WO2020195099A1 - Pants-type disposable wearing article - Google Patents

Pants-type disposable wearing article Download PDFInfo

- Publication number

- WO2020195099A1 WO2020195099A1 PCT/JP2020/002695 JP2020002695W WO2020195099A1 WO 2020195099 A1 WO2020195099 A1 WO 2020195099A1 JP 2020002695 W JP2020002695 W JP 2020002695W WO 2020195099 A1 WO2020195099 A1 WO 2020195099A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- region

- elastic member

- exterior body

- waist

- sheet layer

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

Definitions

- the present invention relates to a disposable wearable article having an improved fit of the inguinal region.

- Pants-type disposable wearable articles include an exterior body that constitutes at least the waist circumference of the front and back bodies, and an interior body that includes an absorber and is attached to the exterior body so as to extend from the front body to the back body.

- a waist opening and a pair of left and right leg openings are formed by joining both sides of the outer body of the front body and both sides of the outer body of the back body to form a side seal portion.

- a stretchable structure provided in the waist circumference area defined as the front-rear direction range corresponding to the side seal portion and the intermediate region located between the front-rear waist circumference areas has a relatively high fit to the body.

- a typical stretchable structure of a pants-type disposable wearable article is provided with an elongated elastic member provided between the overlapping first sheet layer and the second sheet layer along the stretch direction and at intervals from each other. It is a thing.

- the first sheet layer and the second sheet layer form a planar stretchable region and play a role of covering and hiding the elastic member, and the elastic member incorporated between the first sheet layer and the second sheet layer is elastically stretchable. It plays a role in creating power for.

- at least the portions located at both ends of the expansion / contraction region of the elastic member are fixed to the first sheet layer and the second sheet layer.

- the elastic member and the first sheet layer and the second sheet layer are integrated, and the first sheet layer and the second sheet layer are contracted by the contraction force of the elastic member to include folds (including wrinkled ones). It is formed not only in the natural length state but also in the stretched state of the elastic member. Hereinafter, it is also simply referred to as a fold), and when it is stretched from this contracted state against the contraction force of the elastic member, the fold is formed. Is expanded. Normally, the first sheet layer and the second sheet layer are in a developed state without folds at the elastic elongation limit, and the folds are closer as the elastic member contracts, and the folds are most densely brought closer in the natural length state.

- the elastic member creates elasticity, the elastic member extends over the entire expansion and contraction direction of the expansion and contraction region, and at least the portions located at both ends of the expansion and contraction direction of the expansion and contraction region are the first sheet layer and the second sheet layer. In the natural length state, the first sheet layer and the second sheet layer need to be contracted as the elastic member contracts. That is, it is necessary to join the first sheet layer and the second sheet layer and to fix the elastic member to the first sheet layer and the second sheet layer.

- a hot melt adhesive is selected as a means for fixing the elastic member to the first sheet layer and the second sheet layer in most cases.

- the bonding between the first sheet layer and the second sheet layer is often performed by welding such as ultrasonic welding, but the hot melt adhesive is used.

- the structure to be used is also deeply used. In particular, by joining the first sheet layer and the second sheet layer at the position of the elastic member via a hot melt adhesive, the first sheet layer and the second sheet layer can be joined, and the first sheet layer and the second sheet can be joined.

- the combined structure that also fixes the elastic member to the layer is known as the most typical one.

- the waist circumference region and the intermediate region overlap with the front-rear direction range having the absorber, and there are internal and external joints in the range for joining the interior body and the exterior body. Therefore, even if the elastic member is provided so as to cross the range in the front-rear direction having the absorber, its expansion / contraction function is limited by the rigidity of the absorber.

- the absorber may shrink in the width direction to deteriorate the wearing feeling and appearance, or the absorber may be twisted or cracked to deteriorate the absorption performance.

- the elastic member is continuously attached to the outer body along the width direction, and the elasticity generated by the elastic member is killed at the portion overlapping with the absorber, so that the outer body is not stretchable. Regions have been formed (see, eg, Patent Documents 1-6).

- the method of killing the elasticity is roughly classified into two types.

- the first method is a method of finely cutting a portion of the elastic member located in the non-stretchable region.

- an independent shrinkage portion is formed in a portion of the elastic member located in the non-stretchable region, which is not fixed to the first sheet layer and the second sheet layer or is weakly fixed by a hot melt adhesive, and the independent shrinkage portion is formed. It is a method of cutting at one place in the middle of the width direction and shrinking the independently contracted portion to a state of natural length or close to the natural length without the first sheet layer and the second sheet layer.

- the second method has an advantage that the number of cutting points is as small as one as compared with the first method.

- the main object of the present invention is to improve the fit of the wearer to the dent of the inguinal region.

- the pants-type disposable wear items that have solved the above problems are as follows. ⁇ First aspect> An integrated exterior body from the front body to the back body, or an exterior body separately provided on the front body and the back body, An interior body including an absorber attached to the exterior body so as to extend from the front body to the back body, Side seals where both sides of the exterior body on the front body and both sides of the exterior body on the back body are joined, respectively. With a waist opening and a pair of left and right leg openings The exterior body includes a non-stretchable region provided in the central portion in the width direction in the front-rear direction range having the side seal portion and the absorber, and a waist lower stretchable region divided on both sides in the width direction by the non-stretchable region.

- the waist lower elastic region has a built-in waist lower elastic member, contracts in the width direction together with the waist lower elastic member, and can be extended in the width direction together with the waist lower elastic member.

- Rising gathers are provided on both sides of the interior body.

- the root portions attached to both side portions of the interior body, the main body portion extending from the root portions on both sides of the surface of the interior body, and the front end portion and the rear end portion of the main body portion are lodging.

- An inverted portion formed by being fixed to the surface of the interior body in a state, a non-fixed raised portion located between the front and rear inverted portions, and at least the tip portion of the raised portion are provided along the front-rear direction.

- the raised portion contracts in the front-rear direction together with the gathered elastic member and rises from the surface of the interior body, and can extend in the front-rear direction together with the gathered elastic member.

- At least the crotch-side end of the front body in the lower waist stretch region is a highly stretched region extending toward the center in the width direction with respect to the rising gathers.

- the raised portion and the gathered elastic member extend toward the waist opening side into the high extension region of the front body. Pants-type disposable wear items that are characterized by this.

- the highly stretchable region of the lower waist stretch region exists so as to cross the dent in the groin region of the wearer, so that the exterior body follows the expansion and contraction of the groove in the groin region to firmly attach the interior body. Can be pressed.

- the high-extension region does not enter the inguinal region, simply providing the high-extension region does not sufficiently improve the fit of the inguinal region to the indentation, and a gap may occur. Therefore, in this pants-type disposable wearable article, the rising portion of the rising gather and the gather elastic member extend to the portion pressed by this high extension region.

- the portion of the rising portion having the gathered elastic member can rise so as to enter the recess of the inguinal region with the high extension region firmly pressed against the inguinal region as a base. Therefore, in this pants type disposable wear article, the fit to the inguinal region is remarkably improved.

- the widthwise dimension of the non-stretchable region in the anteroposterior range having the highly stretchable region is less than 1/2 of the widthwise dimension of the absorber.

- the distance between the rising gathers on both sides is 1 / 1.8 to 1 / 1.1 times the widthwise dimension of the absorber.

- each part can be appropriately determined, but usually, if it is within the above range, the positional relationship between the high elongation region and the rising gather becomes appropriate, and the fit to the inguinal region becomes particularly good, which is preferable.

- ⁇ Third aspect> The edge of the front body on the non-stretchable region side of the lower waist stretchable region extends stepwise or continuously from the waist opening side toward the crotch side so as to be located on the central side in the width direction.

- the high extension region is provided only on the crotch side in the waist lower extension / contraction region of the front body.

- the exterior body is a front exterior body and a rear exterior body separately provided on the front body and the rear body.

- the front exterior body and the rear exterior body are separated from each other in the front-rear direction on the crotch side.

- the interior body extends in the front-rear direction from the front exterior body to the rear exterior body, and is joined to the front exterior body and the rear exterior body, respectively.

- the side seal portion is a portion where both side portions of the front exterior body and both side portions of the rear exterior body are joined to each other.

- Pants-type disposable wear article according to any one of the first to third aspects.

- the front exterior body and the rear exterior body are known to be separated in the front-rear direction without being continuous on the crotch side.

- Such an exterior bifurcated type has an advantage that it is not necessary to excise the exterior body in order to form a leg opening, or even if it is excised, a small area is required. That is, since the cut pieces (trims) are disposed of, there is an advantage that waste (trim loss) of the materials can be suppressed.

- the fit to the leg circumference has to be lowered, and the fit of the inguinal region is particularly liable to be lowered. That is, since the distance from the position corresponding to the crotch part of the interior body to the intersection position with the exterior body is long in the pants-type disposable wear item of the exterior two-piece type, the interior body tends to swing left and right with the intersection position as a fulcrum. This makes it easier for the interior body to move laterally compared to the type that has an integrated exterior body that is continuous from the front body to the back body.

- the pants-type disposable wear item of the exterior two-piece type has a shape in which the crotch-side edge of the exterior body is straight or close to the width direction, and intersects the side edge of the interior body at a right angle or an angle close to it. To do. These mean that the pants-type disposable wearable article of the two-piece exterior type tends to lack the fit to the inguinal region.

- side flaps extending laterally from the rising gathers extend in the front-rear direction from the front exterior body to the rear exterior body.

- the side flap has a side expansion / contraction region that elastically expands / contracts in the front-rear direction.

- the side elastic region has a built-in side elastic member, is contracted in the front-rear direction together with the side elastic member, and can be extended in the front-rear direction together with the side elastic member.

- the side stretchable region extends toward the waist opening side into the highly stretched region of the front body. Pants-type disposable wear article of the fourth aspect.

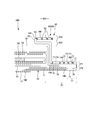

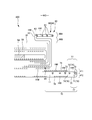

- FIG. 1 It is a top view which shows the inner surface of the pants type disposable diaper in the unfolded state. It is a top view which shows the outer surface of the pants type disposable diaper in the unfolded state. It is a 2-2 sectional view of FIG. It is a cross-sectional view of 3-3 of FIG. (A) is a 4-4 sectional view of FIG. 1, and (b) is a 5-5 sectional view of FIG. It is a perspective view of a pants type disposable diaper. It is a top view which shows the outer surface of the interior body in the unfolded state together with the outline of the exterior body. It is sectional drawing of another example corresponding to the 4-4 cross section of FIG. It is sectional drawing of another example corresponding to the 2-2 cross section of FIG.

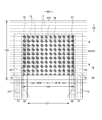

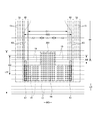

- FIG. 1 It is sectional drawing of another example corresponding to the 3-3 cross section of FIG. It is an enlarged view of the main part of FIG. It is an enlarged view of the main part of FIG. It is an enlarged plan view of the front exterior body. It is an enlarged plan view of the rear exterior body. It is an enlarged plan view of the front exterior body. It is an enlarged plan view of the rear exterior body. It is an enlarged plan view of the front exterior body. It is an enlarged plan view of the rear exterior body. It is an enlarged plan view of the front exterior body. It is an enlarged plan view of the rear exterior body. It is a perspective view of the cutting device. It is an enlarged plan view of the non-stretchable region portion.

- the dotted pattern portion in the cross-sectional view shows an adhesive as a joining means for joining the constituent members located on the front side and the back side thereof, and is a solid, bead, curtain, summit or spiral coating of hot melt adhesive, or pattern coating.

- the fixed part of the elastic member is formed by (transfer of hot melt adhesive by the letterpress method) or by coating the elastic member on the outer peripheral surface of the elastic member such as comb gun or sure wrap coating instead of or together with this. is there.

- hot melt adhesive examples include EVA type, adhesive rubber type (elastomer type), olefin type, polyester / polyamide type and the like, but they can be used without particular limitation.

- a means by welding materials such as a heat seal and an ultrasonic seal can also be used.

- FIGS. 1 to 6 show an example of a pants-type disposable diaper.

- This pants-type disposable diaper includes a rectangular front exterior body 12F that constitutes at least the waist circumference of the front body F, a rectangular rear exterior body 12B that constitutes at least the waist circumference of the back body B, and a crotch from the front exterior body 12F. It is provided with an interior body 200 provided inside the exterior bodies 12F and 12B so as to extend through the portion to the rear exterior body 12B. Both side portions of the front exterior body 12F and both side portions of the rear exterior body 12B are joined to form a side seal portion 12A, whereby an opening formed by the front and rear ends of the exterior bodies 12F and 12B is formed by the wearer.

- the waist opening WO through which the body of the interior body is passed, and the portions surrounded by the lower edges of the exterior bodies 12F and 12B and the side edges of the interior body 200 on both sides in the width direction of the interior body 200 are leg openings LO through which the legs pass.

- the interior body 200 is a part that absorbs and holds excrement such as urine, and the exterior bodies 12F and 12B are parts for supporting the interior body 200 with respect to the wearer's body.

- the reference numeral Y indicates the total length of the diaper in the unfolded state (the length in the front-rear direction from the edge of the waist opening WO of the front body F to the edge of the waist opening WO of the back body B), and the reference numeral X indicates the diaper in the unfolded state. Shows the full width of.

- This pants-type disposable diaper has a waist circumference region T defined as a front-back direction range (a front-back direction range from the waist opening WO to the upper end of the leg opening LO) having a side seal portion 12A, and a front-back direction of a portion forming the leg opening LO. It has an intermediate region L defined as a range (between the front-rear direction region having the side seal portion 12A of the front body F and the front-rear direction region having the side seal portion 12A of the back body B).

- the waist circumference region T can be divided into a "waist portion" W that conceptually forms an edge portion of the waist opening and a "waist lower portion" U that is a portion below this.

- the waist opening WO side is the waist rather than the boundary on the waist opening WO side. If there is no such boundary, the waist extending portion 12E extending toward the waist opening WO side from the absorber 56 or the interior body 200 becomes the waist portion W.

- These lengths in the front-rear direction vary depending on the size of the product and can be appropriately determined.

- the waist portion W can be 15 to 40 mm and the waist lower portion U can be 65 to 120 mm.

- both side edges of the intermediate region L are constricted in a U-shape or a curved shape along the circumference of the wearer's legs, and this is a portion for inserting the wearer's legs.

- the unfolded pants-type disposable diaper has an hourglass shape as a whole.

- the interior body 200 can take any shape, but is rectangular in the illustrated example. As shown in FIGS. 3 to 5, the interior body 200 includes a top sheet 30 on the body side, a liquid-impermeable sheet 11, and an absorbing element 50 interposed between them. Yes, it is the main body that has an absorption function. Reference numeral 40 indicates an intermediate sheet (second sheet) provided between the top sheet 30 and the absorption element 50 in order to quickly transfer the liquid that has passed through the top sheet 30 to the absorption element 50. Shows rising gathers 60 extending from both sides of the interior body 200 so as to be in contact with the wearer's legs in order to prevent excrement from leaking to both sides of the interior body 200.

- the top sheet 30 has a property of allowing liquid to permeate, and examples thereof include a perforated or non-perforated non-woven fabric and a porous plastic sheet. Further, the top sheet 30 may be one made of one sheet or one made of a laminated sheet obtained by laminating two or more sheets. Similarly, the top sheet 30 may be composed of one sheet or two or more sheets in the plane direction.

- Both sides of the top sheet 30 may be folded back on the side edge of the absorbing element 50, or may be projected laterally from the side edge of the absorbing element 50 without being folded back.

- the top sheet 30 may be fixed to a member adjacent to the back side by a joining means by material welding such as heat seal or ultrasonic seal, or by a hot melt adhesive for the purpose of preventing misalignment with respect to the member on the back side. desirable.

- the top sheet 30 is fixed to the surface of the intermediate sheet 40 and the surface of the portion of the packaging sheet 58 located on the front side of the absorber 56 by a hot melt adhesive applied to the back surface thereof.

- an intermediate sheet (also referred to as a "second sheet") 40 having a faster liquid permeation speed than the top sheet 30 can be provided.

- the intermediate sheet 40 is for quickly transferring the liquid to the absorber to enhance the absorption performance by the absorber and prevent the phenomenon of "reversion" of the absorbed liquid from the absorber.

- the intermediate sheet 40 may be omitted.

- the intermediate sheet 40 examples include the same materials as the top sheet 30, spunlace non-woven fabric, spunbonded non-woven fabric, SMS non-woven fabric, pulp non-woven fabric, mixed sheet of pulp and rayon, point-bonded non-woven fabric or crepe paper.

- the air-through non-woven fabric is preferable because it is bulky. It is preferable to use a composite fiber having a core-sheath structure for the air-through non-woven fabric.

- the resin used for the core may be polypropylene (PP), but polyester (PET) having high rigidity is preferable.

- Basis weight is preferably 17 ⁇ 80g / m 2, more preferably 25 ⁇ 60g / m 2.

- the thickness of the raw material fiber of the non-woven fabric is preferably 2.0 to 10 dtex.

- the intermediate sheet 40 in the illustrated example is arranged in the center shorter than the width of the absorber 56, it may be provided over the entire width.

- the length of the intermediate sheet 40 in the front-rear direction may be the same as the total length of the diaper, may be the same as the length of the absorbing element 50, or may be within a short length range centered on the region for receiving the liquid.

- the intermediate sheet 40 may be fixed to a member adjacent to the back side by a joining means by material welding such as a heat seal or an ultrasonic seal or a hot melt adhesive for the purpose of preventing misalignment with respect to the member on the back side. desirable.

- the intermediate sheet 40 is fixed to the surface of the portion of the packaging sheet 58 located on the front side of the absorber 56 by the hot melt adhesive applied to the back surface thereof.

- the material of the liquid-impermeable sheet 11 is not particularly limited, but for example, a plastic film made of an olefin resin such as polyethylene or polypropylene, a laminated non-woven fabric having a plastic film on the surface of the non-woven fabric, or a plastic film.

- a plastic film made of an olefin resin such as polyethylene or polypropylene

- a laminated non-woven fabric having a plastic film on the surface of the non-woven fabric or a plastic film.

- An example can be exemplified of a laminated sheet in which a non-woven fabric or the like is laminated and joined.

- a microporous plastic film obtained by kneading an inorganic filler in an olefin resin such as polyethylene or polypropylene, forming a sheet, and then stretching in a uniaxial or biaxial direction.

- an olefin resin such as polyethylene or polypropylene

- a sheet formed by kneading an inorganic filler in an olefin resin such as polyethylene or polypropylene, forming a sheet, and then stretching in a uniaxial or biaxial direction.

- methods such as non-woven fabrics using microdenyl fibers, strengthening of leakage resistance by reducing the voids of the fibers by applying heat or pressure, and coating of highly water-absorbent resin or hydrophobic resin or water-repellent agent.

- liquid-impermeable sheet without using a plastic film can also be used as the liquid-impermeable sheet 11, but it has sufficient adhesive strength when bonded to the cover non-woven fabric 13 described later via a hot-melt adhesive. Therefore, it is desirable to use a resin film.

- the liquid-impermeable sheet 11 has a width that fits on the back side of the absorbing element 50, and in order to improve leakage resistance, both sides of the absorbing element 50 are wrapped around the side surface of the top sheet 30 of the absorbing element 50. It can also be extended to both sides.

- the width of the extending portion is appropriately about 5 to 20 mm on each side.

- the absorbing element 50 has an absorbing body 56 and a packaging sheet 58 that encloses the entire absorbing body 56.

- the packaging sheet 58 may be omitted.

- the absorber 56 can be formed by an aggregate of fibers.

- the fiber aggregate is a filament aggregate obtained by stacking short fibers such as cotton-like pulp and synthetic fibers, and opening tow (fiber bundle) of synthetic fibers such as cellulose acetate as necessary. Can also be used.

- the fiber texture may be, for example, about 100 to 300 g / m 2 in the case of stacking cotton-like pulp or short fibers, and about 30 to 120 g / m 2 in the case of filament aggregates. Can be done.

- the fineness is, for example, 1 to 16 dtex, preferably 1 to 10 dtex, and more preferably 1 to 5 dtex.

- the filament may be a non-crimped fiber, but is preferably a crimped fiber.

- the degree of crimping of the crimped fibers can be, for example, 5 to 75 fibers per 2.54 cm, preferably 10 to 50 fibers, and more preferably about 15 to 50 fibers.

- uniformly crimped crimped fibers can be used. It is preferable to disperse and hold the highly absorbent polymer particles in the absorber 56.

- the absorber 56 may have a rectangular shape, but as shown in FIG. 7 and the like, if the absorber 56 has an hourglass shape having a constricted portion 56N narrower than both front and rear sides in the middle in the front-rear direction, the absorber 56 itself It is preferable because the fit of the rising gather 60 around the legs is improved.

- the size of the absorber 56 can be appropriately determined as long as it extends to the front, back, left, and right of the urination port position, but it is preferable that the size of the absorber 56 extends to the peripheral edge of the interior body 200 or its vicinity in the front-rear direction LD and the width direction WD. ..

- Reference numeral 56X indicates the entire width of the absorber 56.

- the absorber 56 may contain high-absorbent polymer particles in part or all of the absorber 56.

- the highly absorbent polymer particles include "powder" in addition to "particles".

- the highly absorbent polymer particles those used for this type of disposable diaper can be used as they are. For example, they are sifted by sieving (shaking for 5 minutes) using a standard sieve (JIS Z8801-1: 2006) of 500 ⁇ m. It is desirable that the proportion of particles remaining on the sieve is 30% by weight or less, and the proportion of particles remaining on the sieve is 60 by sieving (shaking for 5 minutes) using a standard sieve of 180 ⁇ m (JIS Z8801-1: 2006). It is desirable that the weight is% or more.

- the material of the highly absorbent polymer particles can be used without particular limitation, but those having a water absorption of 40 g / g or more are preferable.

- Highly absorbent polymer particles include starch-based, cellulose-based and synthetic polymer-based ones, which are starch-acrylic acid (salt) graft copolymers, saponified starch-acrylonitrile copolymers, and crosslinked sodium carboxymethyl cellulose.

- a substance or an acrylic acid (salt) polymer or the like can be used.

- As the shape of the highly absorbent polymer particles a powder or granular material that is usually used is preferable, but other shapes can also be used.

- the highly absorbent polymer particles those having a water absorption rate of 70 seconds or less, particularly 40 seconds or less, are preferably used. If the water absorption rate is too slow, the liquid supplied into the absorber 56 tends to return to the outside of the absorber 56, so-called reversion.

- the highly absorbent polymer particles those having a gel strength of 1000 Pa or more are preferably used. As a result, even when the bulky absorber 56 is used, the sticky feeling after liquid absorption can be effectively suppressed.

- the amount of the highly absorbent polymer particles to be grained can be appropriately determined according to the amount of absorption required for the application of the absorber 56. Therefore, although it cannot be said unconditionally, it can be set to 50 to 350 g / m 2 . If the polymer coating amount is less than 50 g / m 2 , it becomes difficult to secure the absorption amount. Above 350 g / m 2 , the effect saturates.

- tissue paper particularly crepe paper, non-woven fabric, non-woven fabric of polylami, sheet having small holes, or the like can be used. However, it is desirable that the sheet does not allow the highly absorbent polymer particles to escape.

- a non-woven fabric is used instead of the crepe paper, a hydrophilic SMS non-woven fabric (SMS, SMSMS, etc.) is particularly suitable, and polypropylene, polyethylene / polypropylene composite material, or the like can be used as the material.

- the texture is preferably 5 to 40 g / m 2 , especially 10 to 30 g / m 2 .

- the packaging structure of the packaging sheet 58 can be appropriately determined, but from the viewpoint of ease of manufacture and prevention of leakage of highly absorbent polymer particles from the front and rear edge edges, a cylinder is provided so as to surround the front and back surfaces and both side surfaces of the absorber 56. It is preferable that the parts are wound in a shape, the front and rear edges thereof are projected from the front and rear of the absorber 56, and the overlapping portion and the overlapping portion of the front and rear protruding portions are joined by a joining means such as hot melt adhesive or material welding.

- the rising gather 60 has a rising portion 68 that rises from the side portion of the interior body 200, and the rising portion 68 contacts the range from the inguinal region of the wearer to the buttocks via the legs to prevent lateral leakage. It is a thing.

- the base side portion 60B stands up diagonally toward the center side in the width direction

- the tip side portion 60A stands up diagonally toward the outside in the width direction from the middle portion. It is not limited, and it is possible to make appropriate changes such as those standing on the center side in the width direction as a whole.

- a strip-shaped gather sheet 62 having a length equal to the length in the front-rear direction of the interior body 200 is folded back in the width direction WD at the tip portion and folded in two.

- a plurality of elongated gather elastic members 63 are fixed in a stretched state along the longitudinal direction between the folded portion and the sheets in the vicinity thereof at intervals in the width direction WD.

- the base end portion (the end portion opposite to the sheet folded portion in the width direction WD) located on the side opposite to the tip portion of the rising gather 60 is fixed to the side portion on the back side of the liquid permeable sheet 11 in the interior body 200.

- the root portion 65 is formed, and the portion other than the root portion 65 is a main body portion 66 (a portion on the folded-back portion side) extending from the root portion 65. Further, the main body portion 66 has a root side portion 60B extending toward the center in the width direction and a tip side portion 60A folded back at the tip of the root side portion 60B and extending outward in the width direction.

- the front-rear direction intermediate portion of the main body portion 66 is fixed to the side surface of the top sheet 30 in the front-rear direction, while the front-rear direction intermediate portion located between them is not fixed.

- a gathered elastic member 63 along the front-rear direction LD is fixed to at least the tip of the raised portion 68 in an extended state.

- the rising portion 68 rises so as to come into contact with the skin as shown by the arrow in FIG. 3 due to the contraction force of the gather elastic member 63.

- the rising portion 68 stands up so as to open outward in the width direction in the crotch portion and its vicinity, so that the rising gather 60 abuts on the surface around the legs. And the fit will be improved.

- the root portion 65 can also be fixed to the front side of the interior body 200, for example, the surfaces of both side portions of the top sheet 30.

- the main body portion 66 is bent by a root side portion 60B extending toward the center in the width direction and a tip side portion 60A folded back at the tip of the root side portion 60B and extending outward in the width direction.

- the tip side portion 60A and the root side portion 60B are joined to the top sheet 30 in the inverted state at the lodging portion 67

- the root side portion 60B is joined to the top sheet 30 in the inverted state.

- At least one of hot melt adhesives by various coating methods and material welding means such as heat sealing and ultrasonic sealing can be used for joining the facing surfaces in the inverted portion 67.

- the joining of the root side portion 60B and the top sheet 30 and the joining of the tip side portion 60A and the root side portion 60B may be performed by the same means or by different means.

- the root side portion 60B and the top sheet 30 are joined by a hot melt adhesive, and the tip side portion 60A and the root side portion 60B are joined by material welding.

- a flexible, uniform and concealing non-woven fabric such as a spunbonded non-woven fabric (SS, SSS, etc.), an SMS non-woven fabric (SMS, SMSMS, etc.), a melt-blown non-woven fabric, etc.

- a fiber texture of the non-woven fabric is preferably about 10 to 30 g / m 2 .

- the gather elastic member 63 thread rubber or the like can be used. When spandex rubber is used, the thickness is preferably 470 to 1240 dtex, more preferably 620 to 940 dtex.

- the elongation rate of the gathered elastic member 63 in the attached state is preferably 150 to 350%, more preferably 200 to 300%.

- the number of gather elastic members 63 is preferably 2 to 6, and more preferably 3 to 5.

- the arrangement interval of the gather elastic members 63 is appropriately 3 to 10 mm. With this configuration, the gathered elastic member 63 can easily hit the skin in the area where it is arranged.

- the gather elastic member 63 may be arranged not only on the tip side but also on the base side.

- a hot melt adhesive, heat seal, and ultrasonic waves are used for bonding the inner layer and the outer layer of the gather sheet 62 and fixing the gather elastic member 63 sandwiched between them by various coating methods. At least one of the fixing means by welding the material such as a seal can be used. If the entire inner and outer layers of the gather sheet 62 are bonded together, the flexibility is impaired. Therefore, it is preferable that the parts other than the adhesive portion of the gather elastic member 63 are not adhered or are weakly adhered.

- the gather elastic member 63 is sandwiched between the inner layer and the outer layer of the gather sheet 62 by applying a hot melt adhesive only to the outer peripheral surface of the gather elastic member 63 by a coating means such as a comb gun or a sure wrap nozzle. With only the hot melt adhesive applied to the outer peripheral surface of the gather sheet 62, the gather elastic member 63 is fixed to the inner layer and the outer layer of the gather sheet 62, and the inner layer and the outer layer of the gather sheet 62 are fixed. There is.

- At least one of a hot melt adhesive by various coating methods and a means by welding materials such as heat seal and ultrasonic seal can be used.

- Side flaps 70 extending to the side of the absorber 56 are provided on both sides of the interior body 200, and it is preferable that the side flaps 70 are formed with side expansion / contraction region SGs that expand and contract in the front-rear direction.

- the side flaps 70 of the illustrated example include one or a plurality of elongated side elastic members 73 provided along the front-rear direction LD and at intervals from each other, and a first sheet facing the outside of the side elastic members 73. It has a layer 71 and a second sheet layer 72 facing the inside of the side elastic member 73.

- the sheet material forming the first sheet layer 71 and the second sheet layer 72 is not particularly limited, and an appropriate non-woven fabric such as the above-mentioned rising gather 60 and the non-woven fabric that can be used in the above-mentioned exterior bodies 12F and 12B can be selected. .. In the examples shown in FIGS. 3, 4 and 11, as will be described later, the gather sheet 62 of the rising gather 60 is extended to form the first sheet layer 71 and the second sheet layer 72. As shown in FIGS. 9, 10 and 12, a special sheet material 79 different from the rising gather 60 may be added to construct the side flap 70.

- the front and rear ends of the side flap 70 coincide with the front and rear ends of the raised gather 60 (that is, the front and rear ends of the interior body 200 in this case), but in the latter case, the front and rear ends of the side flap 70 are raised and front and rear of the raised gather 60. It may be located on the center side in the front-rear direction from the end.

- the side elastic member 73 is not particularly limited, and an elongated elastic member similar to the gather elastic member 63 described above can be used.

- the elongation rate of the side elastic member 73 in the attached state is preferably 150 to 350%, more preferably 200 to 270%.

- the number of side elastic members 73 is preferably 2 to 16, and more preferably 6 to 10.

- the arrangement interval of the side elastic members 73 is preferably 5 to 10 mm.

- the side elastic member 73 is fixed to the first sheet layer 71 and the second sheet layer 72.

- Hot melt adhesive HM by various coating methods and material welding such as heat seal and ultrasonic seal for bonding the first sheet layer 71 and the second sheet layer 72 and fixing the side elastic member 73 sandwiched between them. Fixing means can be used. If the bonding area of the first sheet layer 71 and the second sheet layer 72 is large, the flexibility is impaired. Therefore, it is preferable that the parts other than the adhesive portion of the side elastic member 73 are not bonded or are weakly bonded.

- the hot melt adhesive HM is applied only to the outer peripheral surface of the side elastic member 73 by a coating means such as a comb gun or a sure wrap nozzle, and sandwiched between the first sheet layer 71 and the second sheet layer 72.

- the side elastic member 73 is fixed to the first sheet layer 71 and the second sheet layer 72 and the first sheet layer 71 and the second sheet layer are fixed only by the hot melt adhesive HM applied to the outer peripheral surface of the side elastic member 73. It has a structure for fixing between 72.

- the attachment range of the side elastic member 73 in the front-rear direction that is, the range in the front-rear direction in which the side expansion / contraction region SG is formed can be appropriately determined, but is the same as or more than the range in the front-rear direction of the non-joining portion 77 described later. It is preferably in a wide range. Further, it is preferable that the range of the side expansion / contraction region SG in the front-rear direction is the same as the contracted portion of the rising gather 60 by the gather elastic member 63, or extends to both front and rear sides.

- the side flap 70 has three or more sheet layers including the first sheet layer 71 and the second sheet layer 72. That is, in addition to the innermost sheet layer 74 and the outermost sheet layer 75, there is at least one inner sheet layer 76 located between them. Some or all of these sheet layers may be formed of separate sheet materials, or one sheet material may be formed by being folded once or a plurality of times.

- the inner sheet layer 76 can be appropriately selected from the above-mentioned gather sheet 62, the liquid-impermeable sheet 11, or the same non-woven fabric as the exterior bodies 12F and 12B described later, and the above-mentioned gather sheet 62 and The liquid impermeable sheet 11 can be formed by appropriately extending or folding back.

- the side flap 70 has a non-joined portion 77 in which at least one of the innermost sheet layer 74 and the outermost sheet layer 75 and the inner sheet layer 76 overlapping the innermost sheet layer 76 are not joined.

- the non-joint portion 77 is a portion that continuously or intermittently continues to the front-rear LD in the range of the width direction WD including the region between the side elastic member 73 located most laterally and the side edge of the side flap 70. Is. That is, as long as one of the innermost sheet layer 74 and the outermost sheet layer 75 and the inner sheet layer 76 overlapping the innermost sheet layer 76 are non-bonded, the non-joining portion 77 is partially or wholly layered with the other layers.

- the portion where the innermost sheet layer 74 and the inner sheet layer 76 overlapping the innermost sheet layer 76 are not joined is the most lateral portion from the side edge.

- the portion where the outermost sheet layer 75 and the inner sheet layer 76 overlapping the outermost sheet layer 75 are not joined up to the fixed position of the side elastic member 73 continues to the central side in the width direction.

- the innermost sheet layer 74 and the inner sheet layer 76 overlapping the innermost sheet layer 74 are non-joined portions, and the outermost sheet layer 75 and the back surface thereof.

- the portion that is not joined to the inner sheet layer 76 that overlaps with the inner sheet layer 76 continues from the side edge to the center side in the width direction from the fixed position of the side elastic member 73 that is the most lateral, but the former is the center in the width direction. It continues to the side.

- the size of the WD in the width direction of the non-joint portion 77 can be appropriately determined, but is preferably 2 to 15 mm, particularly preferably 5 to 10 mm. Further, the dimension of the front-rear LD of the non-joint portion 77 is preferably 30% or more, particularly 40% or more of the total length Y of the product. Further, in the case of a pants-type disposable wear article in which the front exterior body 12F and the rear exterior body 12B are separated as shown in the illustrated example, the non-joint portion 77 extends to a position where the front exterior body 12F and the rear exterior body 12B overlap each other. Is preferable.

- the non-joining portion 77 extends over the entire front-rear LD of the interior body 200. Further, the non-joining portion 77 extends only to a position between the front and rear edges of the interior body 200 and the elastic members 16 and 19 on the LO side of the most leg opening of the front exterior body 12F and the rear exterior body 12B. Is also preferable. Further, the non-joining portion 77 is the elastic members 16 and 19 on the most leg opening LO side of the front exterior body 12F and the rear exterior body 12B and the edges of the leg opening LO (the rear edge of the front exterior body 12F and the front of the rear exterior body 12B). It may extend only to the position between it and the edge.

- the gap between at least one of the innermost sheet layer 74 and the outermost sheet layer 75 and the inner sheet layer 76 overlapping the innermost sheet layer 74 is closed on both sides of the non-joint portion 77 in the width direction WD.

- one side of the gap of the non-joint portion 77 is closed by folding back the sheet material forming the innermost sheet layer 74 or the outermost sheet layer 75 at the side edge of the side flap 70, and the other side is closed. It can be closed by joining the sheet layers adjacent to each other in the thickness direction at appropriate positions using a hot melt adhesive HM, welding means, or the like.

- both sides of the gap of the non-joint portion 77 can be closed by the same method, for example, folding back of the sheet material or hot melt adhesive HM.

- the side flap 70 contracts in the front-rear direction LD with the contraction of the side elastic member 73, and as shown in FIG. 6, the side expansion / contraction region SG is formed in the portion of the side flap 70 including the non-joint portion 77. It is formed. That is, the folds of the side expansion / contraction region SG are formed side by side in the front-rear direction LD in the portion of the side flap 70 including the non-joint portion 77.

- the non-joined portion 77 is a portion where at least one of the innermost sheet layer 74 and the outermost sheet layer 75 and the inner sheet layer 76 overlapping the innermost sheet layer 76 are not joined, and the gap between the sheet layers is formed.

- the non-joint 77 is closed on both sides of the widthwise WD. Further, the non-joining portion 77 has a width direction WD range including a region between the side elastic member 73 located most laterally and the side edge of the intermediate region L (the width direction WD equal to or larger than the region). Range) follows the anteroposterior LD. That is, in the non-joint portion 77, a hollow portion surrounded by the sheet layer continues in the front-rear direction LD. As a result, the folds formed on the non-joint portion 77 are formed by a large bulge of at least one of the innermost sheet layer 74 and the outermost sheet layer 75, and are large and soft (that is, rich in cushioning property). Become. Therefore, since the large and soft folds are formed on the inside, outside, both inside and outside, or the entire thickness direction of the range including the side edge of the side flap 70, the end portion of the leg opening LO is soft to the touch.

- the side elastic member 73 may be located near the side edge of the side flap 70, but the portion of the side flap 70 from the side edge to the center side in the width direction WD of 2 to 15 mm (particularly 5 to 10 mm) is , It is preferable that the side elastic member 73 is not included and a part or all of the non-joint portion 77 is included. As described above, when the side elastic member 73 is sufficiently separated from the side edge of the side flap 70 and the separated portion includes a part or all of the non-joint portion 77, the product is held by hand at the time of mounting or purchasing.

- the positional relationship between the non-joint portion 77 and the side elastic member 73 can be appropriately determined, but as shown in the illustrated example, when at least one side elastic member 73 is provided at a position overlapping the non-joint portion 77 in the thickness direction. , The contraction force of the side elastic member 73 is directly applied to the non-joint portion 77, and the shape retention of the folds in the non-joint portion 77 is high, which is preferable.

- the inner sheet layer 76 is a sheet adjacent to both sides in the thickness direction. It is particularly preferable that it is non-fixed to the layer.

- folds are independently formed in the inner sheet layer 76 due to the contraction force of the side elastic member 73. That is, since the greatly bulging folds formed on the side flap 70 are supported by the folds of the inner sheet layer 76 independently formed inside the side flap 70, folds having better cushioning properties are formed on the side flap 70. Become so.

- the side flap 70 has a folded sheet layer folded back at the side edge of the side flap 70, and at least one of the innermost sheet layer 74 and the outermost sheet layer 75 of the side flap 70.

- the folded sheet layer means a pair of layers formed by folding the sheet material.

- the side flap 70 has a double folded sheet layer folded back at its side edge.

- the innermost sheet layer 74 and the outermost sheet layer 75 of the non-joint portion 77 are an inner portion and an outer portion, respectively, with the folded position of the folded sheet layer located on the outside as a boundary.

- the layer 76 includes an inner portion and an outer portion with the folded position of the folded sheet layer located inside as a boundary.

- the first sheet layer 71 and the second sheet layer 72 are an inner portion with the folded position of the folded sheet layer located inside as a boundary and an inner portion with the folded position of the folded sheet layer located outside as a boundary, respectively. Includes.

- the non-joining portion 77 is a portion in which the outer portion is not joined with the folding position of the folded sheet layer located outside as a boundary and the outer portion is not joined with the folding position of the folded sheet layer located inside as a boundary.

- the side flap 70 has a double folded sheet layer folded back at its side edge, and the first sheet layer 71 and the second sheet layer 72 each have a folded position of the folded sheet layer located inside. It includes one side portion and the other side portion as a boundary (that is, both the first sheet layer 71 and the second sheet layer 72 are the inner sheet layer 76). Further, the innermost sheet layer 74 and the outermost sheet layer 75 in the non-joint portion 77 are one side portion and the other side portion, respectively, with the folded position of the folded sheet layer located on the outside as a boundary.

- the non-bonded portion 77 includes a portion where the innermost sheet layer 74 and the first sheet layer 71 overlapping the innermost sheet layer 74 are not bonded, and the outermost sheet layer 75 and the second sheet layer 72 overlapping the back thereof. Is the part that is not joined.

- the folds formed on the non-joint portion 77 are formed on at least the inner and outer sides of the range including the side edge of the intermediate region L, so that the folds on both the inner and outer sides of the end of the leg opening LO are soft to the touch. ..

- the innermost sheet layer 74 and the outermost sheet layer 75 are one side portion and the other side portion with the folding position of the folded sheet layer located on the outside as a boundary, they are not due to the restoring force against the folding.

- the cushioning property of the folds formed on the joint portion 77 is particularly high.

- the folded sheet layer of the side flap 70 described above includes a first portion P1 formed by a two-layer structure of the gather sheet 62 of the rising gather 60 extending from the starting point of the rising gather 60 to the side edge of the side flap 70.

- the two-layer structure of the gather sheet 62 of the rising gather 60 can be formed by a second portion P2 that is folded back at the side edge of the side flap 70 and extends toward the center of the width direction WD.

- the exterior bodies 12F and 12B include a rectangular front exterior body 12F that constitutes at least the waist circumference portion of the front body F, and a rectangular rear exterior body 12B that is a portion that constitutes at least the waist circumference portion of the rear body B.

- the front exterior body 12F and the rear exterior body 12B are not continuous on the crotch side, but are separated in the front-rear direction LD (exterior two-divided type).

- the separation distance in the front-rear direction can be, for example, about 40 to 60% of the total length Y.

- the lower edges of the front exterior body 12F and the rear exterior body 12B are linear along the width direction WD, but at least one lower edge of the front exterior body 12F and the rear exterior body 12B is along the leg circumference. It may be curved like this.

- the exterior body 12 can be integrated from the front body F to the back body B through the crotch (exterior body integrated type).

- the exterior bodies 12F and 12B have a waist circumference portion that is a range in the front-rear direction corresponding to the waist circumference region T. Further, in this example, the rear exterior body 12B has a longer front-rear dimension than the front exterior body 12F, and the front exterior body 12F does not have a portion corresponding to the intermediate region L, but the rear exterior body The body 12B has a buttock cover portion C extending from the waist circumference region T to the intermediate region L side.

- the front exterior body 12F may also be provided with a groin cover portion extending from the waist circumference region T to the intermediate region L side, or the front exterior body 12F and the front exterior body 12F may be provided with a groin cover portion but not a buttock cover portion. It is not necessary to provide a portion corresponding to the intermediate region L on both of the rear exterior body 12B.

- the exterior bodies 12F and 12B have an inner sheet layer 12H and an outer sheet layer 12S, and elastic members 15 to 19 provided between them.

- Each sheet layer may be a common sheet material or may be an individual sheet material. That is, in the former case, in a part or all of the exterior body, the inner part and the outer part of one sheet material folded back at appropriate positions such as the edge of the waist opening WO and the edge on the leg opening LO side. Elastic members 15 to 19 can be provided between them.

- each waist portion W has a portion including a folded back of the sheet material.

- the sheet material forming the outer sheet layer 12S extends only to the edge of the waist opening WO, but the sheet material forming the inner sheet layer 12H is a sheet forming the second sheet layer. It wraps around the waist side edge of the material and is folded back inside. Further, this folded portion is an interior cover layer 12r extending over the entire width direction of the exterior body to a position overlapping the end portion of the interior body 200 on the waist opening WO side.

- the interior cover layer 12r may be attached with a dedicated sheet material without folding back the sheet material forming the inner sheet layer 12H.

- Elastic members 15 to 19 are built into the exterior bodies 12F and 12B in order to improve the fit to the waist circumference of the wearer, and an elastic region A2 that elastically expands and contracts in the width direction WD with the expansion and contraction of the elastic members is formed. ing. In the expansion / contraction region A2, the exterior bodies 12F and 12B contract with the contraction of the elastic member in the state of natural length, and wrinkles or folds are formed. When the exterior bodies 12F and 12B extend in the longitudinal direction of the elastic member, they completely expand without wrinkles. It can be stretched to a predetermined stretch rate.

- known elastic members such as strips, nets, and films can be used without particular limitation, in addition to elongated elastic members such as rubber threads (illustrated examples).

- synthetic rubber or natural rubber may be used.

- a plurality of waist elastic members 17 are spaced in the front-rear direction so as to be continuous over the entire width direction WD in the waist portions W of the exterior bodies 12F and 12B. It is installed open. Further, among the waist elastic members 17, one or a plurality of members arranged in the region adjacent to the lower waist portion U may overlap with the interior body 200, or may overlap with the interior body 200 in the width direction central portion. May be provided on both sides in the width direction except for.

- the waist elastic member 17 has a thickness of 155 to 1880 dtex, particularly about 470 to 1240 dtex (in the case of synthetic rubber, a cross section of 0.05 to 1.5 mm 2 in the case of natural rubber, particularly 0.1 to 1.0 mm). It is preferable to provide about 2 to 15 rubber threads, particularly about 4 to 10 at intervals of 2 to 12 mm, particularly at intervals of 3 to 7 mm, and thus the extension of the WD in the width direction of the waist portion W.

- the rate is preferably about 150 to 400%, particularly 220 to 320%. Further, it is not necessary for the waist portion W to use the waist elastic member 17 having the same thickness for all of the LDs in the front-rear direction or to have the same elongation rate.

- the pod elongation may be different.

- a plurality of lower waist elastic members 15 and 19 made of elongated elastic members are attached to the lower waist portion U of the exterior bodies 12F and 12B at intervals in the front-rear direction.

- the elastic members 15 and 19 below the waist have a thickness of 155 to 1880 dtex, particularly about 470 to 1240 dtex (in the case of synthetic rubber, a cross section of 0.05 to 1.5 mm 2 in the case of natural rubber, particularly 0.1 to 1). It is preferable to provide about 5 to 30 elastic strips (about 0.0 mm 2 ) at intervals of 1 to 15 mm, particularly 3 to 8 mm, and the elongation rate of the WD in the width direction of the lower waist portion U is 200 to 350%. In particular, it is preferably about 240 to 300%.

- a cover elastic member 16 made of an elongated elastic member is attached to the buttocks cover portion C of the rear exterior body 12B.

- the buttock cover portion C is contracted toward the center of the WD in the width direction by the cover portion elastic member 16.

- the cover elastic member 16 has a thickness of 155 to 1880 dtex, particularly about 470 to 1240 dtex (in the case of synthetic rubber, a cross-sectional area of 0.05 to 1.5 mm 2 in the case of natural rubber, particularly 0.1 to 1.0 mm). It is preferable to provide a rubber thread (about 2 ), and the elongation rate of the WD in the width direction of the buttocks cover portion C is preferably 150 to 300%, particularly 180 to 260%.

- the cover portion elastic member can be provided in the same manner as the buttock cover portion C.

- the width direction of the absorber 56 in a part or all of them.

- the middle width direction (preferably including the entire inner / outer joint portions 201 and 202) including a part or all of the portion overlapping the absorber 56 and the WD in the width direction is defined as the non-stretchable region A1. It is preferable that both sides in the width direction are stretchable regions A2.

- the waist portion W is preferably a stretchable region A2 over the entire width direction WD, but a non-stretchable region A1 may be provided in the middle in the width direction as in the waist lower portion U.

- a non-stretchable region A1 may be provided in the middle in the width direction as in the waist lower portion U.

- the portion located in the front-rear direction LD range having the side seal portion 12A is the waist lower stretchable region A3.

- elastic members 15 to 17, 19 are supplied between the inner sheet layer 12H and the outer sheet layer 12S, and the elastic members 15, 16 and 19 are brought into the elastic region A2.

- the elastic members 15, 16 and 19 are cut by pressurization and heating at one place in the middle in the width direction in the region having the absorber 56, or the elastic member 15 is cut.

- 16 and 19 can be constructed by cutting almost all of them into small pieces by pressurization and heating, and killing the elasticity in the non-stretchable region A1 while leaving the elasticity in the stretchable region A2.

- FIG. 19A shows a case where the elastic members 15, 16 and 19 are cut at one place in the middle in the width direction, and the outer circumference of the pressure portion 171 having the cutting convex part 172 at one place in the circumferential direction.

- An elastic member 15 is provided between the inner sheet layer 12H and the outer sheet layer 12S by a seal roll 170 in which the cutting convex portion 172 is heated to a desired temperature in preparation for a surface and an anvil roll 180 having a smooth surface arranged opposite to the seal roll 170.

- the cut target to which the to 17 and 19 are attached is sandwiched so that the inner sheet layer 12H is on the seal roll side, and the elastic members 15, 16 only are sandwiched between the cut convex portion 172 and the outer peripheral surface of the anvil roll 180. 19 is pressurized and heated to cut.

- the product subjected to such processing as shown in FIG. 20A, between the outer sheet layer 12S and the inner sheet layer 12H, only the cutting residue continuous from the elastic members 15, 16 and 19 of the elastic region A2 is provided. Will remain as an unnecessary elastic member 18 in a state of being contracted to its natural length by itself.

- FIG. 19B shows a case where almost the entire elastic members 15, 16 and 19 are finely cut, and a pressing portion 171 having a large number of cutting convex portions 173 is provided on the outer peripheral surface, and the cutting convex portions are provided.

- Elastic members 15 to 17, 19 were attached between the inner sheet layer 12H and the outer sheet layer 12S by the seal roll 170 in which the 173 was heated to a desired temperature and the surface-smooth anvil roll 180 arranged opposite to the seal roll 170.

- the object to be cut is sandwiched so that the inner sheet layer 12H is on the seal roll side, and the elastic members 15, 16 and 19 are pressurized and heated only at the portion sandwiched between the cutting convex portion 173 and the outer peripheral surface of the anvil roll 180.

- the sheet material forming the inner sheet layer 12H and the outer sheet layer 12S can be used without particular limitation, but a non-woven fabric is preferable. When a non-woven fabric is used, the texture per sheet is preferably about 10 to 30 g / m 2 .

- the elastic members 15 to 19 are fixed to the exterior bodies 12F and 12B by the hot melt adhesive HM by various coating methods.

- the inner sheet layer 12H and the outer sheet layer 12S are preferably joined by a hot melt adhesive HM for fixing the elastic members 15 to 19 at the portions having the elastic members 15 to 19, respectively, and the elastic members 15 to 19 are joined.

- it may be bonded by hot melt adhesive HM, it may be bonded by material welding such as heat seal or ultrasonic seal, or it may not be bonded in part or in whole.

- the hot melt adhesive HM is applied only to the outer peripheral surfaces of the elastic members 15 to 19 by a coating means such as a comb gun or a sure wrap nozzle, and the sheet layers are laminated.

- the elastic members 15 to 19 are fixed to both sheet layers and the layers between the two sheets are fixed only by the hot melt adhesive HM applied to the outer peripheral surfaces of the elastic members 15 to 19 by sandwiching the elastic members 15 to 19.

- the elastic members 15 to 19 may be fixed to both sheet layers only at both ends in the expansion / contraction direction in the expansion / contraction region A2.

- the waist lower elastic region A3 of the front body F is a high extension region A4 extending toward the center in the width direction from the rising gather 60, and the rising portion 68 and the rising portion 68 It is preferable that the gather elastic member 63 extends toward the waist opening WO side into the high extension region A4 of the front body F.

- the high extension region A4 of the waist lower expansion / contraction region A3 exists so as to cross the recess of the wearer's inguinal region, so that the exterior bodies 12F and 12B firmly follow the expansion / contraction of the groove in the inguinal region and firmly carry out the interior body 200. Can be pressed.

- the portion of the rising portion 68 of the rising gather 60 and the gather elastic member 63 extend to the portion pressed by the high extension region A4, the portion of the rising portion 68 having the gather elastic member 63 is relative to the inguinal region.

- the high extension region A4 that is firmly pressed as a base, it is possible to get up so as to enter the dent in the inguinal region. Therefore, in this pants type disposable wear article, the fit to the inguinal region is remarkably improved.

- the fit to the leg circumference has to be lowered, and the fit of the inguinal region is particularly liable to be lowered. That is, since the distance from the position corresponding to the crotch part of the interior body 200 to the intersection position with the exterior bodies 12F and 12B is long in the pants type disposable diaper of the exterior two-split type, the interior body 200 is left and right with the intersection position as a fulcrum. The interior body 200 is easier to move in the lateral direction as compared with the type provided with the integrated outer body 12 continuous from the front body F to the back body B because it is easily shaken by the body.

- the crotch-side edges of the exterior bodies 12F and 12B have a linear shape or a shape close to the straight line along the width direction WD, and are perpendicular to or close to the side edges of the interior body 200. Cross at a close angle.

- the side expansion / contraction region SG elastically supports the lateral movement of the interior body 200, and the side expansion / contraction region SG covers the side of the interior body 200. This is preferable because a gap is less likely to occur on the side of the interior body 200.

- the positional relationship between the high extension region A4 and the rising gather 60 can be appropriately determined, but normally, the dimension of the width direction WD of the non-extension region A1 in the range of the anteroposterior LD having the high extension region A4 is absorbed. It is less than 1/2 of the width direction WD dimension 56X of the body 56, and the distance D1 (the distance between the edges on the center side of the width direction WD in the unfolded state) of the rising gathers 60 on both sides is the dimension of the width direction WD of the absorber 56.

- the rising portion 68 of the rising gather 60 and the gather elastic member 63 preferably extend to the waist side end of the high extension region A4, but may extend only to the middle of the high extension region A4 in the front-rear direction. Further, the dimensions of the front-rear direction LD of the overlapping portion of the high extension region A4, the rising portion 68 of the rising gather 60 and the gather elastic member 63 are the dimensions of the front-rear direction LD of the region where the interior body 200 and the front body F overlap. It is preferably about 4 to 95%, particularly preferably about 7 to 20%.

- the high extension region A4 may be provided over the entire front-back direction of the waist lower extension / contraction region A3 as in the example shown in FIG. 13, but may be only a part as in the example shown in FIG.

- the edge of the waist lower stretchable region A3 on the non-stretchable region A1 side is gradually or continuously located on the WD center side in the width direction from the waist opening WO side toward the crotch side.

- the high extension region A4 is provided only on the crotch side in the waist lower extension / contraction region A3.

- the groin dent is prominent on the crotch side and rarely occurs on the waist side. Therefore, it is preferable to provide the high extension region A4 only in the portion where the depression of the inguinal region tends to be deep, thereby improving the fit to the inguinal region and preventing the absorber 56 from shrinking in the other portions.

- the size of the front-rear LD in the high extension region A4 is preferably about 4 to 95%, particularly about 7 to 20%, of the size of the front-rear LD in the region where the interior body 200 and the front body F overlap. ..

- the waist lower elastic member 19 incorporated in the high extension region A4 is an elongated elastic member

- the high extension region A4 preferably includes a plurality of waist lower elastic members 19.

- the edge of the waist lower stretchable region A3 other than the high stretchable region A4 on the non-stretchable region A1 side extends to the end of the absorber 56 in the width direction WD as shown in the illustrated example.

- the absorber 56 may be located laterally from both side edges. In the latter case, the edge of the lower waist stretchable region A3 other than the high stretchable region A4 on the non-stretchable region A1 side is lateral to the side flap 70 even if it is located on the side flap 70. It may be located.

- the edges may be curved, stepped, or straight along the anteroposterior LD, respectively.

- a high extension region A4 can also be provided in the waist lower extension region A3 of the back body B in order to maintain the front-back expansion / contraction balance.

- the heights of the front body F and the back body B are high. It is particularly preferable that the vertical positions of the extension regions A4 match.

- the interior body 200 can be fixed to the exterior bodies 12F and 12B by joining means such as heat sealing and ultrasonic sealing by welding materials, or by a hot melt adhesive.

- the back surface of the interior body 200 that is, in this case, the back surface of the liquid-impermeable sheet 11 and the inner surface of the exterior bodies 12F and 12B via the hot melt adhesive applied to the root portion 65 of the rising gather 60.

- the inner / outer joints 201 and 202 for fixing the inner body 200 and the outer bodies 12F and 12B can be provided in almost the entire region where the two overlap, for example, the inner body 200. It can also be provided at a portion excluding both ends in the width direction.

- the inner / outer joint portions 201 and 202 are on the non-stretchable region A1 side of one of the lower waist stretchable regions A3 in the range of the anteroposterior LD having the waist lower stretchable region A3. It is also preferable that it is provided only in the range from the end portion to the end portion of the other waist lower stretchable region A3 on the non-stretchable region A1 side. As described above, limiting the width of the inner / outer joint portions 201 and 202 to the same level as the width of the non-stretchable region A1 is preferable because unnecessary contraction of the absorber 56 can be suppressed.

- the fit to the inguinal region is excellent due to the formation of the high elongation region A4 and the positional relationship between the high elongation region A4 and the rising gather 60, so that the fit to the inguinal region is excellent.

- the contradictory actions of improving the above and suppressing unnecessary contraction of the absorber 56 are compatible.

- the inner / outer joints 201 and 202 may be located only in the non-stretchable region A1, but from the end of one waist lower stretchable region A3 on the non-stretchable region A1 side, the other waist lower stretchable region A3 is non-stretchable. It is preferable that it is provided over the end portion on the expansion / contraction region A1 side. In the latter case, for example, as shown in the illustrated example, the edge of the waist lower stretchable region A3 on the non-stretchable region A1 side gradually or continuously is the center of the width direction WD from the waist opening WO side toward the crotch side. When it extends so as to be located on the side, the position of the WD in the width direction of the side edges of the inner and outer joints 201 and 202 also changes from the waist opening WO side toward the crotch side.

- the dimensions of the WD in the width direction of the inner and outer joints 201 and 202 can be appropriately determined, but in the normal case, they can be about 75 to 95% of the dimensions of the WD in the width direction of the non-stretchable region A1.

- the inner / outer joints 201 and 202 may have an appropriate shape regardless of the position of the side edge of the waist lower stretchable region A3 on the non-stretchable region A1 side. Therefore, for example, like the front body F in the illustrated example, the inner / outer joints 201 and 202 can have a constricted shape in which the width of the intermediate portion is narrower than the width of both ends of the LD in the front-rear direction. Further, as in the rear body B of the illustrated example, the inner / outer joints 201 and 202 may have a T-shape in which the width on the crotch side is narrower than the width on the waist opening WO side.

- the interior body 200 is exposed between the front exterior body 12F and the rear exterior body 12B, so that the liquid permeable sheet 11 is not exposed on the back surface of the interior body 200. It is preferable that the back surface of the interior body 200 is provided with a cover non-woven fabric 13 extending between the front exterior body 12F and the interior body 200 and between the rear exterior body 12B and the interior body 200. The inner surface and the outer surface of the cover non-woven fabric 13 can be adhered to the facing surfaces via a hot melt adhesive. As the non-woven fabric used for the cover non-woven fabric 13, for example, the same material as that of the exterior bodies 12F and 12B can be appropriately selected.

- Non-woven fabric As the non-woven fabric in the above description, a known non-woven fabric can be appropriately used depending on the site and purpose.

- the constituent fibers of the non-woven fabric include olefin-based fibers such as polyethylene and polypropylene, polyester-based and polyamide-based synthetic fibers (including single-component fibers and composite fibers such as core sheaths), as well as recycled rayon and cupra. Fibers, natural fibers such as cotton, and the like can be selected without particular limitation, and these can be mixed and used. In order to increase the flexibility of the non-woven fabric, it is preferable that the constituent fibers are crimped fibers.

- the non-woven fabric generally has a short fiber non-woven fabric, a long fiber non-woven fabric, a spunbond non-woven fabric, a melt blown non-woven fabric, a spunlace non-woven fabric, a thermal bond (air-through) non-woven fabric, and a needle punch depending on the fiber length, the sheet forming method, the fiber bonding method, and the laminated structure.

- non-woven fabrics It is classified into non-woven fabrics, point-bonded non-woven fabrics, laminated non-woven fabrics (SMS non-woven fabrics having a melt blown layer sandwiched between spunbond layers, SMMS non-woven fabrics, etc.), and any of these non-woven fabrics can be used.

- SMS non-woven fabrics having a melt blown layer sandwiched between spunbond layers, SMMS non-woven fabrics, etc.

- the "front-back direction” means the direction indicated by the symbol LD in the figure (vertical direction)

- the "width direction” means the direction indicated by WD (horizontal direction) in the figure, and the front-back direction and the width direction. Are orthogonal.

- Front side means the side of the member that is closer to the wearer's skin when wearing a pants-type disposable diaper

- back side means the side of the member that is closer to the wearer's skin when wearing a pants-type disposable diaper. It means the far side.

- Elongation rate means the value when the natural length is 100%. For example, an elongation rate of 200% is synonymous with an elongation ratio of 2 times.