating shaft |

| CN104713691A (en) * | 2015-04-10 | 2015-06-17 | 河海大学 | Device for exerting axis-compression ratio and fixing test specimen for structural seismic performance test and testing method for device |

| CN105043884A (en) * | 2015-08-26 | 2015-11-11 | 宁波交通工程建设集团有限公司 | Testing device for carrying capacity of comprehensive pipe gallery and pipe joint and application method |

| CN105158064A (en) * | 2015-09-30 | 2015-12-16 | 三峡大学 | Counterforce loading frame for multifunctional self-balancing type continuous beam test |

| CN106769414A (en) * | 2017-01-04 | 2017-05-31 | 湖北工业大学 | Load and test specimen durability test device under environment coupled action |

| CN109507029A (en) * | 2018-11-29 | 2019-03-22 | 长江大学 | Apply the auxiliary device of large-tonnage traveling load |

| CN112213211A (en) * | 2020-10-26 | 2021-01-12 | 中国人民解放军军事科学院国防工程研究院工程防护研究所 | Self-balancing structure for medium-high pressure explosive load generator |

| CN113916291A (en) * | 2021-10-09 | 2022-01-11 | 中国建材检验认证集团浙江有限公司 | Device and method for inspecting structure performance of autoclaved aerated concrete slab |

| CN114136681A (en) * | 2021-11-29 | 2022-03-04 | 中交二航局第二工程有限公司 | Crane load test device and method |

| CN114136678A (en) * | 2021-11-29 | 2022-03-04 | 中交二航局第二工程有限公司 | Hoisting equipment load test device and load test method |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101105428A (en) * | 2007-07-10 | 2008-01-16 | 浙江大学 | Comprehensive loading device for reinforced concrete experiment teaching |

| CN101603902A (en) * | 2009-07-03 | 2009-12-16 | 同济大学 | Test-piece torsion test system |

| CN102235943A (en) * | 2010-05-06 | 2011-11-09 | 中国商用飞机有限责任公司 | Loading test device |

| CN202041399U (en) * | 2011-04-26 | 2011-11-16 | 中国葛洲坝集团股份有限公司 | Dead load testing device for stress of precast beam |

| CN202041361U (en) * | 2011-03-09 | 2011-11-16 | 武汉希萌工程咨询有限公司 | Static load test-bed of terrestrial anchor pile self-balanced bridge |

| CN202101902U (en) * | 2011-06-27 | 2012-01-04 | 长沙理工大学 | Anti-position loading device for structure test |

| CN202126375U (en) * | 2011-06-30 | 2012-01-25 | 天津钢管集团股份有限公司 | Full-size bending test device for marine line pipes |

| CN202485971U (en) * | 2012-03-28 | 2012-10-10 | 徐港 | Reverse loading tester for concrete beam |

-

2012

- 2012-03-28 CN CN201210086048XA patent/CN102620982A/en active Pending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101105428A (en) * | 2007-07-10 | 2008-01-16 | 浙江大学 | Comprehensive loading device for reinforced concrete experiment teaching |

| CN101603902A (en) * | 2009-07-03 | 2009-12-16 | 同济大学 | Test-piece torsion test system |

| CN102235943A (en) * | 2010-05-06 | 2011-11-09 | 中国商用飞机有限责任公司 | Loading test device |

| CN202041361U (en) * | 2011-03-09 | 2011-11-16 | 武汉希萌工程咨询有限公司 | Static load test-bed of terrestrial anchor pile self-balanced bridge |

| CN202041399U (en) * | 2011-04-26 | 2011-11-16 | 中国葛洲坝集团股份有限公司 | Dead load testing device for stress of precast beam |

| CN202101902U (en) * | 2011-06-27 | 2012-01-04 | 长沙理工大学 | Anti-position loading device for structure test |

| CN202126375U (en) * | 2011-06-30 | 2012-01-25 | 天津钢管集团股份有限公司 | Full-size bending test device for marine line pipes |

| CN202485971U (en) * | 2012-03-28 | 2012-10-10 | 徐港 | Reverse loading tester for concrete beam |

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102818729A (en) * | 2012-09-07 | 2012-12-12 | 广州市建筑材料工业研究所有限公司 | Apparatus and method for detecting flexural bearing capacity of building wallboard |

| CN103207096B (en) * | 2013-03-21 | 2015-06-03 | 河海大学 | Vertical load loading device for shear wall |

| CN103207096A (en) * | 2013-03-21 | 2013-07-17 | 河海大学 | Vertical load loading device for shear wall |

| CN103175707A (en) * | 2013-03-25 | 2013-06-26 | 同济大学 | Testing apparatus suitable for substructure robustness of beam-column joints of planar frames |

| CN104142270A (en) * | 2014-07-31 | 2014-11-12 | 桂林理工大学 | Large reverse loading device |

| CN104237010A (en) * | 2014-08-14 | 2014-12-24 | 贵州长通电力线路器材有限公司 | Multifunctional concrete electric pole mechanical property detection platform |

| CN104198360A (en) * | 2014-08-28 | 2014-12-10 | 华东交通大学 | Simulation experiment device for coupling effect of acid rain, dampness heat and mechanical load |

| CN104330276A (en) * | 2014-11-11 | 2015-02-04 | 青岛建安建设集团有限公司 | Test method for measuring ultimate bearing capacity of ceiling support system |

| CN104330276B (en) * | 2014-11-11 | 2015-07-29 | 青岛建安建设集团有限公司 | Measure ceiling support system Ultimate Strength Test method |

| CN104458257A (en) * | 2014-11-26 | 2015-03-25 | 西北工业大学 | Bearing reaction simulating device for rotating shaft |

| CN104458257B (en) * | 2014-11-26 | 2017-11-21 | 西北工业大学 | For the support reaction analogue means of rotating shaft |

| CN104713691A (en) * | 2015-04-10 | 2015-06-17 | 河海大学 | Device for exerting axis-compression ratio and fixing test specimen for structural seismic performance test and testing method for device |

| CN104713691B (en) * | 2015-04-10 | 2017-05-10 | 河海大学 | Device for exerting axis-compression ratio and fixing test specimen for structural seismic performance test and testing method for device |

| CN105043884A (en) * | 2015-08-26 | 2015-11-11 | 宁波交通工程建设集团有限公司 | Testing device for carrying capacity of comprehensive pipe gallery and pipe joint and application method |

| CN105043884B (en) * | 2015-08-26 | 2017-11-10 | 宁波交通工程建设集团有限公司 | Pipe gallery tube coupling load carrying capacity test device and application method |

| CN105158064A (en) * | 2015-09-30 | 2015-12-16 | 三峡大学 | Counterforce loading frame for multifunctional self-balancing type continuous beam test |

| CN106769414A (en) * | 2017-01-04 | 2017-05-31 | 湖北工业大学 | Load and test specimen durability test device under environment coupled action |

| CN109507029A (en) * | 2018-11-29 | 2019-03-22 | 长江大学 | Apply the auxiliary device of large-tonnage traveling load |

| CN112213211A (en) * | 2020-10-26 | 2021-01-12 | 中国人民解放军军事科学院国防工程研究院工程防护研究所 | Self-balancing structure for medium-high pressure explosive load generator |

| CN112213211B (en) * | 2020-10-26 | 2024-02-13 | 中国人民解放军军事科学院国防工程研究院工程防护研究所 | Self-balancing structure for medium-high pressure explosion load generator |

| CN113916291A (en) * | 2021-10-09 | 2022-01-11 | 中国建材检验认证集团浙江有限公司 | Device and method for inspecting structure performance of autoclaved aerated concrete slab |

| CN113916291B (en) * | 2021-10-09 | 2024-02-13 | 中国国检测试控股集团浙江有限公司 | Autoclaved aerated concrete slab structural performance inspection device and method |

| CN114136681A (en) * | 2021-11-29 | 2022-03-04 | 中交二航局第二工程有限公司 | Crane load test device and method |

| CN114136678A (en) * | 2021-11-29 | 2022-03-04 | 中交二航局第二工程有限公司 | Hoisting equipment load test device and load test method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102620982A (en) | Concrete beam reverse loading test device | |

| CN202485971U (en) | Reverse loading tester for concrete beam | |

| CN105158064B (en) | A kind of Multifunctional self-leveling weighing apparatus continuous beam test counter-force loading frame of formula | |

| CN206862607U (en) | A kind of new structure slow test loading experiment frame | |

| CN101603899B (en) | Field portable experiment system for tensile mechanical property of plant root system | |

| CN201000411Y (en) | Tool type concrete beam static loading device | |

| CN105259043B (en) | Batch concrete filled steel tube self-balanced loading device | |

| CN111189704B (en) | Concrete tension and compression dual-power creep test device and test method | |

| CN206832583U (en) | It is a kind of to be used for the experimental rig of anchor pole stretching and shearing in jointed rock mass | |

| CN105092365B (en) | A kind of concrete component is pulled and supported lotus loading frame | |

| CN205679468U (en) | A kind of anchor rod drawing test hydraulic support device | |

| CN110398429A (en) | A test device and test method for the seismic performance of concrete filled steel tubes considering the influence of the construction process | |

| CN206504963U (en) | Railway rail clip fatigue experimental device | |

| CN203894112U (en) | Axial compression fatigue testing device | |

| CN103758161B (en) | Pressure testing device and the pressure-measuring method of pile for prestressed pipe is measured with periphery pile tube component | |

| CN204944930U (en) | A kind of concrete component is pulled and supported lotus loading frame | |

| CN204944936U (en) | A kind of Multifunctional self-leveling weighing apparatus formula continuous beam test counter-force loading frame | |

| CN104594397B (en) | Detachable pile tube beam test device | |

| CN203855991U (en) | Device for conducting anti-pulling frictional resistance test on bed rock | |

| CN111576501A (en) | Bending resistance test system for vertically and upwardly loading tubular pile | |

| CN105973576A (en) | Simple device applied to hinge support component manual loading compression test | |

| CN201060092Y (en) | A comprehensive loading device for reinforced concrete experiment teaching | |

| CN204705469U (en) | A kind of lever loading device | |

| CN210946510U (en) | Continuous rigid frame 0# block bracket pre-pressing device | |

| CN204530801U (en) | Foundation pile pulling resistance testing device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20120801 |