WO2024257530A1 - コンデンサ素子 - Google Patents

コンデンサ素子 Download PDFInfo

- Publication number

- WO2024257530A1 WO2024257530A1 PCT/JP2024/017754 JP2024017754W WO2024257530A1 WO 2024257530 A1 WO2024257530 A1 WO 2024257530A1 JP 2024017754 W JP2024017754 W JP 2024017754W WO 2024257530 A1 WO2024257530 A1 WO 2024257530A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- external electrode

- hole

- hole conductor

- capacitor element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/008—Terminals

- H01G9/012—Terminals specially adapted for solid capacitors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/15—Solid electrolytic capacitors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/04—Electrodes or formation of dielectric layers thereon

- H01G9/048—Electrodes or formation of dielectric layers thereon characterised by their structure

Definitions

- the present invention relates to a capacitor element.

- Patent Document 1 describes a solid electrolytic capacitor that includes a foil-shaped anode with a porous portion on at least one side and through holes formed at predetermined positions, a dielectric coating formed on the porous portion of the anode, an insulating layer having an opening formed in the dielectric coating, a solid electrolyte layer formed on the dielectric coating at the opening of the insulating layer, a cathode formed on at least a part of the solid electrolyte layer and disposed approximately parallel to the anode, an electrode formed on the insulating layer, and through-hole electrodes that penetrate the insulating layer and the anode to electrically connect the electrode and the anode and/or penetrate the insulating layer and the cathode to electrically connect the electrode and the cathode, at least one of the through-hole electrodes being elongated.

- the solid electrolytic capacitor described in Patent Document 1 also had room for improvement in terms of improving heat dissipation.

- the present invention has been made to solve the above problems, and aims to provide a capacitor element that can improve heat dissipation.

- the capacitor element of the present invention includes a capacitor section including an anode plate having a porous section on at least one main surface of a core section, a dielectric layer provided on the surface of the porous section, and a cathode layer provided on the surface of the dielectric layer, a sealing layer provided to cover the capacitor section, a first through-hole conductor provided to penetrate the capacitor section and the sealing layer in the thickness direction so as to be electrically connected directly to the anode plate, both ends of which are drawn to the surface of the sealing layer, a second through-hole conductor provided to penetrate the capacitor section and the sealing layer in the thickness direction so as to be electrically connected directly to the cathode layer, both ends of which are drawn to the surface of the sealing layer, a first external electrode layer provided on the surface of the sealing layer so as to be electrically connected to the first through-hole conductor, and a second external electrode layer provided on the surface of the sealing layer so as to be electrically connected to the second through-hole conductor, and at least a portion of the first external

- the present invention provides a capacitor element that can improve heat dissipation.

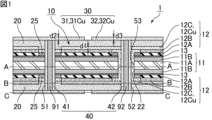

- FIG. 1 is a cross-sectional view illustrating an example of a capacitor element according to a first embodiment of the present invention.

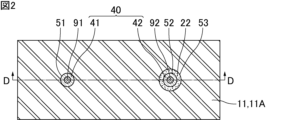

- FIG. 2 is a plan view taken along line AA of the capacitor element shown in FIG.

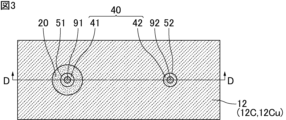

- FIG. 3 is a plan view of the capacitor element shown in FIG. 1 taken along line BB.

- FIG. 4 is a plan view of the capacitor element shown in FIG. 1 taken along line CC.

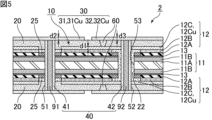

- FIG. 5 is a cross-sectional view illustrating a schematic diagram of another example of the capacitor element according to the first embodiment of the present invention.

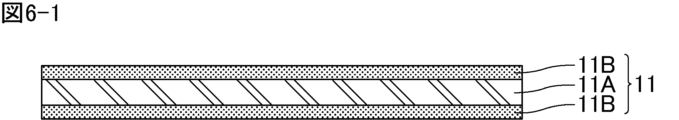

- FIG. 6-1 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, and shows a step of preparing an anode plate.

- FIG. 1 is a cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, and shows a step of preparing an anode plate.

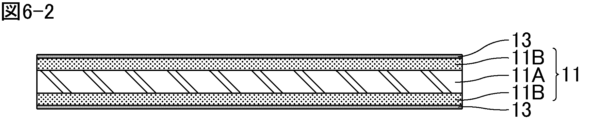

- FIG. 6-2 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, and shows a step of forming a dielectric layer.

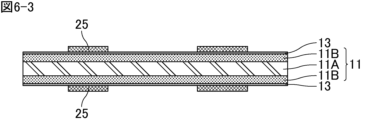

- FIG. 6-3 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, showing a step of forming an insulating mask layer.

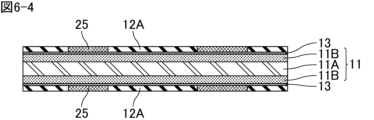

- FIG. 6-4 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, and shows a step of forming a solid electrolyte layer.

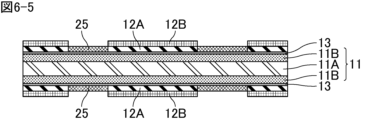

- FIG. 6-5 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, and shows a step of forming a first conductive layer.

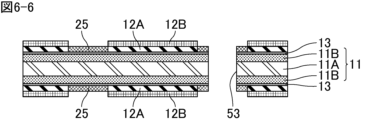

- 6-6 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, showing a step of forming a through hole.

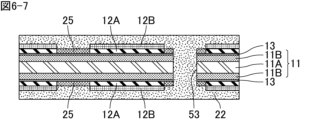

- 6 and 7 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, showing a step of forming an insulating material.

- 6 to 8 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, showing a step of polishing an insulating material.

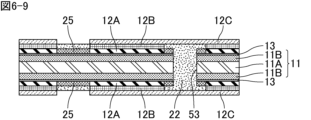

- 6-9 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, illustrating a step of forming a second conductive layer.

- 6 to 10 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG.

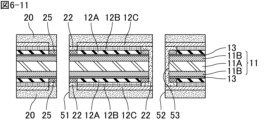

- FIG. 11 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, illustrating steps of forming the first through hole and the second through hole.

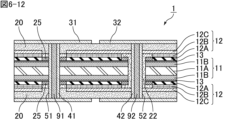

- 6 to 12 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1, illustrating steps of forming through-hole conductors and external electrode layers.

- FIG. 7-1 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, and shows a state after the through holes are formed.

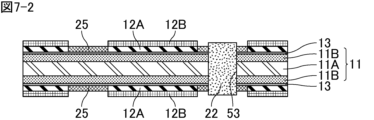

- FIG. 7-2 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating a step of forming an insulating material.

- FIG. 7-1 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating a step of forming an insulating material.

- FIG. 7-1 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element

- FIG. 7-3 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating the step of forming a second conductive layer.

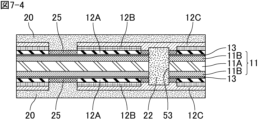

- FIG. 7-4 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating a step of forming a sealing layer.

- FIG. 7-5 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating a step of forming the first through hole and the second through hole.

- FIG. 7-6 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating the steps of forming through-hole conductors and external electrode layers.

- FIG. 7-3 is a schematic cross-sectional view illustrating another example of the method for manufacturing the capacitor element shown in FIG. 1, illustrating the step of forming a second conductive layer.

- FIG. 7-4 is a schematic cross-sectional view illustrating another example

- FIG. 8 is a plan view illustrating an example of a capacitor element according to a second embodiment of the present invention.

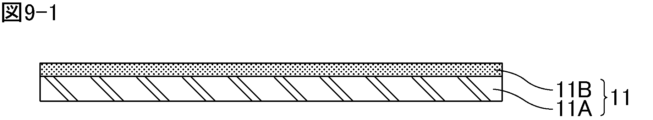

- FIG. 9-1 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of preparing an anode plate.

- FIG. 9-2 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of forming a dielectric layer.

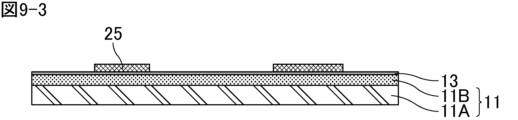

- FIG. 9-3 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of forming an insulating mask layer.

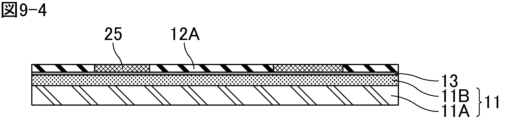

- FIG. 9-4 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG.

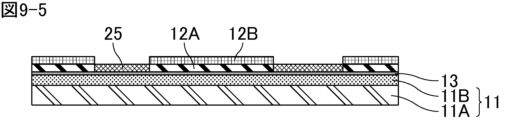

- FIG. 9-5 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of forming a first conductive layer.

- FIG. 9-6 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, showing a step of forming a through hole.

- FIG. 9-7 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of forming an insulating material.

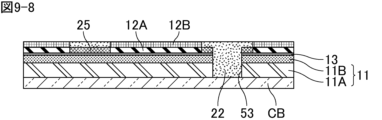

- FIG. 9-8 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG.

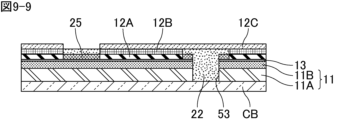

- FIG. 9-9 is a schematic cross-sectional view illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, and shows a step of forming a second conductive layer.

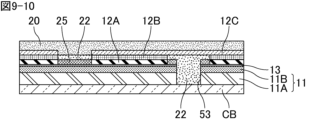

- 9 and 10 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, showing a step of forming a sealing layer.

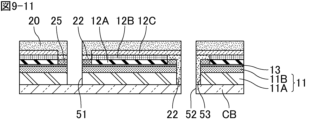

- 9 to 11 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, illustrating steps of forming the first through hole and the second through hole.

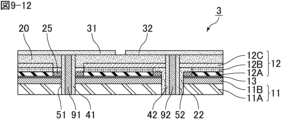

- 9 to 12 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8, showing steps of forming through-hole conductors and external electrode layers.

- the capacitor element of the present invention is described below. Note that the present invention is not limited to the following configuration, and may be modified as appropriate without changing the gist of the present invention. In addition, a combination of multiple individual preferred configurations described below also constitutes the present invention.

- each embodiment will simply be referred to as the "capacitor element of the present invention.”

- terms indicating the relationship between elements e.g., "perpendicular,” “parallel,” “orthogonal,” etc.

- terms indicating the shapes of elements are not expressions that express only a strict meaning, but are expressions that include a range of substantial equivalence, for example, differences of about a few percent.

- Fig. 1 is a cross-sectional view diagrammatically illustrating an example of a capacitor element according to a first embodiment of the present invention.

- Fig. 2 is a plan view taken along line A-A of the capacitor element shown in Fig. 1.

- Fig. 3 is a plan view taken along line B-B of the capacitor element shown in Fig. 1.

- Fig. 4 is a plan view taken along line CC of the capacitor element shown in Fig. 1.

- Fig. 1 is a cross-sectional view taken along line D-D of the capacitor element shown in Figs. 2 to 4.

- the capacitor element 1 shown in Figures 1 to 4 comprises a capacitor section 10, a sealing layer 20 provided to cover the capacitor section 10, a through-hole conductor 40 provided to penetrate the capacitor section 10 and the sealing layer 20 in the thickness direction and with both ends extended to the surface of the sealing layer 20, and an external electrode layer 30 provided on the surface of the sealing layer 20 so as to be electrically connected to the through-hole conductor 40.

- one capacitor section 10 is disposed inside the sealing layer 20.

- the number of capacitor sections 10 disposed inside the sealing layer 20 is not particularly limited, and may be one or more.

- the capacitor section 10 includes an anode plate 11 having a porous section 11B on at least one main surface of a core section 11A, a dielectric layer 13 provided on the surface of the porous section 11B, and a cathode layer 12 provided on the surface of the dielectric layer 13.

- the anode plate 11 has a porous section 11B on both main surfaces of the core section 11A, but it may have a porous section 11B on only one of the main surfaces of the core section 11A.

- the cathode layer 12 includes, for example, a solid electrolyte layer 12A provided on the surface of the dielectric layer 13.

- the capacitor section 10 constitutes a solid electrolytic capacitor.

- the sealing layer 20 is provided on both opposing main surfaces of the capacitor section 10 in the thickness direction.

- the capacitor section 10 is protected by the sealing layer 20.

- the sealing layer 20 may be composed of only one layer, or may be composed of two or more layers. When the sealing layer 20 is composed of two or more layers, the materials constituting each layer may be the same or different.

- the sealing layer 20 is formed to seal the capacitor section 10, for example, by a method of thermocompressing an insulating resin sheet, or by applying an insulating resin paste and then thermally curing it.

- the through-hole conductor 40 includes a first through-hole conductor 41 electrically connected to the anode plate 11 and a second through-hole conductor 42 electrically connected to the cathode layer 12.

- the first through-hole conductor 41 only needs to be provided on at least the inner wall surface of the first through hole 51 that penetrates the capacitor section 10 and the sealing layer 20 in the thickness direction.

- the first through-hole conductor 41 may be provided only on the inner wall surface of the first through hole 51, or may be provided throughout the entire interior of the first through hole 51.

- one first through-hole conductor 41 may be provided inside the cathode layer 12, or two or more first through-hole conductors 41 may be provided.

- the second through-hole conductor 42 may be provided at least on the inner wall surface of the second through hole 52 that penetrates the capacitor section 10 and the sealing layer 20 in the thickness direction.

- the second through-hole conductor 42 may be provided only on the inner wall surface of the second through hole 52, or may be provided throughout the entire interior of the second through hole 52.

- an insulating material 22 is filled between the second through-hole conductor 42 and the capacitor section 10 (particularly the anode plate 11).

- one second through-hole conductor 42 may be provided inside the cathode layer 12, or two or more second through-hole conductors 42 may be provided.

- the through-hole conductor 40 may include a third through-hole conductor that is not electrically connected to the anode plate 11 and the cathode layer 12.

- the external electrode layer 30 includes a first external electrode layer 31 electrically connected to the first through-hole conductor 41 and the anode plate 11, and a second external electrode layer 32 electrically connected to the second through-hole conductor 42 and the cathode layer 12.

- one first external electrode layer 31 may be provided, or multiple first external electrode layers 31 may be provided.

- one second external electrode layer 32 may be provided, or multiple second external electrode layers 32 may be provided.

- the number of first external electrode layers 31 may be the same as the number of second external electrode layers 32, or may be different.

- the planar shape of the external electrode layer 30 when viewed from the thickness direction is not particularly limited, and examples include a rectangle (square or oblong), a quadrangle other than a rectangle, a polygon such as a triangle, a pentagon, or a hexagon, a circle, an ellipse, or a shape that is a combination of these.

- the planar shape of the external electrode layer 30 may be an L-shape, a C-shape, a step shape, etc.

- the planar shape of the first external electrode layer 31 when viewed from the thickness direction may be the same as or different from the planar shape of the second external electrode layer 32 when viewed from the thickness direction.

- the cathode layer 12 may be drawn out by an internal via conductor as in the example shown in FIG. 5 described later, but in the example shown in FIG. 1, the second through-hole conductor 42 is electrically connected directly to the cathode layer 12, and the cathode layer 12 is drawn out by the second through-hole conductor 42. In this way, the second through-hole conductor 42 is electrically connected directly to the cathode layer 12, and the heat dissipation path, i.e., the heat dissipation area, can be increased compared to drawing out only by the internal via conductor.

- at least a portion of the first external electrode layer 31 overlaps the cathode layer 12 in the thickness direction, which also increases the heat dissipation area. As a result, the heat dissipation properties of the capacitor element 1 can be improved. As a result, the temperature rise due to heat generation in the capacitor element 1 can be suppressed.

- the second through-hole conductor 42 and the cathode layer 12 are in direct contact without going through a resin portion, which is a different material, and therefore the rigidity of the capacitor element 1 can be improved.

- the area of the first external electrode layer 31 can be increased, and therefore the rigidity of the capacitor element 1 can be improved.

- the capacitor element 1 can be made thinner, but there is a possibility that the capacitor element 1 may warp.

- the rigidity of the capacitor element 1 is improved and the occurrence of such warping can also be suppressed.

- the area of the first external electrode layer 31 can be increased, thereby preventing moisture, oxygen, etc. from entering the capacitor section 10 from the outside.

- a through-hole conductor when a through-hole conductor is electrically connected directly to a conductive layer such as a cathode layer or an anode plate, this excludes cases where the through-hole conductor only has a structure (connection path) that is electrically connected to the conductive layer via a via conductor or an external electrode layer.

- the through-hole conductor is electrically connected to the conductive layer on the inner wall surface of the through hole, that is, the side wall portion of the through-hole conductor is electrically connected to the conductive layer.

- the second through-hole conductor 42 is electrically connected to the cathode layer 12 on the inner wall surface of the second through hole 52.

- the first through-hole conductor 41 is also electrically connected directly to the anode plate 11, and the first through-hole conductor 41 is electrically connected to the anode plate 11 on the inner wall surface of the first through hole 51.

- the first external electrode layer 31 may only partially overlap the cathode layer 12 in the thickness direction.

- the ratio of the area of the portion overlapping the cathode layer 12 in the thickness direction to the total area of the first external electrode layer 31 is not particularly limited, but is preferably 50% or more and 90% or less, and more preferably 60% or more and 80% or less.

- the cathode layer 12 may include a copper layer 12Cu

- the first external electrode layer 31 may include a copper layer 31Cu

- the second external electrode layer 32 may include a copper layer 32Cu.

- the thickness of the copper layer 12Cu of the cathode layer 12 is d1

- the thickness of the copper layer 31Cu of the first external electrode layer 31 is d2

- the thickness of the copper layer 32Cu of the second external electrode layer 32 is d3

- heat diffusion can be promoted and damage to the capacitor section 10 can be suppressed.

- copper layer 12Cu is the second conductive layer 12C of the cathode layer 12 described below

- copper layer 31Cu is the first external electrode layer

- copper layer 32Cu is the second external electrode layer 32.

- the cathode layer 12 is composed of multiple layers including the copper layer 12Cu, it is preferable that the copper layer 12Cu is one or more layers that are closest to the first external electrode layer 31 and the second external electrode layer 32 among the multiple layers that compose the cathode layer 12.

- the copper layer 31Cu may be any one of the multiple layers that make up the cathode layer 12. The same applies to the second external electrode layer 32.

- the thickness of the core 11A of the anode plate 11 is, for example, 40 ⁇ m or more and 60 ⁇ m or less, and the area of the core 11A of the anode plate 11 is assumed to be approximately 100% in the plane along line A-A in Fig. 1 shown in Fig. 2.

- the thickness of the copper layer 12Cu of each cathode layer 12 is, for example, approximately 30 ⁇ m, and the area of the copper layer 12Cu is assumed to be approximately 100% in the plane along line B-B in Fig. 1 shown in Fig. 3.

- S1>S2 is the area of the first external electrode layer 31 electrically connected to the anode plate 11 and S2 is the area of the second external electrode layer 32 electrically connected to the cathode layer 12. Furthermore, by satisfying S1>S2, undulations (waviness) of the substrate on which the capacitor element 1 is mounted can also be suppressed.

- area means the area in a plan view from the thickness direction.

- the ratio of S1 to S2, i.e., S1/S2, preferably satisfies 1 ⁇ S1/S2 ⁇ 3.5, and more preferably satisfies 1.5 ⁇ S1/S2 ⁇ 3.

- Comparisons such as S1>S2 and S1/S2 are made based on the areas of the first external electrode layer 31 and the second external electrode layer 32 provided on the same main surface side of the capacitor section 10.

- the cathode layer 12 preferably includes a solid electrolyte layer 12A provided on the surface of the dielectric layer 13, a first conductor layer 12B provided on the surface of the solid electrolyte layer 12A, and a second conductor layer 12C provided on the surface of the first conductor layer 12B so as to be electrically connected directly to the second through-hole conductor 42. This allows the second through-hole conductor 42 to be easily electrically connected directly to the cathode layer 12.

- the areas of the first through-hole conductors 41 and the second through-hole conductors 42 provided in the capacitor element 1 are the same, and it is even more preferable that the numbers of the first through-hole conductors 41 and the second through-hole conductors 42 provided in the capacitor element 1 are the same. This makes it possible to make the heat dissipation properties of the capacitor element 1 uniform.

- the through-hole conductors 40 i.e., the first through-hole conductor 41 and the second through-hole conductor 42 are not distinguished from each other

- the through-hole conductors 40 are arranged at an equal pitch. This also makes it possible to make the heat dissipation properties of the capacitor element 1 uniform. It is also possible to suppress the occurrence of peeling called delamination, such as peeling of the cathode layer from the anode plate.

- the capacitor section 10 further includes an insulating mask layer 25 provided around the through-hole conductor 40 on at least one of the main surfaces of the anode plate 11.

- an insulating mask layer 25 is provided between the first through-hole conductor 41 and the cathode layer 12. Also, in the example shown in FIG. 1, an insulating material 22 is filled between the second through-hole conductor 42 and the capacitor section 10 (particularly the anode plate 11), and an insulating mask layer 25 is provided between this insulating material 22 and the cathode layer 12 (e.g., the solid electrolyte layer 12A).

- the capacitor section 10 may further include an insulating mask layer 25 provided on at least one main surface of the anode plate 11 so as to surround the periphery of the cathode layer 12 (e.g., solid electrolyte layer 12A; the same applies hereinafter in this paragraph).

- an insulating mask layer 25 provided on at least one main surface of the anode plate 11 so as to surround the periphery of the cathode layer 12 (e.g., solid electrolyte layer 12A; the same applies hereinafter in this paragraph).

- the insulating mask layer 25 may be provided so as to surround a portion of the periphery of the cathode layer 12, but it is preferable that the insulating mask layer 25 be provided so as to surround the entire periphery of the cathode layer 12.

- FIG. 5 is a cross-sectional view showing a schematic diagram of another example of a capacitor element according to the first embodiment of the present invention.

- the capacitor element 2 shown in FIG. 5 further includes an internal via conductor 60 that is arranged to penetrate the sealing layer 20 in the thickness direction, with one end electrically connected to the second external electrode layer 32 and the other end electrically connected to the cathode layer 12.

- an internal via conductor 60 By providing such an internal via conductor 60, it is possible to further improve heat dissipation. It is also possible to improve adhesion between layers and suppress the occurrence of delamination.

- one end of the internal via conductor 60 is extended to the surface of the sealing layer 20.

- the internal via conductor 60 is also electrically connected to the cathode layer 12. This allows the cathode layer 12 to be electrically led out to the outside of the sealing layer 20 via the internal via conductor 60 and the second through-hole conductor 42, and to be electrically connected to the outside of the sealing layer 20. There may be one internal via conductor 60 electrically connected to the cathode layer 12, or two or more internal via conductors 60.

- the capacitor element 2 may include an internal via conductor 60 electrically connected to the anode plate 11.

- the anode plate 11 is electrically led out to the outside of the sealing layer 20 via the internal via conductor 60, and can be electrically connected to the outside of the sealing layer 20.

- capacitor elements 1, 2, etc. The detailed configuration of capacitor elements 1, 2, etc. is explained below.

- the planar shape of the capacitor section 10 when viewed from the thickness direction may be, for example, a rectangle (square or oblong), a quadrangle other than a rectangle, a polygon such as a triangle, a pentagon, or a hexagon, a circle, an ellipse, or a combination of these.

- the planar shape of the capacitor section 10 may also be an L-shape, a C-shape, a stepped shape, or the like.

- the anode plate 11 is preferably made of a valve metal that exhibits so-called valve action.

- valve metals include simple metals such as aluminum, tantalum, niobium, titanium, and zirconium, or alloys containing at least one of these metals. Of these, aluminum or an aluminum alloy is preferred.

- the shape of the anode plate 11 is preferably flat, and more preferably foil-like.

- plate-like includes “foil-like”.

- the anode plate 11 may have a porous portion 11B on at least one main surface of the core portion 11A.

- the anode plate 11 may have a porous portion 11B on only one main surface of the core portion 11A as in the second embodiment described below, or may have a porous portion 11B on both main surfaces of the core portion 11A.

- the porous portion 11B is preferably a porous layer formed on the surface of the core portion 11A, and is more preferably an etched layer.

- the thickness of the anode plate 11 before the etching process is preferably 60 ⁇ m or more and 200 ⁇ m or less.

- the thickness of the unetched core portion 11A after the etching process is preferably 15 ⁇ m or more and 70 ⁇ m or less.

- the thickness of the porous portion 11B is designed according to the required withstand voltage and electrostatic capacitance, but it is preferable that the combined thickness of the porous portions 11B on both sides of the core portion 11A is 10 ⁇ m or more and 180 ⁇ m or less.

- the pore diameter of the porous portion 11B is preferably 10 nm or more and 600 nm or less.

- the pore diameter of the porous portion 11B means the median diameter D50 measured by a mercury porosimeter.

- the pore diameter of the porous portion 11B can be controlled, for example, by adjusting various etching conditions.

- the dielectric layer 13 provided on the surface of the porous portion 11B is porous, reflecting the surface condition of the porous portion 11B, and has a finely uneven surface shape.

- the dielectric layer 13 is preferably made of an oxide film of the valve metal.

- the dielectric layer 13 made of an oxide film can be formed by anodizing the surface of the aluminum foil in an aqueous solution containing ammonium adipate or the like (also called chemical conversion treatment).

- the thickness of the dielectric layer 13 is designed according to the required withstand voltage and capacitance, but is preferably 10 nm or more and 100 nm or less.

- the cathode layer 12 includes a solid electrolyte layer 12A

- examples of materials constituting the solid electrolyte layer 12A include conductive polymers such as polypyrroles, polythiophenes, and polyanilines. Among these, polythiophenes are preferred, and poly(3,4-ethylenedioxythiophene), also known as PEDOT, is particularly preferred.

- the conductive polymer may also include a dopant such as polystyrene sulfonate (PSS).

- PSS polystyrene sulfonate

- the solid electrolyte layer 12A preferably includes an inner layer that fills the pores (recesses) of the dielectric layer 13, and an outer layer that covers the dielectric layer 13.

- the thickness of the solid electrolyte layer 12A from the surface of the porous portion 11B is preferably 2 ⁇ m or more and 20 ⁇ m or less.

- the solid electrolyte layer 12A is formed, for example, by a method of forming a polymerized film of poly(3,4-ethylenedioxythiophene) or the like on the surface of the dielectric layer 13 using a treatment liquid containing a monomer such as 3,4-ethylenedioxythiophene, or by applying a dispersion of a polymer such as poly(3,4-ethylenedioxythiophene) to the surface of the dielectric layer 13 and drying it.

- the solid electrolyte layer 12A can be formed in a predetermined area by applying the above-mentioned treatment liquid or dispersion liquid to the surface of the dielectric layer 13 by a method such as sponge transfer, screen printing, dispenser application, or inkjet printing.

- the first conductive layer 12B and the second conductive layer 12C each include at least one of a conductive resin layer and a metal layer.

- the first conductive layer 12B and the second conductive layer 12C may each be only a conductive resin layer or only a metal layer, but it is preferable that the first conductive layer 12B is composed only of a conductive resin layer, and the second conductive layer 12C is preferably composed only of a metal layer.

- the first conductive layer 12B preferably covers the entire surface of the solid electrolyte layer 12A.

- the conductive resin layer may be, for example, a conductive adhesive layer (conductive paste layer) containing at least one conductive filler selected from the group consisting of silver filler, copper filler, nickel filler, and carbon filler.

- a conductive adhesive layer conductive paste layer

- conductive filler selected from the group consisting of silver filler, copper filler, nickel filler, and carbon filler.

- the metal layer examples include a metal plating layer and a metal foil layer.

- the metal layer is preferably made of at least one metal selected from the group consisting of nickel, copper, silver, and alloys containing these metals as main components.

- the term "main component" refers to the elemental component with the largest weight ratio.

- the first conductive layer 12B includes, for example, a carbon paste layer provided on the surface of the solid electrolyte layer 12A and a copper paste layer provided on the surface of the carbon paste layer.

- the second conductive layer 12C is composed of a copper layer 12Cu, such as a copper plating layer or a copper foil layer.

- the thickness d1 of the copper layer 12Cu of the cathode layer 12 described above is the combined thickness of the copper layer 12Cu of the second conductor layer 12C and the copper paste layer of the first conductor layer 12B.

- the carbon paste layer of the first conductor layer 12B is provided to electrically and mechanically connect the solid electrolyte layer 12A and the copper paste layer of the first conductor layer 12B.

- the carbon paste layer can be formed in a predetermined area by applying carbon paste to the surface of the solid electrolyte layer 12A by sponge transfer, screen printing, dispenser application, inkjet printing, or other methods. It is preferable to laminate the copper paste layer in the next process to the carbon paste layer while it is still viscous before drying.

- the thickness of the carbon paste layer is preferably 2 ⁇ m or more and 50 ⁇ m or less.

- the copper paste layer of the first conductive layer 12B can be formed in a predetermined area by applying copper paste to the surface of the carbon paste layer by sponge transfer, screen printing, spray application, dispenser application, inkjet printing, or other methods.

- the thickness of the copper paste layer is preferably 2 ⁇ m or more and 50 ⁇ m or less.

- the copper plating layer of the second conductive layer 12C can be formed in a predetermined area by forming a film by electrolytic plating, electroless plating, sputtering, vacuum deposition, etc., and then patterning it by etching (dry or wet).

- the thickness of the copper plating layer is preferably 2 ⁇ m or more and 35 ⁇ m or less.

- the copper foil layer of the second conductive layer 12C can be formed in a predetermined area by laminating copper foil that has previously been patterned by etching (dry or wet) in a press, or by laminating copper foil in a press and then patterning it by etching (dry or wet).

- the thickness of the copper foil layer is preferably 3 ⁇ m or more and 35 ⁇ m or less.

- the sealing layer 20 is made of an insulating material. In this case, it is preferable that the sealing layer 20 is made of an insulating resin.

- Examples of the insulating resin that constitutes the sealing layer 20 include epoxy resin, phenolic resin, etc.

- the sealing layer 20 further contains a filler.

- the filler contained in the sealing layer 20 may be, for example, an inorganic filler such as silica particles or alumina particles.

- a layer such as a stress relief layer or a moisture-proof film may be provided.

- the insulating mask layer 25 is made of an insulating material. In this case, it is preferable that the insulating mask layer 25 is made of an insulating resin.

- Examples of insulating resins constituting the insulating mask layer 25 include polyphenylsulfone resin, polyethersulfone resin, cyanate ester resin, fluororesin (tetrafluoroethylene, tetrafluoroethylene-perfluoroalkylvinylether copolymer, etc.), polyimide resin, polyamideimide resin, epoxy resin, and derivatives or precursors thereof.

- the insulating mask layer 25 may be made of the same resin as the sealing layer 20. Unlike the sealing layer 20, if the insulating mask layer 25 contains inorganic filler, this may adversely affect the effective capacitance portion of the capacitor section 10, so it is preferable that the insulating mask layer 25 is made of a resin alone.

- the insulating mask layer 25 can be formed in a predetermined area by applying a mask material, such as a composition containing an insulating resin, to the surface of the porous portion 11B by a method such as sponge transfer, screen printing, dispenser application, or inkjet printing.

- a mask material such as a composition containing an insulating resin

- the insulating mask layer 25 may be formed on the porous portion 11B either before the dielectric layer 13 or after the dielectric layer 13.

- the first external electrode layer 31 is electrically connected to the anode plate 11.

- the first external electrode layer 31 is provided on the surface of the first through-hole conductor 41, and functions as a connection terminal for the capacitor section 10.

- the first external electrode layer 31 is electrically connected to the anode plate 11 via the first through-hole conductor 41, and functions as a connection terminal for the anode plate 11.

- the constituent material of the first external electrode layer 31 may be, for example, a metal material containing a low-resistance metal such as silver, gold, or copper.

- the first external electrode layer 31 is formed, for example, by plating the surface of the first through-hole conductor 41.

- a mixed material (conductive paste material) of at least one conductive filler selected from the group consisting of silver filler, copper filler, nickel filler, and carbon filler and resin may be used as the constituent material of the first external electrode layer 31.

- the first external electrode layer 31 may include a copper layer 31Cu such as a copper paste layer, a copper plating layer, a copper foil layer, etc.

- the copper paste layer, copper plating layer, and copper foil layer of the first external electrode layer 31 can be formed in the same manner as the copper paste layer of the first conductive layer 12B, and the copper plating layer and copper foil layer of the second conductive layer 12C.

- the second external electrode layer 32 is electrically connected to the cathode layer 12.

- the second external electrode layer 32 is provided on the surface of the second through-hole conductor 42, and functions as a connection terminal for the capacitor section 10.

- the second external electrode layer 32 is electrically connected to the cathode layer 12 via the second through-hole conductor 42, and functions as a connection terminal for the cathode layer 12.

- the second external electrode layer 32 may be made of a metal material containing a low-resistance metal such as silver, gold, or copper.

- the second external electrode layer 32 is formed by, for example, plating the surface of the second through-hole conductor 42.

- a mixed material (conductive paste material) of at least one conductive filler selected from the group consisting of silver filler, copper filler, nickel filler, and carbon filler and resin may be used as the constituent material of the second external electrode layer 32.

- the second external electrode layer 32 may include a copper layer 32Cu, such as a copper paste layer, a copper plating layer, a copper foil layer, etc.

- the copper paste layer, copper plating layer, and copper foil layer of the second external electrode layer 32 can be formed in the same manner as the copper paste layer of the first conductive layer 12B, and the copper plating layer and copper foil layer of the second conductive layer 12C.

- the constituent materials of the first external electrode layer 31 and the second external electrode layer 32 are preferably the same as each other at least in terms of type, but may be different from each other.

- each of the multiple capacitor sections 10 may be provided with a first external electrode layer 31 electrically connected to the anode plate 11 and a second external electrode layer 32 electrically connected to the cathode layer 12, or at least one of the first external electrode layer 31 and the second external electrode layer 32 may be provided in common among the multiple capacitor sections 10.

- the first external electrode layer 31 and the second external electrode layer 32 are provided on both main surfaces of the sealing layer 20, but they may be provided on only one main surface of the sealing layer 20.

- the first through-hole conductor 41 is electrically connected to the anode plate 11 on the inner wall surface of the first through hole 51. More specifically, it is preferable that the first through-hole conductor 41 is electrically connected to the end surface of the anode plate 11 that faces the inner wall surface of the first through hole 51 in the planar direction. As a result, the anode plate 11 is electrically led out to the outside via the first through-hole conductor 41.

- the core portion 11A and the porous portion 11B are exposed on the end face of the anode plate 11 that is electrically connected to the first through-hole conductor 41.

- the porous portion 11B as well as the core portion 11A are electrically connected to the first through-hole conductor 41.

- the first through-hole conductor 41 is electrically connected to the anode plate 11 around the entire circumference of the first through hole 51.

- the number of paths for heat dissipation is increased, and the heat dissipation performance of the capacitor element 1 can be further improved.

- the connection resistance between the anode plate 11 and the first through-hole conductor 41 is likely to decrease, and therefore the equivalent series resistance (ESR) is likely to decrease.

- the first through-hole conductor 41 is formed, for example, as follows. First, a first through hole 51 penetrating the capacitor section 10 and the sealing layer 20 in the thickness direction is formed by drilling, laser processing, or the like. Then, the inner wall surface of the first through hole 51 is metallized with a metal material containing a low-resistance metal such as copper, gold, or silver to form the first through-hole conductor 41. When forming the first through-hole conductor 41, for example, the inner wall surface of the first through hole 51 is metallized with an electroless copper plating process, an electrolytic copper plating process, or the like to facilitate processing.

- the method of forming the first through-hole conductor 41 may be a method of filling the first through hole 51 with a metal material, a composite material of metal and resin, or the like, in addition to a method of metallizing the inner wall surface of the first through hole 51.

- An anode connection layer may be provided between the anode plate 11 and the first through-hole conductor 41 in the surface direction.

- the anode plate 11 and the first through-hole conductor 41 may be electrically connected via the anode connection layer.

- the anode connection layer is provided between the anode plate 11 and the first through-hole conductor 41 in the surface direction, so that the anode connection layer functions as a barrier layer for the anode plate 11, more specifically, as a barrier layer for the core portion 11A and the porous portion 11B.

- the anode connection layer functions as a barrier layer for the anode plate 11

- dissolution of the anode plate 11 that occurs during chemical treatment to form the external electrode layer 30 e.g., the first external electrode layer 31

- the infiltration of the chemical solution into the capacitor portion 10 is suppressed, which tends to improve reliability.

- the anode connection layer preferably includes a layer mainly composed of nickel. In this case, damage to the metal (e.g., aluminum) constituting the anode plate 11 is reduced, and the barrier properties of the anode connection layer against the anode plate 11 are easily improved.

- the metal e.g., aluminum

- an anode connection layer does not have to be provided between the anode plate 11 and the first through-hole conductor 41 in the surface direction.

- the first through-hole conductor 41 may be directly connected to the end surface of the anode plate 11.

- the first through-hole conductor 41 is provided only on the inner wall surface of the first through hole 51.

- the first through hole 51 may be provided with a resin filling portion 91 filled with a resin material.

- the resin filling portion 91 is provided in the space surrounded by the first through-hole conductor 41 in the first through hole 51.

- the resin filling portion 91 may be a conductor or an insulator.

- the second through-hole conductor 42 is electrically connected to the cathode layer 12, particularly to the second conductive layer 12C, on the inner wall surface of the second through hole 52. More specifically, it is preferable that the second through-hole conductor 42 is electrically connected to the end surface of the second conductive layer 12C that faces the inner wall surface of the second through hole 52 in the planar direction. As a result, the cathode layer 12 is electrically led out to the outside via the second through-hole conductor 42.

- the second through-hole conductor 42 is electrically connected to the cathode layer 12, particularly the second conductive layer 12C, around the entire circumference of the second through hole 52.

- the number of paths for heat dissipation is increased, and the heat dissipation properties of the capacitor element 1 can be further improved.

- the connection resistance between the cathode layer 12 and the second through-hole conductor 42 is likely to decrease, and therefore the equivalent series resistance (ESR) is likely to decrease.

- the second through-hole conductor 42 is formed, for example, as follows. First, a through hole 53 penetrating the capacitor section 10 in the thickness direction is formed by drilling, laser processing, etc. Next, the above-mentioned through hole 53 is filled with the insulating material 22. The part filled with the insulating material 22 is drilled, laser processing, etc. to form the second through hole 52. At this time, the diameter of the second through hole 52 is made smaller than the diameter of the through hole 53 filled with the insulating material 22, so that the insulating material 22 is present between the inner wall surface of the previously formed through hole 53 and the inner wall surface of the second through hole 52 in the surface direction.

- the inner wall surface of the second through hole 52 is metallized with a metal material containing a low-resistance metal such as copper, gold, or silver, to form the second through-hole conductor 42.

- a metal material containing a low-resistance metal such as copper, gold, or silver

- the inner wall surface of the second through hole 52 is metallized with electroless copper plating, electrolytic copper plating, etc., to facilitate processing.

- the method of forming the second through-hole conductor 42 may be a method of filling the second through-hole 52 with a metal material, a composite material of metal and resin, or the like, in addition to a method of metallizing the inner wall surface of the second through-hole 52.

- the insulating material 22 is preferably composed of an insulating resin.

- the insulating resin that constitutes the insulating material 22 include epoxy resin and phenol resin.

- the insulating material 22 preferably contains a filler.

- the filler contained in the insulating material 22 include inorganic fillers such as silica particles, alumina particles, and metal particles.

- the insulating material 22 may be made of the same material as the sealing layer 20.

- a cathode connection layer such as an anode connection layer may be provided between the cathode layer 12, particularly the second conductive layer 12C, and the second through-hole conductor 42, but it is preferable that no cathode connection layer is provided.

- the second through-hole conductor 42 may be directly connected to the end face of the second conductive layer 12C.

- the second through-hole conductor 42 is provided only on the inner wall surface of the second through hole 52.

- the second through hole 52 may be provided with a resin filling portion 92 filled with a resin material.

- the resin filling portion 92 is provided in the space surrounded by the second through-hole conductor 42 in the second through hole 52.

- the resin filling portion 92 may be a conductor or an insulator.

- Examples of materials that can be used to form the internal via conductor 60 include metal materials that contain low-resistance metals such as silver, gold, and copper.

- the internal via conductor 60 is formed, for example, by plating the inner wall surface of a through hole that penetrates the sealing layer 20 in the thickness direction with the metal material described above, or by filling it with a conductive paste and then performing a heat treatment.

- FIGS. 6-1 to 6-12 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 1.

- FIG. 6-1 shows the process of preparing an anode plate.

- FIG. 6-2 shows the process of forming a dielectric layer.

- FIG. 6-3 shows the process of forming an insulating mask layer.

- FIG. 6-4 shows the process of forming a solid electrolyte layer.

- FIG. 6-5 shows the process of forming a first conductive layer.

- FIG. 6-6 shows the process of forming a through hole.

- FIG. 6-7 shows the process of forming an insulating material.

- FIG. 6-8 shows the process of polishing the insulating material.

- FIG. 6-9 shows the process of forming a second conductive layer.

- FIG. 6-10 shows the process of forming a sealing layer.

- FIG. 6-11 shows the process of forming a first through hole and a second through hole.

- FIG. 6-12 shows the process of forming

- the capacitor element 1 shown in FIG. 1 is formed, for example, as follows.

- a dielectric layer 13 is formed on the porous portion 11B.

- an insulating mask layer 25 is formed on the dielectric layer 13.

- a solid electrolyte layer 12A is formed on the dielectric layer 13 in the area surrounded by the insulating mask layer 25.

- a first conductive layer 12B is formed on the solid electrolyte layer 12A.

- a through hole 53 is formed through the insulating mask layer 25, the dielectric layer 13, and the anode plate 11.

- an insulating material 22 is laminated to cover the insulating mask layer 25 and the first conductive layer 12B, and the through holes 53 are filled with the insulating material 22.

- the insulating material 22 is polished to thin it until the first conductive layer 12B is exposed.

- a second conductive layer 12C is formed on the first conductive layer 12B and the insulating material 22.

- a sealing layer 20 is formed to cover the second conductive layer 12C and the insulating material 22.

- a first through hole 51 is formed that penetrates the sealing layer 20, the insulating material 22, the insulating mask layer 25, the dielectric layer 13, and the anode plate 11, and a second through hole 52 is formed that penetrates the sealing layer 20, the second conductive layer 12C, and the insulating material 22.

- the second through hole 52 is located inside the area where the through hole 53 was formed.

- a first through-hole conductor 41 is formed in the first through-hole 51, and a second through-hole conductor 42 is formed in the second through-hole 52. Resin filling portions 91 and 92 may be formed in the first through-hole conductor 41 and the second through-hole conductor 42, respectively.

- a first external electrode layer 31 is formed on the sealing layer 20 so as to cover the first through-hole conductor 41, and a second external electrode layer 32 is formed on the sealing layer 20 so as to cover the second through-hole conductor 42.

- FIGS. 7-1 to 7-6 are schematic cross-sectional views illustrating another example of a method for manufacturing the capacitor element shown in FIG. 1.

- FIG. 7-1 shows the state after the through holes have been formed.

- FIG. 7-2 shows the step of forming an insulating material.

- FIG. 7-3 shows the step of forming a second conductive layer.

- FIG. 7-4 shows the step of forming a sealing layer.

- FIG. 7-5 shows the step of forming a first through hole and a second through hole.

- FIG. 7-6 shows the step of forming a through-hole conductor and an external electrode layer.

- the capacitor element 1 shown in FIG. 1 may be formed, for example, as follows.

- a through hole 53 is formed through the insulating mask layer 25, the dielectric layer 13, and the anode plate 11 in the same manner as shown in FIG. 6-1 to FIG. 6-6.

- insulating material 22 is formed only inside through-hole 53 by filling with resin material, screen printing, dispenser application, inkjet printing, or the like.

- the second conductive layer 12C, the sealing layer 20, the first through hole 51, the second through hole 52, the first through-hole conductor 41, the second through-hole conductor 42, the first external electrode layer 31, and the second external electrode layer 32 are formed.

- resin filling portions 91 and 92 may be formed as necessary.

- FIG. 8 is a plan view illustrating an example of a capacitor element according to a second embodiment of the present invention.

- the anode plate 11 has a porous portion 11B on only one main surface of the core portion 11A, and each component such as the capacitor portion 10 (anode plate 11, dielectric layer 13, and cathode layer 12), sealing layer 20, and external electrode layer 30 (first external electrode layer 31 and second external electrode layer 32) is provided on only one side of the capacitor element 3.

- one end of the through-hole conductors 40 (first through-hole conductor 41 and second through-hole conductor 42) is electrically connected to the external electrode layer 30, but the other end is exposed to the surface on which the capacitor section 10, etc. are not provided.

- FIG. 9-1 to FIG. 9-12 are schematic cross-sectional views illustrating an example of a method for manufacturing the capacitor element shown in FIG. 8.

- FIG. 9-1 shows the process of preparing an anode plate.

- FIG. 9-2 shows the process of forming a dielectric layer.

- FIG. 9-3 shows the process of forming an insulating mask layer.

- FIG. 9-4 shows the process of forming a solid electrolyte layer.

- FIG. 9-5 shows the process of forming a first conductive layer.

- FIG. 9-6 shows the process of forming a through hole.

- FIG. 9-7 shows the process of forming an insulating material.

- FIG. 9-8 shows the process of polishing the insulating material.

- FIG. 9-9 shows the process of forming a second conductive layer.

- FIG. 9-10 shows the process of forming a sealing layer.

- FIG. 9-11 shows the process of forming a first through hole and a second through hole.

- FIG. 9-12 shows the process of forming

- the capacitor element 3 shown in FIG. 8 may be formed, for example, as follows.

- the dielectric layer 13, the insulating mask layer 25, the solid electrolyte layer 12A, and the first conductive layer 12B are formed in the same manner as shown in Figures 6-2 to 6-5.

- the capacitor element sheet with the through holes 53 formed therein is placed on the carrier board CB in the same manner as shown in FIG. 6-6.

- the insulating material 22 is laminated and polished, and then the second conductive layer 12C, the sealing layer 20, the first through hole 51, the second through hole 52, the first through-hole conductor 41, the second through-hole conductor 42, the first external electrode layer 31, and the second external electrode layer 32 are formed.

- resin filling portions 91 and 92 may be formed as necessary.

- the capacitor element of the present invention is not limited to the above-described embodiment, and various applications and modifications can be made within the scope of the present invention with respect to the configuration, manufacturing conditions, and the like of the capacitor element.

- one capacitor section may be disposed inside the sealing layer, or multiple capacitor sections may be disposed inside the sealing layer.

- adjacent capacitor parts when multiple capacitor parts are arranged inside the sealing layer, adjacent capacitor parts only need to be physically separated from each other. Therefore, adjacent capacitor parts may be electrically separated from each other or electrically connected to each other. It is preferable that the part where adjacent capacitor parts are separated from each other is filled with an insulating material such as a sealing layer. The distance between adjacent capacitor parts may be constant in the thickness direction or may become smaller in the thickness direction.

- the multiple capacitor parts when multiple capacitor parts are arranged inside the sealing layer, the multiple capacitor parts may be arranged so as to be lined up in the planar direction, or so as to be stacked in the thickness direction, or a combination of both.

- the multiple capacitor parts may be arranged regularly or irregularly.

- the size and shape, etc. of the capacitor elements may be the same, or may be partially or entirely different. It is preferable that the configuration of each capacitor element is the same, but capacitor elements with different configurations may be included.

- the capacitor element of the present invention can be suitably used as a constituent material of a composite electronic component.

- a composite electronic component includes, for example, the capacitor element of the present invention, an external electrode layer provided on the surface of the sealing layer of the capacitor element and electrically connected to each of the anode plate and cathode layer of the capacitor element, and an electronic component connected to the external electrode layer.

- the electronic component connected to the external electrode layer may be a passive element or an active element. Both the passive element and the active element may be connected to the external electrode layer, or either the passive element or the active element may be connected to the external electrode layer. Also, a composite of a passive element and an active element may be connected to the external electrode layer.

- Passive elements include, for example, inductors. Active elements include memory, GPUs (Graphical Processing Units), CPUs (Central Processing Units), MPUs (Micro Processing Units), PMICs (Power Management ICs), etc.

- the capacitor element of the present invention has a sheet-like shape overall. Therefore, in a composite electronic component, the capacitor element can be treated like a mounting board, and electronic components can be mounted on the capacitor element. Furthermore, by making the electronic components to be mounted on the capacitor element into a sheet-like shape, it is also possible to connect the capacitor element and the electronic components in the thickness direction via through-hole conductors that penetrate each electronic component in the thickness direction. As a result, the active elements and passive elements can be configured like a single module.

- a switching regulator can be formed by electrically connecting the capacitor element of the present invention between a voltage regulator including a semiconductor active element and a load to which the converted DC voltage is supplied.

- a circuit layer may be formed on one side of a capacitor matrix sheet on which a plurality of capacitor elements of the present invention are laid out, and the capacitor elements may then be connected to passive or active elements.

- the capacitor element of the present invention may be placed in a cavity portion previously provided in a substrate, embedded in resin, and then a circuit layer may be formed on the resin.

- Another electronic component passive element or active element

- the capacitor element of the present invention may be mounted on a smooth carrier such as a wafer or glass, an outer layer made of resin may be formed, a circuit layer may be formed, and then the capacitor element may be connected to a passive or active element.

- a capacitor section including an anode plate having a porous portion on at least one main surface of a core portion, a dielectric layer provided on a surface of the porous portion, and a cathode layer provided on a surface of the dielectric layer; a sealing layer provided to cover the capacitor portion; a first through-hole conductor provided to penetrate the capacitor portion and the sealing layer in a thickness direction so as to be electrically connected directly to the anode plate, the first through-hole conductor having both ends extending to the surface of the sealing layer; a second through-hole conductor provided to penetrate the capacitor portion and the sealing layer in the thickness direction so as to be electrically connected directly to the cathode layer, the second through-hole conductor having both ends extending to the surface of the sealing layer; a first external electrode layer provided on a surface of the sealing layer so as to be electrically connected to the first through-hole conductor; a second external electrode layer provided on a surface of the sealing layer so as to be electrically connected to the second through-hole conductor

- the cathode layer, the first external electrode layer, and the second external electrode layer each include a copper layer;

- the thickness of the copper layer of the cathode layer is d1

- the thickness of the copper layer of the first external electrode layer is d2

- the thickness of the copper layer of the second external electrode layer is d3

- ⁇ 4> The capacitor element described in any one of ⁇ 1> to ⁇ 3> further comprising an internal via conductor that is provided so as to penetrate the sealing layer in the thickness direction, one end of which is electrically connected to the second external electrode layer and the other end of which is electrically connected to the cathode layer.

- the cathode layer includes: a solid electrolyte layer provided on a surface of the dielectric layer; a first conductor layer provided on the surface of the solid electrolyte layer; and a second conductor layer provided on the surface of the first conductor layer so as to be directly electrically connected to the second through-hole conductor.

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2024564758A JP7619541B1 (ja) | 2023-06-16 | 2024-05-14 | コンデンサ素子 |

| CN202480003565.7A CN119631152A (zh) | 2023-06-16 | 2024-05-14 | 电容器元件 |

| US19/007,874 US20250166927A1 (en) | 2023-06-16 | 2025-01-02 | Capacitor element |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2023099240 | 2023-06-16 | ||

| JP2023-099240 | 2023-06-16 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US19/007,874 Continuation US20250166927A1 (en) | 2023-06-16 | 2025-01-02 | Capacitor element |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2024257530A1 true WO2024257530A1 (ja) | 2024-12-19 |

Family

ID=93852047

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2024/017754 Pending WO2024257530A1 (ja) | 2023-06-16 | 2024-05-14 | コンデンサ素子 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20250166927A1 (enExample) |

| JP (1) | JP7619541B1 (enExample) |

| CN (1) | CN119631152A (enExample) |

| TW (1) | TWI898543B (enExample) |

| WO (1) | WO2024257530A1 (enExample) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004031641A (ja) * | 2002-06-26 | 2004-01-29 | Nec Toppan Circuit Solutions Inc | 印刷配線板及びその製造方法並びに半導体装置 |

| JP2006147606A (ja) * | 2004-11-16 | 2006-06-08 | Nec Toppan Circuit Solutions Inc | シート状コンデンサとその製造方法 |

| JP2007073787A (ja) * | 2005-09-08 | 2007-03-22 | Matsushita Electric Ind Co Ltd | 固体電解コンデンサ内蔵回路基板とその製造方法 |

| WO2023100630A1 (ja) * | 2021-12-01 | 2023-06-08 | 株式会社村田製作所 | モジュール及び半導体複合装置 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003086463A (ja) * | 2001-09-10 | 2003-03-20 | Matsushita Electric Ind Co Ltd | 固体電解コンデンサの製造方法 |

| WO2018150886A1 (ja) * | 2017-02-17 | 2018-08-23 | 株式会社村田製作所 | 固体電解コンデンサ及びその製造方法 |

| JP7180561B2 (ja) * | 2019-03-29 | 2022-11-30 | 株式会社村田製作所 | コンデンサアレイ、及び、複合電子部品 |

| CN116235264B (zh) * | 2021-06-16 | 2024-10-18 | 株式会社村田制作所 | 电容器阵列 |

-

2024

- 2024-04-17 TW TW113114295A patent/TWI898543B/zh active

- 2024-05-14 WO PCT/JP2024/017754 patent/WO2024257530A1/ja active Pending

- 2024-05-14 JP JP2024564758A patent/JP7619541B1/ja active Active

- 2024-05-14 CN CN202480003565.7A patent/CN119631152A/zh active Pending

-

2025

- 2025-01-02 US US19/007,874 patent/US20250166927A1/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004031641A (ja) * | 2002-06-26 | 2004-01-29 | Nec Toppan Circuit Solutions Inc | 印刷配線板及びその製造方法並びに半導体装置 |

| JP2006147606A (ja) * | 2004-11-16 | 2006-06-08 | Nec Toppan Circuit Solutions Inc | シート状コンデンサとその製造方法 |

| JP2007073787A (ja) * | 2005-09-08 | 2007-03-22 | Matsushita Electric Ind Co Ltd | 固体電解コンデンサ内蔵回路基板とその製造方法 |

| WO2023100630A1 (ja) * | 2021-12-01 | 2023-06-08 | 株式会社村田製作所 | モジュール及び半導体複合装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI898543B (zh) | 2025-09-21 |

| CN119631152A (zh) | 2025-03-14 |

| TW202501516A (zh) | 2025-01-01 |

| JPWO2024257530A1 (enExample) | 2024-12-19 |

| US20250166927A1 (en) | 2025-05-22 |

| JP7619541B1 (ja) | 2025-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12308181B2 (en) | Capacitor element, module, and semiconductor composite device | |

| WO2023021881A1 (ja) | コンデンサ素子 | |

| WO2024070531A1 (ja) | コンデンサ素子 | |

| JP2025119022A (ja) | コンデンサ | |

| JP7619541B1 (ja) | コンデンサ素子 | |

| JP7597277B2 (ja) | コンデンサアレイ | |

| TWI831226B (zh) | 電容器 | |

| JP7619540B1 (ja) | コンデンサ素子 | |

| JP7622919B1 (ja) | コンデンサ素子製造用基板及びコンデンサ素子の製造方法 | |

| JP7616492B2 (ja) | コンデンサ素子 | |

| JP7776019B2 (ja) | コンデンサ素子 | |

| JP7729487B2 (ja) | コンデンサアレイ | |

| JP7722616B2 (ja) | コンデンサアレイ | |

| TWI885959B (zh) | 內建電容器之基板 | |

| WO2024106239A1 (ja) | コンデンサ素子 | |

| US20250357053A1 (en) | Capacitor element | |

| WO2025069676A1 (ja) | コンデンサ素子 | |

| WO2025243714A1 (ja) | コンデンサ素子 | |

| WO2025084069A1 (ja) | コンデンサ内蔵基板 | |

| WO2024247589A1 (ja) | コンデンサ素子 | |

| WO2024214424A1 (ja) | コンデンサ素子 | |

| WO2024190398A1 (ja) | コンデンサ素子 | |

| WO2025211168A1 (ja) | コンデンサ内蔵基板 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 2024564758 Country of ref document: JP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 202480003565.7 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 24823152 Country of ref document: EP Kind code of ref document: A1 |

|

| WWP | Wipo information: published in national office |

Ref document number: 202480003565.7 Country of ref document: CN |