CN100402672C - Method and device for controlled straightening and cooling of a wide metal strip, especially a steel strip or sheet metal, running out of a hot rolled strip rolling mill - Google Patents

Method and device for controlled straightening and cooling of a wide metal strip, especially a steel strip or sheet metal, running out of a hot rolled strip rolling mill Download PDFInfo

- Publication number

- CN100402672C CN100402672C CNB028257057A CN02825705A CN100402672C CN 100402672 C CN100402672 C CN 100402672C CN B028257057 A CNB028257057 A CN B028257057A CN 02825705 A CN02825705 A CN 02825705A CN 100402672 C CN100402672 C CN 100402672C

- Authority

- CN

- China

- Prior art keywords

- metal strip

- cooling

- strip

- tensile stress

- roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 78

- 239000002184 metal Substances 0.000 title claims abstract description 50

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 50

- 238000000034 method Methods 0.000 title claims abstract description 18

- 229910000831 Steel Inorganic materials 0.000 title abstract description 22

- 239000010959 steel Substances 0.000 title abstract description 22

- 238000005096 rolling process Methods 0.000 title abstract 2

- 230000000694 effects Effects 0.000 claims abstract description 14

- 238000001125 extrusion Methods 0.000 claims description 41

- 239000000463 material Substances 0.000 claims description 22

- 239000007921 spray Substances 0.000 claims description 15

- 238000007599 discharging Methods 0.000 claims description 5

- 238000012797 qualification Methods 0.000 claims description 3

- 230000001105 regulatory effect Effects 0.000 claims description 3

- 230000001276 controlling effect Effects 0.000 claims description 2

- 230000005465 channeling Effects 0.000 claims 1

- 230000035882 stress Effects 0.000 description 23

- 210000005239 tubule Anatomy 0.000 description 5

- 230000002950 deficient Effects 0.000 description 2

- 229910000734 martensite Inorganic materials 0.000 description 2

- 238000010791 quenching Methods 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- 206010042209 Stress Diseases 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C21D9/54—Furnaces for treating strips or wire

- C21D9/56—Continuous furnaces for strip or wire

- C21D9/573—Continuous furnaces for strip or wire with cooling

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0242—Flattening; Dressing; Flexing

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

- C21D8/0252—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment with application of tension

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/62—Quenching devices

- C21D1/667—Quenching devices for spray quenching

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D11/00—Process control or regulation for heat treatments

- C21D11/005—Process control or regulation for heat treatments for cooling

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Heat Treatment Of Strip Materials And Filament Materials (AREA)

- Metal Rolling (AREA)

- Control Of Heat Treatment Processes (AREA)

- Straightening Metal Sheet-Like Bodies (AREA)

- Investigating Or Analyzing Materials Using Thermal Means (AREA)

- Grinding Of Cylindrical And Plane Surfaces (AREA)

Abstract

A method and device for controlled straightening and cooling of a wide metal strip, especially a steel strip (1) or sheet metal, running out of a hot rolled strip rolling mill, using pinching rollers (5) arranged in the moving direction of the strip (2) behind vertical double rollers (3,4), said pinching rollers producing a tensile stress (6) acting in a longitudinal direction. According to the invention, the range of use of conventional sheet metal cooling systems can be extended to obtain a more even surface of said steel strip (1) with an increased cooling effect. This is achieved by displacing the metal strip (1) or sheet metal between a pre-straightening machine (7) and splash cooling facility (8) in defined conditions of tensile stress (6) by adjusting the tensile stress (6) and by cooling said strip or sheet metal inside said splash cooling facility (8) between successive pairs (5a) of pinching rollers and by additionally controlling the tensile stress (6).

Description

The present invention relates to a kind ofly be used for controllably correcting and cool off wide metal strip, the especially steel band of discharging from hot strip mill or the method and apparatus of sheet material, wherein metal strip at first passes through a two roller in a spray cooling device, single roller that this pair roller has two vertically stacked to arrange, and subsequently by a secondary guiding of first extrusion roll after direction of belt travel is arranged in single roller; Metal strip passes one first cooling unit between the single roller and the first extrusion roll pair; A kind of tensile stress of effect along the longitudinal direction produces between the single roller and the first extrusion roll pair in metal strip.

Method and apparatus by the known substantially this form of DE 33 13 024 A1.Wherein relate to a method and apparatus, be used under the controllably corrigent at the same time condition steel plate, especially slab and the plate that passes through being quenched, wherein correct in a plane at the hot vertical two rollers that are provided with by at least two front and back at the quenching front spring.Then steel plate being passed a quenching device by at least one two roller under tensile stress controllably pulls out.This method can make the steel plate that passes through accurately be quenched into mechanical characteristics given in advance, does not curl and deflection and can not produce, and wherein can reduce simultaneously the roughness that has originally existed.Although the unfairness of taking this measure also always to produce steel plate again, this comes from not enough, the defective cooling of the tensile stress that applies and other disadvantageous adjusting measure.Applied in practice refrigerating unit almost no longer can improve, and they constitute by jet element or in order to cool off by the laminar flow cascade again.Use a U-shaped tubule in principle for the laminar flow cooling unit.But selecting to realize under the situation of relevant parameter accessible high cooling efficiency by nozzle.Defective is also to play poorly controlled and effect control characteristic under the situation of low through-current capacity in the ordinary course of things and especially.

The objective of the invention is, the use range of traditional cooling device of steel plate is widened under the situation that strengthens cooling performance, made steel plate realize higher planarization.

According to above-mentioned purpose of the present invention by being used for controllably correcting and cooling off wide metal strip, the especially steel band of discharging from hot strip mill or the method and apparatus of sheet material is achieved, wherein metal strip at first passes through a two roller in a spray cooling device, single roller that this pair roller has two vertically stacked to arrange, and subsequently by a secondary guiding of first extrusion roll after direction of belt travel is arranged in single roller; Metal strip passes one first cooling unit between the single roller and the first extrusion roll pair; A kind of tensile stress of effect along the longitudinal direction produces between the single roller and the first extrusion roll pair in metal strip.According to the present invention, this metal strip just passed the preposition arbor press of a rotary drive motor that has straightening roll and attached troops to a unit before it enters into described single roller; And between preposition arbor press and single roller, do not pass cooling unit, but metal strip is placed under the tensile stress of qualification by the rotary drive motor that the straightening roll of regulating preposition arbor press is used.Before entering cooling, metal strip or steel plate directly play the effect of viscous deformation thus.This viscous deformation has reduced the metal strip that enters or the roughness of steel plate.Be also advantageous in that correcting process directly is set before cooling, avoid thus producing inherent stress and distortion again owing to the inhomogeneous cooling to metal strip or surface of steel plate causes.

Described cooling performance is subjected to the restriction of the distortion in stress influence and the relevant therewith sheet material in practice, and inhomogeneous cooling effect causes to plate surface owing to heat-eliminating medium (water) for this.Performance was especially obvious when this (bad) effect wide metal sheet for thin the time used higher cooling power.The critical working condition of an equipment provides under the higher cooling intensity condition at maximum width simultaneously by the sheet material with minimum thickness.Cooling intensity by for shorter cooling time the time starting temperature and the temperature difference between the cooling end temp decide.Extrusion roll can hinder this anamorphic effect in practice.But the influence of this compensating form is limited.According to the layout of preposition arbor press plays the effect of viscous deformation and directly reduces to enter before cooling before cooling distortion and stress of the present invention.

Distortion especially effectively can the time be overcome entering cooling, regulates tensile stress by each next one, extrusion roll switching speed last, carrying are walked by metal strip or sheet material stepping.

An improvement project is that described extrusion roll is fixed by a spacing, wherein constitutes a cooling unit according to this spacing between two extrusion rolls.

Can stipulate that in improvement project of the present invention this spacing is half length of the band of minimum thickness or sheet material caused self shape when maximum width and big cooling intensity.

A kind of device that is used for controllably correcting and cools off wide metal strip, the especially steel band of discharging from hot strip mill or sheet material be provided with vertical pair of roller secondary and on direction of belt travel before and after in succession extrusion roll pair, refrigerating unit is set respectively betwixt.

Purpose for this device is achieved thus according to the present invention, and a preposition arbor press is arranged on before the extrusion roll pair with cooling unit, can produce a controlled tensile stress between the extrusion roll pair.Can before cooling, transmit a tensile stress thus, reduce the size of existing distortion thus here.Therefore determine tensile stress more accurately in cooling unit inside.

According to another feature regulation, described cooling unit is respectively according to high designing with a medium cooling intensity.

But, can also increase the refrigerative effect by in the metal strip discharge process, cooling unit being provided with the cooling-part of fine tuning.

High and/or medium cooling power designs according to given product line according to one to make described cooling unit in addition, can further strengthen cooling.

Improvement of the present invention also is, can produce tensile stress equally between the extrusion roll last, carrying on metal strip or the sheet material terminal or extrusion roll on straightening roll and metal strip or the sheet material top or straightening roll.

Embodiments of the invention shown in the drawings are also described below in detail.

Fig. 1 illustrates has extrusion roll that produces tensile stress and the cooling system figure that drives control,

Fig. 2 a illustrates the steel band with middle corrugated form deflection or the stereographic map of sheet material,

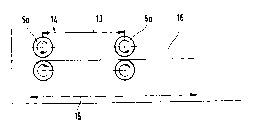

Fig. 2 b illustrates two side-views with the extrusion roll pair of spacing setting,

Fig. 3 illustrates the refrigerating unit structure that is used for each cooling intensity,

Fig. 4 illustrates the view that is used to correct with the whole device of refrigerative.

Using along acting on vertically tensile stress 6 transferring metals, the especially steel band 1 or the sheet material of (direction of belt travel 2) by one under the condition of the extrusion roll 5 that is arranged on vertical single roller 3 and 4 back on the direction of belt travel 2 in order controllably to cool off with correcting.Make at the metal strip 1 between preposition arbor press 7 and the spray cooling device 8 by adjusting tensile stress (by the rotary drive motor of arbor press) and place definite tensile stress 6 times and spray cooling device 8 inside of metal strip 1 between the secondary 5a of extrusion roll in succession of front and back are cooled off and additionally controlling tensile stress 6 at this.Described spray cooling device 8 is formed by being separately positioned on two cooling unit 9 (see figure 1)s between the secondary 5a of extrusion roll.Tensile stress 6 is controlled by a response control 12 on a corresponding rotating torques 11 when acting on metal strip 1 with roller speed of feed 10, with the effect of (A) expression extrusion roll 5 (i) to (i+nc).In case tape terminal 1a passes through the effect with the extrusion roll 5 (i+1) to (i+nc+1) of (B) expression, then corresponding tensile stress 6 is delivered to tape terminal 1a and also measures speed of relative movement outside of tape terminal 1a, control 12 and do not add response.Not only for tape terminal 1a and also for rim end 1b by extrusion roll 5 switching speeds of each next one, last, carrying are passed through to regulate tensile stress 6 (referring to Fig. 1) with metal strip 1 stepping.

Described extrusion roll 5 is provided with certain spacing 13, wherein constitutes cooling unit 9 according to spacing 13 between two extrusion rolls 5.Therefore half length 14 of the corrugation length 15 that for example produces when maximum width and the higher cooling intensity with the metal strip 1 of minimum thickness of spacing 13 is as the criterion.In steel band 11, regulate typical corrugation length 15 (referring to Fig. 2 A).

According to high design with medium cooling intensity (Fig. 2 B), wherein spacing 13 is corresponding to half corrugation length 15 (referring to Fig. 2 B) respectively for described cooling unit 9.Waviness curve 16 is represented significantly with dotted line 17 in Fig. 2 A and 2B.

The cooling performance of the cooling unit 9 of variant form shown in Figure 3.In temperature-time curve figure solid line represent with or the temperature curve 20 at sheet material center and dotted line presentation surface temperature 21.In section (1), drop into spray cooling unit 8a.In the discharge process 18 of steel band 1, be provided with the cooling unit 9 that constitutes by U-shaped tubule unit 22.

Be implemented in the temperature or the temperature Δ T-center (2) at steel band 1 center based on temperature Δ T-center (1).

Also realize temperature Δ T-surface in spray cooling unit 8a zone.Required cooling stops temperature and passes through 22 realizations of U-shaped tubule unit with little paces when using U-shaped tubule unit 22.More than temperature T-martensite, prevent because cold formation martensite is crossed on the surface.

Can be between the straightening roll 24 on the top 1b of the extrusion roll 5 of last, the carrying on the terminal 1a of metal strip 1 or sheet material or straightening roll 23 and metal strip 1 with identical method generation tensile stress 6.

According to Fig. 4 an intact device is shown, in device, on preposition arbor press 7, is connected spray cooling device 8 and connects a cooling facility for laminar flow 25 thereafter with secondary 5a of extrusion roll and cooling unit 9 in direction of belt travel 2.

Reference numeral symbol inventory

1 metal tape, steel band or sheet material

The 1a tape terminal

The 1b rim end

2 direction of belt travel

3 single rollers

4 single rollers

5 extrusion rolls

5a extrusion roll pair

6 tensile stresss

7 preposition arbor presses

8 spray cooling devices

8a sprays cooling unit

9 cooling units

10 roller speed of feed

11 rotating torques

12 response regulation

13 spacings

14 half is long

15 corrugation length that produce

16 ripples extend

17 dotted lines

18 discharge processes

19 cooling-parts

20 band or sheet material centers

21 surface temperatures

22 U-shaped tubules

23 straightening rolls

24 straightening rolls

25 cooling facility for laminar flow

Claims (8)

1. one kind is used for controllably correcting and cools off the wide metal strip (1) of discharging from hot strip mill or the method for sheet material (1), wherein this metal strip or sheet material at first pass through a two roller in a spray cooling device (8), this pair roller has single roller (3 that two vertically stacked are arranged, 4), and be arranged in described single roller (3,4) first extrusion roll pair (5a) channeling conduct afterwards by one along direction of belt travel (2) subsequently; Described metal strip passes one first cooling unit (9) between the single roller (3,4) and the first extrusion roll pair; And a kind of tensile stress of effect in a longitudinal direction is at described single roller (3 in metal strip, 4) and between the first extrusion roll pair produce, it is characterized in that, described metal strip (1) or sheet material enter into the preposition arbor press (7) that described single roller (3,4) just passes a rotary drive motor that has straightening roll and attached troops to a unit before at it; And between this preposition arbor press and described single roller, do not pass cooling unit (9), but the rotary drive motor of using by the straightening roll of regulating preposition arbor press (7) places metal strip under the tensile stress of qualification.

2. the method for claim 1 is characterized in that, the tensile stress in metal strip or the sheet material is carried out additional adjusting two inside along the spray cooling device (8) between the extrusion roll pair (5a) in succession of direction of belt travel (2) front and back respectively.

3. method as claimed in claim 2 is characterized in that, described metal strip or sheet material carry out additional cooling between the extrusion roll pair in succession of described front and back.

4. the method for claim 1 is characterized in that, described extrusion roll is fixed with a spacing, wherein constitutes a cooling unit according to this spacing between two extrusion rolls.

5. one kind is used for controllably correcting and cooling off from the wide metal strip of hot strip mill discharge or the device of sheet material (1), has

A spray cooling device (8), it has a two roller, and this pair roller has single roller (3,4) that two vertically stacked are arranged,

A first extrusion roll pair (5a) after direction of belt travel (2) is arranged in this pair roller, and

First cooling unit (9) of between the described single roller (3,4) and the first extrusion roll pair (5a), arranging; Wherein

In metal strip that passes spray cooling device (8) guiding or sheet material, between the single roller (3,4) and the first extrusion roll pair (5a), can produce a kind of tensile stress of effect in a longitudinal direction,

It is characterized in that, one that pass by metal strip, be arranged on the rotary drive motor that spray cooling device (8) preposition arbor press (7) before is provided with straightening roll and is attached troops to a unit, be used for the metal strip between preposition arbor press (7) and the single roller (3,4) is placed under the tensile stress of qualification at the rotary drive motor that does not have to use by the straightening roll of regulating preposition arbor press (7) under the refrigerative situation.

6. device as claimed in claim 5 is characterized in that a kind of response control, and it is used for controlling tensile stress between two extrusion roll pairs (5a) by the controls revolution torque.

7. device as claimed in claim 6 is characterized in that, described cooling unit (9) is separately positioned between two extrusion roll pairs.

8. as each described device in the claim 5 to 7, it is characterized in that, at cooling unit (9) described in the discharge process (18) of metal strip (1) but be provided with the cooling-part (19) of fine tuning.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10163070A DE10163070A1 (en) | 2001-12-20 | 2001-12-20 | Method and device for the controlled straightening and cooling of wide metal strip, in particular steel strip or sheet metal, emerging from a hot strip rolling mill |

| DE10163070.0 | 2001-12-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1606630A CN1606630A (en) | 2005-04-13 |

| CN100402672C true CN100402672C (en) | 2008-07-16 |

Family

ID=7710240

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB028257057A Expired - Lifetime CN100402672C (en) | 2001-12-20 | 2002-11-21 | Method and device for controlled straightening and cooling of a wide metal strip, especially a steel strip or sheet metal, running out of a hot rolled strip rolling mill |

Country Status (13)

| Country | Link |

|---|---|

| US (2) | US20050016643A1 (en) |

| EP (1) | EP1456421B1 (en) |

| JP (1) | JP4440643B2 (en) |

| CN (1) | CN100402672C (en) |

| AT (1) | ATE328123T1 (en) |

| AU (1) | AU2002350708A1 (en) |

| BR (1) | BR0214598A (en) |

| CA (1) | CA2469073C (en) |

| DE (2) | DE10163070A1 (en) |

| ES (1) | ES2261757T3 (en) |

| RU (1) | RU2307718C2 (en) |

| UA (1) | UA77241C2 (en) |

| WO (1) | WO2003054236A1 (en) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4315951B2 (en) * | 2005-12-26 | 2009-08-19 | 株式会社神戸製鋼所 | Steel plate for welding |

| JP2011042814A (en) * | 2009-08-19 | 2011-03-03 | Chugai Ro Co Ltd | Apparatus and method for cooling metallic strip |

| US9822422B2 (en) | 2009-09-24 | 2017-11-21 | Ati Properties Llc | Processes for reducing flatness deviations in alloy articles |

| CN102548679B (en) | 2009-10-07 | 2014-11-05 | 新日铁住金株式会社 | Cooling apparatus and cooling method for hot rolling |

| EP2353742A1 (en) * | 2010-02-05 | 2011-08-10 | Siemens Aktiengesellschaft | Heat rolling train for rolling hot rolled strips, method for operating same to roll hot rolled strips, control and/or regulating device |

| EP2361699A1 (en) * | 2010-02-26 | 2011-08-31 | Siemens Aktiengesellschaft | Method for cooling sheet metal with a cooling section, cooling section and control and/or regulating device for a cooling section |

| CN101993995B (en) * | 2010-11-26 | 2012-05-30 | 首钢总公司 | Water quenching and cooling method and device for ultrahigh-strength strip steel |

| RU2463122C2 (en) * | 2010-12-16 | 2012-10-10 | Валерий Никитич Гринавцев | Method of strip straightening |

| RU2456109C1 (en) * | 2010-12-16 | 2012-07-20 | Валерий Никитич Гринавцев | Strip straightening machine |

| RU2474623C1 (en) * | 2011-10-31 | 2013-02-10 | Валентин Николаевич Никитин | Method of producing high-strength martensitic sheet steel and thermal strain complex to this end |

| KR101376565B1 (en) * | 2011-12-15 | 2014-04-02 | (주)포스코 | Method and apparatus for controlling the temperature of strip in the rapid cooling section of continuous annealing line |

| DE102012110010B4 (en) * | 2012-10-19 | 2016-09-01 | Bwg Bergwerk- Und Walzwerk-Maschinenbau Gmbh | Apparatus and method for the continuous treatment of a metal strip |

| CN105483343B (en) * | 2014-09-17 | 2017-06-23 | 宝山钢铁股份有限公司 | Medium and Heavy Plate Rolling Production linear velocity control method for improving steel plate flatness |

| CN104451117A (en) * | 2014-09-23 | 2015-03-25 | 中冶赛迪工程技术股份有限公司 | Quenching plate shape control method and device |

| DE102017118244A1 (en) * | 2017-08-10 | 2019-02-14 | Thyssenkrupp Ag | Apparatus and method for producing a hot strip |

| DE102017127470A1 (en) * | 2017-11-21 | 2019-05-23 | Sms Group Gmbh | Chilled beams and cooling process with variable cooling rate for steel sheets |

| US12091239B2 (en) | 2021-11-11 | 2024-09-17 | Advanced Composite Structures, Llc | Formed structural panel with open core |

| CN114959201B (en) * | 2022-06-27 | 2023-10-27 | 江西省科学院应用物理研究所 | Metal material classified annealing cooling device |

| CN117621423B (en) * | 2023-11-07 | 2024-05-14 | 东莞市首誉电子材料有限公司 | Preparation control method, device, equipment and medium of screen optical film |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3604696A (en) * | 1968-12-10 | 1971-09-14 | Dorn Co The Van | Continuous quench apparatus |

| FR2217425A1 (en) * | 1972-11-15 | 1974-09-06 | Creusot Loire | Quenching metal sheet under tension - average or thick sheet is rapidly cooled without warping |

| US4415143A (en) * | 1980-11-27 | 1983-11-15 | Kawasaki Steel Corporation | Continuous hardening device of steel plate |

| DE3313024A1 (en) * | 1983-04-12 | 1984-10-18 | Babcock-BSH AG vormals Büttner-Schilde-Haas AG, 4150 Krefeld | Method and device for quenching passing steel sheets, in particular thick or medium sheets, with simultaneously controlled alignment |

| JPS611420A (en) * | 1984-06-12 | 1986-01-07 | Kobe Steel Ltd | Forced cooling method of hot-rolled thick steel plate and its device |

| US4813652A (en) * | 1981-11-26 | 1989-03-21 | Union Siderurgique Du Nord Et De L'est De La France (Usinor) | Plant for effecting the controlled cooling of metal sheets |

| US4826138A (en) * | 1984-02-24 | 1989-05-02 | Van Dorn Company | Apparatus for heat treating steel plates |

| CN1087954A (en) * | 1992-12-09 | 1994-06-15 | 王德明 | Make the method for hardening hardened steel conveying belt with non-modified band steel |

| US5579658A (en) * | 1994-10-22 | 1996-12-03 | Bwg Berkwerk-Und Walzwerk-Maschinenbau Gmbh | Method of and apparatus for producing large metal plates |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATE31327T1 (en) * | 1984-02-24 | 1987-12-15 | Dorn Co V | METHOD AND DEVICE FOR THE HEAT TREATMENT OF STEEL PLATES. |

| EP1210993B2 (en) * | 2000-03-01 | 2016-07-06 | JFE Steel Corporation | Device and method for cooling hot rolled steel band and method of manufacturing the hot rolled steel band |

-

2001

- 2001-12-20 DE DE10163070A patent/DE10163070A1/en not_active Withdrawn

-

2002

- 2002-11-21 AU AU2002350708A patent/AU2002350708A1/en not_active Abandoned

- 2002-11-21 BR BR0214598-7A patent/BR0214598A/en not_active IP Right Cessation

- 2002-11-21 CN CNB028257057A patent/CN100402672C/en not_active Expired - Lifetime

- 2002-11-21 RU RU2004122098/02A patent/RU2307718C2/en active

- 2002-11-21 AT AT02785402T patent/ATE328123T1/en active

- 2002-11-21 DE DE50207037T patent/DE50207037D1/en not_active Expired - Lifetime

- 2002-11-21 WO PCT/EP2002/013035 patent/WO2003054236A1/en active IP Right Grant

- 2002-11-21 ES ES02785402T patent/ES2261757T3/en not_active Expired - Lifetime

- 2002-11-21 UA UA20040705923A patent/UA77241C2/en unknown

- 2002-11-21 US US10/498,652 patent/US20050016643A1/en not_active Abandoned

- 2002-11-21 JP JP2003554935A patent/JP4440643B2/en not_active Expired - Lifetime

- 2002-11-21 EP EP02785402A patent/EP1456421B1/en not_active Expired - Lifetime

- 2002-11-21 CA CA2469073A patent/CA2469073C/en not_active Expired - Fee Related

-

2011

- 2011-10-11 US US13/270,842 patent/US20120024435A1/en not_active Abandoned

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3604696A (en) * | 1968-12-10 | 1971-09-14 | Dorn Co The Van | Continuous quench apparatus |

| FR2217425A1 (en) * | 1972-11-15 | 1974-09-06 | Creusot Loire | Quenching metal sheet under tension - average or thick sheet is rapidly cooled without warping |

| US4415143A (en) * | 1980-11-27 | 1983-11-15 | Kawasaki Steel Corporation | Continuous hardening device of steel plate |

| US4813652A (en) * | 1981-11-26 | 1989-03-21 | Union Siderurgique Du Nord Et De L'est De La France (Usinor) | Plant for effecting the controlled cooling of metal sheets |

| DE3313024A1 (en) * | 1983-04-12 | 1984-10-18 | Babcock-BSH AG vormals Büttner-Schilde-Haas AG, 4150 Krefeld | Method and device for quenching passing steel sheets, in particular thick or medium sheets, with simultaneously controlled alignment |

| US4826138A (en) * | 1984-02-24 | 1989-05-02 | Van Dorn Company | Apparatus for heat treating steel plates |

| JPS611420A (en) * | 1984-06-12 | 1986-01-07 | Kobe Steel Ltd | Forced cooling method of hot-rolled thick steel plate and its device |

| CN1087954A (en) * | 1992-12-09 | 1994-06-15 | 王德明 | Make the method for hardening hardened steel conveying belt with non-modified band steel |

| US5579658A (en) * | 1994-10-22 | 1996-12-03 | Bwg Berkwerk-Und Walzwerk-Maschinenbau Gmbh | Method of and apparatus for producing large metal plates |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005512816A (en) | 2005-05-12 |

| CA2469073A1 (en) | 2003-07-03 |

| EP1456421A1 (en) | 2004-09-15 |

| RU2004122098A (en) | 2005-03-27 |

| BR0214598A (en) | 2004-11-03 |

| RU2307718C2 (en) | 2007-10-10 |

| CA2469073C (en) | 2011-10-11 |

| EP1456421B1 (en) | 2006-05-31 |

| ATE328123T1 (en) | 2006-06-15 |

| US20120024435A1 (en) | 2012-02-02 |

| WO2003054236A1 (en) | 2003-07-03 |

| US20050016643A1 (en) | 2005-01-27 |

| UA77241C2 (en) | 2006-11-15 |

| AU2002350708A1 (en) | 2003-07-09 |

| JP4440643B2 (en) | 2010-03-24 |

| ES2261757T3 (en) | 2006-11-16 |

| DE10163070A1 (en) | 2003-07-03 |

| CN1606630A (en) | 2005-04-13 |

| DE50207037D1 (en) | 2006-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100402672C (en) | Method and device for controlled straightening and cooling of a wide metal strip, especially a steel strip or sheet metal, running out of a hot rolled strip rolling mill | |

| EP2465620B1 (en) | Method for cooling hot-rolled steel strip | |

| US6463652B1 (en) | Apparatus and methods for manufacturing hot rolled steel sheets | |

| TWI412412B (en) | Cooling device for colling of a metal strip | |

| CN101755058A (en) | Be used for method that the steel band that is formed from steel is carried out hot rolling and heat-treats | |

| EP2025423A1 (en) | Cooler and cooling method of hot rolled steel band | |

| CN100491001C (en) | Casting-milling process method for manufacturing copper and copper alloy band | |

| CN1070393C (en) | Hot-rolling method and arrangement | |

| CN1051259C (en) | Method and apparatus for rolling of belt steel from blocks continously casted | |

| KR20050094045A (en) | Method for milling thin and/or thick slabs made of steel materials into hot-rolled strip | |

| CN102548679A (en) | Cooling apparatus and cooling method for hot rolling | |

| CN114951304B (en) | Roll bending force setting method for cold continuous rolling strip steel head plate shape defect | |

| CN101310029A (en) | Method and finishing train for hot-rolling starting material | |

| JP2000192146A (en) | Method for cooling steel plate and device therefor | |

| JP4277344B2 (en) | Tension leveler and strip straightening method | |

| JP3146786B2 (en) | Hot rolling equipment and hot rolling method | |

| EP3453465A1 (en) | Compact intense cooling device for strip in cold rolling mill | |

| KR100711386B1 (en) | A method for controlling cooling of the hot steel strip | |

| CN220717231U (en) | Board production system | |

| US20230060110A1 (en) | Hot-rolling stand for a hot-rolling mill and for producing a flat metal product, hot-rolling mill and method for operating a hot-rolling mill | |

| KR100241015B1 (en) | Method for manufacturing hot working plate with different metallic property along the width of the plate | |

| US5842367A (en) | Rolling mill train system for the manufacture of hot rolled wide strip | |

| SU1400689A1 (en) | Arrangement for adjusting the cooling of moving strip steel rolled stock | |

| USRE13173E (en) | Rolling black plates or sheets | |

| US20050016242A1 (en) | Continous hot-rolling facility |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20080716 |