WO2020203451A1 - Pulverizer - Google Patents

Pulverizer Download PDFInfo

- Publication number

- WO2020203451A1 WO2020203451A1 PCT/JP2020/012948 JP2020012948W WO2020203451A1 WO 2020203451 A1 WO2020203451 A1 WO 2020203451A1 JP 2020012948 W JP2020012948 W JP 2020012948W WO 2020203451 A1 WO2020203451 A1 WO 2020203451A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mortar

- conical

- crushing

- introduction portion

- cacao

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23G—COCOA; COCOA PRODUCTS, e.g. CHOCOLATE; SUBSTITUTES FOR COCOA OR COCOA PRODUCTS; CONFECTIONERY; CHEWING GUM; ICE-CREAM; PREPARATION THEREOF

- A23G1/00—Cocoa; Cocoa products, e.g. chocolate; Substitutes therefor

- A23G1/04—Apparatus specially adapted for manufacture or treatment of cocoa or cocoa products

- A23G1/16—Circular conches, i.e. rollers being displaced on a closed or circular rolling circuit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C2/00—Crushing or disintegrating by gyratory or cone crushers

- B02C2/02—Crushing or disintegrating by gyratory or cone crushers eccentrically moved

- B02C2/04—Crushing or disintegrating by gyratory or cone crushers eccentrically moved with vertical axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C7/00—Crushing or disintegrating by disc mills

- B02C7/02—Crushing or disintegrating by disc mills with coaxial discs

- B02C7/08—Crushing or disintegrating by disc mills with coaxial discs with vertical axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C7/00—Crushing or disintegrating by disc mills

- B02C7/18—Disc mills specially adapted for grain

Definitions

- One aspect of the present invention relates to a crusher that crushes a solid raw material such as cacao beans.

- the present application claims priority based on Japanese Patent Application No. 2019-068931 filed in Japan on March 29, 2019, the contents of which are incorporated herein by reference.

- an electric powder grinder disclosed in Patent Document 1 As a crusher of this type, for example, an electric powder grinder disclosed in Patent Document 1 is known.

- the material to be crushed is charged and crushed by a charging unit having an opening to be sent to the next stage, a coarse powder grinding unit that roughly crushes the material to be crushed from the introduction adjustment unit, and a coarse powder grinding unit. It is provided with a fine powder grinding unit that further finely crushes the material to be crushed, and an adjusting unit that adjusts the amount of the material to be crushed into the fine powder grinding unit.

- the temperature of the introduction region is configured to be lower than the temperature of the oil content of the object to be crushed

- the temperature of the discharge region is configured to be higher than the temperature of the oil content of the object to be crushed. It is designed to prevent the bean powder from sticking to each other.

- FIG. 12 is a vertical cross-sectional view showing the configuration of a main part of a conventional crusher.

- the crusher 101 shown in FIG. 12 has a conical mortar 111 including an inner mortar 121 which is a rotary mortar and an outer mortar 122 which is a fixed mortar.

- a solid raw material to be crushed is introduced from the introduction portion 112 into the inlet portion 123 between the inner mortar 121 and the outer mortar 122.

- the introduction portion 112 has a cylindrical shape, and the inner diameter of the lower end portion is substantially the same as the inner diameter of the outer mortar 122.

- the solid raw material is, for example, cacao nibs. Cacao nibs are roasted and coarsely crushed cocoa beans.

- the cacao beans have an oil content of about 50% and a melting point of about 35 ° C.

- One aspect of the present invention is to realize a crusher capable of suppressing the deposition of powder of a solid raw material on the inner peripheral surface of the outer mortar at the inlet of the conical mortar.

- the crusher according to one aspect of the present invention has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and the inner mortar and the outer mortar

- FIG. 5 It is a perspective view of the crushing apparatus provided with the crushing unit as the crusher of embodiment of this invention. It is a perspective view of the crushing unit shown in FIG. It is an exploded perspective view of the crushing unit shown in FIG. It is a perspective view which includes the vertical cross section of the crushing unit shown in FIG. It is a front view of the vertical cross-sectional portion of the crushing unit shown in FIG. It is explanatory drawing which shows the detailed structure of the crushing unit shown in FIG. 5, and the operation of a crushing unit. It is explanatory drawing which shows the detailed structure of the crushing unit of another embodiment of this invention, and the operation of a crushing unit. It is explanatory drawing which shows the detailed structure of the pulverization unit of still another embodiment of this invention, and the operation of the pulverization unit.

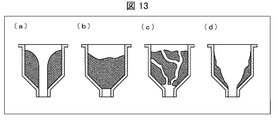

- FIG. 13 (a) is a rat hole

- FIG. 13 (b) is a bridge

- FIG. (C) is a blocking state

- FIG. 13 (d) is a state in which adhesion residue has occurred.

- the crushing method in which the particle size of the crushed material is adjusted by the clearance between the rotating grindstone like a millstone and the fixed grindstone, has the same basic idea even if the material is changed from natural stone to ceramic or metal. is there. This is the same in both dry crushing and wet crushing, which is a typical example in which crushing of buckwheat seeds in buckwheat production is performed by dry method and crushing of soybean in tofu production is performed by wet method. .. Milling by the stone mill method is used in various fields, but it is carried out by adjusting the clearance between the rotary grindstone part and the fixed grindstone part so that the desired particle size can be obtained by one-step crushing regardless of whether it is dry or wet. Has been done. Further, even in a crusher made of a metal such as stainless steel, the clearance between the rotary blade and the fixed blade is designed and implemented so that the crushed product of the desired size can be obtained by one-step crushing. ..

- cocoa beans that have been fermented, dried, roasted, and peeled and processed into what is called cocoa nibs are used.

- the stone mill method may be used, and the clearance between the stone mills is adjusted step by step. Grinding should be repeated multiple times with a gradual reduction in clearance until the desired smooth chocolate is obtained.

- the size of a single grain of cacao, which is the raw material, is relatively large and disadvantageous for clearance. That is, since cacao is gradually finely crushed, it takes time to obtain the desired particles.

- cacao For crushing cacao, wet crushing is adopted by utilizing the fact that the melting point of cacao is about 35 ° C and it becomes a liquid (paste) due to the frictional heat between the mortar and cacao nibs during crushing cacao nibs.

- the temperatures of cacao and mortar during crushing are determined by the circumstances and have not been controlled in the past. If the temperature is low, the cacao cannot flow in the mortar and sticks to the groove, cannot be crushed, and the load on the motor increases. On the other hand, if the temperature is too high, the cocoa may be scorched, degrading the quality of the cocoa.

- FIG. 1 is a perspective view of a crushing device 1 including a crushing unit 11 as the crusher of the present embodiment.

- FIG. 2 is a perspective view of the crushing unit 11 shown in FIG.

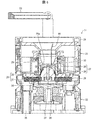

- FIG. 3 is an exploded perspective view of the crushing unit 11 shown in FIG.

- FIG. 4 is a perspective view including a vertical cross section of the crushing unit 11 shown in FIG.

- FIG. 5 is a front view of a vertical cross-sectional portion of the crushing unit 11 shown in FIG.

- the crushing device 1 includes a crushing unit 11, a heat insulating container 12, a hopper 13, a motor 14, and a powder take-out lever 15.

- the crushing unit 11 is housed inside the heat insulating container 12, and the hopper 13 is mounted on the crushing unit 11.

- the hopper 13 accommodates a solid material.

- the case where the solid raw material is cacao nibs will be described.

- the motor 14 is provided below the crushing device 1 and rotates the crushing portion 26 of the crushing unit 11.

- the powder take-out lever 15 is located on the side of the crushing device 1. By rotating the powder take-out lever 15 downward, the cacao nibs powder (cacao powder) crushed by the crushing unit 11 can be taken out from the take-out port 16.

- the crushing unit 11 has a housing portion 21 at the upper portion and a collection / transport portion 22 at the lower portion.

- the housing portion 21 has a handle 23 used when the crushing unit 11 is taken in and out of the inside of the heat insulating container 12.

- a hopper receiving portion 24, an introduction portion 25, and a crushing portion 26 are provided from top to bottom.

- the hopper receiving portion 24 receives the hopper 13 arranged on the crushing unit 11.

- the hopper receiving portion 24 has an opening at the lower end portion.

- the hopper 13 houses the cacao nibs, and the introduction unit 25 receives the cacao nibs supplied from the hopper 13 via the hopper receiving unit 24.

- the introduction portion 25 has an opening 25a at the lower end portion.

- the crushing portion 26 has a conical mortar 27 in the central portion and a flat mortar 28 around the conical mortar 27.

- the conical mortar 27 includes an inner mortar 29 which is a rotary mortar and an outer mortar 30 which is a fixed mortar.

- the outer mortar 30 has a cylindrical shape, and the inner mortar 29 is inserted into the outer mortar 30 and has a shape in which the outer diameter gradually decreases from the lower part to the upper part.

- the inside of the outer mortar 30 at the upper end of the conical mortar 27 is the inlet portion 33 of the cacao nibs.

- the conical mortar 27 crushes the cacao nibs 45 (see FIG. 6, solid raw material) charged from the introduction unit 25 into coarse cacao powder.

- the flat mortar 28 is composed of a lower mortar 31 which is a rotary mortar and an upper mortar 32 which is a fixed mortar.

- the lower mortar 31 is fixed to the outer peripheral portion of the inner mortar 29 and is integrated with the inner mortar 29.

- the upper mortar 32 is fixed to the outer peripheral portion of the outer mortar 30 and is integrated with the outer mortar 30.

- a central shaft 37 is provided at the center of the inner mortar 29 and the lower mortar 31.

- the flat mortar 28 grinds the coarse cacao powder formed by the conical mortar 27 into fine cacao powder.

- the recovery transport unit 22 has a material receiving unit 34 at the upper portion, a transport passage 35 connected to the material receiving unit 34, and a drive transmission unit 36 under the material receiving unit 34.

- a crushing portion 26 is arranged on the material receiving portion 34, and the material receiving portion 34 receives the cacao powder formed by the crushing portion 26.

- the transport passage 35 transports the cacao powder received by the material receiving unit 34 downward.

- the drive transmission unit 36 transmits the driving force of the motor 14 to the central shaft 37 of the crushing unit 26 mounted on the material receiving unit 34, and rotates the crushing unit 26 (inner mill 29 and lower mill 31).

- FIGS. 4 and 5 show a state in which the inner mortar 29 of the conical mortar 27 is provided with the adhesion prevention / stirring member 44 described with reference to FIG.

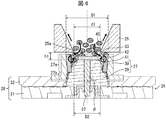

- FIG. 6 is an explanatory diagram showing a detailed configuration of the crushing unit 11 shown in FIG. 5 and an operation of the crushing unit 11.

- the crushing unit 11 includes a rotating anti-adhesion protrusion member 41 between the inner mortar 29 and the outer mortar 30 of the conical mortar 27.

- the adhesion prevention protrusion member 41 is bent diagonally downward so that one end side portion is fixed to the upper surface of the inner mortar 29 with a screw and the other end side portion is inserted between the inner mortar 29 and the outer mortar 30. ing.

- the other end side portion of the adhesion prevention protrusion member 41 scrapes off the accumulated powder 42 generated on the inner peripheral surface of the outer mortar 30.

- the adhesion prevention protrusion member 41 is provided on the inner mortar 29 and is not limited to a configuration in which the inner mortar 29 rotates together, and may be configured to be driven by another mechanism to rotate.

- the conical mortar 27 has a coarse crushing region 27a at the upper portion and a fine crushing region 27b at the lower portion, and the other end portion of the adhesion prevention protrusion member 41 is roughly crushed. It protrudes between the outer mortar 30 and the inner mortar 29 in the region 27a.

- the coarse crushed region 27a has a large gap between the outer mortar 30 and the inner mortar 29

- the fine crushed region 27b has a small gap between the outer mortar 30 and the inner mortar 29, and the deposited powder 42 is coarse. It tends to occur on the inner peripheral surface of the outer mortar 30 of the crushing region 27a. Therefore, by projecting the other end of the adhesion prevention protrusion member 41 between the outer mortar 30 and the inner mortar 29 of the coarse crushing region 27a, the generation of the deposited powder 42 can be appropriately suppressed.

- the diameter of the opening 25a of the introduction portion 25 is smaller than the inner diameter of the outer mortar 30 of the inlet portion 33 of the conical mortar 27.

- the rotational force of the inner mortar 29 propagates between the cocoa nibs 45, and the cocoa nibs 45 of the introduction portion 25 are also moved.

- the cocoa nibs 45 are charged into the inlet 33 of the conical mortar 27.

- the cocoa nibs 45 and the cocoa powder formed by crushing the cocoa nibs 45 rotate in a small area in the inlet 33 of the conical mortar 27 under the introduction portion 25, and it becomes difficult for the cocoa nibs 45 to flow back to the introduction portion 25.

- the range in which the force is propagated can also be suppressed. This is because the lower surface of the introduction portion 25 becomes a so-called barb, and the backflow of the cacao nibs 45 and the cacao powder to the introduction portion 25 is suppressed. Further, the rubbing between the cacao nibs 45 can be reduced, and the generation of cacao powder at the introduction portion 25 can be suppressed. As a result, the accumulation of cacao powder (powder of solid raw material) in the introduction unit 25 (deposited powder 114 shown in FIG. 12) is suppressed, and the cacao nibs 45 are smoothly charged from the introduction unit 25 to the conical mortar 27. Can be done. Further, in the conical mortar 27, the backflow of the charged cacao nibs 45 to the introduction portion 25 is suppressed on the lower surface of the introduction portion 25, and the charged cacao nibs 45 can be efficiently crushed.

- the reason why the deposited powder 114 is generated on the inner peripheral surface of the introduction portion 112 will be described.

- the cacao nibs 113 exceeding the crushing capacity of the conical mortar 111 are charged into the inlet portion 123, the cocoa nibs 113 that cannot fit inside the conical mortar 111 and the cocoa powder formed by crushing the cocoa nibs 113 with the conical mortar 111 , As shown by an arrow in FIG. 12, the backflow flows from the inlet portion 123 of the conical mortar 111 to the introduction portion 112. Further, the cacao powder has heat when it is crushed, the conical mortar 111 has heat due to friction during the crushing operation, and the heat of the conical mortar 111 is transferred to the introduction portion 112.

- the oil is dissolved from the cacao powder, and the cacao powder is deposited on the inner surface of the introduction portion 112 (deposited powder 114 in FIG. 12).

- the cacao nibs 113 cannot be smoothly supplied from the introduction unit 112 to the conical mortar 111.

- FIG. 13 shows a general trouble state resulting from an increase in the deposited powder 114 shown in FIG.

- FIG. 13A shows a rat hole

- FIG. 13B shows a bridge

- FIG. 13C shows a blocking state

- FIG. 13D shows a state in which adhesion remains.

- the inner diameter of the introduction portion 25 gradually decreases from the upper portion toward the opening portion 25a. That is, the inner surface of the introduction portion 25 is an inclined surface whose diameter gradually decreases from the upper portion toward the opening 25a.

- the cacao nibs 45 receive the rotational force propagated from the inlet 33 of the conical mortar 27, and rotate (turn) also at the introduction portion 25 near the opening 25a. Due to this rotation, a force that tends to move in the centrifugal (outward) direction acts on the cacao nibs 45, the cacao nibs 45 and the cacao powder are pressed against the inner surface of the introduction portion 25, and the cacao powder is deposited so as to be gradually compacted. Become.

- the cacao powder can move upward and pass the force of pushing against the inner surface of the introduction portion 25.

- the cacao powder easily moves upward along the slope of the introduction portion 25, and is near the opening 25a of the introduction portion 25. It becomes difficult to accumulate in one place.

- the inclination angle of the inner surface of the introduction portion 25 with respect to the horizontal plane is preferably 45 ° ⁇ ⁇ 75 °, where ⁇ is the inclination angle. If the inclination angle ⁇ is 45 ° or less, the diameter of the introduction portion 25 becomes too large, and cacao nibs may remain on the slope. On the other hand, when the inclination angle ⁇ is 75 ° or more, the effect of releasing the force for compacting the cacao powder acting in the centrifugal direction due to rotation is small. Therefore, the cacao powder returned from the conical mortar 27 to the introduction portion 25 is difficult to move above the introduction portion 25, and easily accumulates in the vicinity of the opening 25a.

- the relationship between the inner diameter of the outer mortar 30 of the inlet 33 of the conical mortar 27 and the diameter of the opening 25a of the introduction portion 25 is that the inner diameter of the outer mortar 30 of the inlet 33 is D1 and the diameter of the opening 25a of the introduction portion 25.

- d1 it is preferable that 0.5 ⁇ d1 / D1 ⁇ 0.8.

- the gap between the lower surface of the introduction portion 25 and the upper surface of the inner mortar 29 and the outer diameter of the upper end portion of the inner mortar 29 is the gap h1 and the inner mortar 29.

- the outer diameter of the upper end portion of the above is D2, it is preferable that 0.5 ⁇ 2h1 / (D1-D2) ⁇ 1.

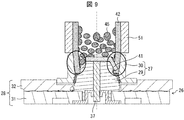

- FIG. 7 is an explanatory diagram showing a detailed configuration of the crushing unit 11 of the present embodiment and the operation of the crushing unit 11.

- FIG. 8 is a perspective view showing a state in which the adhesion prevention / stirring member 44 of the conical mortar 27 is attached to the inner mortar 29.

- the crushing unit 11 of the present embodiment includes a rotating rod-shaped stirring member 43 provided in the moving path of the cacao nibs 45 leading to the introduction portion 25.

- the stirring member 43 is connected to one end of the adhesion prevention protrusion member 41, and is configured as a part of the adhesion prevention / stirring member 44 having the adhesion prevention protrusion member 41 and the stirring member 43.

- the stirring member 43 is inserted into the inside of the introduction portion 25 through the opening 25a of the introduction portion 25 and reaches the lower part of the hopper receiving portion 24. Since the stirring member 43 is provided on the inner mortar 29, it rotates together with the inner mortar 29. As a result, it is possible to prevent the cacao nibs 45 from staying in the movement path of the cacao nibs 45 leading to the introduction unit 25, and to smoothly feed the cacao nibs 45 into the conical mortar 27 via the introduction unit 25. (Effect of claim 3)

- the stirring member 43 is not limited to the configuration provided as a part of the adhesion prevention / stirring member 44, and may be provided independently. Further, the stirring member 43 is not limited to the configuration provided in the inner mortar 29 and rotating together with the inner mortar 29, and may be configured to be driven by another mechanism to rotate.

- FIG. 9 is an explanatory diagram showing a detailed configuration of the crushing unit 11 of the present embodiment and the operation of the crushing unit 11.

- the crushing unit 11 of the present embodiment includes an introduction unit 51 instead of the introduction unit 25 shown in FIG.

- the introduction portion 51 has a cylindrical shape, and the deposited powder 42 is more likely to be generated on the inner peripheral portion as compared with the introduction portion 25.

- the adhesion prevention protrusion member 41 suppresses the generation of the accumulated powder 42 on the inner peripheral surface of the outer mortar 30, it becomes difficult to put the cacao nibs 45 from the introduction portion 51 into the conical mortar 27 as a whole. It can be suppressed.

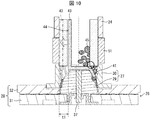

- FIG. 10 is an explanatory diagram showing a detailed configuration of the crushing unit 11 of the present embodiment and the operation of the crushing unit 11.

- FIG. 11 is a plan view showing the positional relationship between the introduction portion 51 and the stirring member 43 shown in FIG.

- the crushing unit 11 of the present embodiment includes an introduction unit 51 instead of the introduction unit 25 shown in FIG. 7.

- the introduction portion 51 has a cylindrical shape, and the deposited powder 42 is more likely to be generated on the inner peripheral portion as compared with the introduction portion 25.

- the adhesion prevention protrusion member 41 suppresses the generation of the accumulated powder 42 on the inner peripheral surface of the outer mortar 30, it becomes difficult to put the cacao nibs 45 from the introduction portion 51 into the conical mortar 27 as a whole. It can be suppressed.

- the gap between the inner surface of the introduction portion 51 and the stirring member 43 of the adhesion prevention / stirring member 44 is t

- the inner diameter of the outer mill 30 of the inlet portion 33 is D1

- the inner diameter of the introduction portion 51 Is D2, and it is preferable that 1 ⁇ 2t / (D1-D2) ⁇ 1.5.

- the introduction portion 51 bites the cacao nibs 45 between the stirring member 43 and the inner peripheral surface of the introduction portion 51 to crush the cacao nibs 45, and the inner peripheral surface of the introduction portion 51 becomes muddy by heat. It is possible to suppress a situation in which a piled portion 46 of the cacao nibs 45 is formed, and the introduced portion 51 is easily clogged by the deposited portion 46.

- the crusher according to the first aspect of the present invention has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and is inserted into an inlet portion between the inner mortar and the outer mortar. It is provided with a crushing portion for crushing a solid raw material having an oil content with the conical mortar, and an adhesion prevention protrusion member provided between the outer mortar and the inner mortar and rotating.

- the conical mortar has a coarse crushing region at an upper portion and a fine crushing region at a lower portion

- the adhesion prevention protrusion member has one end thereof. It may be fixed to the inner mortar and the other end portion may protrude between the outer mortar and the inner mortar in the coarse crushing region.

- the crusher according to the third aspect of the present invention has an opening at the lower end in the first or second aspect, and the solid raw material supplied to the inside is charged from the opening into the inlet of the conical mortar.

- a structure may be configured in which a lower end portion is fixed to the upper end portion of the inner mortar and a rod-shaped stirring member inserted from the opening portion into the inside of the introduction portion is provided.

- the gap between the inner surface of the introduction portion and the stirring member is t

- the inner diameter of the outer mill of the inlet portion is D1

- the inner diameter of the introduction portion is D2. Then, 1 ⁇ 2t / (D1-D2) ⁇ 1.5 may be established.

- the crusher according to the fifth aspect of the present invention may have a standing structure in which the inner diameter of the introduction portion gradually decreases from the upper part toward the opening.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Polymers & Plastics (AREA)

- Mechanical Engineering (AREA)

- Crushing And Grinding (AREA)

Abstract

The purpose of the present invention is to minimize accumulation of solid raw material powder on the inner peripheral surface of an outer mortar in the entrance part of a conical mortar. A pulverizing unit is provided with: a pulverizing section which has a conical mortar composed of an inner mortar and an outer mortar, and in which a solid raw material loaded into an entrance part between the inner mortar and the outer mortar, the solid raw material having an oil component, is pulverized in the conical mortar; and an adhesion-preventing protruding member that is provided between the inner mortar and the outer mortar and that rotates.

Description

本発明の一態様は、カカオ豆等の固体原料を粉砕する粉砕機に関する。本願は、2019年3月29日に日本で出願された特願2019-068931号に基づき優先権を主張し、その内容をここに援用する。

One aspect of the present invention relates to a crusher that crushes a solid raw material such as cacao beans. The present application claims priority based on Japanese Patent Application No. 2019-068931 filed in Japan on March 29, 2019, the contents of which are incorporated herein by reference.

この種の粉砕機としては、例えば特許文献1に開示されている電動粉挽き機が知られている。この電動粉挽き機は、被粉砕物が投入され、次段に送る開口を有する投入部と、導入調整部からの被粉砕物を粗く粉砕する粗粉挽き部と、粗粉挽き部で粉砕された被粉砕物をさらに細かく粉砕する精細粉挽き部と、精細粉挽き部への被粉砕物の導入量を調整する調整部とを備えている。

As a crusher of this type, for example, an electric powder grinder disclosed in Patent Document 1 is known. In this electric powder grinder, the material to be crushed is charged and crushed by a charging unit having an opening to be sent to the next stage, a coarse powder grinding unit that roughly crushes the material to be crushed from the introduction adjustment unit, and a coarse powder grinding unit. It is provided with a fine powder grinding unit that further finely crushes the material to be crushed, and an adjusting unit that adjusts the amount of the material to be crushed into the fine powder grinding unit.

また、特許文献1では、導入領域の温度が被粉砕物が有する油分の温度より低くなるように構成し、排出領域の温度が被粉砕物が有する油分の温度よりも高くなるよう構成し、カカオ豆の粉同士の固着を防止できるようにしている。

Further, in Patent Document 1, the temperature of the introduction region is configured to be lower than the temperature of the oil content of the object to be crushed, and the temperature of the discharge region is configured to be higher than the temperature of the oil content of the object to be crushed. It is designed to prevent the bean powder from sticking to each other.

しかしながら、上記従来の粉砕機は、次のような問題点を有している。図12は、従来の粉砕機の要部の構成を示す縦断面図である。図12に示す粉砕機101は、回転臼である内臼121と固定臼である外臼122とからなるコニカル臼111を有している。内臼121と外臼122との間の入口部123には、粉砕される固体原料が導入部112から投入される。導入部112は、円筒形であり、下端部の内径が外臼122の内径と略同一になっている。固体原料は例えばカカオニブである。カカオニブは、カカオ豆を焙煎して粗粉砕したものである。カカオ豆は、油分が50%程度であり、融点は35℃程度である。

However, the above-mentioned conventional crusher has the following problems. FIG. 12 is a vertical cross-sectional view showing the configuration of a main part of a conventional crusher. The crusher 101 shown in FIG. 12 has a conical mortar 111 including an inner mortar 121 which is a rotary mortar and an outer mortar 122 which is a fixed mortar. A solid raw material to be crushed is introduced from the introduction portion 112 into the inlet portion 123 between the inner mortar 121 and the outer mortar 122. The introduction portion 112 has a cylindrical shape, and the inner diameter of the lower end portion is substantially the same as the inner diameter of the outer mortar 122. The solid raw material is, for example, cacao nibs. Cacao nibs are roasted and coarsely crushed cocoa beans. The cacao beans have an oil content of about 50% and a melting point of about 35 ° C.

このような粉砕機101において、カカオニブ113を粉砕するために、内臼121が回転すると、内臼121と外臼122とによりカカオニブ113が粉砕される。この場合、コニカル臼111では、カカオニブ113を長時間粉砕していると、入口部123における外臼122の内周面に堆積粉末114が生じ、コニカル臼111での粉砕効率が低下する。堆積粉末114が生じる理由は、粉砕されることでカカオ粉末が熱を持ち、コニカル臼111が粉砕動作時の摩擦によって熱を持ち、これら熱によってカカオ粉末から油分が溶け出し、カカオ粉末が入口部123における外臼122の内周面に堆積するためである。

In such a crusher 101, when the inner mortar 121 rotates in order to crush the cacao nibs 113, the cocoa nibs 113 are crushed by the inner mortar 121 and the outer mortar 122. In this case, when the cacao nibs 113 are crushed for a long time in the conical mortar 111, the accumulated powder 114 is generated on the inner peripheral surface of the outer mortar 122 at the inlet portion 123, and the crushing efficiency in the conical mortar 111 is lowered. The reason why the deposited powder 114 is generated is that the cacao powder has heat when it is crushed, and the conical mill 111 has heat due to friction during the crushing operation, and these heats dissolve oil from the cacao powder, and the cacao powder enters the inlet. This is because it is deposited on the inner peripheral surface of the outer mill 122 in 123.

本発明の一態様は、コニカル臼の入口部における外臼の内周面での固体原料の粉末の堆積を抑制することができる粉砕機を実現することを目的とする。

One aspect of the present invention is to realize a crusher capable of suppressing the deposition of powder of a solid raw material on the inner peripheral surface of the outer mortar at the inlet of the conical mortar.

上記の課題を解決するために、本発明の一態様に係る粉砕機は、回転臼である内臼と固定臼である外臼とからなるコニカル臼を有し、前記内臼と前記外臼との間の入口部に投入された、油分を有する固体原料を前記コニカル臼にて粉砕する粉砕部と、下端部に開口部を有し、前記開口部の径が前記入口部の前記外臼の内径よりも小さく、供給された前記固体原料を前記開口部から前記コニカル臼の前記入口部に投入する導入部とを備えている。

In order to solve the above problems, the crusher according to one aspect of the present invention has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and the inner mortar and the outer mortar A crushing portion for crushing a solid raw material having oil content into the inlet portion between the two with the conical mortar, and an opening at the lower end portion, the diameter of the opening portion of the outer mortar of the inlet portion. It is provided with an introduction portion that is smaller than the inner diameter and that feeds the supplied solid raw material from the opening into the inlet of the conical mortar.

本発明の一態様によれば、コニカル臼の入口部における外臼の内周面での固体原料の粉末の堆積を抑制することができる。

According to one aspect of the present invention, it is possible to suppress the deposition of powder of a solid raw material on the inner peripheral surface of the outer mortar at the inlet of the conical mortar.

(固体原料の粉砕についての概要)

穀類や豆類等の固体の粉砕は、固体が粉砕されることによって用途が飛躍的に拡大するため、さまざま食品に対して利用されている。しかしながら、均一な粉砕物を効率良く、かつ風味の劣化を防いで行うことの困難さもまた良く知られているところである。粉砕効率を重視すれば、粉砕物の粒子が粗く不均一となり、小麦粉、蕎麦粉等では滑らかさが失われ、うどんや蕎麦の品質が低下するのみならず、粉砕時に余分な熱が掛かるために酸化による風味の劣化が起こり易い。粉砕時に余分な摩擦熱が粉砕物に加わった場合、お茶では新鮮な風味が損なわれ、豆乳では青臭さの強いものになってしまう。臼をゆっくりと回転させて粉砕物を粉砕するという古くからの考え方は、摩擦熱の発生が抑えられるので、加工中の粉砕物の風味の劣化を防ぐという点で極めて理にかなっている。 (Overview of crushing solid raw materials)

The crushing of solids such as cereals and beans is used for various foods because the crushing of solids dramatically expands the applications. However, it is also well known that it is difficult to efficiently produce a uniform pulverized product and prevent deterioration of flavor. If crushing efficiency is emphasized, the particles of the crushed product will be coarse and non-uniform, and the smoothness of wheat flour, buckwheat flour, etc. will be lost, and not only the quality of udon and buckwheat will deteriorate, but also extra heat will be applied during crushing. Deterioration of flavor due to oxidation is likely to occur. If extra frictional heat is applied to the crushed material during crushing, the fresh flavor of tea will be impaired and the soymilk will have a strong green odor. The old idea of slowly rotating the mortar to crush the crushed material makes a lot of sense in that it suppresses the generation of frictional heat and thus prevents deterioration of the flavor of the crushed material during processing.

穀類や豆類等の固体の粉砕は、固体が粉砕されることによって用途が飛躍的に拡大するため、さまざま食品に対して利用されている。しかしながら、均一な粉砕物を効率良く、かつ風味の劣化を防いで行うことの困難さもまた良く知られているところである。粉砕効率を重視すれば、粉砕物の粒子が粗く不均一となり、小麦粉、蕎麦粉等では滑らかさが失われ、うどんや蕎麦の品質が低下するのみならず、粉砕時に余分な熱が掛かるために酸化による風味の劣化が起こり易い。粉砕時に余分な摩擦熱が粉砕物に加わった場合、お茶では新鮮な風味が損なわれ、豆乳では青臭さの強いものになってしまう。臼をゆっくりと回転させて粉砕物を粉砕するという古くからの考え方は、摩擦熱の発生が抑えられるので、加工中の粉砕物の風味の劣化を防ぐという点で極めて理にかなっている。 (Overview of crushing solid raw materials)

The crushing of solids such as cereals and beans is used for various foods because the crushing of solids dramatically expands the applications. However, it is also well known that it is difficult to efficiently produce a uniform pulverized product and prevent deterioration of flavor. If crushing efficiency is emphasized, the particles of the crushed product will be coarse and non-uniform, and the smoothness of wheat flour, buckwheat flour, etc. will be lost, and not only the quality of udon and buckwheat will deteriorate, but also extra heat will be applied during crushing. Deterioration of flavor due to oxidation is likely to occur. If extra frictional heat is applied to the crushed material during crushing, the fresh flavor of tea will be impaired and the soymilk will have a strong green odor. The old idea of slowly rotating the mortar to crush the crushed material makes a lot of sense in that it suppresses the generation of frictional heat and thus prevents deterioration of the flavor of the crushed material during processing.

石臼のように回転する砥石と固定された砥石の間のクリアランスによって、粉砕物の粒度を調整するという粉砕方式は、材質が天然石からセラミック、金属へと変わっても、基本的な考えは同じである。これは乾式粉砕においても、湿式粉砕に於いても同様であり、蕎麦製造における蕎麦の実の粉砕は乾式で行われ、豆腐製造に於ける大豆の粉砕は湿式で行われている代表例である。石臼方式での粉砕は、様々な分野で利用されているが、乾式、湿式を問わず1段の粉砕で目的の粒子サイズとなるよう、回転砥石部と固定砥石部のクリアランス調整を行って実施されている。また、材質をステンレスの様な金属とした粉砕機においても、その回転刃と固定刃とのクリアランスの調整は、1段の粉砕で目的のサイズの粉砕物となるよう設計され、実施されている。

The crushing method, in which the particle size of the crushed material is adjusted by the clearance between the rotating grindstone like a millstone and the fixed grindstone, has the same basic idea even if the material is changed from natural stone to ceramic or metal. is there. This is the same in both dry crushing and wet crushing, which is a typical example in which crushing of buckwheat seeds in buckwheat production is performed by dry method and crushing of soybean in tofu production is performed by wet method. .. Milling by the stone mill method is used in various fields, but it is carried out by adjusting the clearance between the rotary grindstone part and the fixed grindstone part so that the desired particle size can be obtained by one-step crushing regardless of whether it is dry or wet. Has been done. Further, even in a crusher made of a metal such as stainless steel, the clearance between the rotary blade and the fixed blade is designed and implemented so that the crushed product of the desired size can be obtained by one-step crushing. ..

例えば、チョコレートの場合、カカオ豆を、発酵、乾燥、焙煎、皮の除去処理がなされ、いわゆるカカオニブと呼ばれる状態に加工されたものを使用する。チョコレート工房など店舗で粉砕する場合は石臼方式を利用することがあり、石臼同士のクリアランスを段階的に調整する。所望の滑らかなチョコレートになるまで、クリアランスを徐々に狭くしながら粉砕を複数回繰り返す必要がある。原料であるカカオの一粒のサイズはクリアランスに対して比較的大きく不利である。すなわち、カカオは徐々に細かく粉砕されるので、目的とする粒子となるまでに時間が掛かることとなる。

For example, in the case of chocolate, cocoa beans that have been fermented, dried, roasted, and peeled and processed into what is called cocoa nibs are used. When crushing at a store such as a chocolate workshop, the stone mill method may be used, and the clearance between the stone mills is adjusted step by step. Grinding should be repeated multiple times with a gradual reduction in clearance until the desired smooth chocolate is obtained. The size of a single grain of cacao, which is the raw material, is relatively large and disadvantageous for clearance. That is, since cacao is gradually finely crushed, it takes time to obtain the desired particles.

カカオの粉砕には、カカオの融点が35℃程度であり、カカオニブ粉砕時の臼とカカオニブとの摩擦熱により液(ペースト)状となることを利用し、湿式粉砕を採用する。粉砕中のカカオおよび臼の温度は成り行きで決まることになり従来制御されてこなかった。温度が低ければ、カカオが臼内で流動できず溝に固着し、粉砕できない上、モーターへの負荷が増大することになる。一方温度が高すぎる場合は、カカオが焦げ付くことがあり、カカオの品質を低下させることになる。

For crushing cacao, wet crushing is adopted by utilizing the fact that the melting point of cacao is about 35 ° C and it becomes a liquid (paste) due to the frictional heat between the mortar and cacao nibs during crushing cacao nibs. The temperatures of cacao and mortar during crushing are determined by the circumstances and have not been controlled in the past. If the temperature is low, the cacao cannot flow in the mortar and sticks to the groove, cannot be crushed, and the load on the motor increases. On the other hand, if the temperature is too high, the cocoa may be scorched, degrading the quality of the cocoa.

〔実施形態1〕

以下、本発明の一実施形態について、詳細に説明する。図1は、本実施形態の粉砕機としての粉砕ユニット11を備える粉砕装置1の斜視図である。図2は、図1に示した粉砕ユニット11の斜視図である。図3は、図2に示した粉砕ユニット11の分解斜視図である。図4は、図2に示した粉砕ユニット11の縦断面を含む斜視図である。図5は、図4に示した粉砕ユニット11の縦断面部分の正面図である。 [Embodiment 1]

Hereinafter, one embodiment of the present invention will be described in detail. FIG. 1 is a perspective view of a crushingdevice 1 including a crushing unit 11 as the crusher of the present embodiment. FIG. 2 is a perspective view of the crushing unit 11 shown in FIG. FIG. 3 is an exploded perspective view of the crushing unit 11 shown in FIG. FIG. 4 is a perspective view including a vertical cross section of the crushing unit 11 shown in FIG. FIG. 5 is a front view of a vertical cross-sectional portion of the crushing unit 11 shown in FIG.

以下、本発明の一実施形態について、詳細に説明する。図1は、本実施形態の粉砕機としての粉砕ユニット11を備える粉砕装置1の斜視図である。図2は、図1に示した粉砕ユニット11の斜視図である。図3は、図2に示した粉砕ユニット11の分解斜視図である。図4は、図2に示した粉砕ユニット11の縦断面を含む斜視図である。図5は、図4に示した粉砕ユニット11の縦断面部分の正面図である。 [Embodiment 1]

Hereinafter, one embodiment of the present invention will be described in detail. FIG. 1 is a perspective view of a crushing

(粉砕装置1の概要)

図1に示すように、粉砕装置1は、粉砕ユニット11、保温容器12、ホッパー13、モータ14および粉末取出しレバー15を備えている。 (Outline of crusher 1)

As shown in FIG. 1, the crushingdevice 1 includes a crushing unit 11, a heat insulating container 12, a hopper 13, a motor 14, and a powder take-out lever 15.

図1に示すように、粉砕装置1は、粉砕ユニット11、保温容器12、ホッパー13、モータ14および粉末取出しレバー15を備えている。 (Outline of crusher 1)

As shown in FIG. 1, the crushing

粉砕ユニット11は保温容器12の内部に収容され、ホッパー13は粉砕ユニット11の上に取り付けられている。ホッパー13は固体原料を収容する。本実施形態では固体原料がカカオニブである場合について説明する。モータ14は粉砕装置1の下部に設けられ、粉砕ユニット11の粉砕部26を回転させる。粉末取出しレバー15は粉砕装置1の側部に位置する。粉末取出しレバー15が下方へ回転操作されることにより、粉砕ユニット11にて粉砕されたカカオニブの粉末(カカオ粉末)を取出し口16から取り出すことができる。

The crushing unit 11 is housed inside the heat insulating container 12, and the hopper 13 is mounted on the crushing unit 11. The hopper 13 accommodates a solid material. In this embodiment, the case where the solid raw material is cacao nibs will be described. The motor 14 is provided below the crushing device 1 and rotates the crushing portion 26 of the crushing unit 11. The powder take-out lever 15 is located on the side of the crushing device 1. By rotating the powder take-out lever 15 downward, the cacao nibs powder (cacao powder) crushed by the crushing unit 11 can be taken out from the take-out port 16.

(粉砕ユニット11の構成)

図2から図5示すように、粉砕ユニット11は、上部に筐体部21を有し、下部に回収搬送部22を有している。筐体部21は、粉砕ユニット11を保温容器12の内部に対して出し入れする際に使用するハンドル23を有している。筐体部21の内部には、上から下方へ、ホッパー受部24、導入部25および粉砕部26が設けられている。 (Structure of crushing unit 11)

As shown in FIGS. 2 to 5, the crushingunit 11 has a housing portion 21 at the upper portion and a collection / transport portion 22 at the lower portion. The housing portion 21 has a handle 23 used when the crushing unit 11 is taken in and out of the inside of the heat insulating container 12. Inside the housing portion 21, a hopper receiving portion 24, an introduction portion 25, and a crushing portion 26 are provided from top to bottom.

図2から図5示すように、粉砕ユニット11は、上部に筐体部21を有し、下部に回収搬送部22を有している。筐体部21は、粉砕ユニット11を保温容器12の内部に対して出し入れする際に使用するハンドル23を有している。筐体部21の内部には、上から下方へ、ホッパー受部24、導入部25および粉砕部26が設けられている。 (Structure of crushing unit 11)

As shown in FIGS. 2 to 5, the crushing

ホッパー受部24は、粉砕ユニット11の上に配置されるホッパー13を受ける。ホッパー受部24は下端部に開口部を有する。ホッパー13はカカオニブを収容しており、導入部25は、ホッパー13からホッパー受部24を介して供給されるカカオニブを受け入れる。導入部25は下端部に開口部25aを有する。

The hopper receiving portion 24 receives the hopper 13 arranged on the crushing unit 11. The hopper receiving portion 24 has an opening at the lower end portion. The hopper 13 houses the cacao nibs, and the introduction unit 25 receives the cacao nibs supplied from the hopper 13 via the hopper receiving unit 24. The introduction portion 25 has an opening 25a at the lower end portion.

粉砕部26は、中央部にコニカル臼27を有し、コニカル臼27の周りに平臼28を有する。コニカル臼27は、回転臼である内臼29と固定臼である外臼30とからなる。外臼30は円筒形状を有し、内臼29は外臼30に挿入され、下部から上部へ向かうにしたがって、外径が漸次小さくなった形状を有する。コニカル臼27の上端部における外臼30の内側は、カカオニブの入口部33となっている。コニカル臼27は、導入部25から投入されたカカオニブ45(図6参照、固体原料)を粉砕し、粗いカカオ粉末とする。

The crushing portion 26 has a conical mortar 27 in the central portion and a flat mortar 28 around the conical mortar 27. The conical mortar 27 includes an inner mortar 29 which is a rotary mortar and an outer mortar 30 which is a fixed mortar. The outer mortar 30 has a cylindrical shape, and the inner mortar 29 is inserted into the outer mortar 30 and has a shape in which the outer diameter gradually decreases from the lower part to the upper part. The inside of the outer mortar 30 at the upper end of the conical mortar 27 is the inlet portion 33 of the cacao nibs. The conical mortar 27 crushes the cacao nibs 45 (see FIG. 6, solid raw material) charged from the introduction unit 25 into coarse cacao powder.

平臼28は、回転臼である下臼31と固定臼である上臼32とからなる。下臼31は内臼29の外周部に固定され、内臼29と一体となっている。上臼32は外臼30の外周部に固定され、外臼30と一体となっている。内臼29および下臼31の中心部には中心軸37が設けられている。平臼28は、コニカル臼27にて形成された粗いカカオ粉を微細なカカオ粉末に粉砕する。

The flat mortar 28 is composed of a lower mortar 31 which is a rotary mortar and an upper mortar 32 which is a fixed mortar. The lower mortar 31 is fixed to the outer peripheral portion of the inner mortar 29 and is integrated with the inner mortar 29. The upper mortar 32 is fixed to the outer peripheral portion of the outer mortar 30 and is integrated with the outer mortar 30. A central shaft 37 is provided at the center of the inner mortar 29 and the lower mortar 31. The flat mortar 28 grinds the coarse cacao powder formed by the conical mortar 27 into fine cacao powder.

回収搬送部22は、上部に材料受部34を有し、材料受部34に接続された搬送通路35を有し、材料受部34の下に駆動伝達部36を有している。材料受部34の上には粉砕部26が配置され、材料受部34は粉砕部26にて形成されたカカオ粉末を受ける。搬送通路35は、材料受部34が受けたカカオ粉末を下方へ搬送する。駆動伝達部36は、モータ14の駆動力を材料受部34上に載置されている粉砕部26の中心軸37に伝達し、粉砕部26(内臼29および下臼31)を回転させる。

The recovery transport unit 22 has a material receiving unit 34 at the upper portion, a transport passage 35 connected to the material receiving unit 34, and a drive transmission unit 36 under the material receiving unit 34. A crushing portion 26 is arranged on the material receiving portion 34, and the material receiving portion 34 receives the cacao powder formed by the crushing portion 26. The transport passage 35 transports the cacao powder received by the material receiving unit 34 downward. The drive transmission unit 36 transmits the driving force of the motor 14 to the central shaft 37 of the crushing unit 26 mounted on the material receiving unit 34, and rotates the crushing unit 26 (inner mill 29 and lower mill 31).

なお、図4および図5では、コニカル臼27の内臼29に図7にて説明する付着防止・撹拌部材44が設けられている状態を示している。

Note that FIGS. 4 and 5 show a state in which the inner mortar 29 of the conical mortar 27 is provided with the adhesion prevention / stirring member 44 described with reference to FIG.

(粉砕ユニット11の詳細な構成、動作および利点)

図6は、図5に示した粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。 (Detailed configuration, operation and advantages of the crushing unit 11)

FIG. 6 is an explanatory diagram showing a detailed configuration of the crushingunit 11 shown in FIG. 5 and an operation of the crushing unit 11.

図6は、図5に示した粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。 (Detailed configuration, operation and advantages of the crushing unit 11)

FIG. 6 is an explanatory diagram showing a detailed configuration of the crushing

図6に示すように、粉砕ユニット11は、コニカル臼27の内臼29と外臼30との間に、回転する付着防止突起部材41を備えている。付着防止突起部材41は、一端部側部分が内臼29の上面にねじにて固定され、他端部側部分が内臼29と外臼30との間に入り込むように、斜め下方へ折り曲げられている。付着防止突起部材41の他端部側部分は、外臼30の内周面に生じた堆積粉末42を掻き取るようになっている。これにより、粉砕ユニット11では、コニカル臼27に堆積粉末42が生じることによるコニカル臼27での粉砕効率の低下を抑制できるようにしている。

As shown in FIG. 6, the crushing unit 11 includes a rotating anti-adhesion protrusion member 41 between the inner mortar 29 and the outer mortar 30 of the conical mortar 27. The adhesion prevention protrusion member 41 is bent diagonally downward so that one end side portion is fixed to the upper surface of the inner mortar 29 with a screw and the other end side portion is inserted between the inner mortar 29 and the outer mortar 30. ing. The other end side portion of the adhesion prevention protrusion member 41 scrapes off the accumulated powder 42 generated on the inner peripheral surface of the outer mortar 30. As a result, in the crushing unit 11, it is possible to suppress a decrease in crushing efficiency in the conical mortar 27 due to the formation of the deposited powder 42 in the conical mortar 27.

なお、付着防止突起部材41は、内臼29に設けられ、内臼29ともに回転する構成に限定されず、他の機構に駆動されて回転する構成であってもよい。

The adhesion prevention protrusion member 41 is provided on the inner mortar 29 and is not limited to a configuration in which the inner mortar 29 rotates together, and may be configured to be driven by another mechanism to rotate.

また、粉砕ユニット11では、さらに詳細には、コニカル臼27は、上部に粗粉砕領域27aを有し、下部に細粉砕領域27bを有し、付着防止突起部材41の他端部は、粗粉砕領域27aの外臼30と内臼29との間に突出している。コニカル臼27では、粗粉砕領域27aは外臼30と内臼29との間の隙間が大きく、細粉砕領域27bは外臼30と内臼29との間の隙間が小さく、堆積粉末42は粗粉砕領域27aの外臼30の内周面に生じ易い。したがって、付着防止突起部材41の他端部を粗粉砕領域27aの外臼30と内臼29との間に突出させることにより、堆積粉末42の発生を適切に抑制することができる。

Further, in the crushing unit 11, more specifically, the conical mortar 27 has a coarse crushing region 27a at the upper portion and a fine crushing region 27b at the lower portion, and the other end portion of the adhesion prevention protrusion member 41 is roughly crushed. It protrudes between the outer mortar 30 and the inner mortar 29 in the region 27a. In the conical mortar 27, the coarse crushed region 27a has a large gap between the outer mortar 30 and the inner mortar 29, the fine crushed region 27b has a small gap between the outer mortar 30 and the inner mortar 29, and the deposited powder 42 is coarse. It tends to occur on the inner peripheral surface of the outer mortar 30 of the crushing region 27a. Therefore, by projecting the other end of the adhesion prevention protrusion member 41 between the outer mortar 30 and the inner mortar 29 of the coarse crushing region 27a, the generation of the deposited powder 42 can be appropriately suppressed.

また、粉砕ユニット11では、導入部25の開口部25aの径は、コニカル臼27の入口部33の外臼30の内径よりも小さくなっている。コニカル臼27の入口部33において、内臼29の回転力はカカオニブ45同士を伝搬し、導入部25のカカオニブ45も動かされることになるが、上記構成により、コニカル臼27の入口部33に投入されたカカオニブ45およびカカオニブ45を粉砕して形成されたカカオ粉末は、導入部25の下のコニカル臼27の入口部33内の小さい範囲にて回転し、導入部25へ逆流し難くなり、回転力が伝搬される範囲も抑制できる。これは、導入部25の下面がいわゆる返しとなり、カカオニブ45およびカカオ粉末の導入部25への逆流を抑制するためである。さらに、カカオニブ45同士の擦れを低減し、導入部25でのカカオ粉末の発生を抑制できる。この結果、導入部25でのカカオ粉末(固体原料の粉末)の堆積(図12に示した堆積粉末114)を抑制し、導入部25からコニカル臼27へのカカオニブ45の投入を円滑に行うことができる。また、コニカル臼27では、投入されたカカオニブ45の導入部25への逆流を導入部25の下面にて抑制し、投入されたカカオニブ45を効率よく粉砕することができる。

Further, in the crushing unit 11, the diameter of the opening 25a of the introduction portion 25 is smaller than the inner diameter of the outer mortar 30 of the inlet portion 33 of the conical mortar 27. At the inlet 33 of the conical mortar 27, the rotational force of the inner mortar 29 propagates between the cocoa nibs 45, and the cocoa nibs 45 of the introduction portion 25 are also moved. However, according to the above configuration, the cocoa nibs 45 are charged into the inlet 33 of the conical mortar 27. The cocoa nibs 45 and the cocoa powder formed by crushing the cocoa nibs 45 rotate in a small area in the inlet 33 of the conical mortar 27 under the introduction portion 25, and it becomes difficult for the cocoa nibs 45 to flow back to the introduction portion 25. The range in which the force is propagated can also be suppressed. This is because the lower surface of the introduction portion 25 becomes a so-called barb, and the backflow of the cacao nibs 45 and the cacao powder to the introduction portion 25 is suppressed. Further, the rubbing between the cacao nibs 45 can be reduced, and the generation of cacao powder at the introduction portion 25 can be suppressed. As a result, the accumulation of cacao powder (powder of solid raw material) in the introduction unit 25 (deposited powder 114 shown in FIG. 12) is suppressed, and the cacao nibs 45 are smoothly charged from the introduction unit 25 to the conical mortar 27. Can be done. Further, in the conical mortar 27, the backflow of the charged cacao nibs 45 to the introduction portion 25 is suppressed on the lower surface of the introduction portion 25, and the charged cacao nibs 45 can be efficiently crushed.

ここで、図12示した粉砕機101において、導入部112の内周面に堆積粉末114が発生する理由について説明する。コニカル臼111での粉砕能力以上のカカオニブ113が入口部123に投入された場合、コニカル臼111の内部に入りきらないカカオニブ113、およびコニカル臼111によりカカオニブ113を粉砕して形成されたカカオ粉末は、図12に矢印にて示すように、コニカル臼111の入口部123から導入部112へと逆流する。また、カカオ粉末は粉砕されることで熱を持ち、コニカル臼111は粉砕動作時の摩擦によって熱を持ち、コニカル臼111の熱は導入部112へと伝わる。このため、カカオ粉末から油分が溶け出し、導入部112の内面にカカオ粉末が堆積する(図12の堆積粉末114)。この結果、導入部112からコニカル臼111へのカカオニブ113の供給を円滑に行えなくなる。

Here, in the crusher 101 shown in FIG. 12, the reason why the deposited powder 114 is generated on the inner peripheral surface of the introduction portion 112 will be described. When the cacao nibs 113 exceeding the crushing capacity of the conical mortar 111 are charged into the inlet portion 123, the cocoa nibs 113 that cannot fit inside the conical mortar 111 and the cocoa powder formed by crushing the cocoa nibs 113 with the conical mortar 111 , As shown by an arrow in FIG. 12, the backflow flows from the inlet portion 123 of the conical mortar 111 to the introduction portion 112. Further, the cacao powder has heat when it is crushed, the conical mortar 111 has heat due to friction during the crushing operation, and the heat of the conical mortar 111 is transferred to the introduction portion 112. Therefore, the oil is dissolved from the cacao powder, and the cacao powder is deposited on the inner surface of the introduction portion 112 (deposited powder 114 in FIG. 12). As a result, the cacao nibs 113 cannot be smoothly supplied from the introduction unit 112 to the conical mortar 111.

図13は、図12に示した堆積粉末114が増加した結果に生じる一般的なトラブルの状態を示す。図13の(a)はラットホール、図13の(b)はブリッジ、図13の(c)はブロッキング、図13の(d)は付着残留が生じた状態である。

FIG. 13 shows a general trouble state resulting from an increase in the deposited powder 114 shown in FIG. FIG. 13A shows a rat hole, FIG. 13B shows a bridge, FIG. 13C shows a blocking state, and FIG. 13D shows a state in which adhesion remains.

また、本実施形態の粉砕ユニット11では、導入部25の内径は、上部から開口部25aに向うにしたがって漸次小さくなっている。すなわち、導入部25の内面は、上部から開口部25aに向うにしたがって径が漸次小さくなる傾斜面となっている。カカオニブ45は、コニカル臼27の入口部33から伝搬される回転力を受け、開口部25a付近の導入部25においても回転(旋回)することになる。この回転によりカカオニブ45には遠心(外)方向に移動しようとする力が働き、カカオニブ45およびカカオ粉末は導入部25の内面に押しつけられ、カカオ粉末は徐々に押し固められるように堆積することになる。そこで、導入部25が傾斜面を備えることで、カカオ粉末は、上方へと移動し、導入部25の内面に押しけようとする力を受け流すことが可能となる。これにより、コニカル臼27から導入部25へカカオ粉末が戻ってきた場合であっても、そのカカオ粉末は、導入部25の斜面に沿って上方へ移動し易く、導入部25の開口部25a付近の一か所に堆積し難くなる。

Further, in the crushing unit 11 of the present embodiment, the inner diameter of the introduction portion 25 gradually decreases from the upper portion toward the opening portion 25a. That is, the inner surface of the introduction portion 25 is an inclined surface whose diameter gradually decreases from the upper portion toward the opening 25a. The cacao nibs 45 receive the rotational force propagated from the inlet 33 of the conical mortar 27, and rotate (turn) also at the introduction portion 25 near the opening 25a. Due to this rotation, a force that tends to move in the centrifugal (outward) direction acts on the cacao nibs 45, the cacao nibs 45 and the cacao powder are pressed against the inner surface of the introduction portion 25, and the cacao powder is deposited so as to be gradually compacted. Become. Therefore, when the introduction portion 25 is provided with an inclined surface, the cacao powder can move upward and pass the force of pushing against the inner surface of the introduction portion 25. As a result, even when the cacao powder is returned from the conical mortar 27 to the introduction portion 25, the cacao powder easily moves upward along the slope of the introduction portion 25, and is near the opening 25a of the introduction portion 25. It becomes difficult to accumulate in one place.

導入部25の内面の水平面に対する傾斜角度は、傾斜角度をθとすると、45°<θ<75°であることが好ましい。傾斜角度θは、45°以下にすると、導入部25の径が大きくなり過ぎる上、斜面にカカオニブが残留することがある。一方、傾斜角度θは、75°以上にすると、回転による遠心方向に働くカカオ粉末を押し固めようとする力を上方へ逃がす効果が少ない。したがって、コニカル臼27から導入部25へ戻ってきたカカオ粉末が導入部25の上方へ移動し難く、開口部25a付近にて堆積し易くなる。

The inclination angle of the inner surface of the introduction portion 25 with respect to the horizontal plane is preferably 45 ° <θ <75 °, where θ is the inclination angle. If the inclination angle θ is 45 ° or less, the diameter of the introduction portion 25 becomes too large, and cacao nibs may remain on the slope. On the other hand, when the inclination angle θ is 75 ° or more, the effect of releasing the force for compacting the cacao powder acting in the centrifugal direction due to rotation is small. Therefore, the cacao powder returned from the conical mortar 27 to the introduction portion 25 is difficult to move above the introduction portion 25, and easily accumulates in the vicinity of the opening 25a.

コニカル臼27の入口部33の外臼30の内径と導入部25の開口部25aの径との関係は、入口部33の外臼30の内径をD1、導入部25の開口部25aの径をd1とすると、0.5<d1/D1<0.8であることが好ましい。

The relationship between the inner diameter of the outer mortar 30 of the inlet 33 of the conical mortar 27 and the diameter of the opening 25a of the introduction portion 25 is that the inner diameter of the outer mortar 30 of the inlet 33 is D1 and the diameter of the opening 25a of the introduction portion 25. When d1, it is preferable that 0.5 <d1 / D1 <0.8.

導入部25の下面と内臼29の上面との隙間、および内臼29の上端部の外径の関係は、導入部25の下面と内臼29の上面との隙間を隙間h1、内臼29の上端部の外径をD2とすると、0.5<2h1/(D1-D2)<1であることが好ましい。

Regarding the relationship between the gap between the lower surface of the introduction portion 25 and the upper surface of the inner mortar 29 and the outer diameter of the upper end portion of the inner mortar 29, the gap between the lower surface of the introduction portion 25 and the upper surface of the inner mortar 29 is the gap h1 and the inner mortar 29. When the outer diameter of the upper end portion of the above is D2, it is preferable that 0.5 <2h1 / (D1-D2) <1.

2h1/(D1-D2)は、0.5以下であると、カカオニブ45がコニカル臼27の内臼29と外臼30との間に入り難くなる。一方、2h1/(D1-D2)は、1以上であると、導入部25から入口部33に投入されたカカオニブ45が導入部25へ戻り易くなる。

When 2h1 / (D1-D2) is 0.5 or less, it becomes difficult for cacao nibs 45 to enter between the inner mortar 29 and the outer mortar 30 of the conical mortar 27. On the other hand, if 2h1 / (D1-D2) is 1 or more, the cacao nibs 45 thrown into the inlet portion 33 from the introduction portion 25 are likely to return to the introduction portion 25.

〔実施形態2〕

本発明の他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。 [Embodiment 2]

Other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated.

本発明の他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。 [Embodiment 2]

Other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated.

(粉砕部26の詳細な構成、動作および利点)

図7は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。図8は、コニカル臼27の内臼29に対する付着防止・撹拌部材44の取り付け状態を示す斜視図である。 (Detailed configuration, operation and advantages of the crushing unit 26)

FIG. 7 is an explanatory diagram showing a detailed configuration of the crushingunit 11 of the present embodiment and the operation of the crushing unit 11. FIG. 8 is a perspective view showing a state in which the adhesion prevention / stirring member 44 of the conical mortar 27 is attached to the inner mortar 29.

図7は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。図8は、コニカル臼27の内臼29に対する付着防止・撹拌部材44の取り付け状態を示す斜視図である。 (Detailed configuration, operation and advantages of the crushing unit 26)

FIG. 7 is an explanatory diagram showing a detailed configuration of the crushing

図7に示すように、本実施形態の粉砕ユニット11は、導入部25に至るカカオニブ45の移動経路に設けられた、回転する棒状の撹拌部材43を備えている。本実施形態では、撹拌部材43は、付着防止突起部材41の一端部に接続され、付着防止突起部材41および撹拌部材43を有する付着防止・撹拌部材44の一部として構成されている。

As shown in FIG. 7, the crushing unit 11 of the present embodiment includes a rotating rod-shaped stirring member 43 provided in the moving path of the cacao nibs 45 leading to the introduction portion 25. In the present embodiment, the stirring member 43 is connected to one end of the adhesion prevention protrusion member 41, and is configured as a part of the adhesion prevention / stirring member 44 having the adhesion prevention protrusion member 41 and the stirring member 43.

撹拌部材43は、導入部25の開口部25aから導入部25の内部へ挿入され、ホッパー受部24の下部に達している。撹拌部材43は、内臼29に設けられているので、内臼29とともに回転する。これにより、導入部25に至るカカオニブ45の移動経路において、カカオニブ45が滞留する事態を防止し、導入部25を介してカカオニブ45を円滑にコニカル臼27に投入することができる。(請求項3の効果)

なお、撹拌部材43は、付着防止・撹拌部材44の一部として設けられた構成に限定されず、単独に設けられていてもよい。また、撹拌部材43は、内臼29に設けられ、内臼29ともに回転する構成に限定されず、他の機構に駆動されて回転する構成であってもよい。 The stirringmember 43 is inserted into the inside of the introduction portion 25 through the opening 25a of the introduction portion 25 and reaches the lower part of the hopper receiving portion 24. Since the stirring member 43 is provided on the inner mortar 29, it rotates together with the inner mortar 29. As a result, it is possible to prevent the cacao nibs 45 from staying in the movement path of the cacao nibs 45 leading to the introduction unit 25, and to smoothly feed the cacao nibs 45 into the conical mortar 27 via the introduction unit 25. (Effect of claim 3)

The stirringmember 43 is not limited to the configuration provided as a part of the adhesion prevention / stirring member 44, and may be provided independently. Further, the stirring member 43 is not limited to the configuration provided in the inner mortar 29 and rotating together with the inner mortar 29, and may be configured to be driven by another mechanism to rotate.

なお、撹拌部材43は、付着防止・撹拌部材44の一部として設けられた構成に限定されず、単独に設けられていてもよい。また、撹拌部材43は、内臼29に設けられ、内臼29ともに回転する構成に限定されず、他の機構に駆動されて回転する構成であってもよい。 The stirring

The stirring

〔実施形態3〕

本発明のさらに他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。図9は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。 [Embodiment 3]

Still other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated. FIG. 9 is an explanatory diagram showing a detailed configuration of the crushingunit 11 of the present embodiment and the operation of the crushing unit 11.

本発明のさらに他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。図9は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。 [Embodiment 3]

Still other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated. FIG. 9 is an explanatory diagram showing a detailed configuration of the crushing

図9に示すように、本実施形態の粉砕ユニット11は、図6に示した導入部25に代えて、導入部51を備えている。導入部51は円筒形状であり、導入部25と比較して内周部に堆積粉末42が生じ易くなる。しかしながら、付着防止突起部材41によって外臼30の内周面での堆積粉末42の発生が抑制されるので、全体として、導入部51からコニカル臼27へのカカオニブ45の投入が困難になる事態を抑制することができる。

As shown in FIG. 9, the crushing unit 11 of the present embodiment includes an introduction unit 51 instead of the introduction unit 25 shown in FIG. The introduction portion 51 has a cylindrical shape, and the deposited powder 42 is more likely to be generated on the inner peripheral portion as compared with the introduction portion 25. However, since the adhesion prevention protrusion member 41 suppresses the generation of the accumulated powder 42 on the inner peripheral surface of the outer mortar 30, it becomes difficult to put the cacao nibs 45 from the introduction portion 51 into the conical mortar 27 as a whole. It can be suppressed.

〔実施形態4〕

本発明のさらに他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。図10は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。図11は、図10に示した導入部51と撹拌部材43との位置関係を示す平面図である。 [Embodiment 4]

Still other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated. FIG. 10 is an explanatory diagram showing a detailed configuration of the crushingunit 11 of the present embodiment and the operation of the crushing unit 11. FIG. 11 is a plan view showing the positional relationship between the introduction portion 51 and the stirring member 43 shown in FIG.

本発明のさらに他の実施形態について、以下に説明する。なお、説明の便宜上、上記実施形態にて説明した部材と同じ機能を有する部材については、同じ符号を付記し、その説明を繰り返さない。図10は、本実施形態の粉砕ユニット11の詳細な構成、および粉砕ユニット11の動作を示す説明図である。図11は、図10に示した導入部51と撹拌部材43との位置関係を示す平面図である。 [Embodiment 4]

Still other embodiments of the present invention will be described below. For convenience of explanation, the same reference numerals will be added to the members having the same functions as the members described in the above embodiment, and the description will not be repeated. FIG. 10 is an explanatory diagram showing a detailed configuration of the crushing

図10に示すように、本実施形態の粉砕ユニット11は、図7に示した導入部25に代えて、導入部51を備えている。導入部51は円筒形状であり、導入部25と比較して内周部に堆積粉末42が生じ易くなる。しかしながら、付着防止突起部材41によって外臼30の内周面での堆積粉末42の発生が抑制されるので、全体として、導入部51からコニカル臼27へのカカオニブ45の投入が困難になる事態を抑制することができる。

As shown in FIG. 10, the crushing unit 11 of the present embodiment includes an introduction unit 51 instead of the introduction unit 25 shown in FIG. 7. The introduction portion 51 has a cylindrical shape, and the deposited powder 42 is more likely to be generated on the inner peripheral portion as compared with the introduction portion 25. However, since the adhesion prevention protrusion member 41 suppresses the generation of the accumulated powder 42 on the inner peripheral surface of the outer mortar 30, it becomes difficult to put the cacao nibs 45 from the introduction portion 51 into the conical mortar 27 as a whole. It can be suppressed.

また、本実施形態の粉砕ユニット11では、導入部51の内面と付着防止・撹拌部材44の撹拌部材43との隙間をt、入口部33の外臼30の内径をD1、導入部51の内径をD2とすると、1<2t/(D1-D2)<1.5であることが好ましい。

Further, in the crushing unit 11 of the present embodiment, the gap between the inner surface of the introduction portion 51 and the stirring member 43 of the adhesion prevention / stirring member 44 is t, the inner diameter of the outer mill 30 of the inlet portion 33 is D1, and the inner diameter of the introduction portion 51. Is D2, and it is preferable that 1 <2t / (D1-D2) <1.5.

このような関係とすることにより、撹拌部材43と導入部51の内周面との間において、導入部51がカカオニブ45を噛み込んで粉砕し、導入部51の内周面に熱によりドロドロになったカカオニブ45の堆積部46が生じ、堆積部46によって導入部51が詰まり易くなる事態を抑制することができる。

With such a relationship, the introduction portion 51 bites the cacao nibs 45 between the stirring member 43 and the inner peripheral surface of the introduction portion 51 to crush the cacao nibs 45, and the inner peripheral surface of the introduction portion 51 becomes muddy by heat. It is possible to suppress a situation in which a piled portion 46 of the cacao nibs 45 is formed, and the introduced portion 51 is easily clogged by the deposited portion 46.

〔まとめ〕

本発明の態様1に係る粉砕機は、回転臼である内臼と固定臼である外臼とからなるコニカル臼を有し、前記内臼と前記外臼との間の入口部に投入された、油分を有する固体原料を前記コニカル臼にて粉砕する粉砕部と、前記外臼と前記内臼との間に設けられ、回転する付着防止突起部材とを備えている。 [Summary]

The crusher according to the first aspect of the present invention has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and is inserted into an inlet portion between the inner mortar and the outer mortar. It is provided with a crushing portion for crushing a solid raw material having an oil content with the conical mortar, and an adhesion prevention protrusion member provided between the outer mortar and the inner mortar and rotating.

本発明の態様1に係る粉砕機は、回転臼である内臼と固定臼である外臼とからなるコニカル臼を有し、前記内臼と前記外臼との間の入口部に投入された、油分を有する固体原料を前記コニカル臼にて粉砕する粉砕部と、前記外臼と前記内臼との間に設けられ、回転する付着防止突起部材とを備えている。 [Summary]

The crusher according to the first aspect of the present invention has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and is inserted into an inlet portion between the inner mortar and the outer mortar. It is provided with a crushing portion for crushing a solid raw material having an oil content with the conical mortar, and an adhesion prevention protrusion member provided between the outer mortar and the inner mortar and rotating.

本発明の態様2に係る粉砕機は、上記態様1において、前記コニカル臼は、上部に粗粉砕領域を有し、下部に細粉砕領域を有し、前記付着防止突起部材は、一端部が前記内臼に固定され、他端部が前記粗粉砕領域の前記外臼と前記内臼との間に突出している構成としてもよい。

In the crusher according to the second aspect of the present invention, in the first aspect, the conical mortar has a coarse crushing region at an upper portion and a fine crushing region at a lower portion, and the adhesion prevention protrusion member has one end thereof. It may be fixed to the inner mortar and the other end portion may protrude between the outer mortar and the inner mortar in the coarse crushing region.

本発明の態様3に係る粉砕機は、上記態様1または2において、下端部に開口部を有し、内部に供給された前記固体原料を前記開口部から前記コニカル臼の前記入口部に投入する導入部と、前記内臼の上端部に下端部が固定され、前記開口部から前記導入部の前記内部へ挿入された棒状の撹拌部材とを備えている構成としてもよい。

The crusher according to the third aspect of the present invention has an opening at the lower end in the first or second aspect, and the solid raw material supplied to the inside is charged from the opening into the inlet of the conical mortar. A structure may be configured in which a lower end portion is fixed to the upper end portion of the inner mortar and a rod-shaped stirring member inserted from the opening portion into the inside of the introduction portion is provided.

本発明の態様4に係る粉砕機は、上記態様3において、前記導入部の内面と前記撹拌部材との隙間をt、前記入口部の前記外臼の内径をD1、導入部の内径をD2とすると、1<2t/(D1-D2)<1.5が成り立つ構成としてもよい。

In the crusher according to the fourth aspect of the present invention, in the third aspect, the gap between the inner surface of the introduction portion and the stirring member is t, the inner diameter of the outer mill of the inlet portion is D1, and the inner diameter of the introduction portion is D2. Then, 1 <2t / (D1-D2) <1.5 may be established.

本発明の態様5に係る粉砕機は、上記態様4において、前記導入部の内径は、上部から前記開口部に向うにしたがって漸次小さくなっている立つ構成としてもよい。

In the above aspect 4, the crusher according to the fifth aspect of the present invention may have a standing structure in which the inner diameter of the introduction portion gradually decreases from the upper part toward the opening.

Claims (5)

- 回転臼である内臼と固定臼である外臼とからなるコニカル臼を有し、前記内臼と前記外臼との間の入口部に投入された、油分を有する固体原料を前記コニカル臼にて粉砕する粉砕部と、

前記外臼と前記内臼との間に設けられ、回転する付着防止突起部材とを備えていることを特徴とする粉砕機。 The conical mortar has a conical mortar composed of an inner mortar which is a rotary mortar and an outer mortar which is a fixed mortar, and a solid raw material having an oil content which is charged into the inlet portion between the inner mortar and the outer mortar is used as the conical mortar. And the crushing part to crush

A crusher provided between the outer mortar and the inner mortar and provided with a rotating adhesion prevention protrusion member. - 前記コニカル臼は、上部に粗粉砕領域を有し、下部に細粉砕領域を有し、

前記付着防止突起部材は、一端部が前記内臼に固定され、他端部が前記粗粉砕領域の前記外臼と前記内臼との間に突出していることを特徴とする請求項1に記載の粉砕機。 The conical mortar has a coarse crushed region at the top and a fine crushed region at the bottom.

The first aspect of the anti-adhesion protrusion member is characterized in that one end thereof is fixed to the inner mortar and the other end protrudes between the outer mortar and the inner mortar in the coarsely crushed region. Crusher. - 下端部に開口部を有し、内部に供給された前記固体原料を前記開口部から前記コニカル臼の前記入口部に投入する導入部と、

前記内臼の上端部に下端部が固定され、前記開口部から前記導入部の前記内部へ挿入された棒状の撹拌部材とを備えていることを特徴とする請求項1または2に記載の粉砕機。 An introduction portion having an opening at the lower end and feeding the solid raw material supplied to the inside from the opening into the inlet of the conical mortar.

The pulverization according to claim 1 or 2, wherein a lower end portion is fixed to an upper end portion of the inner mortar, and a rod-shaped stirring member inserted from the opening portion into the inside of the introduction portion is provided. Machine. - 前記導入部の内面と前記撹拌部材との隙間をt、前記入口部の前記外臼の内径をD1、前記導入部の内径をD2とすると、

1<2t/(D1-D2)<1.5

が成り立つことを特徴とする請求項3に記載の粉砕機。 Assuming that the gap between the inner surface of the introduction portion and the stirring member is t, the inner diameter of the outer mill of the inlet portion is D1, and the inner diameter of the introduction portion is D2.

1 <2t / (D1-D2) <1.5

The crusher according to claim 3, wherein the above is satisfied. - 前記導入部の内径は、上部から前記開口部に向うにしたがって漸次小さくなっていることを特徴とする請求項4に記載の粉砕機。 The crusher according to claim 4, wherein the inner diameter of the introduction portion gradually decreases from the upper portion toward the opening.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2021511495A JPWO2020203451A1 (en) | 2019-03-29 | 2020-03-24 | |

| CN202080013553.4A CN113597341A (en) | 2019-03-29 | 2020-03-24 | Disintegrating machine |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019068931 | 2019-03-29 | ||

| JP2019-068931 | 2019-03-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020203451A1 true WO2020203451A1 (en) | 2020-10-08 |

Family

ID=72668073

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/012948 WO2020203451A1 (en) | 2019-03-29 | 2020-03-24 | Pulverizer |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JPWO2020203451A1 (en) |

| CN (1) | CN113597341A (en) |

| TW (1) | TW202035021A (en) |

| WO (1) | WO2020203451A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022239364A1 (en) * | 2021-05-12 | 2022-11-17 | Dari K株式会社 | Grinding device |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60193551A (en) * | 1984-03-15 | 1985-10-02 | 明治機械株式会社 | Upper mortar turning type stone mortar crusher |

| JP2000070742A (en) * | 1998-08-28 | 2000-03-07 | West:Kk | Flour mill |

| JP2005081220A (en) * | 2003-09-08 | 2005-03-31 | Tanaka Juken:Kk | Lower bed stone rotation type mill |

| JP2018069136A (en) * | 2016-10-26 | 2018-05-10 | パナソニックIpマネジメント株式会社 | Electric milling machine |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2254771Y (en) * | 1995-12-28 | 1997-05-28 | 白宗仁 | Pulverizing apparatus with agitating mechanism |

| JPWO2004078354A1 (en) * | 2003-03-04 | 2006-06-08 | シグマ精機株式会社 | Crusher |

| KR100893544B1 (en) * | 2009-02-02 | 2009-04-17 | (주)거산기계 | Circulation aggregate productive concrusher of construction waste crushing matter |

-

2020

- 2020-03-11 TW TW109108086A patent/TW202035021A/en unknown

- 2020-03-24 CN CN202080013553.4A patent/CN113597341A/en active Pending

- 2020-03-24 WO PCT/JP2020/012948 patent/WO2020203451A1/en active Application Filing

- 2020-03-24 JP JP2021511495A patent/JPWO2020203451A1/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60193551A (en) * | 1984-03-15 | 1985-10-02 | 明治機械株式会社 | Upper mortar turning type stone mortar crusher |

| JP2000070742A (en) * | 1998-08-28 | 2000-03-07 | West:Kk | Flour mill |

| JP2005081220A (en) * | 2003-09-08 | 2005-03-31 | Tanaka Juken:Kk | Lower bed stone rotation type mill |

| JP2018069136A (en) * | 2016-10-26 | 2018-05-10 | パナソニックIpマネジメント株式会社 | Electric milling machine |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2022239364A1 (en) * | 2021-05-12 | 2022-11-17 | Dari K株式会社 | Grinding device |

Also Published As

| Publication number | Publication date |

|---|---|

| TW202035021A (en) | 2020-10-01 |

| CN113597341A (en) | 2021-11-02 |

| JPWO2020203451A1 (en) | 2020-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6990846B2 (en) | Electric flour grinder | |

| CN112236235B (en) | Disintegrating machine | |

| JP5849519B2 (en) | Beverage extraction material crusher | |

| JPS6225421B2 (en) | ||

| WO2020203451A1 (en) | Pulverizer | |

| WO2020203450A1 (en) | Pulverizer | |

| JP2017074530A (en) | Pulverizing mill | |

| JP5610190B2 (en) | Crusher | |

| JP5765113B2 (en) | Beverage extraction material crusher | |

| WO2020241463A1 (en) | Grinding device | |

| KR101335691B1 (en) | Pepper Pulverizer | |

| WO2020241462A1 (en) | Grinding device | |

| KR20150143111A (en) | Crusher | |

| WO2021024840A1 (en) | Grinding device | |

| JP4301605B2 (en) | Vertical roller crusher | |

| WO2021015150A1 (en) | Pulverizing system | |

| WO2020203452A1 (en) | Pulverizing device | |

| CN215541340U (en) | Superfine pulverizer | |

| JP2008149271A (en) | Grinder | |

| JP2022080986A (en) | Crusher | |

| KR100425071B1 (en) | A solid pulverization system and the manufacturing method for toner | |

| KR850001173Y1 (en) | Crusher for food stuffs | |

| JP2024036195A (en) | Grinding device | |

| JP2961041B2 (en) | Vertical crusher | |

| KR200426878Y1 (en) | supply device for grain grinder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20784866 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2021511495 Country of ref document: JP Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20784866 Country of ref document: EP Kind code of ref document: A1 |