WO2018079199A1 - Automotive rear imaging device - Google Patents

Automotive rear imaging device Download PDFInfo

- Publication number

- WO2018079199A1 WO2018079199A1 PCT/JP2017/035803 JP2017035803W WO2018079199A1 WO 2018079199 A1 WO2018079199 A1 WO 2018079199A1 JP 2017035803 W JP2017035803 W JP 2017035803W WO 2018079199 A1 WO2018079199 A1 WO 2018079199A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- case

- exterior case

- vehicle

- camera body

- opening

- Prior art date

Links

- 238000003384 imaging method Methods 0.000 title claims abstract description 62

- 230000003287 optical effect Effects 0.000 claims abstract description 62

- 229910052751 metal Inorganic materials 0.000 claims description 13

- 239000002184 metal Substances 0.000 claims description 13

- 230000002093 peripheral effect Effects 0.000 claims description 9

- 229920003002 synthetic resin Polymers 0.000 claims description 7

- 239000000057 synthetic resin Substances 0.000 claims description 7

- 230000000149 penetrating effect Effects 0.000 claims description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract description 50

- 210000000078 claw Anatomy 0.000 description 14

- 238000012856 packing Methods 0.000 description 10

- 239000000428 dust Substances 0.000 description 8

- 229920001971 elastomer Polymers 0.000 description 8

- 239000000806 elastomer Substances 0.000 description 5

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 229920005989 resin Polymers 0.000 description 3

- 239000011347 resin Substances 0.000 description 3

- -1 polybutylene terephthalate Polymers 0.000 description 2

- 229920001707 polybutylene terephthalate Polymers 0.000 description 2

- 229920000515 polycarbonate Polymers 0.000 description 2

- 239000004417 polycarbonate Substances 0.000 description 2

- QMRNDFMLWNAFQR-UHFFFAOYSA-N prop-2-enenitrile;prop-2-enoic acid;styrene Chemical compound C=CC#N.OC(=O)C=C.C=CC1=CC=CC=C1 QMRNDFMLWNAFQR-UHFFFAOYSA-N 0.000 description 2

- 241000251730 Chondrichthyes Species 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000012447 hatching Effects 0.000 description 1

- 230000035699 permeability Effects 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 238000004078 waterproofing Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R11/00—Arrangements for holding or mounting articles, not otherwise provided for

- B60R11/02—Arrangements for holding or mounting articles, not otherwise provided for for radio sets, television sets, telephones, or the like; Arrangement of controls thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60S—SERVICING, CLEANING, REPAIRING, SUPPORTING, LIFTING, OR MANOEUVRING OF VEHICLES, NOT OTHERWISE PROVIDED FOR

- B60S1/00—Cleaning of vehicles

- B60S1/02—Cleaning windscreens, windows or optical devices

- B60S1/56—Cleaning windscreens, windows or optical devices specially adapted for cleaning other parts or devices than front windows or windscreens

- B60S1/60—Cleaning windscreens, windows or optical devices specially adapted for cleaning other parts or devices than front windows or windscreens for signalling devices, e.g. reflectors

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B15/00—Special procedures for taking photographs; Apparatus therefor

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B17/00—Details of cameras or camera bodies; Accessories therefor

- G03B17/02—Bodies

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B17/00—Details of cameras or camera bodies; Accessories therefor

- G03B17/02—Bodies

- G03B17/08—Waterproof bodies or housings

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B17/00—Details of cameras or camera bodies; Accessories therefor

- G03B17/55—Details of cameras or camera bodies; Accessories therefor with provision for heating or cooling, e.g. in aircraft

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01Q—ANTENNAS, i.e. RADIO AERIALS

- H01Q1/00—Details of, or arrangements associated with, antennas

- H01Q1/27—Adaptation for use in or on movable bodies

- H01Q1/32—Adaptation for use in or on road or rail vehicles

-

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N7/00—Television systems

- H04N7/18—Closed-circuit television [CCTV] systems, i.e. systems in which the video signal is not broadcast

Definitions

- the present invention relates to an in-vehicle rear photographing apparatus and the like.

- Patent Document 1 an apparatus mounted on a vehicle roof such as an in-vehicle antenna apparatus is mounted with an imaging device (camera) for photographing the rear.

- an imaging device camera

- an object of the present invention is to provide an in-vehicle rear photographing apparatus capable of removing water droplets attached to an optical member.

- An in-vehicle rear imaging apparatus includes an imaging unit having a camera body with an imaging surface facing the rear of the vehicle, and a lower end having an apex at an upper part on the rear side and at least a front side having a semi-elliptical shape or a leaf shape.

- An outer shape is formed by a slope connecting the periphery of the part and the top part, and a lower back opening for allowing light to enter the lens of the camera body is provided on the back side.

- a base that holds the outer case with the main body sandwiched therebetween, and the outer case is provided with an air guiding portion that guides air to the back surface during traveling.

- the exterior case is provided with a passage penetrating the upper back opening provided at a position higher than the lower back opening on the back of the exterior case and the opening in the exterior case as an air guiding portion.

- an inclined surface whose front side is higher than the rear side is provided between the passage and the upper rear opening or at the end of the passage where the upper rear opening is located.

- a part of the air discharged from the upper back opening is guided downward on the back surface of the exterior case by the inclined surface of the exterior case, and passes through the front surface of the optical member provided on the forefront of the camera body.

- the water droplets or dust adheres to the optical member the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

- the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

- the air passing through the passage cools the camera body disposed at the lower part of the passage, and the temperature rise of the camera body can be suppressed.

- the camera unit further includes an antenna unit having an antenna element, a first interior case made of synthetic resin that covers the antenna element, and a second interior case made of metal, and a housing that holds the image sensor in the camera body Is made of metal, and the camera body is attached to the second interior case via a metal bracket.

- the first interior case and the second interior case are above the base and below the passage. Be placed.

- the air passing through the passage cools the metal parts such as the housing of the camera body, the second interior case, and the bracket disposed at the lower part of the passage, thereby suppressing the temperature rise of the camera body.

- dimple processing is performed as an air guiding portion, or a plurality of fins protruding in the left-right direction and extending in the front-back direction are formed.

- the dimple-processed dent provided on the rear side of the side surface of the exterior case as the air guiding portion has a depth of 0.35 mm.

- the recess is formed so that the distance between the deepest point in the dimple processing recess and the vertical plane including the optical axis of the lens of the camera body is shorter on the rear side than on the front side. Is done.

- the plurality of fins formed on the back side of the side surface of the exterior case as the air guiding portion has a height of 0.75 mm.

- an exterior case cover is provided on the rear side of the side surface of the exterior case as an air guiding portion with a gap penetrating in the front-rear direction.

- an air guide wall is provided on the rear side of the outer case cover so as not to come into contact with the side surface or the back surface of the outer case and project inward.

- the water droplets or dust adheres to the optical member the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member. Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

- dimple processing is performed as an air guiding portion on the rear side of the side surface of the outer case, or a plurality of fins protruding in the left-right direction and extending in the front-rear direction are formed.

- the air flowing near the side of the exterior case passes through the dimple-processed area or fin-formed area on the back side of the exterior case, so that the vicinity of the exterior of the exterior case In this case, a turbulent flow is generated, and the air flowing on the side surface of the outer case does not peel from the outer case, and the air easily flows near the back surface of the outer case. Part of the air that has flowed through the side surface of the outer case is guided to the lower side of the outer case without being separated from the outer case and passes through the front surface of the optical member provided on the forefront of the camera body.

- the optical member When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member. Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

- an in-vehicle rear photographing device capable of removing water droplets attached to an optical member.

- FIG. 8 is a cross-sectional configuration view taken along line AA in FIG. 7.

- FIG. 9 is a cross-sectional view taken along the line BB in FIG. 9 in which members inside the outer case excluding the passage are omitted.

- FIG. 18 is a cross-sectional configuration view taken along the line CC of FIG. In the DD cross-sectional configuration diagram of FIG. 19, members inside the exterior case are omitted.

- FIG. 21 is a sectional view taken along the line EE of FIG. 20. It is the perspective view of the vehicle-mounted back imaging device in 3rd Embodiment, and it looked from upper direction and diagonally forward.

- FIG. 27 is a sectional view taken along the line FF in FIG. 26.

- FIG. 28 is a cross-sectional configuration view taken along the line GG in FIG. 28 and shows the exterior case 11.

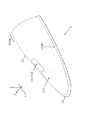

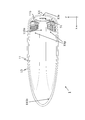

- the in-vehicle rear imaging device 1 in the first embodiment is attached to the upper surface of a vehicle 90 such as a roof, and includes a case 10, an antenna unit 30, and an imaging unit 50 (see FIGS. 1 to 11).

- the front-rear direction of the vehicle 90 to which the in-vehicle rearward imaging device 1 is attached is the x direction

- the left-right direction perpendicular to the x direction is the y direction

- the substantially vertical direction perpendicular to the x direction and the y direction is the z direction.

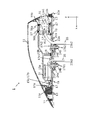

- the case 10 is a member that covers members constituting the in-vehicle rear photographing apparatus 1 such as the antenna element 31 and the camera body 51, and includes an outer case 11, an outer pad 13, and an inner case 15 (first inner case 15a and second inner case 15b). , Base 17, interior pad 19, seal member 21 (first seal member 21a, second seal member 21b), and pre-lock 23 (first pre-lock 23a, second pre-lock 23b).

- the antenna unit 30 includes an antenna element 31 and an antenna cable 35.

- the imaging unit 50 includes a camera body 51 including an imaging element such as a CMOS, a camera cable 55, a first packing 56a, a second packing 56b, a bracket 57, and a ground plate 59.

- the outer case 11 is made of a synthetic resin having a non-light-transmitting property and a radio-transmitting property (a resin molded product formed of a synthetic resin including Polycarbonate and ASA (Acrylate Styrene Acrylonitrile)).

- the exterior case 11 is a member having an open bottom surface and constituting the in-vehicle rear photographing apparatus 1 and other than the exterior case 11 (the exterior pad 13, the interior case 15, the base 17, the interior pad 19, the antenna element 31, the antenna A part of the cable 35, a part of the camera body 51, a part of the camera cable 55, etc.) are covered from above in the z direction (see FIGS. 1 and 10). However, a part of the lens of the camera body 51 may protrude from the back surface of the outer case 11 to the rear side in the x direction.

- the outer case 11 has a top portion 110a at the upper portion on the rear side in the x direction, and is a slope connecting the lower end peripheral portion 110b and the top portion 110a having a ring shape and at least the front side in the x direction having a substantially semi-elliptical shape or a substantially leaf shape.

- An outline is formed.

- the first slope 111 connecting the x-direction front portion of the lower peripheral edge 110b and the top 110a is more gradual than the second slope 112 connecting the x-direction rear portion of the lower peripheral 110b and the top 110a. It has a gentle slope.

- the shape of the exterior case 11 described above is said to be a so-called shark fin shape, for example.

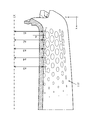

- an opening for allowing light from the rear to enter the lens of the camera body 51 of the imaging unit 50 provided for photographing the back of the vehicle 90.

- a portion other than the lens in the lower back opening 11a1 is covered with a camera cover 11b.

- the camera cover 11 b covers the periphery of the lens of the camera body 51.

- the upper part of the lens of the camera body 51 in the camera cover 11b has an inclined surface (cover inclined surface 11b1) in which the front side in the x direction is higher than the rear side in the x direction.

- An opening (upper back opening 11a2) is provided on the back surface (second slope 112) of the outer case 11 and above the lower back opening 11a1.

- An opening (front opening 11 c) is provided on the front surface of the outer case 11.

- 1st Embodiment demonstrates the form in which the upper part of one opening provided in the back surface of the exterior case 11 comprises the upper back surface opening 11a2, and the lower part comprises the lower back surface opening 11a1, two openings are demonstrated. The form provided may be sufficient.

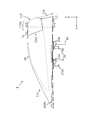

- the passage 11d that connects the upper back opening 11a2 and the front opening 11c is provided inside the exterior case 11.

- the passage 11d has a bottom surface portion 11d1 and a side surface portion 11d2, and has a substantially groove shape (or a substantially cylindrical shape) along the upper portion of the inner wall of the exterior case 11 (see FIG. 2).

- the x direction front side of the bottom surface part 11d1 is in contact with the lower end of the front opening 11c, and the x direction rear side of the bottom surface part 11d1 is in contact with the cover inclined surface 11b1 of the camera cover 11b.

- the bottom surface portion 11d1 is located on the upper side in the z direction with respect to a first inner case 15a and a second inner case 15b described later.

- the side surface portion 11d2 extends upward in the z direction from both ends of the bottom surface portion 11d1 in the y direction.

- the front side of the side part 11d2 in the x direction is in contact with the front opening 11c

- the rear side in the x direction of the side part 11d2 is in contact with the upper back opening 11a2

- the upper end of the side part 11d2 is in contact with the upper part of the inner wall of the exterior case 11.

- the inner wall on the back surface (second inclined surface 112) of the exterior case 11 and above the upper back surface opening 11a2 is such that the front side in the x direction is higher than the rear side in the x direction. It has the inclined surface 11a3 (refer FIG. 10).

- the passage 11d has a substantially cylindrical shape

- the upper surface of the end portion on the upper back opening 11a2 side of the passage 11d has an inclined surface (not shown) in which the front side in the x direction is higher than the rear side in the x direction.

- an inclined surface (an inner wall inclined surface 11a3, a cover) whose front side in the x direction is higher than the rear side in the x direction.

- An inclined surface 11b1) is provided.

- the upper part of the outer case 11, the upper back opening 11a2, the cover inclined surface 11b1, the front opening 11c, and the passage 11d form an air guide path (cavity) that penetrates the inside of the outer case 11 in the x direction, It functions as an air guiding unit that guides air that has entered through the front opening 11c to the back during traveling.

- the upper part of the interior case 15, the base 17, the interior pad 19, the antenna element 31, a part of the antenna cable 35, the camera body 51, a part of the camera cable 55, and the like is hermetically sealed by the inner wall of the exterior case 11 and the passage 11d. Covered with condition.

- the camera main body 51 is attached to the 2nd interior case 15b so that the camera cover 11b attached to the back surface opening 11a may be contacted. Since the water that has entered through the space between the camera cover 11b and the camera body 51 is discharged through the drainage notch 13a provided in the exterior pad 13, the window portion may not be provided.

- a description will be given in a form in which the window portion is not attached to a region covering the lens of the camera body 51 in the camera cover 11b.

- the lens of the camera body 51 that is provided on the forefront is the camera body that will be described later. It functions as an optical member provided on the forefront of 51 (the rear side in the x direction).

- the window portion When the window portion is attached to a region of the camera cover 11b that covers the lens of the camera body 51, the window portion functions as an optical member provided on the foremost surface (the rear side in the x direction) of the camera body 51 described later. .

- the outer case 11 is provided with a first locking claw 11e for attachment to the base 17 so as to protrude downward in the z direction from the inner wall.

- the first locking claw 11e is provided.

- the claw 11e engages with a second locking claw 17a provided on the base 17 (see FIG. 10).

- the exterior pad 13 is an annular elastic member formed of elastomer (Elastomer), rubber, or the like, and is fitted into the lower peripheral edge 110 b of the external case 11, and between the lower peripheral edge 110 b of the external case 11 and the vehicle 90.

- the gap is blindfolded and water intrusion into the outer case 11 is prevented.

- a drainage notch 13a is provided at the lower end of the exterior pad 13 at the rear end in the x direction as a discharge port for water that has entered between the exterior case 11 and the interior case 15 (FIGS. 2 and 5). FIG. 8 and FIG. 10).

- the interior case 15 has a first interior case 15a and a second interior case 15b.

- the first interior case 15a has an open bottom surface, a region on the base 17 in the antenna cable 35 (a region between a portion connected to the antenna element 31 and a portion inserted into the first opening 17c1), and an antenna element. 31 is covered from above in the z direction.

- the first interior case 15a is made of a synthetic resin having a non-light-transmitting property and a radio wave transmitting property (a resin molded product formed of a synthetic resin including polycarbonate and ASA (Acrylate Styrene Acrylonitrile)).

- the second interior case 15b is disposed behind the first interior case 15a in the x direction, the bottom surface and the back surface are open, and the region on the base 17 in the camera cable 55 (second portion from the portion connected to the camera body 51 is second). The region between the portion inserted into the opening 17c2 is covered from above in the z direction.

- the camera body 51 is attached to the opened portion on the back surface of the second interior case 15b via the second packing 56b, the bracket 57, and the first packing 56a.

- the first packing 56a, the second packing 56b, and the bracket 57 The space between the second interior case 15b and the camera body 51 is sealed.

- the second interior case 15b is preferably made of a metal such as aluminum. Screw holes 15c used for screwing to the base 17 are provided at the lower ends of the first inner case 15a and the second inner case 15b.

- the base 17 is a metal base such as aluminum. However, the polybutylene terephthalate (Polybutylene Terephthalate) other than the conductive region connecting the ground plate mounting portion 17e and the second boss 17d2 extending downward in the base 17 and the region including the connection region in contact with the second interior case 15b in the base 17 is used. ) Or the like.

- the base 17 has a second locking claw 17a that engages with the first locking claw 11e of the outer case 11 to lock the outer case 11 on the outer peripheral portion (see FIG. 10).

- the base 17 holds the outer case 11 with the imaging unit 50 including the camera body 51 interposed therebetween.

- the antenna element 31 including the antenna substrate is attached to the upper surface of the base 17 and covered with the first interior case 15a by screwing.

- the periphery of the base 17 is provided with a recess (screw receiver 17b) used for screwing with the interior case 15 (first interior case 15a, second interior case 15b).

- the interior pad 19 is attached to the peripheral edge of the upper surface of the base 17 and inside the screw receiver 17b.

- the base 17 is provided with a wiring opening 17c.

- the wiring opening 17c is different from the two openings (the first opening 17c1 and the first opening 17c1 provided in the region covered with the first interior case 15a in the base 17 and more than the first opening 17c1.

- the second opening 17c2) is provided on the rear side in the direction and is provided in a region of the base 17 covered with the second interior case 15b.

- the antenna cable 35 connected to the antenna element 31 extends downward in the z direction of the base 17 through the first opening 17c1 (see FIGS. 1, 3, and 10).

- the camera cable 55 connected to the camera body 51 extends downward in the z direction of the base 17 via the second opening 17c2.

- bosses 17d On the bottom surface of the base 17, there are provided bosses 17d (first boss 17d1 and second boss 17d2) extending downward in the z direction. Specifically, a first boss 17d1 extending downward in the z direction is provided on the lower surface of the base 17 in the region covered with the first interior case 15a. A second boss 17d2 extending downward in the z direction is provided on the lower surface of the base 17 in the region covered with the second interior case 15b.

- the boss 17d (the first boss 17d1 and the second boss 17d2) may be configured separately from the base 17 (see FIG. 10), or may be configured integrally (not shown). Also good.

- the form in which the boss 17d extends downward from the base 17 in the z direction has been described. However, the form in which the boss 17d is attached to the base 17 by screwing or the like from below in the z direction may be used.

- the in-vehicle rearward imaging device 1 is fixed to the upper surface of the vehicle 90 by a pre-lock 23 (first pre-lock 23a, second pre-lock 23b), a boss 17d (first boss 17d1, second boss 17d2), a washer with a claw or a nut. This is done using mounting brackets (not shown).

- the first boss 17d1 is inserted into the first boss hole 23a1 provided in the first prelock 23a, and the antenna cable 35 passing through the first opening 17c1 is the first provided in the first prelock 23a.

- the first pre-lock 23a is the first

- the fitting hole 91a is fitted from above

- the second pre-lock 23b is provided behind the first attachment hole 91a.

- the base 17 is placed on the roof of the vehicle 90 from above, and a mounting bracket (not shown) such as a claw washer or nut is used from the lower surface of the vehicle 90 roof.

- the first boss 17d1 and the second boss 17d2 are fixed.

- FIG. 29 of the third embodiment the claw washer 24a is connected to the first prelock 23a and the second prelock 23b.

- a state where the nut 24b is attached to the first boss 17d1 and the second boss 17d2 is shown.

- first pre-lock 23a is fitted into the first mounting hole 91a provided in the roof of the vehicle 90 from above

- the second pre-lock 23b is fitted into the second mounting hole 91b from above with the roof of the vehicle 90 to provide a claw washer

- the first boss 17d1 is inserted into the first boss hole 23a1, and the antenna cable 35 passing through the first opening 17c1 is inserted into the first cable hole 23a2.

- the second boss 17d2 is inserted into the second boss hole 23b1, the camera cable 55 passing through the second opening 17c2 is inserted into the second cable hole 23b2, and the base 17 is placed on the roof of the vehicle 90.

- the first boss 17d1 and the second boss 17d2 may be fixed from the lower surface of the roof 90 using a nut (not shown) or the like.

- the lower surface of the base 17 is provided with a seal member 21 (first seal member 21a, second seal member 21b) which is an annular elastic member formed of elastomer (Elastomer), rubber or the like. And the roof of the vehicle 90 and the periphery of the area where the mounting holes 91 (first mounting hole 91a and second mounting hole 91b) are provided is watertightly sealed.

- the first seal member 21a is disposed so that the ring constituting the first seal member 21a passes the first boss 17d1, the first pre-lock 23a, and the antenna cable 35.

- the second seal member 21b is arranged so that the ring constituting the second seal member 21b passes the second boss 17d2, the second pre-lock 23b, and the camera cable 55.

- the ring constituting one seal member 21 includes a first boss 17d1, a first prelock 23a, and an antenna cable. 35, the second boss 17d2, the second pre-lock 23b, and the camera cable 55 may be passed.

- an earth plate attachment portion 17 e for screwing the earth plate 59 for grounding the camera body 51 is provided on the upper surface of the base 17, in the vicinity of the area where the camera body 51 is attached.

- the interior pad 19 is an annular elastic member formed of an elastomer or rubber, and is provided on the upper surface of the base 17 (see FIGS. 1, 3, and 10).

- the interior pad 19 has an annular region facing the lower end of the first interior case 15a, and an annular region facing the lower end of the second interior case 15b.

- the pre-lock 23 is a resin member that fits into the mounting hole 91 of the vehicle 90.

- the pre-lock 23 includes two pre-locks 23 (first pre-lock 23a and second pre-lock 23b).

- the first pre-lock 23a has a first boss hole 23a1 through which the first boss 17d1 passes and a first cable hole 23a2 that faces the first opening 17c1 and passes through the antenna cable 35, and a portion protruding downward in the z direction is the first. It fits into the mounting hole 91a.

- the second pre-lock 23b has a second boss hole 23b1 through which the second boss 17d2 passes, and a second cable hole 23b2 that faces the second opening 17c2 and passes the camera cable 55, and a portion protruding downward in the z direction is the second. It fits into the mounting hole 91b.

- the boss 17d (the first boss 17d1 and the second boss 17d2) may be inserted into another mounting hole (not shown) provided in the vehicle 90 without the pre-lock 23 interposed therebetween. Further, the pre-lock 23 may be attached to the base 17 from below in the z direction as in the first embodiment, but may be attached to the base 17 from above in the z direction.

- the antenna element 31 may be configured by a planar antenna for GPS reception or the like, or may be configured by an upper element and a lower element for receiving AM / FM broadcasts. 17 or the first interior case 15a. However, when the first interior case 15a is not provided, a part of the antenna element 31 may be attached to the exterior case 11 or the passage 11d.

- the antenna cable 35 is used to supply power to an antenna amplifier included in the antenna element 31 and to output a signal obtained by the antenna element 31.

- the imaging unit 50 is arranged so that the imaging surface of the imaging element in the camera body 51 faces the rear of the vehicle 90.

- a housing for holding the circuit board and the image sensor in the camera body 51 is made of metal (for example, aluminum) that also serves as a shield conductor.

- a camera cable 55 used for supplying power and control signals to the camera main body 51 and outputting image signals obtained by the camera main body includes a first packing 56 a and a bracket 57 from the back of the camera main body 51.

- the second packing 56b, the second inner case 15b, and the second opening 17c2 extend downward in the z direction of the base 17.

- the camera cable 55 extending from the camera body 51 extends linearly in the substantially x direction perpendicular to the imaging surface of the image sensor and on the back side (substantially in the x direction front side), and on the lower side in the z direction near the upper side of the second opening 17c2. It is bent and extends downward in the z direction.

- the bracket 57 is made of metal and has a substantially cylindrical shape with an open front surface and a rear surface, and is used to adjust the mounting angle between the second interior case 15 b and the camera body 51. Specifically, the angle formed between the normal of the surface of the bracket 57 facing the camera body 51 and the base 17 is the first angle ⁇ 1 (see FIG. 10), and the angle formed is different from the first angle ⁇ 1. (Not shown) is prepared, and the bracket 57 to be used is selected in accordance with the inclination of the region where the in-vehicle rearward imaging device 1 is attached on the roof of the vehicle 90. A plurality of camera covers 11b having different shapes are prepared in accordance with the brackets 57 to be used, and the camera cover 11b corresponding to the selected bracket 57 is used.

- the housing of the camera body 51 is connected to the ground plate mounting portion 17e via a ground plate 59 made of metal for the purpose of grounding (see FIGS. 1 and 3).

- the roof of the vehicle 90 is provided with mounting holes 91 (first mounting hole 91a and second mounting hole 91b) of the in-vehicle rear photographing apparatus 1.

- the first mounting hole 91a includes a region facing the first opening 17c1

- the second mounting hole 91b includes a region facing the second opening 17c2.

- the first pre-lock 23a is fitted into the first mounting hole 91a

- the second pre-lock 23b is fitted into the second mounting hole 91b.

- two mounting holes (a first mounting hole 91a for passing the first boss 17d1 and the antenna cable 35 and a second mounting hole 91b for passing the second boss 17d2 and the camera cable 55) are provided.

- a form (refer FIG. 1) is demonstrated, the form which provides the attachment hole for letting one boss pass through may be sufficient (not shown). Further, the antenna cable 35 and the camera cable 55 may pass through one mounting hole.

- the air flowing near the side surface of the exterior case 11 is separated from the exterior case 11 near the boundary between the side surface and the back surface while the vehicle 90 is traveling, and in the vicinity of the back surface. Air is difficult to flow through.

- an optical member such as a lens

- the optical member When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member. Thereby, it becomes possible to make the optical member provided in the forefront of the camera main body 51 into a state in which water droplets or the like do not adhere.

- the air passing through the passage 11d cools the metal parts such as the casing of the camera body 51 and the second interior case 15b and the bracket 57 disposed at the lower part of the passage 11d, and suppresses the temperature rise of the camera body 51. It becomes possible.

- a passage 11d penetrating in the front-rear direction (x direction) is provided above the first interior case 15a, the second interior case 15b, and the camera body 51 in the exterior case 11, and the upper portion of the exterior case 11 And the optical member provided on the foremost surface (rear side in the x direction) of the camera body 51 by the air passing through the air guide path formed by the upper rear opening 11a2, the cover inclined surface 11b1, the front opening 11c, and the passage 11d.

- the exterior case cover 12 is formed on the rear side of the side surface of the exterior case 11 with a gap penetrating substantially in the x direction as an air guiding portion that guides air flowing near the side surface of the exterior case 11 to the rear surface during traveling. And an air guide path is formed between the outer case cover 12 and the outer case 11 (see the second embodiment, FIGS. 12 to 22).

- the exterior case cover 12 covers the side surface of the exterior case 11 and the rear side in the x direction, and is separated from the exterior case 11 except that it is connected to the exterior case 11 at several places such as an upper end portion and a lower end portion. Between the outer case cover 12 and the outer case 11, the front side in the x direction and the rear side in the x direction are opened, and air guide paths (cavities) penetrating the front and rear in the x direction are formed (front opening 12a1, rear opening 12a2). .

- An air guide wall 12b is provided at the rear end of the exterior case cover 12 in the x direction so as not to come into contact with the side surface or the back surface of the exterior case 11 and protrudes inward substantially perpendicular to the exterior case cover 12. .

- the exterior case cover 12 may be configured separately from the exterior case 11 or may be configured integrally.

- the exterior case 11 and the exterior case cover 12 are configured separately, and a protruding portion 12 c extending downward in the z direction in the exterior case cover 12 is formed in the attachment hole 110 c provided on the side surface of the exterior case 11.

- the form in which the exterior case cover 12 is attached to the exterior case 11 by being fitted is shown (see FIGS. 13 and 21).

- a part of the air discharged from the rear opening 12a2 is guided by the air guide wall 12b on the back surface (second inclined surface 112) of the outer case 11 and downward in the z direction, and is the foremost surface (back in the x direction) of the camera body 51.

- an optical member such as a lens

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

- the optical member provided in the forefront of the camera main body 51 into a state in which water droplets or the like do not adhere.

- a vortex generator (first vortex generator 11f (third embodiment)) is provided behind the side surface of the outer case 11 as an air guide unit that guides air that flows near the side surface of the outer case 11 during traveling to the back surface. 23 to 30) and a second vortex generator 11g (fourth embodiment, see FIGS. 31 to 36)) may be considered.

- dimple processing is performed on the rear side of the side surface of the outer case 11 (a plurality of substantially spherical crown-shaped recesses are provided).

- the substantially spherical crown-shaped recess has a radius of curvature r of 5 mm and a depth d of 0.35 mm, which is the deepest one arranged on the rear side.

- the rear one is shorter than the front one.

- a substantially spherical crown-shaped recess is arranged (a1 ⁇ a2 ⁇ a3 ⁇ a4 ⁇ a5, see FIG. 30). That is, due to the shape of the side surface of the exterior case 11, except for the substantially spherical crown-shaped recesses arranged in one or two rows on the rear side, the substantially spherical crown-shaped recesses are those on the rear side of the front side. Become deeper.

- the air flowing near the side surface of the outer case 11 passes through the recess of the first vortex generating portion 11 f provided on the rear side of the side surface of the outer case 11. 112) A turbulent flow is generated in the vicinity, and the air flowing on the side surface of the outer case 11 does not separate from the outer case 11 and the air easily flows near the back surface of the outer case 11. A part of the air flowing through the side surface of the outer case 11 is guided by the first vortex generator 11f on the back surface of the outer case 11 and downward in the z direction without being peeled off from the outer case 11, so It passes through the front surface of an optical member (such as a lens) provided on the rear side in the x direction.

- an optical member such as a lens

- the optical member When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member. Thereby, it becomes possible to make the optical member provided in the forefront of the camera main body 51 into a state in which water droplets or the like do not adhere.

- a plurality of substantially V-shaped fins that protrude in the y direction and extend in the x direction are provided on the rear side of the side surface of the outer case 11 as the second vortex generating portion 11g.

- the fins having a substantially V-shaped cross section are arranged in the vertical direction along the side surface of the exterior case 11, and a groove having a substantially V-shaped cross section extending in the x direction is formed between adjacent fins.

- a portion of the fin having a substantially V-shaped cross section close to the back surface (second inclined surface 112) of the outer case 11 has a height h of about 0.75 mm, and the fin is gradually lowered toward the front side in the x direction. It is desirable to be formed.

- the air flowing near the side surface of the outer case 11 passes through the fins of the second vortex generating portion 11g provided on the rear side of the side surface of the outer case 11, so that the rear surface of the outer case 11 (second slope) 112)

- a turbulent flow is generated in the vicinity, and the air flowing on the side surface of the outer case 11 does not separate from the outer case 11 and the air easily flows near the back surface of the outer case 11.

- a part of the air flowing on the side surface of the outer case 11 is guided by the second vortex generator 11g on the back surface of the outer case 11 and downward in the z direction without being separated from the outer case 11, It passes through the front surface of an optical member (such as a lens) provided on the rear side in the x direction.

- an optical member such as a lens

- the optical member When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

- the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member. Thereby, it becomes possible to make the optical member provided in the forefront of the camera main body 51 into a state in which water droplets or the like do not adhere.

- the form which combines several things may be sufficient as the air guidance part which guide

- the vortex generator (the first vortex generator 11f or the second vortex generator 11g) is used as a guide part on the back side of the side surface of the outer case 11, and the air flowing near the side surface of the outer case 11 during traveling is used.

- a form used as an air guiding portion for guiding to the back surface is conceivable.

- the air guiding portion (member) in each of the first to fourth embodiments is an air guiding path or a surface treatment that does not use a member such as a motor that requires electric power

- the antenna portion 30 is used. Water droplets attached to the optical member can be removed with a low possibility of adversely affecting the reception performance.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Multimedia (AREA)

- Signal Processing (AREA)

- Mechanical Engineering (AREA)

- Aviation & Aerospace Engineering (AREA)

- Studio Devices (AREA)

- Camera Bodies And Camera Details Or Accessories (AREA)

- Structure And Mechanism Of Cameras (AREA)

- Cameras Adapted For Combination With Other Photographic Or Optical Apparatuses (AREA)

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

Abstract

Provided is an automotive rear imaging device with which it is possible to remove water droplets adhering to an optical member. The automotive rear imaging device is provided with an imaging unit having a main camera body in which an imaging surface is facing the rear of a vehicle. The automotive rear imaging device is provided with an exterior case 11 covering the imaging unit. The exterior case 11 has, at the upper part on the rear side, a top part, and has, on the back surface, a lower back surface opening 11a for causing light to enter a lens of the main camera body 51. The profile of the exterior case 11 is formed by an inclined surface linking the top part and a lower-end-part edge having a leaf shape on at least the front side. The automotive rear imaging device is provided with a base 17 mounted on the upper surface of the vehicle, the base 17 holding the exterior case 11 with the main camera body 51 sandwiched therebetween. An air guide part (upper part of the exterior case 11, upper back surface opening 11a2, front surface opening 11c, passage 11d, and cover incline surface 11b1) for guiding air entering from the front surface opening 11c during travel to the back surface is provided to the exterior case 11.

Description

本発明は、車載後方撮影装置などに関する。

The present invention relates to an in-vehicle rear photographing apparatus and the like.

従来、特許文献1のように、車載アンテナ装置など車両のルーフに取り付けられるものに、後方を撮影する撮像装置(カメラ)が搭載されたものが提案されている。

2. Description of the Related Art Conventionally, as disclosed in Patent Document 1, an apparatus mounted on a vehicle roof such as an in-vehicle antenna apparatus is mounted with an imaging device (camera) for photographing the rear.

しかしながら、雨水などの水滴が撮像装置のレンズなどの光学部材に付着した水滴を除去する手段は講じられていない。

However, there is no means for removing water droplets such as rainwater adhering to an optical member such as a lens of the imaging device.

したがって本発明の目的は、光学部材に付着した水滴を除去することが可能な車載後方撮影装置を提供することである。

Therefore, an object of the present invention is to provide an in-vehicle rear photographing apparatus capable of removing water droplets attached to an optical member.

本発明に係る車載後方撮影装置は、撮像面が車両の後方を向いたカメラ本体を有する撮像部と、後ろ側の上部に頂上部を有し、少なくとも前側が半楕円形状若しくは木の葉形状を有する下端部周縁と頂上部とを結ぶ斜面で外形が形成され、背面に、カメラ本体のレンズに光を入射させる下部背面開口を有し、撮像部を覆う外装ケースと、車両の上面に取り付けられ、カメラ本体を間に挟んだ状態で外装ケースを保持するベースとを備え、外装ケースには、走行中に空気を背面に誘導する空気誘導部が設けられる。

An in-vehicle rear imaging apparatus according to the present invention includes an imaging unit having a camera body with an imaging surface facing the rear of the vehicle, and a lower end having an apex at an upper part on the rear side and at least a front side having a semi-elliptical shape or a leaf shape. An outer shape is formed by a slope connecting the periphery of the part and the top part, and a lower back opening for allowing light to enter the lens of the camera body is provided on the back side. And a base that holds the outer case with the main body sandwiched therebetween, and the outer case is provided with an air guiding portion that guides air to the back surface during traveling.

車両の走行中、空気誘導部によって、車載後方撮影装置の近くを流れる空気の一部は、外装ケースの背面に誘導され、カメラ本体の最前面に設けられた光学部材(レンズなど)の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, a part of the air flowing near the in-vehicle rear imaging device is guided to the back of the exterior case by the air guiding unit, and the front of the optical member (lens etc.) provided on the forefront of the camera body Pass through.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, a part of the air flowing near the in-vehicle rear imaging device is guided to the back of the exterior case by the air guiding unit, and the front of the optical member (lens etc.) provided on the forefront of the camera body Pass through.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

好ましくは、外装ケースには、空気誘導部として、外装ケースにおける背面の下部背面開口よりも高い位置に設けられた上部背面開口と外装ケースにおける開口とを貫通する通路が設けられる。

Preferably, the exterior case is provided with a passage penetrating the upper back opening provided at a position higher than the lower back opening on the back of the exterior case and the opening in the exterior case as an air guiding portion.

さらに好ましくは、通路と上部背面開口の間、若しくは、通路における上部背面開口がある側の端部には、前側が後ろ側よりも高くなる傾斜面が設けられる。

More preferably, an inclined surface whose front side is higher than the rear side is provided between the passage and the upper rear opening or at the end of the passage where the upper rear opening is located.

車両の走行中、前面開口には、前側から空気が侵入し、外装ケースの上部と上部背面開口と前面開口と通路などで形成された空気誘導路を通って、上部背面開口から排出される。

上部背面開口から排出される空気の一部は、外装ケースの傾斜面によって外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。

また、通路を通る空気が、通路の下部に配置されたカメラ本体を冷却し、カメラ本体の温度上昇を抑えることが可能になる。 During traveling of the vehicle, air enters the front opening from the front side, and is discharged from the upper rear opening through an air guide path formed by the upper part of the exterior case, the upper rear opening, the front opening, and the passage.

A part of the air discharged from the upper back opening is guided downward on the back surface of the exterior case by the inclined surface of the exterior case, and passes through the front surface of the optical member provided on the forefront of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

In addition, the air passing through the passage cools the camera body disposed at the lower part of the passage, and the temperature rise of the camera body can be suppressed.

上部背面開口から排出される空気の一部は、外装ケースの傾斜面によって外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。

また、通路を通る空気が、通路の下部に配置されたカメラ本体を冷却し、カメラ本体の温度上昇を抑えることが可能になる。 During traveling of the vehicle, air enters the front opening from the front side, and is discharged from the upper rear opening through an air guide path formed by the upper part of the exterior case, the upper rear opening, the front opening, and the passage.

A part of the air discharged from the upper back opening is guided downward on the back surface of the exterior case by the inclined surface of the exterior case, and passes through the front surface of the optical member provided on the forefront of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

In addition, the air passing through the passage cools the camera body disposed at the lower part of the passage, and the temperature rise of the camera body can be suppressed.

また、好ましくは、アンテナ素子を有するアンテナ部と、アンテナ素子を覆う合成樹脂製の第1内装ケースと、金属製の第2内装ケースとを更に備え、カメラ本体における、撮像素子を保持する筐体は、金属で構成され、第2内装ケースには、金属製のブラケットを介して、カメラ本体が取り付けられ、第1内装ケースと第2内装ケースは、ベースの上であって、通路の下に配置される。

Preferably, the camera unit further includes an antenna unit having an antenna element, a first interior case made of synthetic resin that covers the antenna element, and a second interior case made of metal, and a housing that holds the image sensor in the camera body Is made of metal, and the camera body is attached to the second interior case via a metal bracket. The first interior case and the second interior case are above the base and below the passage. Be placed.

通路を通る空気が、通路の下部に配置されたカメラ本体の筐体や第2内装ケース及びブラケットなどの金属製の部品を冷却し、カメラ本体の温度上昇を抑えることが可能になる。

The air passing through the passage cools the metal parts such as the housing of the camera body, the second interior case, and the bracket disposed at the lower part of the passage, thereby suppressing the temperature rise of the camera body.

さらに好ましくは、外装ケースにおける側面の後ろ側に、空気誘導部として、ディンプル加工が施される、若しくは、左右方向に突出し前後方向に延びるフィンが複数形成される。

More preferably, on the rear side of the side surface of the outer case, dimple processing is performed as an air guiding portion, or a plurality of fins protruding in the left-right direction and extending in the front-back direction are formed.

さらに好ましくは、空気誘導部として外装ケースにおける側面の後ろ側に施されるディンプル加工の凹みは、0.35mmの深さを有する。

More preferably, the dimple-processed dent provided on the rear side of the side surface of the exterior case as the air guiding portion has a depth of 0.35 mm.

さらに好ましくは、ディンプル加工の凹みにおける最も深い点と、カメラ本体のレンズの光軸を含む鉛直面との距離について、前側のものよりも、後ろ側のものの方が短くなるように、凹みが形成される。

More preferably, the recess is formed so that the distance between the deepest point in the dimple processing recess and the vertical plane including the optical axis of the lens of the camera body is shorter on the rear side than on the front side. Is done.

また、好ましくは、空気誘導部として外装ケースにおける側面の後ろ側に形成される複数のフィンは、0.75mmの高さを有する。

Also preferably, the plurality of fins formed on the back side of the side surface of the exterior case as the air guiding portion has a height of 0.75 mm.

また、好ましくは、外装ケースにおける側面の後ろ側には、空気誘導部として、前後方向に貫通する隙間を形成した状態で外装ケースカバーが設けられる。

Preferably, an exterior case cover is provided on the rear side of the side surface of the exterior case as an air guiding portion with a gap penetrating in the front-rear direction.

さらに好ましくは、外装ケースカバーの後ろ側には、外装ケースの側面や背面と接触せず、且つ内側に向かって突出する空気誘導壁が設けられる。

More preferably, an air guide wall is provided on the rear side of the outer case cover so as not to come into contact with the side surface or the back surface of the outer case and project inward.

車両の走行中、前側から空気が侵入し、外装ケースと外装ケースカバーとで形成された空気誘導路を通って、排出される。

排出される空気の一部は、空気誘導壁によって外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, air enters from the front side and is discharged through an air guide path formed by the outer case and the outer case cover.

Part of the discharged air is guided downward on the back surface of the exterior case by the air guide wall and passes through the front surface of the optical member provided on the forefront surface of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

排出される空気の一部は、空気誘導壁によって外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, air enters from the front side and is discharged through an air guide path formed by the outer case and the outer case cover.

Part of the discharged air is guided downward on the back surface of the exterior case by the air guide wall and passes through the front surface of the optical member provided on the forefront surface of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

また、好ましくは、外装ケースにおける側面の後ろ側に、空気誘導部として、ディンプル加工が施される、若しくは、左右方向に突出し前後方向に延びるフィンが複数形成される。

Preferably, dimple processing is performed as an air guiding portion on the rear side of the side surface of the outer case, or a plurality of fins protruding in the left-right direction and extending in the front-rear direction are formed.

車両の走行中、外装ケースの側面近くを流れる空気が、外装ケースにおける側面の後ろ側に設けられたディンプル加工が施された領域若しくはフィンが形成された領域を通ることで、外装ケースの背面近傍には、乱流が発生せしめられ、外装ケースの側面を流れる空気が外装ケースから剥離せずに外装ケースの背面近傍にも空気が流れやすくなる。

外装ケースの側面を流れた空気の一部は、外装ケースから剥離せずに外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, the air flowing near the side of the exterior case passes through the dimple-processed area or fin-formed area on the back side of the exterior case, so that the vicinity of the exterior of the exterior case In this case, a turbulent flow is generated, and the air flowing on the side surface of the outer case does not peel from the outer case, and the air easily flows near the back surface of the outer case.

Part of the air that has flowed through the side surface of the outer case is guided to the lower side of the outer case without being separated from the outer case and passes through the front surface of the optical member provided on the forefront of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

外装ケースの側面を流れた空気の一部は、外装ケースから剥離せずに外装ケースの背面上で且つ下方に誘導され、カメラ本体の最前面に設けられた光学部材の前面を通る。

当該光学部材に水滴や埃が付着していた場合には、当該水滴などが空気でレンズの周囲に移動せしめられ若しくは飛ばされ、当該光学部材から当該水滴などが除去される。

また、光学部材の前面を通る空気がエアーカーテンとして機能し、雨水などの水滴が当該光学部材の前面に付着しにくい状態となる。

これにより、カメラ本体の最前面に設けられた光学部材について、水滴などが付着しない状態にすることが可能になる。 While the vehicle is running, the air flowing near the side of the exterior case passes through the dimple-processed area or fin-formed area on the back side of the exterior case, so that the vicinity of the exterior of the exterior case In this case, a turbulent flow is generated, and the air flowing on the side surface of the outer case does not peel from the outer case, and the air easily flows near the back surface of the outer case.

Part of the air that has flowed through the side surface of the outer case is guided to the lower side of the outer case without being separated from the outer case and passes through the front surface of the optical member provided on the forefront of the camera body.

When water droplets or dust adheres to the optical member, the water droplets or the like are moved or blown around the lens by air, and the water droplets or the like are removed from the optical member.

In addition, the air passing through the front surface of the optical member functions as an air curtain, and water drops such as rainwater are unlikely to adhere to the front surface of the optical member.

Thereby, it becomes possible to make the optical member provided in the forefront of the camera body not to have water droplets attached thereto.

以上のように本発明によれば、光学部材に付着した水滴を除去することが可能な車載後方撮影装置を提供することができる。

As described above, according to the present invention, it is possible to provide an in-vehicle rear photographing device capable of removing water droplets attached to an optical member.

以下、第1実施形態について、図を用いて説明する。第1実施形態における車載後方撮影装置1は、ルーフなど車両90の上面に取り付けられ、ケース10、アンテナ部30、撮像部50を備える(図1~図11参照)。

Hereinafter, the first embodiment will be described with reference to the drawings. The in-vehicle rear imaging device 1 in the first embodiment is attached to the upper surface of a vehicle 90 such as a roof, and includes a case 10, an antenna unit 30, and an imaging unit 50 (see FIGS. 1 to 11).

方向を説明するために、車載後方撮影装置1が取り付けられる車両90の前後方向をx方向、x方向と垂直な左右方向をy方向、x方向とy方向に垂直な略鉛直方向をz方向として説明する。

また、各部の構成を明確に示すことを優先し、同じ部材でも図面間で異なるハッチングパターンが施されることがある。 In order to describe the direction, the front-rear direction of thevehicle 90 to which the in-vehicle rearward imaging device 1 is attached is the x direction, the left-right direction perpendicular to the x direction is the y direction, and the substantially vertical direction perpendicular to the x direction and the y direction is the z direction. explain.

In addition, priority is given to clearly showing the configuration of each part, and different hatching patterns may be applied to the same member even between the drawings.

また、各部の構成を明確に示すことを優先し、同じ部材でも図面間で異なるハッチングパターンが施されることがある。 In order to describe the direction, the front-rear direction of the

In addition, priority is given to clearly showing the configuration of each part, and different hatching patterns may be applied to the same member even between the drawings.

ケース10は、アンテナ素子31やカメラ本体51など車載後方撮影装置1を構成する部材を覆う部材で、外装ケース11、外装パッド13、内装ケース15(第1内装ケース15a、第2内装ケース15b)、ベース17、内装パッド19、シール部材21(第1シール部材21a、第2シール部材21b)、プリロック23(第1プリロック23a、第2プリロック23b)を有する。

アンテナ部30は、アンテナ素子31、アンテナケーブル35を有する。

撮像部50は、CMOSなどの撮像素子を含むカメラ本体51、カメラケーブル55、第1パッキン56a、第2パッキン56b、ブラケット57、アースプレート59を有する。 Thecase 10 is a member that covers members constituting the in-vehicle rear photographing apparatus 1 such as the antenna element 31 and the camera body 51, and includes an outer case 11, an outer pad 13, and an inner case 15 (first inner case 15a and second inner case 15b). , Base 17, interior pad 19, seal member 21 (first seal member 21a, second seal member 21b), and pre-lock 23 (first pre-lock 23a, second pre-lock 23b).

Theantenna unit 30 includes an antenna element 31 and an antenna cable 35.

Theimaging unit 50 includes a camera body 51 including an imaging element such as a CMOS, a camera cable 55, a first packing 56a, a second packing 56b, a bracket 57, and a ground plate 59.

アンテナ部30は、アンテナ素子31、アンテナケーブル35を有する。

撮像部50は、CMOSなどの撮像素子を含むカメラ本体51、カメラケーブル55、第1パッキン56a、第2パッキン56b、ブラケット57、アースプレート59を有する。 The

The

The

外装ケース11は、非透光性と電波透過性を有する合成樹脂製(ポリカーボネート(Polycarbonate)とASA(Acrylate Styrene Acrylonitrile)を含む合成樹脂などで形成された樹脂成型品)である。

The outer case 11 is made of a synthetic resin having a non-light-transmitting property and a radio-transmitting property (a resin molded product formed of a synthetic resin including Polycarbonate and ASA (Acrylate Styrene Acrylonitrile)).

外装ケース11は、下面が開口し、車載後方撮影装置1を構成する部材であって、外装ケース11以外のもの(外装パッド13、内装ケース15、ベース17、内装パッド19、アンテナ素子31、アンテナケーブル35の一部、カメラ本体51、カメラケーブル55の一部など)を、z方向上方から覆う(図1、図10参照)。

ただし、カメラ本体51のレンズの一部が、外装ケース11の背面からx方向後ろ側に突出する形態であってもよい。 Theexterior case 11 is a member having an open bottom surface and constituting the in-vehicle rear photographing apparatus 1 and other than the exterior case 11 (the exterior pad 13, the interior case 15, the base 17, the interior pad 19, the antenna element 31, the antenna A part of the cable 35, a part of the camera body 51, a part of the camera cable 55, etc.) are covered from above in the z direction (see FIGS. 1 and 10).

However, a part of the lens of thecamera body 51 may protrude from the back surface of the outer case 11 to the rear side in the x direction.

ただし、カメラ本体51のレンズの一部が、外装ケース11の背面からx方向後ろ側に突出する形態であってもよい。 The

However, a part of the lens of the

外装ケース11は、x方向後ろ側の上部に頂上部110aを有し、リング形状で少なくともx方向前側が略半楕円形状若しくは略木の葉形状を有する下端周縁部110bと頂上部110aとを結ぶ斜面で外形が形成される。

下端周縁部110bのうちx方向前側の部分と頂上部110aとを結ぶ第1斜面111は、下端周縁部110bのうちx方向後ろ側の部分と頂上部110aとを結ぶ第2斜面112よりも緩やかな傾斜を有する。以上に説明した外装ケース11の形状は、例えば、所謂シャークフィン形状と言われている。 Theouter case 11 has a top portion 110a at the upper portion on the rear side in the x direction, and is a slope connecting the lower end peripheral portion 110b and the top portion 110a having a ring shape and at least the front side in the x direction having a substantially semi-elliptical shape or a substantially leaf shape. An outline is formed.

Thefirst slope 111 connecting the x-direction front portion of the lower peripheral edge 110b and the top 110a is more gradual than the second slope 112 connecting the x-direction rear portion of the lower peripheral 110b and the top 110a. It has a gentle slope. The shape of the exterior case 11 described above is said to be a so-called shark fin shape, for example.

下端周縁部110bのうちx方向前側の部分と頂上部110aとを結ぶ第1斜面111は、下端周縁部110bのうちx方向後ろ側の部分と頂上部110aとを結ぶ第2斜面112よりも緩やかな傾斜を有する。以上に説明した外装ケース11の形状は、例えば、所謂シャークフィン形状と言われている。 The

The

外装ケース11の背面(第2斜面112)には、車両90の後方を撮影するために設けられた撮像部50のカメラ本体51のレンズに当該後方からの光を入射させる開口(下部背面開口11a1)が設けられ、下部背面開口11a1におけるレンズ以外の部分は、カメラカバー11bで覆われる。

On the back surface (second inclined surface 112) of the exterior case 11, an opening (lower back surface opening 11a1) for allowing light from the rear to enter the lens of the camera body 51 of the imaging unit 50 provided for photographing the back of the vehicle 90. ) And a portion other than the lens in the lower back opening 11a1 is covered with a camera cover 11b.

カメラカバー11bは、カメラ本体51のレンズの周辺を覆う。

カメラカバー11bにおけるカメラ本体51のレンズの上部は、x方向前側がx方向後ろ側よりも高くなる傾斜面(カバー傾斜面11b1)を有する。 Thecamera cover 11 b covers the periphery of the lens of the camera body 51.

The upper part of the lens of thecamera body 51 in the camera cover 11b has an inclined surface (cover inclined surface 11b1) in which the front side in the x direction is higher than the rear side in the x direction.

カメラカバー11bにおけるカメラ本体51のレンズの上部は、x方向前側がx方向後ろ側よりも高くなる傾斜面(カバー傾斜面11b1)を有する。 The

The upper part of the lens of the

外装ケース11の背面(第2斜面112)であって、下部背面開口11a1の上部には、開口(上部背面開口11a2)が設けられる。

外装ケース11の前面には、開口(前面開口11c)が設けられる。

なお、第1実施形態では、外装ケース11の背面に設けられた一つの開口の上部が上部背面開口11a2を構成し、下部が下部背面開口11a1を構成する形態を説明するが、2つの開口が設けられる形態であってもよい。 An opening (upper back opening 11a2) is provided on the back surface (second slope 112) of theouter case 11 and above the lower back opening 11a1.

An opening (front opening 11 c) is provided on the front surface of the outer case 11.

In addition, although 1st Embodiment demonstrates the form in which the upper part of one opening provided in the back surface of theexterior case 11 comprises the upper back surface opening 11a2, and the lower part comprises the lower back surface opening 11a1, two openings are demonstrated. The form provided may be sufficient.

外装ケース11の前面には、開口(前面開口11c)が設けられる。

なお、第1実施形態では、外装ケース11の背面に設けられた一つの開口の上部が上部背面開口11a2を構成し、下部が下部背面開口11a1を構成する形態を説明するが、2つの開口が設けられる形態であってもよい。 An opening (upper back opening 11a2) is provided on the back surface (second slope 112) of the

An opening (

In addition, although 1st Embodiment demonstrates the form in which the upper part of one opening provided in the back surface of the

外装ケース11の内部には、上部背面開口11a2と前面開口11cとを接続する通路11dが設けられる。

通路11dは、底面部11d1と側面部11d2を有し、外装ケース11の内壁上部に沿う略溝形形状(若しくは略筒型形状)を有する(図2参照)。

底面部11d1のx方向前側は前面開口11cの下端と接し、底面部11d1のx方向後ろ側はカメラカバー11bのカバー傾斜面11b1と接する。

底面部11d1は、後述する第1内装ケース15aと第2内装ケース15bよりもz方向上側に位置する。

側面部11d2は、底面部11d1のy方向両端からz方向上方に向かって延びる。

側面部11d2のx方向前側は前面開口11cと接し、側面部11d2のx方向後ろ側は上部背面開口11a2と接し、側面部11d2の上端部は外装ケース11の内壁上部と接する。 Inside theexterior case 11, a passage 11d that connects the upper back opening 11a2 and the front opening 11c is provided.

Thepassage 11d has a bottom surface portion 11d1 and a side surface portion 11d2, and has a substantially groove shape (or a substantially cylindrical shape) along the upper portion of the inner wall of the exterior case 11 (see FIG. 2).

The x direction front side of the bottom surface part 11d1 is in contact with the lower end of thefront opening 11c, and the x direction rear side of the bottom surface part 11d1 is in contact with the cover inclined surface 11b1 of the camera cover 11b.

The bottom surface portion 11d1 is located on the upper side in the z direction with respect to a firstinner case 15a and a second inner case 15b described later.

The side surface portion 11d2 extends upward in the z direction from both ends of the bottom surface portion 11d1 in the y direction.

The front side of the side part 11d2 in the x direction is in contact with thefront opening 11c, the rear side in the x direction of the side part 11d2 is in contact with the upper back opening 11a2, and the upper end of the side part 11d2 is in contact with the upper part of the inner wall of the exterior case 11.

通路11dは、底面部11d1と側面部11d2を有し、外装ケース11の内壁上部に沿う略溝形形状(若しくは略筒型形状)を有する(図2参照)。

底面部11d1のx方向前側は前面開口11cの下端と接し、底面部11d1のx方向後ろ側はカメラカバー11bのカバー傾斜面11b1と接する。

底面部11d1は、後述する第1内装ケース15aと第2内装ケース15bよりもz方向上側に位置する。

側面部11d2は、底面部11d1のy方向両端からz方向上方に向かって延びる。

側面部11d2のx方向前側は前面開口11cと接し、側面部11d2のx方向後ろ側は上部背面開口11a2と接し、側面部11d2の上端部は外装ケース11の内壁上部と接する。 Inside the

The

The x direction front side of the bottom surface part 11d1 is in contact with the lower end of the

The bottom surface portion 11d1 is located on the upper side in the z direction with respect to a first

The side surface portion 11d2 extends upward in the z direction from both ends of the bottom surface portion 11d1 in the y direction.

The front side of the side part 11d2 in the x direction is in contact with the

通路11dが略溝形状を有する場合には、外装ケース11における背面(第2斜面112)であって上部背面開口11a2よりも上部の内壁は、x方向前側がx方向後ろ側よりも高くなる内壁傾斜面11a3を有する(図10参照)。

通路11dが略筒型形状を有する場合には、通路11dにおける上部背面開口11a2側の端部の上面は、x方向前側がx方向後ろ側よりも高くなる傾斜面(不図示)を有する。 When thepassage 11d has a substantially groove shape, the inner wall on the back surface (second inclined surface 112) of the exterior case 11 and above the upper back surface opening 11a2 is such that the front side in the x direction is higher than the rear side in the x direction. It has the inclined surface 11a3 (refer FIG. 10).

When thepassage 11d has a substantially cylindrical shape, the upper surface of the end portion on the upper back opening 11a2 side of the passage 11d has an inclined surface (not shown) in which the front side in the x direction is higher than the rear side in the x direction.

通路11dが略筒型形状を有する場合には、通路11dにおける上部背面開口11a2側の端部の上面は、x方向前側がx方向後ろ側よりも高くなる傾斜面(不図示)を有する。 When the

When the

通路11dと上部背面開口11a2の間(若しくは、通路11dにおける上部背面開口11a2がある側の端部)には、x方向前側がx方向後ろ側よりも高くなる傾斜面(内壁傾斜面11a3、カバー傾斜面11b1)が設けられる。

Between the passage 11d and the upper back opening 11a2 (or the end of the passage 11d on the side where the upper back opening 11a2 is located), an inclined surface (an inner wall inclined surface 11a3, a cover) whose front side in the x direction is higher than the rear side in the x direction. An inclined surface 11b1) is provided.

外装ケース11の上部と、上部背面開口11a2と、カバー傾斜面11b1と、前面開口11cと、通路11dとが、外装ケース11の内部をx方向に貫通する空気誘導路(空洞)を形成し、走行中に前面開口11cから入った空気を背面に誘導する空気誘導部として機能する。

The upper part of the outer case 11, the upper back opening 11a2, the cover inclined surface 11b1, the front opening 11c, and the passage 11d form an air guide path (cavity) that penetrates the inside of the outer case 11 in the x direction, It functions as an air guiding unit that guides air that has entered through the front opening 11c to the back during traveling.

内装ケース15、ベース17、内装パッド19、アンテナ素子31、アンテナケーブル35の一部、カメラ本体51、カメラケーブル55の一部などは、外装ケース11の内壁と通路11dによって、上部が密閉された状態で覆われる。

The upper part of the interior case 15, the base 17, the interior pad 19, the antenna element 31, a part of the antenna cable 35, the camera body 51, a part of the camera cable 55, and the like is hermetically sealed by the inner wall of the exterior case 11 and the passage 11d. Covered with condition.

カメラカバー11bにおけるカメラ本体51のレンズを覆う領域には、防水などの目的で、透光性と電波透過性を有する合成樹脂で形成された窓部(不図示)が取り付けられる形態であってもよい。第1実施形態では、カメラ本体51が背面開口11aに取り付けられたカメラカバー11bと接触するように第2内装ケース15bに取り付けられている。カメラカバー11bとカメラ本体51の間を介して浸入した水は、外装パッド13に設けられた排水切欠き13aを介して排出されるので、当該窓部が設けられない形態であってもよい。以下、窓部がカメラカバー11bにおけるカメラ本体51のレンズを覆う領域に取り付けられない形態で説明する。

Even if a window part (not shown) formed of a synthetic resin having translucency and radio wave permeability is attached to the area of the camera cover 11b covering the lens of the camera body 51 for the purpose of waterproofing or the like. Good. In 1st Embodiment, the camera main body 51 is attached to the 2nd interior case 15b so that the camera cover 11b attached to the back surface opening 11a may be contacted. Since the water that has entered through the space between the camera cover 11b and the camera body 51 is discharged through the drainage notch 13a provided in the exterior pad 13, the window portion may not be provided. Hereinafter, a description will be given in a form in which the window portion is not attached to a region covering the lens of the camera body 51 in the camera cover 11b.

窓部がカメラカバー11bにおけるカメラ本体51のレンズを覆う領域に取り付けられない場合は、カメラ本体51のレンズであって、最前面(x方向後ろ側)に設けられたものが、後述するカメラ本体51の最前面(x方向後ろ側)に設けられた光学部材として機能する。

窓部がカメラカバー11bにおけるカメラ本体51のレンズを覆う領域に取り付けられた場合は、当該窓部が、後述するカメラ本体51の最前面(x方向後ろ側)に設けられた光学部材として機能する。 When the window is not attached to the area of thecamera cover 11b that covers the lens of the camera body 51, the lens of the camera body 51 that is provided on the forefront (the rear side in the x direction) is the camera body that will be described later. It functions as an optical member provided on the forefront of 51 (the rear side in the x direction).

When the window portion is attached to a region of thecamera cover 11b that covers the lens of the camera body 51, the window portion functions as an optical member provided on the foremost surface (the rear side in the x direction) of the camera body 51 described later. .

窓部がカメラカバー11bにおけるカメラ本体51のレンズを覆う領域に取り付けられた場合は、当該窓部が、後述するカメラ本体51の最前面(x方向後ろ側)に設けられた光学部材として機能する。 When the window is not attached to the area of the

When the window portion is attached to a region of the

外装ケース11には、内壁からz方向下方に突出するように、ベース17への取り付け用の第1係止爪11eが設けられ、ベース17を外装ケース11に固定する際に、第1係止爪11eは、ベース17に設けられた第2係止爪17aと係合する(図10参照)。

The outer case 11 is provided with a first locking claw 11e for attachment to the base 17 so as to protrude downward in the z direction from the inner wall. When the base 17 is fixed to the outer case 11, the first locking claw 11e is provided. The claw 11e engages with a second locking claw 17a provided on the base 17 (see FIG. 10).

外装パッド13は、エラストマー(Elastomer)やゴムなどで形成された環状の弾性部材であり、外装ケース11の下端周縁部110bに嵌入され、外装ケース11の下端周縁部110bと車両90との間の隙間を目隠しすると共に外装ケース11内への水の浸入を防止する。