WO2023243387A1 - Bonding method - Google Patents

Bonding method Download PDFInfo

- Publication number

- WO2023243387A1 WO2023243387A1 PCT/JP2023/020014 JP2023020014W WO2023243387A1 WO 2023243387 A1 WO2023243387 A1 WO 2023243387A1 JP 2023020014 W JP2023020014 W JP 2023020014W WO 2023243387 A1 WO2023243387 A1 WO 2023243387A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- laser

- welding

- lead

- strap

- joining

- Prior art date

Links

- 238000000034 method Methods 0.000 title claims abstract description 25

- 239000002253 acid Substances 0.000 claims abstract description 21

- 239000011261 inert gas Substances 0.000 claims abstract description 16

- WABPQHHGFIMREM-UHFFFAOYSA-N lead(0) Chemical compound [Pb] WABPQHHGFIMREM-UHFFFAOYSA-N 0.000 claims abstract description 6

- 238000003466 welding Methods 0.000 claims description 59

- 238000005304 joining Methods 0.000 claims description 15

- 229910000978 Pb alloy Inorganic materials 0.000 claims description 11

- 239000000463 material Substances 0.000 claims description 5

- 238000002844 melting Methods 0.000 claims description 3

- 230000008018 melting Effects 0.000 claims description 3

- 239000002184 metal Substances 0.000 description 14

- 239000007789 gas Substances 0.000 description 9

- 238000010586 diagram Methods 0.000 description 7

- 229920005989 resin Polymers 0.000 description 7

- 239000011347 resin Substances 0.000 description 7

- 229910045601 alloy Inorganic materials 0.000 description 6

- 239000000956 alloy Substances 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 229910000882 Ca alloy Inorganic materials 0.000 description 4

- 230000035515 penetration Effects 0.000 description 4

- 230000002093 peripheral effect Effects 0.000 description 4

- 229910014474 Ca-Sn Inorganic materials 0.000 description 3

- 229910020220 Pb—Sn Inorganic materials 0.000 description 3

- 229910001245 Sb alloy Inorganic materials 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 230000001678 irradiating effect Effects 0.000 description 3

- 239000001301 oxygen Substances 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000011324 bead Substances 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 239000013307 optical fiber Substances 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 229920003002 synthetic resin Polymers 0.000 description 2

- 239000000057 synthetic resin Substances 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 239000011149 active material Substances 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 210000005069 ears Anatomy 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000008151 electrolyte solution Substances 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 150000002926 oxygen Chemical class 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/02—Positioning or observing the workpiece, e.g. with respect to the point of impact; Aligning, aiming or focusing the laser beam

- B23K26/06—Shaping the laser beam, e.g. by masks or multi-focusing

- B23K26/073—Shaping the laser spot

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/20—Bonding

- B23K26/21—Bonding by welding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/531—Electrode connections inside a battery casing

- H01M50/534—Electrode connections inside a battery casing characterised by the material of the leads or tabs

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/543—Terminals

- H01M50/562—Terminals characterised by the material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/50—Current conducting connections for cells or batteries

- H01M50/543—Terminals

- H01M50/564—Terminals characterised by their manufacturing process

- H01M50/566—Terminals characterised by their manufacturing process by welding, soldering or brazing

Definitions

- the present invention relates to a lead-acid battery manufacturing technology.

- Patent Document 1 discloses laser welding of a lead bushing integrally cast into the lid of a lead-acid battery and a pole pole inserted through the lead bushing. Laser welding produces less CO2 than gas burners.

- the pole post 2 and the bushing 1 are made of lead or a lead alloy, and it is generally preferable to use the same material for both. If pole post 2 and bushing 1 are made of lead alloy, various lead alloys such as Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy can be used and are applicable to laser welding.

- Pb-Ca alloys which are particularly susceptible to oxidation, is coated with a black oxide film by the air, which increases the ability to absorb laser beams, making it convenient for relatively deep welding by laser welding. understood.

- paragraph 24 of Patent Document 1 includes the following description.

- oxygen or air is discharged at a desired discharge pressure into the shield cylinder 70 from the respective discharge holes 14, 14, . . . using a compression pump.

- the oxygen or air is discharged toward the opening surface of the cylindrical lower end portion 70a1, that is, toward the terminal portion T. Note that in this case, it is common to use air, which is economically preferable.

- This oxygen or air oxidizes the surface of the welded portion 8 during welding, thereby suppressing the reflection of laser light and making it possible to more efficiently perform welding using laser irradiation light.

- An object of the present invention is to maintain welding quality by ensuring fluidity of molten metal while suppressing the generation of CO 2 during welding.

- This technology can suppress the generation of CO 2 during welding, ensure fluidity of molten metal, and maintain welding quality.

- FIG. 1 Perspective view of lead acid battery Perspective view of battery case Front view of lead-acid battery (partial cross-section) Cross section of lead acid battery Diagram showing the laser welding process Enlarged view of Figure 5 Diagram showing weld depth Plan view of external terminal and strap after laser welding Block diagram of laser welding equipment Diagram showing the difference in beam shape of laser light Diagram showing other embodiments Diagram showing other embodiments

- At least one of the first member and the second member may be made of a lead alloy containing Ca.

- Lead alloys containing Ca are more easily oxidized than lead alloys that do not contain Ca. Therefore, an oxide film tends to form on the surface of the molten metal, and the fluidity of the molten metal tends to decrease.

- a gap may be formed between the first member and the second member before they are joined.

- the first member and the second member may be joined by melting the base material around the gap with laser light to fill the gap.

- the gap formed between the first member and the second member is filled with a molten bead, the amount of weld penetration (welding depth) can be ensured. Therefore, it is effective in maintaining the welding quality of the joint.

- the beam shape of the laser light may be a linear shape.

- the first member and the second member may be joined by scanning the laser beam along the gap.

- Laser light can be applied to a wider area, making it possible to weld in a shorter time. Therefore, the manufacturing efficiency of lead-acid batteries can be improved.

- the first member may be a strap

- the second member may be a connecting terminal electrically connected to the strap via a connecting portion.

- the strap and the connecting portion may be laser welded while supplying the inert gas.

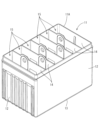

- Lead-acid battery 1 The structure of lead-acid battery 1 will be described with reference to FIG.

- the lead-acid battery 1 is used, for example, as a power source for mobile bodies such as motorcycles and automobiles.

- the lead-acid battery 1 includes a container 10 consisting of a battery case 11 made of synthetic resin and a lid member 16 made of synthetic resin.

- the battery case 11 has four outer walls 12 and a bottom wall 13, and is box-shaped with an open top.

- the battery case 11 is partitioned into six cell chambers 15 by five partition walls 14.

- the lid member 16 is thermally welded to the battery case 11 and closes the opening 11A of the battery case 11.

- the lid member 16 includes a flat plate portion 17, an overhanging portion 18, and an outer peripheral wall 19.

- the projecting portion 18 projects upward from the flat plate portion 17 in a substantially T-shape.

- the outer peripheral wall 19 extends downward from the outer peripheral edge of the flat plate portion 17 and surrounds the upper end of the outer wall 12 of the battery case 11.

- the lead acid battery 1 further includes an electrode plate group 21, a strap 25, a positive external terminal 30P, and a negative external terminal 30N.

- the electrode plate group 21 is made up of positive electrode plates 22P and negative electrode plates 22N alternately stacked in the X direction with separators 23 in between.

- Each of the electrode plates 22P and 22N has a structure in which a grid body is filled with an active material.

- the electrode plate group 21 is accommodated in each cell chamber 15 together with an electrolytic solution made of dilute sulfuric acid.

- the strap 25 is made of lead alloy. Specifically, Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy, etc. can be used. As shown in FIGS. 3 and 4, each of the electrode plates 22P and 22N has an ear portion 24 at the top. The strap 25 connects the ears 24 of the polar plates 22P and 22N of the same polarity within one cell chamber 15.

- the positive external terminal 30P and the negative external terminal 30N are made of lead alloy. Specifically, Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy, etc. can be used. As shown in FIG. 3, the positive external terminal 30P and the negative external terminal 30N are located on both sides of the upper surface of the lid member 16 in the X direction.

- the positive external terminal 30P consists of a terminal portion 31, a pole post 33, and a connecting portion 35.

- the terminal portion 31 has a generally block shape.

- a load or a charger is connected to the terminal portion 31 via a harness terminal (not shown).

- the pole pillar 33 is located below the terminal portion 31 and is located below the flat plate portion 17 in relation to the lid member 16.

- the pole column 33 has a cylindrical shape.

- the pole column 33 has a plurality of annular ribs 34 on its outer peripheral surface.

- a resin portion 40 is provided on the pole pillar 33 so as to cover the annular rib 34.

- the upper part of the resin part 40 is welded to the bottom surface of the flat plate part 17.

- the connecting portion 35 projects horizontally (to the right in FIG. 4) from the bottom of the pole post 33.

- the connecting portion 35 is generally block-shaped.

- the positive external terminal 30P is connected to the strap 25 via the connecting portion 35.

- the negative electrode external terminal 30N has the same structure as the positive electrode, and is connected to the strap 25 via the connecting portion 35.

- the strap 25 corresponds to the "first member” of the present invention

- the positive external terminal 30P and the negative external terminal 30N correspond to the "connection terminal, second member" of the present invention.

- the strap 25 and the connecting portion 35 are positioned on a horizontal base 80 so that they are not tilted using a jig or the like.

- a groove U is formed.

- the weld groove U corresponds to the "gap" of the present invention.

- inert gas G is supplied around the welding groove U.

- the inert gas G is a gas that does not easily cause an oxidation reaction, such as argon gas or nitrogen gas.

- laser light L is irradiated from the laser head 155 and scanned along the welding groove U (see FIG. 6).

- the scanning direction of the laser beam L is indicated by an arrow.

- FIG. 8 is a plan view of the strap 25 and the connection part 35, where the strap 25 is joined to the connection part 35 over its entire width.

- the laser head 155 has an axis R obliquely inclined (indicated by an angle ⁇ ) with respect to the vertical reference line LZ, and with respect to the weld groove U. , irradiate the laser beam L obliquely.

- FIG. 9 is a block diagram (an example) of the laser welding apparatus 100.

- the laser welding apparatus 100 includes a welding stage 110, a laser oscillator 120, an optical fiber 130, a laser head unit 150, a chiller 160, a gas supply source 170, a jetting head 180, and the like.

- the ejection head 180 is arranged above the welding stage 110 and supplies the inert gas G supplied from the gas supply source 170 to the object (lead acid battery 1) on the welding stage 110.

- the laser oscillator 120 is a solid state laser oscillator such as a fiber laser or a YAG laser.

- the output form of the laser oscillator 120 may be a CW output that continuously generates laser light, or a pulse output that outputs intermittently.

- the head unit 150 includes a galvano scanner 151 and a laser head 155, and is connected to the laser oscillator 120 by an optical fiber 130.

- the laser head 155 includes a condenser lens (not shown).

- the head unit 150 is a single mode and focuses the laser light to form a circular spot.

- the head unit 150 is disposed above the welding stage 110, and irradiates the object (lead acid battery 1) on the welding stage 110 with the laser beam L downward from the laser head 155, and uses the galvano scanner 151 to irradiate the laser beam L downward. can be scanned onto the object (lead acid battery 1).

- Step 1 Strap 25 is integrally molded to ear portions 24 of electrode plates 22P and 22N. Molding methods include burning method and COS (cast-on strap).

- Step 2 Insert the electrode plate group 21 integrally molded with the strap 25 halfway into the battery case 11.

- Step 3 While supplying inert gas G, the strap 25 and the connecting portion 35 are joined by laser welding (see FIG. 5). Both members 25 and 35 are joined at the positive external terminal 30P and the negative external terminal 30N, respectively.

- Step 4 Insert the electrode plate group 21 deep into the battery case 11, and then heat-seal the lid member 16 to the battery case 11.

- the inert gas G in combination, it is possible to suppress the formation of an oxide film on the surface of the molten metal, so the fluidity of the molten metal can be maintained.

- the welding groove U is V-shaped, the molten metal can easily reach deep inside. Therefore, it is easy to ensure the amount of weld penetration (welding depth D).

- Embodiment 2 differs from Embodiment 1 in the shape of the laser beam, which is a line shape (straight line shape) as shown by reference numeral 156 in FIG. Specifically, it has a line shape perpendicular to the weld groove U.

- both members located across the welding groove U can be irradiated with the laser beam L at the same time.

- a method of making the laser beam into a line shape there are, for example, a method of using a dedicated condensing lens and a method of using a diffractive optical element.

- the laser welded joints were the strap 25 and the connecting portion 35.

- the joining location is not limited to the example of the embodiment.

- the bushing 210 and the pole post 220 may be laser welded (part A) by irradiating the laser beam L in a circular orbit from above the pole post 220 along the outer periphery of the upper surface of the pole post 220. good.

- a solid-state laser is used for the laser oscillator 120.

- Laser oscillator 120 may be a gas laser.

- a CO2 laser may be used.

- the welding groove U has a V-shape, but it may have a shape other than the V-shape.

- the lower end of the strap 25 and the lower end of the connecting part 35 are brought into contact with each other, but in the state before laser welding, there is a gap between the strap 25 and the connecting part 35. If there is, it is not necessarily necessary that they are in contact.

- the strap 25 and the connecting portion 35 may be separated from each other before laser welding. Then, the strap 25 and the connecting portion 35 may be joined by melting the base material around the gap G formed between them with the laser beam L to fill the gap G.

- the axis R of the laser head 155 was angled, and the welding groove U was irradiated with the laser light L obliquely.

- the laser beam may be irradiated straight down onto the welding groove U from directly above without using an angle.

- the output of the laser beam L was constant during welding, but the output may be switched. For example, the output may be low at the initial stage of welding, and high output thereafter.

- Lead-acid battery 25 Strap (corresponding to the "first member” of the present invention) 30P, 30N Positive external terminal, negative external terminal (corresponding to the "second member” of the present invention) 33 Pole column part 35 Connection part 40 Resin part 100 Laser welding device 120 Laser oscillator 155 Laser head 170 Gas supply source 180 Ejection head U Welding groove (corresponding to the "gap" of the present invention)

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Connection Of Batteries Or Terminals (AREA)

Abstract

The present invention provides a bonding method for a first member 25 and a second member 30 of a lead acid storage battery 1, wherein: the first member 25 and the second member 30 are formed of a lead metal; and the first member 25 and the second member 30 are laser welded with each other, while supplying an inert gas to the first member 25 and the second member 30.

Description

本発明は、鉛蓄電池の製造技術に関する。

The present invention relates to a lead-acid battery manufacturing technology.

近年では、SDGs(Sustainable Development Goals;持続可能な開発目標)から、鉛蓄電池の製造過程においても、CO2の削減が求められている。下記特許文献1は、鉛蓄電池の蓋に一体に鋳込まれた鉛ブッシングと該鉛ブッシングに挿通した極柱との溶接をレーザ溶接する点を開示する。レーザ溶接は、ガスバーナに比べて、CO2の発生が少ない。

In recent years, the SDGs (Sustainable Development Goals) have required the reduction of CO 2 even in the manufacturing process of lead-acid batteries. Patent Document 1 below discloses laser welding of a lead bushing integrally cast into the lid of a lead-acid battery and a pole pole inserted through the lead bushing. Laser welding produces less CO2 than gas burners.

特許文献1の段落08の後段には、次の記載がある。極柱2及びブッシング1は、鉛又は鉛合金から成り、両者は、同材質のものを使用することが一般であり、好ましい。極柱2 及びブッシング1が鉛合金の場合、Pb-Ca合金、Pb-Ca-Sn合金、Pb-Sn合金、Pb-Sb合金などの各種の鉛合金が使用でき、レーザ溶接に適用するが、特に酸化し易いPb-Ca系合金は、表面は空気により黒色の酸化膜で被覆されるので、レーザ光線の吸収力が高くなり、レーザ溶接により、比較的深い溶接を行うに都合が良いことが判った。また、特許文献1の段落24には、次の記載がある。かかるレーザ光線の照射で該被溶接部8の溶接を行うとき、圧縮ポンプにより、酸素又は空気を夫々の吐出孔14,14,…よりシールド筒体70内に所望の吐出圧で吐出させるが、その酸素又は空気は筒状下端部70a1の開口面、即ち、端子部Tに向けて吐出される。尚、この際、空気を使用することが一般であり、経済的に好ましい。この酸素又は空気が被溶接部8の溶接時の表面を酸化せしめることにより、レーザ光の反射が抑止され、レーザ照射光による溶接をより効率良く行うことができる。

The latter part of paragraph 08 of Patent Document 1 includes the following description. The pole post 2 and the bushing 1 are made of lead or a lead alloy, and it is generally preferable to use the same material for both. If pole post 2 and bushing 1 are made of lead alloy, various lead alloys such as Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy can be used and are applicable to laser welding. The surface of Pb-Ca alloys, which are particularly susceptible to oxidation, is coated with a black oxide film by the air, which increases the ability to absorb laser beams, making it convenient for relatively deep welding by laser welding. understood. Further, paragraph 24 of Patent Document 1 includes the following description. When welding the part 8 to be welded by irradiating the laser beam, oxygen or air is discharged at a desired discharge pressure into the shield cylinder 70 from the respective discharge holes 14, 14, . . . using a compression pump. The oxygen or air is discharged toward the opening surface of the cylindrical lower end portion 70a1, that is, toward the terminal portion T. Note that in this case, it is common to use air, which is economically preferable. This oxygen or air oxidizes the surface of the welded portion 8 during welding, thereby suppressing the reflection of laser light and making it possible to more efficiently perform welding using laser irradiation light.

溶融金属の表面に酸化被膜が出来ると、流動性が低下する結果、例えば、溶接の溶け込み量が不均一になり、溶接品質が低下する可能性がある。

When an oxide film forms on the surface of molten metal, its fluidity decreases, resulting in, for example, uneven weld penetration, which may reduce welding quality.

本発明の課題は、溶接におけるCO2の発生を抑制しつつ、溶融金属の流動性を確保して溶接品質維持を図る点にある。

An object of the present invention is to maintain welding quality by ensuring fluidity of molten metal while suppressing the generation of CO 2 during welding.

鉛蓄電池の第1部材と第2部材の接合方法であって、前記第1部材と前記第2部材は、鉛金属であり、前記第1部材と前記第2部材に不活性ガスを供給しながら、前記第1部材と前記第2部材をレーザ溶接する。

A method for joining a first member and a second member of a lead-acid battery, wherein the first member and the second member are made of lead metal, and the method comprises: supplying an inert gas to the first member and the second member; , laser welding the first member and the second member.

本技術は、溶接におけるCO2の発生を抑制しつつ、溶融金属の流動性を確保し、溶接品質を維持することが出来る。

This technology can suppress the generation of CO 2 during welding, ensure fluidity of molten metal, and maintain welding quality.

(本実施形態の概要)

鉛蓄電池の第1部材と第2部材の接合方法であって、前記第1部材と前記第2部材は、鉛金属であり、前記第1部材と前記第2部材に不活性ガスを供給しながら、前記第1部材と前記第2部材をレーザ溶接する。 (Summary of this embodiment)

A method for joining a first member and a second member of a lead-acid battery, wherein the first member and the second member are made of lead metal, and the method comprises: supplying an inert gas to the first member and the second member; , laser welding the first member and the second member.

鉛蓄電池の第1部材と第2部材の接合方法であって、前記第1部材と前記第2部材は、鉛金属であり、前記第1部材と前記第2部材に不活性ガスを供給しながら、前記第1部材と前記第2部材をレーザ溶接する。 (Summary of this embodiment)

A method for joining a first member and a second member of a lead-acid battery, wherein the first member and the second member are made of lead metal, and the method comprises: supplying an inert gas to the first member and the second member; , laser welding the first member and the second member.

この方法は、第1部材と第2部材を、不活性ガスの雰囲気中でレーザ溶接することにより、ガスバーナによる溶接と比べて、CO2を削減できる。不活性ガスの併用により、溶融金属の表面に酸化被膜が出来ることを抑制できる。そのため、溶融金属の流動性を保つことが出来、接合部の溶接品質維持に効果的である。

In this method, by laser welding the first member and the second member in an inert gas atmosphere, CO 2 can be reduced compared to welding using a gas burner. By using an inert gas in combination, it is possible to suppress the formation of an oxide film on the surface of the molten metal. Therefore, the fluidity of the molten metal can be maintained, which is effective in maintaining the welding quality of the joint.

前記第1部材又は前記第2部材のうち、少なくともいずれか一方は、Caを含む鉛合金製でもよい。Caを含む鉛合金は、Caを含まない場合に比べて、酸化し易い。そのため、溶融金属の表面に酸化被膜ができやすく、溶融金属の流動性が低下し易い。酸化被膜が出来やすい第1部材と第2部材の接合に本技術を適用することで、酸化被膜の発生を抑え、溶融金属の流動性を保つことが出来る。そのため、接合部の溶接品質を維持できる。

At least one of the first member and the second member may be made of a lead alloy containing Ca. Lead alloys containing Ca are more easily oxidized than lead alloys that do not contain Ca. Therefore, an oxide film tends to form on the surface of the molten metal, and the fluidity of the molten metal tends to decrease. By applying this technique to joining the first member and the second member where an oxide film is likely to form, it is possible to suppress the formation of an oxide film and maintain the fluidity of the molten metal. Therefore, the welding quality of the joint can be maintained.

前記第1部材と前記第2部材の間には、接合前の状態において隙間が形成されていてもよい。隙間周囲の母材をレーザ光で溶かして前記隙間を埋めることにより、前記第1部材と前記第2部材を接合してもよい。

A gap may be formed between the first member and the second member before they are joined. The first member and the second member may be joined by melting the base material around the gap with laser light to fill the gap.

第1部材と第2部材の間に形成された隙間を、溶融ビードで埋める構成であるから、溶接の溶け込み量(溶接深さ)を確保することが出来る。そのため、接合部の溶接品質維持に効果的である。

Since the gap formed between the first member and the second member is filled with a molten bead, the amount of weld penetration (welding depth) can be ensured. Therefore, it is effective in maintaining the welding quality of the joint.

前記レーザ光のビーム形状は直線形状でもよい。前記レーザ光を、前記隙間に沿って走査することにより、前記第1部材と前記第2部材を接合してもよい。

The beam shape of the laser light may be a linear shape. The first member and the second member may be joined by scanning the laser beam along the gap.

より広い範囲にレーザ光を当てることが出来、短時間の溶接が可能となる。そのため、鉛蓄電池の製造効率を向上させることが出来る。

Laser light can be applied to a wider area, making it possible to weld in a shorter time. Therefore, the manufacturing efficiency of lead-acid batteries can be improved.

前記第1部材は、ストラップであり、前記第2部材は、前記ストラップに対して、接続部を介して電気的に接続される接続端子でもよい。前記不活性ガスを供給しながら、前記ストラップと前記接続部をレーザ溶接してもよい。

The first member may be a strap, and the second member may be a connecting terminal electrically connected to the strap via a connecting portion. The strap and the connecting portion may be laser welded while supplying the inert gas.

<実施形態1>

1.鉛蓄電池の構造

図1を参照して、鉛蓄電池1の構造について説明する。鉛蓄電池1は、例えば、自動二輪、自動車等の移動体の電源として使用される。 <Embodiment 1>

1. Structure of lead-acid battery The structure of lead-acid battery 1 will be described with reference to FIG. The lead-acid battery 1 is used, for example, as a power source for mobile bodies such as motorcycles and automobiles.

1.鉛蓄電池の構造

図1を参照して、鉛蓄電池1の構造について説明する。鉛蓄電池1は、例えば、自動二輪、自動車等の移動体の電源として使用される。 <

1. Structure of lead-acid battery The structure of lead-

鉛蓄電池1は、合成樹脂製の電槽11及び合成樹脂製の蓋部材16からなる収容体10を備えている。

The lead-acid battery 1 includes a container 10 consisting of a battery case 11 made of synthetic resin and a lid member 16 made of synthetic resin.

電槽11は、図2に示すように、4枚の外壁12と底壁13とを有しており、上側が開口する箱型である。電槽11は5つの隔壁14によって、6つのセル室15に仕切られている。蓋部材16は電槽11に熱溶着されて電槽11の開口11Aを閉塞する。

As shown in FIG. 2, the battery case 11 has four outer walls 12 and a bottom wall 13, and is box-shaped with an open top. The battery case 11 is partitioned into six cell chambers 15 by five partition walls 14. The lid member 16 is thermally welded to the battery case 11 and closes the opening 11A of the battery case 11.

蓋部材16は平板部17、張り出し部18、及び外周壁19を備える。張り出し部18は、平板部17から上に向かって略T字状に張り出している。外周壁19は平板部17の外周縁から下向きに延びており、電槽11の外壁12の上端部を囲む。

The lid member 16 includes a flat plate portion 17, an overhanging portion 18, and an outer peripheral wall 19. The projecting portion 18 projects upward from the flat plate portion 17 in a substantially T-shape. The outer peripheral wall 19 extends downward from the outer peripheral edge of the flat plate portion 17 and surrounds the upper end of the outer wall 12 of the battery case 11.

鉛蓄電池1は、更に、極板群21、ストラップ25、正極外部端子30P及び負極外部端子30Nを備える。

The lead acid battery 1 further includes an electrode plate group 21, a strap 25, a positive external terminal 30P, and a negative external terminal 30N.

極板群21は、図3に示すように、正極板22Pと負極板22Nとを間にセパレータ23を挟んでX方向に交互に積層したものである。各極板22P、22Nは格子体に活物質を充填した構造である。

As shown in FIG. 3, the electrode plate group 21 is made up of positive electrode plates 22P and negative electrode plates 22N alternately stacked in the X direction with separators 23 in between. Each of the electrode plates 22P and 22N has a structure in which a grid body is filled with an active material.

極板群21は、各セル室15に対して、希硫酸からなる電解液と共に収容される。

The electrode plate group 21 is accommodated in each cell chamber 15 together with an electrolytic solution made of dilute sulfuric acid.

ストラップ25は、鉛合金製である。具体的には、Pb-Ca合金、Pb-Ca-Sn合金、Pb-Sn合金、Pb-Sb合金などが使用できる。図3及び図4に示すように、各極板22P、22Nは、上部に耳部24を有している。ストラップ25は、1つのセル室15内の同じ極性の極板22P、22Nの耳部24を連結する。

The strap 25 is made of lead alloy. Specifically, Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy, etc. can be used. As shown in FIGS. 3 and 4, each of the electrode plates 22P and 22N has an ear portion 24 at the top. The strap 25 connects the ears 24 of the polar plates 22P and 22N of the same polarity within one cell chamber 15.

正極外部端子30Pと負極外部端子30Nは鉛合金製である。具体的には、Pb-Ca合金、Pb-Ca-Sn合金、Pb-Sn合金、Pb-Sb合金などが使用できる。正極外部端子30Pと負極外部端子30Nは、図3に示すように、蓋部材16の上面のX方向両側に位置する。

The positive external terminal 30P and the negative external terminal 30N are made of lead alloy. Specifically, Pb-Ca alloy, Pb-Ca-Sn alloy, Pb-Sn alloy, Pb-Sb alloy, etc. can be used. As shown in FIG. 3, the positive external terminal 30P and the negative external terminal 30N are located on both sides of the upper surface of the lid member 16 in the X direction.

正極外部端子30Pは、図4に示すように、端子部31、極柱33及び接続部35からなる。端子部31は、概ねブロック形状である。端子部31には、ハーネス端子(図略)を介して、負荷や充電器が接続される。

As shown in FIG. 4, the positive external terminal 30P consists of a terminal portion 31, a pole post 33, and a connecting portion 35. The terminal portion 31 has a generally block shape. A load or a charger is connected to the terminal portion 31 via a harness terminal (not shown).

極柱33は、端子部31の下方に位置しており、蓋部材16との関係では、平板部17の下方に位置している。極柱33は、円筒状である。極柱33は、外周面に環状のリブ34を複数本有している。

The pole pillar 33 is located below the terminal portion 31 and is located below the flat plate portion 17 in relation to the lid member 16. The pole column 33 has a cylindrical shape. The pole column 33 has a plurality of annular ribs 34 on its outer peripheral surface.

極柱33には、環状のリブ34を覆うように、樹脂部40が設けられている。樹脂部40の上部は、平板部17の底面に溶着されている。樹脂部40で極柱33のリブ34を囲むことで、端子周辺のシール性(気密性)を向上させることが出来る。

A resin portion 40 is provided on the pole pillar 33 so as to cover the annular rib 34. The upper part of the resin part 40 is welded to the bottom surface of the flat plate part 17. By surrounding the rib 34 of the pole post 33 with the resin portion 40, the sealing performance (airtightness) around the terminal can be improved.

接続部35は、極柱33の下部から水平(図4の右方向)に突出している。接続部35は、概ねブロック状である。正極外部端子30Pは、接続部35を介して、ストラップ25に接合されている。

The connecting portion 35 projects horizontally (to the right in FIG. 4) from the bottom of the pole post 33. The connecting portion 35 is generally block-shaped. The positive external terminal 30P is connected to the strap 25 via the connecting portion 35.

負極外部端子30Nは、正極と同様の構造であり、接続部35を介して、ストラップ25に接合されている。ストラップ25が本願発明の「第1部材」に相当し、正極外部端子30P、負極外部端子30Nは、本発明の「接続端子、第2部材」に相当する。

The negative electrode external terminal 30N has the same structure as the positive electrode, and is connected to the strap 25 via the connecting portion 35. The strap 25 corresponds to the "first member" of the present invention, and the positive external terminal 30P and the negative external terminal 30N correspond to the "connection terminal, second member" of the present invention.

2.ストラップ25と接続部35の接合方法

ストラップ25と接続部35の接合は、不活性ガスGを併用しつつ、レーザ溶接により行う。 2. Method for joining thestrap 25 and the connecting portion 35 The strap 25 and the connecting portion 35 are joined by laser welding while using an inert gas G in combination.

ストラップ25と接続部35の接合は、不活性ガスGを併用しつつ、レーザ溶接により行う。 2. Method for joining the

具体的に説明すると、図5に示すように、ストラップ25と接続部35とを、水平なベース80上において、治具等により傾きのない状態に位置決めする。位置決めされた状態において、ストラップ25と接続部35の間には、図6、図7に示すように、隙間があり、ストラップ25の端面25Aと接続部35の端面35Aにより、V字型の溶接溝Uが形成される。溶接溝Uは、本発明の「隙間」に相当する。

Specifically, as shown in FIG. 5, the strap 25 and the connecting portion 35 are positioned on a horizontal base 80 so that they are not tilted using a jig or the like. In the positioned state, there is a gap between the strap 25 and the connecting part 35, as shown in FIGS. 6 and 7, and the end surface 25A of the strap 25 and the end surface 35A of the connecting part 35 form a V-shaped weld. A groove U is formed. The weld groove U corresponds to the "gap" of the present invention.

位置決め後、溶接溝Uの周囲に、不活性ガスGを供給する。不活性ガスGは、酸化反応を起こし難い気体であり、アルゴンガスや窒素ガス等である。

After positioning, inert gas G is supplied around the welding groove U. The inert gas G is a gas that does not easily cause an oxidation reaction, such as argon gas or nitrogen gas.

そして、不活性ガスGの雰囲気中で、レーザヘッド155からレーザ光Lを照射し、溶接溝Uに沿って走査する(図6参照)。図6においてレーザ光Lの走査方向を矢印で示す。

Then, in an atmosphere of inert gas G, laser light L is irradiated from the laser head 155 and scanned along the welding groove U (see FIG. 6). In FIG. 6, the scanning direction of the laser beam L is indicated by an arrow.

図6、図7に示すように、レーザ光Lで母材である両部材25、35を溶かし、溶接溝Uを溶接ビードBで埋めることで、両部材25、35は接合される。図8はストラップ25及び接続部35の平面図であり、ストラップ25は、その全幅に亘って、接続部35に対して接合される。

As shown in FIGS. 6 and 7, both members 25 and 35, which are base materials, are melted with laser beam L and the weld groove U is filled with weld bead B, so that both members 25 and 35 are joined. FIG. 8 is a plan view of the strap 25 and the connection part 35, where the strap 25 is joined to the connection part 35 over its entire width.

この実施形態では、図5、図6に示すようにレーザヘッド155は、上下方向の基準線LZに対して軸線Rが斜めに傾斜(角度θで示す)しており、溶接溝Uに対して、レーザ光Lを斜めに照射する。

In this embodiment, as shown in FIGS. 5 and 6, the laser head 155 has an axis R obliquely inclined (indicated by an angle θ) with respect to the vertical reference line LZ, and with respect to the weld groove U. , irradiate the laser beam L obliquely.

レーザ光Lを斜め方向から照射することで、極柱33の外周に位置する樹脂部40から距離を確保できる。樹脂部40までの距離を確保することで、樹脂部40がレーザの熱で変形、変質することを抑制できる。そのため、正極外部端子30P、負極外部端子30Nの気密性を維持できる。

By irradiating the laser beam L from an oblique direction, a distance from the resin part 40 located on the outer periphery of the pole pillar 33 can be secured. By ensuring the distance to the resin part 40, it is possible to suppress the resin part 40 from being deformed or altered by the heat of the laser. Therefore, the airtightness of the positive external terminal 30P and the negative external terminal 30N can be maintained.

図9は、レーザ溶接装置100のブロック図(一例)である。レーザ溶接装置100は、溶接ステージ110、レーザ発振器120、光ファイバ130、レーザヘッドユニット150、チラー160、ガス供給源170及び噴出ヘッド180などから構成されている。

FIG. 9 is a block diagram (an example) of the laser welding apparatus 100. The laser welding apparatus 100 includes a welding stage 110, a laser oscillator 120, an optical fiber 130, a laser head unit 150, a chiller 160, a gas supply source 170, a jetting head 180, and the like.

噴出ヘッド180は、溶接ステージ110の上方に配置されており、ガス供給源170より供給される不活性ガスGを、溶接ステージ110上の対象物(鉛蓄電池1)に供給する。

The ejection head 180 is arranged above the welding stage 110 and supplies the inert gas G supplied from the gas supply source 170 to the object (lead acid battery 1) on the welding stage 110.

レーザ発振器120は、ファイバレーザやYAGレーザ等の固体レーザ発振器である。レーザ発振器120の出力形態は、レーザ光を連続的に発生するCW出力でもよいし、断続的に出力するパルス出力でもよい。

The laser oscillator 120 is a solid state laser oscillator such as a fiber laser or a YAG laser. The output form of the laser oscillator 120 may be a CW output that continuously generates laser light, or a pulse output that outputs intermittently.

ヘッドユニット150は、ガルバノスキャナ151とレーザヘッド155を備え、光ファイバ130によりレーザ発振器120と接続されている。レーザヘッド155は、集光レンズ(図略)を備える。ヘッドユニット150は、シングルモードであり、レーザ光を集光し、円形のスポットを形成する。

The head unit 150 includes a galvano scanner 151 and a laser head 155, and is connected to the laser oscillator 120 by an optical fiber 130. The laser head 155 includes a condenser lens (not shown). The head unit 150 is a single mode and focuses the laser light to form a circular spot.

ヘッドユニット150は、溶接ステージ110の上方に配置されており、レーザヘッド155から溶接ステージ110上の対象物(鉛蓄電池1)に下向きにレーザ光Lを照射し、ガルバノスキャナ151により、レーザ光Lを対象物(鉛蓄電池1)上に走査することが出来る。

The head unit 150 is disposed above the welding stage 110, and irradiates the object (lead acid battery 1) on the welding stage 110 with the laser beam L downward from the laser head 155, and uses the galvano scanner 151 to irradiate the laser beam L downward. can be scanned onto the object (lead acid battery 1).

3.鉛蓄電池1の製造工程

工程1:極板22P、22Nの耳部24に対してストラップ25を一体成形する。成形法には、バーニング法やCOS(キャストオンストラップ)がある。

工程2:ストラップ25を一体成形した極板群21を電槽11の途中まで挿入する。

工程3:不活性ガスGを供給しながら、ストラップ25と接続部35を、レーザ溶接により接合する(図5参照)。両部材25、35の接合を、正極外部端子30Pと負極外部端子30Nついてそれぞれ行う。

工程4:極板群21を電槽11の奥まで挿入し、その後、電槽11に対して蓋部材16を熱溶着(ヒートシール)する。 3. Manufacturing process of lead-acid battery 1 Step 1: Strap 25 is integrally molded to ear portions 24 of electrode plates 22P and 22N. Molding methods include burning method and COS (cast-on strap).

Step 2: Insert theelectrode plate group 21 integrally molded with the strap 25 halfway into the battery case 11.

Step 3: While supplying inert gas G, thestrap 25 and the connecting portion 35 are joined by laser welding (see FIG. 5). Both members 25 and 35 are joined at the positive external terminal 30P and the negative external terminal 30N, respectively.

Step 4: Insert theelectrode plate group 21 deep into the battery case 11, and then heat-seal the lid member 16 to the battery case 11.

工程1:極板22P、22Nの耳部24に対してストラップ25を一体成形する。成形法には、バーニング法やCOS(キャストオンストラップ)がある。

工程2:ストラップ25を一体成形した極板群21を電槽11の途中まで挿入する。

工程3:不活性ガスGを供給しながら、ストラップ25と接続部35を、レーザ溶接により接合する(図5参照)。両部材25、35の接合を、正極外部端子30Pと負極外部端子30Nついてそれぞれ行う。

工程4:極板群21を電槽11の奥まで挿入し、その後、電槽11に対して蓋部材16を熱溶着(ヒートシール)する。 3. Manufacturing process of lead-

Step 2: Insert the

Step 3: While supplying inert gas G, the

Step 4: Insert the

2.効果

鉛金属からなる両部材(ストラップ25と接続部35)を、不活性ガスGの雰囲気中でレーザ溶接することにより、ガスバーナによる溶接と比べて、溶接におけるCO2を削減できる。 2. Effect By laser welding both members (strap 25 and connecting portion 35) made of lead metal in an atmosphere of inert gas G, CO 2 during welding can be reduced compared to welding using a gas burner.

鉛金属からなる両部材(ストラップ25と接続部35)を、不活性ガスGの雰囲気中でレーザ溶接することにより、ガスバーナによる溶接と比べて、溶接におけるCO2を削減できる。 2. Effect By laser welding both members (

レーザ溶接の際に、溶融金属の表面に酸化被膜が出来ると、流動性が低下する結果、溶接の溶け込み量が不均一になり、溶接品質が低下する可能性がある。特に、Caを含む鉛合金は、Caを含まない場合に比べて、酸化膜が出来やすく、溶接品質の低下が懸念される。

If an oxide film is formed on the surface of molten metal during laser welding, fluidity will be reduced, resulting in uneven weld penetration and a possible reduction in welding quality. In particular, lead alloys containing Ca tend to form an oxide film more easily than lead alloys that do not contain Ca, leading to concerns about deterioration in welding quality.

本技術によれば、不活性ガスGの併用により、溶融金属の表面に酸化被膜が出来ることを抑制できるため、溶融金属の流動性を保つことが出来る。

According to the present technology, by using the inert gas G in combination, it is possible to suppress the formation of an oxide film on the surface of the molten metal, so the fluidity of the molten metal can be maintained.

溶融金属の流動性を保つことで、溶接溝Uに溶融金属が均一に行き渡り易くなるため、溶接品質が安定し、溶接品質維持に効果的である。

By maintaining the fluidity of the molten metal, it becomes easier for the molten metal to spread uniformly into the welding groove U, which stabilizes the welding quality and is effective in maintaining the welding quality.

また、図7に示すように、溶接溝Uは、V字型であるから、溶融金属が奥まで到達しやすい。そのため、溶接の溶け込み量(溶接深さD)を確保しやすい。

Furthermore, as shown in FIG. 7, since the welding groove U is V-shaped, the molten metal can easily reach deep inside. Therefore, it is easy to ensure the amount of weld penetration (welding depth D).

<実施形態2>

実施形態2は、実施形態1に対してレーザビームの形状が異なり、図10にて符号156で示すように、ライン形状(直線形状)である。具体的には、溶接溝Uに直交するライン形状である。 <Embodiment 2>

Embodiment 2 differs fromEmbodiment 1 in the shape of the laser beam, which is a line shape (straight line shape) as shown by reference numeral 156 in FIG. Specifically, it has a line shape perpendicular to the weld groove U.

実施形態2は、実施形態1に対してレーザビームの形状が異なり、図10にて符号156で示すように、ライン形状(直線形状)である。具体的には、溶接溝Uに直交するライン形状である。 <Embodiment 2>

Embodiment 2 differs from

レーザビームをライン形状にすることで、円形のビームに比べて広範囲にレーザを照射できる。例えば、溶接溝Uを隔てて位置する両部材(接続部35とストラップ25)に、レーザ光Lを同時に照射できる。

By making the laser beam into a line shape, it is possible to irradiate a wider range of laser beams than with a circular beam. For example, both members (the connecting portion 35 and the strap 25) located across the welding groove U can be irradiated with the laser beam L at the same time.

そのため、円形のビームと比べて、少ない走査回数で、両部材を接合することが可能である。よって、溶接時間を短縮でき、タクトタイムを短くすることが出来る。

Therefore, it is possible to join both members with fewer scans than with a circular beam. Therefore, welding time and takt time can be shortened.

尚、レーザビームをライン形状にする方法として、例えば、専用の集光レンズを使用する方法や、回折光学素子を使用する方法がある。

Note that as a method of making the laser beam into a line shape, there are, for example, a method of using a dedicated condensing lens and a method of using a diffractive optical element.

<他の実施形態>

本発明は上記記述及び図面によって説明した実施形態に限定されるものではなく、例えば次のような実施形態も本発明の技術的範囲に含まれる。 <Other embodiments>

The present invention is not limited to the embodiments described above and illustrated in the drawings; for example, the following embodiments are also included within the technical scope of the present invention.

本発明は上記記述及び図面によって説明した実施形態に限定されるものではなく、例えば次のような実施形態も本発明の技術的範囲に含まれる。 <Other embodiments>

The present invention is not limited to the embodiments described above and illustrated in the drawings; for example, the following embodiments are also included within the technical scope of the present invention.

(1)実施形態1、2では、レーザ溶接の接合箇所は、ストラップ25と接続部35であった。接合箇所は、鉛金属製の部材であれば制約はなく、実施形態の例に限定されない。例えば、図11に示すように、極柱220の上方から極柱220の上面外周に沿ってレーザ光Lを円軌道で照射し、ブッシング210と極柱220をレーザ溶接(A部)してもよい。

(1) In Embodiments 1 and 2, the laser welded joints were the strap 25 and the connecting portion 35. There are no restrictions on the joining location as long as it is a member made of lead metal, and the joining location is not limited to the example of the embodiment. For example, as shown in FIG. 11, the bushing 210 and the pole post 220 may be laser welded (part A) by irradiating the laser beam L in a circular orbit from above the pole post 220 along the outer periphery of the upper surface of the pole post 220. good.

(2)実施形態1、2では、レーザ発振器120に固体レーザを用いた。レーザ発振器120はガスレーザでもよい。例えば、CO2レーザでもよい。

(2) In the first and second embodiments, a solid-state laser is used for the laser oscillator 120. Laser oscillator 120 may be a gas laser. For example, a CO2 laser may be used.

(3)実施形態1、2では、溶接溝Uを、V字形状としたが、V字以外の形状でもよい。また、溶接溝Uを形成するため、実施形態1では、ストラップ25の下端と接続部35の下端を接触させたが、レーザ溶接前の状態において、ストラップ25と接続部35に隙間がある形態であれば、必ずしも、接触している必要はない。例えば、図12に示すように、レーザ溶接前の状態において、ストラップ25と接続部35は、離れていてもよい。そして、両間に形成されたギャップGの周囲の母材をレーザ光Lで溶かして、ギャップGを埋めることにより、ストラップ25と接続部35を接合してもよい。

(3) In Embodiments 1 and 2, the welding groove U has a V-shape, but it may have a shape other than the V-shape. Further, in order to form the welding groove U, in the first embodiment, the lower end of the strap 25 and the lower end of the connecting part 35 are brought into contact with each other, but in the state before laser welding, there is a gap between the strap 25 and the connecting part 35. If there is, it is not necessarily necessary that they are in contact. For example, as shown in FIG. 12, the strap 25 and the connecting portion 35 may be separated from each other before laser welding. Then, the strap 25 and the connecting portion 35 may be joined by melting the base material around the gap G formed between them with the laser beam L to fill the gap G.

(4)実施形態1、2では、レーザヘッド155の軸線Rに角度を付け、溶接溝Uに対してレーザ光Lを斜めに照射した。角度を付けず、レーザ光を真上から、溶接溝Uに対して真っすぐ下に照射してもよい。

(4) In Embodiments 1 and 2, the axis R of the laser head 155 was angled, and the welding groove U was irradiated with the laser light L obliquely. The laser beam may be irradiated straight down onto the welding groove U from directly above without using an angle.

(5)実施形態1、2では、溶接中、レーザ光Lを定出力としたが、出力を切り換えてもよい。例えば、溶接初期段階は低出力、それ以降は高出力としてもよい。

(5) In Embodiments 1 and 2, the output of the laser beam L was constant during welding, but the output may be switched. For example, the output may be low at the initial stage of welding, and high output thereafter.

1 鉛蓄電池

25 ストラップ(本発明の「第1部材」に相当)

30P、30N 正極外部端子、負極外部端子(本発明の「第2部材」に相当)

33 極柱部

35 接続部

40 樹脂部

100 レーザ溶接装置

120 レーザ発振器

155 レーザヘッド

170 ガス供給源

180 噴出ヘッド

U 溶接溝(本発明の「隙間」に相当)

1 Lead-acid battery 25 Strap (corresponding to the "first member" of the present invention)

30P, 30N Positive external terminal, negative external terminal (corresponding to the "second member" of the present invention)

33Pole column part 35 Connection part 40 Resin part 100 Laser welding device 120 Laser oscillator 155 Laser head 170 Gas supply source 180 Ejection head U Welding groove (corresponding to the "gap" of the present invention)

25 ストラップ(本発明の「第1部材」に相当)

30P、30N 正極外部端子、負極外部端子(本発明の「第2部材」に相当)

33 極柱部

35 接続部

40 樹脂部

100 レーザ溶接装置

120 レーザ発振器

155 レーザヘッド

170 ガス供給源

180 噴出ヘッド

U 溶接溝(本発明の「隙間」に相当)

1 Lead-

30P, 30N Positive external terminal, negative external terminal (corresponding to the "second member" of the present invention)

33

Claims (5)

- 鉛蓄電池の第1部材と第2部材の接合方法であって、

前記第1部材と前記第2部材は、鉛金属であり、

前記第1部材と前記第2部材に不活性ガスを供給しながら、前記第1部材と前記第2部材をレーザ溶接する、接合方法。 A method for joining a first member and a second member of a lead-acid battery, the method comprising:

The first member and the second member are lead metal,

A joining method comprising laser welding the first member and the second member while supplying an inert gas to the first member and the second member. - 請求項1に記載の接合方法であって、

前記第1部材又は前記第2部材のうち、少なくともいずれか一方は、Caを含む鉛合金製である、接合方法。 The joining method according to claim 1,

A joining method, wherein at least one of the first member and the second member is made of a lead alloy containing Ca. - 請求項1又は請求項2に記載の接合方法であって、

前記第1部材と前記第2部材の間には、接合前の状態において隙間が形成されており、

隙間周囲の母材をレーザ光で溶かして前記隙間を埋めることにより、前記第1部材と前記第2部材を接合する、接合方法。 The joining method according to claim 1 or claim 2,

A gap is formed between the first member and the second member in a state before joining,

A joining method in which the first member and the second member are joined by melting a base material around the gap with a laser beam to fill the gap. - 請求項3に記載の接合方法であって、

前記レーザ光のビーム形状は直線形状であり、

前記レーザ光を、前記隙間に沿って走査することにより、前記第1部材と前記第2部材を接合する、接合方法。 The joining method according to claim 3,

The beam shape of the laser light is a linear shape,

A method for joining the first member and the second member by scanning the laser beam along the gap. - 請求項1又は請求項2に記載の接合方法であって、

前記第1部材は、ストラップであり、

前記第2部材は、前記ストラップに対して、接続部を介して電気的に接続される接続端子であり、

前記不活性ガスを供給しながら、前記ストラップと前記接続部をレーザ溶接する、接合方法。

The joining method according to claim 1 or claim 2,

The first member is a strap,

The second member is a connection terminal electrically connected to the strap via a connection part,

A joining method comprising laser welding the strap and the connecting portion while supplying the inert gas.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2022-095777 | 2022-06-14 | ||

| JP2022095777 | 2022-06-14 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2023243387A1 true WO2023243387A1 (en) | 2023-12-21 |

Family

ID=89190943

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2023/020014 WO2023243387A1 (en) | 2022-06-14 | 2023-05-30 | Bonding method |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2023243387A1 (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS634312B2 (en) * | 1981-02-25 | 1988-01-28 | Shin Kobe Electric Machinery | |

| JPH10302760A (en) * | 1997-04-30 | 1998-11-13 | Yuasa Corp | Storage battery |

| JP2005190773A (en) * | 2003-12-25 | 2005-07-14 | Japan Storage Battery Co Ltd | Lead accumulator |

| US20150303436A1 (en) * | 2012-01-13 | 2015-10-22 | Energy Power Systems LLC | Method of manufacturing a lead-acid battery |

-

2023

- 2023-05-30 WO PCT/JP2023/020014 patent/WO2023243387A1/en unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS634312B2 (en) * | 1981-02-25 | 1988-01-28 | Shin Kobe Electric Machinery | |

| JPH10302760A (en) * | 1997-04-30 | 1998-11-13 | Yuasa Corp | Storage battery |

| JP2005190773A (en) * | 2003-12-25 | 2005-07-14 | Japan Storage Battery Co Ltd | Lead accumulator |

| US20150303436A1 (en) * | 2012-01-13 | 2015-10-22 | Energy Power Systems LLC | Method of manufacturing a lead-acid battery |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4184663B2 (en) | Manufacturing method of lead-acid battery and jig for manufacturing the same | |

| KR100300499B1 (en) | Square-shaped seal battery and mehtod for manufacturing thereof | |

| KR100571229B1 (en) | Sealed battery suited to production in a slim rectangular form | |

| JP2011204396A (en) | Sealed battery and method for manufacturing the same | |

| EP2859986A1 (en) | Welding device, welding method, and method for producing cell | |

| JP2011212711A (en) | Method for producing sealed battery | |

| JP6725351B2 (en) | Electric storage element and method for manufacturing electric storage element | |

| JPWO2013093965A1 (en) | Battery container and manufacturing method thereof | |

| JP2014004619A (en) | Laser joining method and joining component | |

| JP6084905B2 (en) | Battery and battery manufacturing method | |

| JPH1177347A (en) | Laser welding method of aluminum sheet, manufacture of enclosed cell, and enclosed cell itself | |

| KR102483312B1 (en) | Welding method of secondary battery cap plate assembly | |

| KR101838382B1 (en) | Sealed battery and a method for manufacturing the same | |

| JP2001155698A (en) | Encapsulated type battery | |

| WO2023243387A1 (en) | Bonding method | |

| JP2003181666A (en) | Method of welding container for rectangular battery and method of manufacturing rectangular battery | |

| JPH08315788A (en) | Manufacture of square battery | |

| JPH1190657A (en) | Square pressure-resistant case and its welding method | |

| KR20230082358A (en) | electrode tab welding apparatus and welding method | |

| JP3099670B2 (en) | Welding method for prismatic batteries | |

| KR102610475B1 (en) | Laser welding method of dissimilar metals of secondary battery cap assembly | |

| KR20240138015A (en) | Laser welding Device for Electrode Tab and Electrode Lead and Welding Method Using the Same | |

| KR102571995B1 (en) | Method of manufacturing a secondary battery and secondary battery manufactured thereby | |

| US20230127234A1 (en) | Method of manufacturing secondary battery | |

| JPH11245066A (en) | Laser welding and manufacture of secondary battery |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 23823681 Country of ref document: EP Kind code of ref document: A1 |