CN100582282C - Extrusion of a metal alloy containing copper and zinc - Google Patents

Extrusion of a metal alloy containing copper and zinc Download PDFInfo

- Publication number

- CN100582282C CN100582282C CN200680005168A CN200680005168A CN100582282C CN 100582282 C CN100582282 C CN 100582282C CN 200680005168 A CN200680005168 A CN 200680005168A CN 200680005168 A CN200680005168 A CN 200680005168A CN 100582282 C CN100582282 C CN 100582282C

- Authority

- CN

- China

- Prior art keywords

- metal alloy

- zinc

- extruding

- extrusion

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/02—Making uncoated products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/002—Extruding materials of special alloys so far as the composition of the alloy requires or permits special extruding methods of sequences

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/02—Making uncoated products

- B21C23/04—Making uncoated products by direct extrusion

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C18/00—Alloys based on zinc

- C22C18/02—Alloys based on zinc with copper as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C9/00—Alloys based on copper

- C22C9/04—Alloys based on copper with zinc as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/08—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of copper or alloys based thereon

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Extrusion Of Metal (AREA)

Abstract

The invention relates to a method for producing a metal alloy product (19) containing at least some amount of ss-phase brass by extrusion, a metal alloy product produced by extrusion of metal alloy containing at least some amount of ss-phase brass, an extrusion die (15) for extrusion of a metal alloy containing copper and zinc, and at least some amount of ss-phase, an extrusion device, and a use of a metal alloy for extrusion.

Description

Technical field

The present invention relates to contain the extruding of the metal alloy of copper and zinc, relate to by extruding and contain the product that the metal alloy of copper and zinc is produced, and relate to extrusion mould.

Background technology

Extruding is the method that can produce long, straight metal parts.Producible cross section comprises filled circles, rectangle and L shaped, T shape, tubulose and many other types.Push by instrument by the metal that uses mechanical press or hydropress to be squeezed in the airtight chamber, described instrument is known to be mould.Be squeezed in and produce pressure and shearing force in the blank.But do not produce tensile stress, it may make metal produce high distortion but not tear metal.Holding the chamber of raw material uses high-abrasive material as lining.This can bear the high radial load that is produced during by mould when driving material.

Can push by cold extrusion or hot extrusion.Cold extrusion is at room temperature or the method for carrying out under the temperature that raises a little.This method can be used for the material that great majority meet the condition that can design the sufficiently solid instrument that can bear the stress that produces by extruding.The example of the metal that can be extruded is lead, aluminium alloy, copper, titanium, molybdenum and vanadium.Can be flexible pipe, aluminium pot, cylinder and gear blank by the example of cold-stamped part.The cold-stamped advantage be oxidation does not take place, owing to harsh cold working obtains the favorable mechanical performance and because the suitable lubricant of use obtains surface of good smooth finish.

Hot extrusion is carried out under quite high temperature, is about 50~75% melting point metal.Pressure can be 35~700MPa.Because high temperature and high pressure and, therefore need good lubricated to the disadvantageous effect of die life and other part.Use oil and graphite at a lower temperature, and under comparatively high temps, use glass powder.

Described extruding is usually once only at single object.Develop continuous extrausion process, wherein passed through the mode extruded material of runner.Material forces the metal spout to pass through extrusion mould to expecting and being contained in the circumferential groove of wheel up to plug (abutment).Because adiabatic condition almost in the instrument, the internal friction that material passes through to be produced is heated to above recrystallization temperature, even feed material also is like this in room temperature at first.This continuous extrausion process only is suitable for having low-melting metal, for example aluminium and pure substantially copper.Use continuous extrausion process can not push hard metal usually, for example contain the brass of copper and zinc, this is owing to need high squeeze pressure, damages extrusion mould the most at last.In addition, when pushing complicated shape, continuous processing is also improper.

The production of brazed copper tube such as EP 1,035 are shown in 227.Brazed copper tube comprises α phase brass and β brass mutually.α phase brass contains the zinc of lower aq, is the phase of using at the brass product usually.β phase brass is the brass that contains the zinc of higher percent, and is mutually harder than α.Use is at EP 1,035, disclosed α phase brass and the β composition of brass mutually in 227, but to improve the polishability of production tube.The document is also instructed and can be pushed said composition, because β phase brass at high temperature is soft.Therefore, reduced and pushed required pressure, made it possible to push.

Summary of the invention

An object of the present invention is the inexpensive production that obtains to contain the metal alloy of copper and zinc and comprise the product of complicated shape.

According to an aspect of the present invention, use method to reach this purpose according to claim 1.According to a second aspect of the invention, use metal alloy product to reach this purpose according to claim 13.According to a third aspect of the invention we, use extrusion mould to reach this purpose according to claim 15.According to a forth aspect of the invention, use extrusion mould to reach this purpose according to claim 17.According to a fifth aspect of the invention, use reaches this purpose according to the purposes of the metal alloy of claim 18.

Have realized that now, contain by increase in the metal alloy of copper and zinc zinc content and by adjusting temperature condition, make that metal alloy contains at least one quantitative β phase in extrusion process, metal alloy can be squeezed into meticulous and/or complicated shape.Especially, the metal alloy that contains the β phase can be squeezed into have with the vertical direction of the direction of extrusion of product on have the product that thickness is less than or equal at least one wall part (wall section) of 0.5cm.This is the softness characteristics owing to β phase under elevated temperature.In fact, have realized that the ability of extruding β phase brass even be better than pushing the very ability of the brass of the zinc of low levels that contains that the described brass that contains the unusual zinc of low levels is softer than the brass with high level zinc usually.

Therefore, by pushing β phase metal alloy by comprising the extrusion mould of opening, the shape of described opening makes the distance between at least two opposite sides of opening be less than or equal to 1cm, can push the multiple variant production with the meticulous or complicated shape that comprises extremely thin wall part.These products can't be made by extruding so far.Therefore, obtain more cheaply and production method faster.Before because the hard characteristic of brass, only can push low zinc content, only have the brass for example big pipe of simple and big shape, rod or beam, that have 1dm or bigger wall thickness.In fact, have realized that now, make metal alloy comprise the β phase by improving zinc content, can push be included in the vertical direction of the direction of extrusion on have thickness and be less than or equal to 0.3cm, be more preferably less than 1mm even be more preferably less than 0.7mm and most preferably less than the metal alloy product of the wall part of 0.5mm.

In one embodiment of the invention, be higher than the metal alloy that extruding under 450 ℃ the temperature contains copper and zinc.In another embodiment, be higher than extrusion metal alloy under 550 ℃ the temperature.In preferred embodiments, be higher than extrusion metal alloy under 600 ℃ the temperature.By elevated temperature, increase the softness of β phase.In fact, under comparatively high temps, the extrusion capability of β phase metal alloy is increased to push to be had wall thickness and is less than or equal to 0.5mm, preferably is less than or equal to the degree of the product of 0.3mm.

In one embodiment, be lower than extrusion metal alloy under 900 ℃ the temperature.In another embodiment, be lower than extrusion metal alloy under 800 ℃ the temperature.In preferred embodiments, be lower than extrusion metal alloy under 700 ℃ the temperature.Therefore, after metal alloy is extruded by the opening in mould, guarantee that metal alloy product keeps its shape, because metal alloy has enough rigidity to keep its shape.

Preferably, before extruding, metal alloy is preheating to 500~700 ℃ temperature.Because β is soft mutually, therefore the shearing force during the extruding is too little and the temperature of metal alloy can not be elevated to suitable extrusion temperature.Therefore, by the preheating metal alloy, can obtain extrusion temperature preferably by simple mode.

According to an embodiment, metal alloy comprise more than or equal the zinc of 35 weight %.In another embodiment, metal alloy comprise more than or equal 38 weight % zinc.In preferred embodiments, brass comprise more than or equal 42 weight % zinc.Surplus is copper and unavoidable impurities.Therefore, guarantee that metal alloy comprises the β phase brass of q.s to guarantee softness enough in extrusion process.In fact, comprise the brass of q.s zinc by extruding, β phase brass is enough soft, makes to push to have the metal alloy product of wall thickness less than 0.2mm.

According to one embodiment of the invention, metal alloy comprises the zinc of being less than or equal to 55 weight %.In one embodiment, metal alloy comprises the zinc of being less than or equal to 50 weight %.In a preferred embodiment, metal alloy comprises the zinc of being less than or equal to 48 weight %.Therefore guarantee that zinc content is not too high, do not comprise the γ phase mutually to guarantee that metal alloy comprises β in extrusion process.γ is all much mutually hard than β mutually under all temperature, and therefore, having γ in extrusion process in the metal alloy is deleterious mutually.In addition, guarantee that the product that makes is too not crisp for required application.

According to an embodiment, extrusion metal alloy in the extrusion equipment of operate continuously.Preferably, this extrusion equipment comprises having the wheel that is suitable for receiving with the circumferential groove of guide wire alloy.By using β phase brass, extrusion metal alloy continuously.By extrusion brass continuously, reduce the extruding cost, thereby reduce the cost of product.In the prior art, extrusion brass in batches only.

According to an embodiment, produce metal alloy product elongated, multiform (multiform).By using β phase brass, have realized that now and can push for example multiform, the elongated product of complicated shape, thereby obtain the production method of dog-cheap production product elongated, multiform.Preferably, produce the section bar (profile) of many mouthfuls (multi-port) or hyperchannel (multi-channel).Preferably, described hyperchannel section bar is applicable to the pipe that comprises several smaller channels in pipe.Therefore can improve the pipe internal pressure, and need not to increase the wall thickness of pipe.Preferably, hyperchannel section bar or pipe are applicable to heat transfer apparatus, for example heat exchanger or heat pump.Preferably, hyperchannel section bar or pipe are applicable to automotive heat exchanger, and make by the brass that extruding contains at least one quantitative β phase metal alloy.This multi-channel tube is normally flat, has not to be higher than 1cm, preferably not to be higher than 0.5cm and most preferably not to be higher than the height of 2mm and not to be wider than 25cm, preferably not to be wider than 10cm and most preferably not to be wider than the width of 5cm.Usually, this pipe or section bar have the wall thickness that is less than or equal to 1mm.Before, this pipe or section bar can not be by extrusion brass productions.

In one embodiment, produce elongated product with a plurality of fins.Preferably, many fins section bar is applicable to heat transfer apparatus, for example heat exchanger or heat pump.Fin preferably is suitable for extending to gas for example in the air, to help the heat transfer between air and many fins product.

Description of drawings

With reference now to accompanying drawing, will explain the present invention by non-limiting example of the present invention.

Fig. 1 represents to contain the phasor of the metal alloy of copper and zinc, has shown the out of phase temperature and the zinc content of metal alloy.

Fig. 2 represents the extrusion equipment of the metal alloy product that is used to push.

Extrusion mould in Fig. 3 presentation graphs 2 and the section bar that is used for the extruding of automotive heat exchanger.

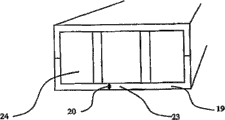

Fig. 4 represents the sectional view that contains copper, zinc and the metal alloy product of at least one quantitative β extruding mutually according to of the present invention.

Fig. 5 represents according to the present invention by the method for extrusion production metal alloy product with the form of schematic block diagram.

Embodiment

In Fig. 1, shown the phasor of the metal alloy that contains copper and zinc.The zinc content that is applicable to the metal alloy that the present invention pushes is zinc content and the temperature that obtains containing at least one quantitative β metal alloy mutually with temperature.Preferably, correspondence markings is the zone of pure β phase and/or is labeled as α mutually and combined zone selection zinc content and the temperature of β.Because the hardness of γ phase should avoid being labeled as β mutually and the zone that combines of γ.

In addition, obtain the temperature limitation value of soft β phase shown in the dotted line under 450~470 ℃ temperature.Yet, preferably, preferably be higher than 550 ℃, most preferably be higher than 600 ℃, to guarantee enough softnesses being higher than extrusion metal alloy under 500 ℃ the temperature.

Phasor has also shown the melt temperature that contains β phase metal alloy, about 900 ℃ temperature.Because β became soft under the high temperature near fusing point, therefore preferably be lower than 800 ℃, most preferably be lower than under 700 ℃ the temperature and push β phase metal alloy.Therefore most preferred extrusion temperature interval is 600~700 ℃ according to the present invention.

Shown in phasor, alpha phase zone territory separately and α mutually+obtain at least one quantitative β phase on the line of β region.Therefore, metal alloy should contain the zinc of at least 35 weight %, to guarantee having at least one quantitative β phase in extrusion process.Yet preferably, metal alloy should contain the more β phase brass of volume, so zinc content preferably is higher than 38 weight %.Most preferably, have at least 90% β phase in metal alloy product, guaranteeing enough softnesses, so metal alloy preferably contains the zinc of at least 42 weight %, and surplus is copper and unavoidable impurities.It should be noted that under comparatively high temps, the admissible zinc content interval that obtains the β phase is a broad, for the present invention, importantly has the β phase under extrusion temperature.

Too not crisp in order to ensure the finished product, and guarantee in extrusion process, not exist harmful γ phase of measuring, zinc, the most preferred no more than 48 weight % zinc of the no more than 50 weight % of amount of preferred zinc.

In Fig. 2, shown according to the continuously extruded extrusion equipment 1 that contains the metal alloy of copper and zinc of the present invention.Extrusion equipment 1 comprises having inlet 5 hollow circular cylinder 3 and be arranged on runner 7 in right cylinder 3 hollow spaces, provides groove 9 along the periphery of described runner 7.Described equipment also comprises the plug 11 and the pressing cavity 13 that is set to link to each other with plug 11 that is arranged in the groove 9, and described chamber 13 ends at extrusion mould 15.Described extrusion mould 15 comprises opening 17, and described opening 17 is so shaped that the distance 20 between opening 17 two opposite side 21a, the 21b at least is less than or equal to 0.5cm.Illustrate in greater detail extrusion mould 15 in conjunction with Fig. 3.

In extrusion process, contain copper and zinc and at least one quantitative β metal alloy mutually of preheating are given and expected inlet 5, and enter the groove 9 of wheel 7.By drive unit (not shown) swiveling wheel 7, make metal alloy press to plug 11 forward, make metal alloy continue to enter into pressing cavity 13.The pressure of accumulation is pressed to extrusion mould 15 and opening 17 with metal alloy continuously in pressing cavity 13.Therefore, the extrusion metal alloy is by opening 17, that is, the extrusion metal alloy also obtains and described opening shape similar shape.Therefore, the metal alloy product 19 through extruding that comprises at least one quantitative β phase is formed, make product 19 comprise at least one wall part that thickness is less than or equal to 0.5cm.

In Fig. 3, show an example of extrusion mould 15.Extrusion mould 15 is made by hard, durable and high-abrasive material, and it can also be high temperature resistant.In this example, extrusion mould is heated to above 600 ℃ temperature, to guarantee enough extrusion temperatures.Extrusion mould 15 provides opening 17, and described opening 17 is so shaped that the distance 20 between at least two opposite side 21a, the 21b of opening is less than or equal to 0.5cm.In this example, the product of extruding is the section bar that is applicable to the multi-channel tube of automotive heat exchanger.In this example, in order to ensure the short range between the two media for the treatment of heat exchange, so the distance between two opposite side 21a, 21b of extrusion mould 15 is less than 0.5mm.Therefore the multi-channel tube, the metal alloy product that comprise at least one quantitative β phase have at least one wall part that thickness is less than or equal to 0.5mm.Therefore, according to the present invention, can be with very effectively and the cheap way product that has unusual complicated shape and/or thin-walled portion by extrusion production.

In addition, opening be shaped as the distance 20 that makes between two opposite side 21a, 21b of extrusion mould 15 more than or equal to 0.05mm, be preferably greater than 0.1mm and most preferably greater than 0.3mm.Therefore with regard to wearing quality, guaranteed that the thickness of product wall part is enough thick.

In Fig. 4, shown the cross section of containing copper, zinc and the metal alloy product 19 of at least one quantitative β extruding mutually according to of the present invention.Described product comprise have with the vertical direction of the direction of extrusion on thickness 20 be less than or equal to the wall 23 of 0.5mm.In this example, product 19 is the section bars that are used for multi-channel tube 24.In this example, multi-channel tube is applicable to heat exchanger.In this example, multi-channel tube is applicable to the automotive heat exchanger between cooling liqs and the air.

In Fig. 5, show the method according to this invention.In first step 27, the metal alloy that will comprise the zinc of at least 38 weight % and surplus and be copper and inevitable impurity is preheating at least 600 ℃ temperature.In second step 29, metal alloy is fed in the extrusion equipment that comprises extrusion mould.In this example, metal alloy is continuously fed in the extrusion equipment.In third step 31, the extrusion metal alloy is by at least one the extruding opening in described extrusion mould, and described opening is so shaped that the distance of at least two opposite sides of opening is less than or equal to 0.5cm.In this example, described distance is less than or equal to 0.7mm.In the 4th step 33, the metal alloy of extruding is cut to the metal alloy product of appropriate length.Subsequently, metal alloy product is cooled to suitable temperature, for example room temperature.

The present invention is not restricted to embodiment shown here, but changes in the framework of claim below.

For example, pressing method and equipment are well known in the art, and corresponding to schematic method and apparatus in this specification sheets, according to any difference or the improvement of prior art to pressing method or equipment, should think within the scope of this specification sheets and claim.

In addition, although specification sheets has mainly shown the metal alloy that mainly comprises copper and zinc, metal alloy also can comprise other alloying element, as long as there are at least some β phases in alloy.

Claims (24)

1. method of producing metal alloy product comprises:

To contain copper and zinc and at least one quantitative β mutually the metal alloy feed (29) of brass to extrusion mould; With

The described metal alloy that contains the β phase of extruding (31) is by at least one the extruding opening in described extrusion mould (15), and the shape of described opening (17) makes the distance between at least two opposite sides of described opening be less than or equal to 1mm.

2. according to the process of claim 1 wherein that described distance is less than or equal to 0.7mm.

3. be higher than the described metal alloy of extruding under 450 ℃ the temperature according to the process of claim 1 wherein.

4. according to the method for claim 3, wherein be higher than the described metal alloy of extruding under 550 ℃ the temperature.

5. according to the method for claim 4, wherein be higher than the described metal alloy of extruding under 600 ℃ the temperature.

6. be lower than the described metal alloy of extruding under 900 ℃ the temperature according to the process of claim 1 wherein.

7. according to the method for claim 6, wherein be lower than the described metal alloy of extruding under 800 ℃ the temperature.

8. according to the method for claim 7, wherein be lower than the described metal alloy of extruding under 700 ℃ the temperature.

9. according to the process of claim 1 wherein that described method comprises:

The temperature of the described metal alloy to 500 of preheating before extruding (27)~700 ℃.

10. according to aforementioned claim method arbitrarily, wherein said metal alloy comprise more than or equal the zinc of 35 weight %, surplus is copper and unavoidable impurities.

11. according to the method for claim 10, wherein said metal alloy comprise more than or equal the zinc of 38 weight %, surplus is copper and unavoidable impurities.

12. according to the method for claim 11, wherein said metal alloy comprise more than or equal the zinc of 42 weight %, surplus is copper and unavoidable impurities.

13. according to the process of claim 1 wherein that described metal alloy comprises the zinc that is less than or equals 55 weight %.

14. according to the method for claim 13, wherein said metal alloy comprises the zinc that is less than or equals 50 weight %.

15. according to the method for claim 14, wherein said metal alloy comprises the zinc that is less than or equals 48 weight %.

16. according to the process of claim 1 wherein that described method is included in the described metal alloy of extruding in the extrusion equipment of operate continuously (1).

17. produce product elongated, multiform (19) according to the process of claim 1 wherein that described method comprises.

18. produce many mouthfuls or hyperchannel section bar (19) according to the process of claim 1 wherein that described method comprises.

19. according to the method for claim 18, wherein said method comprises produces hyperchannel section bar (19) or the pipe (24) that is applicable to heat transfer apparatus.

20. according to the method for claim 19, wherein said heat transfer apparatus is heat exchanger or heat pump.

21. according to the process of claim 1 wherein described method comprise by extruding contain copper and zinc and at least one quantitative β mutually the metal alloy production of brass be applicable to the hyperchannel section bar (19) or the pipe (24) of automotive heat exchanger.

22. one kind contains copper and zinc and at least one quantitative β metal alloy product of the extruding of brass mutually, it is characterized in that described product (19) comprises at least one wall part (23) that thickness is less than or equal to 1mm.

23., it is characterized in that described product is the section bar (19) of the multi-channel tube (24) that is applicable to heat transfer apparatus according to the metal alloy product of the extruding of claim 22.

24. one kind contain copper and zinc and at least one quantitative β mutually the metal alloy of brass have purposes in the metal alloy product of wall part (23) that thickness is less than or equal to 1mm in extruding.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FI20050195 | 2005-02-18 | ||

| FI20050195A FI118328B (en) | 2005-02-18 | 2005-02-18 | Use of alloy |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101120115A CN101120115A (en) | 2008-02-06 |

| CN100582282C true CN100582282C (en) | 2010-01-20 |

Family

ID=34224229

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200680005168A Expired - Fee Related CN100582282C (en) | 2005-02-18 | 2006-02-17 | Extrusion of a metal alloy containing copper and zinc |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20080202653A1 (en) |

| EP (1) | EP1853743A1 (en) |

| JP (1) | JP2008529803A (en) |

| CN (1) | CN100582282C (en) |

| FI (1) | FI118328B (en) |

| WO (1) | WO2006088421A1 (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9023272B2 (en) * | 2010-07-05 | 2015-05-05 | Ykk Corporation | Copper-zinc alloy product and process for producing copper-zinc alloy product |

| KR101340487B1 (en) | 2011-09-30 | 2013-12-12 | 주식회사 풍산 | Leadless Free Cutting Copper Alloy and Process of Production Same |

| CN103157692B (en) * | 2011-12-09 | 2015-06-10 | 北京有色金属研究总院 | Preparation method for zinc-based alloy specially-shaped tube |

| US10287653B2 (en) | 2013-03-15 | 2019-05-14 | Garrett Transportation I Inc. | Brass alloys for use in turbocharger bearing applications |

| US11383280B2 (en) | 2013-03-22 | 2022-07-12 | Battelle Memorial Institute | Devices and methods for performing shear-assisted extrusion, extrusion feedstocks, extrusion processes, and methods for preparing metal sheets |

| US11045851B2 (en) | 2013-03-22 | 2021-06-29 | Battelle Memorial Institute | Method for Forming Hollow Profile Non-Circular Extrusions Using Shear Assisted Processing and Extrusion (ShAPE) |

| US10695811B2 (en) | 2013-03-22 | 2020-06-30 | Battelle Memorial Institute | Functionally graded coatings and claddings |

| US20140328959A1 (en) | 2013-05-03 | 2014-11-06 | Battelle Memorial Institute | System and process for friction consolidation fabrication of permanent magnets and other extrusion and non-extrusion structures |

| CN103556088A (en) * | 2013-10-30 | 2014-02-05 | 沈阳工业大学 | Pre-stress processing mould of high temperature alloys |

| CN104795466B (en) * | 2015-04-13 | 2016-08-24 | 陈恩深 | A kind of hydrogen paralysis facility of solar cell |

| JP6803457B2 (en) * | 2017-03-24 | 2020-12-23 | 株式会社Ihi | Abrasion resistant copper-zinc alloy and machinery using it |

| US11549532B1 (en) | 2019-09-06 | 2023-01-10 | Battelle Memorial Institute | Assemblies, riveted assemblies, methods for affixing substrates, and methods for mixing materials to form a metallurgical bond |

| CN111394609B (en) * | 2020-04-24 | 2021-02-12 | 浙江大学 | Continuous extrusion process of high-strength high-conductivity copper alloy, application of continuous extrusion process and die material |

| US11919061B2 (en) | 2021-09-15 | 2024-03-05 | Battelle Memorial Institute | Shear-assisted extrusion assemblies and methods |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3768288A (en) * | 1971-02-25 | 1973-10-30 | Jury & Spiers Pty Ltd | Process for the production of tube from ductile metal |

| US5119660A (en) * | 1990-08-06 | 1992-06-09 | Outokumpu Oy | Method for manufacturing metal objects |

| JP2000355746A (en) * | 1996-09-09 | 2000-12-26 | Toto Ltd | Production of brass and producing equipment therefor |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE345399B (en) * | 1967-06-30 | 1972-05-29 | Asea Ab | |

| US3535908A (en) * | 1967-07-14 | 1970-10-27 | Ibm | Injection molding of solid metal |

| GB1370894A (en) * | 1971-03-12 | 1974-10-16 | Atomic Energy Authority Uk | Extrusion |

| US3973428A (en) * | 1975-04-07 | 1976-08-10 | Westinghouse Electric Corporation | Uniform land length die |

| US4080817A (en) * | 1976-03-26 | 1978-03-28 | Maurice Bastide | Process and a device for the extrusion of materials in the form of narrow wires |

| JPS56166364A (en) * | 1980-05-24 | 1981-12-21 | Sumitomo Electric Ind Ltd | Cold working method for copper base alloy |

| US5308568A (en) * | 1993-05-20 | 1994-05-03 | Corning Incorporated | Extrusion die and method |

| JPH11189856A (en) * | 1997-10-24 | 1999-07-13 | Toto Ltd | Brass material, brass pipe material and its production |

| JPH11244934A (en) * | 1998-03-06 | 1999-09-14 | Furukawa Electric Co Ltd:The | Manufacture of die and mandrel for conforming extrusion dies |

| JPH11300413A (en) * | 1998-04-22 | 1999-11-02 | Hitachi Cable Ltd | Extruding tool for continuous extruder |

| JPH11309510A (en) * | 1998-04-28 | 1999-11-09 | Hitachi Cable Ltd | Manufacture of metallic pipe coated on inside surface |

| JP3835216B2 (en) * | 2001-08-09 | 2006-10-18 | 住友金属工業株式会社 | Non-oriented electrical steel sheet and manufacturing method thereof |

| JP2003073789A (en) * | 2001-09-05 | 2003-03-12 | Sumitomo Light Metal Ind Ltd | Method for manufacturing unleaded free-cutting brass superior in machinability |

-

2005

- 2005-02-18 FI FI20050195A patent/FI118328B/en not_active IP Right Cessation

-

2006

- 2006-02-17 EP EP06716905A patent/EP1853743A1/en not_active Withdrawn

- 2006-02-17 JP JP2007556113A patent/JP2008529803A/en not_active Abandoned

- 2006-02-17 US US11/816,578 patent/US20080202653A1/en not_active Abandoned

- 2006-02-17 WO PCT/SE2006/000215 patent/WO2006088421A1/en active Application Filing

- 2006-02-17 CN CN200680005168A patent/CN100582282C/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3768288A (en) * | 1971-02-25 | 1973-10-30 | Jury & Spiers Pty Ltd | Process for the production of tube from ductile metal |

| US5119660A (en) * | 1990-08-06 | 1992-06-09 | Outokumpu Oy | Method for manufacturing metal objects |

| JP2000355746A (en) * | 1996-09-09 | 2000-12-26 | Toto Ltd | Production of brass and producing equipment therefor |

Non-Patent Citations (2)

| Title |

|---|

| 金属挤压理论与技术. 谢建新,刘静安,279-284,冶金工业出版社. 2001 |

| 金属挤压理论与技术. 谢建新,刘静安,279-284,冶金工业出版社. 2001 * |

Also Published As

| Publication number | Publication date |

|---|---|

| FI20050195A (en) | 2006-08-19 |

| CN101120115A (en) | 2008-02-06 |

| WO2006088421A1 (en) | 2006-08-24 |

| EP1853743A1 (en) | 2007-11-14 |

| FI20050195A0 (en) | 2005-02-18 |

| JP2008529803A (en) | 2008-08-07 |

| FI118328B (en) | 2007-10-15 |

| US20080202653A1 (en) | 2008-08-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100582282C (en) | Extrusion of a metal alloy containing copper and zinc | |

| CN101579701B (en) | Preparation process of copper pipe material for electronic thermotubes | |

| KR101580975B1 (en) | Continuous extrusion apparatus and method for metal | |

| CN107206447A (en) | The machine for manufacturing the method for pipe fitting and wherein using | |

| CN101391368A (en) | Machining method of deep-hole pin bush parts | |

| CN101195199A (en) | Special-shaped cross section copper strip process technique and special-shaped cross section copper strip produced by using the technique | |

| CN105690045B (en) | The production method of flat-bulb steel | |

| CN112916639A (en) | Preparation method of ultra-flat aluminum alloy section bar with rib plate | |

| CN113560362A (en) | High-performance magnesium-aluminum alloy variable cross-section extrusion-torsion composite processing device and preparation process thereof | |

| CN102575319A (en) | Copper alloy seamless pipe | |

| WO2002046678A3 (en) | Multivoid heat exchanger tubing with ultra small voids and method for making the tubing | |

| EP1880780B1 (en) | Bolt-dedicated shaped product extrusion apparatus and method | |

| CN109702039A (en) | A kind of specially shaped copper tube processing method | |

| CN109013735A (en) | A kind of double blanks fusing soldering bimetallic plates extrusion dies of double rod and its application method | |

| CN112024633B (en) | Composite worm molding method and composite worm manufactured by same | |

| Chien et al. | Extrusion productivity, Part I–billet geometry | |

| CN213559190U (en) | Semi-solid continuous extrusion forming device for wire materials | |

| KR100550375B1 (en) | Aluminum slide rail and manufacturing method thereof | |

| CN114570900A (en) | Device and method for continuous casting and extrusion forming of copper and copper alloy | |

| CN111922106A (en) | Continuous torsion extrusion large plastic deformation method and application thereof | |

| CN1974044A (en) | Continuous rotary deformation magnesium alloy extruder | |

| CN100431728C (en) | Extrusion method and apparatus | |

| CN201482814U (en) | Copper-clad aluminum bus trough isothermal extrusion die | |

| CN112246904A (en) | Semi-solid continuous extrusion forming device for wire materials | |

| CN217832492U (en) | Cold welding mould for hydraulic cold welding machine device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20100120 Termination date: 20110217 |