CN101806247B - 通过性能加热优化燃用低btu燃料的联合循环发电设备 - Google Patents

通过性能加热优化燃用低btu燃料的联合循环发电设备 Download PDFInfo

- Publication number

- CN101806247B CN101806247B CN2010101271356A CN201010127135A CN101806247B CN 101806247 B CN101806247 B CN 101806247B CN 2010101271356 A CN2010101271356 A CN 2010101271356A CN 201010127135 A CN201010127135 A CN 201010127135A CN 101806247 B CN101806247 B CN 101806247B

- Authority

- CN

- China

- Prior art keywords

- gas

- blast furnace

- turbine

- heating unit

- power plant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000010438 heat treatment Methods 0.000 title claims abstract description 46

- 238000005457 optimization Methods 0.000 title description 2

- 239000007789 gas Substances 0.000 claims abstract description 125

- 239000006227 byproduct Substances 0.000 claims abstract description 26

- 239000000446 fuel Substances 0.000 claims abstract description 20

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims abstract description 15

- 239000000203 mixture Substances 0.000 claims abstract description 15

- 239000003546 flue gas Substances 0.000 claims abstract description 14

- 239000002737 fuel gas Substances 0.000 claims description 43

- 238000002485 combustion reaction Methods 0.000 claims description 24

- 239000002912 waste gas Substances 0.000 claims description 24

- 238000000034 method Methods 0.000 claims description 6

- 238000011084 recovery Methods 0.000 claims description 4

- 229910000831 Steel Inorganic materials 0.000 description 7

- 239000010959 steel Substances 0.000 description 7

- 238000010586 diagram Methods 0.000 description 4

- 239000008246 gaseous mixture Substances 0.000 description 4

- 230000014509 gene expression Effects 0.000 description 4

- 239000000047 product Substances 0.000 description 4

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 238000007599 discharging Methods 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 229910000805 Pig iron Inorganic materials 0.000 description 1

- 239000000571 coke Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 230000002269 spontaneous effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C7/00—Features, components parts, details or accessories, not provided for in, or of interest apart form groups F02C1/00 - F02C6/00; Air intakes for jet-propulsion plants

- F02C7/22—Fuel supply systems

- F02C7/224—Heating fuel before feeding to the burner

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01K—STEAM ENGINE PLANTS; STEAM ACCUMULATORS; ENGINE PLANTS NOT OTHERWISE PROVIDED FOR; ENGINES USING SPECIAL WORKING FLUIDS OR CYCLES

- F01K23/00—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids

- F01K23/02—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled

- F01K23/06—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled combustion heat from one cycle heating the fluid in another cycle

- F01K23/10—Plants characterised by more than one engine delivering power external to the plant, the engines being driven by different fluids the engine cycles being thermally coupled combustion heat from one cycle heating the fluid in another cycle with exhaust fluid of one cycle heating the fluid in another cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C3/00—Gas-turbine plants characterised by the use of combustion products as the working fluid

- F02C3/20—Gas-turbine plants characterised by the use of combustion products as the working fluid using a special fuel, oxidant, or dilution fluid to generate the combustion products

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C6/00—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use

- F02C6/04—Gas-turbine plants providing heated or pressurised working fluid for other apparatus, e.g. without mechanical power output

- F02C6/06—Gas-turbine plants providing heated or pressurised working fluid for other apparatus, e.g. without mechanical power output providing compressed gas

- F02C6/08—Gas-turbine plants providing heated or pressurised working fluid for other apparatus, e.g. without mechanical power output providing compressed gas the gas being bled from the gas-turbine compressor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C6/00—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use

- F02C6/18—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use using the waste heat of gas-turbine plants outside the plants themselves, e.g. gas-turbine power heat plants

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F22—STEAM GENERATION

- F22B—METHODS OF STEAM GENERATION; STEAM BOILERS

- F22B1/00—Methods of steam generation characterised by form of heating method

- F22B1/02—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers

- F22B1/18—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines

- F22B1/1807—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines using the exhaust gases of combustion engines

- F22B1/1815—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines using the exhaust gases of combustion engines using the exhaust gases of gas-turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F22—STEAM GENERATION

- F22B—METHODS OF STEAM GENERATION; STEAM BOILERS

- F22B1/00—Methods of steam generation characterised by form of heating method

- F22B1/02—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers

- F22B1/18—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines

- F22B1/1838—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines the hot gas being under a high pressure, e.g. in chemical installations

- F22B1/1846—Methods of steam generation characterised by form of heating method by exploitation of the heat content of hot heat carriers the heat carrier being a hot gas, e.g. waste gas such as exhaust gas of internal-combustion engines the hot gas being under a high pressure, e.g. in chemical installations the hot gas being loaded with particles, e.g. waste heat boilers after a coal gasification plant

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E20/00—Combustion technologies with mitigation potential

- Y02E20/14—Combined heat and power generation [CHP]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E20/00—Combustion technologies with mitigation potential

- Y02E20/16—Combined cycle power plant [CCPP], or combined cycle gas turbine [CCGT]

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

Abstract

本发明涉及通过性能加热优化燃用低BTU燃料的联合循环发电设备。公开了一种使用来自联合循环发电设备(200)中的燃气轮机压缩机(240)的压缩空气流排放物以及性能加热来提高设备性能的优化措施。在一个实施例中,对副产物废气的转向的部分和压缩空气流排放物进行燃烧加热,以产生高温烟气(285),在燃料的加压混合物被供应至燃气轮机燃烧器(245)之前,使用该高温烟气(285)对该燃料的加压混合物进行性能加热。

Description

技术领域

本发明大体涉及燃用低BTU燃料的联合循环发电设备,且更特别地讲,涉及通过对燃料进行性能加热(performance heating)来优化供应给燃气轮机的燃料以及提高联合循环发电设备中的效率和功率输出。背景技术

燃用低BTU燃料的联合循环发电设备是这样一种类型的联合循环发电设备:已经实施这种联合循环发电设备,以便与传统的锅炉发电设备相比提供更高的效率及更低的排放。低-BTU气体,诸如鼓风炉气体(BFG)和焦炉气(COG),通常在炼钢厂中生产生铁期间作为焦炭燃烧以及鼓风炉中的铁矿石熔体的副产物而产生。在发电设备现场中,回收低BTU气体,并将其用作燃气轮机联合循环发电解决方案中的燃料,燃气轮机联合循环发电解决方案可产生用于炼钢厂以及出售给公共电网两者的电能。发明内容

在本发明的一方面,提供了一种基于低BTU燃料的联合循环发电设备。该联合循环发电设备包括混合副产物废气的气体混合单元。联接到气体混合单元上的燃料气体压缩机对副产物废气的混合物加压。燃气轮机由来自燃料气体压缩机的副产物废气的加压混合物供以燃料。燃气轮机包括:压缩机;燃烧器,该燃烧器接收来自压缩机的空气以及来自燃料气体压缩机的副产物废气的加压混合物,以使它们燃烧;以及涡轮,该涡轮使由来自压缩机的空气和来自燃料气体压缩机的副产物废气的加压混合物的燃烧所产生的热气体膨胀。该联合 循环发电设备进一步包括燃烧加热(fired heating)单元,该燃烧加热单元接收副产物废气的转向的部分和来自燃气轮机压缩机的压缩空气流排放物,以使它们进行燃烧。副产物废气的转向的部分和压缩空气流排放物在燃烧加热单元中的燃烧产生高温烟气。联合循环发电设备还包括性能加热单元,在来自燃料气体压缩机的副产物废气的加压混合物进入燃气轮机燃烧器之前,该性能加热单元利用由燃烧加热单元产生的高温烟气来加热该来自燃料气体压缩机的副产物废气的加压混合物。

在本发明的另一方面,提供了一种燃用鼓风炉气体的联合循环发电设备。在本发明的该方面中,鼓风炉气体联合循环发电设备包括混合鼓风炉气体与焦炉气的气体混合单元。联接到气体混合单元上的燃料气体压缩机对鼓风炉气体和焦炉气的混合物加压。燃气轮机由来自燃料气体压缩机的鼓风炉气体与焦炉气的加压混合物供以燃料。燃气轮机包括:压缩机;燃烧器,其接收来自压缩机的空气和来自燃料气体压缩机的鼓风炉气体与焦炉气的加压混合物,以使它们进行燃烧;以及涡轮,涡轮使由来自压缩机的空气和来自燃料气体压缩机的鼓风炉气体与焦炉气的加压混合物的燃烧所产生的热气体膨胀。鼓风炉气体联合循环发电设备进一步包括燃烧加热单元,该燃烧加热单元接收鼓风炉气体的转向的部分和来自燃气轮机压缩机的压缩空气流排放物,以使它们进行燃烧。鼓风炉气体的转向的部分和压缩空气流排放物在燃烧加热单元中的燃烧产生高温烟气。鼓风炉气体联合循环发电设备还包括性能加热单元,在来自燃料气体压缩机的鼓风炉气体和焦炉气的加压混合物进入燃气轮机燃烧器之前,性能加热单元利用由燃烧加热单元所产生的高温烟气加热该来自燃料气体压缩机的鼓风炉气体和焦炉气的加压混合物。

在本发明的第三方面中,存在一种提高在鼓风炉气体联合循环发电设备中使用的低-BTU燃料的温度的方法。在本发明的该方面中,该方法包括:使鼓风炉气体与焦炉气混合;对鼓风炉气体和焦 炉气的混合物加压;对鼓风炉气体的转向的部分和来自燃气轮机压缩机的压缩空气流排放物进行燃烧加热,以使它们燃烧;以及在供应至燃气轮机燃烧器之前,利用由鼓风炉气体的转向的部分和压缩空气流排放物燃烧而产生的高温烟气对鼓风炉气体和焦炉气的加压混合物进行性能加热。附图说明

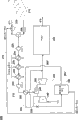

图1是传统的燃用BFG的联合循环发电设备的示意图;以及

图2是根据本发明的一个实施例的燃用BFG的联合循环发电设备的示意图。具体实施方式

参看附图,图1显示了传统的燃用BFG的联合循环发电设备100的示意图。如图1中所示,包括BFG和COG的副产物废气从炼钢厂110被供应到气体混合单元105。虽然图1中未示出,但可将从炼钢厂110排放的其它副产物废气(诸如Linz Donawitz气体(LDG)和COREX气体)用作低-BTU燃料。通常,供应至气体混合单元105的BFG的量远远多于COG的量。例如,混合单元105可从炼钢厂110接收大约250pps的BFG和大约10pps的COG。自炼钢厂110供应的BFG和COG两者的量通常处于低压,且因此由气体混合单元105产生的BFG和COG的混合物大体处于大约15.5psia的低压。该气体混合物需要被提高到较高的压力,以便用作用于燃气轮机燃烧器的燃料。

燃用BFG的联合循环发电设备100使用离心燃料气体压缩机115来将BFG和COG的气体混合物的压力提高到大约300psia。如图1中所示,燃料气体压缩机115是多级燃料气体压缩机,其在该实施例中包括第一燃料气体压缩机(FGC1)120和第二燃料气体压缩机 (FGC2)125。中间冷却单元130位于FGC1 120和FGC2 125之间,以便提高燃料气体压缩机115的效率。

燃料气体压缩机115将BFG和COG的该气体混合物供应给燃气轮机135。燃气轮机包括:压缩机140,其从入口导叶(IGV)抽取空气;燃烧器145,其接收来自压缩机140的压缩空气和来自燃料气体压缩机115的副产物废气的加压混合物,以使它们燃烧;以及涡轮150,其使由来自压缩机140的空气与来自燃料气体压缩机115的副产物废气的加压混合物燃烧而产生的热气体膨胀。如图1中所示,从压缩机140中排出压缩空气流排放物,其由参考元素155表示。供应压缩空气流排放物,以便与由涡轮150产生的排气产物(其由参考元素160表示)混合。压缩空气流的从压缩机140到涡轮150的排气的这种排放物被称为压缩机向外排放物(over-board bleed)(OBB),且完成其以防止压缩机140中的喘振。

热回收蒸汽发生器(HRSG)165接收来自涡轮150的排气产物,以便从该排气产物中回收废热。从排气产物回收的热被传递到HRSG 165中的废物/蒸汽中,以便产生被供应给蒸汽轮机(未示出)以驱动发电机(未示出)的蒸汽。来自HRSG165的冷却气体通过烟囱被排出到大气中。本领域技术人员将认识到,BFG联合循环发电设备100的该部分可具有其它构件(例如冷凝器,水管等),但为了便于示意本发明的实施例而将其省略。类似地,本领域技术人员将认识到,燃用BFG的联合循环发电设备100的与燃气轮机135相关的部分可具有未显示的其它构件(例如燃气轮机发电机),但为了便于示意本发明的实施例而省略了这些构件。

如本文所确定的,存在一些与燃用BFG的联合循环发电设备100的运行相关联的缺点。例如,因为BFG和COG的气体混合物具有低LHV,所以需要极大量的燃料在燃气轮机135的燃烧器145中获得燃烧温度。需要大量燃料的结果是燃料气体压缩机115将必须压缩更多的这种低LHV燃料。结果,燃料气体压缩机115有大量的功 率消耗,这会降低联合循环净输出。与燃用BFG的联合循环发电设备100的运行相关联的另一个缺点是利用OBB的方式。特别地,此处已发现将OBB从压缩机140排到涡轮150的排气160会降低联合循环发电设备100的总体效率。

图2是已经优化了以上所提到的缺点以便提高效率和功率输出的燃用BFG的联合循环发电设备200的示意图。图2中的与图1中所使用的构件类似的构件被赋予了相似的参考元素,只是图2中所使用的参考元素前面加了标号2。类似于图1,图2仅显示了燃用BFG的联合循环发电设备200的、阐述其运行和涉及其优化的本文所述的实施例所必须的部分。

如图2中所示,BFG气体分流器270在来自炼钢厂210的BFG于气体混合单元205中与COG混合之前使该BFG的一部分转向。在一个实施例中,BFG气体分流器270使具有大约15.5psia的压力以及大约104℉(40℃)的温度的大约21.5pps的BFG转向。BFG的转向的部分由参考元素275表示。

燃烧加热单元280接收BFG的转向的部分和从压缩机240排出的OBB255,以使它们燃烧。燃烧加热单元280产生由参考元素285表示的高温烟气。性能加热单元290使用高温烟气285来加热由燃料气体压缩机215所产生的BFG和COG的加压混合物,之后该混合物才进入燃气轮机255的燃烧器245。在一个实施例中,性能加热单元290是在将BFG和COG的加压混合物供应至燃烧器245之前使BFG和COG的加压混合物的温度升高大约250℉(121℃)的热交换器。来自性能加热单元295的排气295与来自燃气轮机255的涡轮250的排气260混合。虽然在一个实施例中,排气295与来自涡轮250的排气260在HRSG入口之前混合,但本领域技术人员将认识到,可将排气295供应至HRSG 265的其它中间位置而不与排气260混合。

如本文中所示,图2的效率和功率输出已得到提高,因为性能加热单元290利用来自燃烧加热单元280的高温烟气285预加热了BFG和COG的加压混合物。该特征表示需要较少的燃料通过燃料气体压缩机215来在燃气轮机255的燃烧器245中获得燃烧温度。结果,减少了燃料气体压缩机215的功率消耗,这会转化成燃用BFG的联合循环发电设备200的净输出和净效率的提高。同样,因为降低了燃料气体压缩机215的燃料流要求,所以在压缩机240处喘振边界有所放宽,这会转化成排出较少的OBB(即,减少大约30%)。结果,该特征还有助于提高燃用BFG的联合循环发电设备200的总体效率。因此,实施本文所包括的构思将提供大约+1.44MW的净联合循环输出增长和大约+0.37%的效率增长。

虽然已特别地显示了且结合本公开的优选实施例描述了本公开,但将了解的是,本领域技术人员将会想到变型和修改。因此,将理解的是,所附的权利要求书意图覆盖落在本公开的实际精神内的所有这样的修改和改变。

Claims (10)

1.一种基于低BTU燃料的联合循环发电设备,包括:

混合副产物废气的气体混合单元,其中,所述副产物废气包括鼓风炉气体和焦炉气;

联接到所述气体混合单元上、对副产物废气的混合物加压的燃料气体压缩机;

由来自所述燃料气体压缩机的副产物废气的加压混合物供以燃料的燃气轮机,所述燃气轮机包括:压缩机;燃烧器,所述燃烧器接收来自所述压缩机的空气以及来自所述燃料气体压缩机的副产物废气的加压混合物,以使该空气和该加压混合物燃烧;以及涡轮,所述涡轮使得由来自所述压缩机的空气和来自所述燃料气体压缩机的所述副产物废气的加压混合物的燃烧所产生的热气体膨胀;

燃烧加热单元,所述燃烧加热单元接收所述副产物废气的转向的部分和来自所述燃气轮机压缩机的压缩空气流排放物,以使该转向的部分和该排放物燃烧,其中由所述燃烧加热单元接收的所述副产物废气的转向的部分包括所述鼓风炉气体的一部分,所述副产物废气的转向的部分和所述压缩空气流排放物在所述燃烧加热单元中的燃烧产生高温烟气;以及

性能加热单元,在来自所述燃料气体压缩机的所述副产物废气的加压混合物进入所述燃气轮机燃烧器之前,所述性能加热单元利用由所述燃烧加热单元所产生的所述高温烟气来加热该来自所述燃料气体压缩机的所述副产物废气的加压混合物,其中,来自所述性能加热单元的排气与来自所述燃气轮机的排气混合。

2.根据权利要求1所述的联合循环发电设备,其特征在于,所述燃料气体压缩机包括多级燃料气体压缩机,其中至少一个中间冷却单元位于各级之间。

3.根据权利要求1所述的联合循环发电设备,其特征在于,所述性能加热单元包括热交换器。

4.根据权利要求1所述的联合循环发电设备,其特征在于,进一步包括接收来自所述燃气轮机的排气的热回收蒸汽发生器。

5.一种燃用鼓风炉气体的联合循环发电设备,包括:

使鼓风炉气体与焦炉气混合的气体混合单元;

联接到所述气体混合单元上、对所述鼓风炉气体和焦炉气的混合物加压的燃料气体压缩机;

由来自所述燃料气体压缩机的所述鼓风炉气体和焦炉气的加压混合物供以燃料的燃气轮机,所述燃气轮机包括:压缩机;燃烧器,所述燃烧器接收来自所述压缩机的空气和来自所述燃料气体压缩机的所述鼓风炉气体和焦炉气的加压混合物,以使该空气和该加压混合物燃烧;以及涡轮,所述涡轮使由来自所述压缩机的空气与来自所述燃料气体压缩机的所述鼓风炉气体和焦炉气的加压混合物的燃烧所产生的热气体膨胀;

燃烧加热单元,所述燃烧加热单元接收所述鼓风炉气体的转向的部分以及来自所述燃气轮机压缩机的压缩空气流排放物,以使该转向的部分和该排放物燃烧,所述鼓风炉气体的转向的部分和所述压缩空气流排放物在所述燃烧加热单元中的燃烧产生高温烟气;以及

性能加热单元,在来自所述燃料气体压缩机的所述鼓风炉气体和焦炉气的加压混合物进入所述燃气轮机燃烧器之前,所述性能加热单元利用由所述燃烧加热单元所产生的所述高温烟气来加热来自所述燃料气体压缩机的所述鼓风炉气体和焦炉气的加压混合物,其中,来自所述性能加热单元的排气与来自所述燃气轮机的排气混合。

6.根据权利要求5所述的鼓风炉气体联合循环发电设备,其特征在于,所述燃料气体压缩机包括多级燃料气体压缩机,其中至少一个中间冷却单元位于各级之间。

7.根据权利要求5所述的鼓风炉气体联合循环发电设备,其特征在于,所述性能加热单元包括热交换器。

8.根据权利要求5所述的鼓风炉气体联合循环发电设备,其特征在于,所述鼓风炉气体联合循环发电设备进一步包括接收来自所述燃气轮机的排气的热回收蒸汽发生器。

9.一种提高在鼓风炉气体联合循环发电设备中所使用的低-BTU燃料的温度的方法,包括:

混合鼓风炉气体和焦炉气;

对所述鼓风炉气体和焦炉气的混合物加压;

对所述鼓风炉气体的转向的部分和来自燃气轮机压缩机的压缩空气流排放物进行燃烧加热,以使该转向的部分和该排放物燃烧;以及

在将所述鼓风炉气体和焦炉气的加压混合物供应到燃气轮机燃烧器之前,利用由所述鼓风炉气体的转向的部分和所述压缩空气流排放物的燃烧所产生的高温烟气对所述鼓风炉气体和焦炉气的加压混合物进行性能加热,以及使来自所述性能加热的排气与来自所述燃气轮机的排气混合。

10.根据权利要求9所述的方法,其特征在于,所述方法进一步包括将来自燃气轮机的排气供应至热回收蒸汽发生器。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US12/369,180 | 2009-02-11 | ||

| US12/369,180 US8117821B2 (en) | 2009-02-11 | 2009-02-11 | Optimization of low-BTU fuel-fired combined-cycle power plant by performance heating |

| US12/369180 | 2009-02-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101806247A CN101806247A (zh) | 2010-08-18 |

| CN101806247B true CN101806247B (zh) | 2013-06-19 |

Family

ID=41718827

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010101271356A Expired - Fee Related CN101806247B (zh) | 2009-02-11 | 2010-02-11 | 通过性能加热优化燃用低btu燃料的联合循环发电设备 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US8117821B2 (zh) |

| EP (1) | EP2218888A2 (zh) |

| JP (1) | JP5101642B2 (zh) |

| CN (1) | CN101806247B (zh) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013058209A1 (ja) * | 2011-10-17 | 2013-04-25 | 川崎重工業株式会社 | 希薄燃料吸入ガスタービン |

| US8677729B2 (en) * | 2011-10-25 | 2014-03-25 | General Electric Company | System for heating a fuel |

| US9377202B2 (en) | 2013-03-15 | 2016-06-28 | General Electric Company | System and method for fuel blending and control in gas turbines |

| US9382850B2 (en) | 2013-03-21 | 2016-07-05 | General Electric Company | System and method for controlled fuel blending in gas turbines |

| CN104075344B (zh) | 2013-03-25 | 2016-07-06 | 通用电气公司 | 用低热值燃料启动和运作燃气轮机的燃料喷嘴系统和方法 |

| CN103670712B (zh) * | 2013-12-13 | 2017-01-04 | 中国大唐集团科学技术研究院有限公司 | 一种燃气轮机发电系统 |

| US20160273396A1 (en) * | 2015-03-19 | 2016-09-22 | General Electric Company | Power generation system having compressor creating excess air flow and heat exchanger therefor |

| US9828887B2 (en) * | 2015-03-19 | 2017-11-28 | General Electric Company | Power generation system having compressor creating excess air flow and turbo-expander to increase turbine exhaust gas mass flow |

| CN107869391A (zh) * | 2016-09-23 | 2018-04-03 | 熵零技术逻辑工程院集团股份有限公司 | 一种零排热发动机 |

| CA3053053C (en) * | 2017-03-20 | 2020-04-14 | Lanzatech, Inc. | A process and system for product recovery and cell recycle |

| JP7067349B2 (ja) * | 2018-08-02 | 2022-05-16 | 三浦工業株式会社 | 副生ガス利用システム |

| BR112021015449A2 (pt) | 2019-02-08 | 2021-10-05 | Lanzatech, Inc. | Métodos para recuperar produto a partir de um caldo de fermentação e para recuperar produto a partir de uma corrente enriquecida com produto |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4202168A (en) * | 1977-04-28 | 1980-05-13 | Gulf Research & Development Company | Method for the recovery of power from LHV gas |

| US6313544B1 (en) * | 1997-09-19 | 2001-11-06 | Solo Energy Corporation | Self-contained energy center for producing mechanical, electrical, and heat energy |

| CN1475663A (zh) * | 1997-09-18 | 2004-02-18 | 东芝株式会社 | 燃气轮机装置 |

| CN1671956A (zh) * | 2002-07-25 | 2005-09-21 | 西门子公司 | 用于冷却燃气轮机的冷却空气的冷却系统和方法 |

| CN101270689A (zh) * | 2008-04-30 | 2008-09-24 | 杭州杭氧透平机械有限公司 | 煤气化增压联合循环发电系统的能量转化和回收方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2925712A (en) * | 1952-12-12 | 1960-02-23 | Rolls Royce | Aircraft fuel system with fuel heating means |

| US5392595A (en) * | 1993-08-06 | 1995-02-28 | United Technologies Corporation | Endothermic fuel energy management system |

| US6216441B1 (en) | 1997-09-17 | 2001-04-17 | General Electric Co | Removal of inert gases from process gases prior to compression in a gas turbine or combined cycle power plant |

| US6065280A (en) | 1998-04-08 | 2000-05-23 | General Electric Co. | Method of heating gas turbine fuel in a combined cycle power plant using multi-component flow mixtures |

| DE19952885A1 (de) * | 1999-11-03 | 2001-05-10 | Alstom Power Schweiz Ag Baden | Verfahren und Betrieb einer Kraftwerksanlage |

| US6442941B1 (en) | 2000-09-11 | 2002-09-03 | General Electric Company | Compressor discharge bleed air circuit in gas turbine plants and related method |

| EP1199445A1 (de) | 2000-10-17 | 2002-04-24 | Siemens Aktiengesellschaft | Vorrichtung und Verfahren zur Brennstoffvorwärmung in kombinierten Gas- und Dampfturbinenanlagen |

| JP2002155762A (ja) * | 2000-11-17 | 2002-05-31 | Kawasaki Steel Corp | ガスタービン発電設備及びその制御方法 |

| US6499302B1 (en) | 2001-06-29 | 2002-12-31 | General Electric Company | Method and apparatus for fuel gas heating in combined cycle power plants |

| JP2003254085A (ja) * | 2002-03-04 | 2003-09-10 | Yuzo Terai | 製鉄コプロダクションの高炉送風加熱方式 |

| JP3905829B2 (ja) * | 2002-12-13 | 2007-04-18 | 三菱重工業株式会社 | ガスタービンの燃料ガスカロリー推定装置およびガスタービン |

| JP2006233920A (ja) | 2005-02-28 | 2006-09-07 | Mitsubishi Heavy Ind Ltd | 燃料ガスカロリー制御装置及びガスタービンシステム |

-

2009

- 2009-02-11 US US12/369,180 patent/US8117821B2/en not_active Expired - Fee Related

-

2010

- 2010-02-05 EP EP10152845A patent/EP2218888A2/en not_active Withdrawn

- 2010-02-09 JP JP2010026027A patent/JP5101642B2/ja not_active Expired - Fee Related

- 2010-02-11 CN CN2010101271356A patent/CN101806247B/zh not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4202168A (en) * | 1977-04-28 | 1980-05-13 | Gulf Research & Development Company | Method for the recovery of power from LHV gas |

| CN1475663A (zh) * | 1997-09-18 | 2004-02-18 | 东芝株式会社 | 燃气轮机装置 |

| US6313544B1 (en) * | 1997-09-19 | 2001-11-06 | Solo Energy Corporation | Self-contained energy center for producing mechanical, electrical, and heat energy |

| CN1671956A (zh) * | 2002-07-25 | 2005-09-21 | 西门子公司 | 用于冷却燃气轮机的冷却空气的冷却系统和方法 |

| CN101270689A (zh) * | 2008-04-30 | 2008-09-24 | 杭州杭氧透平机械有限公司 | 煤气化增压联合循环发电系统的能量转化和回收方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5101642B2 (ja) | 2012-12-19 |

| CN101806247A (zh) | 2010-08-18 |

| JP2010185454A (ja) | 2010-08-26 |

| US8117821B2 (en) | 2012-02-21 |

| EP2218888A2 (en) | 2010-08-18 |

| US20100199683A1 (en) | 2010-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101806247B (zh) | 通过性能加热优化燃用低btu燃料的联合循环发电设备 | |

| JP6591524B2 (ja) | 効率が向上した動力発生方法およびシステム | |

| US20070256424A1 (en) | Heat recovery gas turbine in combined brayton cycle power generation | |

| US7584598B2 (en) | Method for operating a gas turbine and a gas turbine for implementing the method | |

| EP2423467A2 (en) | Systems, Methods, And Apparatus For Modifying Power Output And Efficiency of A Combined Cycle Power Plant | |

| JP2010185454A5 (zh) | ||

| CN102128086A (zh) | 用于燃气涡轮的喷射器机外排出方案 | |

| AU659903B2 (en) | Apparatus and method for firing low caloric-value gas | |

| US20110266726A1 (en) | Gas turbine exhaust as hot blast for a blast furnace | |

| CN106762158A (zh) | 用于操作燃气涡轮的同时维持排放标准的系统和方法 | |

| EP1285151B1 (en) | Method and apparatus for power augmentation for gas turbine power cycles | |

| CN105443244A (zh) | 燃气-蒸汽联合循环发电机组两级煤气加压系统 | |

| US5906094A (en) | Partial oxidation power plants and methods thereof | |

| CN202328161U (zh) | 燃气轮机发电机组的三级煤气冷却装置 | |

| CN202643715U (zh) | 燃气蒸汽联合循环发电工艺余热利用系统 | |

| JP2013133823A (ja) | ガスタービンからの酸素エミッションを制御するシステム及び方法 | |

| CN113565589A (zh) | 喷射补燃压缩空气储能系统 | |

| CA2618007C (en) | A method for operating a gas turbine and a gas turbine for implementing the method | |

| Komori et al. | CO2 emission reduction method through various gas turbine fuels applications | |

| US11549401B2 (en) | Coal plant supplementary air and exhaust injection systems and methods of operation | |

| CN102337937A (zh) | 一种煤整体气化烟气再热联合循环动力系统 | |

| CN215863334U (zh) | 一种电站冷风加热及烟气余热梯级利用系统 | |

| CN102564145A (zh) | 一种提高水泥窑余热利用效果的方法 | |

| RU2384720C1 (ru) | Детандер - генераторная установка электростанции | |

| KR101529431B1 (ko) | 다중 출력 증대 수단을 구비하는 고효율 복합발전 시스템 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20130619 Termination date: 20140211 |