WO2022065026A1 - Analysis device, analysis system, analysis method, calibration method, and program - Google Patents

Analysis device, analysis system, analysis method, calibration method, and program Download PDFInfo

- Publication number

- WO2022065026A1 WO2022065026A1 PCT/JP2021/032846 JP2021032846W WO2022065026A1 WO 2022065026 A1 WO2022065026 A1 WO 2022065026A1 JP 2021032846 W JP2021032846 W JP 2021032846W WO 2022065026 A1 WO2022065026 A1 WO 2022065026A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- particulate matter

- image data

- sample gas

- unit

- acquisition unit

- Prior art date

Links

- 238000004458 analytical method Methods 0.000 title claims abstract description 183

- 238000000034 method Methods 0.000 title claims description 22

- 239000012470 diluted sample Substances 0.000 claims abstract description 89

- 239000000126 substance Substances 0.000 claims abstract description 16

- 239000013618 particulate matter Substances 0.000 claims description 434

- 239000000523 sample Substances 0.000 claims description 156

- 239000002245 particle Substances 0.000 claims description 41

- 238000005070 sampling Methods 0.000 claims description 37

- 238000011088 calibration curve Methods 0.000 claims description 18

- 238000007664 blowing Methods 0.000 claims 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 abstract description 39

- 229910052799 carbon Inorganic materials 0.000 abstract description 39

- 239000007789 gas Substances 0.000 description 295

- 238000002485 combustion reaction Methods 0.000 description 50

- 239000002956 ash Substances 0.000 description 24

- 230000005250 beta ray Effects 0.000 description 24

- 238000001514 detection method Methods 0.000 description 18

- 238000010586 diagram Methods 0.000 description 17

- 230000008859 change Effects 0.000 description 15

- 238000011049 filling Methods 0.000 description 14

- 238000002156 mixing Methods 0.000 description 13

- 238000012986 modification Methods 0.000 description 12

- 230000004048 modification Effects 0.000 description 12

- 238000007865 diluting Methods 0.000 description 7

- 238000012545 processing Methods 0.000 description 7

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 6

- 239000003245 coal Substances 0.000 description 6

- 239000003085 diluting agent Substances 0.000 description 6

- 239000000428 dust Substances 0.000 description 6

- 238000004868 gas analysis Methods 0.000 description 6

- 230000010365 information processing Effects 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 150000001722 carbon compounds Chemical class 0.000 description 4

- 239000010883 coal ash Substances 0.000 description 4

- 238000009434 installation Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 4

- 230000036962 time dependent Effects 0.000 description 4

- 229910002092 carbon dioxide Inorganic materials 0.000 description 3

- 239000001569 carbon dioxide Substances 0.000 description 3

- 238000000921 elemental analysis Methods 0.000 description 3

- 238000010248 power generation Methods 0.000 description 3

- 230000003014 reinforcing effect Effects 0.000 description 3

- 238000004891 communication Methods 0.000 description 2

- 238000010790 dilution Methods 0.000 description 2

- 239000012895 dilution Substances 0.000 description 2

- 239000012717 electrostatic precipitator Substances 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 230000001678 irradiating effect Effects 0.000 description 2

- 239000004973 liquid crystal related substance Substances 0.000 description 2

- 229910052757 nitrogen Inorganic materials 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- OKTJSMMVPCPJKN-NJFSPNSNSA-N Carbon-14 Chemical compound [14C] OKTJSMMVPCPJKN-NJFSPNSNSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000010881 fly ash Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- -1 polyethylene Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 230000010349 pulsation Effects 0.000 description 1

- 238000000746 purification Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 206010037844 rash Diseases 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 238000009628 steelmaking Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/02—Investigating particle size or size distribution

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/06—Investigating concentration of particle suspensions

Definitions

- the present invention implements an analyzer that analyzes particulate matter contained in sample gas, an analysis system that includes the analyzer, an analysis method for particulate matter, and a calibration method, analysis method or calibration method for the analyzer. Regarding the program to do.

- an analyzer that analyzes particulate matter contained in sample gas such as the atmosphere is known.

- the amount (mass concentration) of the particulate matter collected by the collection filter by spraying the sample gas onto the collection filter to collect the particulate matter contained in the sample gas on the collection filter.

- an analyzer for measuring an element (and the content of the element) contained in the particulate matter is known (see, for example, Patent Document 1).

- an analyzer that collects particulate matter collected at a predetermined location and installs the collected particulate matter at another location is used. It was analyzed using. That is, with the conventional analysis method, particulate matter could not be continuously analyzed at the place where exhaust gas or the like is discharged.

- An object of the present invention is to accurately and continuously analyze particulate matter containing carbon as a main component.

- the analysis device includes an inflow unit, a first image acquisition unit, a content information acquisition unit, and an analysis unit.

- the inflow section allows sample gas containing particulate matter to flow in.

- the first image acquisition unit acquires the first image data of the particulate matter flowing in the sample gas flowing through the inflow unit.

- the content information acquisition unit acquires content information regarding the content of particulate matter contained in the sample gas.

- the analysis unit analyzes the particulate matter based on the first image data and the content information.

- the particulate matter is based on the first image data of the particulate matter flowing in the sample gas flowing into the inflow portion and the content information regarding the content of the particulate matter contained in the sample gas.

- the first image data contains information on the appearance of the particulate matter flowing in the sample gas, and since the carbon-based particulate matter has a characteristic appearance, it is included with the first image data. Based on the quantity information, it is possible to accurately analyze the particulate matter whose main component is carbon.

- the sample gas is made to flow into the inflow part, and the first image acquisition part acquires the image data (first image data) of the particulate matter contained in the sample gas flowing in the inflow part and analyzes it.

- the unit analyzes the particulate matter based on the first image data. Since the above-mentioned analyzer can analyze particulate matter using image data in which the sample gas containing particulate matter is flowing, the sample gas is continuously flowed into the inflow portion to continuously form particulate matter. Can analyze substances.

- the analysis unit may calculate information on the particle shape of the particulate matter based on the first image data. As a result, it is possible to accurately analyze the particulate matter containing carbon as a main component based on the particle shape of the particulate matter.

- the analysis unit may calculate the first particle size information regarding the particle size of the particulate matter based on the first image data. This makes it possible to accurately analyze the carbon-based particulate matter based on the particle size of the particulate matter.

- the analyzer may further include a scattered light information acquisition unit.

- the scattered light information acquisition unit acquires scattered light information regarding the scattered light generated by the light incident on the sample gas flowing through the inflow unit being scattered by the particulate matter.

- the analysis unit calculates the second particle size information regarding the particle size of the particulate matter contained in the sample gas based on the scattered light information. This makes it possible to accurately analyze the carbon-based particulate matter based on the particle size calculated from the information on the scattered light scattered by the particulate matter.

- the inflow portion may have a first flow path and a second flow path.

- a sample gas for acquiring the first image data by the first image acquisition unit flows in the first flow path.

- a sample gas for acquiring content information flows through the second flow path by the content information acquisition unit.

- the analysis unit may calculate the mass concentration of the particulate matter based on the content information. This makes it possible to accurately analyze the carbon-based particulate matter based on the mass concentration of the particulate matter and the appearance of the particulate matter.

- the analyzer may further include a collection filter and a second image acquisition unit.

- the collection filter collects particulate matter contained in the sample gas.

- the second image acquisition unit acquires the second image data including the image of the particulate matter collected by the collection filter.

- the analysis unit calculates information about the colored particulate matter based on the second image data. This makes it possible to more accurately analyze the carbon-based particulate matter based on the color of the particulate matter.

- the analysis unit includes information on the brightness of the pixels of the image portion corresponding to the collection area where the particulate matter is collected in the second image data and the amount of the particulate matter collected by the collection filter.

- Information on particulate matter may be calculated based on the calibration curve representing the relationship between.

- the calibration curve may be calculated using the second image data obtained by collecting the particulate matter to be actually measured by the collection filter. As a result, information on particulate matter can be calculated more accurately.

- the analysis unit standardizes the brightness of the pixels of the image portion corresponding to the collection area where the particulate matter is collected in the second image data with a predetermined parameter for the particulate matter, and obtains information about the particulate matter. It may be calculated. This makes it possible to calculate various information about particulate matter.

- An analytical system includes a sampling probe, a diluter, and an analyzer.

- the sampling probe samples a sample gas containing particulate matter.

- the diluter dilutes the sample gas to produce a diluted sample gas.

- the analyzer is an apparatus for analyzing particulate matter contained in the diluted sample gas, and has an inflow unit, a first image acquisition unit, a content information acquisition unit, and an analysis unit.

- the inflow section allows the diluted sample gas to flow in.

- the first image acquisition unit acquires the first image data of the particulate matter flowing in the diluted sample gas flowing through the inflow unit.

- the content information acquisition unit acquires content information regarding the content of particulate matter contained in the diluted sample gas.

- the analysis unit analyzes the particulate matter based on the first image data and the content information.

- the sample gas sampled by the sampling probe is diluted by the diluter to generate the diluted sample gas.

- the analyzer analyzes the particulate matter contained in the diluted sample gas.

- the first image data of the particulate matter flowing in the diluted sample gas flowing into the inflow portion and the content information regarding the content of the particulate matter contained in the diluted sample gas And, based on the analysis of particulate matter.

- the first image data contains information on the appearance of particulate matter flowing in the diluted sample gas, the carbon-based particulate matter is characteristic in appearance, and further, the diluted sample gas contains information.

- the first image data Since only the particulate matter that can be discerned from the appearance of the particulate matter is contained from the first image data, even if the sample gas contains an excessive amount of the particulate matter, the first image data and the content information Based on the above, it is possible to accurately analyze particulate matter containing carbon as a main component.

- the sample gas collected by the sampling probe is made to flow into the inflow section, and the first image acquisition section is the image data of the particulate matter contained in the sample gas flowing in the flow section (first image data). ) Is acquired, and the analysis unit analyzes the particulate matter based on the first image data.

- the above analysis system can analyze particulate matter using image data in which the sample gas containing particulate matter is flowing, the sample gas is continuously sampled with a sampling probe and the sample gas is sampled. Can be continuously flowed into the inflow section to continuously analyze particulate matter.

- the above analysis system may further include a blowback unit.

- the blowback unit blows back the sampling probe.

- the blowback by the blowback unit and the sampling of the sample gas may be executed at a predetermined time ratio. This makes it possible to sample an appropriate amount of particulate matter while reducing the amount of particulate matter deposited on the sampling probe.

- the analysis method is an analysis method using an analyzer provided with an inflow portion capable of inflowing sample gas containing particulate matter.

- the analysis method comprises the following steps. ⁇ Step to make sample gas flow into the inflow section. ⁇ The step of acquiring the first image data of the particulate matter flowing in the sample gas flowing through the inflow part. ⁇ Step to acquire content information regarding the content of particulate matter contained in the sample gas. ⁇ First step of analyzing particulate matter based on image data and content information.

- the above analysis method is based on the first image data of the particulate matter flowing in the sample gas flowing into the inflow portion of the analyzer and the content information regarding the content of the particulate matter contained in the sample gas.

- the first image data contains information on the appearance of the particulate matter flowing in the sample gas, and since the carbon-based particulate matter has a characteristic appearance, it is included with the first image data. Based on the quantity information, it is possible to accurately analyze the particulate matter whose main component is carbon.

- image data (first image data) of the particulate matter contained in the sample gas flowing in the flow part is acquired, and the particulate matter is analyzed based on the first image data.

- the sample gas is continuously flowed into the inflow portion to continuously flow the particles.

- the program according to still another aspect of the present invention is a program for causing an analyzer provided with an inflow portion capable of inflowing sample gas to execute an analysis method for analyzing particulate matter contained in sample gas.

- the above analytical method has the following steps: ⁇ Step to make sample gas flow into the inflow section. ⁇ The step of acquiring the first image data of the particulate matter flowing in the sample gas flowing through the inflow part. ⁇ Step to acquire content information regarding the content of particulate matter contained in the sample gas. ⁇ First step of analyzing particulate matter based on image data and content information.

- the analyzer has a collection filter that collects particulate matter, a collection area in which the particulate matter of the collection filter is collected, and the particulate matter is not collected. It includes an image acquisition unit that acquires image data including a non-collection region, an analysis unit that analyzes particulate matter based on the image data, and a calibration unit that calibrates the image acquisition unit.

- the calibration section An image based on the relationship between the amount of particulate matter collected in the collection area and the brightness of the pixels corresponding to the non-collection area and the amount of particulate matter collected when the image data was acquired. Calculate the theoretical brightness of the pixels corresponding to the non-collection area of the data, The image acquisition unit is calibrated based on the difference between the theoretical brightness and the actual brightness of the pixels corresponding to the non-collection region of the image data.

- the theoretical value (theoretical brightness) of the brightness of the pixel corresponding to the non-collection region of the image data acquired by collecting the particulate matter with the collection filter is calculated, and the theoretical brightness and the image data are calculated.

- the image acquisition unit is calibrated based on the difference from the actual luminance value (actual luminance) of the pixel corresponding to the non-collection region of. In this way, since the particulate matter collected by the collection filter is used for calibration, it is not necessary to separately arrange a calibration sample on the collection filter to acquire image data in order to calibrate the image acquisition unit, and the image is imaged.

- the acquisition unit can be calibrated automatically.

- the image acquisition unit may include a light source that irradiates the collected area and the non-collected area with light when acquiring image data.

- the calibration unit adjusts the amount of light from the light source based on the difference between the theoretical brightness and the actual brightness. This makes it possible to acquire image data capable of accurately analyzing particulate matter.

- a collection filter that collects particulate matter, a collection area where particulate matter is collected, and no particulate matter is collected.

- It is a calibration method of an analyzer that includes an image acquisition unit that acquires image data including a non-collection area and analyzes particulate matter based on the image data.

- the calibration method includes the following steps. ⁇ Based on the relationship between the amount of particulate matter collected in the collection area and the brightness of the pixels corresponding to the non-collection area, and the amount of particulate matter collected when image data was acquired. A step of calculating the theoretical brightness of a pixel corresponding to a non-collection area of image data. ⁇ A step of calibrating the image acquisition unit based on the difference between the theoretical brightness and the actual brightness of the pixels corresponding to the non-collection area of the image data.

- the theoretical value (theoretical brightness) of the brightness of the pixel corresponding to the non-collection region of the image data acquired by collecting the particulate matter with the collection filter is calculated, and the theoretical brightness is used.

- the image acquisition unit is calibrated based on the difference from the actual luminance value (actual luminance) of the pixel corresponding to the non-collection region of the image data. In this way, since the particulate matter collected by the collection filter is used for calibration, it is not necessary to separately arrange a calibration sample on the collection filter to acquire image data in order to calibrate the image acquisition unit, and the image is imaged.

- the acquisition unit can be calibrated automatically and accurately.

- the program according to still another aspect of the present invention is a collection filter for collecting particulate matter, a collection area where particulate matter is collected, and a non-collection where particulate matter is not collected. It is a program for causing the analyzer to execute a calibration method of an analyzer that analyzes particulate matter based on the image data, including an image acquisition unit that acquires image data including a collection area.

- the above calibration method has the following steps. ⁇ Based on the relationship between the amount of particulate matter collected in the collection area and the brightness of the pixels corresponding to the non-collection area, and the amount of particulate matter collected when image data was acquired. A step of calculating the theoretical brightness of a pixel corresponding to a non-collection area of image data. ⁇ A step of calibrating the image acquisition unit based on the difference between the theoretical brightness and the actual brightness of the pixels corresponding to the non-collection area of the image data.

- the above program calculates the theoretical value (theoretical brightness) of the brightness of the pixels corresponding to the non-collection region of the image data acquired by collecting the particulate matter with the collection filter, and calculates the theoretical brightness and the image data.

- the analyzer is made to execute the process of calibrating the image acquisition unit based on the difference from the actual luminance value (actual luminance) of the pixel corresponding to the non-collection region. In this way, since the particulate matter collected by the collection filter is used for calibration, it is not necessary to separately arrange a calibration sample on the collection filter to acquire image data in order to calibrate the image acquisition unit, and the image is imaged.

- the acquisition unit can be calibrated automatically and accurately.

- the figure which shows an example of the time-dependent change of brightness The figure which shows an example of the time-dependent change of brightness standardized by the amount of particulate matter collected.

- the analysis system 100 is a system for analyzing particulate matter FP generated in various combustion processes (for example, combustion process in thermal power generation, combustion process in steelmaking plant, combustion process of incinerator, combustion process of coal, etc.).

- the particulate matter FP that can be measured is, for example, unburned content in ash produced in the combustion process of coal, fly ash produced in various combustion processes, and the like.

- particulate matter FP generated in the combustion process and for example, dust (brake, tire, internal combustion engine, steam engine, exhaust gas purification device, dust from motor) generated from various transportation devices (automobiles, ships, etc.), etc.

- dust can be the particulate matter FP to be measured by the analysis system 100.

- dust generated by natural disasters such as volcanic eruptions (for example, volcanic ash), dust generated in mine development, and the like can also be measured as particulate matter FP.

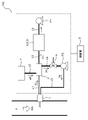

- FIG. 1 is a schematic diagram showing the configuration of an analysis system.

- the analysis system 100 shown in FIG. 1 is a system that analyzes the particulate matter FP contained in the exhaust gas by using the exhaust gas generated in the combustion process as the measurement target gas (hereinafter referred to as sample gas SG).

- the analysis system 100 mainly includes a sampling probe 1, a diluent 3, an analyzer 5, and a control unit 9.

- the sampling probe 1 is fixed at a predetermined position on the side wall of the flue FL, and samples the sample gas SG from the flue FL through which the sample gas SG flows.

- the sampling probe 1 has a gas suction amount by the first suction device P1 connected via the diluter 3 and the analyzer 5, and a gas suction amount by the second suction device P2 connected via the diluent 3.

- the amount of diluted gas AR (described later) supplied to the diluter 3 and the sample gas SG at a flow rate determined by the sample gas SG are sampled from the flue FL.

- the diluter 3 dilutes the sample gas SG by mixing the sample gas SG sampled by the sampling probe 1 and the diluting gas AR supplied from the supply device 7.

- the gas produced by diluting the sample gas SG with the diluted gas AR is called a diluted sample gas DG.

- the diluted gas AR is, for example, air.

- the supply device 7 is, for example, a device that adjusts the flow rate and supplies the instrumenting air as a diluent gas AR.

- the supply device 7 can be a device that adjusts the flow rate and supplies nitrogen or air supplied from a nitrogen cylinder or a (dry) air cylinder as a diluted gas AR.

- air in the atmosphere sucked by a pump can be supplied as a diluted gas AR by removing dust with a dust filter and removing water with a drying treatment device to adjust the flow rate.

- the analyzer 5 is an apparatus that analyzes the particulate matter FP contained in the diluted sample gas DG sampled from the diluter 3. As will be described later, the analyzer 5 includes an inflow section for inflowing the diluted sample gas DG, and the image data (first image data) obtained by photographing the particulate matter FP flowing in the diluted sample gas DG flowing through the inflow section. Based on this, the particulate matter FP is analyzed.

- the control unit 9 has a CPU, a storage device (for example, RAM, ROM, hard disk, SSD, etc.), a display (for example, a liquid crystal display, etc.), and various interfaces (I / O port, communication interface, etc.). It is a computer system. Further, the control unit 9 may be hardware such as a SoC in which a computer system is integrated on one chip.

- the control unit 9 controls each component of the analysis system 100 and performs various information processing related to the control.

- a part or all of the control and information processing executed by the control unit 9 may be stored in the storage device of the control unit 9 and realized by a program that can be executed by the computer system constituting the control unit 9. Further, a part of the control and information processing by the control unit 9 may be realized by hardware.

- control unit 9 may be a computer system in which the function of the calculation unit 55 of the analyzer 5 described later is incorporated, that is, the function of the control unit 9 and the function of the calculation unit 55 are the same in the computer system. It may be integrated, or the control unit 9 and the arithmetic unit 55 may be configured by individual computer systems.

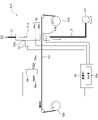

- FIG. 2 is a perspective view of the diluter.

- FIG. 3 is a cross-sectional view of the diluter.

- the diluter 3 has a mixing unit 31 and a diluting gas filling unit 33.

- the mixing unit 31 is a hollow member having an internal space IS1 (FIG. 3). One end of the mixing unit 31 in the length direction is connected to the sampling probe 1 via the first gas line L1, and the other end is the first suction via the second gas line L2, the analyzer 5, and the third gas line L3. It is connected to the device P1. Further, the other end side of the mixing unit 31 (the side to which the second gas line L2 is connected) is connected to the second suction device P2 via the fourth gas line L4. A plurality of introduction ports 31a are provided on the side wall of the mixing portion 31, so that gas can flow into the internal space IS1 from the introduction port 31a.

- the exhaust port of the second suction device P2 can be connected to the sampling probe 1 via the fifth gas line L5.

- the fifth gas line L5 discharges the diluted sample gas DG discharged from the discharge port of the second suction device P2 from the sampling probe 1 to the flue FL. This makes it possible to prevent the particulate matter FP from being discharged to the outside such as in the atmosphere.

- the first suction device P1 is, for example, a pump or the like.

- the second suction device P2 is, for example, a pump, a blower, or the like.

- the diluted gas filling portion 33 is in a “nested” state at the portion where a plurality of introduction ports 31a are formed in the length direction of the mixing portion 31, and the gap portion between the diluted gas filling portion 33 and the mixing portion 31 is gas tight. It is a hollow member that is stored in a state.

- a diluted gas filling space IS2 is formed between the inner wall of the diluted gas filling unit 33 and the outer wall of the mixing unit 31.

- the diluted gas filling space IS2 is connected to the supply device 7 via the fifth gas line L5.

- the supply device 7 fills the diluted gas filling space IS2 with the diluted gas AR having a pressure higher than the pressure of the internal space IS1 of the mixing unit 31.

- the sample gas SG flowing through the flue FL is inside via the sampling probe 1 and the first gas line L1 by the suction force of the first suction device P1 and the second suction device P2. Introduced in space IS1. Further, since the pressure of the diluted gas AR filled in the diluted gas filling space IS2 is higher than the pressure of the sample gas SG introduced into the internal space IS1, the diluted gas AR is introduced into the internal space IS1 through the introduction port 31a. ..

- the sample gas SG is diluted with the diluted gas AR to generate the diluted sample gas DG.

- the dilution ratio of the sample gas SG is determined by the amount of the sample gas SG introduced into the internal space IS1 and the amount of the diluted gas AR.

- the diluted sample gas DG drawn into the second gas line L2 by suction by the first suction device P1 is introduced into the analyzer 5.

- the remaining diluted sample gas DG is discharged to the outside by suction of the second suction device P2.

- a particulate matter FP contained in the diluted sample gas DG is placed between the third gas line L3 and the first suction device P1 and / or between the fourth gas line L4 and the second suction device P2.

- a filter for removing (not shown), a buffer tank for suppressing the pulsation of the diluted sample gas DG (not shown), a drain pot for removing water from the diluted sample gas DG, and the like may be provided.

- a three-way switch is made between the second suction device P2 and the diluter 3 to enable gas flow or not.

- a valve V (an example of a blowback portion) may be provided.

- the control unit 9 controls the three-way valve V to make the second suction device P2 and the diluter 3 unable to flow gas, the control unit 9 enables gas flow between the second suction device P2 and the atmosphere.

- the control unit 9 controls the three-way valve V to make gas flow impossible between the second suction device P2 and the diluent 3, so that the diluted gas AR cannot flow from the diluter 3.

- Diluted gas AR is discharged from the sampling probe 1 to the flue FL after passing through the first gas line L1 to remove the particulate matter FP deposited and adhered to the sampling probe 1 and the first gas line L1 to the flue FL. It can be discharged (called blowback). At this time, the diluted gas AR flows into the analyzer 5 from the supply device 7.

- control unit 9 can control the three-way valve V as described above to execute blowback for each analysis of the particulate matter FP.

- the control unit 9 predetermineds blowback and sampling of the sample gas SG within a predetermined period (for example, 1 hour). Run at the specified time rate. For example, if it is predicted that the amount of particulate matter FP collected will be large (for example, if the previous amount of collected material was large), the period for performing blowback will be increased and the sample gas SG will be sampled. The period can be reduced. This makes it possible to prevent the particulate matter FP from being excessively collected by the collection filter 52 (FIG. 4) while reducing the amount of the particulate matter FP deposited in the sampling probe 1, the first gas line L1, and the like. ..

- the period for performing blowback is reduced and the sample gas SG is sampled. You can increase the period.

- the amount of particulate matter FP deposited in the sampling probe 1, the first gas line L1, etc. the amount of particulate matter sufficient to accurately perform the analysis on the collection filter 52 (FIG. 4, etc.). Can collect material FP.

- blowback may be performed when the particulate matter FP deposited in the flow path of the sample gas SG exceeds a predetermined amount.

- blowback execution control is realized by, for example, a program that can be executed by the computer system constituting the control unit 9. This allows blowback (and sampling of particulate matter FP) to be performed automatically.

- the method for removing the particulate matter FP deposited in the flow path of the sample gas SG is not limited to the method by executing the above blowback.

- particles deposited in the flow path by a method such as vibrating or giving an impact to a portion of the analysis system 100 in which the particulate matter FP is deposited for example, the connection portion between the sampling probe 1 and the first gas line L1). Particulate matter FP can be removed.

- the analyzer 5 of the present embodiment mainly contains the first image data obtained by photographing the particulate matter FP flowing in the diluted sample gas DG and the particulate matter FP contained in the diluted sample gas DG. It is a device that analyzes particulate matter FP based on information on the content (called content information).

- FIG. 4 is a diagram showing a specific configuration of the analyzer.

- the analyzer 5 mainly includes an inflow unit 51a, a first image acquisition unit 53, a content information acquisition unit 54, and a calculation unit 55.

- the inflow portion 51a is a hollow member, one end thereof is connected to the second gas line L2, and the other end is in an open state. The other end of the inflow portion 51a in the open state faces the suction portion 51b.

- the suction portion 51b is a hollow member, one end of which faces the inflow portion 51a, and is in an open state.

- the other end of the suction portion 51b is connected to the first suction device P1 via the third gas line L3.

- a suction force is generated at one end of the suction unit 51b in the open state. Due to this suction force, the diluted sample gas DG generated in the diluter 3 passes through the second gas line L2 and flows into the inside of the inflow portion 51a.

- the diluted sample gas DG that has flowed into the inside of the inflow section 51a due to the suction force generated by the suction section 51b is discharged from the open side of the inflow section 51a and is sucked into the suction section 51b.

- the collection filter 52 is arranged between the inflow section 51a and the suction section 51b, the diluted sample gas DG discharged from the inflow section 51a is sucked by the suction section 51b. It passes through the collection filter 52 before.

- the collection filter 52 collects the particulate matter FP contained in the diluted sample gas DG that passes through the collection filter 52.

- the collection filter 52 is, for example, a white tape-like member having a reinforcing layer and a collecting layer formed by laminating on the reinforcing layer.

- the reinforcing layer is formed of, for example, a non-woven fabric made of a polymer material (polyethylene or the like).

- the collection layer has pores capable of collecting the particulate matter FP.

- the collection layer is formed of, for example, a fluororesin-based material.

- the collection filter 52 can be moved in the length direction (direction indicated by the thick arrow in FIG. 4) by sending out from the delivery reel 52a and winding up by the take-up reel 52b.

- the first image acquisition unit 53 acquires image data (referred to as first image data) of the particulate matter FP flowing in the diluted sample gas DG that has flowed into the inflow unit 51a.

- the first image acquisition unit 53 is, for example, a camera attached to an optical window 53a provided on the side wall of the inflow unit 51a.

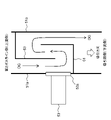

- the flow path changing member 61 that changes the flow path of the diluted sample gas DG as shown in FIG. 5 in the vicinity of the portion of the inside of the inflow portion 51a to which the first image acquisition portion 53 is attached. 63 is provided.

- FIG. 5 is a diagram showing an example of a flow path of the diluted sample gas by the flow path changing member.

- the flow path of the diluted sample gas DG introduced from the second gas line L2 is changed on the side closer to the suction portion 51b (downstream side).

- the member 61 changes the direction opposite to the suction direction by the suction portion 51b.

- the flow direction of the diluted sample gas DG is further changed to the suction direction by the flow path changing member 63 provided on the side closer to the second gas line L2 (upstream side).

- the flow path changing members 61 and 63 are provided in the vicinity of the portion to which the first image acquisition portion 53 is attached, and the diluted sample gas DG tends to stay in the vicinity of the first image acquisition portion 53.

- the first image acquisition unit 53 can photograph the same particulate matter FP flowing in the diluted sample gas DG for a longer period of time.

- the content information acquisition unit 54 measures the data for calculating the mass concentration of the particulate matter FP collected by the collection filter 52. That is, in the present embodiment, the content information acquisition unit 54 measures the data for calculating the mass concentration of the particulate matter FP as the content information regarding the content of the particulate matter FP contained in the diluted sample gas DG. do.

- the content information acquisition unit 54 has a ⁇ -ray source 54a and a ⁇ -ray detection unit 54b.

- the ⁇ -ray source 54a is provided inside the inflow portion 51a, and irradiates ⁇ -rays toward the particulate matter FP collected by the collection filter 52.

- the ⁇ -ray source 54a is, for example, a ⁇ -ray source having carbon-14 ( 14C ) as a radiation source.

- the ⁇ -ray detection unit 54b is provided inside the suction unit 51b so as to face the ⁇ -ray source 54a, and calculates the mass concentration of the intensity of ⁇ -rays transmitted through the particulate matter FP collected by the collection filter 52. It is measured as content information to be used.

- the ⁇ -ray detection unit 54b is, for example, a photomultiplier tube provided with a scintillator.

- the arithmetic unit 55 includes a CPU, a storage device (for example, RAM, ROM, hard disk, SSD, etc.), a display (for example, a liquid crystal display, etc.), and various interfaces (I / O port, communication interface, etc.). It is a computer system. Further, the arithmetic unit 55 may be hardware such as SoC in which a computer system is integrated on one chip.

- the calculation unit 55 performs various controls and information processing for analyzing the particulate matter FP contained in the diluted sample gas DG.

- a part or all of the various controls and information processing executed by the arithmetic unit 55 may be stored in the storage device of the arithmetic unit 55 and realized by a program that can be executed by the computer system constituting the arithmetic unit 55. Further, a part of various control and information processing may be realized by hardware.

- the calculation unit 55 has an analysis unit 55a as a functional block.

- the analysis unit 55a contains the first image data of the particulate matter FP flowing in the diluted sample gas DG that has flowed into the inflow unit 51a acquired by the first image acquisition unit 53, and the ⁇ of the content information acquisition unit 54.

- the particulate matter FP is analyzed based on the ⁇ -ray intensity measured by the line detection unit 54b.

- the analysis unit 55a provides information on the shape of the particulate matter FP contained in the diluted sample gas DG (for example, the aspect ratio of the particulate matter FP) and the particulate matter, based on the first image data.

- the first particle size information regarding the particle size (for example, the particle size distribution of the particulate matter FP) can be calculated. Further, the analysis unit 55a can calculate the mass concentration of the particulate matter FP based on the content information which is the ⁇ -ray intensity measured by the ⁇ -ray detection unit 54b.

- the analyzer 5 of the present embodiment further includes a second image acquisition unit 56.

- the second image acquisition unit 56 is provided at a predetermined position in the length direction of the collection filter 52 so that the light receiving surface faces the surface of the collection filter 52 on the side where the particulate matter FP is collected.

- a CCD image sensor in which coupling elements (CCDs) are arranged in a two-dimensional array, and a CMOS image sensor in which light receiving elements are arranged in an array.

- the second image acquisition unit 56 acquires image data (second image data) of the particulate matter FP collected by the collection filter 52 by suction of the suction unit 51b. Specifically, the portion of the collection filter 52 (referred to as the collection area) in which the particulate matter FP is collected by the suction of the suction unit 51b is moved in the length direction of the collection filter 52 to acquire a second image. After moving to just below the unit 56, the second image acquisition unit 56 determines that the collection area of the collection filter 52 and the area around which the particulate matter FP is not collected (referred to as a non-collection area). The second image data including the above is acquired.

- the analyzer 5 is provided with a first light source 56a in order for the second image acquisition unit 56 to acquire appropriate second image data.

- the first light source 56a is composed of, for example, a plurality of surface-mounted white LEDs, and uniformly illuminates the field of view of the second image acquisition unit 56 with white light. By irradiating the field of view of the second image acquisition unit 56 with uniform white light, it is possible to avoid acquiring the second image data affected by the distribution of the irradiation amount of the light.

- the analysis unit 55a calculates information on the colored particulate matter FP based on the second image data acquired by the second image acquisition unit 56. For example, the analysis unit 55a is based on the difference between the brightness of the pixels included in the image portion corresponding to the collection region and the brightness of the pixels included in the image portion corresponding to the non-collection region in the second image data. Therefore, the content of the black particulate matter FP (for example, the particulate matter FP containing carbon as a main component) in the diluted sample gas DG can be calculated.

- the black particulate matter FP for example, the particulate matter FP containing carbon as a main component

- FIG. 6 will be used to explain the analytical operation of the particulate matter FP using the analysis system 100 having the above configuration.

- FIG. 6 is a flowchart showing an analysis operation of particulate matter.

- an operation example will be described when the period for executing blowback and the period for sampling the particulate matter FP are executed at a predetermined ratio when sampling the particulate matter FP.

- step S1 the above blowback is executed.

- the control unit 9 operates the second suction device P2, and in a state where the dilution gas AR is supplied from the supply device 7, controls the three-way valve V to control the second suction device P2 and the diluent 3. It is assumed that gas cannot flow, and gas can flow between the second suction device P2 and the atmosphere.

- the diluted gas AR is discharged from the diluter 3 through the first gas line L1 and from the sampling probe 1 to the flue FL, and blowback of the sampling probe 1 and the first gas line L1 is executed.

- step S2 determines in step S2 whether or not it is time to end the blowback after a predetermined period has elapsed from the start of the blowback.

- the control unit 9 maintains a state in which the second suction device P2 and the diluter 3 cannot flow gas, and blowback is performed. Continue to run.

- step S3 the sample gas SG is diluted with the diluted gas AR to generate a diluted sample gas DG.

- the control unit 9 operates the first suction device P1 and the second suction device P2 to sample the sample gas SG flowing through the flue FL by the sampling probe 1, and the internal space IS1 of the mixing unit 31 of the diluent 3 is used.

- the sample gas SG is charged into the diluted gas AR by filling the diluted gas AR into the diluted gas filling space IS2 from the supply device 7 and flowing the diluted gas AR from the diluted gas filling space IS2 into the internal space IS1. Dilute.

- step S4 After diluting the sample gas SG to generate the diluted sample gas DG, in step S4, a part of the diluted sample gas DG in the internal space IS1 is sucked by the suction force of the first suction device P1 to the inflow portion 51a of the analyzer 5. Inflow to.

- the diluted sample gas DG is introduced into the inflow portion 51a by suction of the suction portion 51b. Further, a collection filter 52 is provided between the inflow portion 51a and the suction portion 51b. Therefore, while the diluted sample gas DG flows into the inflow section 51a and then is sucked into the suction section 51b, the particulate matter FP contained in the diluted sample gas DG is collected by the collection filter 52.

- the flow velocity of the diluted sample gas DG in the inflow portion 51a is controlled so that the shape of the particulate matter FP flowing in the inflow portion 51a can be discriminated by image processing or the like from the first image data.

- the flow rate of the diluted sample gas DG in the inflow unit 51a can be controlled, for example, by controlling the suction flow rate of the diluted sample gas DG by the first suction device P1.

- the first image acquisition section 53 acquires the first image data of the particulate matter FP flowing in the diluted sample gas DG flowing through the inflow section 51a. do.

- the first image data acquired by the first image acquisition unit 53 is transmitted to the analysis unit 55a.

- the first image acquisition unit 53 adjusts the shutter speed for acquiring the first image data according to the flow velocity of the diluted sample gas DG in the inflow unit 51a. As a result, the first image acquisition unit 53 can acquire the first image data in which the shape of the particulate matter FP can be clearly discriminated.

- the content information acquisition unit 54 acquires the content information regarding the content of the particulate matter FP contained in the diluted sample gas DG in step S6.

- the ⁇ -ray source 54a of the content information acquisition unit 54 emits ⁇ -rays toward the particulate matter FP collected by the collection filter 52, and ⁇ -rays after passing through the particulate matter FP.

- the ⁇ -ray detection unit 54b measures the intensity of the above. The ⁇ -ray intensity measured by the ⁇ -ray detection unit 54b is transmitted to the analysis unit 55a.

- a diluted sample gas DG is allowed to flow into the inflow section 51a for a predetermined period of time (for example, 1 hour) to collect the particulate matter FP in the collection filter 52, and then the collection filter 52 is used. By moving in the length direction, the collection region of the particulate matter FP is moved directly under the second image acquisition unit 56.

- the predetermined period for inflowing the diluted sample gas DG is determined based on the ratio of the blowback period and the sampling period determined in advance according to predetermined conditions.

- the second image acquisition unit 56 After moving the collection area directly under the second image acquisition unit 56, in step S7, the second image acquisition unit 56 captures the collection area and its surroundings with the light from the first light source 56a. The second image data including the collecting area and the non-collecting area is acquired. The second image data acquired by the second image acquisition unit 56 is transmitted to the analysis unit 55a.

- the analysis unit 55a determines the particles contained in the diluted sample gas DG (sample gas SG) based on these information.

- the state substance FP is analyzed.

- the properties of the particulate matter FP contained in the exhaust gas generated in the combustion process were investigated. As a result, it was found that the non-spherical particulate matter FP is often unburned in ash. It was also found that there is a strong correlation between the average particle size of the particulate matter FP and the proportion of unburned content in the ash contained in the particulate matter FP. Specifically, it was found that the larger the average particle size of the particulate matter FP, the larger the proportion of unburned content in the ash contained in the particulate matter FP.

- the particulate matter FP contained a large amount of unburned content in the ash, the particulate matter FP became blacker. Specifically, it was found that the blacker the particulate matter FP collected by the collection filter 52, the higher the proportion of unburned matter in the ash contained in the collected particulate matter FP. ..

- the analysis unit 55a executes, for example, a process of grasping the shape of the image included in the image such as edge processing on the first image data to obtain the shape of the particulate matter FP included in the first image data. grasp. After grasping the shape of the particulate matter FP, the analysis unit 55a provides information on the particle shape such as the aspect ratio of the particulate matter FP (ratio of the major axis to the minor axis of the particulate matter FP) included in the first image data. , Calculate information on particle size such as the average particle size of particulate matter FP.

- the analysis unit 55a When the aspect ratio of the analysis unit 55a deviates greatly from 1 (meaning a true sphere) and the first image data contains many images of the non-spherical particulate matter FP, the analysis unit 55a has an average particle size of the particulate matter FP. When is large, it can be determined that the particulate matter FP contains a large amount of unburned matter in the ash. Further, the analysis unit 55a uses a relational expression expressing the relationship between the average particle size of the particulate matter FP and the ratio of the unburned portion in the ash contained in the particulate matter FP, and the particulate matter contained in the first image data. From the average particle size of the particulate matter FP, the ratio of the unburned content in the ash contained in the particulate matter FP can be specifically calculated.

- the analysis unit 55a calculates the mass concentration of the particulate matter FP based on the ⁇ -ray intensity measured by the ⁇ -ray detection unit 54b.

- the analysis unit 55a can calculate the mass concentration of the unburned portion in the ash by using the ratio of the unburned portion in the ash contained in the particulate matter FP and the mass concentration of the particulate matter FP.

- the analysis unit 55a can calculate information on the colored particulate matter FP collected by the collection filter 52 based on the second image data acquired in step S7 above. Specifically, the analysis unit 55a can calculate information about the particulate matter FP by using the brightness of the pixels included in the second image data.

- FIG. 7 is a diagram showing an example of a luminance histogram.

- peaks are seen in the luminance Br1 and the luminance Br2.

- the first peak PE1 in the small luminance Br1 shifts to the smaller luminance side as the amount of the particulate matter FP collected by the collection filter 52 and / or the amount of carbon contained in the particulate matter FP increases. That is, the luminance Br1 at which the first peak PE1 appears becomes smaller as the amount of collected particulate matter FP and / or the amount of carbon contained in the particulate matter FP increases.

- the second peak PE2 at the high luminance Br2 slightly shifts depending on the amount of the particulate matter FP collected, but the shift amount is not as large as the first peak PE1. That is, the luminance Br2 at which the second peak PE2 appears is hardly affected by the presence of the particulate matter FP.

- the first peak PE1 in the luminance Br1 represents the luminance distribution of the image portion corresponding to the collection region where the particulate matter FP is collected

- the second peak PE2 in the luminance Br2 is the particulate matter FP collected. It can be seen that it represents the luminance distribution of the image portion corresponding to the non-collected region. Therefore, the analysis unit 55a can calculate information on the collection amount of the particulate matter FP collected by the collection filter 52 based on the brightness of the pixels of the image portion having a small brightness in the second image data.

- the analysis unit 55a has, for example, the brightness of the pixels of the image portion corresponding to the collection region in the second image data and the amount of carbon contained in the particulate matter FP collected by the collection filter 52. Based on the calibration curve showing the relationship with (information on the amount of particulate matter FP collected), the amount of carbon contained in the particulate matter FP collected by the collection filter 52 is captured by the particulate matter FP. It can be calculated as information on the amount of collection.

- the above calibration curve shows the second image data acquired by collecting the particulate matter FP and the carbon contained in the particulate matter FP collected by the collection filter 52 when the second image data was acquired. It can be calculated from the relationship between the amount and.

- the amount of carbon contained in the collected particulate matter FP is, for example, the amount of carbon dioxide generated when the collecting filter that has collected the particulate matter FP is burned at a predetermined temperature (for example, 2000 ° C.). Can be calculated from.

- FIG. 8 is an example of graphing the relationship between the brightness of the pixels of the image portion having a small brightness in the second image data and the amount of carbon contained in the particulate matter FP collected by the collection filter. It is a figure which shows.

- the second image data used when calculating the calibration curve is acquired by collecting the particulate matter FP, which is the actual measurement target, with the collection filter 52 at the installation location of the analysis system 100.

- the present inventor collects the standard substance with a collection filter and acquires the second image data, or the second image acquired by collecting the particulate substance using an experimental device imitating the analysis system 100. Different calibration curves are calculated when using the data and when using the second image data obtained by collecting the particulate matter FP to be actually measured at the installation location of the analysis system 100. I found it.

- the condition was different from the condition when the particulate matter was collected by the collection filter using the experimental device.

- the sample gas SG that is, the gas generated in the combustion process

- Collection using experimental equipment is carried out at room temperature.

- the calibration curve used when analyzing the particulate matter FP based on the second image data is collected by the collection filter 52 at the installation site of the analysis system 100 for the particulate matter FP to be actually measured.

- a more accurate calibration curve can be calculated and the particulate matter FP can be analyzed more accurately.

- the information on the particulate matter FP can be calculated by using the data in which the luminance Br1 of the pixel of the image portion having a small brightness in the second image data is standardized by a predetermined parameter on the particulate matter FP.

- a predetermined parameter on the particulate matter FP For example, as shown in FIG. 9, when the luminance Br1 changes with time, when the luminance Br1 is standardized by the amount of the particulate matter FP collected, the luminance Br1 is collected as shown in FIG. 10A.

- the change over time (indicated by a solid line in FIG. 10A) of the value (brightness / collected amount) standardized in 1 is different from the change over time in brightness Br1 (indicated by a broken line in FIG. 10A).

- FIG. 9 is a diagram showing an example of a change in brightness with time.

- FIG. 10A is a diagram showing an example of a change in brightness over time, which is standardized by the amount of particulate matter collected.

- the above-mentioned difference in the change with time suggests that the ratio of the unburned content in the ash contained in the particulate matter FP collected at each time changes with time. Since the unburned component in the ash has a black color, the brightness Br1 when the proportion of the unburned component in the ash contained in the particulate matter FP is large is the brightness Br1 when the proportion of the unburned component in the ash is small. In comparison, even if the collected amount of the particulate matter FP is the same, it becomes smaller.

- FIG. 10B the change over time of the product value (luminance * (collection amount / collection time)) of the luminance Br1 and the collection amount of the particulate matter FP per unit time is shown in FIG. 10C.

- the change over time of the value (luminance / (collection amount / collection time)) in which the brightness Br1 is standardized by the collection amount of the particulate matter FP per unit time for example, the combustion conditions in the combustion process.

- FIG. 10B is a diagram showing an example of a change over time in the value of the product of the luminance and the amount of particulate matter collected per unit time.

- FIG. 10C is a diagram showing an example of a change over time in which the luminance is standardized by the amount of particulate matter collected per unit time.

- the analysis unit 55a replaces the luminance Br1 of the second image data with the luminance Br1 of the image portion corresponding to the collection region of the second image data and the image portion corresponding to the non-collection region of the second image data.

- Information on the particulate matter FP collected by the collection filter 52 may be calculated based on the difference ⁇ BR (FIG. 7) from the brightness Br2 of the above. For example, in the analysis unit 55a, if the difference ⁇ BR between the luminance Br1 of the first peak PE1 and the luminance Br2 of the second peak PE2 is large, the ratio of the unburned portion in the ash is large, and if it is small, the proportion of the unburned portion in the ash is small. Can be determined.

- the brightness histogram shown in FIG. 7 is generated by using the second image data as it is, but is not limited to this, and the second image data is used when analyzing the particulate matter using the second image data. May be reversed in black and white.

- the first peak PE1 is the luminance distribution of the image portion corresponding to the non-collection region

- the second peak PE2 is the luminance distribution of the image portion corresponding to the capture region. It becomes a distribution.

- the first image data of the particulate matter FP flowing in the diluted sample gas DG flowing into the inflow portion 51a and the content of the particulate matter contained in the diluted sample gas DG are contained.

- Particulate matter FP is analyzed based on the amount information.

- the first image data contains information on the appearance of the particulate matter FP flowing in the sample gas SG, and the carbon-based particulate matter FP produced in the combustion process is characterized by its appearance. Based on the first image data and the content information, it is possible to accurately analyze the particulate matter FP whose main component is carbon. Further, by analyzing the particulate matter FP based on the second image data in addition to the first image data and the mass concentration of the particulate matter FP, the particulate matter FP can be analyzed more accurately.

- the analyzer 5 can analyze the particulate matter FP using the image data in which the diluted sample gas DG containing the particulate matter FP is flowing, the diluted sample gas DG is continuously applied to the inflow portion 51a. Particulate matter FP can be continuously analyzed by inflowing.

- the analysis unit 55a displays the analysis result of the particulate matter FP on the display.

- the first image display unit D1 for displaying the first image data, the second image display unit D2 for displaying the second image data, and the particle size distribution of the particulate matter FP are displayed.

- a display screen D having a particle size distribution display unit D3, a ratio display unit D4 for displaying the ratio of unburned content in ash, and a concentration display unit D5 for displaying the concentration of unburned content in ash can be displayed.

- FIG. 11 is a diagram showing an example of an analysis result display screen.

- the inflow unit 51a includes a first flow path FL1 in which the first image acquisition unit 53 is provided and a diluted sample gas DG for acquiring the first image data flows.

- a ⁇ -radioactive source 54a may be provided and may have a second flow path FL2 through which a diluted sample gas DG for acquiring content information flows.

- FIG. 12 is a diagram showing an example of a modification of the inflow portion.

- the flow velocity of the diluted sample gas DG in the first flow path FL1 for acquiring the first image data and the flow velocity of the diluted sample gas DG for acquiring the content information can be independently adjusted.

- the first image data and the content information can be acquired under the optimum conditions.

- a ⁇ -ray source to prevent clogging of the particulate matter FP while slowing the flow velocity of the diluted sample gas DG in the first flow path FL1 in order to acquire the particulate matter FP as a clear image in the first image data. It is possible to prevent the flow velocity of the diluted sample gas DG in the second flow path FL2 provided with 54a from becoming excessively slow.

- the analyzer 5 includes a first image acquisition unit 53 for acquiring the first image data of the particulate matter FP flowing in the inflow unit 51a, a content information acquisition unit 54 for acquiring content information ( ⁇ -ray intensity), and a content information acquisition unit 54. It may further have an apparatus for acquiring information used for analysis of particulate matter FP other than the above. For example, as shown in FIG. 13, the analyzer 5 acquires scattered light information regarding scattered light generated by scattering light incident on the diluted sample gas DG flowing through the inflow portion 51a by the particulate matter FP. It may further have an acquisition unit 57.

- FIG. 13 is a diagram showing an example of a modification of the analyzer.

- the scattered light information acquisition unit 57 has a second light source 57a that emits the laser light L toward the diluted sample gas DG inside the inflow unit 51a, and particles while the laser light L passes through the diluted sample gas DG. It has a scattered light detection unit 57b that detects scattered light generated by scattering by the state substance FP.

- the analysis unit 55a has, for example, the number of particulate matter FPs contained in the diluted sample gas DG and the particle size distribution (second) based on the intensity of the scattered light (scattered light information) detected by the scattered light detection unit 57b. An example of particle size information) can be calculated.

- the scattered light information (scattered light intensity) obtained by the scattered light information acquisition unit 57 can also be used to calculate the number of particulate matter FP contained in the diluted sample gas DG.

- the number of particulate matter FP contained in the diluted sample gas DG corresponds to the content of the particulate matter FP. Therefore, in the analyzer 5 including the scattered light information acquisition unit 57, as shown in FIG. 14, the ⁇ -ray source 54a and the ⁇ -ray detection unit 54b are omitted, and the analysis unit 55a is obtained by the scattered light information acquisition unit 57.

- the content of the particulate matter FP contained in the diluted sample gas DG may be calculated based on the scattered light information (scattered light intensity).

- FIG. 14 is a diagram showing another example of a modification of the analyzer.

- the analyzer for analyzing the particulate matter FP may be further provided with another analyzer. Specifically, as shown in FIG. 15, the analyzer 5'according to the second embodiment performs gas analysis in addition to the first image acquisition unit 53, the content information acquisition unit 54, and the second image acquisition unit 56. A portion 58 may be further provided.

- FIG. 15 is a diagram showing the configuration of the analyzer according to the second embodiment. As will be described later, since the gas analysis unit 58 burns the particulate matter FP to generate gas, in the analyzer 5'according to the second embodiment, the particulate matter FP is collected by the collection filter 52. Instead, a member that collects the particulate matter FP (for example, a member similar to the collection filter 52) is placed on the sample support portion 52'made of a heat-resistant material such as copper.

- the gas analysis unit 58 detects the gas generated by burning the particulate matter FP (for example, carbon dioxide (CO 2 ), hydrocarbon (for example, methane (CH 4 ))), and thereby contains carbon as a main component.

- the particulate matter FP is analyzed.

- the gas analysis unit 58 has a combustion unit 58a and a gas detection unit 58b.

- the combustion unit 58a burns the collected particulate matter FP to generate gas.

- the combustion unit 58a is, for example, a heating device such as a heater.

- the gas generated by burning the particulate matter FP depends on the gas atmosphere around the combustion portion 58a.

- oxygen air

- carbon dioxide is generated by the combustion of the particulate matter FP.

- methane is generated by the combustion of the particulate matter FP.

- the gas detection unit 58b detects the gas generated by the combustion of the particulate matter FP by the combustion unit 58a.

- the gas detection unit 58b is a device that detects gas by absorbing light (infrared light) by a measurement target gas such as a non-dispersive infrared absorption (NDIR) method.

- NDIR non-dispersive infrared absorption

- the gas detection unit 58b can be used as a hydrogen flame ionization detector (FID).

- the analyzer 5' having the above configuration can analyze the carbon content of the particulate matter FP containing carbon as a component and what kind of carbon compound constitutes the particulate matter FP. For example, it is possible to analyze the carbon compounds constituting the particulate matter FP and the content ratio of each carbon compound by utilizing the fact that the combustion temperature differs depending on the type of carbon compound.

- the particulate matter FP when the generation of gas is detected when the particulate matter FP is heated to about 580 ° C, the particulate matter FP contains organic carbon (OC). Can be judged.

- the generation of gas when the particulate matter FP is heated to about 840 ° C, it can be determined that the particulate matter FP contains elemental carbon (EC). It is also possible to calculate the ratio of organic carbon and elemental carbon constituting the particulate matter FP from the amount of gas generated when heated to about 580 ° C and the amount of gas generated when heated to about 840 ° C. can.

- the particulate matter FP is obtained using the second image data.

- the device for analysis is provided with a first light source 56a that illuminates the viewing range of the second image acquisition unit 56.

- the characteristics of the first light source 56a change with time.

- the brightness of the second image data may be different.

- the same amount of particulate matter is analyzed. Even if the second image data is acquired when the FPs are collected, if the brightness of the second image data is different, different analysis results are calculated due to the difference in brightness.

- the device is calibrated at predetermined intervals.

- a calibration sample is manually placed on the collection filter 52

- a second image data is acquired using the calibration sample placed on the collection filter 52

- the device is calibrated using the second image data.

- the device calibration for the analysis of the particulate matter FP using the second image data is automatically performed without arranging the calibration sample on the collection filter 52.

- the functional block configuration of the arithmetic unit 55 that executes the calibration method of the device is different from that of the first embodiment, and the other configurations and functions are related to the first embodiment. It is the same as the analyzer 5. Therefore, in the following, only the functional block configuration of the calculation unit 55 ′′ of the analyzer 5 ′′ will be described, and the description of other configurations other than the calculation unit 55 ′ will be omitted.

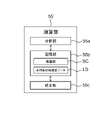

- FIG. 16 is a diagram showing a functional block configuration of a calculation unit of the analyzer according to the third embodiment.

- the calculation unit 55' has a storage unit 55b and a calibration unit 55c as functional blocks in addition to the analysis unit 55a according to the first embodiment.

- the storage unit 55b is a part or all of the storage area formed in the storage device provided in the computer system constituting the calculation unit 55', controls the analysis device 5'', and is in the form of particles using the second image data.

- Various parameters for analyzing the substance FP are stored.

- the storage unit 55b stores the calibration curve SC and the non-collection region luminance data LD.

- the calibration curve SC represents the relationship between the amount of the particulate matter FP collected in the collection area and the brightness of the pixel of the image portion corresponding to the collection area of the second image data.

- the calibration curve SC is used to calculate the amount of the particulate matter FP collected using the second image data actually acquired.

- the calibration curve SC changes the collection amount of the particulate matter FP, for example, by changing the second image data including the collection area and the non-collection area where the particulate matter FP is collected at a known collection amount.

- a plurality of data are acquired, the brightness histogram described in the first embodiment is generated for each second image data, and an approximate expression expressing the relationship between the brightness of the first peak of each brightness histogram and the corresponding collection amount is fitted or the like. It can be obtained by calculating in advance.

- the luminance histogram can be generated, for example, by scanning the pixels included in the second image data, counting the number of pixels having a specific luminance, and associating the luminance with the number of pixels having the luminance.

- the calibration curve SC can be used as data (table) in which the brightness of the first peak of each luminance histogram and the corresponding collection amount are associated with each other.

- the non-collection region brightness data LD represents the relationship between the collection amount of the particulate matter FP collected in the collection region and the brightness of the pixels of the image portion corresponding to the non-collection region of the second image data. .. As described in the first embodiment, the brightness of the image portion corresponding to the non-collection region of the second image data slightly changes depending on the collection amount of the particulate matter FP collected in the collection region.