WO2019207492A1 - Dense media separation method - Google Patents

Dense media separation method Download PDFInfo

- Publication number

- WO2019207492A1 WO2019207492A1 PCT/IB2019/053362 IB2019053362W WO2019207492A1 WO 2019207492 A1 WO2019207492 A1 WO 2019207492A1 IB 2019053362 W IB2019053362 W IB 2019053362W WO 2019207492 A1 WO2019207492 A1 WO 2019207492A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- dms

- feed

- density

- grade

- mixture

- Prior art date

Links

- 238000000926 separation method Methods 0.000 title claims abstract description 40

- 239000000203 mixture Substances 0.000 claims abstract description 31

- 239000007787 solid Substances 0.000 claims abstract description 21

- 238000000034 method Methods 0.000 claims abstract description 20

- 239000011236 particulate material Substances 0.000 claims abstract description 15

- 239000000725 suspension Substances 0.000 claims abstract description 15

- 239000007788 liquid Substances 0.000 claims abstract description 7

- 239000006249 magnetic particle Substances 0.000 claims abstract description 5

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 67

- 239000002245 particle Substances 0.000 claims description 55

- 229910000519 Ferrosilicon Inorganic materials 0.000 claims description 52

- 229910052742 iron Inorganic materials 0.000 claims description 41

- 238000007885 magnetic separation Methods 0.000 claims description 2

- 230000010355 oscillation Effects 0.000 claims description 2

- 238000005406 washing Methods 0.000 claims description 2

- 239000000047 product Substances 0.000 description 59

- 239000002609 medium Substances 0.000 description 45

- 238000009826 distribution Methods 0.000 description 36

- 238000012360 testing method Methods 0.000 description 32

- LIKBJVNGSGBSGK-UHFFFAOYSA-N iron(3+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[Fe+3].[Fe+3] LIKBJVNGSGBSGK-UHFFFAOYSA-N 0.000 description 27

- 229910052595 hematite Inorganic materials 0.000 description 26

- 239000011019 hematite Substances 0.000 description 26

- 241000196324 Embryophyta Species 0.000 description 24

- 239000000463 material Substances 0.000 description 22

- 229910052500 inorganic mineral Inorganic materials 0.000 description 18

- 239000011707 mineral Substances 0.000 description 18

- 238000011084 recovery Methods 0.000 description 18

- 238000004458 analytical method Methods 0.000 description 17

- 239000006148 magnetic separator Substances 0.000 description 17

- 239000002699 waste material Substances 0.000 description 17

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 16

- 230000000694 effects Effects 0.000 description 10

- 238000005192 partition Methods 0.000 description 9

- 238000002360 preparation method Methods 0.000 description 9

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 9

- 238000004453 electron probe microanalysis Methods 0.000 description 8

- 230000005484 gravity Effects 0.000 description 7

- 239000000126 substance Substances 0.000 description 7

- 238000012512 characterization method Methods 0.000 description 6

- 238000002156 mixing Methods 0.000 description 6

- 230000005291 magnetic effect Effects 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- 238000005188 flotation Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 238000012216 screening Methods 0.000 description 4

- 238000003556 assay Methods 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000010790 dilution Methods 0.000 description 3

- 239000012895 dilution Substances 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 239000010453 quartz Substances 0.000 description 3

- 238000010992 reflux Methods 0.000 description 3

- 238000000518 rheometry Methods 0.000 description 3

- 238000004088 simulation Methods 0.000 description 3

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- 101000993059 Homo sapiens Hereditary hemochromatosis protein Proteins 0.000 description 2

- 241001198066 Solanum aethiopicum Species 0.000 description 2

- 235000018650 Solanum gilo Nutrition 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000011362 coarse particle Substances 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 229920002635 polyurethane Polymers 0.000 description 2

- 239000004814 polyurethane Substances 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 239000000843 powder Substances 0.000 description 2

- 239000000377 silicon dioxide Substances 0.000 description 2

- 239000002002 slurry Substances 0.000 description 2

- 230000003019 stabilising effect Effects 0.000 description 2

- 238000004846 x-ray emission Methods 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- MWRWFPQBGSZWNV-UHFFFAOYSA-N Dinitrosopentamethylenetetramine Chemical compound C1N2CN(N=O)CN1CN(N=O)C2 MWRWFPQBGSZWNV-UHFFFAOYSA-N 0.000 description 1

- 102100032670 Endophilin-B1 Human genes 0.000 description 1

- 101000654648 Homo sapiens Endophilin-B1 Proteins 0.000 description 1

- ROAIXOJGRFKICW-UHFFFAOYSA-N Methenamine hippurate Chemical compound C1N(C2)CN3CN1CN2C3.OC(=O)CNC(=O)C1=CC=CC=C1 ROAIXOJGRFKICW-UHFFFAOYSA-N 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 238000000889 atomisation Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 229940112112 capex Drugs 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- AIXMJTYHQHQJLU-UHFFFAOYSA-N chembl210858 Chemical compound O1C(CC(=O)OC)CC(C=2C=CC(O)=CC=2)=N1 AIXMJTYHQHQJLU-UHFFFAOYSA-N 0.000 description 1

- 239000002734 clay mineral Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 229910052681 coesite Inorganic materials 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 230000001010 compromised effect Effects 0.000 description 1

- 239000000356 contaminant Substances 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 229910052906 cristobalite Inorganic materials 0.000 description 1

- 230000001186 cumulative effect Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 238000000280 densification Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- YGANSGVIUGARFR-UHFFFAOYSA-N dipotassium dioxosilane oxo(oxoalumanyloxy)alumane oxygen(2-) Chemical compound [O--].[K+].[K+].O=[Si]=O.O=[Al]O[Al]=O YGANSGVIUGARFR-UHFFFAOYSA-N 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012526 feed medium Substances 0.000 description 1

- 239000000706 filtrate Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- FEBLZLNTKCEFIT-VSXGLTOVSA-N fluocinolone acetonide Chemical compound C1([C@@H](F)C2)=CC(=O)C=C[C@]1(C)[C@]1(F)[C@@H]2[C@@H]2C[C@H]3OC(C)(C)O[C@@]3(C(=O)CO)[C@@]2(C)C[C@@H]1O FEBLZLNTKCEFIT-VSXGLTOVSA-N 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000009689 gas atomisation Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000011835 investigation Methods 0.000 description 1

- SZVJSHCCFOBDDC-UHFFFAOYSA-N iron(II,III) oxide Inorganic materials O=[Fe]O[Fe]O[Fe]=O SZVJSHCCFOBDDC-UHFFFAOYSA-N 0.000 description 1

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 1

- 229910052622 kaolinite Inorganic materials 0.000 description 1

- 239000006194 liquid suspension Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000005065 mining Methods 0.000 description 1

- 229910052627 muscovite Inorganic materials 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 238000011027 product recovery Methods 0.000 description 1

- 238000004537 pulping Methods 0.000 description 1

- 238000001812 pycnometry Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000001878 scanning electron micrograph Methods 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 238000005029 sieve analysis Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 241000894007 species Species 0.000 description 1

- 229910052682 stishovite Inorganic materials 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 229910052905 tridymite Inorganic materials 0.000 description 1

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03B—SEPARATING SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS

- B03B5/00—Washing granular, powdered or lumpy materials; Wet separating

- B03B5/28—Washing granular, powdered or lumpy materials; Wet separating by sink-float separation

- B03B5/30—Washing granular, powdered or lumpy materials; Wet separating by sink-float separation using heavy liquids or suspensions

- B03B5/32—Washing granular, powdered or lumpy materials; Wet separating by sink-float separation using heavy liquids or suspensions using centrifugal force

- B03B5/34—Applications of hydrocyclones

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03B—SEPARATING SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS

- B03B5/00—Washing granular, powdered or lumpy materials; Wet separating

- B03B5/28—Washing granular, powdered or lumpy materials; Wet separating by sink-float separation

- B03B5/30—Washing granular, powdered or lumpy materials; Wet separating by sink-float separation using heavy liquids or suspensions

- B03B5/44—Application of particular media therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03B—SEPARATING SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS

- B03B7/00—Combinations of wet processes or apparatus with other processes or apparatus, e.g. for dressing ores or garbage

Definitions

- the present invention relates to the separation of solids.

- the invention relates particularly to fine (less than 1 mm) feed Dense Media Separation (DMS).

- DMS Dense Media Separation

- DMS Dense Media Separation

- the DMS process involves the use of a suspension of particulate material in a liquid, typically water.

- the particulate material, or media preferably comprises magnetic particles, for example magnetite or ferrosilicon (FeSi) particles because this facilitates the recovery of the particulate material for reuse after the separation process.

- the particles of the particulate material are sufficiently fine to allow their stable suspension in the relevant liquid, and typically take the form of powder, while being sufficiently dense/heavy to provide the required media density.

- the media particles are typically formed by milling or atomisation.

- the resulting media suspension is commonly referred to as a dense medium.

- the particulate material comprises magnetic or magnetised particles

- the media suspension has a density greater than that of the liquid alone.

- a typical dense medium may have an apparent density of, say, 2.65 specific gravity while the specific gravity of water is 1 .

- the advantage of using a magnetic particulate material is to facilitate subsequent retrieval of the particulate material for reuse.

- the media suspension is contained in a separation vessel, for example a cyclone vessel (sometimes referred to as a dense medium cyclone).

- the media suspension is usually mixed with the solids to be separated (typically comprising ore) before being transferred to the separation vessel.

- separation is effected by differences in centrifugal force experienced by particles of the solids to be separated of differing density, the less dense material tending to float in the liquid suspension and so exiting the cyclone at the top (“floats”), while the denser material sinks and exits through the bottom (“sinks”).

- Fine suspension media adheres to the ore/solids surface and is difficult to wash off from the recovered product at the end of the process. 2. Fine suspension media is more susceptible to corrosion (e.g. oxidation) due to the high surface area to volume.

- Ferrosilicon is manufactured as either milled or atomised.

- the atomised version is commonly manufactured in five size fractions: Special Coarse, Coarse, Fine, Cyclone 60 and Cyclone 40 and, because it is spherical, it is more easily washed, more resistant to corrosion but is more expensive.

- Milled ferrosilicon is cheaper and is commercially available in six different sizes: 1 00#, 65D, 1 00D, 1 50D, 270D, 270F (from for example DMS Powders (www.dmspowders.com) or M & M Alloys Limited (www.mandmalloys.com).

- DMS Powders www.dmspowders.com

- M & M Alloys Limited www.mandmalloys.com

- ferrosilicon losses in cyclone DMS circuits range from 1 20g ferrosilicon per tonne (g/t) up to 500 g/t.

- Media losses are known to represent from 20% to 40% of the total operating costs of a DMS plant.

- the invention provides a method of separating solids, the method comprising: i) adding the solids to a suspension of particulate material comprising magnetic particles in a liquid to create a mixture, ii) locating the mixture in a separation vessel such that rotation is imparted to the mixture around a space bounded by an outer wall of the vessel to impart a centrifugal force on the solids; iii) the mixture is separated into a floats and sinks fractions;

- said particulate material is ferrosilicon having D90 particle size of below 200pm

- the solids is iron ore having a particle size of less than 1 mm and greater than 200 micron (-1 mm +200 pm), for example (- 1 mm+212pm), preferably greater than 400 micron (pm) (- 1 +400pm),

- the feed density of the mixture is less than 3.8 g/cm 3 , preferably less than 3.6 g/cm 3 ,

- the operating pressure of the mixture is from 10 to 1 5D

- the cut point differential is between 0.1 and 0.6 of the feed density

- the mixture includes a slimes iron ore fraction of less than 1 0%.wt. having a particle size of less than 45pm.

- the suspension of particulate material comprising magnetic particles in a liquid may be known as the medium.

- the floats and sinks fractions are subject to magnetic separation before washing to recover the particulate material.

- the floats and sinks fractions may be passed over separation screens vibrating at a frequency of greater than about 50Hz.

- the separation screens may have a double oscillation.

- cyclone Operating Head is a function of Feed Pressure and Feed Density (and is reported as a ratio of Total Head (m) and

- Testwork has previously been conducted on samples from Kumba Iron Ore to compare the performance of DMS to that of a spiral circuit on fine iron ore

- the current objective of the testwork was therefore to compare the performance of both atomised FeSi types across a range of operating conditions in the presence of slimes build-up, as well as to define DMS modeling parameters for each of the FeSi types.

- Particle size distribution was done on a 2x1 kg sub-sample, using root two sizing.

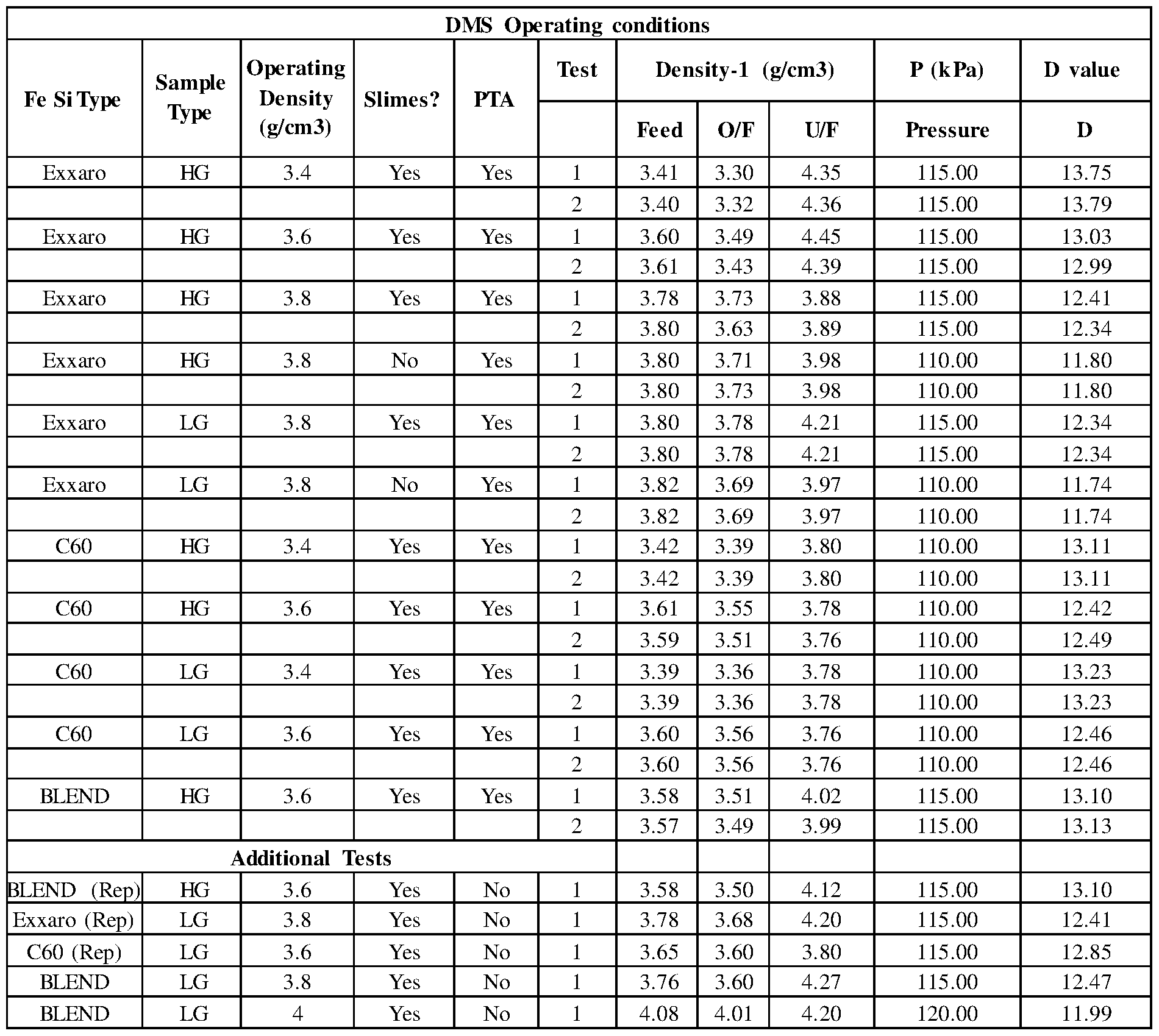

- Test work strategy Figure 1 and Table 1 below outlines the test work strategy for the DMS runs. In total, 1 6 DMS tests were conducted - an initial 1 1 tests followed by an additional 5 tests.

- Mineralogy Particle Tracking Analysis - PTA was used to characterize each ore type in terms of mineral, density and size distribution of the feed and DMS products. The liberation characteristics of each mineral by size class were also reported.

- Particle characterisation data pertaining to mineral types/compositions, particle size, density, weight percent of the particle population, area of particle, shape factor, circularity, and perimeter of each particle were ascertained during offline processing.

- shape descriptors such as shape factor, circularity and equivalent circle diameter (ECD) were included in the overall data set for each size fraction.

- FIG. 2 and Figure 3 shows the pilot DMS test rig flowsheet and DMS pilot plant setup respectively used for the testwork.

- the DMS plant is equipped with a 250mm diameter Multotec cyclone.

- the pilot test operating parameters were monitored during the test. These include circulating feed density, cyclone underflow and overflow densities to ensure steady state conditions. Feed pressure was also monitored to ensure constant feed pressure to the cyclone.

- the DMS sieve bands of 600mGP were covered with wire mesh of 250pm to help avoid fines going through sieve bands.

- the DMS testwork was conducted to target above 1 2D values at different feed densities. A density differential less than 0.4 RD is recommended for the efficient operation of the cyclone when the proportion of near gravity feed material is high.

- the unit has no moving parts which reduces the maintenance requirements.

- the float and sinks products from each run were collected over a period of 30-45 minutes, sun dried and weighed.

- the products were screened using 212pm screen to remove FeSi and a magnet was used to further remove residual FeSi on the +212pm fractions.

- Representative 7 sub-samples of 1 0kg from both float and sinks of each run were sub-sampled and the products were sent for chemical as well as mineralogical analysis.

- the PTA results obtained from all the DMS tests conducted were used to determine the parameters of a standard DMS Weibull model for each of the FeSi types.

- the model takes the mineral, density and size distribution of the feed material into account to predict DMS performance, once the parameters are defined. Correct characterisation of the feed material is essential in order to predict performance with confidence.

- Mineralogical evaluation of the BIF (low grade) sample indicated that the hematite particles did not contain porosity or micro-inclusions. The hematite was thus classified as high density, high Fe grade particles and EMPA was thus not conducted on this sample.

- EMPA was conducted on the high grade sample, in order to classify the hematite phases correctly and then reliably assign an Fe -grade and density to each phase identified.

- Figure 6 shows a SEM image of the high grade sample. Note that the number within the grains shows the sites of individual EPMA measurements.

- the dark grey grains in the above image were classified as hematite A and consist of clean high-quality hematite.

- the medium gray grains represent clean high-quality hematite containing micropores and were classified as hematite B.

- the presence of the micropores resulted in a lower average relative density for this hematite class which will be realistically experienced in water based separation. The lower density will not be evident when pycnometry is done, since the particles will be pulverised and the pores removed.

- the light gray grains were classified as “hematite” C and are inherently low-quality hematites which contain both micro pores and micro-inclusions of Si, Al and K bearing minerals.

- a minerals reference list is defined, which is used by the MLA, to classify the particles identified correctly.

- Tables 3 and Table 4 show the mineral reference lists for the BIF (low grade) and Jig Fines Feed (high grade) samples respectively.

- Table 3 shows only one phase of hematite (A) being present in the low grade sample, with a pure hematite content reported as 66.8% Fe at a density of 5.05g/cm 3 .

- Three hematite phases (Table 4) were observed in the high grade sample with hematite classes ranging from 62.0% to 67.2% and densities between 4.5-5.1 g/cm 3 .

- Table 3 Mineral reference list for low grade sample

- Table 4 Mineral reference list for high grade sample

- Table 6 shows a significant portion of hematite C (26.3%) present in the high grade sample. This will contribute to a high amount of near-density material of the DMS feed as well as negatively affect the attainable product Fe grade.

- Figure 7 comparatively summarises hematite liberation for the three phases identified, for both the high grade and low grade sample.

- Density distribution Figures 8 to 1 1 show the density by size distribution of the hematite types present in the low grade and high grade samples. These figures attempt to visually represent the contribution of each size class of DMS feed, highlighting the mass percent and amount of near-density fractions present.

- FIG Fe grade in the density class 4.9g/ml is given as 62.66%Fe. This is due to the material in this class being dominated by Flematite C (1 1 .6% mass) locked with Flematite A (3.5% mass)).

- Table 7 Feed density distribution for low grade and high grade

- DMS Dense Medium Separation

- DMS testwork was conducted on a pilot plant equipped with a 250mm DMS Multotec cyclone.

- the -1 mm +21 2pm batches prepared from each ore type were run on the DMS plant, using Cyclone 60 and Exxaro FeSi, as well as a blend of the two FeSi types.

- the blend was prepared by mixing 30% Cyclone 60 and 70% of Exxaro FeSi.

- Table 9 shows feed to the DMS reconstituted from the sinks and float products at different test conditions.

- the table shows that at different conditions, the content of hematite A in the feed was fairly consistent, ranging from 57.2% to 60.7%, with the bulk gangue contribution being quartz.

- Table 10 summarises the results obtained, for testwork on the low grade sample.

- the D operating pressure values ranged between 1 2.8 and 1 3.8.

- the table attempts to give an indication of the reliability and reproducibility of the test results.

- Values of Fe grade that are coloured compare chemically assayed and recalculated head or sinks grades using PTA.

- the values in brackets are of directly measured feed samples and are not recalculated. It can be seen that the PTA agreed reasonably well with the measured data. Note all S1O2 and AI2O3 values reported are calculated using PTA.

- Table 1 1 shows feed to the DMS, reconstituted from the sinks and float product at different conditions for the high grade sample. The results indicate the significant presence of Flematite C, which will have an effect on the quality of product expected. Compared to the low grade material quartz is present as the predominant gangue mineral while the clay mineral content has increased to around 5%.

- Table 1 1 Reconstituted feed to DMS using sinks and float PTA results for high grade sample

- Table 12 summarises the results obtained for testwork on the high grade sample. The D value calculated was around 1 1 .8 for all tests. The table indicates that the head grade for the sample was around 48%Fe, measured by chemical assay or via PTA.

- Table 13 shows the model parameters obtained to describe the DMS performance for the low grade sample. The results show that the actual cut-points for 1 mm particles obtained during the pilot DMS runs on low grade material for all conditions were much higher than expected for coarse particle DMS operation, in all cases even exceeding the DMS U/F density.

- the modelled DMS partitions by size and density are plotted in Figure 1 2 to 1 6 for selected tests on the low grade BIF sample. All the modelling was done using the PTA data obtained on the product of each DMS test. Solid lines in both size and density partition graphs represent the PTA data as measured, while the dotted lines represent the best fit results of the Weibull model. Note that no stereological corrections have been made (size or liberation) during this Weibull model parameter optimisation phase.

- Results show reasonably good fits between the measured and modelled cyclone performance for each of the different operating conditions.

- the DMS sinks showed particle size distributions showing preferential coarse particle recovery.

- Table 14 shows the model parameters to describe the DMS performance for the high grade sample tests. The same behaviour is observed as in the low grade sample, with the actual cut- points obtained during the pilot DMS runs for all conditions being much higher than the feed density.

- Table 15 and Table 1 6 show the comparative efficiencies of each of the two FeSi types as well as the Blend case.

- Table 15 uses a 1 mm particle separating at a D50 of 4.50 as the base case and shows how both Ep and D50 for finer sized particles would separate. In all cases D50 for the finer size classes increases and Ep decrease.

- Table 1 6 uses a 1 mm particle separating at a D50 of 3.20 as the base case and shows how both Ep and D50 for finer sized particles would separate. In comparison to Table 14, note that much more efficient separation across all size classes is evident, with quite similar Ep values for both Cyclone 60 and Exxaro fine FeSi.

- Figure 24 and 25 shows the results comparing the grade / recovery profiles for the upgrading of the low grade sample using the different FeSi types. Both figures are very similar with the trends produced, giving the following findings: 1 . At high Fe recoveries to the sinks product, all the different FeSi types produced very similar results. Although the Exxaro FeSi is expected to be the most unstable at low feed FeSi densities, it appears as though the addition of the slimes fraction has assisted in stabilising both atomised FeSi types.

- Figures 26 to 28 show the results comparing the grade / recovery profiles for the upgrading of the high grade sample using the different FeSi types. All three figures are very similar with the trends produced, and are in agreement with those obtained for the low grade sample.

- Figure 28 shows the predicted DMS performance with increased Hematite A content and decreased Hematite C content. As expected, the results indicate further improvement in product grade at all operating conditions due to less near density material with the lower Hematite C content.

- Table 1 8 Low grade feed size distribution using screening

- Feed comprises of -1 mm crushed iron ore in one tonne bulk bags fed into a hopper with the use of a jib crane. Material is withdrawn from the hopper onto a conveyor belt which discharges material into a feed preparation screen mixing box where material is re-pulped prior to screening at 400pm.

- the mixture of ore and medium is pumped to a 1 50mm dense medium cyclone where feed pressure is controlled using a variable speed drive fitted on the cyclone feed pump.

- the dense medium cyclone underflow (sinks) gravitates to the product magnetic separator via a mixing box where it is diluted with effluent water.

- the dense medium cyclone overflow (floats) gravitates to a waste medium drainage screen fitted with 212 pm polyurethane panels.

- the waste medium drainage screen undersize reports to the pipe densifier feed tank.

- the waste medium drainage screen (2.1 m by 1 .08 m high frequency screen) oversize is re-pulped with effluent water prior to feeding the waste magnetic separator for FeSi recovery.

- Magnetic separator effluent and non-magnetics report to the waste dewatering/rinse screen to recover excess water from discard prior to disposal.

- the waste dewatering screen undersize reports to the effluent tank.

- Dense medium cyclone underflow is suitably diluted with effluent water ahead of the product magnetic separator (2000 Gauss CRM 60:60) for FeSi recovery.

- the dense medium cyclone overflow reports to a waste medium drainage screen prior to feeding the waste magnetic separator (2000 Gauss CRM 60:1 00) for FeSi recovery.

- the overdense (magnetics) from the both the product and waste stream magnetic separators report to the circulating medium tank via a demagnetizing coil.

- the product magnetic separator underflow containing effluent and product report to a 2.9 m by 1 .08 m high frequency dewatering screen.

- Waste magnetic separator recovers FeSi from the waste medium drainage screen oversize. Effluent and waste material from the waste magnetic separator report to the waste dewatering screen for excess water recovery prior to waste disposal. Effluent water reports to the effluent tank and used as dilution water to both product and discard magnetic separators. A portion of the effluent water is pumped to the effluent magnetic separator to scavenge any FeSi that might be in the effluent. The effluent magnetic separator underflow is used for fresh feed re-pulping and dilution ahead of the feed preparation screen.

- a portion of the correct medium from the header box feeds to the circulating medium tank (3 m3) together with the magnetic separators overdense, densifying cyclone underflow, pipe densify underflow and product medium drainage screen underflow.

- the tank is fitted with an agitator to keep FeSi in suspension.

- the circulating medium tank is fitted with 2 pumps, namely, the circulating medium pump and primary densifier pump.

- the circulating medium pump discharges the correct medium at the medium headbox.

- a portion of the medium is distributed to the primary feed mixing box while a portion of the medium is recycled back to the circulation medium tank.

- the primary densifier cyclone pump feeds the densifying cyclone (1 50mm diameter).

- the primary densifier underflow gravitates back to the circulating medium while the overflow gravitates to the secondary pipe densifier feed tank.

- Pipe densifier overflow reports to the waste magnetic separator for FeSi recovery.

- Circulating medium density control is achieved with a use of a DebTech density controller fitted with a density gauge mounted on the correct medium delivery pipe.

- the density controller is linked to an automatic valve for dilution water to the circulating medium tank.

- the dewatered iron ore product and discard from the dewatering screens will be discharged into one tonne bags and removed with a use of pallets jacks and occasionally with the use of a forklift. Filtered slimes will also be removed with a use of a fork lift.

- the feed preparation screen undersize gravitates to a desliming tank from where it is pumped to a geotube for dewatering. Dewatered solids together with a geotube will be removed using a forklift for storage and further processing if required. The geotube filtrate will gravitate to the geotube area sump from where it is pumped to the clarified water tank.

- the DMS piloting was conducted using Exxaro Fine NGA FeSi at operating densities ranging from 3.2 up to 4.0 t/m 3 .

- Optimum operating DMS cyclone pressure (Cyc. Operating Pressure) was found to be at 1 5D.

- different operating pressures and FeSi types were tested until the plant was operating stably with optimal differentials for the fines between 25% and 6%.

- One of the objectives for the DMS plant was to produce a fine product at 63.5% Fe in line with the current Sishen fine product specification.

- the DMS plant achieved the fine product specification at 3.4 operating density with 54.5% yield as per Table 223.

- the DMS cyclone was also fed with Shale samples a bottom size of 200pm to determine the impact of size range as the breakaway size for the 1 50mm Diameter cyclone is around 200pm. Moving from a 400pm bottom size, to 200pm bottom size thus feeding the plant with -1 +400pm results in 29% more material in the feed for shale. As expected, the yield achieved from the -1 +200pm drops for the same operating conditions as compared to the feed at -1 +400pm due to poor separation of the fines. The impact gets worse as the operating density increases which is effectively the effect of viscosity on the fines.

- the piloting work on Shale show that the -1 +400pm fraction can produce on specification fine product qualities at relatively low operating densities of 3.4 t/m 3 .

- the -1 mm DMS separation efficiencies are negatively affected by lowering the feed bottom size from 400pm to 200pm and makes it difficult for to achieve on specification fine product from the low grade Shale.

- the DMS plant was to produce from BIF a fine product at 63.5% Fe in line with the current Sishen fine product specification as well as a 55% Fe for flotation.

- the DMS plant achieved the fine product at 63% Fe while operating at 3.6 t/m 3 density with 44% yield as per Table 24.

- the DMS plant was operated to produce a fine product at 63.5% Fe in line with the current Sishen fine product specification as well as a 55% Fe for flotation. From the -1 +400pm, the DMS plant achieved the fine product at 63.8% Fe while operating at 3.6 t/m 3 density which resulted in 47% yield as per Table 25.

- the DMS plant was operated to produce a fine product at 63.5%

- JIG Grit (-1+400mih) Mass Balance Results As part of the Low Grade -1 mm beneficiation technology development, the current Jig -1 mm was processed through the DMS pilot plant to evaluate the potential for producing on specification fines product which the current test module Reflux Classifier at Sishen battles to achieve for various reasons. Jig -1 mm received was deslimed at 200pm and processed as - 1 mm+200pm as well as -1 mm+400pm, results of which are summarised in Table 27.

- the -1 mm DMS pilot plant was able to achieve 64.0% Fe and above from 3.4 t/m 3 operating medium density for the -1 +400pm grit as presented in Table 27.

- reducing the DMS cyclone feed bottom size from 400pm to 200pm has a negative impact on yield as would be expected due to poor recovery of material closer to the breakaway size.

- What is also noticeable is the significant drop in product yield from 3.6 t/m 3 operating densities and furthermore to 3.8 t/m 3 as illustrated in Figure 33.

- Figure 34 shows the medium rheology for the Exxaro fine nitrogen gas atomised FeSi used at the DMS pilot plant.

- Mineralogical analysis on the -1 mm+400pm feeding the DMS pilot plant was performed to determine the theoretical grade yield potential for each ore type as illustrated in Figure 35.

- the DMS pilot plant operated with reasonable separation efficiencies as measured by how close the piloting grade yield performance approached the theoretical grade yield curve.

- Scott Napier Munn model is further applied to assess the actual Ep (separation efficiency) and cut densities in the sections to follow.

- the DMS pilot plant on -1 mm+400pm performance relative ore potential is similar to what was achieved on the Coarse Reflux classifier with the largest average difference between actual and theoretical yield grade curve at 1 5%.

- Metallurgical performance of the -1 mm DMS plant and - 1 mm Reflux classier were found to be relatively similar.

- the choice of which processing technology to apply on the -1 mm flowsheet will be dependent on the outcomes of a trade-off study considering Capex, Opex and operability amongst other elements.

Landscapes

- Separation Of Solids By Using Liquids Or Pneumatic Power (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Cyclones (AREA)

Abstract

Description

Claims

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU2019259777A AU2019259777B2 (en) | 2018-04-24 | 2019-04-24 | Dense media separation method |

| CA3097994A CA3097994A1 (en) | 2018-04-24 | 2019-04-24 | Dense media separation method |

| BR112020021665-8A BR112020021665B1 (en) | 2018-04-24 | 2019-04-24 | SOLIDS SEPARATION METHOD |

| ZA2020/06584A ZA202006584B (en) | 2018-04-24 | 2020-10-22 | Dense media separation method |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB1806674.6 | 2018-04-24 | ||

| GBGB1806674.6A GB201806674D0 (en) | 2018-04-24 | 2018-04-24 | Dense media separation method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019207492A1 true WO2019207492A1 (en) | 2019-10-31 |

Family

ID=62236176

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/IB2019/053362 WO2019207492A1 (en) | 2018-04-24 | 2019-04-24 | Dense media separation method |

Country Status (5)

| Country | Link |

|---|---|

| AU (1) | AU2019259777B2 (en) |

| CA (1) | CA3097994A1 (en) |

| GB (1) | GB201806674D0 (en) |

| WO (1) | WO2019207492A1 (en) |

| ZA (1) | ZA202006584B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111135633A (en) * | 2020-03-10 | 2020-05-12 | 威海市海王科技有限公司 | Recycling and recycling treatment system and treatment process for silicon iron powder |

| CN115007308A (en) * | 2022-06-02 | 2022-09-06 | 北京科技大学 | A device and method for evaluating the effect of gravity separation based on intelligent ore |

| US20230001426A1 (en) * | 2019-12-06 | 2023-01-05 | Iron Ore Company Of Canada | Fluid-borne particle classification system and method of use |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2430762A (en) * | 1944-06-12 | 1947-11-11 | Minerals Beneficiation Inc | Ferrosilicon-magnetite as heavy media in separtion of ores |

| CA904796A (en) * | 1972-07-11 | N. J. Leeman Jan. | Reconditioning of suspensions used in the separation of minerals | |

| WO2015128486A1 (en) * | 2014-02-28 | 2015-09-03 | Eco-Nomic Innovations Limited | Dense media separation method |

-

2018

- 2018-04-24 GB GBGB1806674.6A patent/GB201806674D0/en not_active Ceased

-

2019

- 2019-04-24 AU AU2019259777A patent/AU2019259777B2/en active Active

- 2019-04-24 CA CA3097994A patent/CA3097994A1/en active Pending

- 2019-04-24 WO PCT/IB2019/053362 patent/WO2019207492A1/en active Application Filing

-

2020

- 2020-10-22 ZA ZA2020/06584A patent/ZA202006584B/en unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA904796A (en) * | 1972-07-11 | N. J. Leeman Jan. | Reconditioning of suspensions used in the separation of minerals | |

| US2430762A (en) * | 1944-06-12 | 1947-11-11 | Minerals Beneficiation Inc | Ferrosilicon-magnetite as heavy media in separtion of ores |

| WO2015128486A1 (en) * | 2014-02-28 | 2015-09-03 | Eco-Nomic Innovations Limited | Dense media separation method |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20230001426A1 (en) * | 2019-12-06 | 2023-01-05 | Iron Ore Company Of Canada | Fluid-borne particle classification system and method of use |

| US12115536B2 (en) * | 2019-12-06 | 2024-10-15 | Iron Ore Company Of Canada | Fluid-borne particle classification system and method of use |

| CN111135633A (en) * | 2020-03-10 | 2020-05-12 | 威海市海王科技有限公司 | Recycling and recycling treatment system and treatment process for silicon iron powder |

| CN111135633B (en) * | 2020-03-10 | 2023-09-22 | 威海市海王科技有限公司 | Ferrosilicon powder recycling treatment system and treatment process |

| CN115007308A (en) * | 2022-06-02 | 2022-09-06 | 北京科技大学 | A device and method for evaluating the effect of gravity separation based on intelligent ore |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2019259777B2 (en) | 2024-04-04 |

| GB201806674D0 (en) | 2018-06-06 |

| ZA202006584B (en) | 2022-01-26 |

| AU2019259777A1 (en) | 2020-12-03 |

| BR112020021665A2 (en) | 2021-01-26 |

| CA3097994A1 (en) | 2019-10-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2019259777B2 (en) | Dense media separation method | |

| RU2533792C2 (en) | Method of obtaining of bulk concentrate from ferruginous quartzites | |

| Tripathy et al. | Effect of desliming on the magnetic separation of low-grade ferruginous manganese ore | |

| CN106861891B (en) | A kind of method for separating of low-grade black and white tungsten ore | |

| CN104437833B (en) | A kind of method of physical upgrading enrichment carbonaceous shale type navajoite | |

| US9901932B2 (en) | Dense media separation method | |

| Galvin et al. | Single-stage recovery and concentration of mineral sands using a reflux™ classifier | |

| Schriner et al. | Centrifugal concentration of rare earth minerals from calcitic gangue | |

| US5819945A (en) | Bimodal dense medium for fine particles separation in a dense medium cyclone | |

| CN109967226A (en) | A kind of recoverying and utilizing method of fine cleaned coal | |

| Nzeh et al. | Exploration and characterization of barite mineral from Azara-Nassarawa ore deposits from suitabiity in industrial applications | |

| Legault-Seguin et al. | Dense Medium Separation—An Effective and Robust Preconcentration Technology | |

| Rao et al. | Iron ore beneficiation: an overview | |

| Balasubramanian | Gravity separation in ore dressing | |

| OA20455A (en) | Dense media separation method | |

| JP2013139005A (en) | Dry separation method and dry separator | |

| Gülcan et al. | Concentration characteristics of a complex antimony ore | |

| CN112827658B (en) | Scheelite beneficiation method | |

| US2315536A (en) | Classification method and apparatus | |

| BR112020021665B1 (en) | SOLIDS SEPARATION METHOD | |

| Noori et al. | Use of density tracers in evaluating performance of Tri-Flo circuits Case study: Tabas (Iran) coal preparation plant | |

| Setlhabi et al. | Evaluation of advanced gravity and magnetic concentration of a PGM tailings waste for chromite recovery | |

| PL235524B1 (en) | Ferrite weight for heavy suspension liquid and method for producing it and application of ferrite as a weight for heavy liquid | |

| Little | Performance of the vertical roller mill in a mineral processing application when coupled with internal and external classifiers | |

| Fitzpatrick et al. | Quantitative mineralogy for improved modelling of shaking tables |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 19728120 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 3097994 Country of ref document: CA |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112020021665 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 2019259777 Country of ref document: AU Date of ref document: 20190424 Kind code of ref document: A |

|

| ENP | Entry into the national phase |

Ref document number: 112020021665 Country of ref document: BR Kind code of ref document: A2 Effective date: 20201022 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19728120 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19728120 Country of ref document: EP Kind code of ref document: A1 |

|

| 32PN | Ep: public notification in the ep bulletin as address of the adressee cannot be established |

Free format text: NOTING OF LOSS OF RIGHTS PURSUANT TO RULE 112(1) EPC (EPO FORM 1205A DATED 14/04/2021) |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 19728120 Country of ref document: EP Kind code of ref document: A1 |