CN100336210C - Barrier layer made of a curable resin containing polymeric polyol - Google Patents

Barrier layer made of a curable resin containing polymeric polyol Download PDFInfo

- Publication number

- CN100336210C CN100336210C CNB038030160A CN03803016A CN100336210C CN 100336210 C CN100336210 C CN 100336210C CN B038030160 A CNB038030160 A CN B038030160A CN 03803016 A CN03803016 A CN 03803016A CN 100336210 C CN100336210 C CN 100336210C

- Authority

- CN

- China

- Prior art keywords

- layer

- separator

- solar cell

- curable resin

- resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229920005989 resin Polymers 0.000 title claims description 57

- 239000011347 resin Substances 0.000 title claims description 57

- 230000004888 barrier function Effects 0.000 title abstract description 8

- 229920005862 polyol Polymers 0.000 title abstract description 3

- 150000003077 polyols Chemical class 0.000 title abstract description 3

- 239000003822 epoxy resin Substances 0.000 claims abstract description 14

- 229920000647 polyepoxide Polymers 0.000 claims abstract description 14

- 239000011159 matrix material Substances 0.000 claims description 34

- 150000005846 sugar alcohols Polymers 0.000 claims description 30

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 claims description 18

- 239000006096 absorbing agent Substances 0.000 claims description 11

- 239000011521 glass Substances 0.000 claims description 11

- KTSFMFGEAAANTF-UHFFFAOYSA-N [Cu].[Se].[Se].[In] Chemical compound [Cu].[Se].[Se].[In] KTSFMFGEAAANTF-UHFFFAOYSA-N 0.000 claims description 2

- 229920003023 plastic Polymers 0.000 claims description 2

- 239000004033 plastic Substances 0.000 claims description 2

- 239000000758 substrate Substances 0.000 abstract 2

- 239000007795 chemical reaction product Substances 0.000 abstract 1

- 239000010410 layer Substances 0.000 description 92

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 16

- 239000010408 film Substances 0.000 description 14

- 239000000463 material Substances 0.000 description 13

- 208000034189 Sclerosis Diseases 0.000 description 11

- 239000007788 liquid Substances 0.000 description 11

- 239000002648 laminated material Substances 0.000 description 10

- 239000011342 resin composition Substances 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 8

- 238000002161 passivation Methods 0.000 description 8

- 239000011787 zinc oxide Substances 0.000 description 8

- 239000000203 mixture Substances 0.000 description 7

- 238000006243 chemical reaction Methods 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 6

- 238000002474 experimental method Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 239000002904 solvent Substances 0.000 description 6

- 239000010409 thin film Substances 0.000 description 6

- -1 aromatic epoxide Chemical class 0.000 description 5

- 238000000151 deposition Methods 0.000 description 5

- 230000008021 deposition Effects 0.000 description 5

- 150000002118 epoxides Chemical class 0.000 description 5

- 239000012790 adhesive layer Substances 0.000 description 4

- 125000001931 aliphatic group Chemical group 0.000 description 4

- 230000007797 corrosion Effects 0.000 description 4

- 238000005260 corrosion Methods 0.000 description 4

- 238000009792 diffusion process Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 238000005538 encapsulation Methods 0.000 description 4

- 239000005038 ethylene vinyl acetate Substances 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 4

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 description 3

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 3

- 238000005229 chemical vapour deposition Methods 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 239000000945 filler Substances 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 230000006872 improvement Effects 0.000 description 3

- 238000002955 isolation Methods 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000005855 radiation Effects 0.000 description 3

- 239000000376 reactant Substances 0.000 description 3

- 239000000243 solution Substances 0.000 description 3

- 239000002966 varnish Substances 0.000 description 3

- 239000004593 Epoxy Substances 0.000 description 2

- 239000004831 Hot glue Substances 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical group O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 125000002723 alicyclic group Chemical group 0.000 description 2

- 239000003513 alkali Substances 0.000 description 2

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- GPBUGPUPKAGMDK-UHFFFAOYSA-N azanylidynemolybdenum Chemical compound [Mo]#N GPBUGPUPKAGMDK-UHFFFAOYSA-N 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 2

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 2

- 238000007766 curtain coating Methods 0.000 description 2

- 239000011353 cycloaliphatic epoxy resin Substances 0.000 description 2

- 238000010790 dilution Methods 0.000 description 2

- 239000012895 dilution Substances 0.000 description 2

- HNRMPXKDFBEGFZ-UHFFFAOYSA-N ethyl trimethyl methane Natural products CCC(C)(C)C HNRMPXKDFBEGFZ-UHFFFAOYSA-N 0.000 description 2

- 239000012948 isocyanate Substances 0.000 description 2

- 150000002513 isocyanates Chemical group 0.000 description 2

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 2

- 229910052753 mercury Inorganic materials 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 239000011733 molybdenum Substances 0.000 description 2

- 238000000465 moulding Methods 0.000 description 2

- 238000010606 normalization Methods 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- 235000012424 soybean oil Nutrition 0.000 description 2

- 239000003549 soybean oil Substances 0.000 description 2

- 238000004441 surface measurement Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- 239000011701 zinc Substances 0.000 description 2

- GTACSIONMHMRPD-UHFFFAOYSA-N 2-[4-[2-(benzenesulfonamido)ethylsulfanyl]-2,6-difluorophenoxy]acetamide Chemical compound C1=C(F)C(OCC(=O)N)=C(F)C=C1SCCNS(=O)(=O)C1=CC=CC=C1 GTACSIONMHMRPD-UHFFFAOYSA-N 0.000 description 1

- QGHDLJAZIIFENW-UHFFFAOYSA-N 4-[1,1,1,3,3,3-hexafluoro-2-(4-hydroxy-3-prop-2-enylphenyl)propan-2-yl]-2-prop-2-enylphenol Chemical group C1=C(CC=C)C(O)=CC=C1C(C(F)(F)F)(C(F)(F)F)C1=CC=C(O)C(CC=C)=C1 QGHDLJAZIIFENW-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- 101710130081 Aspergillopepsin-1 Proteins 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- 102100031007 Cytosolic non-specific dipeptidase Human genes 0.000 description 1

- ZNZYKNKBJPZETN-WELNAUFTSA-N Dialdehyde 11678 Chemical compound N1C2=CC=CC=C2C2=C1[C@H](C[C@H](/C(=C/O)C(=O)OC)[C@@H](C=C)C=O)NCC2 ZNZYKNKBJPZETN-WELNAUFTSA-N 0.000 description 1

- 229920000877 Melamine resin Polymers 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- 239000005062 Polybutadiene Substances 0.000 description 1

- 229920002367 Polyisobutene Polymers 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- QOSMNYMQXIVWKY-UHFFFAOYSA-N Propyl levulinate Chemical compound CCCOC(=O)CCC(C)=O QOSMNYMQXIVWKY-UHFFFAOYSA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 1

- 238000012644 addition polymerization Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001278 adipic acid derivatives Chemical class 0.000 description 1

- 238000007743 anodising Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000004841 bisphenol A epoxy resin Substances 0.000 description 1

- 229940106691 bisphenol a Drugs 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 230000001680 brushing effect Effects 0.000 description 1

- 239000011469 building brick Substances 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 238000010538 cationic polymerization reaction Methods 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- QSAWQNUELGIYBC-UHFFFAOYSA-N cyclohexane-1,2-dicarboxylic acid Chemical compound OC(=O)C1CCCCC1C(O)=O QSAWQNUELGIYBC-UHFFFAOYSA-N 0.000 description 1

- 239000013530 defoamer Substances 0.000 description 1

- 239000004205 dimethyl polysiloxane Substances 0.000 description 1

- 235000013870 dimethyl polysiloxane Nutrition 0.000 description 1

- 238000003618 dip coating Methods 0.000 description 1

- 239000002019 doping agent Substances 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000005007 epoxy-phenolic resin Substances 0.000 description 1

- 229920006244 ethylene-ethyl acrylate Polymers 0.000 description 1

- 229920006225 ethylene-methyl acrylate Polymers 0.000 description 1

- 239000005357 flat glass Substances 0.000 description 1

- 239000005329 float glass Substances 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 150000002440 hydroxy compounds Chemical class 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000003475 lamination Methods 0.000 description 1

- 238000003698 laser cutting Methods 0.000 description 1

- 239000002346 layers by function Substances 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 238000004020 luminiscence type Methods 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- 150000001451 organic peroxides Chemical class 0.000 description 1

- INSIURULIZUZHA-UHFFFAOYSA-N oxacyclotridecane Chemical compound C1CCCCCCOCCCCC1 INSIURULIZUZHA-UHFFFAOYSA-N 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 229920000435 poly(dimethylsiloxane) Polymers 0.000 description 1

- 229920002857 polybutadiene Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 229920005672 polyolefin resin Polymers 0.000 description 1

- 229920001451 polypropylene glycol Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920005749 polyurethane resin Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000003678 scratch resistant effect Effects 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 239000005361 soda-lime glass Substances 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- IFHVCUGTUBHOML-UHFFFAOYSA-N trimethyl (3-methyloxiran-2-yl) silicate Chemical compound CC1C(O1)O[Si](OC)(OC)OC IFHVCUGTUBHOML-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10009—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets

- B32B17/10036—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets comprising two outer glass sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10761—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer containing vinyl acetal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/26—Layered products comprising a layer of synthetic resin characterised by the use of special additives using curing agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/38—Layered products comprising a layer of synthetic resin comprising epoxy resins

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G18/00—Polymeric products of isocyanates or isothiocyanates

- C08G18/06—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen

- C08G18/28—Polymeric products of isocyanates or isothiocyanates with compounds having active hydrogen characterised by the compounds used containing active hydrogen

- C08G18/40—High-molecular-weight compounds

- C08G18/4009—Two or more macromolecular compounds not provided for in one single group of groups C08G18/42 - C08G18/64

- C08G18/4063—Mixtures of compounds of group C08G18/62 with other macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G59/00—Polycondensates containing more than one epoxy group per molecule; Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups

- C08G59/02—Polycondensates containing more than one epoxy group per molecule

- C08G59/027—Polycondensates containing more than one epoxy group per molecule obtained by epoxidation of unsaturated precursor, e.g. polymer or monomer

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G59/00—Polycondensates containing more than one epoxy group per molecule; Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups

- C08G59/18—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing

- C08G59/40—Macromolecules obtained by polymerising compounds containing more than one epoxy group per molecule using curing agents or catalysts which react with the epoxy groups ; e.g. general methods of curing characterised by the curing agents used

- C08G59/62—Alcohols or phenols

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L63/00—Compositions of epoxy resins; Compositions of derivatives of epoxy resins

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L31/00—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof

- H01L31/04—Semiconductor devices sensitive to infrared radiation, light, electromagnetic radiation of shorter wavelength or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof adapted as photovoltaic [PV] conversion devices

- H01L31/042—PV modules or arrays of single PV cells

- H01L31/048—Encapsulation of modules

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/80—Constructional details

- H10K50/84—Passivation; Containers; Encapsulations

- H10K50/841—Self-supporting sealing arrangements

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K50/00—Organic light-emitting devices

- H10K50/80—Constructional details

- H10K50/84—Passivation; Containers; Encapsulations

- H10K50/844—Encapsulations

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31551—Of polyamidoester [polyurethane, polyisocyanate, polycarbamate, etc.]

- Y10T428/31627—Next to aldehyde or ketone condensation product

- Y10T428/3163—Next to acetal of polymerized unsaturated alcohol [e.g., formal butyral, etc.]

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Electromagnetism (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Photovoltaic Devices (AREA)

- Laminated Bodies (AREA)

- Sealing Material Composition (AREA)

- Epoxy Resins (AREA)

Abstract

A component involving a substrate, a layered structure arranged on the substrate, and a barrier layer arranged over the layered structure, wherein the barrier layer has the reaction product of an epoxy resin and a polymeric polyol.

Description

The present invention relates to a kind of assembly, it comprises matrix and the layer structure that is arranged on this matrix, and wherein layer structure also should be protected moisture-sensitive.In order to protect layer structure, assembly further comprises the separator (barrier layer) that covers this layer structure.Separator is also referred to as cover layer.Because the layer to moisture-sensitive equally may be to corrosion-susceptible, so wording " to moisture-sensitive " is used for expression " to moisture-sensitive ", " to corrosion-susceptible " or " the two is all responsive to moisture and corrosion ".

The example of assembly involved in the present invention is that wherein layer structure comprises the assembly of light or electroactive film, as radiation detector, solar cell or solar energy module or photoelectric subassembly, as light-emitting display device and liquid crystal display (LCD) screen.

In the middle of solar cell, thin-film solar cells is in the position of particular importance.Thin-film solar cells is represented the marked improvement of technology, and this is because they can be basically than more effectively making on the conventional solar cell cost.Thin film technique is the direct deposition of absorber layer on matrix of 0.002mm based on thickness.Layer structure further is included in molybdenum backplate on the matrix and the front electrode on absorber layer.A series of connections of integrated increase module voltage and avoided expensive welding sequence in such a way in manufacturing process.Absorber layer is the layer to moisture-sensitive.Yet not only absorber layer damages easily, and the electrode pair moisture-sensitive.

Suitable film absorber layer comprises copper-indium-diselenide (CuInSe

2, be called for short CIS).The CIS technology has that particularly advantageous realization is efficient, good long term is stable and prospect cheaply.Suitable matrix is float glass.The efficient of the maximum 17-18% that is realized is the highest in all hull cells.Under the simple scenario of compact battery, realize even greater than these numerical value, nearly 14% module efficient proves the potentiality of this technology.Another advantage is to make a layer material in force, can by laser cutting be connected the fact that is connected on the module by integrated series afterwards.

In order to satisfy the quality requirement in market, the necessary successful operation of solar energy module is by a series of different test procedures.One of these steps should be tested the weatherability of solar energy module, and this is a humid heat test.In this test, according to known standard IEC 1215, module is being exposed under 85 ℃ the temperature 1000 hours under 85% the relative air humidity.

When the moisture-sensitive layer suffered moisture, its sheet resistance increased, and the quality of encapsulation has determined the increase of sheet resistance.

Sheet resistance, ρ

s(unit is ohm) is to see the edge as layer resistance of interior material thin-layer measure.At equation: ρ

sAmong=ρ/t, wherein t is bed thickness (unit be centimetre), wherein ρ be material resistivity (unit is ohm. centimetre), and resistivity is defined by ρ=RA/l, wherein R is the resistance (unit ohm) of this layer, A is that the cross-sectional area (unit be square centimeter) of this layer and l are layer long (units be centimetre).

Can not realize reducing the susceptibility of assembly to moisture by simplified package with the stacked arrangement that comprises adhesive foil and possible second glass plate.

Avoid moisture to diffuse in the lamination layer structure, a kind of possibility that especially enters in the solar energy module is to make the moisture the evolving path longer.This requires enough wide edge or border (rim) greater than 15cm.Yet edge that this is wide or border are unacceptable in the solar energy module, and this is because the surface of active module is significantly reduced on the border.

Another solution is disclosed among the open No.19707280 of German patent application.This solution provides and is selected from Al

2O

3, Si

3N

4, TiN, MoN and SiO

xN

yIn inorganic barrier.

German patent specification No.19514908 has disclosed a kind of assembly, it comprises matrix and the layer structure that is arranged on this matrix, with the separator on this layer structure, wherein separator comprises PIC and based on the product of the trifunctional polyalcohol of trimethyl propane.This is conventional polyurethane system.

The purpose of this invention is to provide a kind of to the insensitive assembly of moisture, its comparable inorganic barrier is easier and do not having to make under the high extra manufacturing cost and proving above-described experimental condition and the stability that has increase under normal operating condition.

For this reason, assembly of the present invention comprises matrix, is arranged in the layer structure on this matrix, with the separator that is arranged on this layer structure, wherein separator comprises the product of polymerized polyalcohol and curable resin, it is characterized in that curable resin is an epoxy resin.

In specification and claims, wording " curable resin " is used in reference to for crosslinked resin, thermosetting resin maybe can vulcanize resin.

Refer now to the open No.903790 of european patent application.The disclosure has disclosed a kind of assembly, it comprises matrix and the layer structure that is arranged on this matrix, with the top encapsulation material that is arranged on this layer structure, wherein the top encapsulation material comprises polyolefin resin, as ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and polyvinyl butyral resin, polyurethane resin, organic siliconresin and fluororesin.The bottom package material comprises ethylene-vinyl acetate or polyvinyl butyral resin.The disclosure and the present invention are uncorrelated.

Further with reference to USA patent specification No.6204443.The disclosure has disclosed a kind of assembly, it comprises matrix and the layer structure that is arranged on this matrix, with the face side filler (surface side filler) that is arranged on this layer structure, wherein the face side filler comprises the not crosslinked resin layer (ethylene-vinyl acetate copolymer, polyvinyl butyral resin, epoxy resin, acrylic resin, organic siliconresin and fluororesin) that is clipped between the two-layer crosslinked resin layer.Crosslinking agent is isocyanates, melamine or organic peroxide.The disclosure and the present invention are uncorrelated.

In addition, with reference to USA patent specification No.6288326.The disclosure has disclosed a kind of assembly, and it comprises matrix and be arranged in the layer structure on this matrix and be arranged in encapsulating material on this layer structure that wherein encapsulating material comprises ethylene-vinyl acetate and polyisobutene resin.The disclosure and the present invention are uncorrelated.

Description is described the present invention in more detail by embodiment, wherein

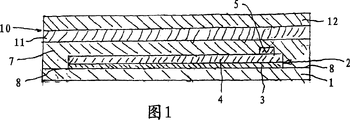

Fig. 1 schematically and not in scale shows assembly of the present invention cross section;

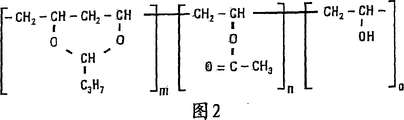

Fig. 2 shows the structural formula of polyvinyl butyral resin;

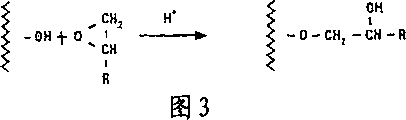

Fig. 3 shows the reaction of polyvinyl butyral resin and epoxy resin; With

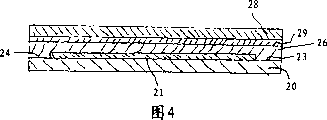

Fig. 4 schematically and not in scale shows the cross section of the assembly that uses in test.

Refer now to Fig. 1.Assembly of the present invention comprises matrix 1, deposition layer structure 2 on described matrix.Layer structure is included on the matrix 1 backplate 3 of deposition, the absorber layer 4 of deposition on the electrode 3, at least one front electrode 5 of accepting to arrange on the surface at the light of absorber layer 4 overleaf.

Assembly of the present invention further comprises separator 7, and this separator 7 comprises the product of curable resin and polymerized polyalcohol.Separator 7 is extending on the outer surface of layer structure 2 and is ending on the border 8 of matrix 1.The thickness of separator is suitably in the 100nm-2mm scope.

For complete covering assemblies, apply conventional laminated material.This laminated material is made up of the cover layer 10 and the adhesive layer 11 of clear glass, wherein with adhesive layer laminated material is bonded on the separator 7.Adhesive layer 11 is the layer of being made up of the polyvinyl butyral resin of thickness 0.5mm suitably.Under 150 ℃ temperature, apply laminated material.

For simplicity, we do not illustrate and are connected to the electric current that will generate on backplate 3 and the front electrode 5 carry the electric contact that leaves in course of normal operation.

The mode that is formed separator by the liquid resin composition that contains curable resin and polymerized polyalcohol was discussed in the stage subsequently.

Separator of the present invention is not only damp proof, and it is bonded on the matrix so well, so that prevent the diffusion of moisture along the interface at 8 places, border between matrix 1 and separator 4.The applicant finds, with moisture along comparing in the diffusion at the interface between separator and the matrix, moisture is not remarkable through the diffusion of separator itself.

Separator of the present invention comprises the product of curable resin and polymerized polyalcohol.By apply contain curable resin and polymerized polyalcohol liquid resin composition to assembly surface to be covered, make this polymerized polyalcohol and resin reaction then, thereby obtain separator.

Can carry out applying of liquid resin composition by spraying, brushing, dip-coating and spin coating (spin on) method, screen printing or the like.

In order to apply, liquid resin composition can further be used solvent dilution, for example in order to spray or to brush, with the dilution of acetic acid ethyoxyl propyl ester.

After applying liquid resin composition, carry out the reaction between polymerized polyalcohol and the curable resin.

Polymerized polyalcohol is a higher molecular weight, and especially molal weight is about 1000 or higher polyalcohol.The example of polymerized polyalcohol is polyvinyl alcohol, PEPA and/or PPG.

Especially suitable polymerized polyalcohol is a structural formula polyvinyl butyral resin (PVB) as shown in Figure 2, and it has free hydroxyl group.Depend on m, n, o, realize different physics and chemical property.The molal weight or the degree of polymerization demonstrate big importance to heat with mechanical performance with to solution viscosity respectively.

Polymerized polyalcohol can be the mixture of the polymerized polyalcohol of above-mentioned example equally.

Second kind of component is the curable resin of epoxy resin form.Second kind of component can be the mixture of epoxy resin and isocyanates equally.

Reaction between polymerized polyalcohol and the curable resin is called sclerosis, curing or crosslinked.If there is solvent, then after flashing away solvent, begin reaction.By ultraviolet (UV) radiation treatment, for example react with commercially available mercury emission lamp.

Schematically shown the reaction of polyvinyl butyral resin and epoxy resin among Fig. 3.

Curable resin is an epoxy resin.The epoxy resin that is incorporated in the separator can be aliphatic, alicyclic or aromatic epoxide, wherein preferred aliphatic series and alicyclic (promptly encircling by epoxidised) epoxides.Advantageously, epoxy resin is made up of aliphatic series and/or the cycloaliphatic epoxides of 〉=70wt%.

Especially epoxidized polybutadiene or epoxidized soybean oil are aliphatic epoxides; Further available epoxides is the 2-glycidyl ester of dodecylene oxide and hexahydrophthalic acid for example.The preferred diepoxide of cycloaliphatic epoxides.This diepoxide for example is 3,4-epoxycyclohexyl methyl-3 ', 4 '-epoxy hexamethylene carboxylate (EEC) and two (3,4-epoxycyclohexyl methyl) adipate ester.Other such epoxides for example is that the aliphatic chain of the adipic acid derivative wherein be made up of 4 MUs is had the compound that the chain of 5-15 MU replaces.

Basis sclerosis chemistry be epoxy resin cationic polymerization and with the common addition polymerization of suitable polyol.PVB is this class hydroxy compounds, is therefore mixed or participate in being cross-linked to form of gained high-quality moulding material by chemistry.The gained moulding material is hard plastic material, demonstrates good bonding and proof and has good tensile and elasticity.In addition, it has good transmittancy, and this makes it be particularly suitable for using in solar cell and luminescence component.

With the ability of UV photo-initiated crosslinking, might the quick-hardening layer of varnish.Sclerosis is not to be caused by heat purely, and when getting rid of short wavelength light with box lunch, prescription has the almost useful life of endless.This provides flexibility that applies technology and the automation of quickening the latter.For applying and hardening, do not need vacuum or high temperature usually.Flash away the solvent that may exist and after under being exposed to UV, promote final sclerosis just to promotion, increase temperature slightly and come in handy.

With lamp or with the laser under the absorbing wavelength of the preferred light trigger that comprises in corresponding to curable resin, the curable resin that contains PVB is exposed under the UV light.Under situation about exemplifying, adopting the power density in UV A scope is 100mW/cm

2Mercury emission lamp, under 20 seconds radiated time section, expose.With under 60 ℃ through the following heat treatment of 20 minute duration, additional improvement is to the isolation effect of water and oxygen.

The liquid resin composition that is applicable to separator of the present invention contains epoxy compounds, especially diepoxide (30-95% of composition weight), the polyvinyl butyral resin of composition weight 1-15%, and light trigger suitably.Randomly also can contain varnish additive such as defoamer, levelling agent and/or adhesive accelerant.Depend on to apply technology, they can contain solvent in addition, wherein flash away described solvent before the UV sclerosis.

Depend on OH content, further use the crosslinked PVB of other co-reactant.In actual applications, use reactant such as epoxy resin, phenolic resins and melmac.Apply for other, correspondingly the phenol carbamide resin of catalysis or melmac and PIC and dialdehyde can be used as co-reactant.The also alternative UV sclerosis of thermmohardening herein.

Especially, the sclerosis of the curable resin that cation causes, promptly UV hardens, and obtains the polymer molecule of " single " to a certain extent, and it does not contain the low molecular component that outgases, and these low molecular components that outgas can be damaged the electric capacity of assembly to be protected.Advantageously, heat-treat the heat treatment under preferred maximum 120 ℃ temperature after the UV sclerosis.Usually, lowest temperature is lower 10-20 ℃ than the glass transition temperature of the curable resin of sclerosis.With heat treatment (after-hardening), can further increase the isolation effect of separator to water and oxygen.

Especially, resin is the resin of UV-curable, and promptly it solidifies under the effect of UV light.In this application, the epoxy resin of UV-curable is specially suitable.

The consumption of polymerized polyalcohol is suitably greater than 1% of curable resin weight, especially greater than 5wt%.The amount ranges of preferred polymeric polyalcohol is the 1%-15% of curable resin weight, but can mostly be 30% of curable resin weight most.

Separator preferably almost completely is made up of the product of curable resin and polymerized polyalcohol.

Can apply separator with known step as impermeable barrier, promptly it does not contain the hole, optical clear and edges cover.Depend on that to make this layer impermeable or do not contain the degree in hole, thickness is that 1 micron separator can enough have been guaranteed the abundant protection to moisture.Certainly, thicker separator is possible.For wherein obtain not contain fully the hole not exclusively evenly or do not cover well the border separator apply technology, the preferred separator of selecting big thickness.When the step that on layer structure, has high pattern (high topographic step), select the layer of the about at most 2mm of thickness, so that edges cover separator well.

By polymerized polyalcohol is added in the curable resin, especially improve the filming performance of curable resin.In addition, in the assembling process of assembly or in the manufacture process of solar cell, PVB layer or other polymerized polyalcohol layer are very frequently as laminate layers.This separator forms especially closely with the separator of being made by the polymerized polyalcohol that contains curable resin and is connected, this be in curable resin, be coupled on the polymerized polyalcohol because of them goodly due to.

Separator is formed the separator that prevents moisture and is positioned at least one outer surface of assembly, and described outer surface is at least a portion surface of the outer surface of layer structure and the matrix that do not covered by the stratiform structure.

This separator that employing is made by the curable resin that contains polymerized polyalcohol, but Production Example such as thin film solar module, it has passed through the warm test mentioned at first and performance loss less than 5% and there is not a macroscopic radiation damage.

Because function and for example optical clear or the electric insulation of the layer structure that separator of the present invention is suitable for covering, so it does not demonstrate negative effect to layer structure.It does not influence yet layer structure mix wherein optics or the operation of electric assembly, do not damage its performance yet.

The separator proof has good bonding on most of materials that are used as electricity or optical functional layer or matrix.Possibly, may need to provide the layer of extra bonding.

Because layer structure can comprise separator as the additional layer that contains the conventional layered structure of one deck or any amount layer, so it can for example cover with laminated material further with conventional cover layer.Therefore, the laminated material of being made up of glass plate and intermediate adhesion layer also can be provided on the separator that covers layer structure.Other assembly can in addition or or cover or seal with curtain coating resin bed or other curtain coating compound on separator.

Separator of the present invention is particularly suitable for applying the laminated material that covers it because prove it on the conventional hot melt adhesive layer that uses up to now or below have good bonding, this comes from tight connection the between polymerized polyalcohol and the laminated material.The bonds well of hot melt adhesive film, and and then the bonds well of whole laminar structure, cause improved impenetrability, this prevents that moisture is respectively along between layer structure and the laminated material or the interfacial diffusion between separator and the laminated material.

Preferred separator seals the layer structure to moisture-sensitive from the top of the matrix for example is made of glass with from the side of lower edge and end.Separator of the present invention also can cover metal level or passivation layer.Passivation layer also can be an inorganic barrier.The suitable material of passivation layer is silica, titanium nitride and molybdenum nitride.Two kinds of hard especially and scratch-resistants in back.Separator of the present invention proof to all layers have good bonding and and then with these layers formation moisture impermeable and chemically stable interface.

In one embodiment of the invention, layer structure is the electronic building brick with at least two electrodes, wherein forms an electrode by the electrode layer that is located immediately on the matrix.This electrode is called as backplate and can constructs backplate, to obtain to be particularly suitable for the electrode structure of the integrated serial thin film solar module that connects.

Except necessary electrode structure, also can form the electrical connection of at least two electrodes and derive device region from the side by this backplate layer.The advantage of this device is, do not having can to form especially smooth structure under the extra configuration steps situation, and this conventional equipment with the electrical connection of for example adopting welding is opposite.Adopt separator of the present invention, this helps edges cover to seal.

Below separator, derive the layer structure of assembly and can form by corrosion resistant metal by the electrical connection that first electrode layer forms.Yet preferably they are covered by conductive passivation layer, are especially covered by titanium nitride or nitrogenize molybdenum layer.Passivation layer can cover the lower electrode layer fully and make in view of the above.Also might only in being electrically connected the zone, by being connected in the zone of deriving below separator, cover the lower electrode layer with passivation layer with especially only.

Another advantageous embodiment of the present invention relates to the CIS thin film solar module of having mentioned.For example known according to Deutsche Bundespatent No.DE4442824C1, the regulation alkali content in the CIS absorber layer is necessary for the maximal efficiency of solar cell.Because when adopting glass matrix, the regulation alkali content of CIS absorber layer only directly just may realize under the situation above the electrode layer above the glass matrix or overleaf at alkaline separator, so the electrode top separator of the present invention that forms passivation layer can use in this separator in an advantageous manner overleaf.Simultaneously, can serve as the passivation layer of the electrical connection usefulness of leading the outside respectively, or serve as the separator of whole lower electrode by the separator of titanium nitride or molybdenum nitride manufacturing.It demonstrates especially good bonding and forms especially good and impermeable interface with this separator simultaneously the additional isolation layer of solar cell top.

Now by some experiments, the mode by embodiment further describes the present invention.In order to obtain repeatably result, the applicant carries out humid heat test containing on the specific components of glass matrix, wherein on described glass matrix with chemical vapour deposition technique dopant deposition anodizing zinc, and surface measurements resistance.Yet,, need lower numerical value in order to realize the duty factor of solar energy module.

Refer now to Fig. 4, Fig. 4 has schematically shown the cross section of test assembly.Applying thickness with chemical vapour deposition (CVD) on the matrix 20 of the thick window glass plate soda-lime glass of 2mm (length is that 10cm and width are 10cm) is 1.5 microns boron doped zinc oxide film 21.After applying zinc oxide film, take out the oxidation zink rod of width 10mm from matrix 20, so that make 4 borders that are not capped, show wherein border 23 and 24 at Fig. 4.Then two metal intercell connector (not shown) are connected on the zinc oxide film on the opposite side of zinc oxide film, so that can determine the sheet resistance of zinc oxide film reliably.

As described below, applied after the bow strip, apply separator 26.After this adhesive layer 29 of glass cover layer 28 with polyvinyl butyral resin is bonded on the separator.Under reduced pressure, making thickness is that the separator 29 of 0.5mm solidified 30 minutes down at 145 ℃.With separating the film (not shown) of vacuum chamber (wherein assembly is in this vacuum chamber) with the compression chamber, on glass cover layer 28, to exert pressure, the pressure reduction on the film is 450mbar.

In order to realize the validity of separator of the present invention, carry out 4 experiments, to determine the sheet resistance of zinc oxide film under humid heat test.In this test, module is being exposed under 85 ℃ the temperature 1000 hours under 85% the relative air humidity.

Preparation as described below separator of the present invention.At first prepare liquid resin composition.Liquid resin composition is made up of following: 35g polyvinyl butyral resin, 357g cycloaliphatic epoxy resin, 236g OH-134 (is that 1: 3 bisphenol-A and cycloaliphatic epoxy resin Araldit CY179 forms by ratio), 157g epoxidized soybean oil, 197g trifunctional group polyester polyalcohol, 9.8g triaryl matte hexafluoro antimonate, 3.9g (3-epoxypropoxy) trimethoxy silane, 3.4g dimethyl polysiloxane derivative.

On assembly, brush liquid resin composition then, so that the border 23 and 24 around capping oxidation zinc layer and the zinc oxide film.With under the UV condition, make the resin combination sclerosis.

Make then and being electrically connected (not shown) and test assembly is placed in the confession container of damp and hot test of Metal Contact bar (not shown).Surface measurements resistance in process of the test.

In order to compare the gained result, compare experiment.At first, assembly does not cover with separator.

Adopt the separator of forming by conventional resin to carry out two groups of comparative experimentss then, in first comparative experiments, the liquid resin composition that use is made up of bi-component varnish 1640 (available from RhenatechElektroisoliersysteme) is made separator (Comparative Examples A), with in second comparative experiments, use acrylate composition Multi-Cure 984 (trade (brand) name) LVUF (available from Dymax EuropeGmbH) of liquid UV-curable to make separator (comparative example B).

With reference to composition of the present invention, on the test assembly of being discussed, brush resin combination and make it sclerosis.

Under the condition identical, measure the sheet resistance of these three test assemblies then with the sheet resistance of measuring assembly of the present invention.The normalization sheet resistance, so that for all component, initial sheet resistance is 1.

Following table shows the result.

Table adopts the present invention and three comparative examples' separator to measure

The normalization sheet resistance of zinc oxide

| Time (hour) | The present invention | There is not separator | Comparative Examples A | |

| 0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 200 | 1.0 | 1.7 | 1.1 | 1.0 |

| 400 | 1.1 | 3.0 | 1.7 | 1.2 |

| 600 | 1.4 | 4.1 | 2.5 | 1.4 |

| 800 | 1.5 | 4.8 | 3.2 | 2.0 |

| 1000 | 1.8 | 5.7 | 4.2 | 2.9 |

This has expressed the improvement that obtains with separator of the present invention.

Utilize the present invention, can successfully comprise any layer structure of weather and corrosion-susceptible layer and especially have the weather and the stable encapsulation of corrosion of the film apparatus on big surface.The present invention is particularly suitable for being exposed to this film apparatus under heat and/or the wet environment, as solar cell.Certainly, for usually be not exposed to this corrosion promote under the environmental condition layer structure this also be effective.

Claims (13)

1. solar cell, it comprises matrix, be arranged in the layer structure on this matrix, with the separator that is arranged on this layer structure, wherein layer structure comprises light or electroactive film, wherein separator comprises the product of polymerized polyalcohol and curable resin, it is characterized in that curable resin is that epoxy resin and polymerized polyalcohol are polyvinyl butyral resins.

2. the solar cell of claim 1 is characterized in that separator is positioned at least one outer surface of solar cell.

3. claim 1 or 2 solar cell is characterized in that separator is impermeable and the edges cover layer.

4. claim 1 or 2 solar cell is characterized in that this solar cell further comprises the laminar structure with cover layer and intermediate adhesion layer that is arranged on the separator.

5. the solar cell of claim 4 is characterized in that cover layer comprises one deck plastic layer at least.

6. the solar cell of claim 4 is characterized in that cover layer is a glass plate.

7. the solar cell of claim 4, wherein intermediate adhesion layer is the polyvinyl butyral resin layer.

8. claim 1 or 2 solar cell, the consumption that it is characterized in that polymerized polyalcohol is greater than 1% of curable resin weight.

9. claim 1 or 2 solar cell, the amount ranges that it is characterized in that polymerized polyalcohol is the 1%-30% of curable resin weight.

10. claim 1 or 2 solar cell is characterized in that curable resin is a uV curable.

11. the solar cell of claim 1 or 2, wherein layer structure comprises the absorber layer to moisture-sensitive.

12. the solar cell of claim 11, wherein the absorber layer to moisture-sensitive comprises copper-indium-diselenide.

13. the solar cell of claim 1 or 2, wherein separator extends on the outer surface on the layer structure.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10204049 | 2002-02-01 | ||

| DE10204049.4 | 2002-02-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1625582A CN1625582A (en) | 2005-06-08 |

| CN100336210C true CN100336210C (en) | 2007-09-05 |

Family

ID=27634753

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB038030160A Expired - Fee Related CN100336210C (en) | 2002-02-01 | 2003-01-31 | Barrier layer made of a curable resin containing polymeric polyol |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7255926B2 (en) |

| EP (1) | EP1470191B1 (en) |

| JP (1) | JP4927317B2 (en) |

| CN (1) | CN100336210C (en) |

| ES (1) | ES2396118T3 (en) |

| WO (1) | WO2003064529A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2742680C1 (en) * | 2020-09-18 | 2021-02-09 | Федеральное государственное бюджетное научное учреждение "Федеральный научный агроинженерный центр ВИМ" (ФГБНУ ФНАЦ ВИМ) | Window sash with a built-in photovoltaic module with extended service life and a method of its manufacture |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007287894A (en) * | 2006-04-17 | 2007-11-01 | Showa Shell Sekiyu Kk | Cis thin-film solar module with pattern display function, and its manufacturing method |

| WO2008112985A1 (en) * | 2007-03-14 | 2008-09-18 | Evergreen Solar, Inc. | Solar module with a stiffening layer |

| US20080295882A1 (en) * | 2007-05-31 | 2008-12-04 | Thinsilicon Corporation | Photovoltaic device and method of manufacturing photovoltaic devices |

| AT506100A1 (en) * | 2007-12-13 | 2009-06-15 | Isovolta | PHOTOVOLTAIC MODULE WITH PRIMER LAYER |

| WO2010037102A2 (en) * | 2008-09-29 | 2010-04-01 | Thinsilicon Corporation | Monolithically-integrated solar module |

| JP2012522404A (en) * | 2009-06-10 | 2012-09-20 | シンシリコン・コーポレーション | Photovoltaic module and method of manufacturing a photovoltaic module having multiple semiconductor layer stacks |

| US20110048505A1 (en) * | 2009-08-27 | 2011-03-03 | Gabriela Bunea | Module Level Solution to Solar Cell Polarization Using an Encapsulant with Opened UV Transmission Curve |

| JP5310436B2 (en) * | 2009-09-18 | 2013-10-09 | デクセリアルズ株式会社 | Solar cell module and manufacturing method thereof |

| US20120291866A1 (en) * | 2010-02-15 | 2012-11-22 | Sony Chemical & Information Device Corporation | Method of manufacturing thin-film solar cell module |

| TWI432320B (en) | 2010-08-09 | 2014-04-01 | Ind Tech Res Inst | Encapsulation film, package structure utilizing the same, and method for forming the package structure |

| CN104795465A (en) * | 2015-04-10 | 2015-07-22 | 杭州福斯特光伏材料股份有限公司 | Packaging method of solar module |

| DE102015112233B4 (en) | 2015-07-27 | 2021-12-09 | Granula Polymer Gmbh | Process for the production of films and membranes comprising hyperbranched copolymers based on oxetane, films and membranes obtained by this process, and their use |

| CN111315570A (en) * | 2017-11-07 | 2020-06-19 | 东洋制罐集团控股株式会社 | Moisture barrier laminated film |

| CN112789164B (en) | 2018-10-04 | 2023-12-01 | 中央硝子株式会社 | Multifunctional light-adjusting film and structure comprising same |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4193799A (en) * | 1976-07-09 | 1980-03-18 | General Electric Company | Method of making printing plates and printed circuit |

| DE3013037A1 (en) * | 1980-04-03 | 1981-10-08 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | Lightweight weather-resistant terrestrial solar generator - has solar cells embedded in flexible plastics with metal support and protective cover |

| US4719255A (en) * | 1984-08-23 | 1988-01-12 | Kabushiki Kaisha Toshiba | Epoxy resin composition for encapsulation of semi-conductor device |

| DD263647A1 (en) * | 1987-08-19 | 1989-01-04 | Zentr Wissenschaft & Tech Veb | PROCESS FOR CONVERTING ELECTRICAL MODULES WITH SOFT RESINS |

| US5043221A (en) * | 1985-12-19 | 1991-08-27 | Union Carbide Chemicals And Plastics Technology Corporation | Conformal coatings cured with actinic radiation |

| JPH05222167A (en) * | 1991-06-19 | 1993-08-31 | Ciba Geigy Ag | New resin system at lower molding temperature |

| US5242715A (en) * | 1991-02-18 | 1993-09-07 | Siemens Aktiengesellschaft | Process for coating or bonding electronic components and subassemblies |

| US5354939A (en) * | 1991-10-29 | 1994-10-11 | Ciba-Geigy Corporation | Stabilized epoxy resin compositions |

| EP0764690A2 (en) * | 1995-09-19 | 1997-03-26 | THERA Patent GmbH & Co. KG Gesellschaft für industrielle Schutzrechte | Cationically photocurable, permanently flexible epoxy resin composition and its use |

| US6165677A (en) * | 1997-05-26 | 2000-12-26 | Sumitomo Chemical Company, Limited | Photoresist composition |

| DE19943149A1 (en) * | 1999-09-09 | 2001-04-05 | Siemens Ag | Process for encapsulating components |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US628326A (en) * | 1898-01-26 | 1899-07-04 | P H Keefe | Belt-fastener. |

| AU517415B2 (en) * | 1976-07-09 | 1981-07-30 | General Electric Company | Curable polymer composition |

| JPS6153320A (en) * | 1984-08-23 | 1986-03-17 | Toshiba Corp | Epoxy resin composition for sealing semiconductor device |

| JPH0692467B2 (en) | 1986-10-06 | 1994-11-16 | 信越化学工業株式会社 | Reversible hydrogel and method for producing the same |

| US5631315A (en) * | 1993-07-01 | 1997-05-20 | Monsanto Company | Plasticized polyvinyl butyral sheet containing epoxy resin |

| DE4442824C1 (en) | 1994-12-01 | 1996-01-25 | Siemens Ag | Solar cell having higher degree of activity |

| US5602457A (en) * | 1995-01-03 | 1997-02-11 | Exide Corporation | Photovoltaic solar cell laminated in vehicle windshield |

| DE19514908C1 (en) | 1995-04-22 | 1996-04-18 | Ver Glaswerke Gmbh | Large scale solar panels for building and vehicles |

| WO1997002728A1 (en) * | 1995-07-04 | 1997-01-23 | Mitsui Mining & Smelting Co., Ltd. | Resin-coated copper foil for multilayer printed wiring board and multilayer printed wiring board provided with said copper foil |

| DE19707280A1 (en) | 1997-02-24 | 1998-08-27 | Siemens Ag | Climate and corrosion-stable layer structure |

| JP3740251B2 (en) * | 1997-06-09 | 2006-02-01 | キヤノン株式会社 | Manufacturing method of solar cell module |

| JPH11135820A (en) * | 1997-08-27 | 1999-05-21 | Canon Inc | Solar battery module and reinforcing member therefor |

| JP2000150936A (en) * | 1998-11-17 | 2000-05-30 | Canon Inc | Semiconductor device and photovoltaic power generation device |

| EP1039551B2 (en) | 1999-03-23 | 2010-09-15 | Kaneka Corporation | Photovoltaic module |

| DE10065530A1 (en) * | 2000-12-28 | 2002-07-04 | Bosch Gmbh Robert | Device for power generation and shading in motor vehicles |

-

2003

- 2003-01-31 CN CNB038030160A patent/CN100336210C/en not_active Expired - Fee Related

- 2003-01-31 JP JP2003564133A patent/JP4927317B2/en not_active Expired - Fee Related

- 2003-01-31 ES ES03704525T patent/ES2396118T3/en not_active Expired - Lifetime

- 2003-01-31 EP EP03704525A patent/EP1470191B1/en not_active Expired - Lifetime

- 2003-01-31 WO PCT/EP2003/001073 patent/WO2003064529A1/en active Application Filing

- 2003-01-31 US US10/503,165 patent/US7255926B2/en not_active Expired - Fee Related

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4193799A (en) * | 1976-07-09 | 1980-03-18 | General Electric Company | Method of making printing plates and printed circuit |

| DE3013037A1 (en) * | 1980-04-03 | 1981-10-08 | Licentia Patent-Verwaltungs-Gmbh, 6000 Frankfurt | Lightweight weather-resistant terrestrial solar generator - has solar cells embedded in flexible plastics with metal support and protective cover |

| US4719255A (en) * | 1984-08-23 | 1988-01-12 | Kabushiki Kaisha Toshiba | Epoxy resin composition for encapsulation of semi-conductor device |

| US5043221A (en) * | 1985-12-19 | 1991-08-27 | Union Carbide Chemicals And Plastics Technology Corporation | Conformal coatings cured with actinic radiation |

| DD263647A1 (en) * | 1987-08-19 | 1989-01-04 | Zentr Wissenschaft & Tech Veb | PROCESS FOR CONVERTING ELECTRICAL MODULES WITH SOFT RESINS |

| US5242715A (en) * | 1991-02-18 | 1993-09-07 | Siemens Aktiengesellschaft | Process for coating or bonding electronic components and subassemblies |

| JPH05222167A (en) * | 1991-06-19 | 1993-08-31 | Ciba Geigy Ag | New resin system at lower molding temperature |

| US5354939A (en) * | 1991-10-29 | 1994-10-11 | Ciba-Geigy Corporation | Stabilized epoxy resin compositions |

| EP0764690A2 (en) * | 1995-09-19 | 1997-03-26 | THERA Patent GmbH & Co. KG Gesellschaft für industrielle Schutzrechte | Cationically photocurable, permanently flexible epoxy resin composition and its use |

| US6165677A (en) * | 1997-05-26 | 2000-12-26 | Sumitomo Chemical Company, Limited | Photoresist composition |

| DE19943149A1 (en) * | 1999-09-09 | 2001-04-05 | Siemens Ag | Process for encapsulating components |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2742680C1 (en) * | 2020-09-18 | 2021-02-09 | Федеральное государственное бюджетное научное учреждение "Федеральный научный агроинженерный центр ВИМ" (ФГБНУ ФНАЦ ВИМ) | Window sash with a built-in photovoltaic module with extended service life and a method of its manufacture |

Also Published As

| Publication number | Publication date |

|---|---|

| US20050072459A1 (en) | 2005-04-07 |

| JP2005515920A (en) | 2005-06-02 |

| EP1470191B1 (en) | 2012-11-21 |

| EP1470191A1 (en) | 2004-10-27 |

| JP4927317B2 (en) | 2012-05-09 |

| CN1625582A (en) | 2005-06-08 |

| US7255926B2 (en) | 2007-08-14 |

| WO2003064529A1 (en) | 2003-08-07 |

| ES2396118T3 (en) | 2013-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100336210C (en) | Barrier layer made of a curable resin containing polymeric polyol | |

| CN1185705C (en) | Encapsulant resin member for semiconductor, and semiconductor element | |

| CN1147006C (en) | Solar cell module and reinforcing member for solar cell module | |

| CN1065073C (en) | Solar cell module | |

| CN1145220C (en) | Solar energy cell assembly | |

| KR100376896B1 (en) | Photovoltaic device | |

| CN1112734C (en) | Solar cell module having surface coating material for three-layer structure | |

| EP3070748B1 (en) | Silicone adhesive sheet having ultraviolet ray shielding properties for sealing solar cell and solar cell module using same | |

| US20080283117A1 (en) | Solar Cell Module and Method of Manufacturing Solar Cell Module | |

| WO2010100948A1 (en) | Frameless solar cell panel and manufacturing method therefor | |

| KR20100124812A (en) | Photovoltaic cell module and method of forming same | |

| CN1119787A (en) | Light-transmissive resin sealed semiconductor and production process thereof | |

| JP5680071B2 (en) | Laminated structure | |

| EP2403915B1 (en) | Adhesive tape, in particular for bonding photovoltaic laminates | |

| EP3093139A1 (en) | Method for producing glass base laminated body, method for manufacturing optical element, optical element and concentrator photovoltaic system | |

| CN103890967A (en) | Sealing film for solar cells, and solar cell using same | |

| JP5482276B2 (en) | Solar cell encapsulant and solar cell module | |

| CN1302530C (en) | Method for packaging electronic component | |

| JP2017226208A (en) | Illuminant protective film, wavelength conversion sheet, backlight unit and electroluminescence luminescent unit | |

| JP2010278375A (en) | Back protection sheet for solar cell module and solar cell using the same | |

| KR101126864B1 (en) | Back sheet for solar cell having an excellent durability and preparing process thereof | |

| JP2001068703A (en) | Solar-battery module, building material using the same, and photovoltaic generating-unit | |

| KR20140142388A (en) | Encapsulation composition for a solarcell and preparing process of the sheet using the same | |

| JP2013008867A (en) | Method of manufacturing solar cell module |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20070905 Termination date: 20170131 |