WO2018123247A1 - Absorbent article - Google Patents

Absorbent article Download PDFInfo

- Publication number

- WO2018123247A1 WO2018123247A1 PCT/JP2017/039090 JP2017039090W WO2018123247A1 WO 2018123247 A1 WO2018123247 A1 WO 2018123247A1 JP 2017039090 W JP2017039090 W JP 2017039090W WO 2018123247 A1 WO2018123247 A1 WO 2018123247A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lateral direction

- absorbent article

- waistline portion

- absorbent

- lateral

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/493—Absorbent articles specially adapted to be worn around the waist, e.g. diapers adjustable by adding or removing material, e.g. umbilical cord arrangements

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/56—Supporting or fastening means

Definitions

- the present invention relates to an absorbent article such as a disposable diaper.

- Patent Document 1 discloses the technology of the tape-type diaper.

- Patent Document 2 discloses a technique of a so-called single-open pant diaper in which a tape diaper and a pant diaper are combined. That is, the diaper has a leg-hole opening on one side in the horizontal direction, but a male material and a female material of a hook-and-loop fastener are provided on the other side of the diaper. By locking the male material and the female material, a leg-hole opening is formed on the other side of the diaper, and a waist-hole opening is formed on the upper side of the diaper.

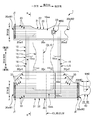

- Patent Document 1 when the technique described in Patent Document 1 is applied to such a single-open pants-type diaper, a single-open pants-type diaper 1 'as shown in FIG. 1 is formed.

- the single-open pants-type diaper 1 ′ has a waistline opening BH ′ on the upper side in the vertical direction intersecting the lateral direction in cooperation with the front waistline portion 20 ′ along the lateral direction and the front waistline portion 20 ′.

- Crotch part 10 ' provided between the two.

- the one end 20eW1 ′ in the lateral direction of the front waistline portion 20 ′ and the one end 30eW1 ′ in the lateral direction of the rear waistline portion 30 ′ are joined by the joint j1 ′, thereby Only one leg opening LH1 ′ is formed on the one side.

- a female member 40 ′ is provided as a locking portion 40 ′ at the other end 30eW2 ′ in the lateral direction of the rear waistline portion 30 ′, and the female material 40 ′ is locked at the front waistline portion 20 ′.

- a possible male material 50 ' is provided.

- the front waistline portion 20 ′ is provided with a plurality of elastic members 23 ′, 23 ′,... For imparting lateral stretchability to the front waistline portion 20 ′.

- the part provided with the members 23 ′, 23 ′,... Functions as a stretchable region AEL ′ having lateral stretchability.

- the stretchable region AEL ′ of the front waistline portion 20 ′ overlaps the male material 50 ′ with respect to the lateral position. Therefore, the expansion / contraction of the expansion / contraction region AEL ′ is likely to affect the male member 50 ′, that is, wrinkles along the vertical direction may occur in the male member 50 ′ in the horizontal direction. When such wrinkles occur, the area contributing to the engagement of the rear waistline 30 'with the female member 40' in the male member 50 'decreases, or the locking protrusion (not shown) of the male member 50' There is a possibility that it may face a direction different from the proper design direction, and as a result, the locking force as designed cannot be exhibited. That is, the locking force between the male member 50 'and the female member 40' can be reduced.

- the present invention has been made in view of the above problems, and an object thereof is to suppress a decrease in locking force of a male member provided in a front waistline portion.

- the main invention for achieving the above object is: An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction, A front waistline portion along the lateral direction; A rear waistline portion along the lateral direction; A crotch portion provided between the front waistline portion and the rear waistline portion, An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

- the front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

- the front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction, The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

- FIG. 3A It is a schematic perspective view of an example of a single-opening pants-type diaper 1 '. It is a schematic perspective view of the single-opening pants-type diaper 1 of the present embodiment. It is the schematic plan view which looked at the diaper 1 of the unfolding state from the wearer's non-skin side. It is BB sectional drawing in FIG. 3A. 4A to 4C are schematic explanatory diagrams of a procedure for attaching the diaper 1. It is a schematic enlarged view of the front waistline part 20 in FIG. 3A.

- FIG. 6A is a schematic plan view of the modified diaper 1 viewed from the non-skin side of the wearer. 6B is a cross-sectional view taken along the line BB in FIG. 6A.

- An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction, A front waistline portion along the lateral direction; A rear waistline portion along the lateral direction; A crotch portion provided between the front waistline portion and the rear waistline portion, An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

- the front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

- the front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction, The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

- the stretchable region of the front waistline portion does not overlap with the male material with respect to the lateral position. That is, the positions in the lateral direction are shifted from each other. Therefore, the male material is hardly affected by the expansion and contraction of the elastic member, and this can suppress the generation of wrinkles of the male material. As a result, it is possible to suppress a decrease in the locking force of the male material.

- the expansion / contraction region is located on the one side portion in the lateral direction with respect to the male material in the front waistline portion.

- the stretchable region is located in a portion on one side in the lateral direction with respect to the male material in the front waistline portion. Therefore, it is possible to ensure that the stretchable region and the male material do not overlap with respect to the lateral position.

- the stretchable region is located on the one side with respect to the lateral center line of the crotch part,

- the male member is preferably located on the other side of the center line.

- the male material is arranged at a position away from the stretchable region in the lateral direction. Therefore, the influence which the elasticity of an expansion-contraction area

- Such an absorbent article When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the crotch portion in the front waistline portion.

- the rigidity of the crotch part in addition to the rigidity of the front waistline part contributes to supplementing the rigidity of the male material. Therefore, generation

- the crotch has a liquid-absorbent absorbent core, When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the absorbent core in the front waistline portion.

- the large rigidity of the absorbent core in the crotch also contributes to supplementing the rigidity of the male material. Therefore, generation

- the crotch portion has a liquid-absorbing absorbent core at a position on the center side in the lateral direction, and the crotch portion projects to the one side and the other side in the lateral direction from the absorbent core, respectively.

- the sheet-like part protruding to the other side is provided with a first elastic member along the longitudinal direction for imparting the stretchability in the longitudinal direction to the sheet-like part. It is desirable that the male material is provided at a position closer to the center in the lateral direction than the first elastic member.

- the male material is provided at a position on the center side in the lateral direction with respect to the first elastic member, but the absorbent core is located at the position on the center side. . Therefore, wrinkles of the male material that can be caused by the vertical expansion and contraction of the first elastic member can be effectively suppressed by the rigidity of the absorbent core.

- the crotch portion has a liquid-absorbent absorbent core at a position on the central side in the lateral direction, When viewed from the front-rear direction, the crotch portion is a sheet for forming a three-dimensional gather at a position overlapping the absorbent core on the other side in the lateral direction from the lateral center line of the absorbent core.

- the second elastic member along the longitudinal direction is fixed to the sheet in a state of extending in the longitudinal direction. It is desirable that the male material is provided at a position closer to the center in the lateral direction than the second elastic member.

- the male material is provided at a position on the center side in the lateral direction with respect to the second elastic member, but the absorbent core is located at the position on the center side. . Therefore, wrinkles of the male material that can be caused by the expansion and contraction in the vertical direction of the second elastic member can be effectively suppressed by the rigidity of the absorbent core.

- FIG. 2 is a schematic perspective view of the diaper 1.

- This diaper 1 has a “vertical direction”, a “horizontal direction” orthogonal to the vertical direction, and a “front-rear direction” orthogonal to the vertical direction and the horizontal direction in a single-open pants-type state before wearing as shown in FIG. ,have. And while wearing the diaper 1, the vertical direction often faces the vertical direction. Therefore, hereinafter, the vertical direction is also referred to as “vertical direction”.

- corresponds to a wearer's waistline side

- corresponds to a wearer's inseam side

- corresponds to a wearer's belly side

- corresponds to a wearer's back side

- corresponds to a wearer's left side

- corresponds to a wearer's right side.

- the terms “one side” and “the other side” refer to the one side and the other side in the horizontal direction.

- the diaper 1 is located in the front waistline portion 20 along the lateral direction and the front waistline portion 20 while being positioned in the vertical direction, in cooperation with the front waistline portion 20.

- the absorptive main body 10 protrudes and is located below the front waistline part 20 and the back waistline part 30 in the vertical direction.

- the one end 20eW1 in the lateral direction of the front waistline portion 20 and the one end 30eW1 in the lateral direction of the rear waistline portion 30 are joined by a joint j1.

- the front waistline portion 20 and the rear waistline portion 30 together with the absorbent main body 10 form one leg opening LH1 at a position on one side and below in the lateral direction.

- the junction j1 is formed by welding or adhesion.

- a locking portion 40 that can be locked to the front surface of the front waistline portion 20 is provided at the other end 30eW2 in the lateral direction of the rear waistline portion 30. Then, as virtually indicated by a two-dot chain line in FIG.

- the locking portion 40 is locked to the front surface of the front waistline portion 20, so that the front waistline portion 20, the rear waistline portion 30, Jointly form the waistline opening BH on the upper side, and the front waistline part 20, the rear waistline part 30, and the absorbent main body 10 together, so that the leg circumference opening LH2 is also provided at the other side and the lower position. Form one. And thereby, the said diaper 1 will be in the state worn by the wearer.

- FIG. 3A is a schematic plan view of the unfolded diaper 1 as viewed from the non-skin side of the wearer.

- FIG. 3B is a cross-sectional view taken along line BB in FIG. 3A.

- the unfolded state means that the front waistline portion 20 and the rear waistline portion 30 are formed by unbonding the above-described joint portion j1 that the diaper 1 in the single-open pants-type state in FIG. 2 has on one side in the lateral direction. It is the state which expanded the diaper 1 on the plane by separating and opening the diaper 1 longitudinally.

- the diaper 1 is shown in a virtual state in which each member constituting the diaper 1 has no elasticity.

- the diaper 1 is provided with a plurality of elastic members 16, 23, 33 for the purpose of imparting stretchability to the diaper 1.

- the elastic members 16, 23, 33 are provided in this expanded state.

- the diaper 1 is shown in a virtual state where there is no 33 stretchability (contraction force).

- the diaper 1 In the unfolded state, the diaper 1 has a longitudinal direction, a lateral direction, and a thickness direction (a direction penetrating the paper surface in FIG. 3A) as three directions orthogonal to each other.

- the longitudinal direction is along the above-described longitudinal direction.

- One side in the longitudinal direction corresponds to the ventral side, and the other side corresponds to the back side.

- the outer side in the longitudinal direction corresponds to the upper side in the vertical direction

- the inner side in the longitudinal direction corresponds to the lower side in the vertical direction. Since the longitudinal direction and the longitudinal direction are similar to each other as described above, hereinafter, for the convenience of explanation, even in this expanded state, the longitudinal direction may be used instead of the longitudinal direction. .

- the lateral direction is synonymous with the lateral direction in the above-described single-opening pants type state.

- corresponds to the skin side which contact

- the thickness direction is along the aforementioned front-rear direction. For this reason, in the following description, even in this expanded state, the front-rear direction may be used instead of the thickness direction for the convenience of explanation.

- the front waistline portion 20 is disposed along the lateral direction, and the rear waistline portion 30 is laterally spaced from the front waistline portion 20 at a predetermined interval in the longitudinal direction. Arranged along the direction. And while the absorptive main body 10 is spanned along the longitudinal direction between the front waistline part 20 and the rear waistline part 30, the longitudinal ends 10ea, 10eb of the absorptive body 10 are nearest to each other. Are joined and fixed to the waist portions 20 and 30, so that the external shape thereof is substantially H-shaped in plan view.

- the absorptive main body 10 has a substantially rectangular shape in plan view in the developed state of FIG. 3A. And the longitudinal direction of the absorptive main body 10 is distribute

- the absorbent body 11 has a liquid absorbent absorbent core 11c and a core wrap sheet (not shown) that covers the outer peripheral surface of the core 11c.

- the absorbent core 11c is a molded body obtained by molding a predetermined liquid absorbent material into a substantially hourglass shape in plan view as an example of a predetermined shape.

- a liquid absorptive material liquid absorptive granular materials, such as liquid absorptive fibers, such as pulp fiber, and superabsorbent polymer (what is called SAP) can be illustrated.

- the core wrap sheet may be a liquid permeable sheet such as tissue paper or non-woven fabric, but the core wrap sheet may be omitted.

- the shape of the absorptive core 11c is not limited to the above-mentioned substantially hourglass shape in plan view, but may be other shapes.

- the top sheet 13 is a liquid-permeable flexible sheet such as a nonwoven fabric.

- the back sheet 15 is a liquid-impermeable flexible sheet.

- a liquid-impermeable leak-proof sheet 15 a such as a polyethylene film or a polypropylene film and a non-woven exterior sheet 15 b bonded to the non-skin side of the leak-proof sheet 15 a are provided.

- a laminated sheet 15 having a two-layer structure is shown (FIG. 3B).

- At least the back sheet 15 is a flat sheet that protrudes in the longitudinal and lateral directions from the absorbent core 11c.

- the leg gather LG which each expands-contracts in a longitudinal direction is formed in the part protruded in the horizontal direction. That is, a plurality of elastic members 16, 16... Such as rubber thread are fixed to the protruding portion in the longitudinal direction along the longitudinal direction. LG is formed.

- the rear waistline portion 30 is a sheet member having a substantially rectangular shape in plan view made of a flexible sheet such as a nonwoven fabric as shown in FIG. 3A.

- the back trunk part 30 is formed by joining the nonwoven fabrics 31 and 32 on 2 sheets.

- the rear waistline portion 30 is arranged so as to protrude on both sides in the lateral direction from the absorbent main body 10, while the back end portion 10 eb of the absorbent main body 10 has no skin. It is overlapped and joined from the side.

- a plurality of elastic members 33, 33..., Such as thread rubber, along the lateral direction are vertically disposed between the two nonwoven fabrics 31, 32 associated with the rear waistline 30.

- the nonwoven fabrics 31 and 32 are joined and fixed in a state of being stretched in the lateral direction while being inserted side by side in the direction.

- the rear waistline portion 30 is provided with lateral stretchability.

- the elastic members 33, 33... Generally extend from one end in the horizontal direction to the other end in the vertical upper end 30 eu of the rear waistline portion 30. It is arranged continuously.

- the elastic member 33 is disposed so as to be discontinuous at a part in the lateral direction with respect to a portion 30d below the upper end portion 30eu. That is, the elastic member 33 is not disposed in the lower portion 30d that overlaps the central portion in the horizontal direction of the absorbent core 11c, but one side and the other in the horizontal direction relative to the portion 30c.

- a plurality of elastic members 33 along the horizontal direction are arranged side by side in the vertical direction. And thereby, the elastic member 33 is arrange

- the elastic member 33 does not have to be disposed at all in a portion overlapping the absorbent core 11c in the lower portion 30d.

- the aforementioned locking portion 40 is joined to the other end 30eW2 in the lateral direction of the rear waistline 30 as a separate member from the rear waistline 30 by a joint j2. ing.

- the locking portion 40 is made of a flexible sheet such as a nonwoven fabric as in the case of the rear waistline portion 30.

- the two nonwoven fabrics 41 and 42 are bonded together.

- locking part 40 made from this nonwoven fabric 41 and 42 functions as a female material in the case of the above-mentioned latching. That is, the locking portion 40 is hooked on a male material 50 of a locking target portion 50 described later of the front waistline portion 20 to lock the locking portion 40 to the front waistline portion 20.

- the joint j2 is formed by welding or adhesion.

- FIG. 3A also shows a center line CL30 indicating the center position in the lateral direction of the rear waistline portion 30, and this center line CL30 is used by the wearer of FIG. 4A described later to diaper the leg ML1 on one side. It is designed to coincide with the center position CLM in the lateral direction of the wearer's body in a state where it is placed in one leg opening LH1 on one side.

- the center line CL ⁇ b> 30 is shifted laterally with respect to the center line CL ⁇ b> 10 indicating the horizontal center position of the absorbent main body 10.

- the center line CL10 of the absorbent main body 10 matches the center position CLM of the wearer's body.

- the front waistline portion 20 is also a sheet member having a substantially rectangular shape in a plan view made of a flexible sheet such as a nonwoven fabric as shown in FIG. 3A.

- the front waistline part 20 is formed by joining the nonwoven fabrics 21 and 22 on two sheets.

- the said front waistline part 20 is arranged so that it may protrude on the both sides of a horizontal direction rather than the absorptive main body 10, and non-skin is provided in the abdominal side edge part 10ea in the absorptive main body 10. It is overlapped and joined from the side.

- a plurality of elastic members 23, 23... Such as thread rubber along the transverse direction are also vertically disposed between the two non-woven fabrics 21, 22 associated with the front waistline portion 20.

- the nonwoven fabrics 21 and 22 are joined and fixed in a state of being stretched in the lateral direction while being inserted side by side in the direction. As a result, the front waistline portion 20 is given lateral stretchability.

- the elastic member 23 is provided only in the portion 20 w 1 on the one side in the lateral direction from the central portion in the lateral direction of the absorbent core 11 c in the front waistline portion 20, and absorbs in the front waistline portion 20.

- the portion 20c corresponding to the central portion in the horizontal direction of the core 11c and the portion 20w2 on the other side in the horizontal direction from the portion 20c are not provided. Therefore, with respect to the front waistline portion 20, only the one-side portion 20w1 is given lateral stretchability, and the other-side portion 20w2 is not given stretchability.

- the non-skin surface (corresponding to the above-described front surface in the front-rear direction) of the other-side portion 20w2 is provided with a locking target portion 50 that locks with the above-described locking portion 40.

- the locking target portion 50 is a male material 50 of a hook-and-loop fastener made of, for example, resin. That is, a plurality of locking projections (not shown) are provided on the substantially rectangular non-skin side surface of the male material 50. Therefore, the locking portion 40 is locked to the locking target portion 50 when these locking projections are hooked on the fibers of the locking portion 40 formed by the nonwoven fabrics 41 and 42 described above.

- Examples of the shape of the locking protrusion include a fishhook type and a mushroom type.

- FIG. 4A to 4C are explanatory diagrams of a procedure for attaching the diaper 1.

- FIG. 4A one leg ML1 in the lateral direction of a wearer such as an infant is put into the leg opening LH1 on one side of the diaper 1. And as shown to FIG. 4A, the same diaper 1 is put toward a wearer's crotch (inseam) so that the absorptive main body 10 which makes a part of the leg periphery opening LH1 may contact the buttocks ML1P of the one leg ML1. Pull up. Then, from the viewpoint of preventing leakage at the flange ML2P of the other leg ML2 in FIG.

- the other end 20eW2 of the front waistline portion 20 and the absorptive main body 10 abut on the flange ML2P.

- the engaging portion 40 of the other end 30eW2 of the rear waistline portion 30 is gripped by each hand of a wearer such as a mother and pulled to the other side in the lateral direction. Then, while pulling them, the locking portion 40 is turned around to one side and the front side, and the locking portion 40 is locked to the male member 50 of the front waistline portion 20 as shown in FIG. 4C.

- the leg opening LH2 on the other side is formed so as to cover the other leg ML2, and the waist opening BH is formed so as to cover the wearer's waist.

- work of the diaper 1 to a wearer is complete

- the male material 50 is provided on the front surface of the front waistline portion 20, and the rear waistline portion 30 is made of nonwoven fabrics 41 and 42 as the locking portion 40.

- Female material is provided. Therefore, from the state shown in FIG. 4B to the state shown in FIG. 4C, the rear waistline portion 30 is changed from the front side to the front waistline portion 20 to lock the locking portion 40 of the rear waistline portion 30 with the female member 50 of the front waistline portion 20.

- the locking portion 40 is a non-woven female material. Therefore, it does not hurt the wearer's skin.

- the locking force between the locking portion 40 and the male material 50 of the front waistline portion 20 is increased, and as a result, the locking portion 40 is intentionally removed from the male material 50 of the front waistline portion 20 while the diaper 1 is worn. It is possible to effectively prevent it from coming off without it.

- marks M40 and M50 are provided on the locking portion 40 and the male material 50, respectively, so that the wearer can lock the locking portion 40 and the male material 50 in an appropriate design positional relationship.

- the engagement portion 40 is provided with a mark M40, for example, as a mark M40 so as to be visible from the skin side at a substantially central position in the vertical direction on the skin side surface.

- a circular mark M50 is provided on the male material 50 as a mark M50 so as to be visible from the non-skin side. Therefore, the wearer can lock the locking portion 40 and the male member 50 in an appropriate positional relationship without any error by overlapping the circles M40 and M50.

- the mark M40 of the locking portion 40 and the mark M50 of the male member 50 are made to have the same circular shape, that is, the same pattern is aligned, but this is not restrictive.

- different symbols may be used as the marks M40 and M50.

- the symbols M40 and M50 are not limited to circles. For example, it may be a geometric pattern such as a polygon such as a rectangle, or may be a character or an illustration.

- an illustration sheet (not shown) in which the mark M40 is printed on the side of the skin between the nonwoven fabrics 41 and 42 constituting the locking part 40 is used. Insertion is mentioned. And if it does in this way, the mark M40 of an illustration sheet can be visually recognized from the skin side through the gap between the fibers of the nonwoven fabric 41.

- the male material 50 is formed of a transparent or translucent material, and the mark M50 is formed between the nonwoven fabrics 21 and 22 constituting the front waistline portion 20. It is possible to insert an illustration sheet (not shown) printed on the non-skin side. And if it does in this way, the mark M50 of an illustration sheet can be visually recognized from the non-skin side through the male material 50 and the gap between the fibers of the nonwoven fabric 22.

- the vertical size of the locking portion 40 may be larger than the maximum vertical size of the male member 50 over the entire area AM40 in the horizontal direction. And if it becomes like this, when the latching

- the locking force between the male member 50 and the locking portion 40 is reduced. That is, for example, when wrinkles along the vertical direction are formed in the male material 50 in the horizontal direction, the area contributing to the engagement of the male material 50 with the female material 40 that is the locking portion 40 of the rear waistline portion 30 is reduced. Otherwise, the locking protrusions of the male member 50 may face in a direction different from the proper design direction. As a result, the locking force as designed may not be exhibited.

- FIG. 5 is an explanatory view of the device, and is a schematic enlarged view of the front waistline portion 20 in FIG. 3A.

- the front waistline portion 20 has a portion 20P1 provided with the elastic members 23, 23... And a portion 20P2 not provided side by side in the horizontal direction.

- the former portion 20P1 is a stretchable region AEL having lateral stretchability in the front waistline portion 20, and the latter portion 20P2 is stretched in the lateral direction more than the stretchable region AEL. It is a low stretch region ANEL with low elasticity, and more correctly, it is a non-stretch region ANEL that does not have lateral stretch property.

- region AEL of the front waistline part 20 does not overlap with the male material 50 regarding the position of a horizontal direction.

- the stretchable region AEL is provided only on one side of the front waistline portion 20 in the lateral direction from the male member 50. That is, the other end AELe2 in the horizontal direction in the stretchable region AEL set so as to extend from the other side in the horizontal direction does not reach the position of the male material 50 in the horizontal direction. , Located in the non-stretchable region ANEL.

- the male material 50 is hardly affected by the expansion / contraction of the expansion / contraction region AEL, and as a result, generation of wrinkles of the male material 50 can be suppressed. And it becomes possible to suppress the fall of the locking force of the male material 50 by this.

- the stretchable region AEL is located on one side in the lateral direction with respect to the center line CL10 of the absorbent main body 10, but in contrast, The male material 50 is located on the other side in the lateral direction from the center line CL10. Therefore, the male material 50 is disposed at a position in the lateral direction away from the stretchable region AEL, and thereby the influence of the stretchability of the stretchable region AEL on the male material 50 can be further reduced.

- the male material 50 is formed in the absorbent body at the front waistline portion 20 when viewed from the thickness direction (front-rear direction, the direction penetrating the paper surface in FIG. 5). 10 is provided in a portion overlapping with 10.

- the absorbent main body 10 also contributes to supplementing the rigidity of the male material 50, thereby further suppressing the generation of wrinkles in the male material 50.

- the male member 50 is provided so as to overlap a portion where the absorbent core 11 c is not located in the absorbent main body 10 when viewed from the thickness direction (front-rear direction).

- the male material 50 may be provided so as to overlap the absorbent core 11c.

- the rigidity of the male material 50 can be supplemented also by the big rigidity of the same core 11c, Thereby, the wrinkle of the same male material 50 can be suppressed further.

- at least a part of the male material 50 may overlap the core 11c, but preferably the entire male material 50 overlaps the core 11c.

- the absorbent main body 10 has leg gathers LG and LG on one side and the other side in the lateral direction, respectively.

- the sheet-like portions 10es and 10es located on the one side and the other side of the absorbent main body 10 in the lateral direction from the absorbent core 11c are elastic members along the vertical direction. 16 is provided.

- the elastic member is preferably located in the sheet-like portion 10es on the other side in the horizontal direction.

- the male member 50 is provided at a position closer to the center in the lateral direction than 16 (corresponding to the first elastic member). Specifically, it is preferable that the male member 50 is located closer to the center than the elastic member 16 located closest to the center in the lateral direction among the elastic members 16 and 16 of the sheet-like portion 10es.

- the absorptive core 11c is located in the position of this center side. Therefore, the absorptive core 11c can receive the contraction force related to the expansion and contraction of the elastic member 16. Thereby, wrinkles of the male material 50 that may be caused by the vertical expansion and contraction of the elastic member 16 can be effectively suppressed by the rigidity of the absorbent core 11c.

- 6A and 6B are schematic explanatory views of a modification of the present embodiment.

- 6A is a schematic plan view of the unfolded diaper 1a as seen from the non-skin side of the wearer, and

- FIG. 6B is a cross-sectional view taken along line BB in FIG. 6A.

- the absorbent main body 10 does not have a so-called three-dimensional gather LSG for preventing side leakage.

- the absorbent main body 10 absorbs when viewed from the thickness direction (front-rear direction).

- the main difference is that the three-dimensional gather LSG is provided at a lateral position that overlaps the absorbent core 11c in the sex main body 10.

- the points other than this are substantially the same as those of the above-described embodiment. Therefore, in the following, this difference will be mainly described, and the same components as those in the above-described embodiment will be denoted by the same reference numerals, and description thereof will be omitted.

- the three-dimensional gather LSG is formed using the exterior sheet 15b of the back sheet 15. That is, the exterior sheet 15b is a sheet having a size protruding to one side and the other side in the lateral direction from the leak-proof sheet 15a of the back sheet 15. Then, the protruding portion 15bf is folded back to the center side of the absorbent body 10 in the lateral direction with the position forming the lateral end 10es of the absorbent body 10 being the folded position, and in the longitudinal direction near the folded position.

- An elastic member 16 such as a rubber thread is fixed in a longitudinal direction along (the direction penetrating the paper surface in FIG. 6B), whereby the aforementioned leg gather LG is first formed.

- the folded portion 15bg further extends toward the center in the lateral direction, and is joined to the top sheet 13 at a position covering the lateral end 11ce of the absorbent core 11c or in the vicinity thereof.

- the portion joined to the top sheet 13 functions as the base end portion LSGb of the three-dimensional gather LSG, that is, the portion on the tip side in the lateral direction further than the base end portion LSGb serves as the free end portion LSGf. 13 can stand up.

- an elastic member 18 such as rubber thread is fixed to the front end portion of the free end portion LSGf in the longitudinal direction under extension. Further, as shown in FIG.

- both end portions LSGfea and LSGfeb in the longitudinal direction of the free end portion LSGf are fixed with an adhesive in a state where they are faced down to the top sheet 13, respectively.

- LSGfea and LSGfeb cannot stand up.

- a contraction force in the longitudinal direction is applied to the free end portion LSGf from the elastic member 18, and as a result, the free end portion LSGf contracts in the longitudinal direction while forming a plurality of wrinkles.

- the free end portion LSGf functions as a three-dimensional gather LSG.

- the center line CL10 of the absorbent main body 10 illustrated in FIG. 6A is defined as the center in the horizontal direction, in this modification, the other side in the horizontal direction.

- the male member 50 is provided at a position on the center side in the lateral direction with respect to the elastic member 18 (corresponding to the second elastic member) of the three-dimensional gather LSG located in the center. Specifically, the male member 50 is located at a position closer to the center than the elastic member 18 located on the most lateral side of the elastic members 18 and 18 related to the other-side solid gather LSG. And the centerline CL10 of the absorptive core 11c is located in the position of this center side.

- the absorptive core 11c can receive the contraction force related to the expansion and contraction of the elastic member 18. And thereby, it becomes possible to effectively suppress the wrinkles of the male material that may be caused by the vertical expansion and contraction of the elastic member 18 by the rigidity of the absorbent core 11c.

- the female material made of the nonwoven fabrics 41 and 42 is illustrated as the locking portion 40 of the rear waistline portion 30, but the present invention is not limited thereto. That is, a so-called hook-and-loop female member having a plurality of loops protruding on one side may be used.

- a so-called three-piece type disposable diaper 1 is illustrated as an example of an absorbent article. That is, in the diaper 1, the front waistline portion 20, the rear waistline portion 30, and the absorbent main body 10 that is the crotch portion are separate members, but the invention is not limited thereto.

- a so-called two-piece having an exterior sheet in which a rear waistline part and a front waistline part are integrated via a crotch as a first part and an absorbent main body 10 fixed to the skin side surface of the exterior sheet as a second part. It may be a disposable disposable diaper.

- the rubber thread is illustrated as an example of the elastic members 16, 23, and 33, but the present invention is not limited thereto.

- the elasticity of the stretchable area AEL in the front waistline portion 20 is provided by the elastic member 23, but this is not a limitation.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Abstract

Provided is an absorbent article (1) having a longitudinal direction, a lateral direction which crosses the longitudinal direction, and a front-rear direction which is perpendicular to both the longitudinal direction and the lateral direction. The absorbent article (1) is provided with a laterally extending front waist section (20), a laterally extending rear waist section (30), and a crotch section (10) which is provided between the front waist section (20) and the rear waist section (30). One lateral end (20eW1) of the front waist section (20) and one lateral end (30eW1) of the rear waist section (30) are joined at a joint section (j1). The front surface, in the front-rear direction, of the front waist section (20) is provided with a male material (50) capable of engaging with a female material (40) at the other lateral end (30eW2) of the rear waist section (30). The front waist section (20) has a laterally extending elastic region (AEL) having lateral elasticity. The elastic region (AEL) does not laterally overlap the male material (50).

Description

本発明は、使い捨ておむつ等の吸収性物品に関する。

The present invention relates to an absorbent article such as a disposable diaper.

従来、排泄物を吸収する吸収性物品として所謂テープ型おむつが知られている。そして、特許文献1には、当該テープ型おむつの技術が開示されている。一方、特許文献2には、テープ型おむつとパンツ型おむつとを組み合わせた所謂片開きパンツ型おむつの技術が開示されている。すなわち、同おむつは、横方向の一方側には脚回り開口を有するが、同おむつの他方側には、面ファスナーの雄材と雌材とが設けられている。そして、雄材と雌材とを係止することにより、おむつの他方側に脚回り開口を形成するとともに、同おむつの上側に胴回り開口を形成するようになっている。

Conventionally, so-called tape-type diapers are known as absorbent articles that absorb excrement. Patent Document 1 discloses the technology of the tape-type diaper. On the other hand, Patent Document 2 discloses a technique of a so-called single-open pant diaper in which a tape diaper and a pant diaper are combined. That is, the diaper has a leg-hole opening on one side in the horizontal direction, but a male material and a female material of a hook-and-loop fastener are provided on the other side of the diaper. By locking the male material and the female material, a leg-hole opening is formed on the other side of the diaper, and a waist-hole opening is formed on the upper side of the diaper.

ここで、かような片開きパンツ型おむつに、特許文献1に記載の技術を適用すると、図1のような片開きパンツ型おむつ1’が形成される。

Here, when the technique described in Patent Document 1 is applied to such a single-open pants-type diaper, a single-open pants-type diaper 1 'as shown in FIG. 1 is formed.

すなわち、先ず、片開きパンツ型おむつ1’は、横方向に沿った前胴回り部20’と、前胴回り部20’と共同して、横方向と交差する縦方向の上側に胴回り開口BH’を形成するための横方向に沿った後胴回り部30’と、前胴回り部20’及び後胴回り部30’よりも縦方向の下方に位置しつつ、前胴回り部20’と後胴回り部30’との間に設けられた股下部10’と、を有している。また、前胴回り部20’における横方向の一方側の端部20eW1’と後胴回り部30’における横方向の一方側の端部30eW1’とは、接合部j1’で接合されていて、これにより、当該一方側には脚回り開口LH1’が一つだけ形成されている。更に、後胴回り部30’における横方向の他方側の端部30eW2’には係止部40’として雌材40’が設けられ、前胴回り部20’には、同雌材40’を係止可能な雄材50’が設けられている。また、同前胴回り部20’には、当該前胴回り部20’に横方向の伸縮性を付与するための弾性部材23’,23’…が横方向に沿って複数設けられていて、当該弾性部材23’,23’…が設けられた部分は、横方向の伸縮性を有した伸縮領域AEL’として機能する。

That is, first, the single-open pants-type diaper 1 ′ has a waistline opening BH ′ on the upper side in the vertical direction intersecting the lateral direction in cooperation with the front waistline portion 20 ′ along the lateral direction and the front waistline portion 20 ′. A rear waistline portion 30 ′ along the lateral direction for forming, and a front waistline portion 20 ′ and a rear waistline portion 30 ′ while being positioned below the front waistline portion 20 ′ and the rear waistline portion 30 ′ in the vertical direction. Crotch part 10 'provided between the two. Further, the one end 20eW1 ′ in the lateral direction of the front waistline portion 20 ′ and the one end 30eW1 ′ in the lateral direction of the rear waistline portion 30 ′ are joined by the joint j1 ′, thereby Only one leg opening LH1 ′ is formed on the one side. Further, a female member 40 ′ is provided as a locking portion 40 ′ at the other end 30eW2 ′ in the lateral direction of the rear waistline portion 30 ′, and the female material 40 ′ is locked at the front waistline portion 20 ′. A possible male material 50 'is provided. In addition, the front waistline portion 20 ′ is provided with a plurality of elastic members 23 ′, 23 ′,... For imparting lateral stretchability to the front waistline portion 20 ′. The part provided with the members 23 ′, 23 ′,... Functions as a stretchable region AEL ′ having lateral stretchability.

しかし、このおむつ1’では、前胴回り部20’の上記伸縮領域AEL’が、横方向の位置に関して雄材50’とオーバーラップしている。そのため、伸縮領域AEL’の伸縮の影響が雄材50’に及び易く、つまり、雄材50’に縦方向に沿った皺が横方向に並んで生じる恐れがある。そして、かかる皺が生じると、雄材50’において後胴回り部30’の雌材40’との係止に寄与する面積が減ってしまったり、雄材50’の係止用突起(不図示)が、設計上の適正な向きとは別の方向を向いてしまったりして、結果、設計通りの係止力を発揮できなくなる恐れがある。つまり、雄材50’と雌材40’との係止力の低下を招き得る。

However, in the diaper 1 ′, the stretchable region AEL ′ of the front waistline portion 20 ′ overlaps the male material 50 ′ with respect to the lateral position. Therefore, the expansion / contraction of the expansion / contraction region AEL ′ is likely to affect the male member 50 ′, that is, wrinkles along the vertical direction may occur in the male member 50 ′ in the horizontal direction. When such wrinkles occur, the area contributing to the engagement of the rear waistline 30 'with the female member 40' in the male member 50 'decreases, or the locking protrusion (not shown) of the male member 50' There is a possibility that it may face a direction different from the proper design direction, and as a result, the locking force as designed cannot be exhibited. That is, the locking force between the male member 50 'and the female member 40' can be reduced.

本発明は、上記のような問題に鑑みてなされたものであって、その目的は、前胴回り部に設けられた雄材の係止力の低下を抑制することにある。

The present invention has been made in view of the above problems, and an object thereof is to suppress a decrease in locking force of a male member provided in a front waistline portion.

上記目的を達成するための主たる発明は、

縦方向と、前記縦方向と交差する横方向と、前記縦方向及び前記横方向と直交する前後方向と、を有した吸収性物品であって、

前記横方向に沿った前胴回り部と、

前記横方向に沿った後胴回り部と、

前記前胴回り部と前記後胴回り部との間に設けられた股下部と、を備え、

前記前胴回り部における前記横方向の一方側の端部と前記後胴回り部における前記横方向の一方側の端部とは、接合部で接合されており、

前記前胴回り部における前記前後方向の前側の面には、前記後胴回り部における前記横方向の他方側の端部の雌材を係止可能な雄材が設けられており、

前記前胴回り部は、前記横方向の伸縮性を有する伸縮領域を前記横方向に沿って有し、

前記伸縮領域は、前記横方向の位置に関して前記雄材とオーバーラップしていないことを特徴とする吸収性物品である。

本発明の他の特徴については、本明細書及び添付図面の記載により明らかにする。 The main invention for achieving the above object is:

An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction,

A front waistline portion along the lateral direction;

A rear waistline portion along the lateral direction;

A crotch portion provided between the front waistline portion and the rear waistline portion,

An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

The front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

The front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction,

The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

Other features of the present invention will become apparent from the description of the present specification and the accompanying drawings.

縦方向と、前記縦方向と交差する横方向と、前記縦方向及び前記横方向と直交する前後方向と、を有した吸収性物品であって、

前記横方向に沿った前胴回り部と、

前記横方向に沿った後胴回り部と、

前記前胴回り部と前記後胴回り部との間に設けられた股下部と、を備え、

前記前胴回り部における前記横方向の一方側の端部と前記後胴回り部における前記横方向の一方側の端部とは、接合部で接合されており、

前記前胴回り部における前記前後方向の前側の面には、前記後胴回り部における前記横方向の他方側の端部の雌材を係止可能な雄材が設けられており、

前記前胴回り部は、前記横方向の伸縮性を有する伸縮領域を前記横方向に沿って有し、

前記伸縮領域は、前記横方向の位置に関して前記雄材とオーバーラップしていないことを特徴とする吸収性物品である。

本発明の他の特徴については、本明細書及び添付図面の記載により明らかにする。 The main invention for achieving the above object is:

An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction,

A front waistline portion along the lateral direction;

A rear waistline portion along the lateral direction;

A crotch portion provided between the front waistline portion and the rear waistline portion,

An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

The front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

The front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction,

The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

Other features of the present invention will become apparent from the description of the present specification and the accompanying drawings.

本発明によれば、前胴回り部に設けられた雄材の係止力の低下を抑制可能となる。

According to the present invention, it is possible to suppress a decrease in the locking force of the male material provided in the front waistline portion.

本明細書及び添付図面の記載により、少なくとも以下の事項が明らかとなる。

縦方向と、前記縦方向と交差する横方向と、前記縦方向及び前記横方向と直交する前後方向と、を有した吸収性物品であって、

前記横方向に沿った前胴回り部と、

前記横方向に沿った後胴回り部と、

前記前胴回り部と前記後胴回り部との間に設けられた股下部と、を備え、

前記前胴回り部における前記横方向の一方側の端部と前記後胴回り部における前記横方向の一方側の端部とは、接合部で接合されており、

前記前胴回り部における前記前後方向の前側の面には、前記後胴回り部における前記横方向の他方側の端部の雌材を係止可能な雄材が設けられており、

前記前胴回り部は、前記横方向の伸縮性を有する伸縮領域を前記横方向に沿って有し、

前記伸縮領域は、前記横方向の位置に関して前記雄材とオーバーラップしていないことを特徴とする吸収性物品である。 At least the following matters will become apparent from the description of the present specification and the accompanying drawings.

An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction,

A front waistline portion along the lateral direction;

A rear waistline portion along the lateral direction;

A crotch portion provided between the front waistline portion and the rear waistline portion,

An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

The front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

The front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction,

The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

縦方向と、前記縦方向と交差する横方向と、前記縦方向及び前記横方向と直交する前後方向と、を有した吸収性物品であって、

前記横方向に沿った前胴回り部と、

前記横方向に沿った後胴回り部と、

前記前胴回り部と前記後胴回り部との間に設けられた股下部と、を備え、

前記前胴回り部における前記横方向の一方側の端部と前記後胴回り部における前記横方向の一方側の端部とは、接合部で接合されており、

前記前胴回り部における前記前後方向の前側の面には、前記後胴回り部における前記横方向の他方側の端部の雌材を係止可能な雄材が設けられており、

前記前胴回り部は、前記横方向の伸縮性を有する伸縮領域を前記横方向に沿って有し、

前記伸縮領域は、前記横方向の位置に関して前記雄材とオーバーラップしていないことを特徴とする吸収性物品である。 At least the following matters will become apparent from the description of the present specification and the accompanying drawings.

An absorbent article having a longitudinal direction, a transverse direction intersecting the longitudinal direction, and a longitudinal direction perpendicular to the longitudinal direction and the transverse direction,

A front waistline portion along the lateral direction;

A rear waistline portion along the lateral direction;

A crotch portion provided between the front waistline portion and the rear waistline portion,

An end portion on one side in the lateral direction in the front waistline portion and an end portion on the one side in the lateral direction in the rear waistline portion are joined at a joint portion,

The front surface in the front-rear direction of the front waistline portion is provided with a male material capable of locking the female material on the other side end in the lateral direction of the rear waistline portion,

The front waistline portion has a stretchable region having the stretchability in the lateral direction along the lateral direction,

The stretchable region is an absorbent article that does not overlap the male material with respect to the lateral position.

このような吸収性物品によれば、前胴回り部の伸縮領域は、横方向の位置に関して雄材とオーバーラップしていない。すなわち、互いの横方向の位置がずれている。よって、雄材は、弾性部材の伸縮の影響を受け難くなっていて、これにより、雄材の皺の発生を抑制することができる。そして、その結果、雄材の係止力の低下を抑制可能となる。

According to such an absorbent article, the stretchable region of the front waistline portion does not overlap with the male material with respect to the lateral position. That is, the positions in the lateral direction are shifted from each other. Therefore, the male material is hardly affected by the expansion and contraction of the elastic member, and this can suppress the generation of wrinkles of the male material. As a result, it is possible to suppress a decrease in the locking force of the male material.

かかる吸収性物品であって、

前記伸縮領域は、前記前胴回り部における前記雄材よりも前記横方向の前記一方側の部分に位置しているのが望ましい。 Such an absorbent article,

It is desirable that the expansion / contraction region is located on the one side portion in the lateral direction with respect to the male material in the front waistline portion.

前記伸縮領域は、前記前胴回り部における前記雄材よりも前記横方向の前記一方側の部分に位置しているのが望ましい。 Such an absorbent article,

It is desirable that the expansion / contraction region is located on the one side portion in the lateral direction with respect to the male material in the front waistline portion.

このような吸収性物品によれば、伸縮領域は、前胴回り部における雄材よりも横方向の一方側の部分に位置している。よって、伸縮領域と雄材とを、横方向の位置に関して確実にオーバーラップしないようにすることができる。

According to such an absorbent article, the stretchable region is located in a portion on one side in the lateral direction with respect to the male material in the front waistline portion. Therefore, it is possible to ensure that the stretchable region and the male material do not overlap with respect to the lateral position.

かかる吸収性物品であって、

前記伸縮領域は、前記股下部の前記横方向の中心線よりも前記一方側に位置しており、

前記雄材は、前記中央線よりも前記他方側に位置しているのが望ましい。 Such an absorbent article,

The stretchable region is located on the one side with respect to the lateral center line of the crotch part,

The male member is preferably located on the other side of the center line.

前記伸縮領域は、前記股下部の前記横方向の中心線よりも前記一方側に位置しており、

前記雄材は、前記中央線よりも前記他方側に位置しているのが望ましい。 Such an absorbent article,

The stretchable region is located on the one side with respect to the lateral center line of the crotch part,

The male member is preferably located on the other side of the center line.

このような吸収性物品によれば、雄材は、伸縮領域から横方向の離れた位置に配置されている。よって、伸縮領域の伸縮性が雄材に及ぼす影響をより小さくすることができる。

According to such an absorbent article, the male material is arranged at a position away from the stretchable region in the lateral direction. Therefore, the influence which the elasticity of an expansion-contraction area | region has on a male material can be made smaller.

かかる吸収性物品であって、

前記前後方向から見た場合に、前記前胴回り部において前記股下部と重なる部分に、前記雄材が設けられているのが望ましい。 Such an absorbent article,

When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the crotch portion in the front waistline portion.

前記前後方向から見た場合に、前記前胴回り部において前記股下部と重なる部分に、前記雄材が設けられているのが望ましい。 Such an absorbent article,

When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the crotch portion in the front waistline portion.

このような吸収性物品によれば、前胴回り部の剛性に加えて股下部の剛性も、雄材の剛性を補うことに寄与する。よって、当該雄材の皺の発生をより一層抑制可能となる。

According to such an absorbent article, the rigidity of the crotch part in addition to the rigidity of the front waistline part contributes to supplementing the rigidity of the male material. Therefore, generation | occurrence | production of the wrinkle of the said male material can be suppressed further.

かかる吸収性物品であって、

前記股下部は、液吸収性の吸収性コアを有し、

前記前後方向から見た場合に、前記前胴回り部において前記吸収性コアと重なる部分に、前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch has a liquid-absorbent absorbent core,

When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the absorbent core in the front waistline portion.

前記股下部は、液吸収性の吸収性コアを有し、

前記前後方向から見た場合に、前記前胴回り部において前記吸収性コアと重なる部分に、前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch has a liquid-absorbent absorbent core,

When viewed from the front-rear direction, it is desirable that the male material is provided in a portion overlapping the absorbent core in the front waistline portion.

このような吸収性物品によれば、股下部の吸収性コアの大きな剛性も、雄材の剛性を補うことに寄与する。よって、当該雄材の皺の発生をより一層抑制可能となる。

According to such an absorbent article, the large rigidity of the absorbent core in the crotch also contributes to supplementing the rigidity of the male material. Therefore, generation | occurrence | production of the wrinkle of the said male material can be suppressed further.

かかる吸収性物品であって、

前記股下部は、液吸収性の吸収性コアを前記横方向の中央側の位置に有するとともに、前記股下部は、前記吸収性コアよりも前記横方向の前記一方側及び前記他方側にそれぞれ突出したシート状部分を有し、

前記他方側に突出した前記シート状部分には、前記シート状部分に前記縦方向の伸縮性を付与するための第1弾性部材が前記縦方向に沿って設けられており、

前記第1弾性部材よりも前記横方向の中央側の位置に前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch portion has a liquid-absorbing absorbent core at a position on the center side in the lateral direction, and the crotch portion projects to the one side and the other side in the lateral direction from the absorbent core, respectively. Having a sheet-like portion

The sheet-like part protruding to the other side is provided with a first elastic member along the longitudinal direction for imparting the stretchability in the longitudinal direction to the sheet-like part.

It is desirable that the male material is provided at a position closer to the center in the lateral direction than the first elastic member.

前記股下部は、液吸収性の吸収性コアを前記横方向の中央側の位置に有するとともに、前記股下部は、前記吸収性コアよりも前記横方向の前記一方側及び前記他方側にそれぞれ突出したシート状部分を有し、

前記他方側に突出した前記シート状部分には、前記シート状部分に前記縦方向の伸縮性を付与するための第1弾性部材が前記縦方向に沿って設けられており、

前記第1弾性部材よりも前記横方向の中央側の位置に前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch portion has a liquid-absorbing absorbent core at a position on the center side in the lateral direction, and the crotch portion projects to the one side and the other side in the lateral direction from the absorbent core, respectively. Having a sheet-like portion

The sheet-like part protruding to the other side is provided with a first elastic member along the longitudinal direction for imparting the stretchability in the longitudinal direction to the sheet-like part.

It is desirable that the male material is provided at a position closer to the center in the lateral direction than the first elastic member.

このような吸収性物品によれば、上記の第1弾性部材よりも横方向の中央側の位置に雄材が設けられているが、かかる中央側の位置には、吸収性コアが位置している。よって、第1弾性部材の縦方向の伸縮起因で生じ得る雄材の皺を、吸収性コアの剛性で効果的に抑制することができる。

According to such an absorbent article, the male material is provided at a position on the center side in the lateral direction with respect to the first elastic member, but the absorbent core is located at the position on the center side. . Therefore, wrinkles of the male material that can be caused by the vertical expansion and contraction of the first elastic member can be effectively suppressed by the rigidity of the absorbent core.

かかる吸収性物品であって、

前記股下部は、液吸収性の吸収性コアを前記横方向の中央側の位置に有し、

前記前後方向から見た場合に、前記股下部は、前記吸収性コアの横方向の中心線よりも前記横方向の他方側において当該吸収性コアと重なる位置に、立体ギャザーを形成するためのシートを前記縦方向に沿って有するとともに、前記シートには、前記縦方向に伸長した状態で前記縦方向に沿った第2弾性部材が固定されており、

前記第2弾性部材よりも前記横方向の中央側の位置に前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch portion has a liquid-absorbent absorbent core at a position on the central side in the lateral direction,

When viewed from the front-rear direction, the crotch portion is a sheet for forming a three-dimensional gather at a position overlapping the absorbent core on the other side in the lateral direction from the lateral center line of the absorbent core. The second elastic member along the longitudinal direction is fixed to the sheet in a state of extending in the longitudinal direction.

It is desirable that the male material is provided at a position closer to the center in the lateral direction than the second elastic member.

前記股下部は、液吸収性の吸収性コアを前記横方向の中央側の位置に有し、

前記前後方向から見た場合に、前記股下部は、前記吸収性コアの横方向の中心線よりも前記横方向の他方側において当該吸収性コアと重なる位置に、立体ギャザーを形成するためのシートを前記縦方向に沿って有するとともに、前記シートには、前記縦方向に伸長した状態で前記縦方向に沿った第2弾性部材が固定されており、

前記第2弾性部材よりも前記横方向の中央側の位置に前記雄材が設けられているのが望ましい。 Such an absorbent article,

The crotch portion has a liquid-absorbent absorbent core at a position on the central side in the lateral direction,

When viewed from the front-rear direction, the crotch portion is a sheet for forming a three-dimensional gather at a position overlapping the absorbent core on the other side in the lateral direction from the lateral center line of the absorbent core. The second elastic member along the longitudinal direction is fixed to the sheet in a state of extending in the longitudinal direction.

It is desirable that the male material is provided at a position closer to the center in the lateral direction than the second elastic member.

このような吸収性物品によれば、上記の第2弾性部材よりも横方向の中央側の位置に雄材が設けられているが、かかる中央側の位置には、吸収性コアが位置している。よって、第2弾性部材の縦方向の伸縮起因で生じ得る雄材の皺を、吸収性コアの剛性で効果的に抑制することができる。

According to such an absorbent article, the male material is provided at a position on the center side in the lateral direction with respect to the second elastic member, but the absorbent core is located at the position on the center side. . Therefore, wrinkles of the male material that can be caused by the expansion and contraction in the vertical direction of the second elastic member can be effectively suppressed by the rigidity of the absorbent core.

===本実施形態===

本実施形態の吸収性物品は使い捨ておむつ1である。また、同おむつ1の着用者は新生児や乳幼児等である。

図2は、当該おむつ1の概略斜視図である。

このおむつ1は、図2のような着用前の片開きパンツ型状態において、「縦方向」と、縦方向と直交する「横方向」と、縦方向及び横方向と直交する「前後方向」と、を有している。そして、同おむつ1の着用中に、縦方向は、上下方向を向いていることが多い。そのため、以下では、縦方向のことを「上下方向」とも言う。

なお、上下方向については、上側が、着用者の胴回り側に対応し、下側が、着用者の股下側に対応している。また、前後方向については、前側が着用者の腹側に対応し、後側が着用者の背側に対応している。更に、横方向については、一方側が着用者の左側に対応し、他方側が着用者の右側に対応している。なお、以下の説明で、単に「一方側」及び「他方側」と言う場合には、横方向の一方側及び他方側を指しているものとする。 === This Embodiment ===

The absorbent article of this embodiment is adisposable diaper 1. Moreover, the wearer of the diaper 1 is a newborn baby or an infant.

FIG. 2 is a schematic perspective view of thediaper 1.

Thisdiaper 1 has a “vertical direction”, a “horizontal direction” orthogonal to the vertical direction, and a “front-rear direction” orthogonal to the vertical direction and the horizontal direction in a single-open pants-type state before wearing as shown in FIG. ,have. And while wearing the diaper 1, the vertical direction often faces the vertical direction. Therefore, hereinafter, the vertical direction is also referred to as “vertical direction”.

In addition, about an up-down direction, the upper side respond | corresponds to a wearer's waistline side, and the lower side respond | corresponds to a wearer's inseam side. Moreover, about the front-back direction, the front side respond | corresponds to a wearer's belly side, and the back side respond | corresponds to a wearer's back side. Furthermore, about the horizontal direction, one side respond | corresponds to a wearer's left side, and the other side respond | corresponds to a wearer's right side. In the following description, the terms “one side” and “the other side” refer to the one side and the other side in the horizontal direction.

本実施形態の吸収性物品は使い捨ておむつ1である。また、同おむつ1の着用者は新生児や乳幼児等である。

図2は、当該おむつ1の概略斜視図である。

このおむつ1は、図2のような着用前の片開きパンツ型状態において、「縦方向」と、縦方向と直交する「横方向」と、縦方向及び横方向と直交する「前後方向」と、を有している。そして、同おむつ1の着用中に、縦方向は、上下方向を向いていることが多い。そのため、以下では、縦方向のことを「上下方向」とも言う。

なお、上下方向については、上側が、着用者の胴回り側に対応し、下側が、着用者の股下側に対応している。また、前後方向については、前側が着用者の腹側に対応し、後側が着用者の背側に対応している。更に、横方向については、一方側が着用者の左側に対応し、他方側が着用者の右側に対応している。なお、以下の説明で、単に「一方側」及び「他方側」と言う場合には、横方向の一方側及び他方側を指しているものとする。 === This Embodiment ===

The absorbent article of this embodiment is a

FIG. 2 is a schematic perspective view of the

This

In addition, about an up-down direction, the upper side respond | corresponds to a wearer's waistline side, and the lower side respond | corresponds to a wearer's inseam side. Moreover, about the front-back direction, the front side respond | corresponds to a wearer's belly side, and the back side respond | corresponds to a wearer's back side. Furthermore, about the horizontal direction, one side respond | corresponds to a wearer's left side, and the other side respond | corresponds to a wearer's right side. In the following description, the terms “one side” and “the other side” refer to the one side and the other side in the horizontal direction.

図2の片開きパンツ型状態においては、おむつ1は、横方向に沿った前胴回り部20と、この前胴回り部20の後側に位置しつつ、当該前胴回り部20と共同して、縦方向の上側に胴回り開口BHを形成するための横方向に沿った後胴回り部30と、前胴回り部20と後胴回り部30との間に設けられた股下部としての吸収性本体10と、を備えている。そして、吸収性本体10は、前胴回り部20及び後胴回り部30よりも縦方向の下方に突出して位置している。

また、前胴回り部20における横方向の一方側の端部20eW1と後胴回り部30における横方向の一方側の端部30eW1とは、接合部j1で接合されている。そして、これにより、前胴回り部20及び後胴回り部30が、吸収性本体10と共同して、横方向の一方側且つ下側の位置に脚回り開口LH1を一つ形成している。ちなみに、接合部j1は、溶着又は接着等で形成されている。

更に、後胴回り部30における横方向の他方側の端部30eW2には、前胴回り部20における前側の面に係止可能な係止部40が設けられている。そして、図2中に2点鎖線で仮想的に示すように、当該係止部40が前胴回り部20の上記前側の面に係止されることで、前胴回り部20と後胴回り部30とが共同して上側に胴回り開口BHを形成するとともに、前胴回り部20と後胴回り部30と吸収性本体10とが共同することで、他方側且つ下側の位置にも脚回り開口LH2を一つ形成する。そして、これにより、当該おむつ1は、着用者に着用された状態となる。 2, thediaper 1 is located in the front waistline portion 20 along the lateral direction and the front waistline portion 20 while being positioned in the vertical direction, in cooperation with the front waistline portion 20. A rear waistline portion 30 along the lateral direction for forming a waistline opening BH on the upper side in the direction, and an absorbent main body 10 as a crotch portion provided between the front waistline portion 20 and the rear waistline portion 30. I have. And the absorptive main body 10 protrudes and is located below the front waistline part 20 and the back waistline part 30 in the vertical direction.

Further, the one end 20eW1 in the lateral direction of thefront waistline portion 20 and the one end 30eW1 in the lateral direction of the rear waistline portion 30 are joined by a joint j1. As a result, the front waistline portion 20 and the rear waistline portion 30 together with the absorbent main body 10 form one leg opening LH1 at a position on one side and below in the lateral direction. Incidentally, the junction j1 is formed by welding or adhesion.

Further, a lockingportion 40 that can be locked to the front surface of the front waistline portion 20 is provided at the other end 30eW2 in the lateral direction of the rear waistline portion 30. Then, as virtually indicated by a two-dot chain line in FIG. 2, the locking portion 40 is locked to the front surface of the front waistline portion 20, so that the front waistline portion 20, the rear waistline portion 30, Jointly form the waistline opening BH on the upper side, and the front waistline part 20, the rear waistline part 30, and the absorbent main body 10 together, so that the leg circumference opening LH2 is also provided at the other side and the lower position. Form one. And thereby, the said diaper 1 will be in the state worn by the wearer.

また、前胴回り部20における横方向の一方側の端部20eW1と後胴回り部30における横方向の一方側の端部30eW1とは、接合部j1で接合されている。そして、これにより、前胴回り部20及び後胴回り部30が、吸収性本体10と共同して、横方向の一方側且つ下側の位置に脚回り開口LH1を一つ形成している。ちなみに、接合部j1は、溶着又は接着等で形成されている。

更に、後胴回り部30における横方向の他方側の端部30eW2には、前胴回り部20における前側の面に係止可能な係止部40が設けられている。そして、図2中に2点鎖線で仮想的に示すように、当該係止部40が前胴回り部20の上記前側の面に係止されることで、前胴回り部20と後胴回り部30とが共同して上側に胴回り開口BHを形成するとともに、前胴回り部20と後胴回り部30と吸収性本体10とが共同することで、他方側且つ下側の位置にも脚回り開口LH2を一つ形成する。そして、これにより、当該おむつ1は、着用者に着用された状態となる。 2, the

Further, the one end 20eW1 in the lateral direction of the

Further, a locking

図3Aは、展開状態のおむつ1を着用者の非肌側から見た概略平面図である。また、図3Bは、図3A中のB-B断面図である。

ここで、展開状態とは、図2の片開きパンツ型状態のおむつ1が横方向の一方側に有する前述の接合部j1の接合を解くことで、前胴回り部20と後胴回り部30とを分離するとともに、おむつ1を縦方向に開くことで、おむつ1を平面上に展開した状態のことである。

また、この展開状態においては、おむつ1を構成する各部材の伸縮性が皆無であるという仮想的状態で同おむつ1を示している。例えば、この例では、おむつ1には、同おむつ1に伸縮性を付与する目的で複数の弾性部材16,23,33が設けられているが、この展開状態では、かかる弾性部材16,23,33の伸縮性(収縮力)が全く無いという仮想的状態で同おむつ1を示している。 FIG. 3A is a schematic plan view of the unfoldeddiaper 1 as viewed from the non-skin side of the wearer. FIG. 3B is a cross-sectional view taken along line BB in FIG. 3A.

Here, the unfolded state means that thefront waistline portion 20 and the rear waistline portion 30 are formed by unbonding the above-described joint portion j1 that the diaper 1 in the single-open pants-type state in FIG. 2 has on one side in the lateral direction. It is the state which expanded the diaper 1 on the plane by separating and opening the diaper 1 longitudinally.

Moreover, in this unfolded state, thediaper 1 is shown in a virtual state in which each member constituting the diaper 1 has no elasticity. For example, in this example, the diaper 1 is provided with a plurality of elastic members 16, 23, 33 for the purpose of imparting stretchability to the diaper 1. In this expanded state, the elastic members 16, 23, 33 are provided. The diaper 1 is shown in a virtual state where there is no 33 stretchability (contraction force).

ここで、展開状態とは、図2の片開きパンツ型状態のおむつ1が横方向の一方側に有する前述の接合部j1の接合を解くことで、前胴回り部20と後胴回り部30とを分離するとともに、おむつ1を縦方向に開くことで、おむつ1を平面上に展開した状態のことである。

また、この展開状態においては、おむつ1を構成する各部材の伸縮性が皆無であるという仮想的状態で同おむつ1を示している。例えば、この例では、おむつ1には、同おむつ1に伸縮性を付与する目的で複数の弾性部材16,23,33が設けられているが、この展開状態では、かかる弾性部材16,23,33の伸縮性(収縮力)が全く無いという仮想的状態で同おむつ1を示している。 FIG. 3A is a schematic plan view of the unfolded

Here, the unfolded state means that the

Moreover, in this unfolded state, the

展開状態においては、おむつ1は、互いに直交する三方向として長手方向と横方向と厚さ方向(図3Aでは紙面を貫通する方向)とを有している。なお、長手方向は、前述の縦方向に沿っている。そして、長手方向の一方側が腹側に対応し、他方側が背側に対応している。また、長手方向の外側が、縦方向の上側に対応し、長手方向の内側が、縦方向の下側に対応している。そして、このように長手方向と縦方向とは互いに似通った方向であることから、以下では、説明の都合上、この展開状態においても、長手方向に代えて縦方向を用いて説明することもある。一方、横方向は、前述の片開きパンツ型状態における横方向と同義である。また、厚さ方向については、一方側が、着用者の身体に接する肌側に対応し、他方側が、その逆側の非肌側に対応している。なお、厚さ方向は、前述の前後方向に沿っている。そのため、以下では、説明の都合上、この展開状態においても、厚さ方向に代えて前後方向を用いて説明することもある。

In the unfolded state, the diaper 1 has a longitudinal direction, a lateral direction, and a thickness direction (a direction penetrating the paper surface in FIG. 3A) as three directions orthogonal to each other. The longitudinal direction is along the above-described longitudinal direction. One side in the longitudinal direction corresponds to the ventral side, and the other side corresponds to the back side. Further, the outer side in the longitudinal direction corresponds to the upper side in the vertical direction, and the inner side in the longitudinal direction corresponds to the lower side in the vertical direction. Since the longitudinal direction and the longitudinal direction are similar to each other as described above, hereinafter, for the convenience of explanation, even in this expanded state, the longitudinal direction may be used instead of the longitudinal direction. . On the other hand, the lateral direction is synonymous with the lateral direction in the above-described single-opening pants type state. Moreover, about the thickness direction, one side respond | corresponds to the skin side which contact | connects a wearer's body, and the other side respond | corresponds to the non-skin side of the opposite side. The thickness direction is along the aforementioned front-rear direction. For this reason, in the following description, even in this expanded state, the front-rear direction may be used instead of the thickness direction for the convenience of explanation.

図3Aの展開状態においては、前胴回り部20は、横方向に沿って配されており、また、後胴回り部30は、前胴回り部20と長手方向に所定の間隔をあけた位置で、横方向に沿って配されている。そして、これら前胴回り部20と後胴回り部30との間に吸収性本体10が長手方向に沿って掛け渡されつつ、同吸収性本体10の長手方向の各端部10ea,10ebが、それぞれ最寄りの胴回り部20,30に接合固定されていて、これにより、その外観形状は、平面視略H型状をなしている。

3A, the front waistline portion 20 is disposed along the lateral direction, and the rear waistline portion 30 is laterally spaced from the front waistline portion 20 at a predetermined interval in the longitudinal direction. Arranged along the direction. And while the absorptive main body 10 is spanned along the longitudinal direction between the front waistline part 20 and the rear waistline part 30, the longitudinal ends 10ea, 10eb of the absorptive body 10 are nearest to each other. Are joined and fixed to the waist portions 20 and 30, so that the external shape thereof is substantially H-shaped in plan view.

吸収性本体10は、図3Aの展開状態において平面視略長方形状をなしている。そして、吸収性本体10の長手方向が、おむつ1の長手方向に沿うように配されている。また、図3Bに示すように、吸収性本体10は、吸収体11と、同吸収体11を肌側から覆って設けられたトップシート13と、同吸収体11を非肌側から覆って設けられたバックシート15と、を備えている。

The absorptive main body 10 has a substantially rectangular shape in plan view in the developed state of FIG. 3A. And the longitudinal direction of the absorptive main body 10 is distribute | arranged so that the longitudinal direction of the diaper 1 may be followed. Moreover, as shown to FIG. 3B, the absorptive main body 10 is provided with the absorber 11, the top sheet 13 provided by covering the absorber 11 from the skin side, and covering the absorber 11 from the non-skin side. The back sheet 15 is provided.

吸収体11は、液体吸収性の吸収性コア11cと、同コア11cの外周面を被覆する不図示のコアラップシートと、を有する。吸収性コア11cは、所定の液体吸収性素材を所定形状の一例としての平面視略砂時計形状に成形した成形体である。液体吸収性素材としては、パルプ繊維等の液体吸収性繊維や、高吸収性ポリマー(所謂SAP)等の液体吸収性粒状物を例示できる。また、コアラップシートには、ティッシュペーパーや不織布等の液透過性シートを使用可能であるが、コアラップシートについては無くても良い。また、吸収性コア11cの形状は、何等上記の平面視略砂時計形状に限らず、他の形状でも良い。

The absorbent body 11 has a liquid absorbent absorbent core 11c and a core wrap sheet (not shown) that covers the outer peripheral surface of the core 11c. The absorbent core 11c is a molded body obtained by molding a predetermined liquid absorbent material into a substantially hourglass shape in plan view as an example of a predetermined shape. As a liquid absorptive material, liquid absorptive granular materials, such as liquid absorptive fibers, such as pulp fiber, and superabsorbent polymer (what is called SAP) can be illustrated. The core wrap sheet may be a liquid permeable sheet such as tissue paper or non-woven fabric, but the core wrap sheet may be omitted. Moreover, the shape of the absorptive core 11c is not limited to the above-mentioned substantially hourglass shape in plan view, but may be other shapes.

トップシート13は、不織布等の液透過性の柔軟なシートである。また、バックシート15は、液不透過性の柔軟なシートである。そして、同バックシート15の一例としては、ポリエチレンフィルムやポリプロピレンフィルム等の液不透過性の防漏シート15aと、防漏シート15aの非肌側に貼り合わされた不織布製の外装シート15bとを有した二層構造のラミネートシート15が挙げられる(図3B)。

The top sheet 13 is a liquid-permeable flexible sheet such as a nonwoven fabric. The back sheet 15 is a liquid-impermeable flexible sheet. As an example of the back sheet 15, a liquid-impermeable leak-proof sheet 15 a such as a polyethylene film or a polypropylene film and a non-woven exterior sheet 15 b bonded to the non-skin side of the leak-proof sheet 15 a are provided. A laminated sheet 15 having a two-layer structure is shown (FIG. 3B).

なお、図3Aに示すように、少なくともバックシート15は、吸収性コア11cから長手方向及び横方向に突出するような平面サイズのシートである。そして、横方向に突出した部分に、それぞれ長手方向に伸縮するレッグギャザーLGが形成されている。すなわち、当該突出した部分には、長手方向に沿って糸ゴム等の複数の弾性部材16,16…が長手方向に伸長した状態で固定されていて、これにより、当該部分に伸縮性のレッグギャザーLGが形成されている。

Note that, as shown in FIG. 3A, at least the back sheet 15 is a flat sheet that protrudes in the longitudinal and lateral directions from the absorbent core 11c. And the leg gather LG which each expands-contracts in a longitudinal direction is formed in the part protruded in the horizontal direction. That is, a plurality of elastic members 16, 16... Such as rubber thread are fixed to the protruding portion in the longitudinal direction along the longitudinal direction. LG is formed.

後胴回り部30は、同図3Aに示すように、不織布等の柔軟なシートを素材とした平面視略矩形形状のシート部材である。この例では、図3Bに示すように、不織布31,32を二枚重ねに接合することで後胴回り部30は形成されている。そして、図3Aに示すように、当該後胴回り部30は、吸収性本体10よりも横方向の両側に突出するように配されつつ、同吸収性本体10における背側の端部10ebに非肌側から重ねられて接合されている。

The rear waistline portion 30 is a sheet member having a substantially rectangular shape in plan view made of a flexible sheet such as a nonwoven fabric as shown in FIG. 3A. In this example, as shown to FIG. 3B, the back trunk part 30 is formed by joining the nonwoven fabrics 31 and 32 on 2 sheets. As shown in FIG. 3A, the rear waistline portion 30 is arranged so as to protrude on both sides in the lateral direction from the absorbent main body 10, while the back end portion 10 eb of the absorbent main body 10 has no skin. It is overlapped and joined from the side.

また、図3A及び図3Bに示すように、後胴回り部30に係る2枚の不織布31,32同士の間には、横方向に沿った糸ゴム等の複数の弾性部材33,33…が縦方向に並んで介挿されつつ、横方向に伸長した状態で同不織布31,32に接合固定されている。そして、これにより、後胴回り部30には、横方向の伸縮性が付与されている。

As shown in FIGS. 3A and 3B, a plurality of elastic members 33, 33..., Such as thread rubber, along the lateral direction are vertically disposed between the two nonwoven fabrics 31, 32 associated with the rear waistline 30. The nonwoven fabrics 31 and 32 are joined and fixed in a state of being stretched in the lateral direction while being inserted side by side in the direction. As a result, the rear waistline portion 30 is provided with lateral stretchability.