WO2023188482A1 - Adhesive sheet - Google Patents

Adhesive sheet Download PDFInfo

- Publication number

- WO2023188482A1 WO2023188482A1 PCT/JP2022/038804 JP2022038804W WO2023188482A1 WO 2023188482 A1 WO2023188482 A1 WO 2023188482A1 JP 2022038804 W JP2022038804 W JP 2022038804W WO 2023188482 A1 WO2023188482 A1 WO 2023188482A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- weight

- less

- adhesive

- adhesive sheet

- adhesive layer

- Prior art date

Links

- 230000001070 adhesive effect Effects 0.000 title claims abstract description 306

- 239000000853 adhesive Substances 0.000 title claims abstract description 298

- 239000000178 monomer Substances 0.000 claims abstract description 165

- 229920000058 polyacrylate Polymers 0.000 claims abstract description 120

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 claims abstract description 42

- ZWEDFBKLJILTMC-UHFFFAOYSA-N ethyl 4,4,4-trifluoro-3-hydroxybutanoate Chemical compound CCOC(=O)CC(O)C(F)(F)F ZWEDFBKLJILTMC-UHFFFAOYSA-N 0.000 claims abstract description 35

- 229920000642 polymer Polymers 0.000 claims abstract description 23

- 229920005989 resin Polymers 0.000 claims description 241

- 239000011347 resin Substances 0.000 claims description 241

- 239000012790 adhesive layer Substances 0.000 claims description 136

- 239000004820 Pressure-sensitive adhesive Substances 0.000 claims description 98

- 239000003431 cross linking reagent Substances 0.000 claims description 85

- 239000000203 mixture Substances 0.000 claims description 54

- -1 polypropylene Polymers 0.000 claims description 46

- 239000010410 layer Substances 0.000 claims description 45

- 239000004743 Polypropylene Substances 0.000 claims description 32

- 229920001155 polypropylene Polymers 0.000 claims description 32

- 239000004698 Polyethylene Substances 0.000 claims description 31

- 229920000573 polyethylene Polymers 0.000 claims description 31

- 238000012360 testing method Methods 0.000 claims description 12

- 229910001220 stainless steel Inorganic materials 0.000 claims description 7

- 239000010935 stainless steel Substances 0.000 claims description 7

- 238000006073 displacement reaction Methods 0.000 claims description 4

- 239000000463 material Substances 0.000 abstract description 192

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 104

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 104

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 104

- 239000002585 base Substances 0.000 description 78

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 75

- 239000002028 Biomass Substances 0.000 description 74

- 239000010408 film Substances 0.000 description 60

- 150000003505 terpenes Chemical class 0.000 description 47

- 235000007586 terpenes Nutrition 0.000 description 46

- 150000002148 esters Chemical class 0.000 description 40

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 38

- 239000004593 Epoxy Substances 0.000 description 35

- 238000000034 method Methods 0.000 description 31

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 30

- 125000000217 alkyl group Chemical group 0.000 description 30

- 229910052799 carbon Inorganic materials 0.000 description 30

- 239000005011 phenolic resin Substances 0.000 description 28

- 239000012948 isocyanate Substances 0.000 description 24

- 150000002513 isocyanates Chemical class 0.000 description 24

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 23

- 238000005516 engineering process Methods 0.000 description 23

- 239000000047 product Substances 0.000 description 23

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 21

- 238000005259 measurement Methods 0.000 description 21

- 125000000524 functional group Chemical group 0.000 description 19

- 230000000694 effects Effects 0.000 description 18

- 239000000243 solution Substances 0.000 description 14

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 13

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 12

- 230000001747 exhibiting effect Effects 0.000 description 12

- 239000002904 solvent Substances 0.000 description 12

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 11

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerol Natural products OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 11

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 10

- 239000002184 metal Chemical class 0.000 description 10

- WFDIJRYMOXRFFG-UHFFFAOYSA-N Acetic anhydride Chemical compound CC(=O)OC(C)=O WFDIJRYMOXRFFG-UHFFFAOYSA-N 0.000 description 9

- 230000015572 biosynthetic process Effects 0.000 description 9

- 230000000052 comparative effect Effects 0.000 description 9

- 238000006116 polymerization reaction Methods 0.000 description 9

- 238000011282 treatment Methods 0.000 description 9

- 229920002799 BoPET Polymers 0.000 description 8

- 239000005057 Hexamethylene diisocyanate Substances 0.000 description 8

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 8

- 238000004132 cross linking Methods 0.000 description 8

- 239000003208 petroleum Substances 0.000 description 8

- 239000005056 polyisocyanate Substances 0.000 description 8

- 229920001228 polyisocyanate Polymers 0.000 description 8

- 239000000126 substance Substances 0.000 description 8

- 238000003786 synthesis reaction Methods 0.000 description 8

- GOXQRTZXKQZDDN-UHFFFAOYSA-N 2-Ethylhexyl acrylate Chemical compound CCCCC(CC)COC(=O)C=C GOXQRTZXKQZDDN-UHFFFAOYSA-N 0.000 description 7

- 125000003118 aryl group Chemical group 0.000 description 7

- CQEYYJKEWSMYFG-UHFFFAOYSA-N butyl acrylate Chemical compound CCCCOC(=O)C=C CQEYYJKEWSMYFG-UHFFFAOYSA-N 0.000 description 7

- 238000006243 chemical reaction Methods 0.000 description 7

- 239000003795 chemical substances by application Substances 0.000 description 7

- 229920001971 elastomer Polymers 0.000 description 7

- 235000011187 glycerol Nutrition 0.000 description 7

- 239000000123 paper Substances 0.000 description 7

- 239000003505 polymerization initiator Substances 0.000 description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 7

- OZAIFHULBGXAKX-UHFFFAOYSA-N 2-(2-cyanopropan-2-yldiazenyl)-2-methylpropanenitrile Chemical compound N#CC(C)(C)N=NC(C)(C)C#N OZAIFHULBGXAKX-UHFFFAOYSA-N 0.000 description 6

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 6

- WYURNTSHIVDZCO-UHFFFAOYSA-N Tetrahydrofuran Chemical compound C1CCOC1 WYURNTSHIVDZCO-UHFFFAOYSA-N 0.000 description 6

- 125000004432 carbon atom Chemical group C* 0.000 description 6

- 229920001577 copolymer Polymers 0.000 description 6

- 238000007334 copolymerization reaction Methods 0.000 description 6

- 238000010528 free radical solution polymerization reaction Methods 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 6

- XMGQYMWWDOXHJM-UHFFFAOYSA-N limonene Chemical compound CC(=C)C1CCC(C)=CC1 XMGQYMWWDOXHJM-UHFFFAOYSA-N 0.000 description 6

- YLLIGHVCTUPGEH-UHFFFAOYSA-M potassium;ethanol;hydroxide Chemical compound [OH-].[K+].CCO YLLIGHVCTUPGEH-UHFFFAOYSA-M 0.000 description 6

- 235000013311 vegetables Nutrition 0.000 description 6

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 description 5

- 125000003647 acryloyl group Chemical group O=C([*])C([H])=C([H])[H] 0.000 description 5

- 239000000654 additive Substances 0.000 description 5

- 150000001298 alcohols Chemical class 0.000 description 5

- 125000001931 aliphatic group Chemical group 0.000 description 5

- 150000001875 compounds Chemical class 0.000 description 5

- 239000000835 fiber Substances 0.000 description 5

- 229910052731 fluorine Inorganic materials 0.000 description 5

- 239000011737 fluorine Substances 0.000 description 5

- 229920000728 polyester Polymers 0.000 description 5

- 229920000139 polyethylene terephthalate Polymers 0.000 description 5

- 239000005020 polyethylene terephthalate Substances 0.000 description 5

- 229920000098 polyolefin Polymers 0.000 description 5

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 5

- 239000004810 polytetrafluoroethylene Substances 0.000 description 5

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 5

- 239000005060 rubber Substances 0.000 description 5

- 238000003756 stirring Methods 0.000 description 5

- GRWFGVWFFZKLTI-IUCAKERBSA-N (-)-α-pinene Chemical compound CC1=CC[C@@H]2C(C)(C)[C@H]1C2 GRWFGVWFFZKLTI-IUCAKERBSA-N 0.000 description 4

- 241000196324 Embryophyta Species 0.000 description 4

- 206010040844 Skin exfoliation Diseases 0.000 description 4

- ZJCCRDAZUWHFQH-UHFFFAOYSA-N Trimethylolpropane Chemical compound CCC(CO)(CO)CO ZJCCRDAZUWHFQH-UHFFFAOYSA-N 0.000 description 4

- 239000003153 chemical reaction reagent Substances 0.000 description 4

- 238000001035 drying Methods 0.000 description 4

- 238000005227 gel permeation chromatography Methods 0.000 description 4

- RRAMGCGOFNQTLD-UHFFFAOYSA-N hexamethylene diisocyanate Chemical compound O=C=NCCCCCCN=C=O RRAMGCGOFNQTLD-UHFFFAOYSA-N 0.000 description 4

- 229930195733 hydrocarbon Natural products 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 230000014759 maintenance of location Effects 0.000 description 4

- 239000003960 organic solvent Substances 0.000 description 4

- DVKJHBMWWAPEIU-UHFFFAOYSA-N toluene 2,4-diisocyanate Chemical class CC1=CC=C(N=C=O)C=C1N=C=O DVKJHBMWWAPEIU-UHFFFAOYSA-N 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 3

- 239000004215 Carbon black (E152) Substances 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 3

- 239000004793 Polystyrene Substances 0.000 description 3

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 3

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 3

- 125000002723 alicyclic group Chemical group 0.000 description 3

- 239000007795 chemical reaction product Substances 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 125000003700 epoxy group Chemical group 0.000 description 3

- 239000006260 foam Substances 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- 239000011521 glass Substances 0.000 description 3

- 150000002430 hydrocarbons Chemical class 0.000 description 3

- 239000003999 initiator Substances 0.000 description 3

- IQPQWNKOIGAROB-UHFFFAOYSA-N isocyanate group Chemical group [N-]=C=O IQPQWNKOIGAROB-UHFFFAOYSA-N 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000012528 membrane Substances 0.000 description 3

- 150000004702 methyl esters Chemical class 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 3

- 239000004745 nonwoven fabric Substances 0.000 description 3

- 150000002978 peroxides Chemical class 0.000 description 3

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N phenol group Chemical group C1(=CC=CC=C1)O ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 3

- 229920001568 phenolic resin Polymers 0.000 description 3

- 229920006267 polyester film Polymers 0.000 description 3

- 229920001225 polyester resin Polymers 0.000 description 3

- 239000004645 polyester resin Substances 0.000 description 3

- 229920005672 polyolefin resin Polymers 0.000 description 3

- 229920002223 polystyrene Polymers 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- YLQBMQCUIZJEEH-UHFFFAOYSA-N tetrahydrofuran Natural products C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 3

- 239000013638 trimer Substances 0.000 description 3

- 239000002759 woven fabric Substances 0.000 description 3

- WTARULDDTDQWMU-RKDXNWHRSA-N (+)-β-pinene Chemical compound C1[C@H]2C(C)(C)[C@@H]1CCC2=C WTARULDDTDQWMU-RKDXNWHRSA-N 0.000 description 2

- WTARULDDTDQWMU-IUCAKERBSA-N (-)-Nopinene Natural products C1[C@@H]2C(C)(C)[C@H]1CCC2=C WTARULDDTDQWMU-IUCAKERBSA-N 0.000 description 2

- HASUCEDGKYJBDC-UHFFFAOYSA-N 1-[3-[[bis(oxiran-2-ylmethyl)amino]methyl]cyclohexyl]-n,n-bis(oxiran-2-ylmethyl)methanamine Chemical compound C1OC1CN(CC1CC(CN(CC2OC2)CC2OC2)CCC1)CC1CO1 HASUCEDGKYJBDC-UHFFFAOYSA-N 0.000 description 2

- BBMCTIGTTCKYKF-UHFFFAOYSA-N 1-heptanol Chemical compound CCCCCCCO BBMCTIGTTCKYKF-UHFFFAOYSA-N 0.000 description 2

- IMSODMZESSGVBE-UHFFFAOYSA-N 2-Oxazoline Chemical compound C1CN=CO1 IMSODMZESSGVBE-UHFFFAOYSA-N 0.000 description 2

- 125000000954 2-hydroxyethyl group Chemical group [H]C([*])([H])C([H])([H])O[H] 0.000 description 2

- UPMLOUAZCHDJJD-UHFFFAOYSA-N 4,4'-Diphenylmethane Diisocyanate Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=C(N=C=O)C=C1 UPMLOUAZCHDJJD-UHFFFAOYSA-N 0.000 description 2

- OZAIFHULBGXAKX-VAWYXSNFSA-N AIBN Substances N#CC(C)(C)\N=N\C(C)(C)C#N OZAIFHULBGXAKX-VAWYXSNFSA-N 0.000 description 2

- HRPVXLWXLXDGHG-UHFFFAOYSA-N Acrylamide Chemical compound NC(=O)C=C HRPVXLWXLXDGHG-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- NOWKCMXCCJGMRR-UHFFFAOYSA-N Aziridine Chemical compound C1CN1 NOWKCMXCCJGMRR-UHFFFAOYSA-N 0.000 description 2

- 239000004342 Benzoyl peroxide Substances 0.000 description 2

- OMPJBNCRMGITSC-UHFFFAOYSA-N Benzoylperoxide Chemical compound C=1C=CC=CC=1C(=O)OOC(=O)C1=CC=CC=C1 OMPJBNCRMGITSC-UHFFFAOYSA-N 0.000 description 2

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- 229920000298 Cellophane Polymers 0.000 description 2

- VZCYOOQTPOCHFL-OWOJBTEDSA-N Fumaric acid Chemical compound OC(=O)\C=C\C(O)=O VZCYOOQTPOCHFL-OWOJBTEDSA-N 0.000 description 2

- 244000043261 Hevea brasiliensis Species 0.000 description 2

- OAKJQQAXSVQMHS-UHFFFAOYSA-N Hydrazine Chemical compound NN OAKJQQAXSVQMHS-UHFFFAOYSA-N 0.000 description 2

- MHAJPDPJQMAIIY-UHFFFAOYSA-N Hydrogen peroxide Chemical compound OO MHAJPDPJQMAIIY-UHFFFAOYSA-N 0.000 description 2

- 229920000877 Melamine resin Polymers 0.000 description 2

- WTARULDDTDQWMU-UHFFFAOYSA-N Pseudopinene Natural products C1C2C(C)(C)C1CCC2=C WTARULDDTDQWMU-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 2

- 230000021736 acetylation Effects 0.000 description 2

- 238000006640 acetylation reaction Methods 0.000 description 2

- 239000003522 acrylic cement Substances 0.000 description 2

- 125000005250 alkyl acrylate group Chemical group 0.000 description 2

- XCPQUQHBVVXMRQ-UHFFFAOYSA-N alpha-Fenchene Natural products C1CC2C(=C)CC1C2(C)C XCPQUQHBVVXMRQ-UHFFFAOYSA-N 0.000 description 2

- MVNCAPSFBDBCGF-UHFFFAOYSA-N alpha-pinene Natural products CC1=CCC23C1CC2C3(C)C MVNCAPSFBDBCGF-UHFFFAOYSA-N 0.000 description 2

- 230000003712 anti-aging effect Effects 0.000 description 2

- 239000003963 antioxidant agent Substances 0.000 description 2

- 239000002216 antistatic agent Substances 0.000 description 2

- 229920005601 base polymer Polymers 0.000 description 2

- 235000019400 benzoyl peroxide Nutrition 0.000 description 2

- 229930006722 beta-pinene Natural products 0.000 description 2

- 229920005549 butyl rubber Polymers 0.000 description 2

- 239000003086 colorant Substances 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 239000000539 dimer Substances 0.000 description 2

- 229910001873 dinitrogen Inorganic materials 0.000 description 2

- 239000012153 distilled water Substances 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- FJKIXWOMBXYWOQ-UHFFFAOYSA-N ethenoxyethane Chemical compound CCOC=C FJKIXWOMBXYWOQ-UHFFFAOYSA-N 0.000 description 2

- 238000011156 evaluation Methods 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 239000000945 filler Substances 0.000 description 2

- LCWMKIHBLJLORW-UHFFFAOYSA-N gamma-carene Natural products C1CC(=C)CC2C(C)(C)C21 LCWMKIHBLJLORW-UHFFFAOYSA-N 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 125000003187 heptyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 2

- ZFSLODLOARCGLH-UHFFFAOYSA-N isocyanuric acid Chemical group OC1=NC(O)=NC(O)=N1 ZFSLODLOARCGLH-UHFFFAOYSA-N 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 2

- 229920003052 natural elastomer Polymers 0.000 description 2

- 229920001194 natural rubber Polymers 0.000 description 2

- 239000004014 plasticizer Substances 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 229920006122 polyamide resin Polymers 0.000 description 2

- 229920001707 polybutylene terephthalate Polymers 0.000 description 2

- 229920001721 polyimide Polymers 0.000 description 2

- 229920001296 polysiloxane Polymers 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 238000003918 potentiometric titration Methods 0.000 description 2

- GRWFGVWFFZKLTI-UHFFFAOYSA-N rac-alpha-Pinene Natural products CC1=CCC2C(C)(C)C1C2 GRWFGVWFFZKLTI-UHFFFAOYSA-N 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 239000002356 single layer Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- 238000004381 surface treatment Methods 0.000 description 2

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 2

- LDHQCZJRKDOVOX-UHFFFAOYSA-N trans-crotonic acid Natural products CC=CC(O)=O LDHQCZJRKDOVOX-UHFFFAOYSA-N 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 235000021122 unsaturated fatty acids Nutrition 0.000 description 2

- 150000004670 unsaturated fatty acids Chemical group 0.000 description 2

- DTGKSKDOIYIVQL-WEDXCCLWSA-N (+)-borneol Chemical group C1C[C@@]2(C)[C@@H](O)C[C@@H]1C2(C)C DTGKSKDOIYIVQL-WEDXCCLWSA-N 0.000 description 1

- FKTHNVSLHLHISI-UHFFFAOYSA-N 1,2-bis(isocyanatomethyl)benzene Chemical class O=C=NCC1=CC=CC=C1CN=C=O FKTHNVSLHLHISI-UHFFFAOYSA-N 0.000 description 1

- ZTNJGMFHJYGMDR-UHFFFAOYSA-N 1,2-diisocyanatoethane Chemical compound O=C=NCCN=C=O ZTNJGMFHJYGMDR-UHFFFAOYSA-N 0.000 description 1

- VGHSXKTVMPXHNG-UHFFFAOYSA-N 1,3-diisocyanatobenzene Chemical compound O=C=NC1=CC=CC(N=C=O)=C1 VGHSXKTVMPXHNG-UHFFFAOYSA-N 0.000 description 1

- 239000005059 1,4-Cyclohexyldiisocyanate Substances 0.000 description 1

- ALQLPWJFHRMHIU-UHFFFAOYSA-N 1,4-diisocyanatobenzene Chemical compound O=C=NC1=CC=C(N=C=O)C=C1 ALQLPWJFHRMHIU-UHFFFAOYSA-N 0.000 description 1

- OVBFMUAFNIIQAL-UHFFFAOYSA-N 1,4-diisocyanatobutane Chemical class O=C=NCCCCN=C=O OVBFMUAFNIIQAL-UHFFFAOYSA-N 0.000 description 1

- 229940008841 1,6-hexamethylene diisocyanate Drugs 0.000 description 1

- IANQTJSKSUMEQM-UHFFFAOYSA-N 1-benzofuran Chemical compound C1=CC=C2OC=CC2=C1 IANQTJSKSUMEQM-UHFFFAOYSA-N 0.000 description 1

- LFSYUSUFCBOHGU-UHFFFAOYSA-N 1-isocyanato-2-[(4-isocyanatophenyl)methyl]benzene Chemical compound C1=CC(N=C=O)=CC=C1CC1=CC=CC=C1N=C=O LFSYUSUFCBOHGU-UHFFFAOYSA-N 0.000 description 1

- DTZHXCBUWSTOPO-UHFFFAOYSA-N 1-isocyanato-4-[(4-isocyanato-3-methylphenyl)methyl]-2-methylbenzene Chemical compound C1=C(N=C=O)C(C)=CC(CC=2C=C(C)C(N=C=O)=CC=2)=C1 DTZHXCBUWSTOPO-UHFFFAOYSA-N 0.000 description 1

- XLPJNCYCZORXHG-UHFFFAOYSA-N 1-morpholin-4-ylprop-2-en-1-one Chemical compound C=CC(=O)N1CCOCC1 XLPJNCYCZORXHG-UHFFFAOYSA-N 0.000 description 1

- KQSMCAVKSJWMSI-UHFFFAOYSA-N 2,4-dimethyl-1-n,1-n,3-n,3-n-tetrakis(oxiran-2-ylmethyl)benzene-1,3-diamine Chemical compound CC1=C(N(CC2OC2)CC2OC2)C(C)=CC=C1N(CC1OC1)CC1CO1 KQSMCAVKSJWMSI-UHFFFAOYSA-N 0.000 description 1

- HIXDQWDOVZUNNA-UHFFFAOYSA-N 2-(3,4-dimethoxyphenyl)-5-hydroxy-7-methoxychromen-4-one Chemical compound C=1C(OC)=CC(O)=C(C(C=2)=O)C=1OC=2C1=CC=C(OC)C(OC)=C1 HIXDQWDOVZUNNA-UHFFFAOYSA-N 0.000 description 1

- JAHNSTQSQJOJLO-UHFFFAOYSA-N 2-(3-fluorophenyl)-1h-imidazole Chemical compound FC1=CC=CC(C=2NC=CN=2)=C1 JAHNSTQSQJOJLO-UHFFFAOYSA-N 0.000 description 1

- AOBIOSPNXBMOAT-UHFFFAOYSA-N 2-[2-(oxiran-2-ylmethoxy)ethoxymethyl]oxirane Chemical compound C1OC1COCCOCC1CO1 AOBIOSPNXBMOAT-UHFFFAOYSA-N 0.000 description 1

- WTYYGFLRBWMFRY-UHFFFAOYSA-N 2-[6-(oxiran-2-ylmethoxy)hexoxymethyl]oxirane Chemical compound C1OC1COCCCCCCOCC1CO1 WTYYGFLRBWMFRY-UHFFFAOYSA-N 0.000 description 1

- TXBCBTDQIULDIA-UHFFFAOYSA-N 2-[[3-hydroxy-2,2-bis(hydroxymethyl)propoxy]methyl]-2-(hydroxymethyl)propane-1,3-diol Chemical compound OCC(CO)(CO)COCC(CO)(CO)CO TXBCBTDQIULDIA-UHFFFAOYSA-N 0.000 description 1

- 125000000022 2-aminoethyl group Chemical group [H]C([*])([H])C([H])([H])N([H])[H] 0.000 description 1

- DPNXHTDWGGVXID-UHFFFAOYSA-N 2-isocyanatoethyl prop-2-enoate Chemical compound C=CC(=O)OCCN=C=O DPNXHTDWGGVXID-UHFFFAOYSA-N 0.000 description 1

- QOXOZONBQWIKDA-UHFFFAOYSA-N 3-hydroxypropyl Chemical group [CH2]CCO QOXOZONBQWIKDA-UHFFFAOYSA-N 0.000 description 1

- SXIFAEWFOJETOA-UHFFFAOYSA-N 4-hydroxy-butyl Chemical group [CH2]CCCO SXIFAEWFOJETOA-UHFFFAOYSA-N 0.000 description 1

- 229920001342 Bakelite® Polymers 0.000 description 1

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- OTMSDBZUPAUEDD-UHFFFAOYSA-N Ethane Chemical class CC OTMSDBZUPAUEDD-UHFFFAOYSA-N 0.000 description 1

- 239000004831 Hot glue Substances 0.000 description 1

- 239000013032 Hydrocarbon resin Substances 0.000 description 1

- 239000005058 Isophorone diisocyanate Substances 0.000 description 1

- CERQOIWHTDAKMF-UHFFFAOYSA-M Methacrylate Chemical compound CC(=C)C([O-])=O CERQOIWHTDAKMF-UHFFFAOYSA-M 0.000 description 1

- BZLVMXJERCGZMT-UHFFFAOYSA-N Methyl tert-butyl ether Chemical compound COC(C)(C)C BZLVMXJERCGZMT-UHFFFAOYSA-N 0.000 description 1

- 240000000907 Musa textilis Species 0.000 description 1

- WHNWPMSKXPGLAX-UHFFFAOYSA-N N-Vinyl-2-pyrrolidone Chemical compound C=CN1CCCC1=O WHNWPMSKXPGLAX-UHFFFAOYSA-N 0.000 description 1

- IIGAAOXXRKTFAM-UHFFFAOYSA-N N=C=O.N=C=O.CC1=C(C)C(C)=C(C)C(C)=C1C Chemical class N=C=O.N=C=O.CC1=C(C)C(C)=C(C)C(C)=C1C IIGAAOXXRKTFAM-UHFFFAOYSA-N 0.000 description 1

- 241000238413 Octopus Species 0.000 description 1

- 235000019482 Palm oil Nutrition 0.000 description 1

- 229930040373 Paraformaldehyde Natural products 0.000 description 1

- 229920000538 Poly[(phenyl isocyanate)-co-formaldehyde] Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000002202 Polyethylene glycol Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004721 Polyphenylene oxide Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- 239000006087 Silane Coupling Agent Substances 0.000 description 1

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 1

- QYKIQEUNHZKYBP-UHFFFAOYSA-N Vinyl ether Chemical compound C=COC=C QYKIQEUNHZKYBP-UHFFFAOYSA-N 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000006096 absorbing agent Substances 0.000 description 1

- 229920006221 acetate fiber Polymers 0.000 description 1

- 150000001242 acetic acid derivatives Chemical class 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 125000004018 acid anhydride group Chemical group 0.000 description 1

- 239000003377 acid catalyst Substances 0.000 description 1

- 238000010306 acid treatment Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 238000007259 addition reaction Methods 0.000 description 1

- 239000002313 adhesive film Substances 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 150000001335 aliphatic alkanes Chemical class 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 150000004703 alkoxides Chemical class 0.000 description 1

- 125000003545 alkoxy group Chemical group 0.000 description 1

- 125000005370 alkoxysilyl group Chemical group 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 125000003368 amide group Chemical group 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 239000003125 aqueous solvent Substances 0.000 description 1

- 125000001204 arachidyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 150000001491 aromatic compounds Chemical class 0.000 description 1

- 150000004945 aromatic hydrocarbons Chemical class 0.000 description 1

- 125000003710 aryl alkyl group Chemical group 0.000 description 1

- 125000005160 aryl oxy alkyl group Chemical group 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000007869 azo polymerization initiator Substances 0.000 description 1

- 239000004637 bakelite Substances 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 125000001797 benzyl group Chemical group [H]C1=C([H])C([H])=C(C([H])=C1[H])C([H])([H])* 0.000 description 1

- HIFVAOIJYDXIJG-UHFFFAOYSA-N benzylbenzene;isocyanic acid Chemical class N=C=O.N=C=O.C=1C=CC=CC=1CC1=CC=CC=C1 HIFVAOIJYDXIJG-UHFFFAOYSA-N 0.000 description 1

- 230000001588 bifunctional effect Effects 0.000 description 1

- 238000012662 bulk polymerization Methods 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 150000001718 carbodiimides Chemical class 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 239000004359 castor oil Substances 0.000 description 1

- 235000019438 castor oil Nutrition 0.000 description 1

- 239000013522 chelant Substances 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 229920006026 co-polymeric resin Polymers 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000003240 coconut oil Substances 0.000 description 1

- 235000019864 coconut oil Nutrition 0.000 description 1

- 239000011889 copper foil Substances 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- LDHQCZJRKDOVOX-NSCUHMNNSA-N crotonic acid Chemical compound C\C=C\C(O)=O LDHQCZJRKDOVOX-NSCUHMNNSA-N 0.000 description 1

- 238000007766 curtain coating Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 125000004093 cyano group Chemical group *C#N 0.000 description 1

- 125000000753 cycloalkyl group Chemical group 0.000 description 1

- BRYSLIOQYFVAJD-UHFFFAOYSA-N cyclohexane;1,2-dichloroethane Chemical compound ClCCCl.C1CCCCC1 BRYSLIOQYFVAJD-UHFFFAOYSA-N 0.000 description 1

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000001511 cyclopentyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 125000002704 decyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000004512 die casting Methods 0.000 description 1

- 125000005442 diisocyanate group Chemical group 0.000 description 1

- KIQKWYUGPPFMBV-UHFFFAOYSA-N diisocyanatomethane Chemical compound O=C=NCN=C=O KIQKWYUGPPFMBV-UHFFFAOYSA-N 0.000 description 1

- USIUVYZYUHIAEV-UHFFFAOYSA-N diphenyl ether Natural products C=1C=CC=CC=1OC1=CC=CC=C1 USIUVYZYUHIAEV-UHFFFAOYSA-N 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 239000003480 eluent Substances 0.000 description 1

- 238000007720 emulsion polymerization reaction Methods 0.000 description 1

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 125000005448 ethoxyethyl group Chemical group [H]C([H])([H])C([H])([H])OC([H])([H])C([H])([H])* 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 239000001530 fumaric acid Substances 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- 239000011086 glassine Substances 0.000 description 1

- ZEMPKEQAKRGZGQ-XOQCFJPHSA-N glycerol triricinoleate Natural products CCCCCC[C@@H](O)CC=CCCCCCCCC(=O)OC[C@@H](COC(=O)CCCCCCCC=CC[C@@H](O)CCCCCC)OC(=O)CCCCCCCC=CC[C@H](O)CCCCCC ZEMPKEQAKRGZGQ-XOQCFJPHSA-N 0.000 description 1

- MDNFYIAABKQDML-UHFFFAOYSA-N heptyl 2-methylprop-2-enoate Chemical compound CCCCCCCOC(=O)C(C)=C MDNFYIAABKQDML-UHFFFAOYSA-N 0.000 description 1

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 1

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 229920001519 homopolymer Polymers 0.000 description 1

- 229920006270 hydrocarbon resin Polymers 0.000 description 1

- 125000004435 hydrogen atom Chemical group [H]* 0.000 description 1

- 125000005462 imide group Chemical group 0.000 description 1

- 238000005470 impregnation Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000011256 inorganic filler Substances 0.000 description 1

- 229910003475 inorganic filler Inorganic materials 0.000 description 1

- 125000000959 isobutyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- LDHQCZJRKDOVOX-IHWYPQMZSA-N isocrotonic acid Chemical compound C\C=C/C(O)=O LDHQCZJRKDOVOX-IHWYPQMZSA-N 0.000 description 1

- 125000001972 isopentyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])C([H])([H])* 0.000 description 1

- NIMLQBUJDJZYEJ-UHFFFAOYSA-N isophorone diisocyanate Chemical compound CC1(C)CC(N=C=O)CC(C)(CN=C=O)C1 NIMLQBUJDJZYEJ-UHFFFAOYSA-N 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 125000000468 ketone group Chemical group 0.000 description 1

- 239000002655 kraft paper Substances 0.000 description 1

- 239000004611 light stabiliser Substances 0.000 description 1

- 235000001510 limonene Nutrition 0.000 description 1

- 229940087305 limonene Drugs 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- VZCYOOQTPOCHFL-UPHRSURJSA-N maleic acid Chemical compound OC(=O)\C=C/C(O)=O VZCYOOQTPOCHFL-UPHRSURJSA-N 0.000 description 1

- 239000011976 maleic acid Substances 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 125000002960 margaryl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 125000005395 methacrylic acid group Chemical group 0.000 description 1

- AYLRODJJLADBOB-QMMMGPOBSA-N methyl (2s)-2,6-diisocyanatohexanoate Chemical compound COC(=O)[C@@H](N=C=O)CCCCN=C=O AYLRODJJLADBOB-QMMMGPOBSA-N 0.000 description 1

- XJRBAMWJDBPFIM-UHFFFAOYSA-N methyl vinyl ether Chemical compound COC=C XJRBAMWJDBPFIM-UHFFFAOYSA-N 0.000 description 1

- LVHBHZANLOWSRM-UHFFFAOYSA-N methylenebutanedioic acid Natural products OC(=O)CC(=C)C(O)=O LVHBHZANLOWSRM-UHFFFAOYSA-N 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 238000005065 mining Methods 0.000 description 1

- 239000012046 mixed solvent Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- CWQXQMHSOZUFJS-UHFFFAOYSA-N molybdenum disulfide Chemical compound S=[Mo]=S CWQXQMHSOZUFJS-UHFFFAOYSA-N 0.000 description 1

- 229930003658 monoterpene Natural products 0.000 description 1

- 150000002773 monoterpene derivatives Chemical class 0.000 description 1

- 235000002577 monoterpenes Nutrition 0.000 description 1

- 125000001421 myristyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000003136 n-heptyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- SLCVBVWXLSEKPL-UHFFFAOYSA-N neopentyl glycol Chemical compound OCC(C)(C)CO SLCVBVWXLSEKPL-UHFFFAOYSA-N 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 125000004433 nitrogen atom Chemical group N* 0.000 description 1

- 125000001196 nonadecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000001400 nonyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 239000012766 organic filler Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000003346 palm kernel oil Substances 0.000 description 1

- 235000019865 palm kernel oil Nutrition 0.000 description 1

- 239000002540 palm oil Substances 0.000 description 1

- 125000000913 palmityl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000002958 pentadecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000001147 pentyl group Chemical group C(CCCC)* 0.000 description 1

- JRKICGRDRMAZLK-UHFFFAOYSA-L persulfate group Chemical group S(=O)(=O)([O-])OOS(=O)(=O)[O-] JRKICGRDRMAZLK-UHFFFAOYSA-L 0.000 description 1

- 150000002989 phenols Chemical class 0.000 description 1

- 125000001997 phenyl group Chemical group [H]C1=C([H])C([H])=C(*)C([H])=C1[H] 0.000 description 1

- 230000029553 photosynthesis Effects 0.000 description 1

- 238000010672 photosynthesis Methods 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 229920000223 polyglycerol Polymers 0.000 description 1

- 239000009719 polyimide resin Substances 0.000 description 1

- 230000000379 polymerizing effect Effects 0.000 description 1

- 229920006324 polyoxymethylene Polymers 0.000 description 1

- 229920001451 polypropylene glycol Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 229920002689 polyvinyl acetate Polymers 0.000 description 1

- 239000011118 polyvinyl acetate Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- USHAGKDGDHPEEY-UHFFFAOYSA-L potassium persulfate Chemical compound [K+].[K+].[O-]S(=O)(=O)OOS([O-])(=O)=O USHAGKDGDHPEEY-UHFFFAOYSA-L 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000002250 progressing effect Effects 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000002964 rayon Substances 0.000 description 1

- 239000012966 redox initiator Substances 0.000 description 1

- 238000010992 reflux Methods 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 125000004079 stearyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 150000005846 sugar alcohols Polymers 0.000 description 1

- 230000001629 suppression Effects 0.000 description 1

- 238000006557 surface reaction Methods 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 238000010557 suspension polymerization reaction Methods 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 239000003784 tall oil Substances 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000000954 titration curve Methods 0.000 description 1

- RUELTTOHQODFPA-UHFFFAOYSA-N toluene 2,6-diisocyanate Chemical compound CC1=C(N=C=O)C=CC=C1N=C=O RUELTTOHQODFPA-UHFFFAOYSA-N 0.000 description 1

- 125000002889 tridecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000002948 undecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 239000003981 vehicle Substances 0.000 description 1

- 229920001567 vinyl ester resin Polymers 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

- 210000000707 wrist Anatomy 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/02—Non-macromolecular additives

- C09J11/06—Non-macromolecular additives organic

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/02—Homopolymers or copolymers of acids; Metal or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C09J133/08—Homopolymers or copolymers of acrylic acid esters

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

Definitions

- the present invention relates to an adhesive sheet.

- This application claims priority based on Japanese Patent Application No. 2022-54421 filed on March 29, 2022 and Japanese Patent Application No. 2022-164655 filed on October 13, 2022. , the entire contents of those applications are incorporated herein by reference.

- adhesives also referred to as pressure-sensitive adhesives, hereinafter the same

- adhesives exhibit a soft solid (viscoelastic) state in a temperature range around room temperature, and have the property of adhering to adherends under pressure.

- adhesives are widely used in various industrial fields such as home appliances, automobiles, and OA equipment, typically in the form of adhesive sheets containing an adhesive layer, for purposes such as bonding parts and protecting surfaces. It's being used.

- Technical documents related to adhesive sheets include Patent Documents 1 and 2.

- Patent Documents 1 and 2 describe adhesives containing acrylic polymers polymerized using n-heptyl acrylate as a monomer component.

- pressure-sensitive adhesive sheets are required to have good adhesion performance to various materials.

- one of the objects to be bonded is made of a highly polar material such as a stainless steel plate, and the other is made of a low polar material such as polyolefin.

- the ability to reliably fix a member whose surface is composed of a highly polar material and a low polar material may be required.

- a soft adhesive whose storage modulus is limited to a predetermined value or less, adhesiveness to different types of materials such as high polarity materials and low polarity materials can be easily obtained.

- such adhesives generally tend to have reduced holding power.

- an object of the present invention is to provide a pressure-sensitive adhesive sheet that can achieve both high levels of adhesive strength for highly polar materials, adhesive strength for low polar materials, and holding power.

- a pressure-sensitive adhesive sheet having a pressure-sensitive adhesive layer containing an acrylic polymer is provided.

- the acrylic polymer is a polymer of monomer components including n-heptyl acrylate and a carboxyl group-containing monomer. Furthermore, the monomer component of the acrylic polymer contains more than 3% by weight of the carboxy group-containing monomer. Furthermore, the gel fraction of the adhesive layer is less than 70%. The weight average molecular weight of the acrylic polymer is greater than 600,000.

- Patent Document 1 the adhesive strength and holding power for polypropylene (40 ° C., adhesive area 25 mm ⁇ 25 mm, load 1 kg) are evaluated, and in Patent Document 2, the holding force (80 ° C., adhesive area 25 mm ⁇ 25 mm,

- the acrylic polymers used either have a low Mw or have a low copolymerization ratio of carboxyl group-containing monomers, so the retention will be evaluated in the examples below. (80° C., adhesion area 10 mm x 20 mm, load 1.5 kg) was not obtained, and the adhesion force to high polarity materials, the adhesion force to low polarity materials, and the holding force were not fully satisfied.

- the adhesive composition for forming the adhesive layer includes a crosslinking agent.

- a crosslinking agent By using a crosslinking agent, the cohesive force of the adhesive increases, and sufficient holding power can be suitably achieved.

- the adhesive layer includes a tackifying resin.

- a tackifying resin By using a tackifying resin, the gel fraction of the adhesive layer can be adjusted to an appropriate range, and the adhesive strength to high polarity materials and low polarity materials can be improved.

- the thickness of the adhesive layer is 0.1 to 500 ⁇ m.

- the technology disclosed herein can be implemented with a configuration including an adhesive layer having the above thickness.

- the adhesive layer has a gel fraction of 20% or more and less than 70%.

- the adhesive sheet according to some preferred embodiments has a 180 degree peel strength against a stainless steel plate (adhesive strength against SUS) of 15 N/25 mm or more.

- the pressure-sensitive adhesive sheet having the adhesive strength against SUS can exhibit excellent adhesive strength against highly polar materials.

- Adhesive sheets according to some preferred embodiments have a 180 degree peel strength against polypropylene (adhesive strength against PP) of 10 N/25 mm or more.

- the pressure-sensitive adhesive sheet having the above-mentioned adhesive strength to PP can have sufficient adhesion reliability to low polarity materials.

- Adhesive sheets according to some preferred embodiments have a 180 degree peel strength against polyethylene (adhesion strength against PE) of 5 N/25 mm or more.

- the pressure-sensitive adhesive sheet having the above-mentioned adhesive strength to PE can have sufficient adhesion reliability to low polarity materials.

- Adhesive sheets according to some preferred embodiments have a displacement distance of 10 mm or less in a holding force test conducted at 80° C., adhesive area 10 mm x 20 mm, load 1.5 kg, and for 1 hour.

- a pressure-sensitive adhesive sheet that does not easily shift in the above-mentioned holding power test can have sufficient holding power (specifically, high temperature holding power).

- the adhesive sheet disclosed herein has both adhesion and holding power to different materials, so it can be preferably used for adhesion to highly polar or low polar materials, or for applications that require long-term adhesion reliability. can be done. For example, it is suitable for fixing members in electronic devices including home appliances, office automation equipment, and portable electronic devices such as smartphones. As described above, this specification provides an electronic device using any of the adhesive sheets disclosed herein, in other words, an electronic device including the adhesive sheet.

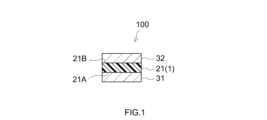

- FIG. 1 is a cross-sectional view schematically showing the configuration of a pressure-sensitive adhesive sheet according to an embodiment.

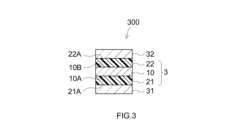

- FIG. 3 is a cross-sectional view schematically showing the configuration of a pressure-sensitive adhesive sheet according to another embodiment.

- FIG. 3 is a cross-sectional view schematically showing the configuration of a pressure-sensitive adhesive sheet according to another embodiment.

- FIG. 1 is a front view schematically showing an example of a portable electronic device including an adhesive sheet.

- the term "adhesive” as used herein refers to a material that exhibits a soft solid (viscoelastic) state in the temperature range around room temperature and has the property of easily adhering to an adherend under pressure. .

- the adhesive referred to here generally has a complex tensile modulus E * (1Hz) as defined in "C. A. Dahlquist, “Adhesion: Fundamentals and Practice", McLaren & Sons, (1966) P. 143". ⁇ 10 7 dyne/cm 2 (typically, a material having the above properties at 25° C.).

- biomass-derived carbon means carbon derived from biomass materials, that is, materials derived from renewable organic resources (renewable carbon).

- biomass materials are typically materials derived from biological resources (typically plants that perform photosynthesis) that can be reproduced sustainably in the presence of sunlight, water, and carbon dioxide. means. Therefore, materials derived from fossil resources that are depleted through use after mining (fossil resource-based materials) are excluded from the concept of biomass materials here.

- the biomass carbon ratio of the adhesive layer and the adhesive sheet that is, the proportion of biomass-derived carbon in the total carbon contained in the adhesive layer and the adhesive sheet, is the carbon isotope content with a mass number of 14 measured in accordance with ASTM D6866. It can be estimated from the amount.

- the adhesive sheet disclosed herein includes an adhesive layer.

- the above-mentioned pressure-sensitive adhesive sheet is, for example, a base material-less double-sided pressure-sensitive adhesive sheet comprising a first pressure-sensitive adhesive surface formed by one surface of the pressure-sensitive adhesive layer, and a second pressure-sensitive adhesive surface formed by the other surface of the pressure-sensitive adhesive layer.

- the pressure-sensitive adhesive sheet disclosed herein may be in the form of a pressure-sensitive adhesive sheet with a base material, in which the pressure-sensitive adhesive layer is laminated on one or both sides of a support base material.

- the supporting base material may be simply referred to as "base material”.

- adhesive sheet here may include what is called an adhesive tape, an adhesive label, an adhesive film, and the like.

- the pressure-sensitive adhesive sheet disclosed herein may be in the form of a roll or a sheet. Alternatively, the adhesive sheet may be further processed into various shapes.

- FIG. 1 The structure of a pressure-sensitive adhesive sheet according to one embodiment is schematically shown in FIG.

- This adhesive sheet 1 is configured as a double-sided adhesive sheet without a base material, which includes an adhesive layer 21.

- the adhesive sheet 1 has a first adhesive surface 21A constituted by one surface (first surface) of the adhesive layer 21 and a second adhesive surface constituted by the other surface (second surface) of the adhesive layer 21. 21B are attached to different parts of the adherend.

- the locations on which the adhesive surfaces 21A and 21B are attached may be on different members, or may be on different locations within a single member. As shown in FIG.

- the adhesive sheet 1 before use (that is, before being attached to an adherend) has a first adhesive surface 21A and a second adhesive surface 21B that are peeled off at least on the side facing the adhesive layer 21. It may be a component of the adhesive sheet 100 with a release liner that is protected by the release liners 31 and 32 serving as surfaces.

- the release liners 31 and 32 it is preferable to use, for example, a sheet-like base material (liner base material) that is constructed by providing a release layer made of a release treatment agent on one side so that one side becomes a release surface. obtain.

- the release liner 32 may be omitted and a release liner 31 having release surfaces on both sides may be used, and this and the adhesive sheet 1 may be overlapped and spirally wound so that the second adhesive surface 21B is on the release liner 31.

- the pressure-sensitive adhesive sheet with a release liner may be in a protected form (roll form) in contact with the back surface of the adhesive sheet.

- FIG. 2 The structure of a pressure-sensitive adhesive sheet according to another embodiment is schematically shown in FIG. 2.

- This adhesive sheet 2 is a base material comprising a sheet-shaped support base material (for example, a resin film) 10 having a first surface 10A and a second surface 10B, and an adhesive layer 21 provided on the first surface 10A side. It is constructed as a single-sided adhesive sheet.

- the adhesive layer 21 is fixedly provided on the first surface 10A side of the support base material 10, that is, without the intention of separating the adhesive layer 21 from the support base material 10. As shown in FIG.

- the pressure-sensitive adhesive sheet 2 before use has a surface (adhesive surface) 21A of the pressure-sensitive adhesive layer 21 protected by a release liner 31 having a release surface at least on the side facing the pressure-sensitive adhesive layer 21. It may be a component of the pressure-sensitive adhesive sheet 200 with a release liner. Alternatively, the release liner 31 may be omitted, the second surface 10B may be the release surface, and the adhesive sheet 2 may be wound so that the adhesive surface 21A is the second surface (back surface) of the support substrate 10. ) 10B may be in a protected form (roll form).

- FIG. 3 schematically shows the structure of a pressure-sensitive adhesive sheet according to yet another embodiment.

- This adhesive sheet 3 includes a sheet-shaped support base material (for example, a resin film) 10 having a first surface 10A and a second surface 10B, and a first adhesive layer 21 fixedly provided on the first surface 10A side. and a second adhesive layer 22 fixedly provided on the second surface 10B side.

- 32 may be a component of the adhesive sheet 300 with a release liner.

- the release liner 32 may be omitted and a release liner 31 having release surfaces on both sides may be used, and this and the adhesive sheet 3 may be overlapped and spirally wound so that the second adhesive surface 22A is on the release liner 31.

- the pressure-sensitive adhesive sheet with a release liner may be in a protected form (roll form) in contact with the back surface of the adhesive sheet.

- the first pressure-sensitive adhesive layer and the second pressure-sensitive adhesive layer may be the pressure-sensitive adhesive layer described below.

- the other adhesive layer (for example, the second adhesive layer) may be the adhesive layer disclosed herein, and the adhesive layer disclosed herein (specifically, the one adhesive layer described above) may be the adhesive layer disclosed herein.

- the adhesive layer may have a composition different from that of the adhesive layer (for example, the first adhesive layer).

- the other pressure-sensitive adhesive layer may be formed from a known or commonly used pressure-sensitive adhesive, for example.

- the adhesive layer constituting the adhesive sheet disclosed herein contains an acrylic polymer.

- the pressure-sensitive adhesive layer is typically a pressure-sensitive adhesive layer containing an acrylic polymer as a base polymer.

- Such an adhesive layer is also referred to as an acrylic adhesive layer.

- the base polymer refers to the main component of a rubbery polymer (a polymer that exhibits rubber elasticity in a temperature range around room temperature) contained in the adhesive layer.

- the term "main component” refers to a component contained in an amount exceeding 50% by weight, unless otherwise specified.

- the following description regarding the adhesive and the components that can be included in the adhesive layer is also applicable to the adhesive composition used to form the adhesive (layer) unless otherwise specified.

- the term "acrylic polymer” refers to a polymer containing monomer units derived from a monomer having at least one (meth)acryloyl group in one molecule, as monomer units constituting the polymer. .

- a monomer having at least one (meth)acryloyl group in one molecule will also be referred to as an "acrylic monomer.”

- an acrylic polymer in this specification is defined as a polymer containing monomer units derived from acrylic monomers.

- (meth)acryloyl” refers comprehensively to acryloyl and methacryloyl.

- (meth)acrylate” comprehensively refers to acrylate and methacrylate

- (meth)acrylic” comprehensively refers to acrylic and methacrylic.

- acrylic polymer As the acrylic polymer used in the technique disclosed herein, a polymer of monomer components containing n-heptyl acrylate is used. Acrylic polymers polymerized using monomer components containing n-heptyl acrylate have superior flexibility than polymers of other alkyl acrylates such as n-butyl acrylate (BA) and 2-ethylhexyl acrylate (2EHA). It can exhibit superior adhesive strength to both high polarity materials and low polarity materials. The reason for this is not particularly limited, but is because polymers containing n-heptyl acrylate as a monomer unit have relatively long linear side chains in addition to having a low glass transition temperature. This is thought to be due to the relatively large space between the main chains within the adhesive.

- BA n-butyl acrylate

- 2EHA 2-ethylhexyl acrylate

- the proportion of n-heptyl acrylate in the monomer components of the acrylic polymer is 50% by weight or more (for example, more than 50% by weight), preferably 70% by weight or more, more preferably 80% by weight. % or more, more preferably 85% by weight or more, particularly preferably 90% by weight or more, may be 92% by weight or more, may be 94% by weight or more, or may be 96% by weight or more.

- the proportion of n-heptyl acrylate in the monomer components is less than 97% by weight, and in some embodiments is 95% by weight or less.

- the content may be 93% by weight or less, or may be 91% by weight or less.

- the acrylic polymer may be copolymerized with an alkyl (meth)acrylate (hereinafter also referred to as "optional alkyl (meth)acrylate”) other than n-heptyl acrylate.

- an alkyl (meth)acrylate hereinafter also referred to as "optional alkyl (meth)acrylate

- optional alkyl (meth)acrylate for example, a compound represented by the following formula (1) can be suitably used.

- CH 2 C(R 1 )COOR 2 (1)

- R 1 in the above formula (1) is a hydrogen atom or a methyl group.

- R 2 is a chain alkyl group having 1 to 20 carbon atoms (excluding n-heptyl group).

- optional alkyl (meth)acrylate examples include methyl (meth)acrylate, ethyl (meth)acrylate, propyl (meth)acrylate, isopropyl (meth)acrylate, n-butyl (meth)acrylate, isobutyl (meth)acrylate, s -Butyl (meth)acrylate, pentyl (meth)acrylate, isopentyl (meth)acrylate, hexyl (meth)acrylate, heptyl methacrylate, 2-ethylhexyl (meth)acrylate, octyl (meth)acrylate, isooctyl (meth)acrylate, nonyl ( meth)acrylate, isononyl(meth)acrylate, decyl(meth)acrylate, isodecyl(meth)acrylate, undecyl(meth)acrylate, lauryl(meth)acryl

- optional alkyl (meth)acrylates can be used alone or in combination of two or more.

- Optional alkyl (meth)acrylates that may be preferably used include n-butyl acrylate (BA) and 2-ethylhexyl acrylate (2EHA).

- the proportion of optional alkyl (meth)acrylate included in the monomer component is, for example, in some embodiments less than 47% by weight, may be less than 45% by weight, may be less than 30% by weight, and may be less than 10% by weight. It may be less than 5% by weight, or less than 1% by weight.

- the technology disclosed herein can be preferably carried out in an embodiment in which the monomer component does not substantially contain any alkyl (meth)acrylate.

- the monomer component does not substantially contain monomer A (for example, the above-mentioned optional alkyl (meth)acrylate), it means that the monomer A is not used, at least intentionally, and the monomer component is For example, unintentional inclusion of about 0.01% by weight or less is acceptable.

- monomer A for example, the above-mentioned optional alkyl (meth)acrylate

- the monomer component may include an alkyl (meth)acrylate having a biomass-derived alkyl group at the ester end (hereinafter also referred to as "biomass alkyl (meth)acrylate”).

- biomass alkyl (meth)acrylate having a biomass-derived alkyl group at the ester end

- biomass alkyl (meth)acrylate it is possible to suitably realize an acrylic pressure-sensitive adhesive that is designed to reduce dependence on fossil resource-based materials.

- the biomass alkyl (meth)acrylate is not particularly limited, and is, for example, an ester of a biomass-derived alkanol and a biomass-derived or non-biomass-derived (meth)acrylic acid.

- alkanols derived from biomass include biomass ethanol, alkanols derived from plant materials such as palm oil, palm kernel oil, coconut oil, and castor oil.

- the biomass-derived alkanol has three or more carbon atoms, the alkanol may be linear or branched.

- an ester of a biomass-derived alkanol and a non-biomass-derived (meth)acrylic acid is used as the biomass alkyl (meth)acrylate used in the synthesis of the acrylic polymer.

- biomass alkyl (meth)acrylate In such a biomass alkyl (meth)acrylate, the greater the number of carbon atoms in the alkanol, the greater the number ratio of biomass-derived carbon to the total number of carbons contained in the biomass alkyl (meth)acrylate, that is, the biomass carbon ratio of the alkyl (meth)acrylate. becomes higher. Therefore, in the above-mentioned biomass alkyl (meth)acrylate, it is desirable that the alkyl group derived from biomass has a large number of carbon atoms in order to reduce dependence on fossil resource materials.

- biomass-derived n-heptyl acrylate (biomass n-heptyl acrylate) is used as n-heptyl acrylate.

- biomass n-heptyl acrylate is an ester of a biomass-derived alkanol and a biomass-derived or non-biomass-derived acrylic acid.

- an ester of a biomass-derived alkanol and a non-biomass-derived acrylic acid can be used. In such compounds, only the linear heptyl groups are derived from biomass.

- the proportion of biomass alkyl (meth)acrylate (preferably biomass n-heptyl acrylate) in the monomer components of the acrylic polymer is, for example, 50% by weight or more (for example, more than 50% by weight) in some embodiments, Preferably 70% by weight or more, more preferably 80% by weight or more, further preferably 85% by weight or more, particularly preferably 90% by weight or more, may be 92% by weight or more, may be 94% by weight or more, and may be 96% by weight. The above is fine.

- the proportion of biomass alkyl (meth)acrylate (preferably biomass n-heptyl acrylate) among the monomer components is less than 97% by weight, and in some embodiments may be 95% by weight or less, and in some embodiments may be 93% by weight or less. % or less, or 91% by weight or less. In some other embodiments, the proportion of biomass alkyl (meth)acrylate in the monomer component may be 90% by weight or less, 70% by weight or less, 50% by weight or less, 30% by weight or less, It may be 10% by weight or less, or 1% by weight or less.

- the monomer component of the acrylic polymer contains more than 3% by weight of a carboxyl group-containing monomer.

- Carboxy group-containing monomers can exhibit improved cohesiveness based on their polarity.

- a crosslinking agent such as an isocyanate type crosslinking agent or an epoxy type crosslinking agent

- the carboxy group can serve as a crosslinking point of the acrylic polymer.

- carboxy group-containing monomers examples include acrylic acid (AA), methacrylic acid (MAA), carboxyethyl (meth)acrylate, carboxypentyl (meth)acrylate, itaconic acid, maleic acid, fumaric acid, crotonic acid, isocrotonic acid, etc. be done.

- preferred carboxy group-containing monomers include AA and MAA.

- AA is particularly preferred.

- Carboxy group-containing monomers can be used singly or in combination of two or more.

- the proportion of the carboxy group-containing monomer in the monomer component of the acrylic polymer is more than 3% by weight (specifically more than 3.0% by weight), preferably 4.0% by weight or more, more preferably 4% by weight or more.

- the content is .5% by weight or more, more preferably 5.0% by weight or more (for example, more than 5.0% by weight), particularly preferably 5.5% by weight or more, and may be 6.0% by weight or more.

- the proportion of the carboxy group-containing monomer in the monomer component may be 7.0% by weight or more, 8.0% by weight or more (for example, more than 8.0% by weight), and 9. It may be 0% by weight or more.

- the amount of the carboxy group-containing monomer is, for example, suitably 20% by weight or less of the total monomer components, preferably 15% by weight or less, and more preferably 12% by weight or less. In some embodiments, the amount of the carboxy group-containing monomer may be less than 10% by weight, may be less than 8% by weight, may be less than 6% by weight, and may be less than 5% by weight.

- the acrylic polymer may be copolymerized with a functional group-containing monomer (any functional group-containing monomer) other than the carboxy group-containing monomer.

- a functional group-containing monomer any functional group-containing monomer

- optional functional group-containing monomers that can introduce functional groups that can serve as crosslinking base points into acrylic polymers or contribute to improving adhesive strength include hydroxyl group (OH group)-containing monomers (2-hydroxyethyl (meth)acrylate, 2-hydroxyethyl (meth)acrylate, 2- Hydroxyalkyl (meth)acrylates such as hydroxypropyl (meth)acrylate, 3-hydroxypropyl (meth)acrylate, 2-hydroxybutyl (meth)acrylate, 4-hydroxybutyl (meth)acrylate; polypropylene glycol mono(meth)acrylate, etc.

- OH group hydroxyl group

- 2-hydroxyethyl (meth)acrylate 2-hydroxyethyl (meth)acrylate

- acid anhydride group-containing monomers acid anhydride group-containing monomers, amide group-containing monomers ((meth)acrylamide, N,N-dimethyl(meth)acrylamide, etc.), amino group-containing monomers (aminoethyl (meth)acrylate, N,N-dimethylaminoethyl (meth)acrylate, etc.), epoxy group-containing monomers, cyano group-containing monomers, keto group-containing monomers, monomers with nitrogen atom-containing rings (N-vinyl-2-pyrrolidone, N-(meth)acryloylmorpholine, etc.), alkoxysilyl Examples include group-containing monomers, imide group-containing monomers, and the like. The above arbitrary functional group-containing monomers can be used alone or in combination of two or more.

- the content of the optional functional group-containing monomer in the monomer component is not particularly limited.

- the content of the optional functional group-containing monomer in the monomer component can be, for example, 0.1% by weight or more, and 0.5% by weight or more. It is appropriate that the amount is 1% by weight or more.

- the content of the arbitrary functional group-containing monomer in the monomer component is 40% by weight or less.

- the content of optional functional group-containing monomers in the monomer component is, for example, less than 3% by weight, may be less than 1% by weight, may be less than 0.5% by weight, and may be less than 0.3% by weight. % or less than 0.1% by weight.

- the technique disclosed herein can be preferably carried out in an embodiment in which the monomer component of the acrylic polymer does not substantially contain any functional group-containing monomer.

- the content thereof may generally be approximately 0.001% by weight or more of the total monomer components, or approximately 0.01% by weight or more, It may be approximately 0.02% by weight or more.

- the content of the hydroxyl group-containing monomer is suitably about 10% by weight or less, preferably about 5% by weight or less, more preferably about 2% by weight or less, based on the total monomer components.

- the content of hydroxyl group-containing monomer in the monomer component may be less than 1% by weight, may be less than 0.5% by weight, may be less than 0.3% by weight, and may be less than 0.1% by weight. % or less than 0.01% by weight.

- the monomer component of the acrylic polymer may be substantially free of hydroxyl group-containing monomers. According to the technology disclosed herein, desired effects can be achieved without relying on hydroxyl group-containing monomers.

- the ratio of the carboxy group-containing monomer to the total functional group-containing monomers (total functional group-containing monomers including the carboxy group-containing monomer) used as a copolymerization component of the acrylic polymer is determined by the effect of copolymerizing the carboxy group-containing monomer.

- the content is suitably 30% by weight or more, preferably 50% by weight or more, more preferably 70% by weight or more, further preferably 80% by weight or more, particularly preferably 90% by weight or more, such as It may be 95% by weight or more, 97% by weight or more, 98% by weight or more, or 99% by weight or more (for example, 99.9% by weight or more).

- the upper limit of the proportion of the carboxy group-containing monomer to the total of the functional group-containing monomers is 100% by weight, and may be, for example, 95% by weight or less.

- the monomer components constituting the acrylic polymer may contain copolymerization components other than the above-mentioned functional group-containing monomers for the purpose of improving cohesive force and the like.

- copolymerization components include vinyl ester monomers such as vinyl acetate; aromatic vinyl compounds such as styrene; cycloalkyl (meth)acrylates such as cyclohexyl (meth)acrylate, cyclopentyl (meth)acrylate, and isobornyl ) acrylates; aryl (meth)acrylates (e.g. phenyl (meth)acrylate), aryloxyalkyl (meth)acrylates (e.g.

- Aromatic ring-containing (meth)acrylate Olefinic monomer; Chlorine-containing monomer; Isocyanate group-containing monomer such as 2-(meth)acryloyloxyethyl isocyanate; Alkoxy such as methoxyethyl (meth)acrylate and ethoxyethyl (meth)acrylate Group-containing monomers; vinyl ether monomers such as methyl vinyl ether and ethyl vinyl ether; and the like.

- the other copolymerization components mentioned above can be used alone or in combination of two or more.

- the amount of such other copolymerized components is not particularly limited as long as it can be selected as appropriate depending on the purpose and use, but from the viewpoint of appropriately exhibiting the effects of use, it is appropriate to set it to 0.05% by weight or more. , 0.5% by weight or more.