CN102333461A - Smoking articles and method for manufacturing smoking articles - Google Patents

Smoking articles and method for manufacturing smoking articles Download PDFInfo

- Publication number

- CN102333461A CN102333461A CN2010800093326A CN201080009332A CN102333461A CN 102333461 A CN102333461 A CN 102333461A CN 2010800093326 A CN2010800093326 A CN 2010800093326A CN 201080009332 A CN201080009332 A CN 201080009332A CN 102333461 A CN102333461 A CN 102333461A

- Authority

- CN

- China

- Prior art keywords

- paper

- pattern

- smoking article

- retardant

- fire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/02—Manufacture of tobacco smoke filters

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D1/00—Cigars; Cigarettes

- A24D1/02—Cigars; Cigarettes with special covers

- A24D1/025—Cigars; Cigarettes with special covers the covers having material applied to defined areas, e.g. bands for reducing the ignition propensity

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D1/00—Cigars; Cigarettes

- A24D1/02—Cigars; Cigarettes with special covers

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/062—Use of materials for tobacco smoke filters characterised by structural features

- A24D3/063—Use of materials for tobacco smoke filters characterised by structural features of the fibers

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/08—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent

- A24D3/10—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent of cellulose or cellulose derivatives

Abstract

The invention relates to a method of manufacturing a plurality of smoking articles, comprising providing a wrapping paper having a permeability of less than 15 CU and applying a burn retardant additive material in a predetermined pattern to the wrapping paper. The wrapping paper is wrapped about a tobacco material to form a wrapped rod and the wrapped rod is cut to form the plurality of smoking articles. The invention also relates to a smoking article manufactured by the method, wherein the wrapping paper has a permeability of less than 15 CU in areas without the burn retardant additive and a lower permeability in areas where the additive is applied.

Description

Technical field

The present invention relates to a kind of method of making smoking article, specifically be meant a kind of fire-retardant interpolation material has the smoking article of low combustible with manufacturing method that before wrapping paper being held on the tobacco-containing material, on wrapping paper, applies.

Background technology

A lot of diverse ways have been suggested and have been used to make the cigarette of smoking article with low combustible-for example, and above-mentioned combustibility means when the smoker does not suck cigarette from the tendency of horizontal blanking.Its purpose is to pawn when dropping on or placing on the inflammable substrate, and these cigarettes can be from horizontal blanking before lighting inflammable substrate.People recognize that the structure of packaging material has appreciable impact to the combustion rate of cigarette, and through adopting the whole bag of tricks material that changes package, can produce a kind of cigarette from horizontal blanking.

According to disclosing of EP0483998 and EP0262550; The method of packaging material that a kind of manufacturing is used to have the smoking article of low combustible is to add tape loading to wrapping paper; Wherein, the composition of wrapping paper and paper tape is selected so that produce the synthetic paper with required combustion rate.

According to US4,945,932 disclose, another kind of method is through such as impression on paper the paper tape with littler and bigger gas permeability being provided.

A kind of further method is with the chemical mode treatment paper through on cigarette paper, applying fire proofing.Flame-retardant additive generally is applied in the pattern such as band, extends all around around cigarette at band described in the cigarette that finally assembles.A kind ofly be used for making this suitable method that band paper is arranged and be disclosed W098/01233.These have band paper to have a plurality of defectives.At first, the cost of these paper generally is four to five times of cost of standard cigarette paper.This is owing to due to the following cost: add the cost of material and in order before making cigarette with conventional method, to apply banded additive and dry paper provides the independent equipment and the additional manufacturing cost of manufacturing procedure.In addition, when paper was used to make cigarette, said band was in the optional position along the length of cigarette.Have only that said to take being only near filter-tip part of present cigarette out of optimal, and paper tape is unsatisfactory when appearing at an end of the other end of cigarette-promptly sucked at first.This is expectation towards sucking terminal from horizontal blanking because of cigarette, and cigarette is not just expected from horizontal blanking when sucking initial several millimeters.When use has band paper, can't guarantee that said band is placed in ad-hoc location along cigarette.

A kind of further method of making low combustible cigarette is to use does not have band paper, and this paper has extremely low permeability, and general about is 5 Coresta units (CU).These do not have band paper ratio has band paper cheap, but also has number of drawbacks.At first, and the band stationery is arranged seemingly, along the total length of paper be constant from the horizontal blanking element, so cigarette maybe be in any position from horizontal blanking.In addition, extremely low permeability means that vexed combustion rate is very low in the smoking overall process, and therefore, in order to discharge whole tar contents, every suction tar content once is very low.The low naturally osmotic property of paper means that more carbon monoxide is difficult to from tobacco rod, spread, and makes that the carbon monoxide/tar rate in the cigarette usually can be very high.The increase of ventilation-can not increase combustion rate significantly such as bore a hole through static (EP), but can dilute the cigarette amount that every suction once produces.In addition, have been found that the physics that changes paper and chemical characteristic possibly influence it through lighting the ability of flammable test (LIPT) relatively lessly, so the CU standard of hypotonicity paper is set at needs and is lower than optimum value, to guarantee to meet and pass through LIPT.

Attempted in the cigarette manufacture process, applying band.This method allows when tobacco has been packaged in the band paper, through make be coated be with and the excision forming tobacco rod synchronous, and make said band be placed in desired position.This method has overcome along with making the band orientation problem that band paper is arranged and produce in advance.This online method that is coated with band is disclosed among WO2004/057986 and the US2004/0261805.Yet these processes have other defective, and this means does not have such system to be applied to commodity production.A problem is in case fire-retardant solvent is applied in, and then also needs dry paper.At first, paper must be at the decorative position of machine-be that tobacco is dried by before the place of wrapper, if because paper is still humidity with stage that tobacco contact the time, paper may fade so.In addition, the machine that is used for containers of cigarettes can be repacked into comprises the part that applies fire-retardant solvent, and this machine applies very big pulling force to paper, and when paper is humidity, be easy to take place tearing of paper to such an extent as to its tensile strength can obviously reduce.Various heaters can be placed in the machine helping dry paper, but in order to reserve paper by suitable time of oven dry of these heaters, machine must slow down.The deceleration of machine also can alleviate the problem that paper is torn, but this can reduce production efficiency.

Summary of the invention

The invention provides a kind of method of making a plurality of smoking articles, this method comprises: provide permeability to be lower than the wrapping paper of 15CU; According to predetermined pattern fire-retardant interpolation material is applied to said wrapping paper; Hold tobacco-containing material with said wrapping paper and pack bar to form; And cut said packing bar to form said a plurality of smoking article.

The present invention also provides a kind of smoking article, and this smoking article comprises: the bar of tobacco-containing material; Wrapping paper around the bar of said tobacco-containing material; This wrapping paper has the pattern that is applied to the fire-retardant interpolation material on it, and in the zone that does not have flame-retardant additive, the permeability of this wrapping paper is lower than 15CU; In the zone that is applied with additive, the permeability of this wrapping paper is lower.

The hypotonicity of paper means, only needs to add more a spot of fire proofing and just can obtain desired from the horizontal blanking effect.This has reduced the problem that more a large amount of fire proofings brings that applies, for example the problem of tearing when paper is moist.This means that in a continuous process of cigarette manufacture, applying of fire proofing can more easily be implemented.The required step of heating/drying reduces, and is applied before or after the flame-retardant additive although heating steps possibly still can be added on alternatively.In addition, the more hypotonicity of the minimizing of flame-retardant additive quantity and paper combines, and makes On-line Control to a certain degree be maintained, such as so that consider the variation of lateral lattice and density of tobacco.

Preferably, the permeability of wrapping paper is 5 to 10CU.

In the method for the invention, preferably, the cutting that applies and pack bar of fire-retardant interpolation material is synchronous, so that pattern is positioned at the precalculated position with respect to an end of each smoking article.Preferably, the packing bar is cut so that pattern all is positioned at identical substantially position on each smoking article.Preferably, the packing bar is cut so that pattern covers the length of smoking article 25%-50% at an end of smoking article.Preferably, filter tip is attached to an end that forms figuratum smoking article.

Preferably, pattern comprises a plurality of bands, and in smoking article, these bands extend around the periphery of smoking article.

Preferably,, add 10% the fire-retardant interpolation material be lower than paper weight, be preferably lower than 8% in the figuratum zone of applying of said paper.More preferably, add the fire-retardant interpolation material of the 0%-5% of paper weight, be most preferably 2%-5%.

Preferably, flame-retardant additive comprises in the following one or more: glue, for example guar gum, Arabic gum etc.; Adhesive, for example starch, hot melt adhersive, PVA etc.; Organic salt, for example alginates and citrate; Inorganic salts, for example chlorate (such as KCL) and saline oxide (such as MgO).

Can apply said pattern through the mode of printing or spraying.

Preferably, additive is applied to the inner surface of paper, and the additive that is applied is in viscosity, type, temperature and the level of liquid form, comes dry said paper thereby need not extra heating operation.In this case, additive can directly be applied before tobacco is added into the zone on the paper bed, thereby only need do minimum repacking to manufacturing installation, and production efficiency can not be affected yet.

Description of drawings

To illustrate and describe preferred implementation of the present invention at present, in the accompanying drawing:

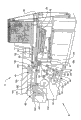

Fig. 1 is the sketch map of cigarette manufacturing machine that is applicable to the method for embodiment of the present invention; And

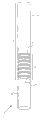

Fig. 2 shows the smoking article according to an embodiment of the invention.

The specific embodiment

Fig. 1 shows a kind of cigarette production machine 10 of type known in this field, and this device is refitted and before wrapping paper being formed cigarette, on wrapping paper, applies fire-retardant interpolation material for being used for.Cigarette production machine 10 comprises a kind of tobacco-containing material 20, and it is provided to chimney zone 16, and it is upwards blown to the lower external face of ring-type induction system 28 by air-flow 22 in this zone.Ring-type induction system 28 comprises porous belts 32; This porous belts 32 has area of low pressure 41; Tobacco-containing material 20 is drawn in the area of low pressure 41, and wherein porous belts 32 bottom that abuts against induction system 28 maintains tobacco-containing material, to form the tobacco-containing material stream of carrying towards decorative parts 45.

Selectively, paper 55 can be heated to help dry paper before through applying portion 70.After pattern was applied in, further heater 120-was such as infrared heater, but heating paper.

The side that applying portion 70 is set to be used for paper feeding 50 applies fire-retardant interpolation material, and this side will be the inboard of packaging material, just when packaging material in decorative parts 45 during around tobacco-containing material 20 packings in the face of the side of tobacco.

According to the present invention, packaging material 55 are a kind of paper, and the initial permeability of this paper is lower than 15CU, is preferably 5 to 10CU.The use of hypotonicity paper means that even without flame-retardant additive, finished cigarette has also had the bigger tendency from horizontal blanking, though there is not flame-retardant additive, will be not enough to through lighting flammable test from the horizontal blanking characteristic.Yet the amount that hypotonicity paper allows to add the flame-retardant additive in the paper to really is reduced to certain level, thereby makes that on finished paper the addition of flame-retardant additive is lower than 8% of paper weight, is preferably 0% to 5%, more preferably is 2% to 5%.

Owing to the decrement of fire retardant,, the drying of paper 55 possibly no longer need heater 120 thereby being able to improvement.If do not need heater 120, preferably, the inlet location that applying portion 70 will be positioned as close to decorative parts 45 is to prevent gathering or losing of when paper 55 forms the packing tobacco rod before through further cylinder in decorative parts 45 LIP solution.

In decorative parts 45, decorate conveyer belt 130 and below rail assembly 140, carry paper 55 along passing through to decorate approach cone 144.Tobacco-containing material 20 is carried by conveyer belt 32, and is placed on the paper web 55, and finger-like rail assembly 140 guides to decorative parts 45 with filling material 20 from porous conveyer belt 32 with decoration approach cone 144.Decorative parts 45 also comprises the tongue piece 160 that is positioned on the path of decorating conveyer belt 132.Thereby tongue piece 160 makes smokable filler 20 shrink tongue piece 160 on wrapping paper 55 and limits the passage that a cross section reduces with conveyer belt 130, thereby forms tobacco-containing material bar 170 so that tobacco-containing material is compressed.The fold mechanism 180 that is positioned at the downstream of tongue piece 160 further compresses tobacco-containing material 20 and folds paper webs 55 around bar 170.Adhesive applicator 184 applies the lap that adhesive also is fixed to this edge paper web 55 for the edge of paper web.Bar 170 leads to cutting part 186 then continuously, and it is divided into a plurality of smoking articles 190,191 by cutter at this cutting part.Cutter is positioned on the knife rest 192.

Cutter and applying portion 70 are synchronous, thereby bar 170 is cut in some position, make the pattern of the fire proofing on the wrapping paper be positioned in a plurality of smoking articles 190,191 specific location on each.Particularly, pattern can be applied to an end of each bar, preferably along initial 25%-50% of bar length.Filter tip is applied to the end with fire proofing pattern subsequently, and is fixed on the tipping paper with mode as known in the art.

Bar is cut into can the realizing through machinery or electrical method synchronously of position of cutter and the band of a plurality of parts.In mechanical means, the gear drive that moves cutter applies device through a series of connectors and additive and directly links to each other.In electrical method, be used for by cutter electric pulse regularly and apply device mechanism regularly.

Fig. 2 shows one according to the smoking article of making through above-mentioned technology 1 of the present invention.Smoking article 1 comprises the packing bar 2 of tobacco-containing material, and the one of which end has filter tip 3.With tipping paper with filter tip with pack bar 2 and link to each other, and packing bar 2 comprise pack paper around the tobacco core.Wrapping paper has the pattern that is applied to the fire-retardant interpolation material on it, and this pattern comprises a plurality ofly isolatedly is with 4.This pattern is positioned at filter tip one end of bar 2.Preferably, be with 4 will be 1 millimeter or wideer (being preferably the 2-5 millimeter), be applied with length 1 with 4 packing bar 2

2Be the length 1 of whole packing bar 2

125% to 50%.

In the zone that does not have flame-retardant additive, the permeability of wrapping paper is lower than 15CU, and in the zone that is applied with additive, its permeability is lower.Preferably, in the zone that does not have flame-retardant additive, the permeability of paper is 5 to 10CU.

Claims (22)

1. method of making a plurality of smoking articles comprises:

Provide permeability to be lower than the wrapping paper of 15CU;

According to predetermined pattern fire-retardant interpolation material is applied to said wrapping paper;

Hold tobacco-containing material with said wrapping paper and pack bar to form; And

Cut said packing bar to form said a plurality of smoking article.

2. the method for claim 1, the permeability of wherein said wrapping paper are 5 to 10CU.

3. according to claim 1 or claim 2 method comprises that further to make applying with the cutting of said packing bar of fire-retardant interpolation material synchronous, so that said pattern is positioned at the precalculated position with respect to an end of each smoking article.

4. method as claimed in claim 3, wherein said packing bar is cut, so that said pattern all is positioned at identical substantially position on each smoking article.

5. like the described method of aforementioned each claim, wherein said pattern comprises a plurality of bands, extends around the periphery of smoking article at a plurality of bands described in the smoking article.

6. like the described method of aforementioned each claim, wherein, in the zone that is applied with said pattern of said paper, the addition of fire-retardant interpolation material is lower than 10% of paper weight.

7. like the described method of aforementioned each claim, wherein, in the zone that is applied with said pattern of said paper, the addition of fire-retardant interpolation material is the 2%-5% of paper weight.

8. like the described method of aforementioned each claim, wherein said pattern is applied to said paper, thereby forms the 25%-50% that accounts for the packing pole length at an end of packing bar.

9. method as claimed in claim 8 further comprises an end that is formed with said pattern that filter tip is attached to the packing bar.

10. like the described method of aforementioned each claim, wherein flame-retardant additive comprises glue, adhesive or organic salt or inorganic salts.

11. like the described method of aforementioned each claim, wherein said pattern applies through printing.

12. like the described method of aforementioned each claim, wherein said pattern applies through spraying.

13. as the described method of aforementioned each claim, comprise the heating said additive and will heat after additive be applied on the said paper.

14. as the described method of aforementioned each claim, be included in to apply and heat said paper after the said pattern.

15. a smoking article comprises:

The bar of tobacco-containing material;

Wrapping paper around the bar of said tobacco-containing material; This wrapping paper has the pattern that is applied to the fire-retardant interpolation material on it, and in the zone that does not have flame-retardant additive, the permeability of this wrapping paper is lower than 15CU; In the zone that is applied with additive, the permeability of this wrapping paper is lower.

16. smoking article as claimed in claim 15, wherein in the zone that does not have flame-retardant additive, the permeability of this wrapping paper is 5 to 10CU.

17. like claim 15 or 16 described smoking articles, wherein said pattern comprises a plurality of bands, said a plurality of bands extend around the periphery of smoking article.

18. like claim 15,16 or 17 described smoking articles, wherein, in the zone that is applied with said pattern of said paper, the content of fire-retardant interpolation material is lower than 10% of paper weight.

19. like each described smoking article in the claim 15 to 18, wherein, in the zone that is applied with said pattern of said paper, the addition of fire-retardant interpolation material is the 2%-5% of paper weight.

20. like each described smoking article in the claim 15 to 19, further comprise the filter tip that is positioned at packing bar one end, wherein said pattern is formed on a part of length adjacent with said filter tip of packing bar.

21. like each described smoking article in the claim 15 to 20, wherein said pattern is formed on the zone of half length that accounts for the packing bar substantially.

22. like each described smoking article in the claim 15 to 21, wherein flame-retardant additive comprises glue, adhesive or organic salt or inorganic salts.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GBGB0903136.0A GB0903136D0 (en) | 2009-02-25 | 2009-02-25 | Smoking articles and method for manufacturing smoking articles |

| GB0903136.0 | 2009-02-25 | ||

| PCT/EP2010/050803 WO2010097258A1 (en) | 2009-02-25 | 2010-01-25 | Smoking articles and method for manufacturing smoking articles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102333461A true CN102333461A (en) | 2012-01-25 |

Family

ID=40565647

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010800093326A Pending CN102333461A (en) | 2009-02-25 | 2010-01-25 | Smoking articles and method for manufacturing smoking articles |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US20110315153A1 (en) |

| EP (1) | EP2400864A1 (en) |

| JP (1) | JP6016364B2 (en) |

| KR (1) | KR20110120968A (en) |

| CN (1) | CN102333461A (en) |

| AU (1) | AU2010219107B2 (en) |

| BR (1) | BRPI1007863A2 (en) |

| CA (1) | CA2751670A1 (en) |

| CL (1) | CL2011002058A1 (en) |

| GB (1) | GB0903136D0 (en) |

| MX (1) | MX2011008646A (en) |

| NZ (1) | NZ594550A (en) |

| RU (1) | RU2542548C2 (en) |

| UA (1) | UA102433C2 (en) |

| WO (1) | WO2010097258A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111065283A (en) * | 2017-08-24 | 2020-04-24 | 日本烟草国际股份有限公司 | Wrapping paper for smoking articles |

| CN114051382A (en) * | 2019-06-11 | 2022-02-15 | 尼科创业贸易有限公司 | Mouthpiece and article for use in an aerosol provision system |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB201007946D0 (en) * | 2010-05-12 | 2010-06-30 | British American Tobacco Co | Filter additive |

| ES2393460B1 (en) * | 2011-06-09 | 2013-10-18 | Miquel Y Costas & Miquel, S.A. | COMPOSITION FOR COVERING A PAPER WRAPPING OF SMOKING ITEMS |

| EP2570041A1 (en) | 2011-09-15 | 2013-03-20 | British American Tobacco (Investments) Limited | Smoking article and manufacture thereof |

| US8807140B1 (en) * | 2012-08-24 | 2014-08-19 | Njoy, Inc. | Electronic cigarette configured to simulate the texture of the tobacco rod and cigarette paper of a traditional cigarette |

| ES2746864T3 (en) | 2015-05-29 | 2020-03-09 | Philip Morris Products Sa | Method for making cut tobacco filler |

| GB201719523D0 (en) * | 2017-11-24 | 2018-01-10 | British American Tobacco Investments Ltd | Smoking article |

| CN113453567B (en) * | 2019-03-22 | 2023-05-05 | 日本烟草产业株式会社 | Method for manufacturing smoking article |

| EP4152972A1 (en) * | 2020-05-19 | 2023-03-29 | Philip Morris Products S.A. | Modified aerosol-generating article with flame retardant wrapper |

| EP4152973A1 (en) * | 2020-05-19 | 2023-03-29 | Philip Morris Products S.A. | Aerosol-generating article with combustion preventing wrapper |

| GB202115008D0 (en) * | 2021-10-20 | 2021-12-01 | Nicoventures Trading Ltd | Article with combustion retarding properties and uses thereof |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0482568A1 (en) * | 1990-10-23 | 1992-04-29 | R.J. Reynolds Tobacco Company | Cigarette |

| US5152304A (en) * | 1989-10-31 | 1992-10-06 | Philip Morris Incorporated | Wrapper for a smoking article |

| US5450863A (en) * | 1992-03-18 | 1995-09-19 | Philip Morris Incorporated | Smoking article wrapper and method for making same |

| EP0532193B1 (en) * | 1991-09-10 | 1996-07-03 | Philip Morris Products Inc. | Smoking article wrapper for controlling burn rate and method for making same |

| CN1612700A (en) * | 2002-01-23 | 2005-05-04 | 施韦特-莫迪国际公司 | Smoking articles with reduced ignition proclivity characteristics |

| US20060005847A1 (en) * | 2001-08-14 | 2006-01-12 | R.J. Reynolds Tobacco Company | Wrapping materials for smoking articles |

| CN1903570A (en) * | 2005-07-27 | 2007-01-31 | 豪尼机械制造股份公司 | Printing unit of the tobacco processing industry |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4739775A (en) | 1986-09-26 | 1988-04-26 | Kimberly-Clark Corporation | Wrapper constructions for self-extinguishing and reduced ignition proclivity smoking articles |

| DE3802645A1 (en) | 1988-01-29 | 1989-08-10 | Reemtsma H F & Ph | QUICK OR SELF-EXTINGUISHING CIGARETTE |

| EP0483998A1 (en) | 1990-10-30 | 1992-05-06 | Philip Morris Products Inc. | Wrapper making process for smoking articles |

| AU2401801A (en) * | 1999-12-27 | 2001-07-09 | Japan Tobacco Inc. | Wrapping paper for cigarette and cigarette |

| AU2001284488A1 (en) * | 2000-09-08 | 2002-03-22 | Japan Tobacco Inc. | Method and device for producing low flame propagation cigarette |

| US6645605B2 (en) * | 2001-01-15 | 2003-11-11 | James Rodney Hammersmith | Materials and method of making same for low ignition propensity products |

| US20020179105A1 (en) * | 2001-02-26 | 2002-12-05 | Zawadzki Michael A. | Reduced ignition propensity smoking article |

| US7073514B2 (en) * | 2002-12-20 | 2006-07-11 | R.J. Reynolds Tobacco Company | Equipment and methods for manufacturing cigarettes |

| AT5523U1 (en) * | 2001-10-22 | 2002-08-26 | Tann Papier | CIGARETTE WITH INCREASED SELF-DELETING TENDENCY |

| US20040261805A1 (en) | 2002-04-30 | 2004-12-30 | Brown & Williamson Tobacco Corporation | Smoking article |

| WO2004047572A1 (en) * | 2002-11-25 | 2004-06-10 | R.J. Reynolds Tobacco Company | Wrapping materials for smoking articles |

| US7234471B2 (en) * | 2003-10-09 | 2007-06-26 | R. J. Reynolds Tobacco Company | Cigarette and wrapping materials therefor |

| US7281540B2 (en) * | 2002-12-20 | 2007-10-16 | R.J. Reynolds Tobacco Company | Equipment and methods for manufacturing cigarettes |

-

2009

- 2009-02-25 GB GBGB0903136.0A patent/GB0903136D0/en not_active Ceased

-

2010

- 2010-01-25 MX MX2011008646A patent/MX2011008646A/en active IP Right Grant

- 2010-01-25 WO PCT/EP2010/050803 patent/WO2010097258A1/en active Application Filing

- 2010-01-25 EP EP10701147A patent/EP2400864A1/en not_active Withdrawn

- 2010-01-25 CN CN2010800093326A patent/CN102333461A/en active Pending

- 2010-01-25 JP JP2011550496A patent/JP6016364B2/en not_active Expired - Fee Related

- 2010-01-25 CA CA2751670A patent/CA2751670A1/en not_active Abandoned

- 2010-01-25 NZ NZ594550A patent/NZ594550A/en not_active IP Right Cessation

- 2010-01-25 UA UAA201111255A patent/UA102433C2/en unknown

- 2010-01-25 KR KR1020117022369A patent/KR20110120968A/en active Search and Examination

- 2010-01-25 RU RU2011139186/12A patent/RU2542548C2/en not_active IP Right Cessation

- 2010-01-25 AU AU2010219107A patent/AU2010219107B2/en not_active Ceased

- 2010-01-25 US US13/203,118 patent/US20110315153A1/en not_active Abandoned

- 2010-01-25 BR BRPI1007863A patent/BRPI1007863A2/en not_active IP Right Cessation

-

2011

- 2011-08-23 CL CL2011002058A patent/CL2011002058A1/en unknown

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5152304A (en) * | 1989-10-31 | 1992-10-06 | Philip Morris Incorporated | Wrapper for a smoking article |

| EP0482568A1 (en) * | 1990-10-23 | 1992-04-29 | R.J. Reynolds Tobacco Company | Cigarette |

| EP0532193B1 (en) * | 1991-09-10 | 1996-07-03 | Philip Morris Products Inc. | Smoking article wrapper for controlling burn rate and method for making same |

| US5450863A (en) * | 1992-03-18 | 1995-09-19 | Philip Morris Incorporated | Smoking article wrapper and method for making same |

| US20060005847A1 (en) * | 2001-08-14 | 2006-01-12 | R.J. Reynolds Tobacco Company | Wrapping materials for smoking articles |

| CN1612700A (en) * | 2002-01-23 | 2005-05-04 | 施韦特-莫迪国际公司 | Smoking articles with reduced ignition proclivity characteristics |

| CN1903570A (en) * | 2005-07-27 | 2007-01-31 | 豪尼机械制造股份公司 | Printing unit of the tobacco processing industry |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111065283A (en) * | 2017-08-24 | 2020-04-24 | 日本烟草国际股份有限公司 | Wrapping paper for smoking articles |

| CN111065283B (en) * | 2017-08-24 | 2022-04-26 | 日本烟草国际股份有限公司 | Wrapping paper for smoking articles |

| CN114051382A (en) * | 2019-06-11 | 2022-02-15 | 尼科创业贸易有限公司 | Mouthpiece and article for use in an aerosol provision system |

Also Published As

| Publication number | Publication date |

|---|---|

| GB0903136D0 (en) | 2009-04-08 |

| AU2010219107A1 (en) | 2011-09-01 |

| JP6016364B2 (en) | 2016-10-26 |

| CL2011002058A1 (en) | 2012-04-20 |

| WO2010097258A1 (en) | 2010-09-02 |

| RU2011139186A (en) | 2013-04-10 |

| AU2010219107B2 (en) | 2014-10-02 |

| KR20110120968A (en) | 2011-11-04 |

| NZ594550A (en) | 2013-03-28 |

| CA2751670A1 (en) | 2010-09-02 |

| JP2012518393A (en) | 2012-08-16 |

| RU2542548C2 (en) | 2015-02-20 |

| EP2400864A1 (en) | 2012-01-04 |

| MX2011008646A (en) | 2011-09-06 |

| BRPI1007863A2 (en) | 2016-02-23 |

| UA102433C2 (en) | 2013-07-10 |

| US20110315153A1 (en) | 2011-12-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102333461A (en) | Smoking articles and method for manufacturing smoking articles | |

| JP7258942B2 (en) | Rods used for smoking articles | |

| JP6668318B2 (en) | Electrically operated aerosol generation system | |

| TWI612906B (en) | Flavoured rods for use in aerosol-generating articles | |

| KR102311146B1 (en) | Heated aerosol-generating articles comprising improved rods | |

| RU2628987C2 (en) | Mixed rods for use in aerosol-generating products | |

| KR100524295B1 (en) | Method of manufacturing low spreading smoking article | |

| KR102142343B1 (en) | Thermally conducting rods for use in aerosol-generating articles | |

| RU2352228C1 (en) | Device for production of rodlike smoking products | |

| CN102939020A (en) | Method for manufacturing smoking articles and smoking articles | |

| CZ291345B6 (en) | Fuel component for a smoking article and process for producing thereof | |

| HU228650B1 (en) | Cigarette and method of manufacturing cigarette for electrical smoking system | |

| KR20170100502A (en) | Hydrophobic filter | |

| CN102892313A (en) | Lip smoking article wrapper, smoking article, method and apparatus | |

| JP2023082072A (en) | Apparatus and method for producing rod of aerosol-generating material | |

| US20220015410A1 (en) | Conveyor and method for conveying strands of aerosol-generating material, and apparatus and method for producing a rod of aerosol-generating material | |

| MXPA97009722A (en) | Cigarette and method to manufacture a cigarette for an electrical system for fu |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1166451 Country of ref document: HK |

|

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20120125 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1166451 Country of ref document: HK |