WO2017170516A1 - Flexible polarizing film, manufacturing method for same and image display device - Google Patents

Flexible polarizing film, manufacturing method for same and image display device Download PDFInfo

- Publication number

- WO2017170516A1 WO2017170516A1 PCT/JP2017/012588 JP2017012588W WO2017170516A1 WO 2017170516 A1 WO2017170516 A1 WO 2017170516A1 JP 2017012588 W JP2017012588 W JP 2017012588W WO 2017170516 A1 WO2017170516 A1 WO 2017170516A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- polyvinyl alcohol

- polarizing film

- meth

- resin

- flexible polarizing

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

- G02B5/3025—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state

- G02B5/3033—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid

- G02B5/3041—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid comprising multiple thin layers, e.g. multilayer stacks

- G02B5/305—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid comprising multiple thin layers, e.g. multilayer stacks including organic materials, e.g. polymeric layers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/042—Coating with two or more layers, where at least one layer of a composition contains a polymer binder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/02—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/306—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl acetate or vinyl alcohol (co)polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L29/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an alcohol, ether, aldehydo, ketonic, acetal or ketal radical; Compositions of hydrolysed polymers of esters of unsaturated alcohols with saturated carboxylic acids; Compositions of derivatives of such polymers

- C08L29/02—Homopolymers or copolymers of unsaturated alcohols

- C08L29/04—Polyvinyl alcohol; Partially hydrolysed homopolymers or copolymers of esters of unsaturated alcohols with saturated carboxylic acids

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

- G09F9/30—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements

- G09F9/301—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements flexible foldable or roll-able electronic displays, e.g. thin LCD, OLED

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/02—Details

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/12—Light sources with substantially two-dimensional radiating surfaces

- H05B33/14—Light sources with substantially two-dimensional radiating surfaces characterised by the chemical or physical composition or the arrangement of the electroluminescent material, or by the simultaneous addition of the electroluminescent material in or onto the light source

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2329/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an alcohol, ether, aldehydo, ketonic, acetal, or ketal radical; Hydrolysed polymers of esters of unsaturated alcohols with saturated carboxylic acids; Derivatives of such polymer

- C08J2329/02—Homopolymers or copolymers of unsaturated alcohols

- C08J2329/04—Polyvinyl alcohol; Partially hydrolysed homopolymers or copolymers of esters of unsaturated alcohols with saturated carboxylic acids

Definitions

- the present invention relates to a flexible polarizing film and a manufacturing method thereof.

- the flexible polarizing film can form an image display device such as a liquid crystal display device (LCD) or an organic EL display device alone or as an optical film obtained by laminating the flexible polarizing film.

- LCD liquid crystal display device

- organic EL display device alone or as an optical film obtained by laminating the flexible polarizing film.

- a polarizer In a liquid crystal display device, it is indispensable to dispose a polarizer on both sides of a glass substrate that forms the surface of a liquid crystal panel because of its image forming method.

- the polarizer generally used is a polyvinyl alcohol polarizer in which a polyvinyl alcohol resin is oriented in one direction and iodine or a dichroic dye is adsorbed and oriented on the polyvinyl alcohol resin.

- polyvinyl alcohol polarizers have the problem that they are brittle and easy to tear.

- a polyvinyl alcohol-based polarizer is easy to tear parallel to the direction in which the polyvinyl alcohol-based resin is oriented (absorption axis direction). For example, when an external force that contracts in the absorption axis direction is applied, it is easily broken. .

- the polyvinyl alcohol polarizer is used as a polarizing film in which a transparent protective film is bonded to one or both sides.

- a general polarizing film using a polyvinyl alcohol-based polarizer has rigidity (rigidity) because a transparent protective film is bonded, and lacks flexibility (flexibility). Therefore, when twisting is applied to the polarizing film, the entire film may be cracked, broken marks (folded marks) may remain, or light leakage may occur in the polarizer. It was constrained.

- the grid polarizer has flexibility but lacks versatility.

- An object of the present invention is to provide a flexible polarizing film having a high degree of flexibility despite the use of a polyvinyl alcohol polarizer and a method for producing the same.

- Another object of the present invention is to provide an image display device having the flexible polarizing film.

- the present invention comprises a polyvinyl alcohol polarizer having a thickness of 10 ⁇ m or less, wherein the polyvinyl alcohol resin is oriented in one direction and iodine or a dichroic dye is adsorbed and oriented on the polyvinyl alcohol resin, and

- the present invention relates to a flexible polarizing film characterized by being free from cracks, folds, and light leakage after being subjected to a twist test in which the polyvinyl alcohol resin is twisted in the direction in which the polyvinyl alcohol resin is oriented.

- the flexible polarizing film after performing a U-shaped expansion / contraction test that repeatedly expands and contracts in a U-shape in an alignment direction in which the polyvinyl alcohol-based resin is aligned and in a direction orthogonal to the alignment direction, cracks occur in any direction. It is preferable that there are no folds and no light leakage.

- the bent shape is maintained in any direction. In addition, it is preferable that no cracks occur.

- the bending resistance (mm) is preferably 60 mm or less in the bending test in the alignment direction in which the polyvinyl alcohol-based resin is aligned and in the direction orthogonal to the alignment direction.

- the tensile strength in the direction orthogonal to the orientation direction in which the polyvinyl alcohol resin is oriented in a tensile test is 5 N / 10 mm or more.

- the polyvinyl alcohol polarizer has an optical property represented by the following formula: P> ⁇ (10 0.929T-42.4 ⁇ 1) ⁇ 100 However, T ⁇ 42.3) or It is preferable that the lens is configured to satisfy the condition of P ⁇ 99.9 (however, T ⁇ 42.3).

- the flexible polarizing film preferably has a reinforcing film in close contact with the polyvinyl alcohol polarizer on at least one surface of the polyvinyl alcohol polarizer.

- the thickness of the reinforcing film is preferably 15 ⁇ m or less.

- the flexible polarizing film preferably has a first reinforcing film having a thickness of 15 ⁇ m or less on the first side of the polyvinyl alcohol-based polarizer and a second reinforcing film having a thickness of 15 ⁇ m or less on the other second side. .

- the thickness difference between the first reinforcing film and the second reinforcing film is preferably 10 ⁇ m or less.

- the ratio of the thickness of the reinforcing film to the thickness of the polyvinyl alcohol polarizer is preferably 0.4 or more.

- the reinforcing film preferably has a compressive elastic modulus at 23 ° C. of 1 MPa or more.

- the reinforcing film that is not substantially oriented can be used.

- a resin film can be used as the reinforcing film.

- the resin film is preferably a thermosetting resin or an active energy ray curable resin.

- the present invention is a method for producing the flexible polarizing film, A step (1) of preparing a polyvinyl alcohol polarizer having a thickness of 10 ⁇ m or less, wherein the polyvinyl alcohol resin is oriented in one direction and iodine or a dichroic dye is adsorbed and oriented on the polyvinyl alcohol resin; By applying a liquid material containing a curable component capable of constituting a resin component or a resin film on at least one surface of the polyvinyl alcohol polarizer, and then solidifying or curing the liquid material, a reinforcing film

- the manufacturing method of the flexible polarizing film characterized by including the process (2) of forming.

- the present invention also relates to an image display device having the flexible polarizing film.

- the flexible polarizing film of the present invention uses a polyvinyl alcohol polarizer and can satisfy general versatility. Moreover, the polyvinyl alcohol-type polarizer is 10 micrometers or less in thickness, and is suitable also at the point currently made thin.

- the flexible polarizing film of the present invention has a high degree of flexibility despite the fact that it uses a polyvinyl alcohol polarizer that is brittle and easy to tear, and has deformed its shape by twisting. Even in this case, there is no occurrence of cracks in the entire film, no broken marks (fold marks), and no light leakage from the polarizer.

- the flexible polarizing film of the present invention can have flexibility against various deformations such as expansion and contraction. As described above, the flexible polarizing film of the present invention itself has flexibility, and a normal polyvinyl alcohol-based polarizer alone has a remarkably small tensile breaking stress, so that it is substantially impossible to handle. On the other hand, it is thin and easy to handle.

- the flexible polarizing film of the present invention has flexibility even when used in combination with other members or by using the flexibility, and can suppress cracks in the polarizer. Yes, it can be used for various purposes. For this reason, the use of the flexible polarizing film is greatly expanded by expanding the application of the flexible polarizing film alone or expanding the tolerance in the process. Therefore, the flexible polarizing film of the present invention can be used as an alternative to a polarizer, for example, a design that could not be applied due to the brittleness and tearing of conventional polarizers, and a polarizing film (transparent protection to the polarizer). As an alternative to the one provided with a film), for example, it is possible to deal with various deformed shapes that could not be applied due to the rigidity of the conventional polarizing film, and the application development can be expanded.

- the flexible polarizing film of the present invention has a polyvinyl alcohol polarizer.

- the polyvinyl alcohol-based polarizer is obtained by aligning a polyvinyl alcohol-based resin in one direction (absorption axis direction) and adsorbing or aligning iodine or a dichroic dye on the polyvinyl alcohol-based resin.

- the polyvinyl alcohol-based resin include polyvinyl alcohol, partially formalized polyvinyl alcohol, ethylene / vinyl acetate copolymer partially saponified products, and the like.

- a polarizer can be obtained by adsorbing a dichroic dye such as iodine or a dichroic dye to a polyvinyl alcohol film using the polyvinyl alcohol resin and stretching the film uniaxially.

- a polarizer obtained by dying a polyvinyl alcohol film with iodine or a dichroic dye and uniaxially stretching it is prepared, for example, by immersing polyvinyl alcohol in an aqueous solution of iodine and stretching it 3 to 7 times the original length. can do. If necessary, it may contain boric acid, zinc sulfate, zinc chloride, or the like, or may be immersed in an aqueous solution such as potassium iodide. Further, if necessary, the polyvinyl alcohol film may be immersed in water and washed before dyeing.

- Stretching may be performed after dyeing with iodine or a dichroic dye, may be performed while dyeing, or may be dyed with iodine or a dichroic dye after stretching.

- the film can be stretched even in an aqueous solution such as boric acid or potassium iodide or in a water bath.

- the polyvinyl alcohol polarizer preferably contains boric acid from the viewpoint of stretching stability and optical durability.

- the boric acid content contained in the polarizer is preferably 25% by weight or less, more preferably 20% by weight or less, based on the total amount of the polarizer, from the viewpoint of suppressing the occurrence of light leakage. Further, it is preferably 18% by weight or less, more preferably 16% by weight or less.

- the boric acid content with respect to the total amount of the polarizer is preferably 10% by weight or more, and more preferably 12% by weight or more.

- a polyvinyl alcohol polarizer having a thickness of 10 ⁇ m or less is used.

- the thickness of the polarizer is preferably 8 ⁇ m or less, more preferably 7 ⁇ m or less, and further preferably 6 ⁇ m or less from the viewpoints of thinning and flexibility.

- the thickness of the polarizer is preferably 2 ⁇ m or more, and more preferably 3 ⁇ m or more.

- Such a thin polarizer has less thickness unevenness, excellent visibility, and less dimensional change, and therefore excellent durability against thermal shock.

- Patent No. 4751486 Japanese Patent No. 4751481, Patent No. 4815544, Patent No. 5048120, International Publication No. 2014/077599 pamphlet, International Publication No. 2014/077636 Pamphlet, And the thin polarizers obtained from the production methods described therein.

- the polarizer has an optical characteristic expressed by a single transmittance T and a polarization degree P of the following formula P> ⁇ (10 0.929T-42.4 ⁇ 1) ⁇ 100 (where T ⁇ 42.3), Or It is configured to satisfy the condition of P ⁇ 99.9 (however, T ⁇ 42.3).

- a polarizer configured so as to satisfy the above-described conditions uniquely has performance required as a display for a liquid crystal television using a large display element. Specifically, the contrast ratio is 1000: 1 or more and the maximum luminance is 500 cd / m 2 or more. As other uses, for example, it is bonded to the viewing side of the organic EL display device.

- a polarizer configured to satisfy the above conditions has a high orientation of a polymer (for example, a polyvinyl alcohol-based molecule), so that the thickness of the polarizer is 10 ⁇ m or less.

- the tensile rupture stress in the direction orthogonal to the absorption axis direction (transmission axis direction) is significantly reduced.

- the flexible polarizing film of the present invention has excellent flexibility in spite of the use of such a polyvinyl alcohol-based polarizer that is weak against impact of 10 ⁇ m or less.

- Patent No. 4751486, Patent in that it can be stretched at a high magnification and the polarization performance can be improved.

- stretching in a boric-acid aqueous solution as described in the 4751481 specification and the patent 4815544 specification is preferable, and it describes especially in the patent 4751481 specification and the patent 4815544 specification.

- stretching in the boric-acid aqueous solution which has this is preferable.

- These thin polarizers can be obtained by a production method including a step of stretching a polyvinyl alcohol-based resin (hereinafter also referred to as PVA-based resin) layer and a stretching resin base material in a laminated state and a step of dyeing.

- PVA-based resin polyvinyl alcohol-based resin

- a stretching resin base material in a laminated state

- dyeing a step of dyeing

- the flexible polarizing film of the present invention is characterized in that after the twist test shown in the examples is performed, the polyvinyl alcohol-based polarizer is free from cracks, generation of fold marks, and light leakage.

- the twist test is an index indicating the flexibility in the twisted state in the orientation direction (absorption axis direction) in which the polyvinyl alcohol-based resin that is likely to generate cracks, fold marks, and light leakage is oriented. It can be seen that the flexible polarizing film of the present invention has excellent flexibility in a twisted state in the twisting test without occurrence of cracks, folds and light leakage.

- the flexible polarizing film of the present invention is preferably capable of suppressing the generation of cracks, creases and light leakage after the U-shaped expansion / contraction test shown in the examples.

- the U-shaped expansion / contraction test is an index indicating the flexibility related to unfolded bending in a U-shape in the alignment direction (absorption axis direction) in which the polyvinyl alcohol-based resin is aligned and in the orthogonal direction (transmission axis direction). .

- the flexible polarizing film of the present invention has excellent unfolded bendability in both the absorption axis direction and the transmission axis direction by suppressing the generation of cracks, fold marks and light leakage in the U-shaped stretch test. It can be seen that it has the flexibility involved.

- the flexible polarizing film of the present invention preferably retains the bent shape and suppresses cracking after the bending holding test shown in the examples.

- the flexible polarizing film maintains its original shape even when it is bent and bent in the orientation direction (absorption axis direction) in which the polyvinyl alcohol resin is oriented and in the orthogonal direction (transmission axis direction). It is an index indicating the flexibility related to the retention that can be performed. It can be seen that the flexible polarizing film of the present invention has excellent holding properties in both the absorption axis direction and the transmission axis direction by holding the bent shape and suppressing cracking in the bending holding test.

- the flexible polarizing film of the present invention preferably satisfies the bending resistance (mm) of 60 mm or less in the bending resistance test specifically shown in the examples.

- the bending resistance test is an index indicating flexibility related to the bending followability (low resistance to bending) in the orientation direction (absorption axis direction) in which the polyvinyl alcohol-based resin is oriented and in the orthogonal direction (transmission axis direction).

- the flexible polarizing film of the present invention has a bending flexibility (low resistance to bending) having a bending resistance of 60 mm or less.

- the index indicating the flexibility of the bending resistance (mm) is preferably 50 mm or less, and more preferably 40 mm or less.

- the flexible polarizing film of the present invention preferably satisfies a tensile strength of 5 N / 10 mm or more in the tensile test specifically shown in the examples.

- the tensile test is an index indicating the strength in the direction (transmission axis direction) orthogonal to the orientation direction (absorption axis direction) in which the polyvinyl alcohol-based resin is oriented. It can be seen that the flexible polarizing film of the present invention has strength in the transmission axis direction when the tensile strength satisfies 5 N / 10 mm or more.

- the tensile strength is preferably 7 N / 10 mm or more, more preferably 10 N / 10 mm or more from the viewpoint of strength.

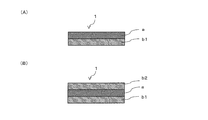

- the flexible polarizing film 1 in FIG. 1A is a case where the first reinforcing film b1 is provided only on the first one surface of the polyvinyl alcohol polarizer a.

- the flexible polarizing film 1 of FIG. 1 (B) has the 1st reinforcement film

- the first reinforcing film b1 and / or the second reinforcing film b2 are provided directly on the polyvinyl alcohol polarizer 1.

- the flexible polarizing film 1 of the present invention has flexibility in the twist test, and has a transparent protective film or the like on one side or both sides of the polyvinyl alcohol-based polarizer a, and cannot satisfy the flexibility. This is clearly distinguished from a normal polarizing film.

- the thickness of the reinforcing membrane is preferably 15 ⁇ m or less from the viewpoint of thinning and flexibility, more preferably 10 ⁇ m or less, and further preferably 7 ⁇ m or less.

- the thickness of the reinforcing membrane is preferably 1 ⁇ m or more, more preferably 3 ⁇ m or more, and further preferably 5 ⁇ m or more from the viewpoint of flexibility and strength.

- the ratio (t2 / t1) of the thickness (t2) of the reinforcing film to the thickness (t1) of the polyvinyl alcohol polarizer is preferably 0.4 or more from the viewpoint of flexibility and strength, and more preferably 0. .6 or more is preferable, and further 0.8 or more is preferable.

- the ratio (t2 / t1) is preferably 2.0 or less, more preferably 1.5 or less, and further preferably 1.2 or less from the viewpoint of thinning. preferable.

- the reinforcing film has a polyvinyl alcohol polarizer as shown in FIG. 1 (B), rather than having the first reinforcing film b1 only on one side of the polyvinyl alcohol polarizer 1 as shown in FIG. 1 (A).

- 1 having both the first reinforcing film b1 and the second reinforcing film b2 can satisfy the flexibility in the twist test, the U-shaped stretch test, and the like, and can satisfy the strength in the tensile test. It is preferable from the point.

- each reinforcing film may be the same or different.

- the thickness difference between the first reinforcing film b1 and the second reinforcing film b2 is good, it is normal (a state where the flexible polarizing film is left alone) and a flexibility test (various tests such as a twist test). Is preferably 10 ⁇ m or less, more preferably 7 ⁇ m or less, and even more preferably 5 ⁇ m or less, because the stress in the flexible polarizing film is made uniform (symmetric) and strength and flexibility are easily secured. It is preferable that they have the same thickness.

- the reinforcing membrane preferably has a compressive elastic modulus at 23 ° C. of 1 MPa or more from the viewpoint of strength. Furthermore, the compressive elastic modulus of the reinforcing membrane is preferably 10 MPa or more, and more preferably 100 MPa or more. On the other hand, when the compressive elastic modulus of the reinforcing membrane layer increases, the compressive elastic modulus is preferably 10 GPa or less, and more preferably 1 GPa or less, because it tends to be too hard and poor flexibility.

- the reinforcing film can be formed from various forming materials.

- the reinforcing film can be formed, for example, by applying a resin material to a polyvinyl alcohol polarizer, or by depositing an inorganic oxide such as SiO 2 on the polyvinyl alcohol polarizer by a sputtering method or the like. You can also

- the reinforcing film is preferably a resin film formed from a resin material from the viewpoint of simple formation.

- the reinforcing film may or may not be oriented, and any of them can be used.

- the reinforcing film When the reinforcing film is oriented, a phase difference occurs and the optical characteristics of the polyvinyl alcohol polarizer change. Therefore, when maintaining the optical characteristics of the polarizer, the reinforcing film that is not substantially oriented.

- “Substantially not oriented” refers to a state in which the treatment for positively orienting the reinforcing film is not performed although the orientation exists inside the reinforcing film due to the orientation of the polarizer.

- a reinforcing film that is not practically oriented can be formed by, for example, applying a resin film forming material to a polyvinyl alcohol polarizer.

- an oriented film can be used as the reinforcing film.

- the oriented reinforcing film expresses a phase difference and can be used as an optical compensation film or the like.

- a material for forming the reinforcing film is not particularly limited as long as it is a material that can be adhered to a polyvinyl alcohol polarizer.

- a polyester resin, a polyether resin, a polycarbonate resin, a polyurethane resin, a silicone resin examples thereof include resins, polyamide resins, polyimide resins, PVA resins, acrylic resins, and epoxy resins. These resin materials can be used singly or in combination of two or more, and among these, one or more selected from the group consisting of polyurethane resins, PVA resins, acrylic resins, and epoxy resins Are preferred, and polyurethane resins and acrylic resins are more preferred.

- the reinforcing film is formed by applying a liquid material containing a curable component capable of constituting the surface of the polarizer, the resin component or the resin, and then solidifying or curing the liquid material. Can do.

- the form of the liquid coating liquid is not particularly limited as long as it exhibits a liquid state, and may be any of water-based, water-dispersed, solvent-based, and solvent-free.

- the forming material may contain an additive as long as the function of the reinforcing film is not impaired.

- silane coupling agents polyalkylene glycol polyether compounds such as polypropylene glycol

- powders such as colorants and pigments, dyes, surfactants, plasticizers, tackifiers, antistatic agents, surface lubricants,

- leveling agents softeners, antioxidants, antioxidants, light stabilizers, UV absorbers, polymerization inhibitors, inorganic or organic fillers, metal powders, particles, foils, etc. It can be added as appropriate.

- the liquid (coating liquid) has a lower viscosity.

- the viscosity measured at 25 ° C. is preferably 2000 mPa ⁇ s or less, more preferably 1000 mPa ⁇ s or less, further preferably 500 mPa ⁇ s or less, and further 100 mPa ⁇ s. It is preferable that:

- the resin component is solidified according to the type.

- the liquid substance containing the resin component is a solution obtained by dissolving or dispersing the resin component in a solvent, and is used as, for example, an aqueous solution, an aqueous dispersion, or a solvent solution.

- the solidification means forming a resin layer by removing a solvent from the liquid material.

- An aqueous resin emulsion can be used as the aqueous dispersion.

- the aqueous resin emulsion contains emulsion resin particles emulsified in water (dispersion medium).

- the reinforcing film of the present invention can be formed by directly applying a forming material containing the aqueous resin emulsion to a polarizer and drying it.

- the resin constituting the emulsion resin is not particularly limited, and examples thereof include acrylic resins, silicone resins, polyurethane resins, and fluorine resins. Among these, in the present invention, polyurethane resins and acrylic resins are preferable because they are excellent in optical transparency and weather resistance and heat resistance.

- water-based resin emulsion examples include trade name: SE-2915E (acrylic emulsion containing UV absorber) manufactured by Taisei Fine Chemical Co., Ltd., trade names: Aron A-104 and Aron A-106 manufactured by Toagosei Co., Ltd. It is done.

- SE-2915E acrylic emulsion containing UV absorber

- the curable component forms a resin according to the type of the curable component.

- the liquid material containing a curable component that can constitute the resin can be used in a solventless system as long as the curable component exhibits a liquid material.

- the liquid material may be a solution in which the curable component is dissolved in a solvent.

- the said curable component exhibits a liquid substance, it can be used as a solution.

- the solvent can be appropriately selected according to the curable component to be used.

- the liquid material containing the curable component is irradiated with active energy rays (ultraviolet rays). Curing by irradiation) or the like can be performed.

- a curable forming material containing a curable component capable of constituting a resin will be described.

- the curable component can be roughly classified into an active energy ray curable type such as an electron beam curable type, an ultraviolet ray curable type, and a visible light curable type, and a thermosetting type.

- the ultraviolet curable type and the visible light curable type can be classified into a radical polymerization curable type and a cationic polymerization curable type.

- an active energy ray having a wavelength range of 10 nm to less than 380 nm is expressed as ultraviolet light

- an active energy ray having a wavelength range of 380 nm to 800 nm is expressed as visible light.

- the radical polymerization curable component can be used as a thermosetting curable component.

- the curable component examples include a radical polymerizable compound.

- the radical polymerizable compound examples include compounds having a radical polymerizable functional group of a carbon-carbon double bond such as a (meth) acryloyl group and a vinyl group.

- these curable components either a monofunctional radical polymerizable compound or a bifunctional or higher polyfunctional radical polymerizable compound can be used.

- these radically polymerizable compounds can be used individually by 1 type or in combination of 2 or more types.

- compounds having a (meth) acryloyl group are suitable.

- (meth) acryloyl means an acryloyl group and / or methacryloyl group, and “(meth)” has the same meaning hereinafter.

- Examples of the monofunctional radical polymerizable compound include (meth) acrylamide derivatives having a (meth) acrylamide group.

- the (meth) acrylamide derivative is preferable in terms of ensuring adhesion with the polarizer and having a high polymerization rate and excellent productivity.

- (meth) acrylamide derivatives include, for example, N-methyl (meth) acrylamide, N, N-dimethyl (meth) acrylamide, N, N-diethyl (meth) acrylamide, N-isopropyl (meth) acrylamide, N N-alkyl group-containing (meth) acrylamide derivatives such as butyl (meth) acrylamide and N-hexyl (meth) acrylamide; N-methylol (meth) acrylamide, N-hydroxyethyl (meth) acrylamide, N-methylol-N— N-hydroxyalkyl group-containing (meth) acrylamide derivatives such as propane (meth) acrylamide; N-aminoalkyl group-containing (meth) acrylamide derivatives such as aminomethyl (meth) acrylamide and aminoethyl (meth) acrylamide; N-methoxymethyl N-alkoxy group-containing (meth) acrylamide derivatives such as

- heterocyclic-containing (meth) acrylamide derivative in which the nitrogen atom of the (meth) acrylamide group forms a heterocyclic ring examples include, for example, N-acryloylmorpholine, N-acryloylpiperidine, N-methacryloylpiperidine, N-acryloylpyrrolidine. Etc.

- an N-hydroxyalkyl group-containing (meth) acrylamide derivative is preferable from the viewpoint of adhesion to a polarizer, and N-hydroxyethyl (meth) acrylamide is particularly preferable.

- examples of the monofunctional radical polymerizable compound include various (meth) acrylic acid derivatives having a (meth) acryloyloxy group. Specifically, for example, methyl (meth) acrylate, ethyl (meth) acrylate, n-propyl (meth) acrylate, isopropyl (meth) acrylate, 2-methyl-2-nitropropyl (meth) acrylate, n-butyl ( (Meth) acrylate, isobutyl (meth) acrylate, s-butyl (meth) acrylate, t-butyl (meth) acrylate, n-pentyl (meth) acrylate, t-pentyl (meth) acrylate, 3-pentyl (meth) acrylate, 2,2-dimethylbutyl (meth) acrylate, n-hexyl (meth) acrylate, cetyl (meth) acrylate, n-

- Examples of the (meth) acrylic acid derivative include cycloalkyl (meth) acrylates such as cyclohexyl (meth) acrylate and cyclopentyl (meth) acrylate; Aralkyl (meth) acrylates such as benzyl (meth) acrylate; 2-isobornyl (meth) acrylate, 2-norbornylmethyl (meth) acrylate, 5-norbornen-2-yl-methyl (meth) acrylate, 3-methyl-2-norbornylmethyl (meth) acrylate, dicyclo Polycyclic (meth) acrylates such as pentenyl (meth) acrylate, dicyclopentenyloxyethyl (meth) acrylate, dicyclopentanyl (meth) acrylate, and the like; 2-methoxyethyl (meth) acrylate, 2-ethoxyethyl (meth) acrylate, 2-methoxymethoxyethyl (

- Examples of the (meth) acrylic acid derivative include 2-hydroxyethyl (meth) acrylate, 2-hydroxypropyl (meth) acrylate, 3-hydroxypropyl (meth) acrylate, 2-hydroxybutyl (meth) acrylate, 4- Hydroxyalkyl (meth) acrylates such as hydroxybutyl (meth) acrylate, 6-hydroxyhexyl (meth) acrylate, 8-hydroxyoctyl (meth) acrylate, 10-hydroxydecyl (meth) acrylate, 12-hydroxylauryl (meth) acrylate, etc.

- hydroxyl groups such as [4- (hydroxymethyl) cyclohexyl] methyl acrylate, cyclohexanedimethanol mono (meth) acrylate, 2-hydroxy-3-phenoxypropyl (meth) acrylate, etc.

- Meth) acrylate Epoxy group-containing (meth) acrylates such as glycidyl (meth) acrylate and 4-hydroxybutyl (meth) acrylate glycidyl ether; 2,2,2-trifluoroethyl (meth) acrylate, 2,2,2-trifluoroethylethyl (meth) acrylate, tetrafluoropropyl (meth) acrylate, hexafluoropropyl (meth) acrylate, octafluoropentyl (meth) ) Halogen-containing (meth) acrylates such as acrylate, heptadecafluorodecyl (meth) acrylate, 3-chloro-2-hydroxypropyl (meth) acrylate; Alkylaminoalkyl (meth) acrylates such as dimethylaminoethyl (meth) acrylate; 3-Oxetanylmethyl (meth) acrylate

- examples of the monofunctional radically polymerizable compound include carboxyl group-containing monomers such as (meth) acrylic acid, carboxyethyl acrylate, carboxypentyl acrylate, itaconic acid, maleic acid, fumaric acid, crotonic acid, and isocrotonic acid.

- carboxyl group-containing monomers such as (meth) acrylic acid, carboxyethyl acrylate, carboxypentyl acrylate, itaconic acid, maleic acid, fumaric acid, crotonic acid, and isocrotonic acid.

- Examples of the monofunctional radical polymerizable compound include lactam vinyl monomers such as N-vinylpyrrolidone, N-vinyl- ⁇ -caprolactam, and methylvinylpyrrolidone; vinylpyridine, vinylpiperidone, vinylpyrimidine, vinylpiperazine, vinylpyrazine, Examples thereof include vinyl monomers having a nitrogen-containing heterocyclic ring such as vinyl pyrrole, vinyl imidazole, vinyl oxazole and vinyl morpholine.

- lactam vinyl monomers such as N-vinylpyrrolidone, N-vinyl- ⁇ -caprolactam, and methylvinylpyrrolidone

- vinylpyridine vinylpiperidone

- vinylpyrimidine vinylpiperazine

- vinylpyrazine examples thereof include vinyl monomers having a nitrogen-containing heterocyclic ring such as vinyl pyrrole, vinyl imidazole, vinyl oxazole and vinyl morpholine.

- a radically polymerizable compound having an active methylene group can be used as the monofunctional radically polymerizable compound.

- the radical polymerizable compound having an active methylene group is a compound having an active methylene group having an active double bond group such as a (meth) acryl group at the terminal or in the molecule.

- the active methylene group include an acetoacetyl group, an alkoxymalonyl group, and a cyanoacetyl group.

- the active methylene group is preferably an acetoacetyl group.

- radical polymerizable compound having an active methylene group examples include 2-acetoacetoxyethyl (meth) acrylate, 2-acetoacetoxypropyl (meth) acrylate, 2-acetoacetoxy-1-methylethyl (meth) acrylate, and the like.

- Examples include acrylamide, N- (4-acetoacetoxymethylbenzyl) acrylamide, and N- (2-acetoacetylaminoethyl) acrylamide.

- the radical polymerizable compound having an active methylene group is preferably acetoacetoxyalkyl (meth) acrylate.

- Examples of the bifunctional or higher polyfunctional radical polymerizable compound include tripropylene glycol di (meth) acrylate, tetraethylene glycol di (meth) acrylate, 1,6-hexanediol di (meth) acrylate, 1,9 -Nonanediol di (meth) acrylate, 1,10-decanediol diacrylate, 2-ethyl-2-butylpropanediol di (meth) acrylate, bisphenol A di (meth) acrylate, bisphenol A ethylene oxide adduct di (meth) ) Acrylate, bisphenol A propylene oxide adduct di (meth) acrylate, bisphenol A diglycidyl ether di (meth) acrylate, neopentyl glycol di (meth) acrylate, tricyclodecane dimethanol di (meth) Acryte, cyclic trimethylol

- Aronix M-220, M-306 manufactured by Toagosei Co., Ltd.

- light acrylate 1,9ND-A manufactured by Kyoeisha Chemical Co., Ltd.

- light acrylate DGE-4A manufactured by Kyoeisha Chemical Co., Ltd.

- light acrylate DCP- A manufactured by Kyoeisha Chemical Co., Ltd.

- SR-531 manufactured by Sartomer

- CD-536 manufactured by Sartomer

- various epoxy (meth) acrylates, urethane (meth) acrylates, polyester (meth) acrylates, various (meth) acrylate monomers, and the like are included as necessary.

- the radical polymerizable compound is preferably used in combination with a monofunctional radical polymerizable compound and a polyfunctional radical polymerizable compound from the viewpoint of achieving both adhesion to the polarizer and optical durability.

- the radical polymerization curable forming material can be used as an active energy ray curable forming material or a thermosetting forming material.

- the active energy ray curable forming material does not need to contain a photopolymerization initiator, but when using ultraviolet rays or visible light for the active energy ray, It preferably contains a photopolymerization initiator.

- the curable component when used as a thermosetting component, the forming material preferably contains a thermal polymerization initiator.

- the photopolymerization initiator in the case of using the radical polymerizable compound is appropriately selected depending on the active energy ray.

- a photopolymerization initiator for ultraviolet light or visible light cleavage is used.

- photopolymerization initiator examples include benzophenone compounds such as benzyl, benzophenone, benzoylbenzoic acid, 3,3′-dimethyl-4-methoxybenzophenone; 4- (2-hydroxyethoxy) phenyl (2-hydroxy-2 -Propyl) ketone, aromatic ketone compounds such as ⁇ -hydroxy- ⁇ , ⁇ '-dimethylacetophenone, 2-methyl-2-hydroxypropiophenone, ⁇ -hydroxycyclohexyl phenyl ketone; methoxyacetophenone, 2,2-dimethoxy- Acetophenone compounds such as 2-phenylacetophenone, 2,2-diethoxyacetophenone, 2-methyl-1- [4- (methylthio) -phenyl] -2-morpholinopropane-1; benzoin methyl ether; Benzoin ethyl ether, benzoin Benzoin ether compounds such as isopropyl ether, benzoin butyl ether and ani

- the blending amount of the photopolymerization initiator is 20 parts by weight or less with respect to 100 parts by weight of the total amount of the curable component (radical polymerizable compound).

- the blending amount of the photopolymerization initiator is preferably 0.01 to 20 parts by weight, more preferably 0.05 to 10 parts by weight, and further preferably 0.1 to 5 parts by weight.

- a photopolymerization initiator that is particularly sensitive to light of 380 nm or more.

- a photopolymerization initiator that is highly sensitive to light of 380 nm or more will be described later.

- the compound represented by following General formula (1) (Wherein R 1 and R 2 represent —H, —CH 2 CH 3 , —iPr or Cl, and R 1 and R 2 may be the same or different), respectively, or a general formula ( It is preferable to use together the compound represented by 1) and a photopolymerization initiator that is highly sensitive to light of 380 nm or more, which will be described later.

- the adhesion is excellent as compared with the case where a photopolymerization initiator having high sensitivity to light of 380 nm or more is used alone.

- diethylthioxanthone in which R 1 and R 2 are —CH 2 CH 3 is particularly preferable.

- the composition ratio of the compound represented by the general formula (1) in the forming material is preferably 0.1 to 5 parts by weight with respect to 100 parts by weight of the total amount of the curable component, and preferably 0.5 to 4 parts. More preferred are parts by weight, and even more preferred is 0.9 to 3 parts by weight.

- polymerization initiators include triethylamine, diethylamine, N-methyldiethanolamine, ethanolamine, 4-dimethylaminobenzoic acid, methyl 4-dimethylaminobenzoate, ethyl 4-dimethylaminobenzoate, isoamyl 4-dimethylaminobenzoate, etc. Among them, ethyl 4-dimethylaminobenzoate is particularly preferable.

- a polymerization initiation assistant When a polymerization initiation assistant is used, its addition amount is usually 0 to 5 parts by weight, preferably 0 to 4 parts by weight, most preferably 0 to 3 parts by weight, based on 100 parts by weight of the total amount of the curable component. is there.

- a known photopolymerization initiator can be used in combination as necessary.

- the photopolymerization initiator it is preferable to use a photopolymerization initiator that is highly sensitive to light of 380 nm or more.

- a photopolymerization initiator in addition to the photopolymerization initiator of the general formula (1), a compound represented by the following general formula (2); Wherein R 3 , R 4 and R 5 represent —H, —CH 3 , —CH 2 CH 3 , —iPr or Cl, and R 3 , R 4 and R 5 may be the same or different. It is preferable to use it.

- the compound represented by the general formula (2) 2-methyl-1- (4-methylthiophenyl) -2-morpholinopropan-1-one (trade name: IRGACURE907 manufacturer: BASF) which is also a commercial product is suitable. Can be used.

- 2-benzyl-2-dimethylamino-1- (4-morpholinophenyl) -butanone-1 (trade name: IRGACURE369 manufacturer: BASF)

- 2- (dimethylamino) -2-[(4-methylphenyl) Methyl] -1- [4- (4-morpholinyl) phenyl] -1-butanone (trade name: IRGACURE379 manufacturer: BASF) is preferred because of its high sensitivity.

- a radical polymerizable compound having an active methylene group when used as the radical polymerizable compound, it is preferably used in combination with a radical polymerization initiator having a hydrogen abstraction function.

- radical polymerization initiator having a hydrogen abstracting action examples include thioxanthone radical polymerization initiators and benzophenone radical polymerization initiators.

- the radical polymerization initiator is preferably a thioxanthone radical polymerization initiator.

- examples of the thioxanthone radical polymerization initiator include compounds represented by the above general formula (1).

- Specific examples of the compound represented by the general formula (1) include thioxanthone, dimethylthioxanthone, diethylthioxanthone, isopropylthioxanthone, and chlorothioxanthone.

- diethylthioxanthone in which R 1 and R 2 are —CH 2 CH 3 is particularly preferable.

- the radical polymerizable compound having an active methylene group and a radical polymerization initiator having a hydrogen abstraction function when the total amount of the curable component is 100% by weight, It is preferable to contain 1 to 50% by weight of the radical polymerizable compound having an active methylene group and 0.1 to 10 parts by weight of the radical polymerization initiator with respect to 100 parts by weight of the total amount of the curable component.

- thermal polymerization initiator those in which polymerization does not start by thermal cleavage when the reinforcing film is formed are preferable.

- thermal polymerization initiator those having a 10-hour half-life temperature of 65 ° C. or higher, more preferably 75 to 90 ° C. are preferable.

- the half-life is an index representing the decomposition rate of the polymerization initiator and refers to the time until the remaining amount of the polymerization initiator is halved.

- the decomposition temperature for obtaining a half-life at an arbitrary time and the half-life time at an arbitrary temperature are described in the manufacturer catalog, for example, “Organic peroxide catalog 9th edition by Nippon Oil & Fats Co., Ltd.” (May 2003) ".

- thermal polymerization initiator examples include lauroyl peroxide (10 hour half-life temperature: 64 ° C.), benzoyl peroxide (10 hour half-life temperature: 73 ° C.), 1,1-bis (t-butylperoxy) -3.

- thermal polymerization initiator examples include 2,2′-azobisisobutyronitrile (10 hour half-life temperature: 67 ° C.), 2,2′-azobis (2-methylbutyronitrile) (10 hours). And azo compounds such as 1,1-azobis-cyclohexane-1-carbonitrile (10 hour half-life temperature: 87 ° C.).

- the blending amount of the thermal polymerization initiator is 0.01 to 20 parts by weight with respect to 100 parts by weight of the total amount of the curable component (radical polymerizable compound).

- the blending amount of the thermal polymerization initiator is preferably 0.05 to 10 parts by weight, more preferably 0.1 to 3 parts by weight.

- Examples of the curable component of the cationic polymerization curable forming material include compounds having an epoxy group or an oxetanyl group.

- the compound having an epoxy group is not particularly limited as long as it has at least two epoxy groups in the molecule, and various generally known curable epoxy compounds can be used.

- a preferable epoxy compound a compound having at least two epoxy groups and at least one aromatic ring in the molecule (aromatic epoxy compound), or at least two epoxy groups in the molecule, at least one of them. Examples thereof include a compound (alicyclic epoxy compound) formed between two adjacent carbon atoms constituting an alicyclic ring.

- the cationic polymerization curable forming material contains the epoxy compound and the oxetane compound described above as the curable component, and both of these are cured by cationic polymerization, and therefore, a photocationic polymerization initiator is blended therein.

- This cationic photopolymerization initiator generates a cationic species or a Lewis acid by irradiation with active energy rays such as visible light, ultraviolet rays, X-rays, and electron beams, and starts a polymerization reaction of an epoxy group or an oxetanyl group.

- the curable forming material according to the present invention preferably contains the following components.

- the active energy ray-curable forming material according to the present invention can contain an acrylic oligomer obtained by polymerizing a (meth) acrylic monomer, in addition to the curable component related to the radical polymerizable compound.

- an acrylic oligomer in the active energy ray-curable forming material curing shrinkage when irradiating and curing the active energy ray to the reinforcing film is reduced, and the interfacial stress between the reinforcing film and the polarizer is reduced. can do.

- the content of the acrylic oligomer is preferably 20 parts by weight or less and more preferably 15 parts by weight or less with respect to 100 parts by weight of the total amount of the curable component.

- the acrylic oligomer is preferably contained in an amount of 3 parts by weight or more, more preferably 5 parts by weight or more, based on 100 parts by weight of the total amount of the curable component.

- the active energy ray-curable forming material preferably has a low viscosity in consideration of workability and uniformity during coating, and thus an acrylic oligomer obtained by polymerizing a (meth) acrylic monomer also has a low viscosity. It is preferable.

- the acrylic oligomer having a low viscosity and capable of preventing curing shrinkage of the reinforcing film preferably has a weight average molecular weight (Mw) of 15000 or less, more preferably 10,000 or less, and particularly preferably 5000 or less. .

- the weight average molecular weight (Mw) of the acrylic oligomer is preferably 500 or more, more preferably 1000 or more, and preferably 1500 or more. Particularly preferred.

- the (meth) acrylic monomer constituting the acrylic oligomer include, for example, methyl (meth) acrylate, ethyl (meth) acrylate, n-propyl (meth) acrylate, isopropyl (meth) acrylate, 2-methyl- 2-nitropropyl (meth) acrylate, n-butyl (meth) acrylate, isobutyl (meth) acrylate, S-butyl (meth) acrylate, t-butyl (meth) acrylate, n-pentyl (meth) acrylate, t-pentyl (Meth) acrylate, 3-pentyl (meth) acrylate, 2,2-dimethylbutyl (meth) acrylate, n-hexyl (meth) acrylate, cetyl (meth) acrylate, n-octyl (meth) acrylate, 2-ethylhexyl (

- acrylic oligomer examples include “ARUFON” manufactured by Toagosei Co., Ltd., “Act Flow” manufactured by Soken Chemical Co., Ltd., “JONCRYL” manufactured by BASF Japan.

- the active energy ray-curable forming material may contain a photoacid generator.

- the active energy ray-curable forming material contains a photoacid generator, the water resistance and durability of the reinforcing film can be dramatically improved as compared with a case where no photoacid generator is contained.

- the photoacid generator can be represented by the following general formula (3).

- onium salts constituting the photoacid generator include PF 6 ⁇ , SbF 6 ⁇ , AsF 6 ⁇ , SbCl 6 ⁇ , BiCl 5 ⁇ , SnCl 6 ⁇ , ClO 4 ⁇ , dithiocarbamate anion, SCN ⁇ . It is an onium salt comprising an anion selected from more.

- the content of the photoacid generator is 10 parts by weight or less, preferably 0.01 to 10 parts by weight, and preferably 0.05 to 5 parts by weight with respect to 100 parts by weight of the total amount of the curable component. More preferred is 0.1 to 3 parts by weight.

- the formation of the reinforcing film by the curable forming material is performed by coating the curable forming material on the surface of the polarizer and then curing.

- the polarizer may be subjected to a surface modification treatment before coating the curable forming material.

- Specific examples of the treatment include corona treatment, plasma treatment, and saponification treatment.

- the coating method of the curable forming material is appropriately selected depending on the viscosity of the curable forming material and the target thickness.

- coating methods include reverse coaters, gravure coaters (direct, reverse and offset), bar reverse coaters, roll coaters, die coaters, bar coaters, rod coaters and the like.

- a method such as a dapping method can be appropriately used.

- the curable forming material is used as an active energy ray curable forming material or a thermosetting forming material.

- the active energy ray curable forming material can be used in an electron beam curable type, an ultraviolet curable type, or a visible light curable type.

- active energy ray curing type In the active energy ray curable forming material, after applying the active energy ray curable forming material to the polarizer, the active energy ray (electron beam, ultraviolet ray, visible light, etc.) is irradiated, and the active energy ray curable forming material is applied. Curing to form a reinforcing film.

- the irradiation direction of active energy rays can be irradiated from any appropriate direction. Preferably, irradiation is performed from the reinforcing film side.

- the acceleration voltage is preferably 5 kV to 300 kV, and more preferably 10 kV to 250 kV. If the acceleration voltage is less than 5 kV, the electron beam may not reach the deepest part of the reinforcing film and may be insufficiently cured. If the acceleration voltage exceeds 300 kV, the penetrating force through the sample is too strong and damages the polarizer. There is a fear.

- the irradiation dose is 5 to 100 kGy, more preferably 10 to 75 kGy.

- the adhesive is insufficiently cured, and when it exceeds 100 kGy, the polarizer is damaged, resulting in a decrease in mechanical strength and yellowing, and the predetermined optical characteristics cannot be obtained.

- the electron beam irradiation is usually performed in an inert gas, but if necessary, it may be performed in the atmosphere or under a condition where a little oxygen is introduced.

- an active energy ray containing visible light having a wavelength range of 380 nm to 450 nm particularly an active energy ray having the largest irradiation amount of visible light having a wavelength range of 380 nm to 450 nm.

- the active energy ray a gallium-filled metal halide lamp and an LED light source that emits light in the wavelength range of 380 to 440 nm are preferable.

- low pressure mercury lamp medium pressure mercury lamp, high pressure mercury lamp, ultra high pressure mercury lamp, incandescent lamp, xenon lamp, halogen lamp, carbon arc lamp, metal halide lamp, fluorescent lamp, tungsten lamp, gallium lamp, excimer laser or sunlight

- a light source including visible light can be used, and ultraviolet light having a wavelength shorter than 380 nm can be blocked using a band pass filter.

- thermosetting type forming material after applying to a polarizer, by heating, polymerization is started by a thermal polymerization initiator to form a cured product layer (reinforcing film).

- the heating temperature is set according to the thermal polymerization initiator, but is about 60 to 200 ° C., preferably 80 to 150 ° C.

- a material for forming the reinforcing film for example, a cyanoacrylate-based forming material, an epoxy-based forming material, or an isocyanate-based forming material can be used.

- Examples of the cyanoacrylate-based forming material include alkyl- ⁇ -cyanoacrylates such as methyl- ⁇ -cyanoacrylate, ethyl- ⁇ -cyanoacrylate, butyl- ⁇ -cyanoacrylate, octyl- ⁇ -cyanoacrylate, and cyclohexyl- ⁇ -. And cyanoacrylate and methoxy- ⁇ -cyanoacrylate.

- alkyl- ⁇ -cyanoacrylates such as methyl- ⁇ -cyanoacrylate, ethyl- ⁇ -cyanoacrylate, butyl- ⁇ -cyanoacrylate, octyl- ⁇ -cyanoacrylate, and cyclohexyl- ⁇ -.

- cyanoacrylate and methoxy- ⁇ -cyanoacrylate methoxy- ⁇ -cyanoacrylate.

- those used as a cyanoacrylate-based adhesive can be used as the cyanoacrylate-based adhesive can be used.

- the epoxy-based forming material may be used alone as an epoxy resin or may contain an epoxy curing agent. When the epoxy resin is used alone, it is cured by adding a photopolymerization initiator and irradiating active energy rays. When an epoxy curing agent is added as an epoxy-based forming material, for example, those used as an epoxy-based adhesive can be used.

- the usage form of the epoxy-based forming material can be used as a one-component type containing an epoxy resin and its curing agent, but it is used as a two-component type in which a curing agent is blended with the epoxy resin.

- Epoxy-based forming materials are usually used as solutions.

- the solution may be a solvent system or an aqueous system such as an emulsion, a colloidal dispersion, or an aqueous solution.

- the epoxy resin examples include various compounds containing two or more epoxy groups in the molecule.

- the epoxy resin examples include various compounds containing two or more epoxy groups in the molecule.

- bisphenol type epoxy resin aliphatic type epoxy resin, aromatic type epoxy resin, halogenated bisphenol type epoxy resin, biphenyl And epoxy resin.

- an epoxy resin can be suitably determined according to an epoxy equivalent and the number of functional groups, the epoxy equivalent of 500 or less is used suitably from a durable viewpoint.

- the curing agent for the epoxy resin is not particularly limited, and various types such as phenol resin type, acid anhydride type, carboxylic acid type, and polyamine type can be used.

- phenol resin-based curing agent for example, phenol novolak resin, bisphenol novolak resin, xylylene phenol resin, cresol novolak resin, or the like is used.

- acid anhydride-based curing agents include: maleic anhydride, tetrahydrophthalic anhydride, hexahydrophthalic anhydride, succinic anhydride, and the like.

- carboxylic acid-based curing agents include carboxylic acids such as pyromellitic acid and trimellitic acid.

- Examples thereof include block carboxylic acids added with acids and vinyl ether.

- an epoxy-type two-component formation material what consists of two liquids of an epoxy resin and a polythiol, what consists of two liquids of an epoxy resin and polyamide, etc. can be used, for example.

- the blending amount of the curing agent varies depending on the equivalent to the epoxy resin, but is preferably 30 to 70 parts by weight, more preferably 40 to 60 parts by weight with respect to 100 parts by weight of the epoxy resin.

- curing accelerators can be used for the epoxy-based forming material.

- the curing accelerator include various imidazole compounds and derivatives thereof, dicyandiamide, and the like.

- Examples of the isocyanate-based forming material include those used as a crosslinking agent in the formation of the pressure-sensitive adhesive layer.

- As the isocyanate-based crosslinking agent a compound having at least two isocyanate groups can be used.

- the polyisocyanate compound can be used as an isocyanate-based forming material.

- Examples include those reacted with polyhydric alcohols and polyhydric amines.

- isocyanate-based crosslinking agent those having three or more isocyanate groups such as isocyanuric acid tris (6-inocyanate hexyl) are preferable.

- isocyanate type formation material what is used as an isocyanate type adhesive agent is mention

- the isocyanate-based forming materials in the present invention, it is preferable to use those having a rigid structure in which a cyclic structure (benzene ring, cyanurate ring, isocyanurate ring, etc.) accounts for a large proportion in the structure.

- a cyclic structure benzene ring, cyanurate ring, isocyanurate ring, etc.

- the isocyanate-based forming material for example, trimethylolpropane-tri-tolylene isocyanate, tris (hexamethylene isocyanate) isocyanurate and the like are preferably used.

- the said isocyanate type crosslinking agent can also use what provided the protective group to the terminal isocyanate group.

- Protecting groups include oximes and lactams. In the case where the isocyanate group is protected, the protecting group is dissociated from the isocyanate group by heating, and the isocyanate group reacts.

- a reaction catalyst can be used to increase the reactivity of the isocyanate group.

- the reaction catalyst is not particularly limited, but a tin-based catalyst or an amine-based catalyst is suitable.

- the reaction catalyst can use 1 type (s) or 2 or more types.

- the amount of the reaction catalyst used is usually 5 parts by weight or less with respect to 100 parts by weight of the isocyanate-based crosslinking agent. When the amount of the reaction catalyst is large, the crosslinking reaction rate increases and foaming of the forming material occurs. Even if the forming material after foaming is used, sufficient adhesion cannot be obtained.

- a reaction catalyst it is preferably 0.01 to 5 parts by weight, more preferably 0.05 to 4 parts by weight.

- the tin-based catalyst both inorganic and organic catalysts can be used, but an organic catalyst is preferred.

- the inorganic tin-based catalyst include stannous chloride and stannic chloride.

- the organic tin-based catalyst is preferably one having at least one organic group such as an aliphatic group or alicyclic group having a skeleton such as a methyl group, an ethyl group, an ether group or an ester group. Examples include tetra-n-butyltin, tri-n-butyltin acetate, n-butyltin trichloride, trimethyltin hydroxide, dimethyltin dichloride, dibutyltin dilaurate, and the like.

- the amine catalyst is not particularly limited. For example, those having at least one organic group such as an alicyclic group such as quinoclidine, amidine, and diazabicycloundecene are preferable.

- examples of the amine catalyst include triethylamine.

- reaction catalysts other than the above include cobalt naphthenate and benzyltrimethylammonium hydroxide.

- the isocyanate-based forming material is usually used as a solution.

- the solution may be a solvent system or an aqueous system such as an emulsion, a colloidal dispersion, or an aqueous solution.

- the organic solvent is not particularly limited as long as the components constituting the forming material are uniformly dissolved. Examples of the organic solvent include toluene, methyl ethyl ketone, ethyl acetate and the like.

- alcohols such as n-butyl alcohol and isopropyl alcohol and ketones such as acetone can be blended.

- a dispersant is used, or an isocyanate-based crosslinking agent, a functional group having low reactivity with an isocyanate group such as a carboxylate, a sulfonate, or a quaternary ammonium salt, or an aqueous dispersion such as polyethylene glycol. It can carry out by introduce

- the formation (curing) of the reinforcing film by the cyanoacrylate-based forming material, the epoxy-based forming material, or the isocyanate-based forming material can be appropriately selected depending on the type of the forming material, but is usually 30 to 100 ° C. It is carried out by drying at a temperature of preferably about 50 to 80 ° C. for about 0.5 to 15 minutes. In the case of a cyanoacrylate-based forming material, since the curing is fast, the reinforcing film can be formed in a time shorter than the above time.

- polyurethane can be used as a material for forming the reinforcing film.

- polyurethane it is preferable to use a reaction product of a high-molecular polyol compound and / or a low-molecular polyol and an isocyanate compound and an isocyanate compound.

- the polyurethane can be further reacted with a low molecular polyamino compound and / or a polyol compound as a chain extender.

- the polymer polyol compound preferably has a weight average molecular weight of 100 to 4000 and has two or more hydroxyl groups in one molecule, and polyether polyol, polyester polyol, polycarbonate polyol and the like are used.

- the polymer polyol compound preferably has a weight average molecular weight of 500 to 4000, more preferably 600 to 3500, and even more preferably 1000 to 3000.

- polyether polyols examples include aliphatic polyether polyols and aromatic polyether polyols. More specifically, for example, low molecular polyols such as dihydric alcohols such as ethylene glycol, diethylene glycol, propylene glycol, butylene glycol and hexamethylene glycol, and trihydric alcohols such as trimethylolpropane, glycerin and pentaerythritol, ethylene oxide , Polyether obtained by addition polymerization of propylene oxide, tetrahydrofuran, or the like is used. These may be used singly or in combination of two or more.

- low molecular polyols such as dihydric alcohols such as ethylene glycol, diethylene glycol, propylene glycol, butylene glycol and hexamethylene glycol

- trihydric alcohols such as trimethylolpropane, glycerin and pentaerythritol, ethylene oxide

- polyester polyols examples include aliphatic polyester polyols and aromatic polyester polyols. More specifically, alcohols such as the above dihydric alcohols, dipropylene glycol, 1,4-butanediol, 1,6-hexanediol and neopentyl glycol, and two bases such as adipic acid, azelaic acid and sebacic acid Polyester composed of a polycondensate with an acid is used. These may be used singly or in combination of two or more.

- polydiene-based polyols such as polybutadiene, butadiene-acrylonitrile copolymer, polyisoprene having hydroxyl groups at both ends of the molecule, polybutadiene hydrogenated products, polyisoprene hydrogenated products having hydroxyl groups at both ends of the molecules, polyisoprene

- polyolefin polyols such as isobutylene.

- examples of the polyamino compound used as the chain extender include aliphatic polyamino compounds and aromatic polyamino compounds. More specifically, for example, ethylenediamine, 3,3′-dichloro-4,4′-diaminodiphenylmethane (MOCA), diethyltoluenediamine (DETDA), 44′-bis- (sec-butyl) diphenylmethane, 2,4 -Tolylenediamine, 2,6-tolylenediamine, xylylenediamine, hexanediamine, isophoronediamine and the like. Of these, ethylenediamine and the like are preferable. These may be used singly or in combination of two or more.

- MOCA 3,3′-dichloro-4,4′-diaminodiphenylmethane

- DETDA diethyltoluenediamine

- 44′-bis- (sec-butyl) diphenylmethane 2,4 -To

- examples of the low molecular polyol and the polyol compound used as the chain extender include low molecular polyols exemplified in polyether polyol and polyester polyol.

- the chain extender is preferably used in an amount of 0.1 to 10 parts by weight, more preferably 0.5 to 7 parts by weight, more preferably 1 to 5 parts by weight, based on 100 parts by weight of the polymer polyol compound. More preferably, The use of a chain extender can sufficiently increase the molecular weight and improve the durability.

- the isocyanate compound is a polyisocyanate (isocyanate compound) having two or more isocyanate groups, and the same as the isocyanate-based forming material can be used.

- the isocyanate compound can also be used as a urethane prepolymer obtained by reacting the low-molecular polyol exemplified in the polyester polyol and the exemplified isocyanate compound in advance.

- the formation (curing) of the reinforcing film with polyurethane may be usually performed by applying a liquid material (coating solution) of polyurethane prepared in advance to the polarizer, or contains the polymer polyol compound and the isocyanate compound. After applying the composition to the polarizer, a reinforcing film may be formed of polyurethane as a cured reaction product.

- the reinforcing membrane can be formed usually by drying at about 30 to 100 ° C., preferably 50 to 80 ° C., for about 0.5 to 15 minutes.

- an annealing treatment may be performed.

- Annealing treatment promotes the reaction especially when isocyanate is not sufficiently reacted even after the initial curing in the isocyanate-based forming agent, polyurethane-based forming material, etc. (reactive group remains in the reinforcing film).

- the annealing treatment can be performed in any atmosphere of a dry condition or a humidified condition.

- the annealing temperature is about 30 to 100 ° C., preferably 50 to 80 ° C., similarly to the conditions for the initial curing. There is no particular limitation on the annealing time.

- the weight average molecular weight of polyurethane is preferably 30,000 to 200,000, more preferably 40 to 150,000, and still more preferably 50,000 to 130,000.

- the weight average molecular weight of the polymer polyol compound and polyurethane was measured under the following conditions of GPC (gel permeation chromatography).

- Analyzing apparatus HLC-8120GPC manufactured by Tosoh Corporation. Column: manufactured by Tosoh Corporation, G7000HXL + GMHXL + GMHXL. Column size: 7.8 mm ⁇ ⁇ 30 cm each 90 cm in total. Column temperature: 40 ° C. Flow rate: 0.8 ml / min. Injection volume: 100 ⁇ l.

- Eluent tetrahydrofuran.

- Detector Suggested refractometer. Standard sample: polystyrene.

- the reinforcing film has a functional group capable of forming a covalent bond with PVA such as an isocyanate group or an epoxy group, and has a carbon-carbon double bond such as a (meth) acryloyl group or a vinyl group.

- a compound having a radical polymerizable functional group can be used. Examples of the compound include 2-isocyanatoethyl acrylate (manufactured by Showa Denko, product name Karenz AOI), 1,1- (bisacryloyloxymethyl) ethyl isocyanate (manufactured by Showa Denko, Karenz BEI), and the like. It is done.

- a reaction product of a polymer containing a diisocyanate compound as a constituent and a hydroxyl group-containing hydroxyl group-containing (meth) acrylate, or the like can be used as the compound.

- a reaction product of 2-hydroxyethyl acrylate and a polymer containing 1,6-diisocyanatohexane BASF, product name Ralomer LR9000.

- the compound has a functional group such as an isocyanate group or an epoxy group, a reinforcing film can be formed by thermosetting in the same manner as the isocyanate-based forming agent, and further, an annealing treatment can be performed.

- the said compound since the said compound has a radically polymerizable functional group, it can be used as an active energy ray hardening type or thermosetting type forming material concerning a radical polymerization hardening type forming material.

- the compound can be used in combination with other radical polymerizable compounds.

- the reinforcing film may be formed from a forming material that does not contain a curable component, for example, a forming material that contains the polyvinyl alcohol-based resin as a main component.

- the polyvinyl alcohol resin forming the reinforcing film may be the same as or different from the polyvinyl alcohol resin contained in the polarizer as long as it is a “polyvinyl alcohol resin”.

- polyvinyl alcohol resin examples include polyvinyl alcohol.

- Polyvinyl alcohol is obtained by saponifying polyvinyl acetate.

- polyvinyl alcohol-based resin examples include a saponified product of a copolymer of vinyl acetate and a monomer having copolymerizability.

- the copolymerizable monomer is ethylene

- an ethylene-vinyl alcohol copolymer is obtained.

- the copolymerizable monomer include unsaturated carboxylic acids such as (anhydrous) maleic acid, fumaric acid, crotonic acid, itaconic acid, (meth) acrylic acid, and esters thereof; ethylene, propylene, etc.

- ⁇ -olefin (meth) allylsulfonic acid (soda), sulfonic acid soda (monoalkylmalate), disulfonic acid soda alkylmalate, N-methylolacrylamide, acrylamide alkylsulfonic acid alkali salt, N-vinylpyrrolidone, N- Examples include vinyl pyrrolidone derivatives.

- These polyvinyl alcohol resins can be used alone or in combination of two or more.

- Polyvinyl alcohol obtained by saponifying polyvinyl acetate is preferable from the viewpoint of satisfying moisture heat resistance and water resistance by controlling the heat of crystal fusion of the reinforcing film to 30 mj / mg or more.

- the saponification degree of the polyvinyl alcohol-based resin can be, for example, 95% or more, but the heat of crystal fusion of the reinforcing film is controlled to 30 mj / mg or more to satisfy the heat and moisture resistance and water resistance. From the viewpoint, the degree of saponification is preferably 99.0% or more, and more preferably 99.7% or more.

- the degree of saponification represents the proportion of units that are actually saponified to vinyl alcohol units among the units that can be converted to vinyl alcohol units by saponification, and the residue is a vinyl ester unit.

- the degree of saponification can be determined according to JIS K 6726-1994.

- the average degree of polymerization of the polyvinyl alcohol-based resin can be, for example, 500 or more, but the viewpoint of satisfying moisture heat resistance and water resistance by controlling the heat of crystal fusion of the reinforcing film to 30 mj / mg or more. Therefore, the average degree of polymerization is preferably 1000 or more, more preferably 1500 or more, and further preferably 2000 or more.

- the average degree of polymerization of the polyvinyl alcohol resin is measured according to JIS-K6726.

- a modified polyvinyl alcohol resin having a hydrophilic functional group in the side chain of the polyvinyl alcohol or a copolymer thereof can be used.

- the hydrophilic functional group include an acetoacetyl group and a carbonyl group.

- modified polyvinyl alcohol obtained by acetalization, urethanization, etherification, grafting, phosphoric esterification or the like of a polyvinyl alcohol resin can be used.